Patents

Literature

210 results about "Diaphragm compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A diaphragm compressor is a variant of the classic reciprocating compressor with backup and piston rings and rod seal. The compression of gas occurs by means of a flexible membrane, instead of an intake element. The back and forth moving membrane is driven by a rod and a crankshaft mechanism. Only the membrane and the compressor box come in touch with pumped gas. For this reason this construction is the best suited for pumping toxic and explosive gases. The membrane has to be reliable enough to take the strain of pumped gas. It must also have adequate chemical properties and sufficient temperature resistance.

Oxygen concentrator apparatus and method

InactiveUS20090065007A1Small radiusSensitivity to pressure changeRespiratorsAnalysing fluids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorInhalation

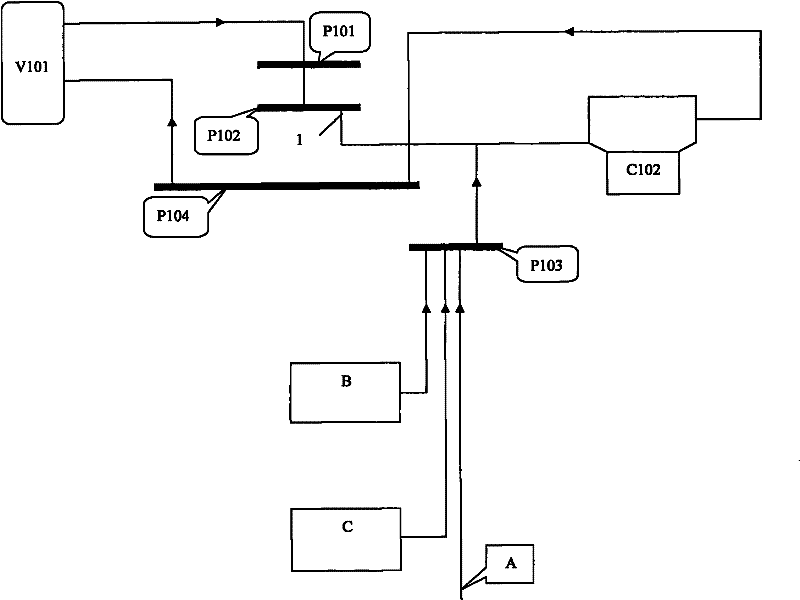

In some embodiments, an oxygen concentrator may include lightweight injection molded housing components coupled to dual-pump diaphragm compressors. The oxygen concentrator may be coupled to a pressure transducer that detects a user's inhalation. The detected inhalation may signal the release of a bolus of oxygen. The sensitivity of the pressure transducer readings may be adjusted based on a detected environment. The user's breathing rate may also be determined to control the number of compressors used for increased efficiency. An ultrasonic sensor and gas flow rate meter may be used to determine an amount of oxygen being delivered to the user. Other components such as step valves and a solar panel may also be used to further conserve battery power. The oxygen concentrator may also incorporate an audio device such as a mobile phone.

Owner:INOVA LABS

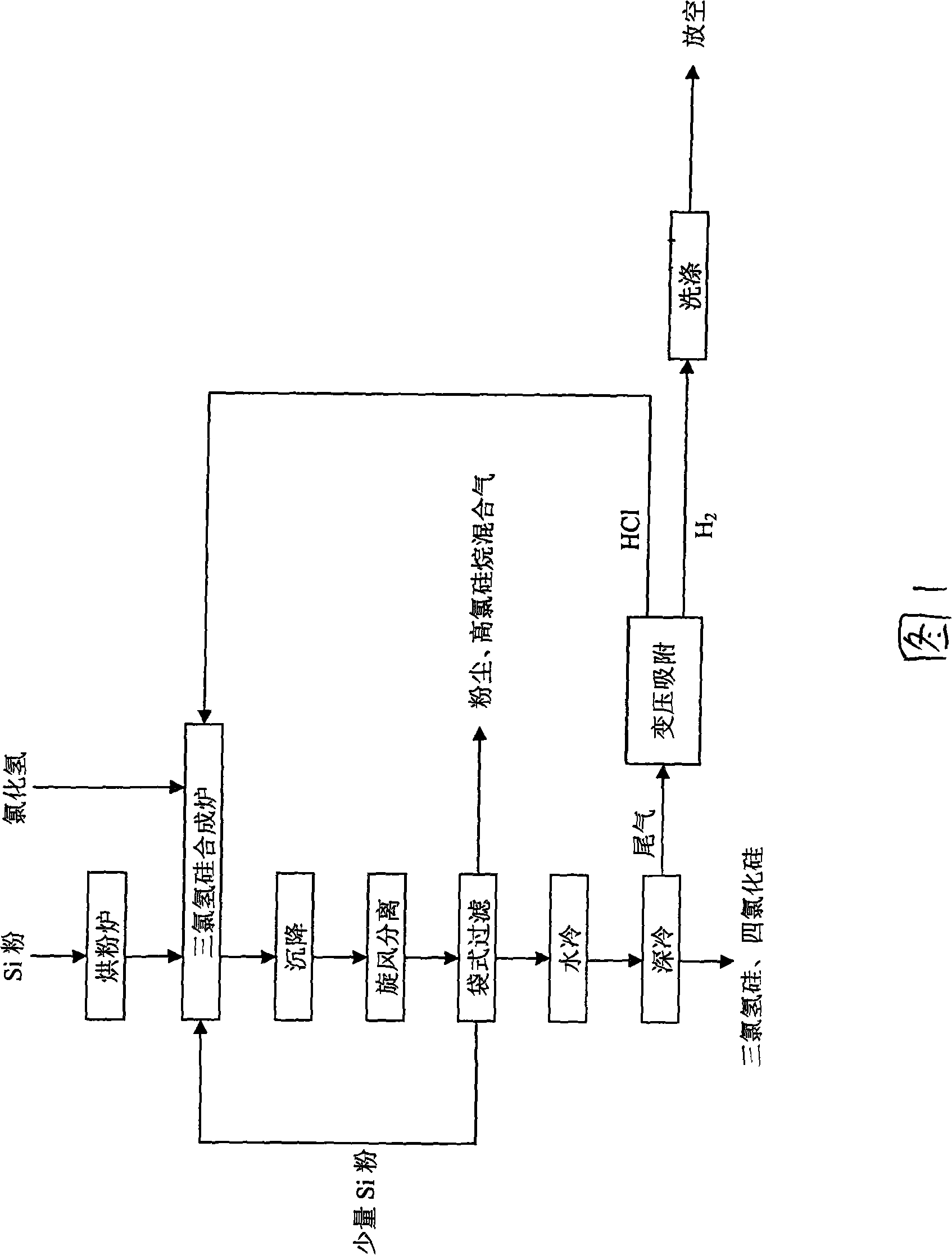

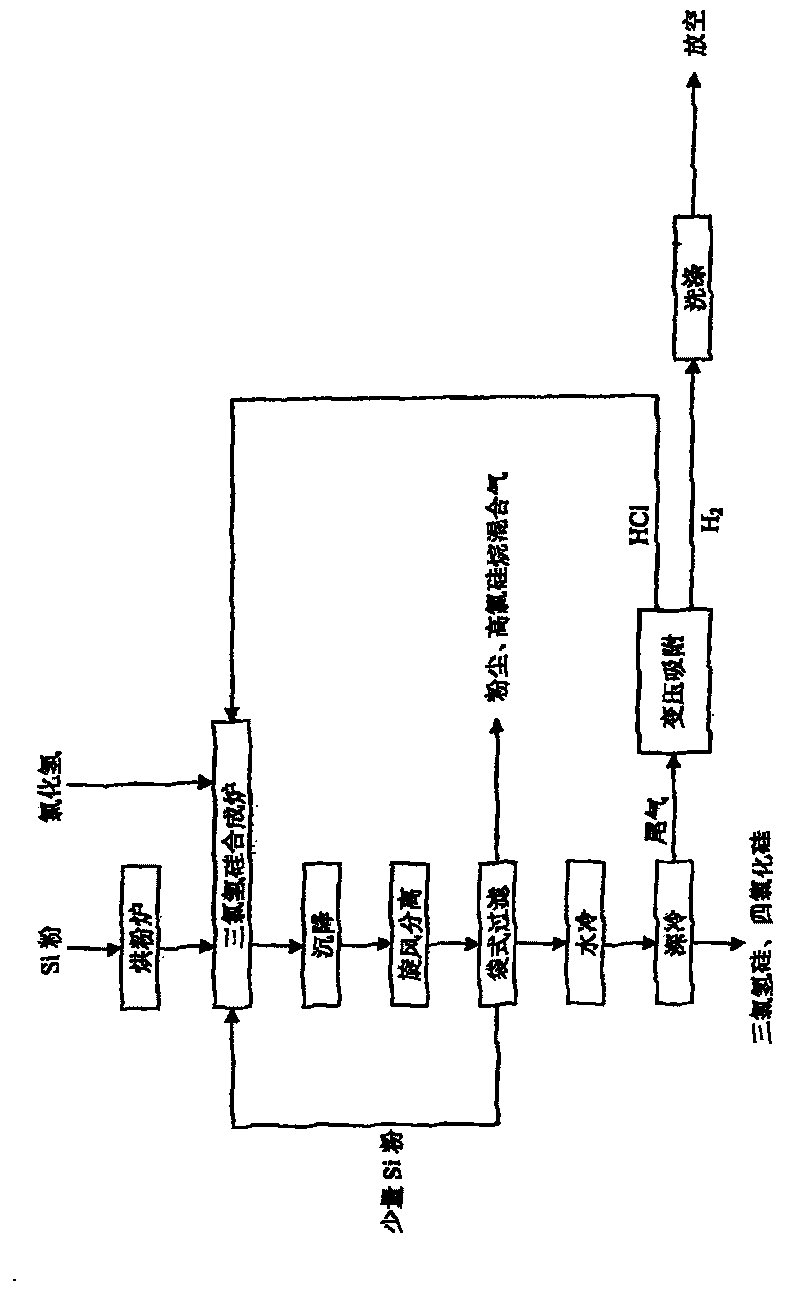

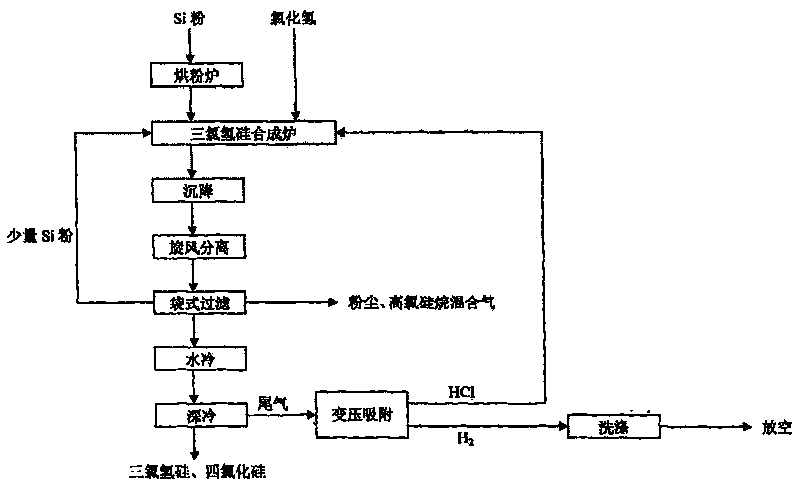

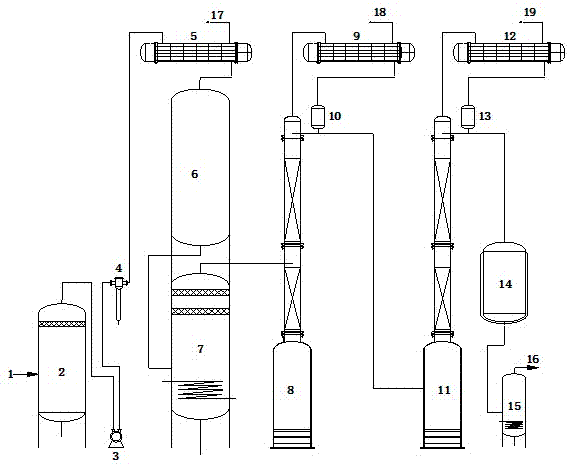

Method for synthesizing polysilicon raw material trichlorosilane

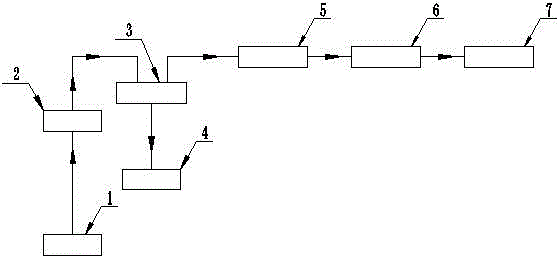

The invention discloses a method for the synthesis of a polysilicon raw material trichlorosilane. The method comprises the following steps: A) silica powder is conveyed to a trichlorosilane synthesis furnace by dried hydrogen chloride gas; B) hydrogen chloride for reaction is input into the synthesis furnace from the bottom of the trichlorosilane synthesis furnace proportionally and proper amount of hydrogen and silicon tetrachloride are added in the synthesis furnace at the same time; C) silica powder and hydrogen chloride react at the temperature of 280-310 DEG C to generate mixing gas containing trichlorosilane and silicon tetrachloride; D) the mixing gas of dust and high chlorosilane is removed, after water cooling and pressuring by a diaphragm compressor, trichlorosilane and silicon tetrachloride are condensed into liquid by a refrigerant with -40 DEG C, wherein, noncondensable gas containing H2 and HCI is separated. The method of the invention can improve the yield of trichlorosilane from 82 percent to more than 88 percent.

