Method for preparing ferro-silicon and magnesium using ferro-nickel slag, preparation apparatus used therefor, and smelting reduction furnace

A preparation device and reduction furnace technology, which is applied in the field of magnesium preparation devices, can solve the problems of slag becoming industrial waste and adding, and achieve the effects of enhancing cost competitiveness, reducing energy costs, and reducing carbon monoxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

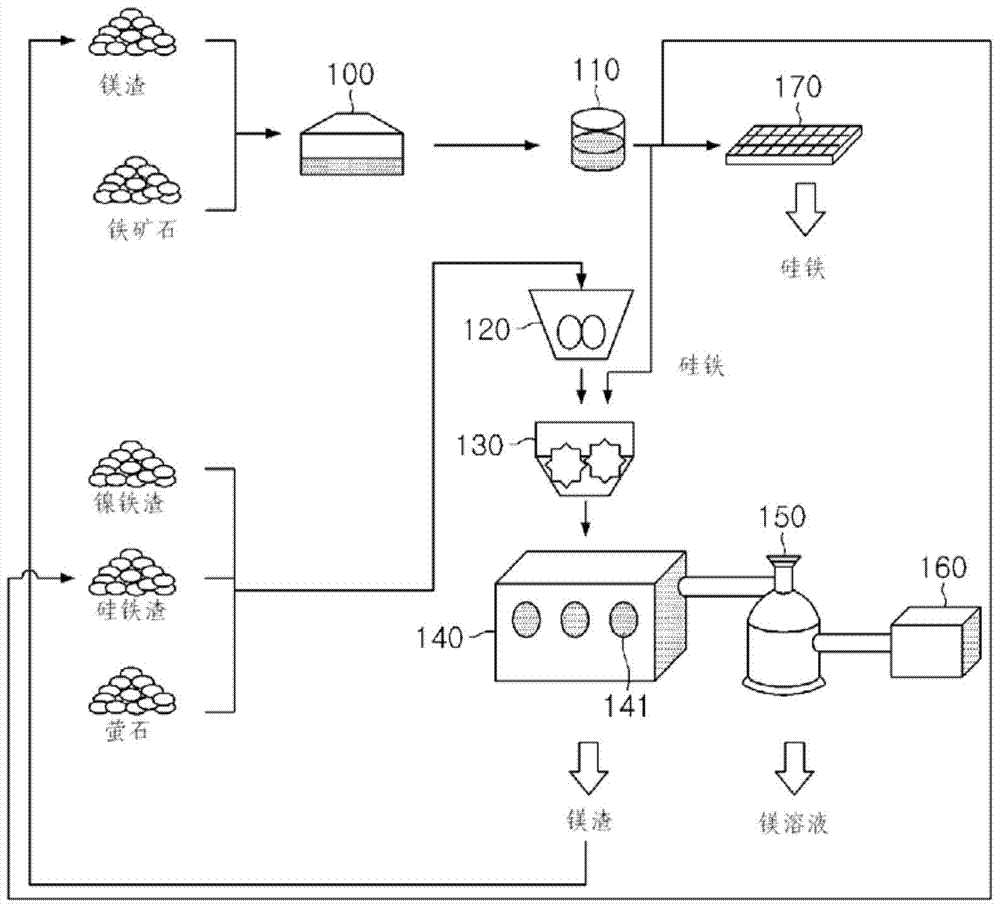

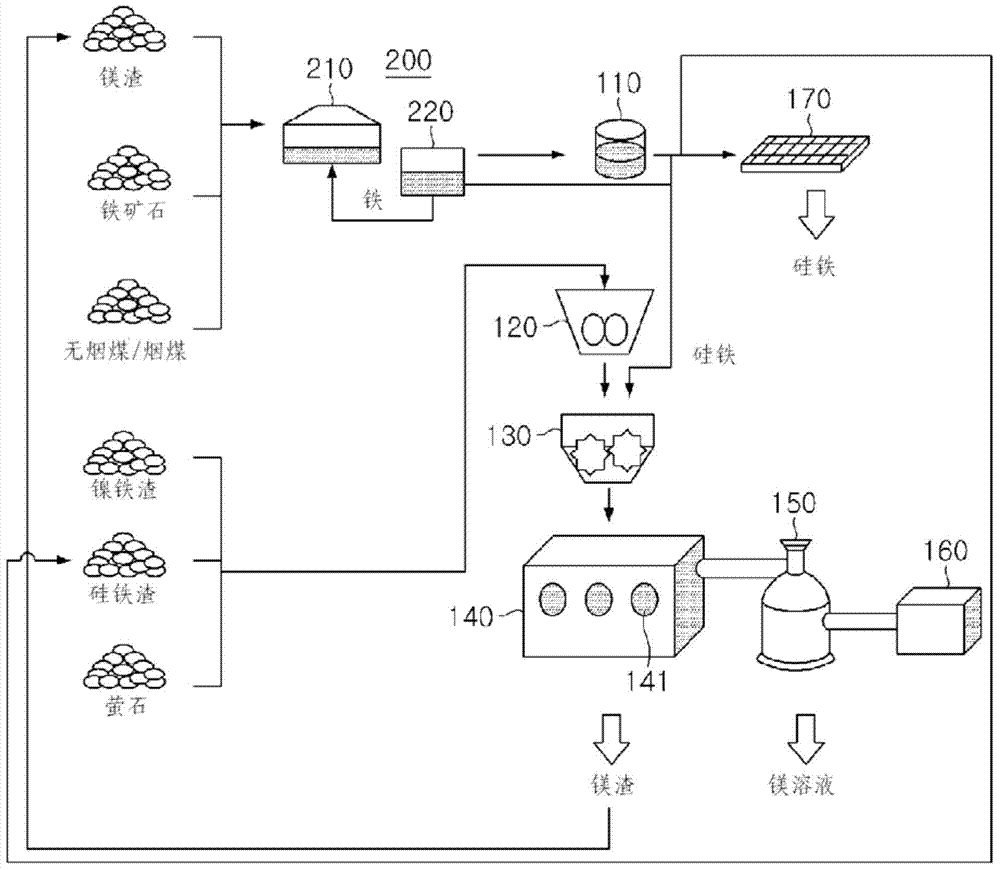

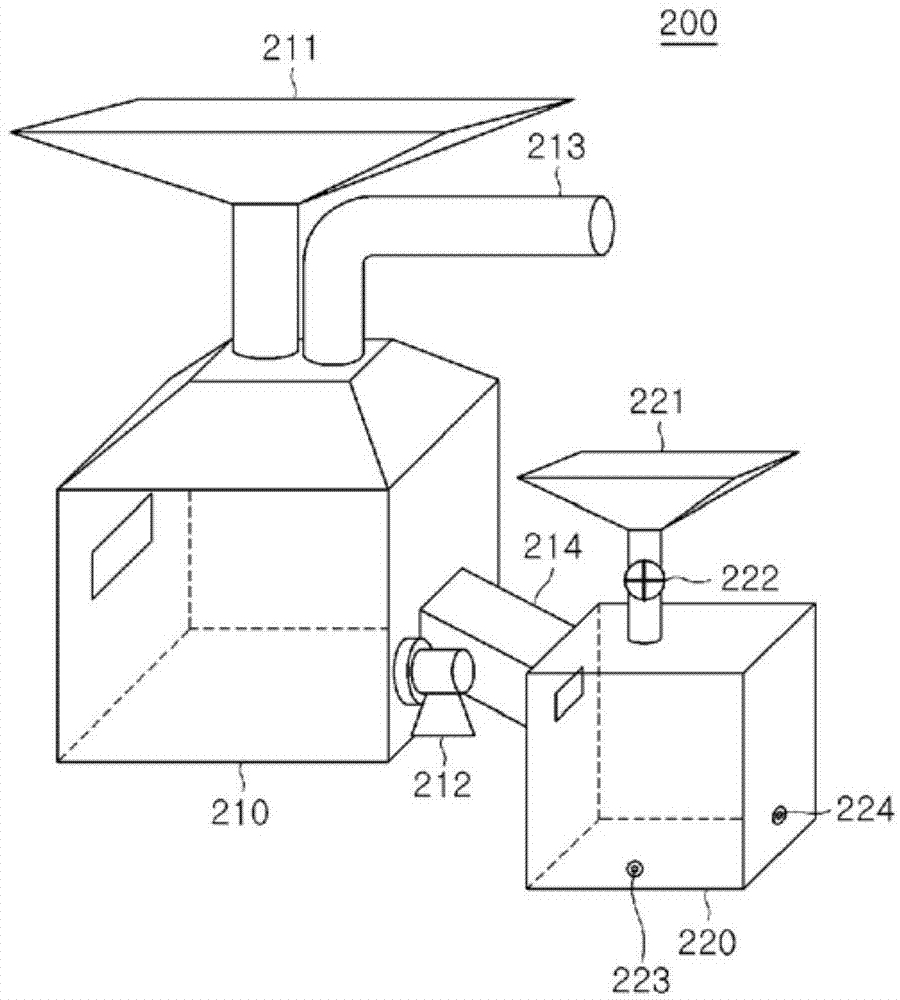

[0043] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings to describe the present invention in detail.

[0044] The embodiments of the present invention are intended to enable those skilled in the art to which the present invention pertains to understand the present invention more completely. Therefore, in order to more clearly describe the present invention, the shapes, sizes, and the like of elements in the drawings are exaggerated.

[0045] Ferronickel slag is a by-product produced during the production of ferronickel, and contains magnesium compounds and iron components. For example, ferronickel slag after extracting ferronickel from nickel ore in New Caledonia consists of the following components (percentage by weight).

[0046] Table 1

[0047] differentiate

SiO 2

MgO

al 2 o 3

T.Fe

CaO

other

content

53.45

35.5

1.45

4.5

0.65

4.45 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com