Inversed umbrella type composite impeller surface aeration machine

A technology of surface aerator and composite impeller, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve low power efficiency, poor aeration effect, high energy consumption cost high or low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

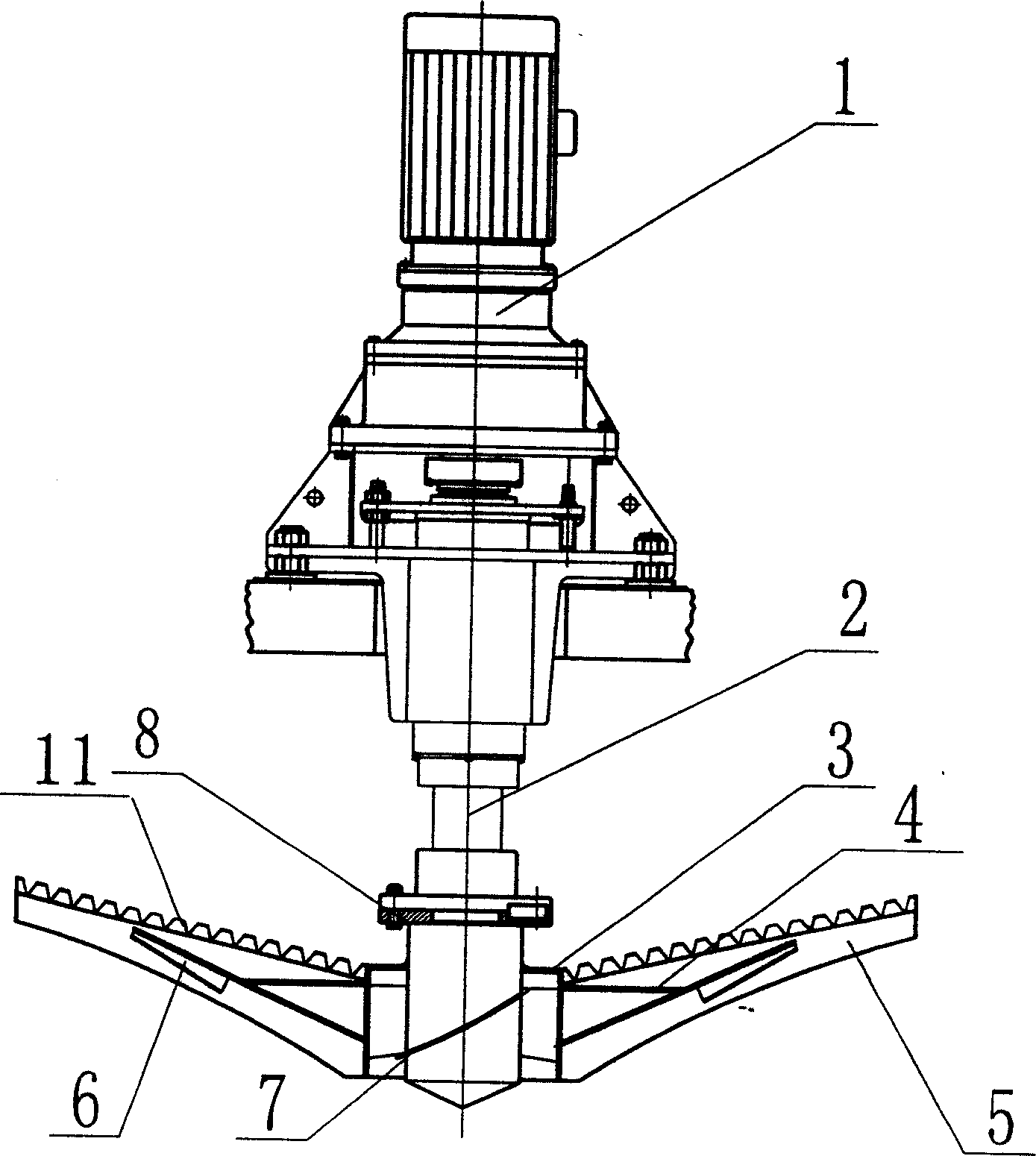

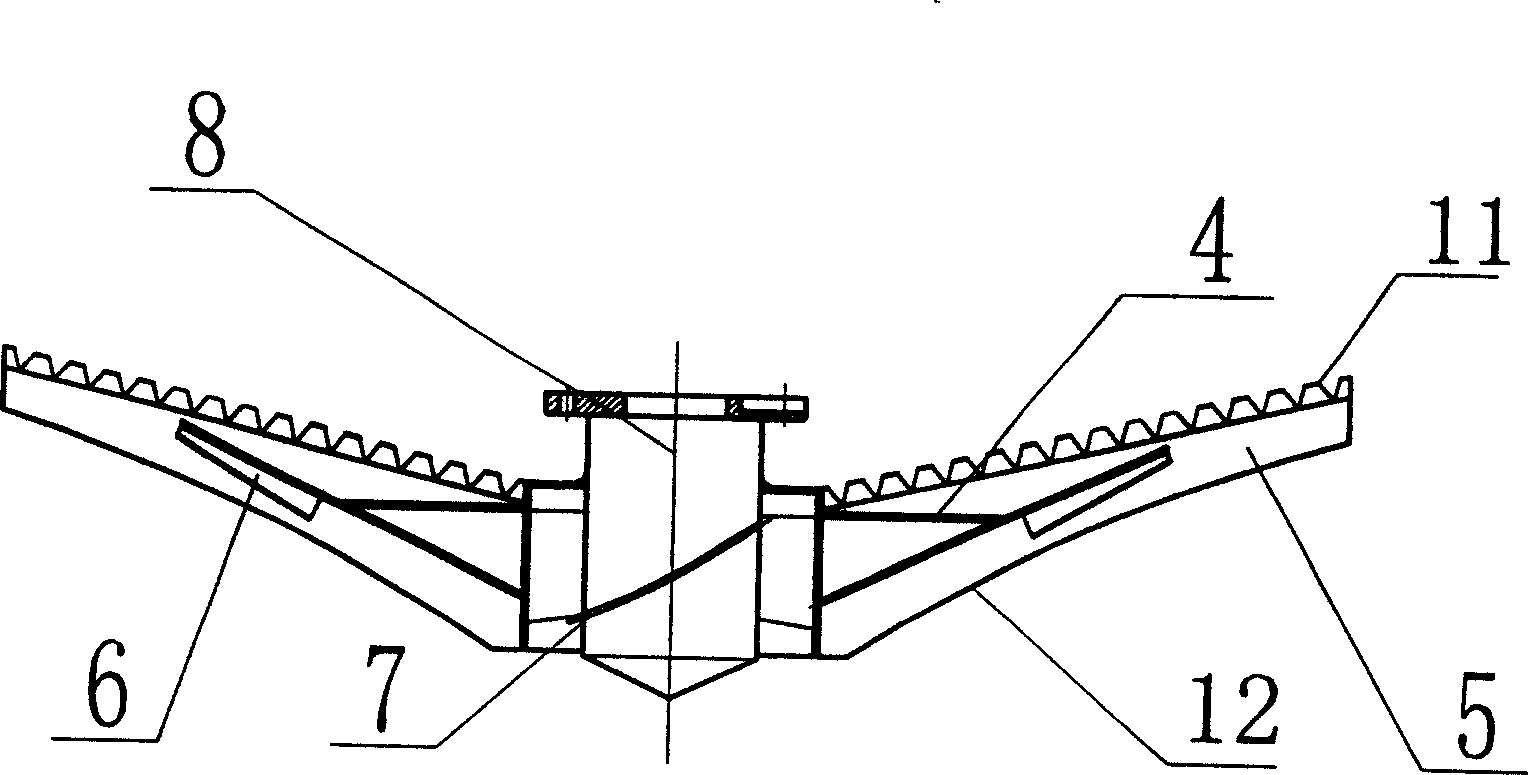

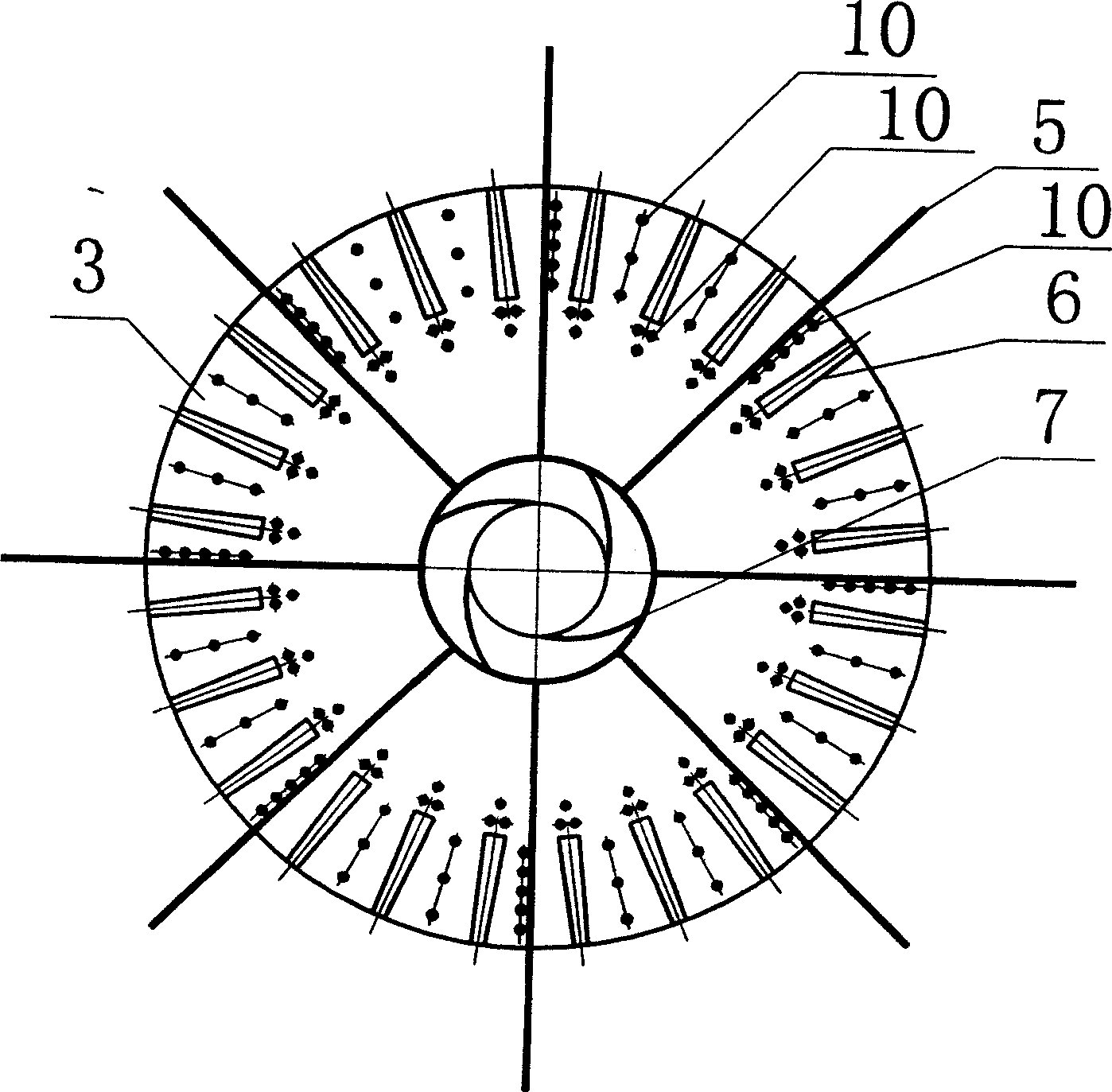

[0015] exist figure 1 Among them, the inverted umbrella type composite impeller surface aerator, which is fixedly connected by the motor and reducer 1 and the transmission connector 2, the coupling 8 at the lower end of the transmission connector 2 is connected with the impeller body 3, and the impeller body 3 is an inverted umbrella , is made up of skeleton supporting surface 4 and cone, and the top angle of cone is 120-150 degree. The blades 5 are radially fixed on the concave and convex surfaces of the cone of the impeller body 3, and can be fixed by welding, riveting or bolts. The transmission connector 2 includes a shaft coupling 8. The lower end of the shaft coupling 8 is located in the central through hole of the impeller body 3. The diameter of the central through hole is greater than the diameter of the lower end of the shaft coupling 8. The outer peripheral surface of the coupling 8 is connected to the impeller A plurality of rotating blades are evenly fixed between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com