Owner:HUBEI HUIFU NANOMATERIAL CO LTD

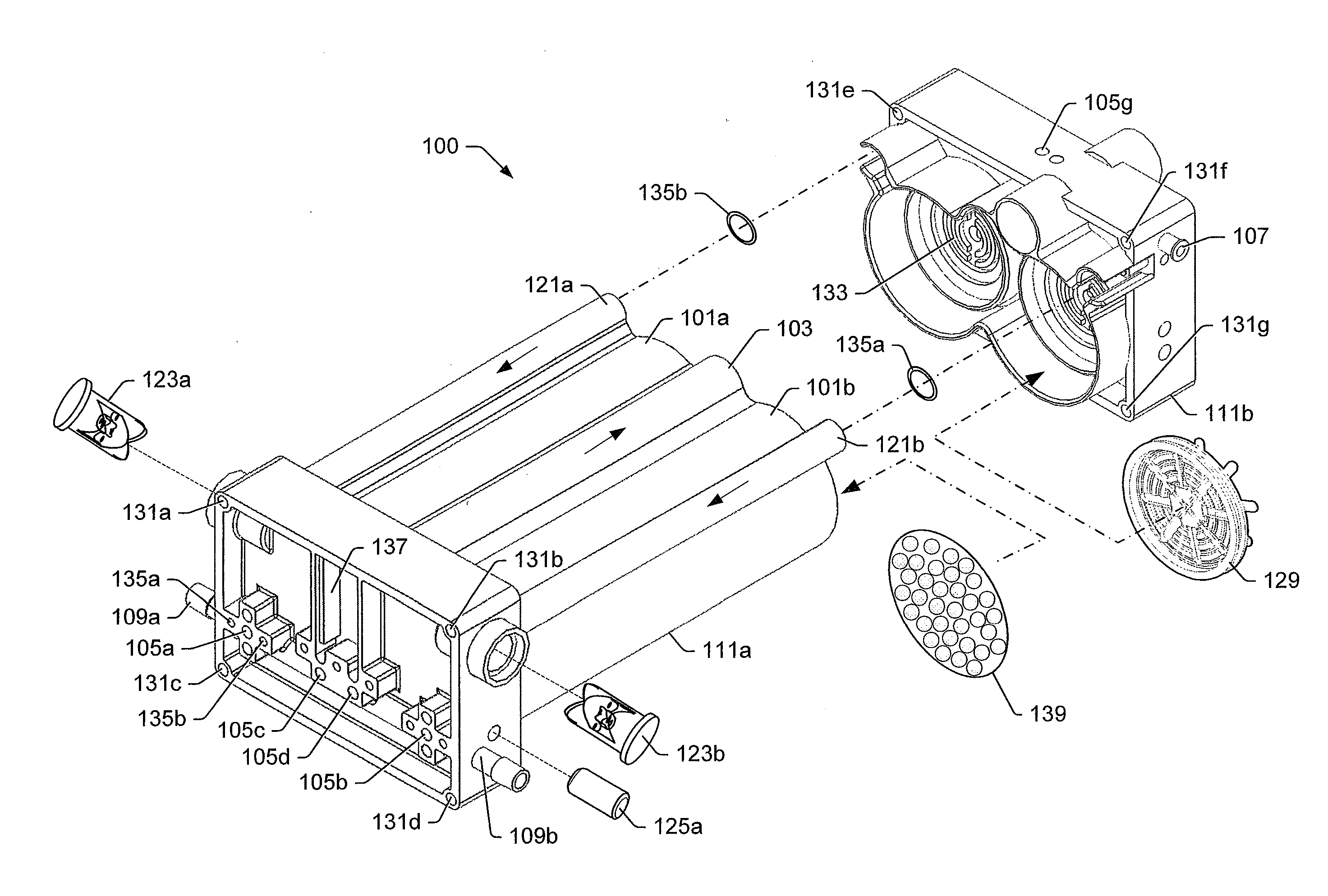

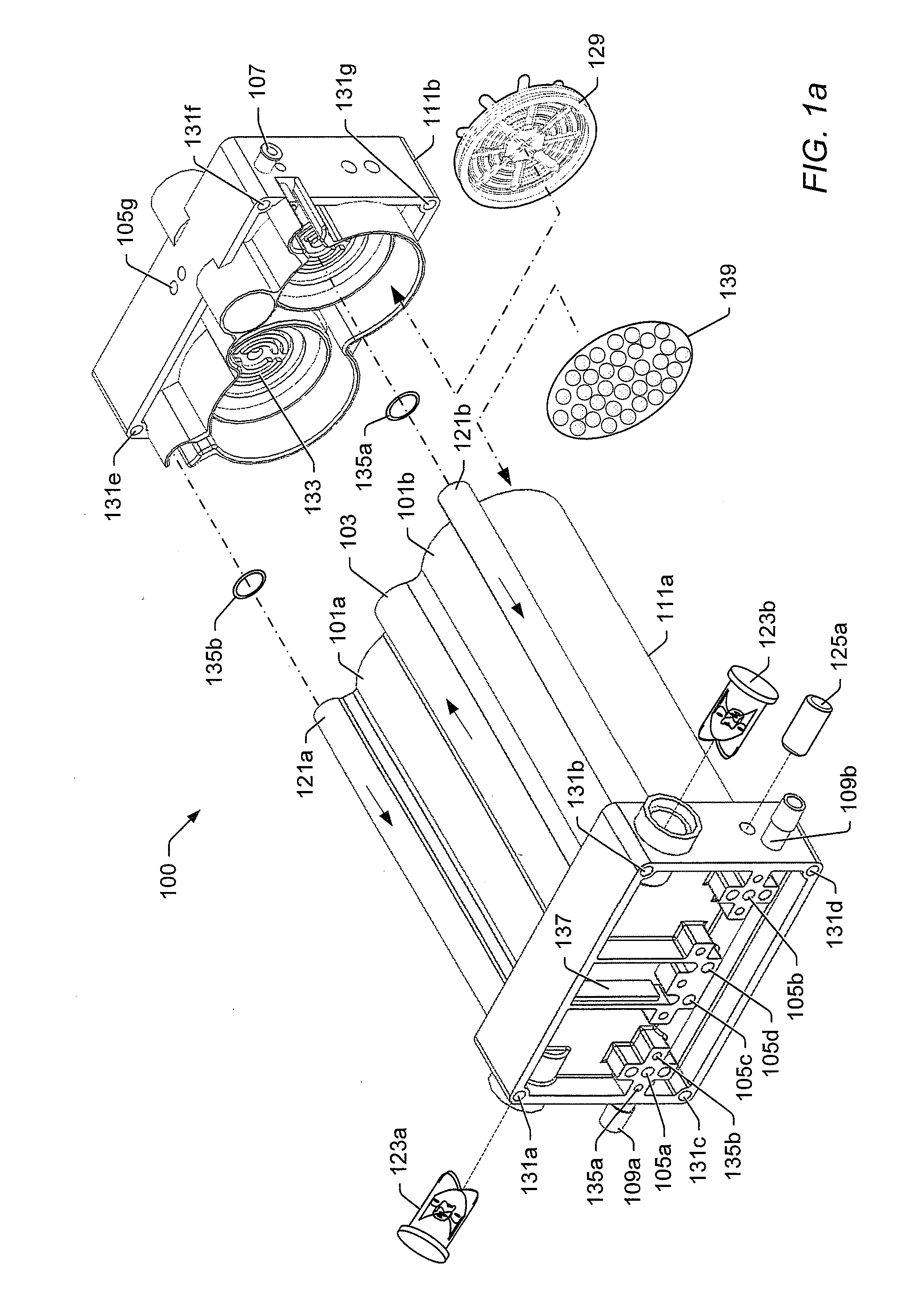

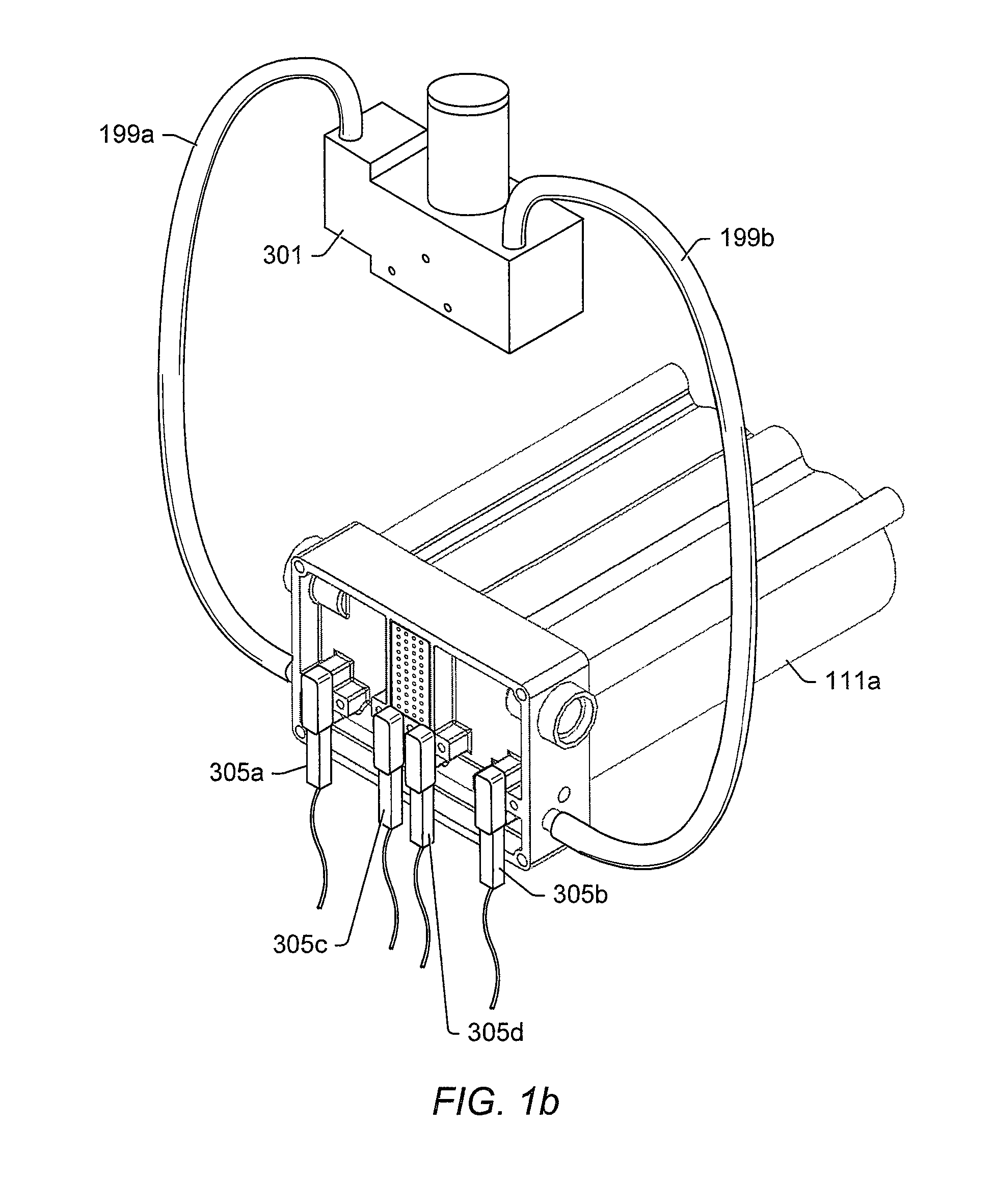

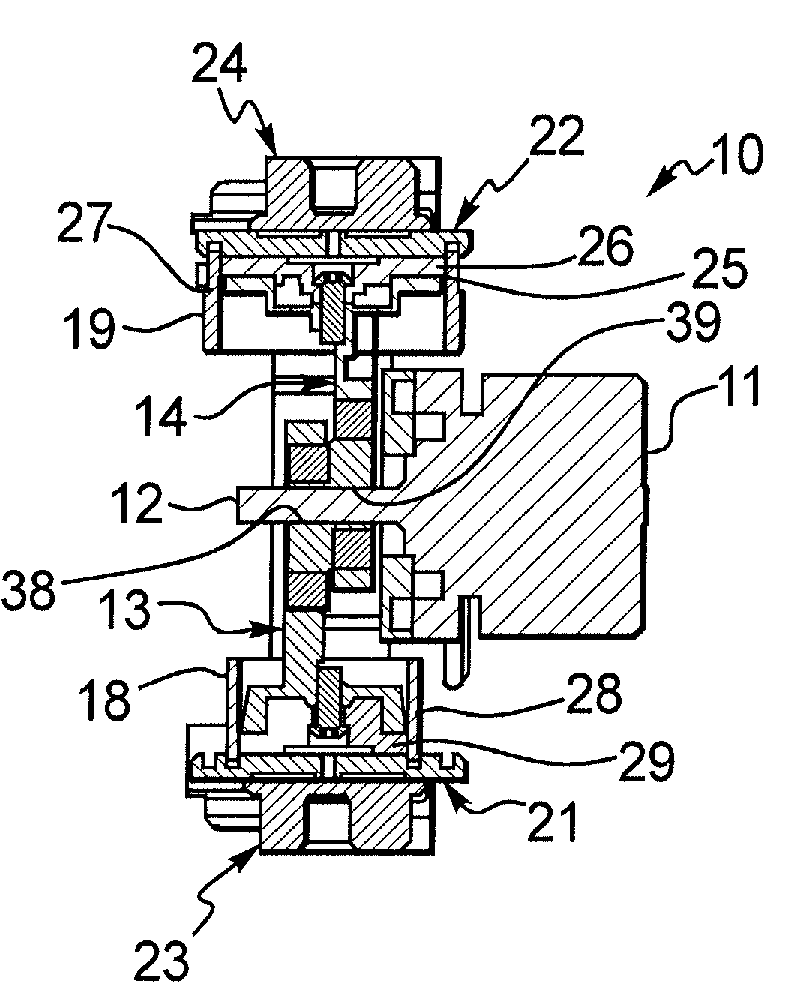

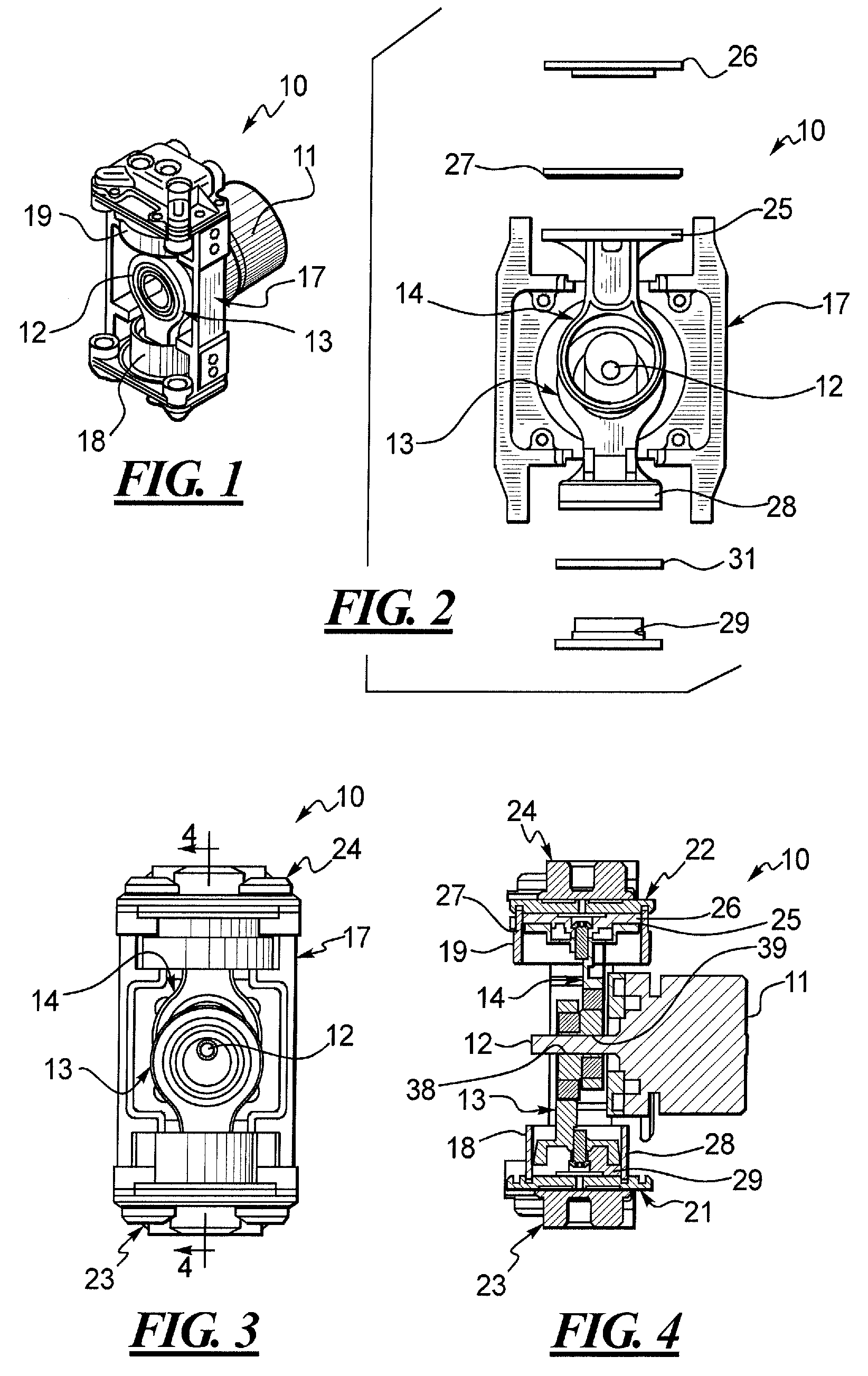

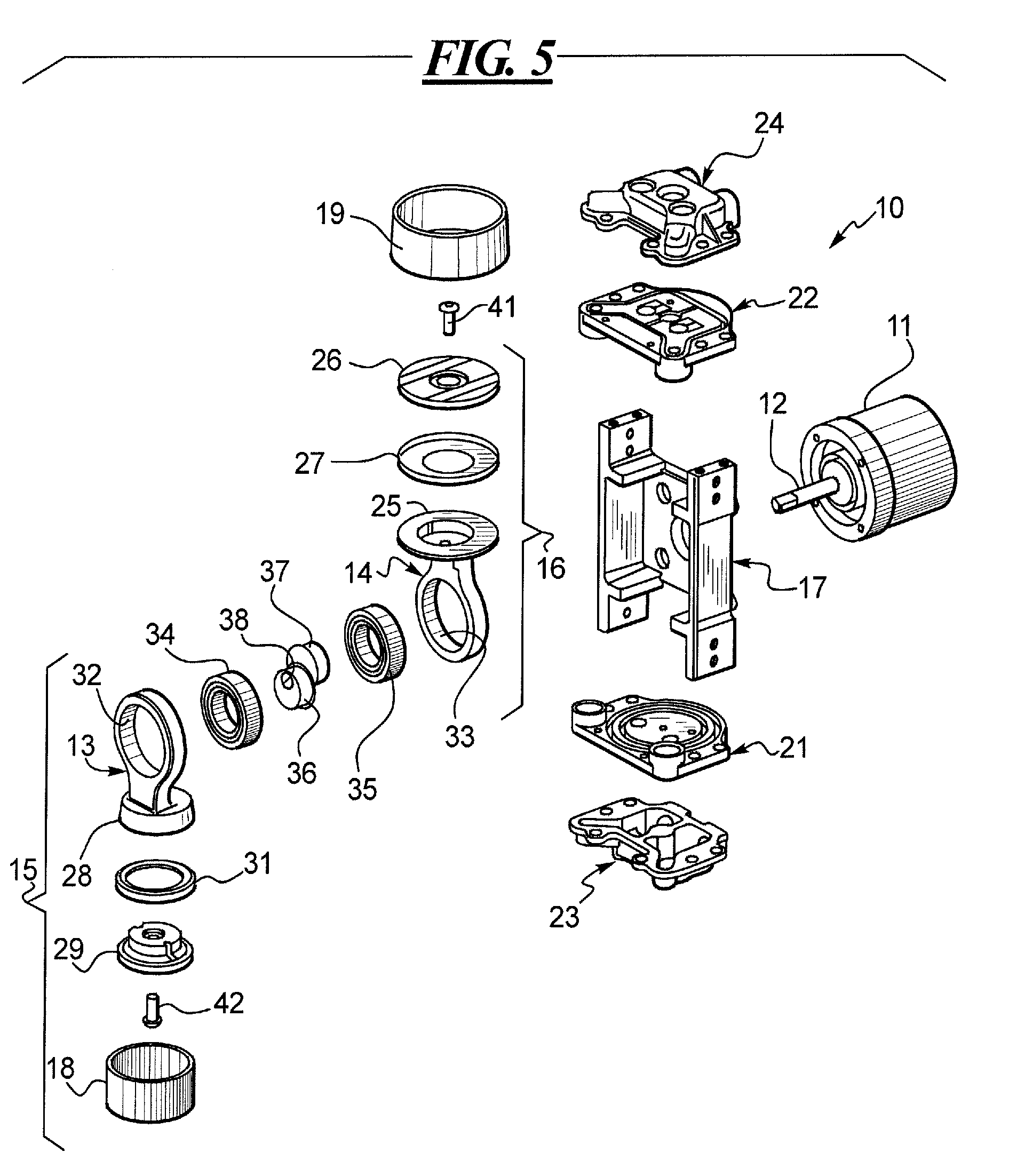

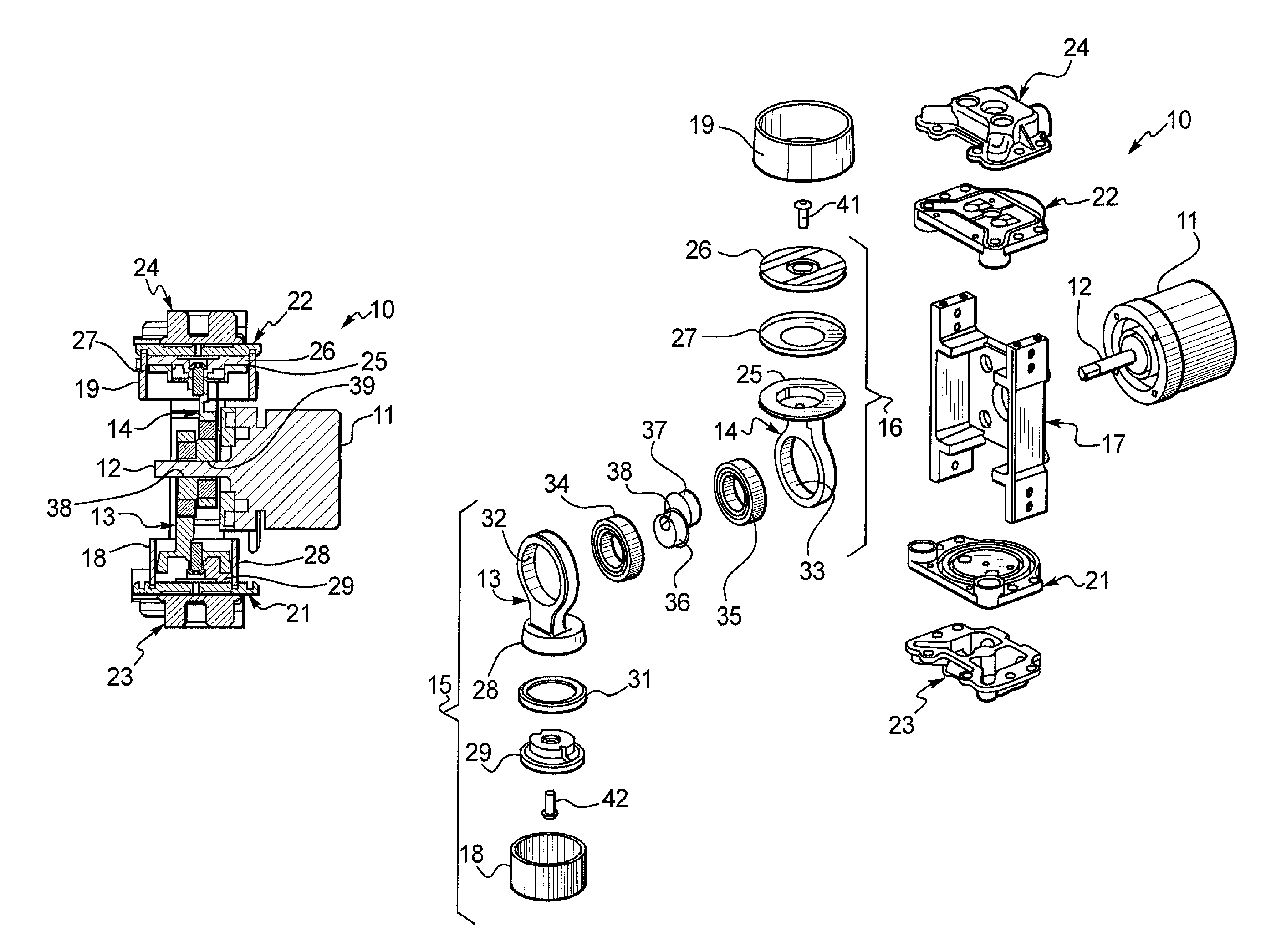

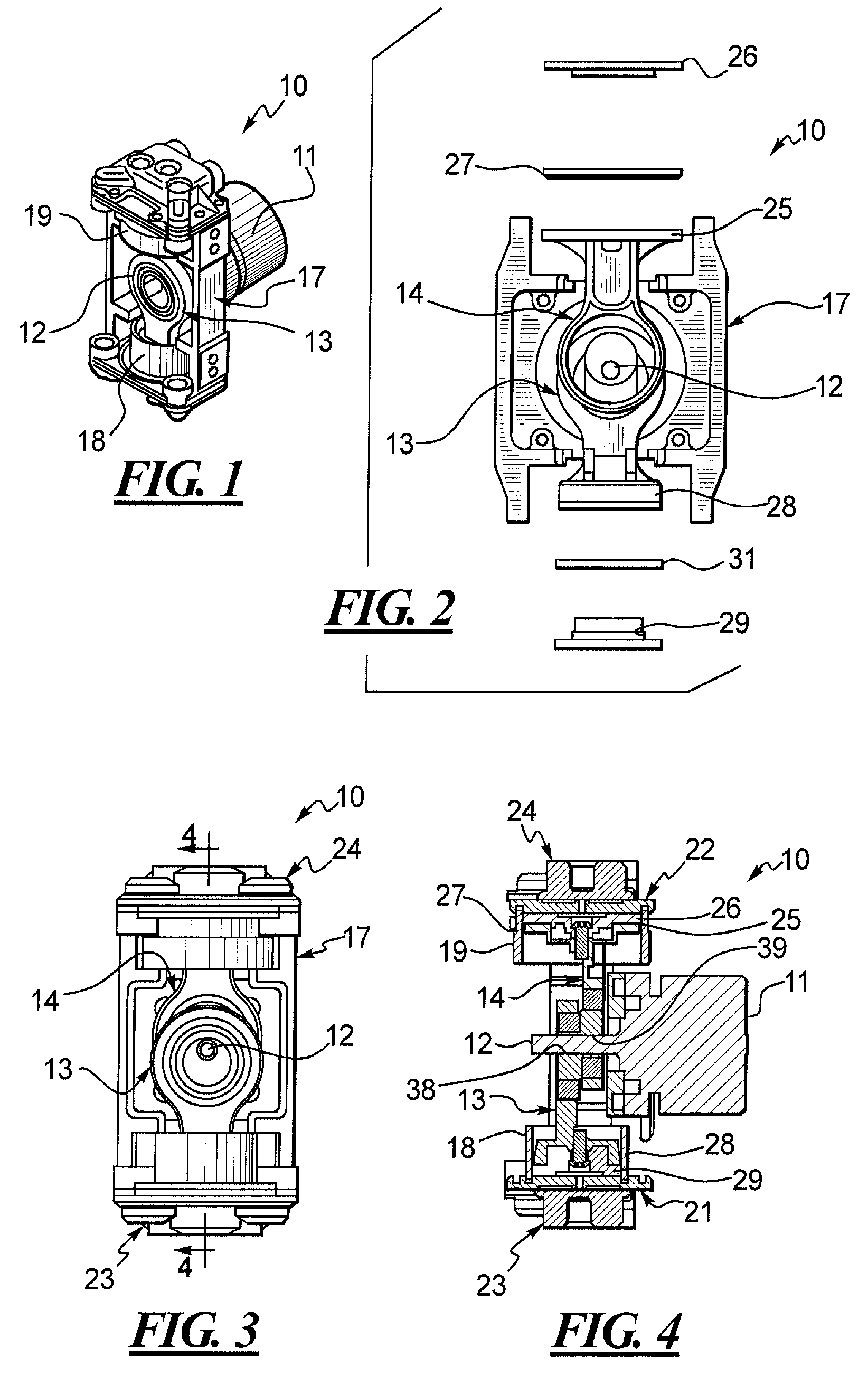

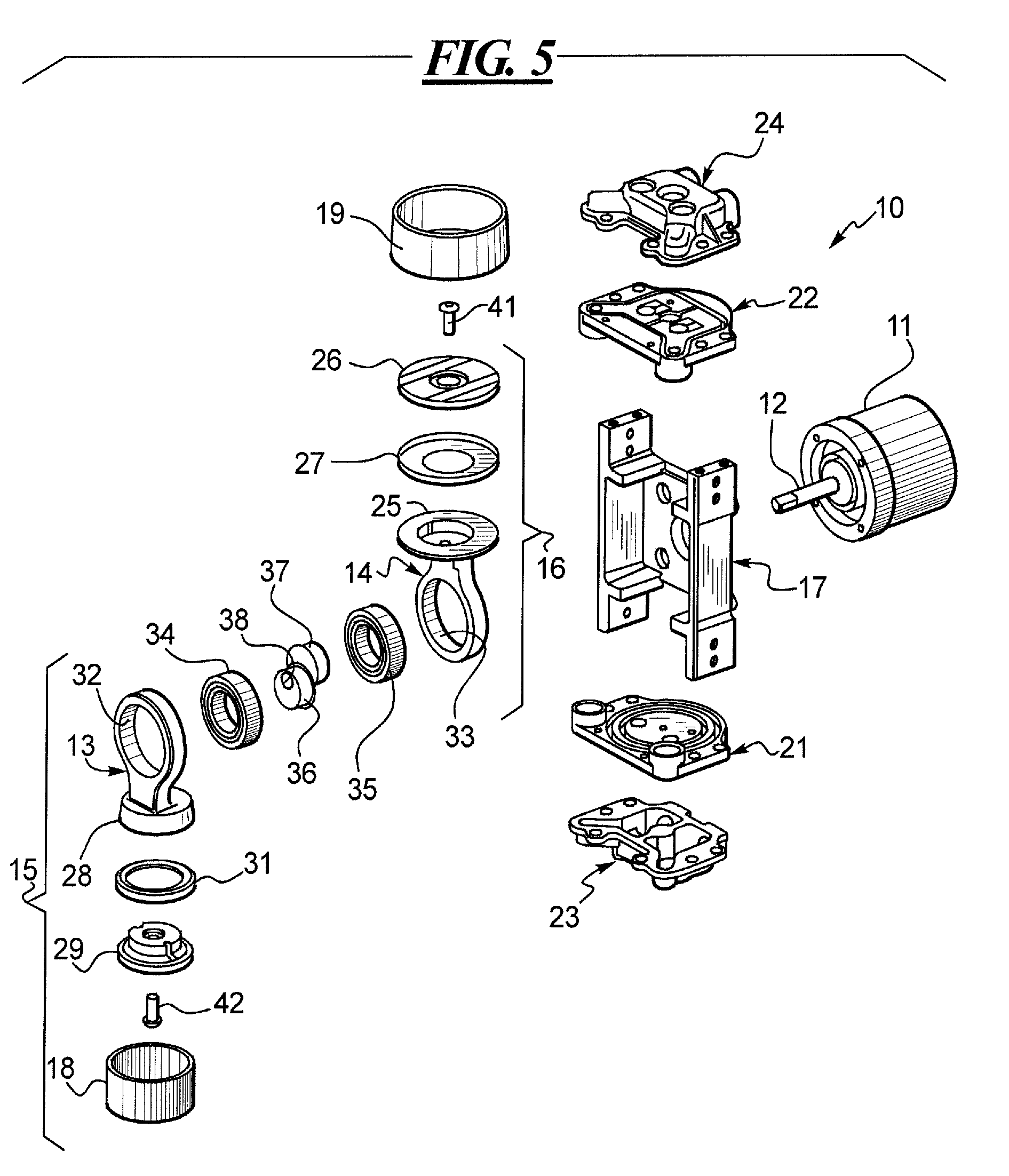

Balanced dual rocking piston pumps

ActiveUS20090016913A1Positive displacement pump componentsFlexible member pumpsDrive shaftGravity center

Piston assemblies for rocking piston compressors, diaphragm compressors and vacuum pumps are provided wherein the overall mass of each piston assembly is identical to that of the other assembly despite having rod tops, retainers and diaphragms of different diameters and therefore different capacities. Each piston assembly includes a connecting rod connected to a rod top that supports a cup seal and a retainer or retainer plate. The mass of each rod is equal to that of the other rod despite the differing geometries. The mass of each retainer is the same as that of the other retainer despite the differing geometries. The overall length and stroke length of each piston assembly is the same. As a result, centers of gravity of the piston assemblies are continuously balanced on either side of the drive shaft in terms of distance from the drive shaft and in absolute value. Alternatively, in embodiments where the first and second piston assemblies have unequal stroke lengths, and / or the first and second connecting rods having different masses, and / or the first and second retainers having different masses, balance is achieve by equalizing a product of an acceleration of the first piston assembly and combined masses of the first retainer and the first connecting rod with a product of an acceleration of the second piston assembly and combined masses of the second retainer and the second connecting rod according to the equation:(Mretainer1+Mrod1)·Aside1=(Mretainer2+Mrod2)·Aside2.

Owner:GAST MFG

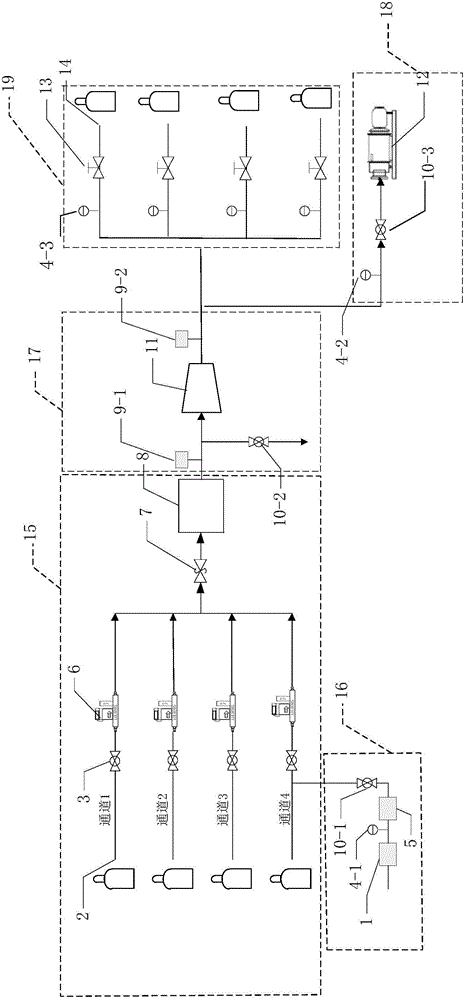

Anti-explosion multi-component dynamic air distribution device and method

ActiveCN104147948AStable pressureAnti-explosion effectMixer accessoriesMixing gases with gases/vapoursEngineeringAir compressor

The invention discloses an anti-explosion multi-component dynamic air distribution device and method. The device comprises a low-pressure air distribution system 15, an air compression generation device 16, a pressurization system 17, a vacuumization system 18 and a filling system 19. Through the adoption of a back pressure valve, the pressure of gas at the gas outlet end of the back pressure valve is stable before the gas enters a gas mixer, so that an anti-explosion effect is achieved; due to the adoption of a variable frequency diaphragm compressor, product gas is high in purity and free of impurity gas pollution; moreover, the pressure in the low-pressure air distribution channel is stabilized in a safe pressure range by adjusting the working frequency of the variable frequency diaphragm compressor to achieve the anti-explosion effect; flow control ranges of n mass flow controllers are distributed in a trapezoidal shape for real-time control on gas flow, so that the air distribution precision is improved; air generated by the air compressor is utilized as a diluent gas channel, so that the cost is saved; an alarm function can be performed in an air distribution process.

Owner:PERIC SPECIAL GASES CO LTD

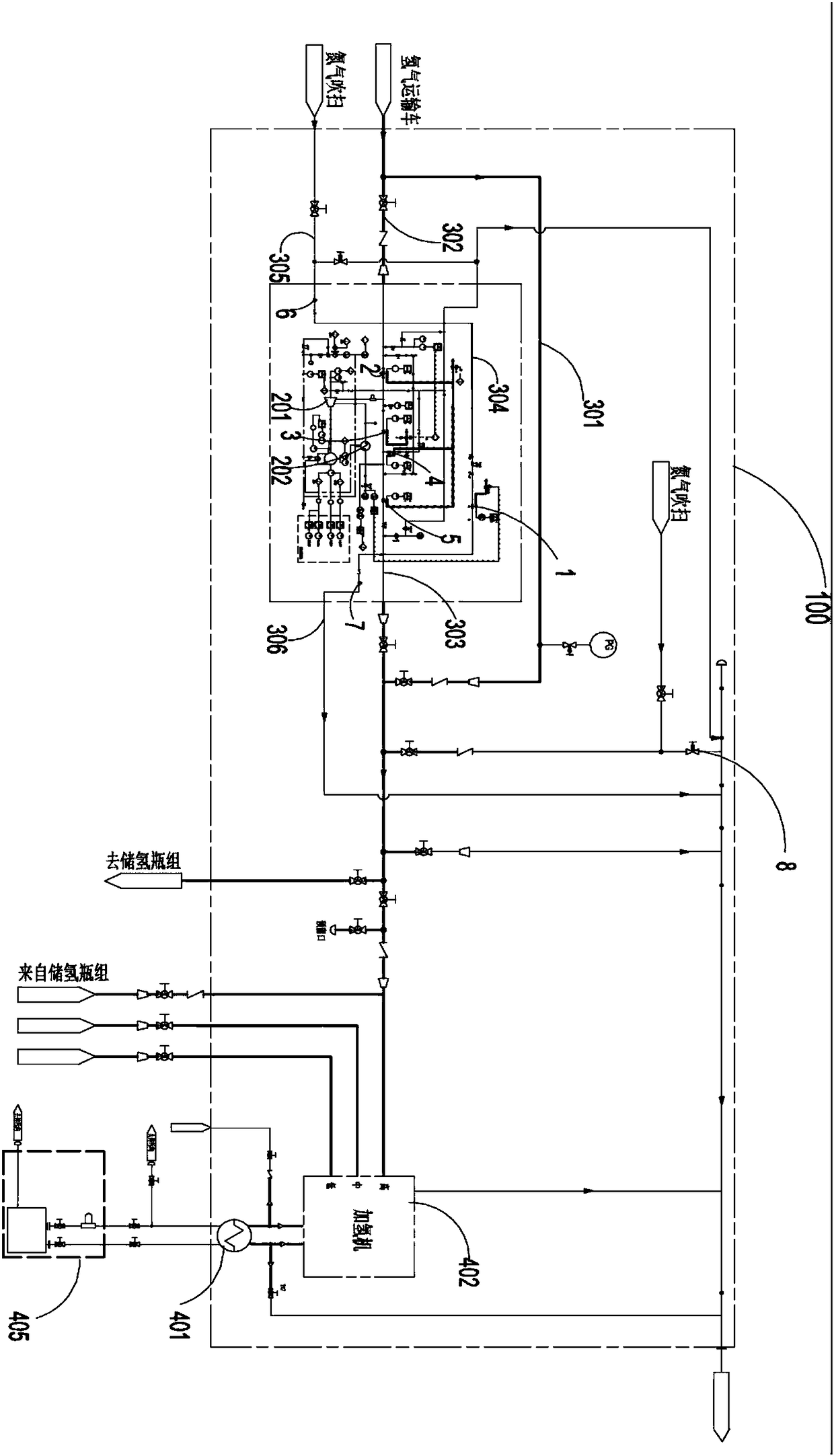

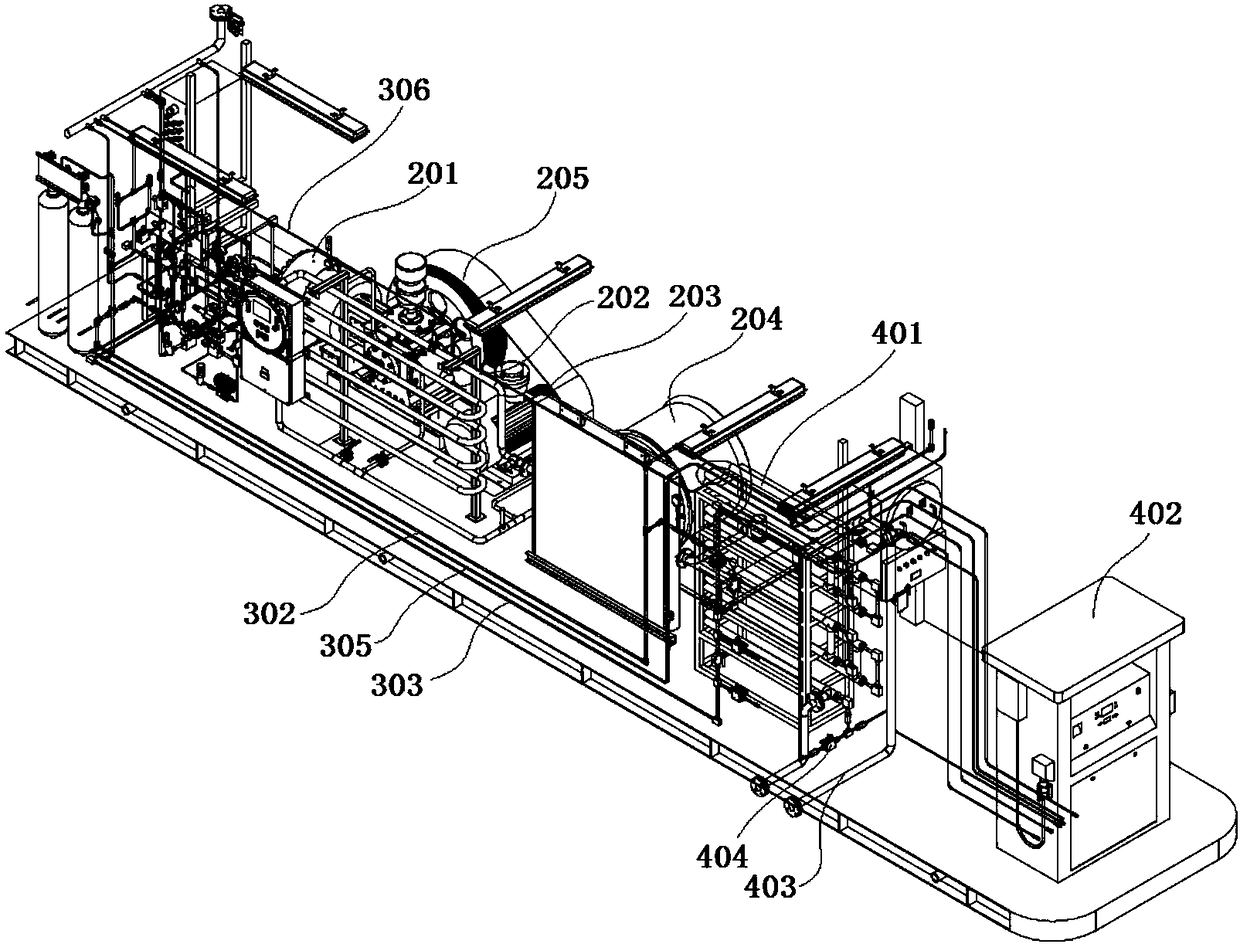

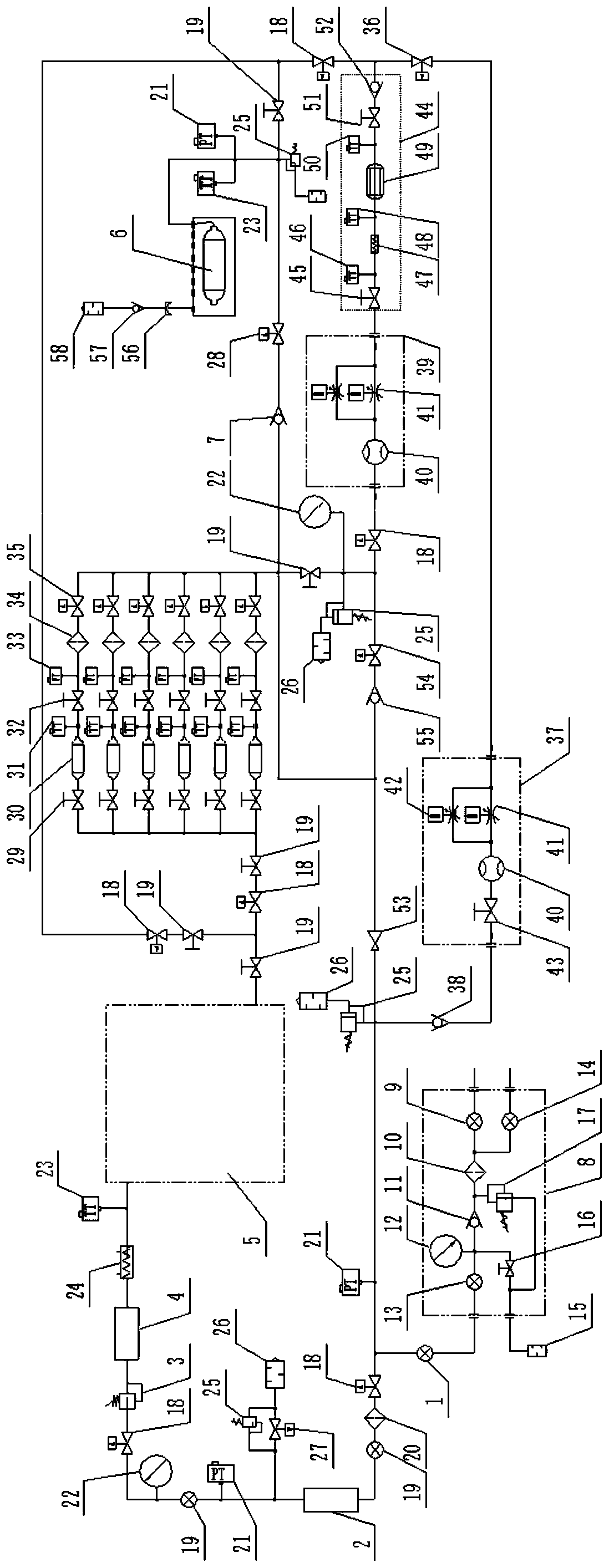

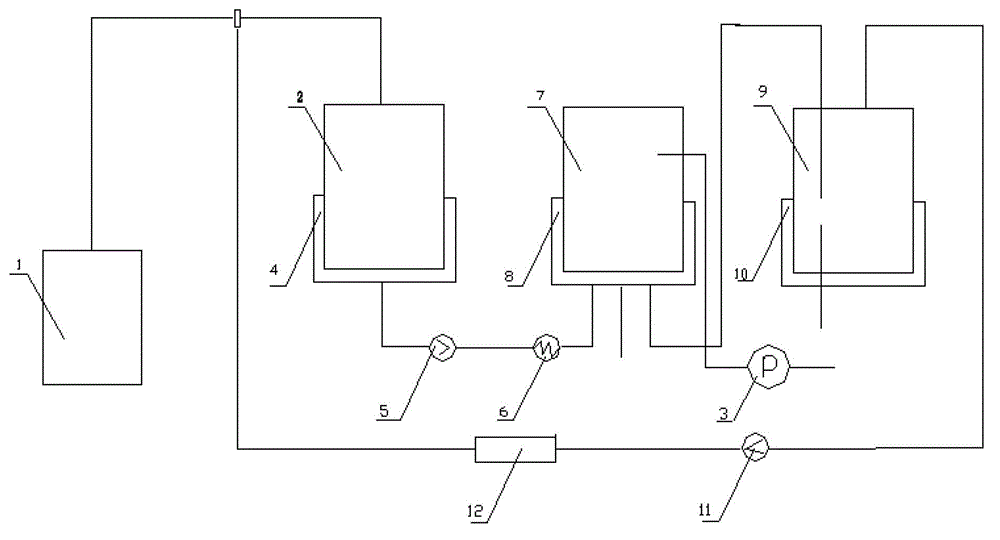

Hydrogeneration system of hydrogen compressor skid-mounted hydrogeneration equipment and hydrogeneration method thereof

ActiveCN108361546ACompact structureSmall footprintVessel geometry/arrangement/sizeSecondary cellsProcess engineeringSmall footprint

The invention provides a hydrogeneration system of hydrogen compressor skid-mounted hydrogeneration equipment and a hydrogenation method. The system comprises the following components arranged insidea skid-mounted shell: a pressurizing component, a hydrogen dispenser, a circulation loop and a controller, wherein a gas inlet of a diaphragm compressor in the pressurizing component is connected witha hydrogen inlet pipe, the end of the hydrogen inlet pipe is provided with an input end connected with a gas outlet of a hydrogen transporting truck, a gas outlet of the diaphragm compressor is connected with a hydrogen outlet pipe, and hydrogen in the hydrogen outlet pipe is cooled when flowing through a first cooling heat exchange element; a gas inlet pipeline of the hydrogen dispenser is connected with the hydrogen outlet pipe, and hydrogen in the gas inlet pipeline is cooled when flowing through a second cooling heat exchange element; one end of the circulation loop communicates with thehydrogen inlet pipe, and the other end of the circulation loop communicates with the hydrogen outlet pipe; and a first control valve, a second control valve and a third control valve which are used for controlling on and off of the pipelines are arranged on the hydrogen inlet pipe, the hydrogen outlet pipe and the circulation loop correspondingly, and are all connected with the controller. The whole hydrogeneration system is compact in structural arrangement, small in occupied area, and large in hydrogeneration capacity.

Owner:上海氢枫能源技术有限公司

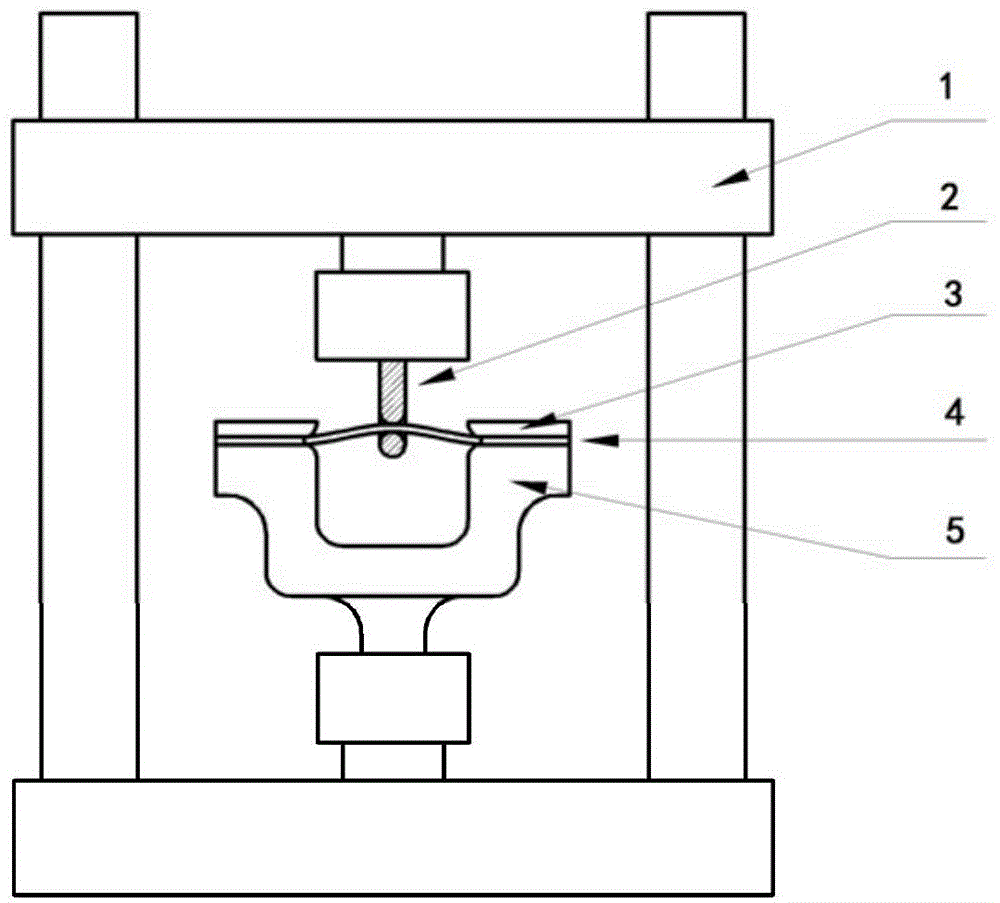

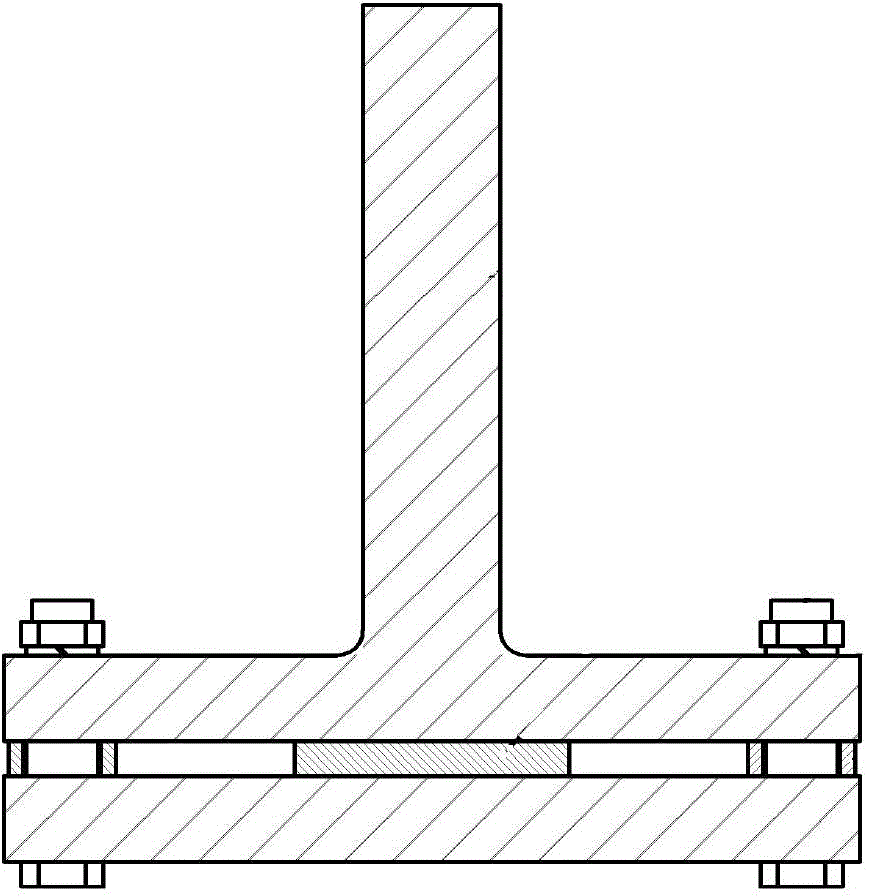

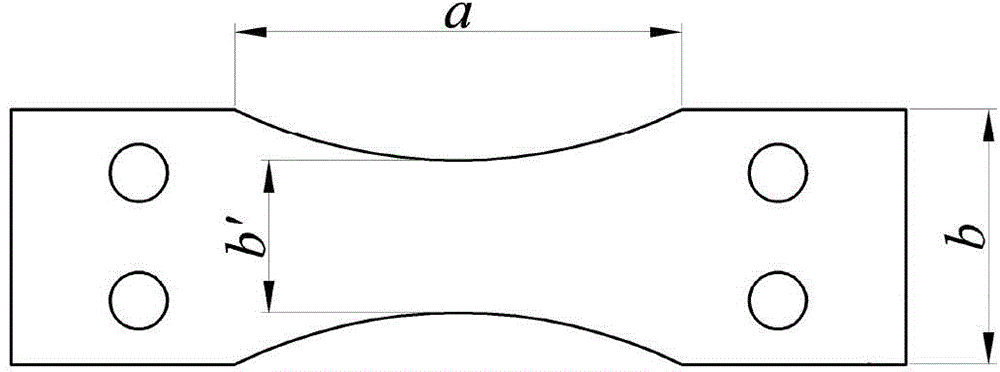

Metal diaphragm bending fatigue measurement device and method for diaphragm compressor

InactiveCN104677749AMaintain stabilityMaterial strength using steady bending forcesTension compressionMeasurement device

The invention relates to a metal diaphragm bending fatigue measurement device and method for a diaphragm compressor, provides a simple and easy bending fatigue measurement method for a metal diaphragm with a thickness of smaller than 1mm, and aims to make a bending fatigue test on the metal diaphragm on a tension-compression fatigue tester. A test clamping device consists of a base, a clamping block and a chuck, wherein a sample is fixed by the base and the clamping block; the middle of the sample is clamped by the chuck; the sample is processed into a middle-arc shape, so that the middle of the sample can be fractured. A fatigue tester program is designed, displacement amplitude is positioned for test, and stress variations are observed to judge whether the sample is fractured or not to obtain fatigue cycle data. An elastic mechanics mechanism is used for calculating a corresponding stress value by virtue of displacement amplitude, thereby obtaining a corresponding relationship between stress amplitude and a fatigue cycle. The method is simple in design and convenient to use, and is used for testing the fatigue resistance of the metal diaphragm of the diaphragm compressor.

Owner:UNIV OF SCI & TECH BEIJING

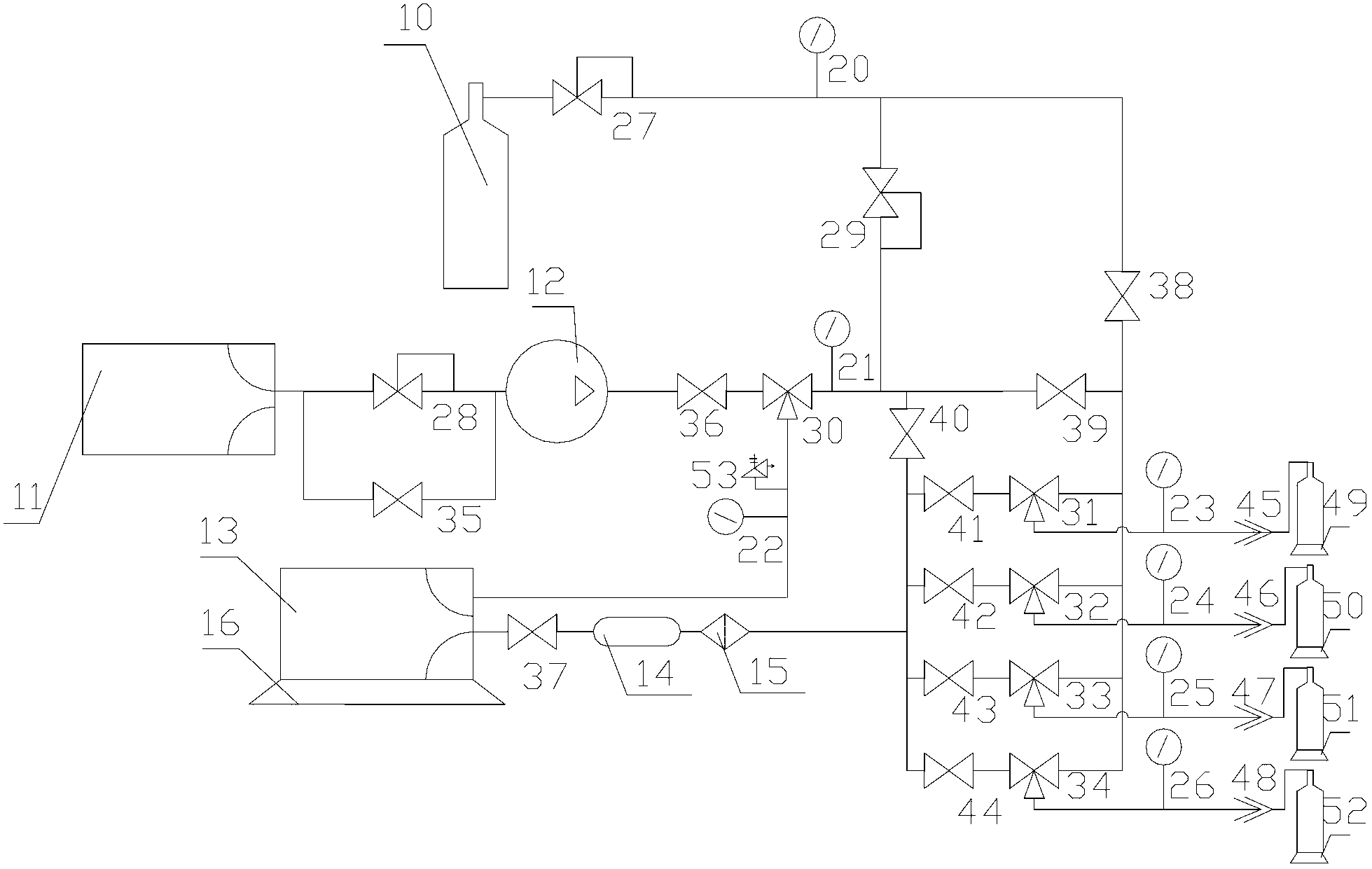

Ultrahigh pressure hydrogen pressure test system

PendingCN110702528AHigh test pressureImprove the efficiency of inflation experimentsMachine part testingMaterial strength using tensile/compressive forcesUltra high pressureGas cylinder

The invention discloses an ultrahigh pressure hydrogen pressure test system. The system comprises a hydrogen input port, wherein the hydrogen input port is connected with a gas inlet of a first gas cylinder group through a first pipeline provided with a first stop valve, a gas outlet of the first gas cylinder group is connected with a gas inlet of a second gas cylinder group through a second pipeline provided with a pressure reducing valve, a gas outlet of the second gas cylinder group is connected with a gas inlet of a 120MPa hydrogen compressor through a third pipeline, a gas outlet of the 120 MPa hydrogen compressor is connected with a gas inlet of a high pressure gas cylinder group through a fourth pipeline, a gas outlet of the high pressure gas cylinder group is connected with a hydrogen inlet and a hydrogen outlet of a test gas cylinder through a fifth pipeline, and the fifth pipeline is also connected with the first pipeline through a sixth pipeline provided with a fifth pneumatic ball valve and a second one-way valve. The ultrahigh pressure hydrogen pressure test system is high in test pressure, and adopts a combined pressurization mode of a diaphragm compressor and a high-pressure liquid-driven oil-free piston machine, and the pressurization pressure can reach 120MPa.

Owner:北京海德利森科技有限公司

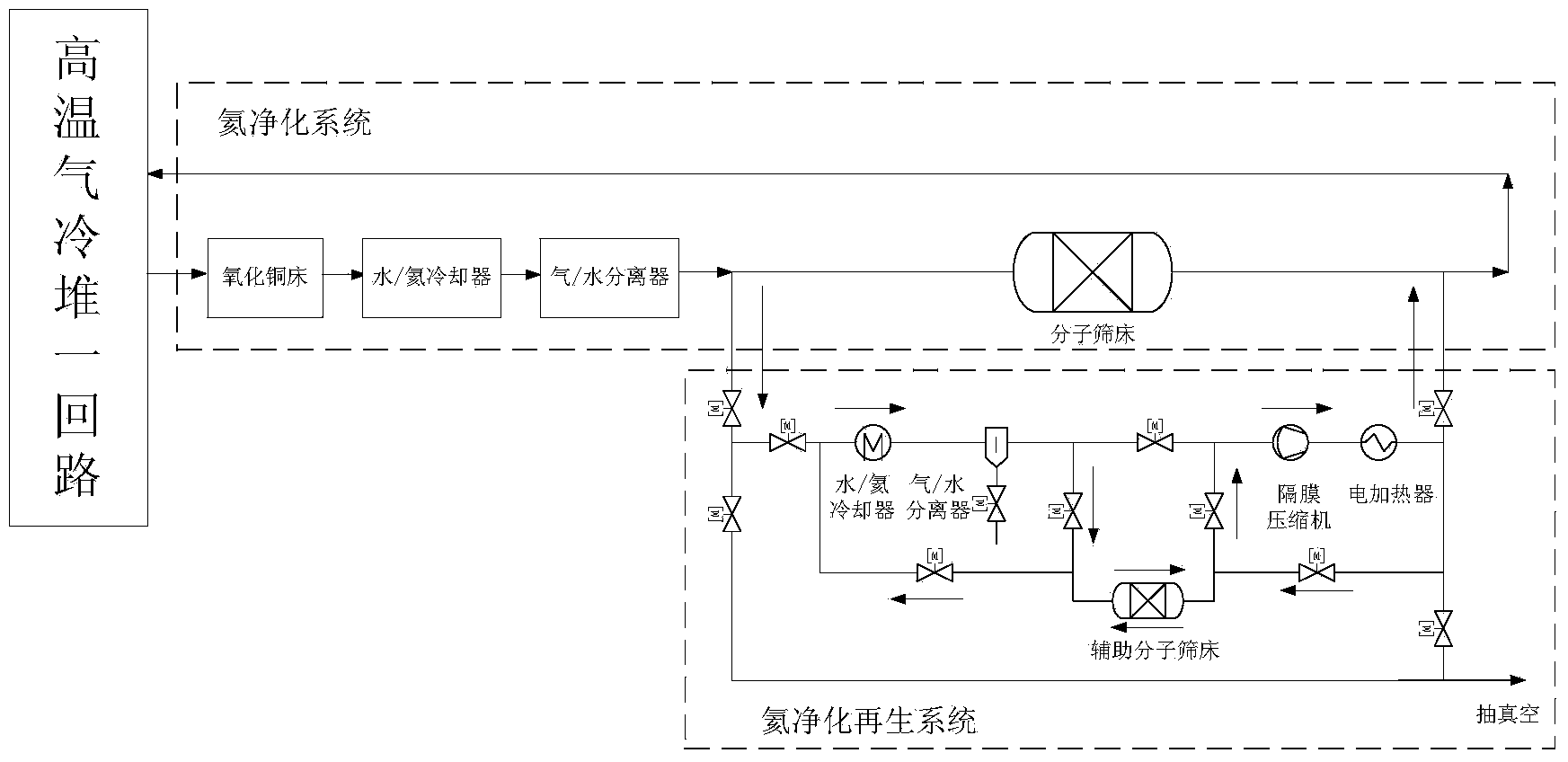

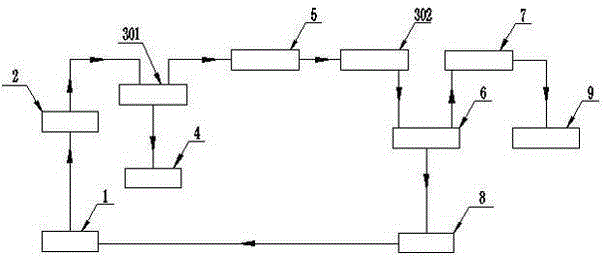

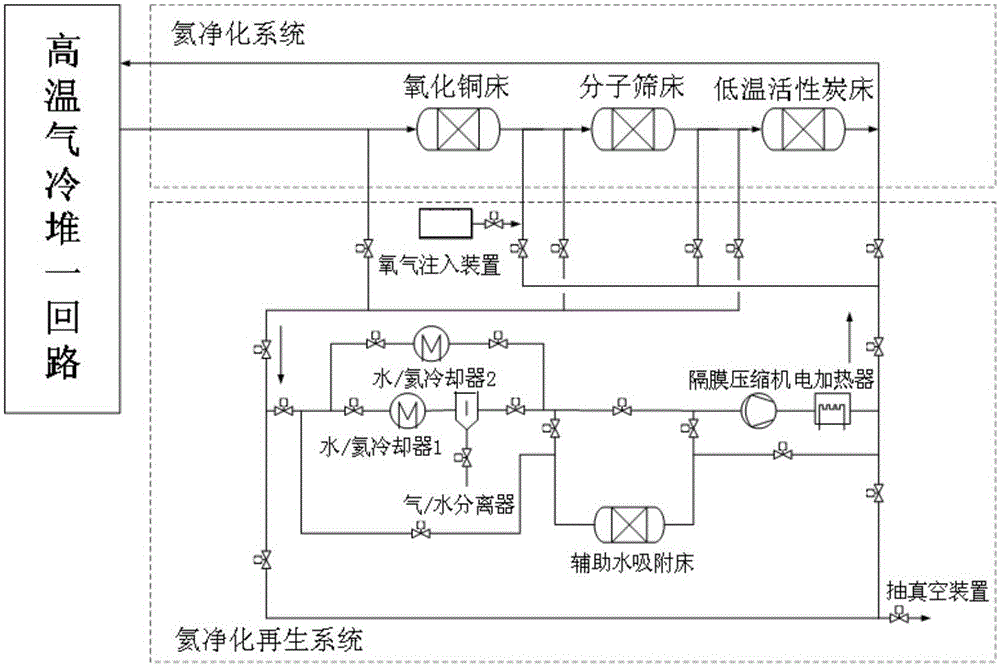

High temperature gas cooled reactor tritium-contained wastewater optimization collection system and technology

The invention relates to a high temperature gas cooled reactor tritium-contained wastewater optimization collection system. The system is composed of a first closed-loop circulation system and a second closed-loop circulation system. The first closed-loop circulation system is formed by sequentially connecting a helium purification regeneration system diaphragm compressor, a helium purification regeneration system electric heater, a helium purification system molecular sieve bed, a helium purification regeneration system water and helium cooler, a helium purification regeneration system gas and water separator and an auxiliary molecular sieve bed. The second closed-loop circulation system is formed by sequentially connecting a helium purification regeneration system diaphragm compressor, a helium purification regeneration system electric heater, an auxiliary molecular sieve bed, a helium purification regeneration system water and helium cooler, and a helium purification regeneration system gas and water separator. By the adoption of the system and technology, high temperature gas cooled reactor tritium-contained wastewater can be effectively collected, the running time of a whole high temperature gas cooled reactor helium purification system is prolonged, efficient running of the helium purification system is kept, and the system and technology have great significance in implementation of industrialization of a high temperature gas cooled reactor technology.

Owner:CHINERGY CO LTD

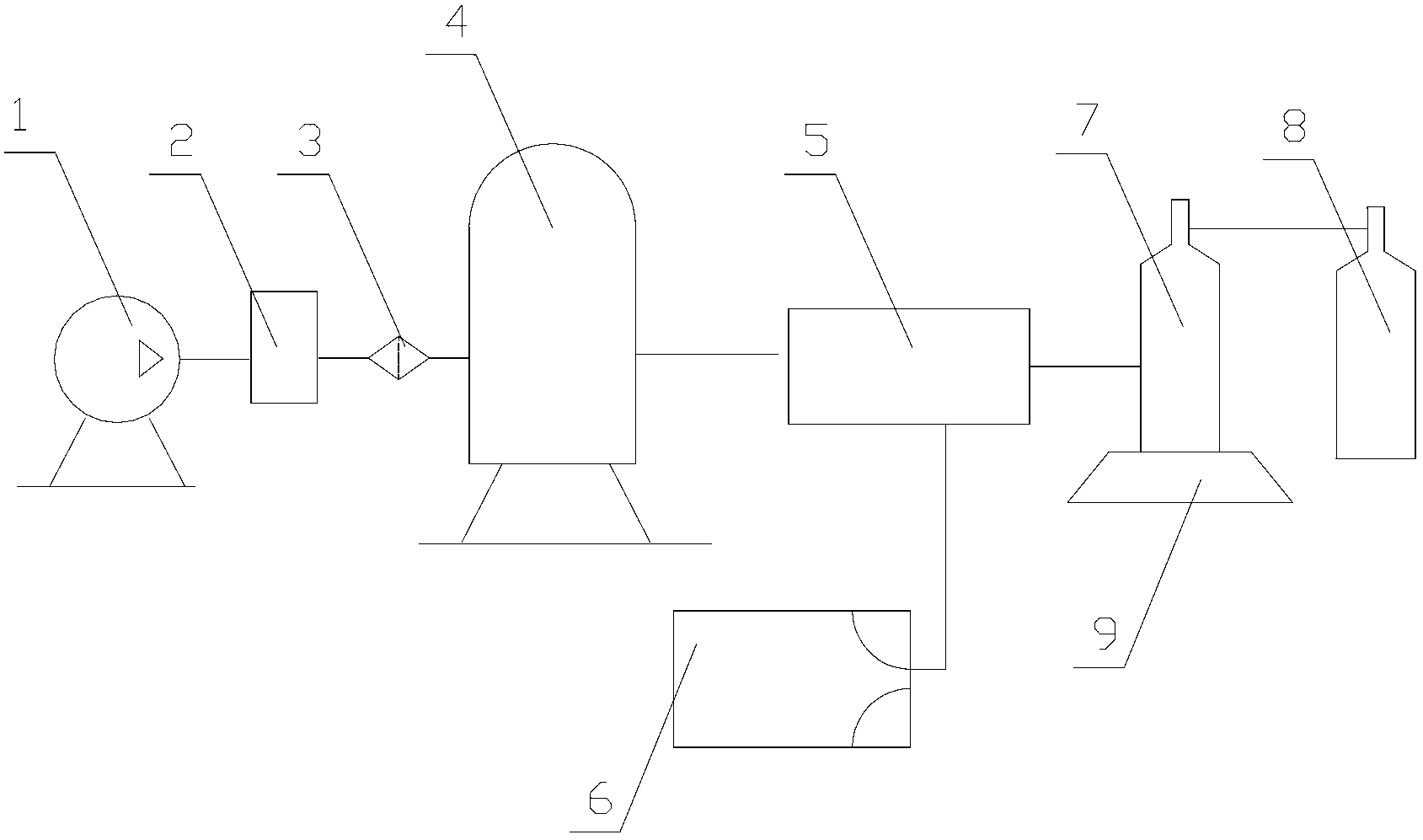

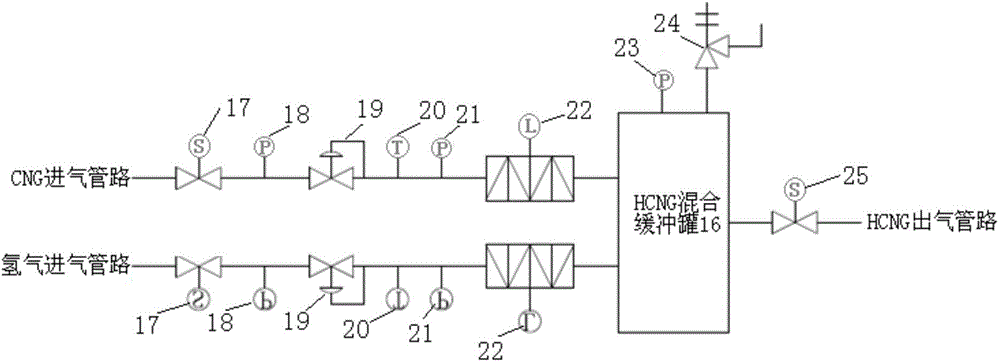

Mixed gas filling device and mixed gas filling method of CNG and HCNG

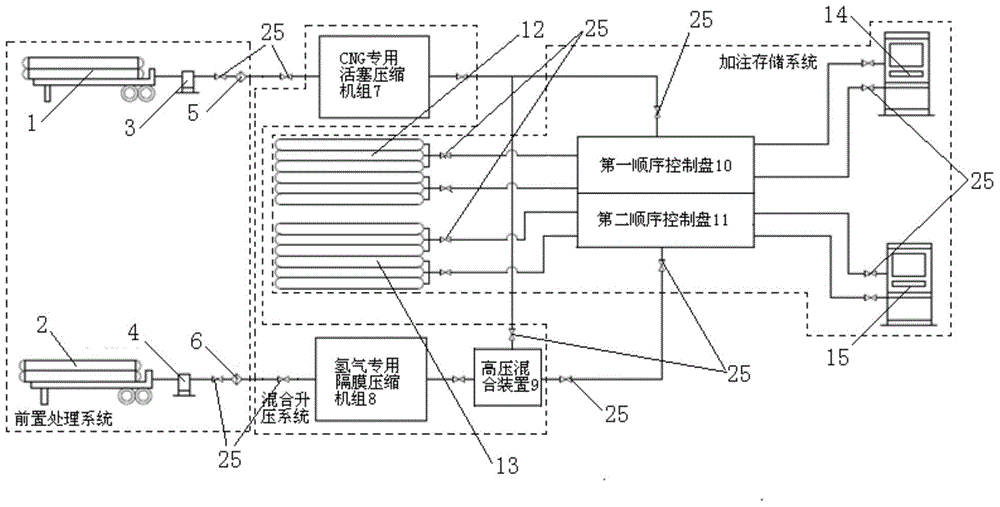

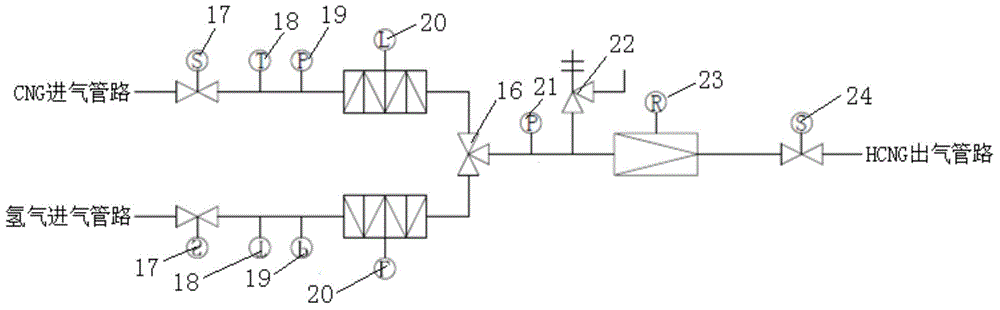

ActiveCN104456067ALow costEasy procedurePipeline systemsContainer discharging methodsProcess engineeringHigh pressure

The invention relates to a mixed gas filling device and a mixed gas filling method of CNG and HCNG. The device comprises a pre-processing system, a mixed pressure raising system and a filling and storing system, wherein the pre-processing system is connected with the mixed pressure raising system and the filling and storing system and comprises a tube bundle CNG conveying trailer, a tube bundle hydrogen conveying trailer, a CNG gas discharging column, a hydrogen discharging column, a CNG purifier and a hydrogen purifier; the mixed pressure raising system comprises a special piston compressor unit for CNG, a special diaphragm compressor unit for hydrogen and a high pressure mixing device; the gas inlet of the special piston compressor unit for CNG is connected with the gas outlet of the CNG purifier, and the gas outlet of the special piston compressor unit for CNG is connected with the CNG gas inlet pipeline of the high pressure mixing device; the gas inlet of the special diaphragm compressor unit for hydrogen is connected with the gas outlet of the hydrogen purifier, and the gas outlet of the special diaphragm compressor unit for hydrogen is connected with a hydrogen inlet pipeline of the high pressure mixing device; and an HCNG gas outlet pipeline of the high pressure mixing device is connected with the filling and storing system. The mixed gas filling device and the mixed gas filling method provided by the invention can be widely applied to gas stations of HCNG automobiles and CNG automobiles.

Owner:TSINGHUA UNIV

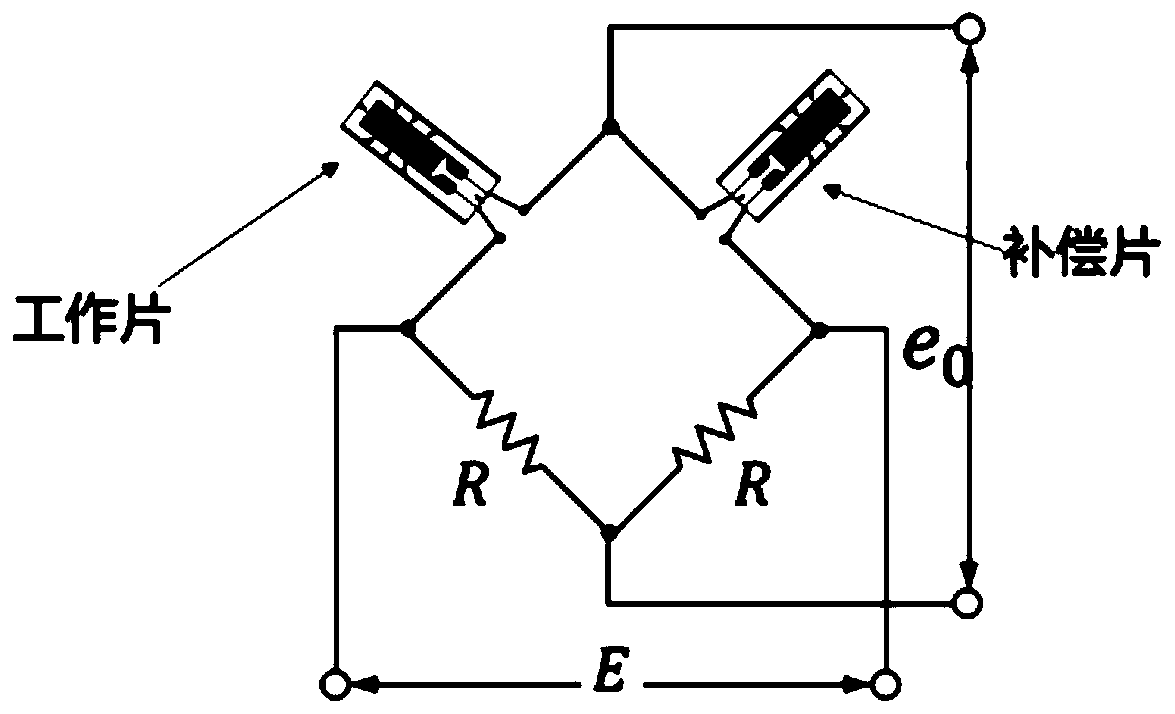

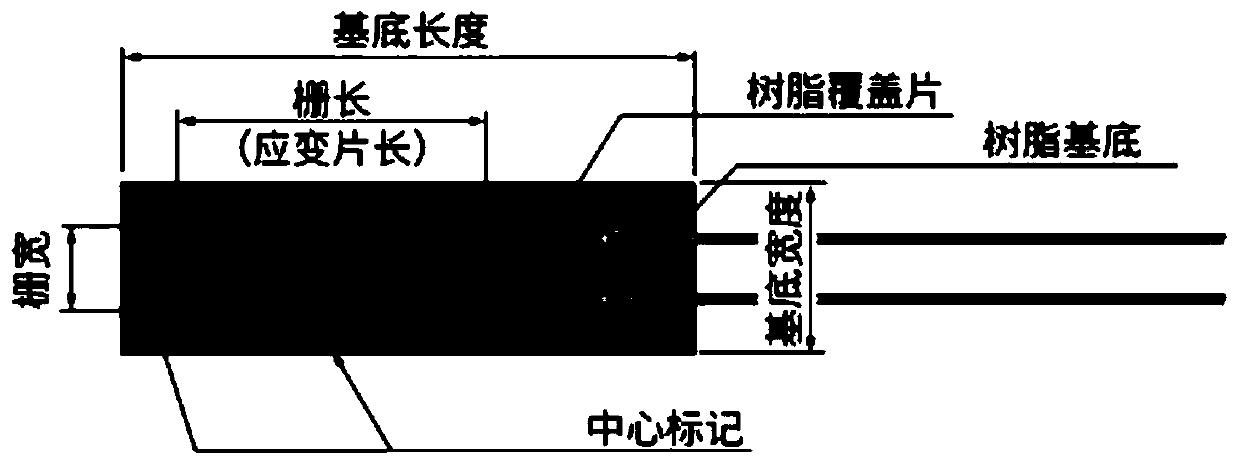

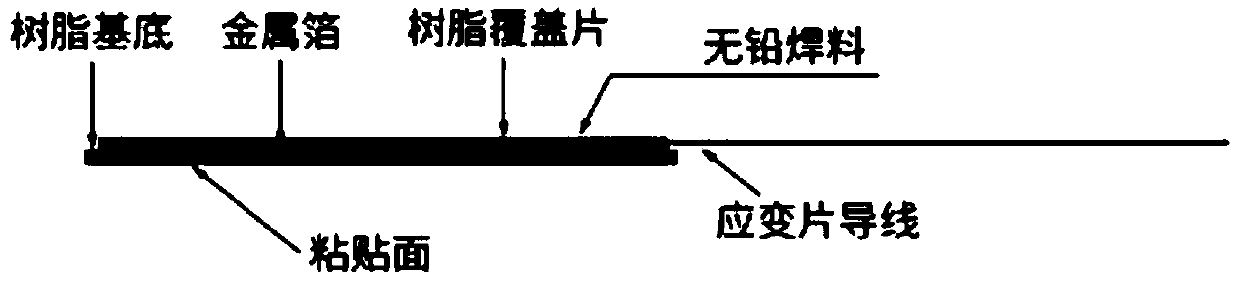

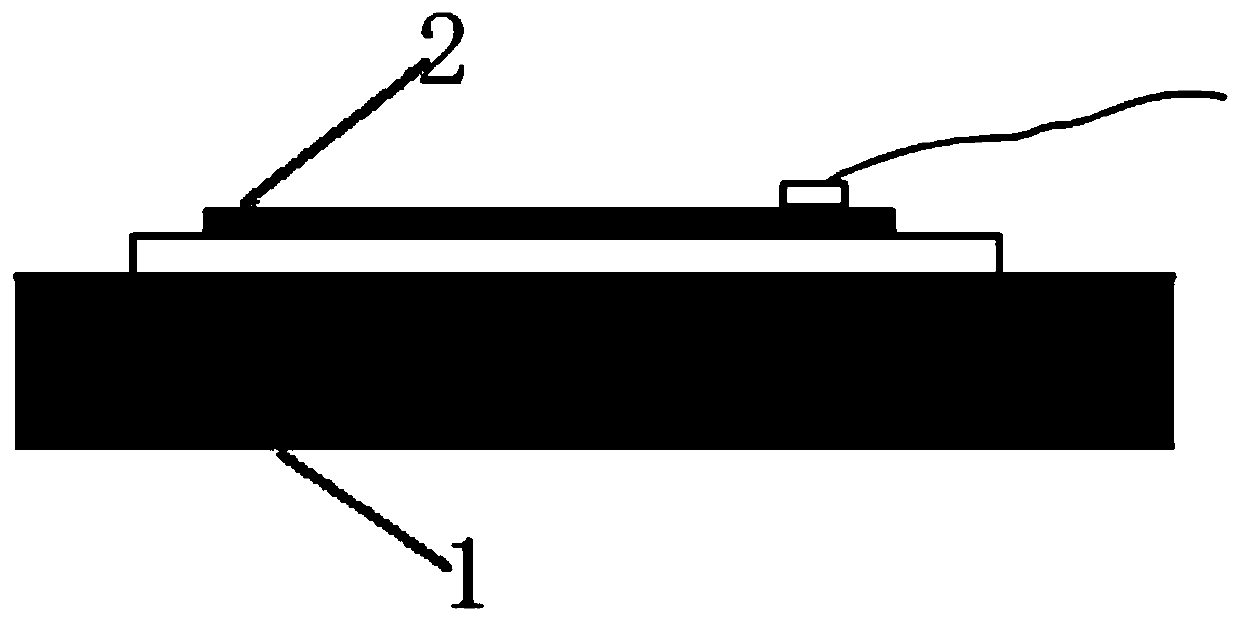

Oil pressure and air pressure monitoring device and method for diaphragm compressor

ActiveCN110374857ANo damageHigh sensitivityPump testingFlexible member pumpsLinear relationshipEngineering

The invention belongs to the technical field of compressors, and particularly relates to an oil pressure and air pressure monitoring device and method for a diaphragm compressor. Due to the fact thatthe diaphragm compressor is high in operational pressure ratio and large in pressure range, and the exhaust pressure can reach 300 MPa to the maximum extent; and if the method of machining pressure measuring holes in a cylinder body, not only is the cylinder strength affected, but also leakage can be caused, and potential safety hazards are brought. The oil pressure and air pressure monitoring device for the diaphragm compressor comprises a cylinder and a strain gage circuit, and the cylinder comprises a cylinder head; and the strain gage circuit comprises a strain gage assembly and a bridge circuit which are mutually connected, and the strain gage assembly is arranged on the cylinder head. The strain gage assembly is arranged on the cylinder head and connected with the bridge circuit, sothat the sensitivity of the strain gage assembly is improved, and the input and the output are in a linear relationship. The monitoring device is safe and reliable and has no damage to the diaphragm compressor, and especially under the high-pressure working condition, the hydraulic pressure in the oil-side cylinder head and the air pressure in the air-side cylinder head of the diaphragm compressorcan be monitored.

Owner:陕西康谱智慧科技有限责任公司

Method for synthesizing polysilicon raw material trichlorosilane

The invention discloses a method for the synthesis of a polysilicon raw material trichlorosilane. The method comprises the following steps: A) silica powder is conveyed to a trichlorosilane synthesisfurnace by dried hydrogen chloride gas; B) hydrogen chloride for reaction is input into the synthesis furnace from the bottom of the trichlorosilane synthesis furnace proportionally and proper amountof hydrogen and silicon tetrachloride are added in the synthesis furnace at the same time; C) silica powder and hydrogen chloride react at the temperature of 280-310 DEG C to generate mixing gas containing trichlorosilane and silicon tetrachloride; D) the mixing gas of dust and high chlorosilane is removed, after water cooling and pressuring by a diaphragm compressor, trichlorosilane and silicon tetrachloride are condensed into liquid by a refrigerant with -40 DEG C, wherein, noncondensable gas containing H2 and HCI is separated. The method of the invention can improve the yield of trichlorosilane from 82 percent to more than 88 percent.

Owner:HUBEI HUIFU NANOMATERIAL CO LTD

Oil pressure monitoring device and method for diaphragm compressor cylinder

ActiveCN110073190AAccurate monitoringHigh sensitivityExternal parameterFluid pressure measurement using ohmic-resistance variationHigh pressureUltimate tensile strength

The present application belongs to the technical field of compressors, and in particular to an oil pressure monitoring device and method for a diaphragm compressor cylinder. Diaphragm compressors canoperate within a wide range of the pressure, and the exhaust pressure can be up to 300 MPa. However, if the pressure is monitored by a pressure monitoring hole machined in the cylinder, the integrityof the cylinder is seriously damaged, the cylinder strength will be affected, and leakage is resulted in. The present application provides an oil pressure monitoring device for a diaphragm compressorcylinder, including a piston rod and a strain strip circuit, the strain strip circuit including an strain strip assembly and a bridge circuit connected to each other, and the strain strip assembly isdisposed on the piston rod surface. Since the strain strip assembly is non-invasively placed on the piston rod of the diaphragm compressor to measure the piston rod load, the oil pressure can be measured indirectly, and the diaphragm compressor oil pressure can be safely measured without damage. No damage is caused to the diaphragm compressor, non-intrusive monitoring is safe and reliable, especially in high pressure conditions can achieve accurate monitoring of oil pressure.

Owner:XI AN JIAOTONG UNIV

Charging equipment for heptafluoropropane firefighting gas and technology thereof

ActiveCN102797971AImprove sealingReduce energy consumptionContainer filling under pressureGas cylinderEngineering

The invention relates to the technical field of gas charging, particularly to charging equipment for heptafluoropropane firefighting gas and technology thereof. Compared with the prior art, according to the invention, a diaphragm compressor with the power of 5.5kW is adopted, and electric energy is used as the driving force so as to reduce energy consumption; and the structure of the charging equipment is changed so that the charging equipment for heptafluoropropane firefighting gas can simultaneously charge a plurality of firefighting gas cylinders and can be massively produced.

Owner:SHANGHAI LEINUO SECURITY TECH CO

System and method for tail gas treatment of conversion reaction of organic silicon low-boiling-point substances

ActiveCN105251231AReduce wasteImprove conversion rateSilicon organic compoundsUsing liquid separation agentChemical reactionDiaphragm compressor

The invention relates to the field of organic silicon low-boiling-point substance conversion and especially relates to a system and a method for tail gas treatment of conversion reaction of organic silicon low-boiling-point substances. The system comprises a conversion kettle, a washing tower, a return tank and a condenser, wherein the condenser is connected with a tail gas buffering tank through a gas diaphragm compressor, and the tail gas buffering tank is connected with an inlet of the conversion kettle through a circulating pump. The method comprises the following steps: causing the substances to enter into the conversion kettle and have a chemical reaction; washing the gas generated from the reaction through the washing tower, and then condensing through a first-level condenser; causing the condensate to enter into the return tank, performing gas pressurizing, and then entering into a second-level condenser; causing the cooled gas-liquid mixture to enter into the tail gas buffering tank; pumping the condensate into the conversion kettle through the circulating pump; and performing acid pickling on the gas in a tail gas water washing tower, and then emptying. The method has the advantages that the technique is simple; the waste of carried materials is reduced; the conversion ratio of the low-boiling-point substances is increased; the system is in closed cycle, so that the running time of the system is prolonged; the influence of direct tail gas emission on environment is avoided.

Owner:TANGSHAN SANYOU SILICON IND

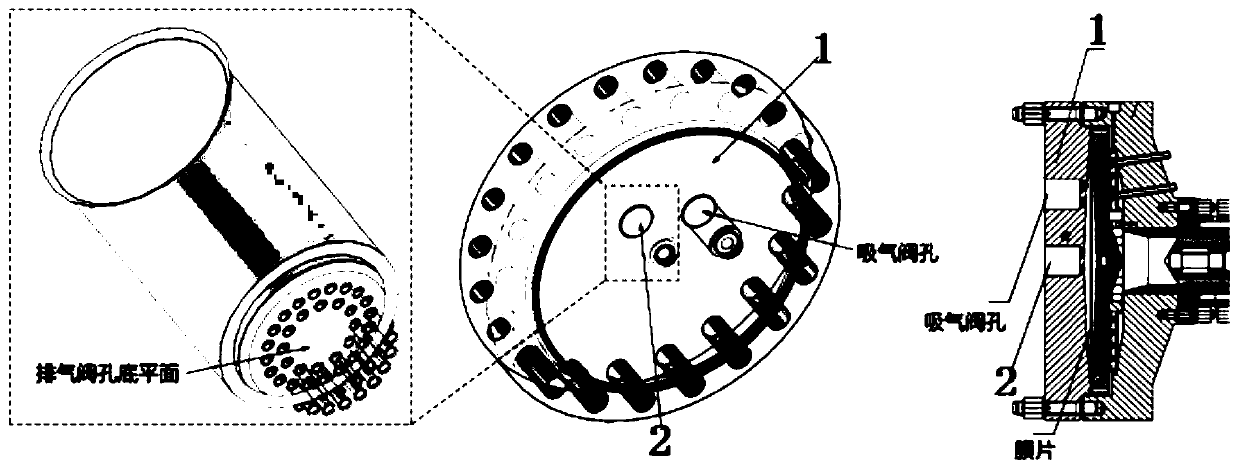

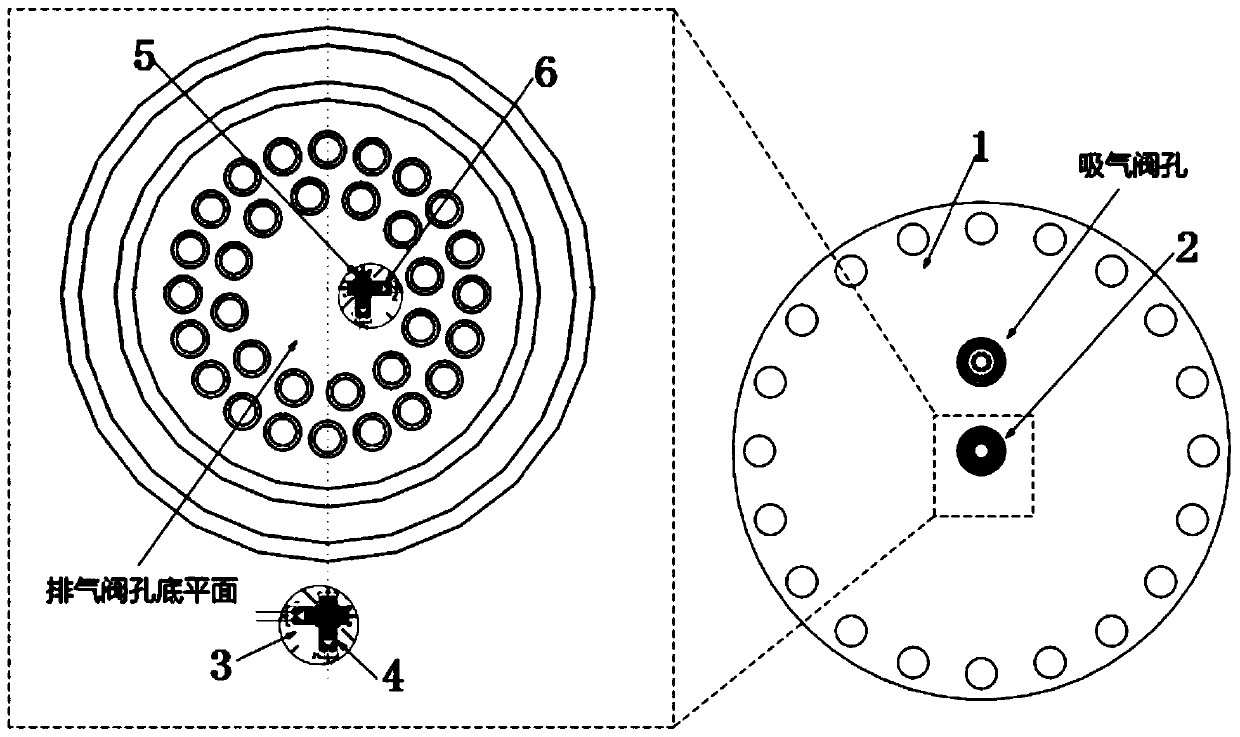

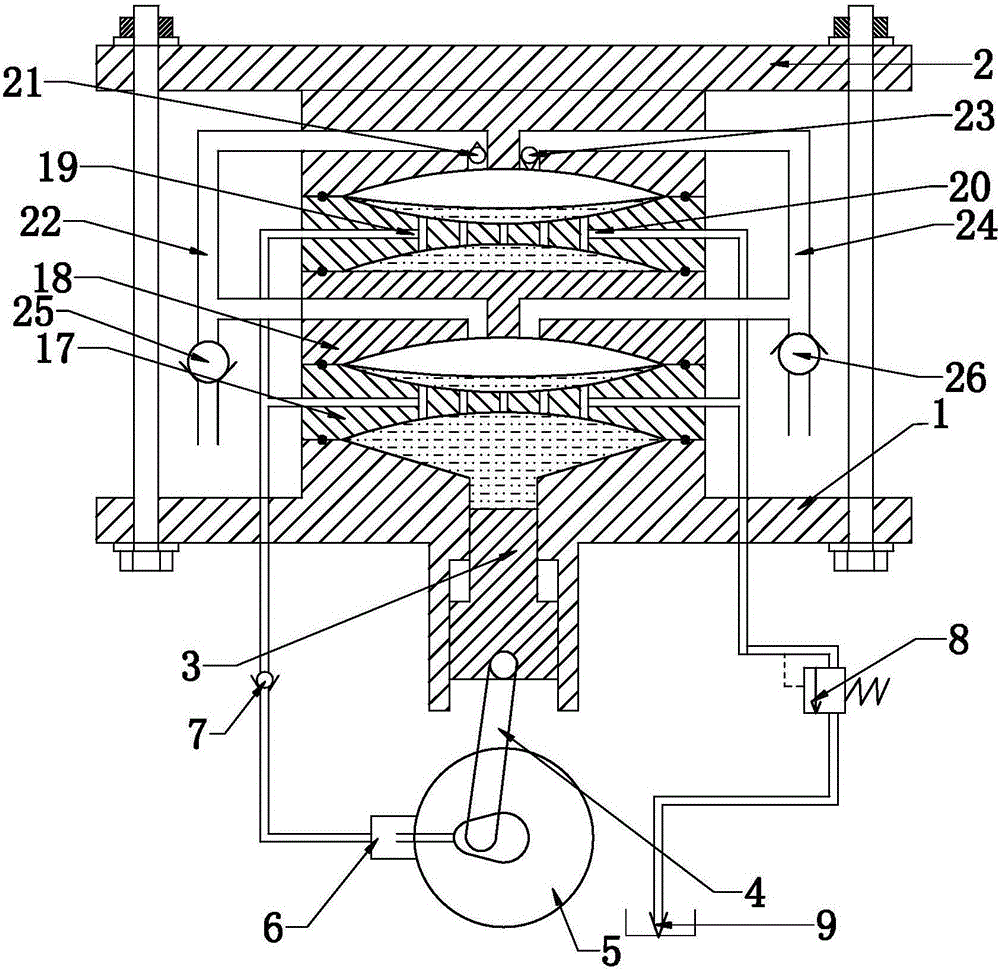

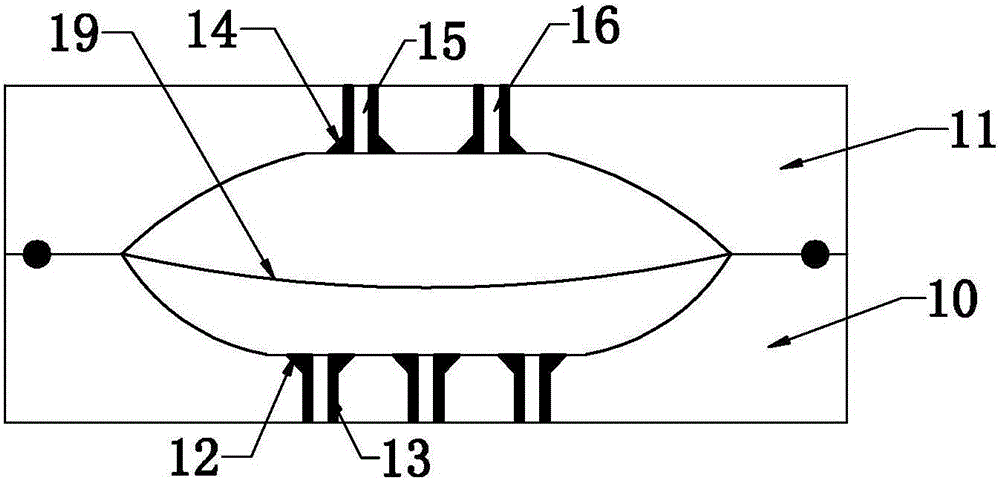

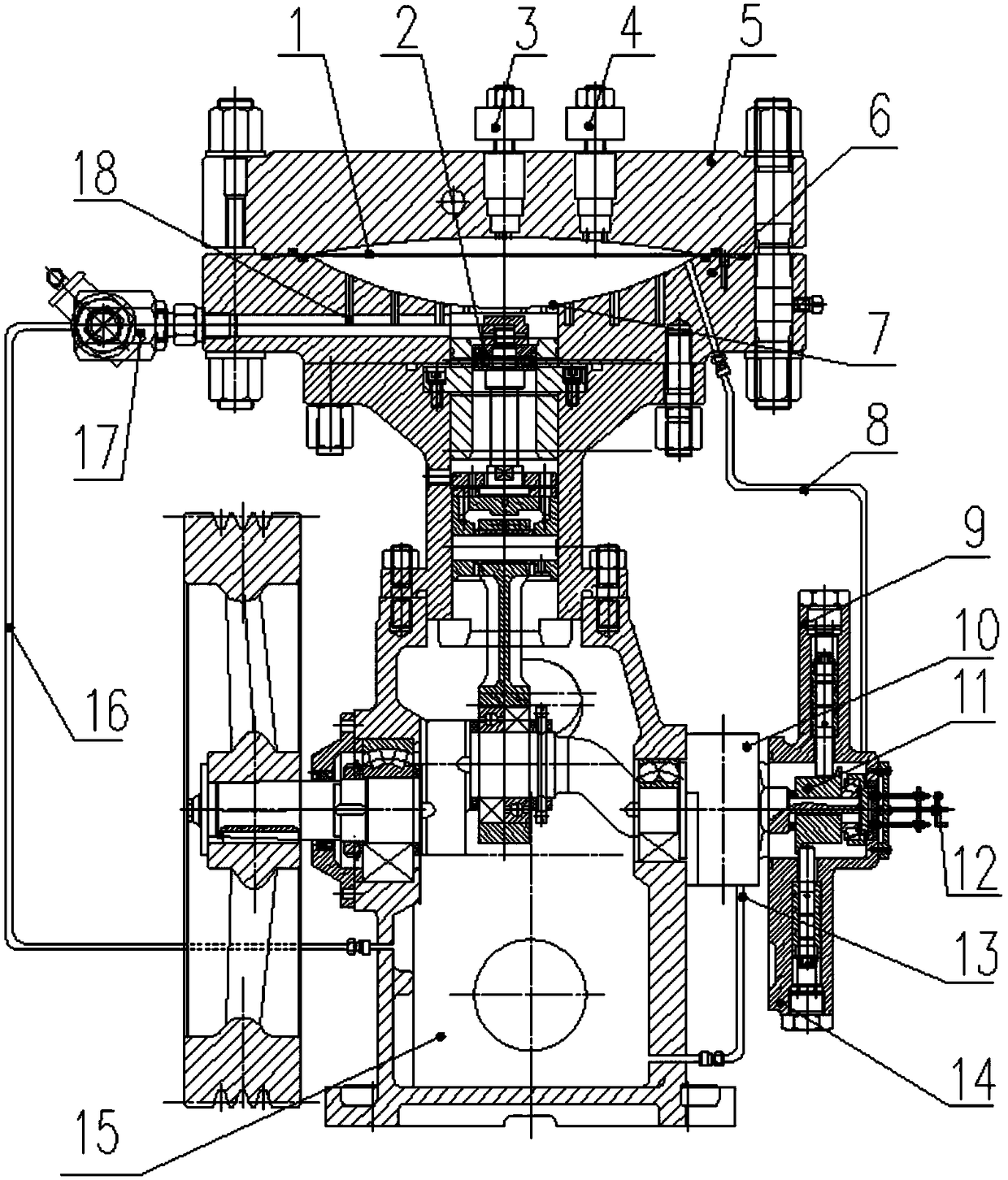

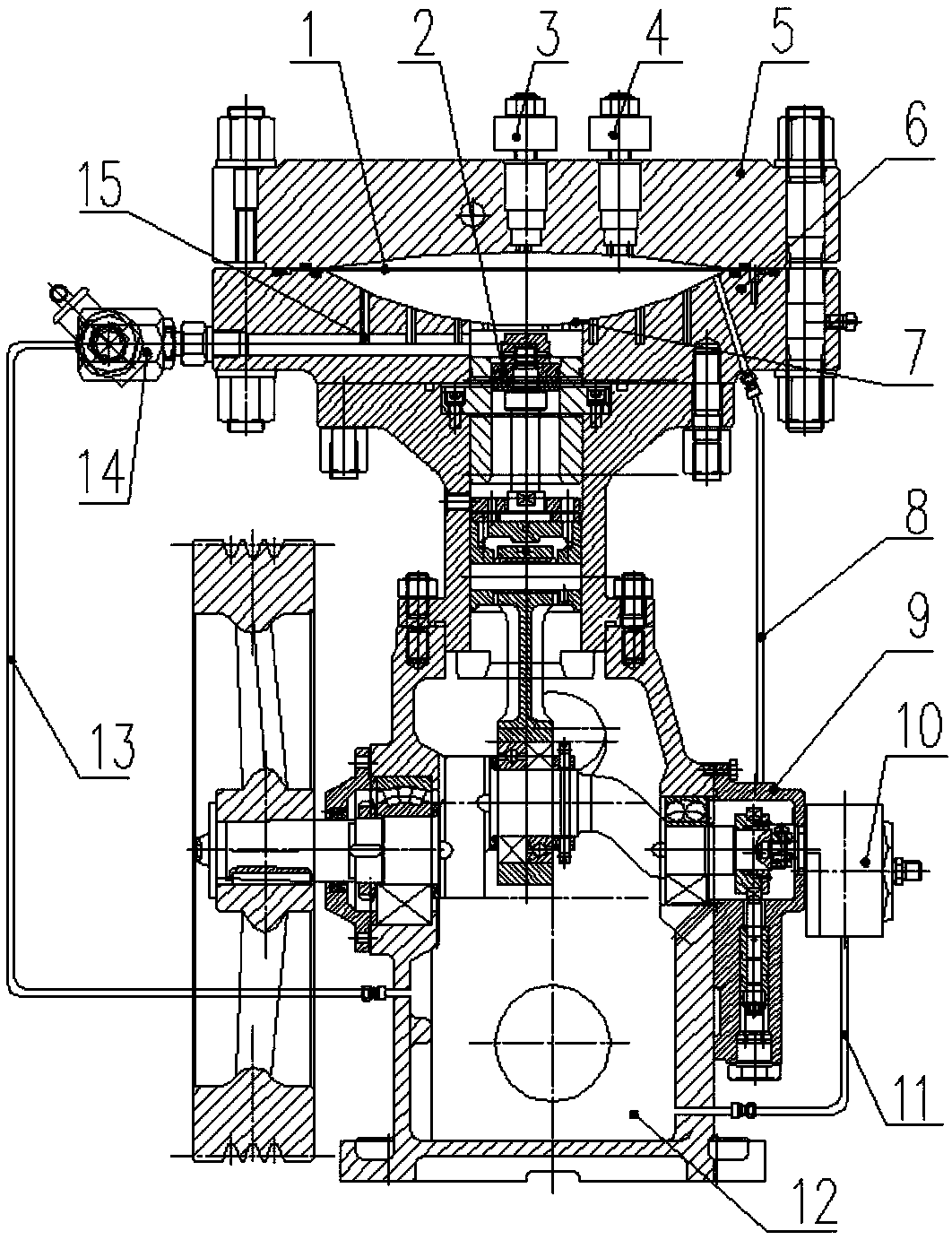

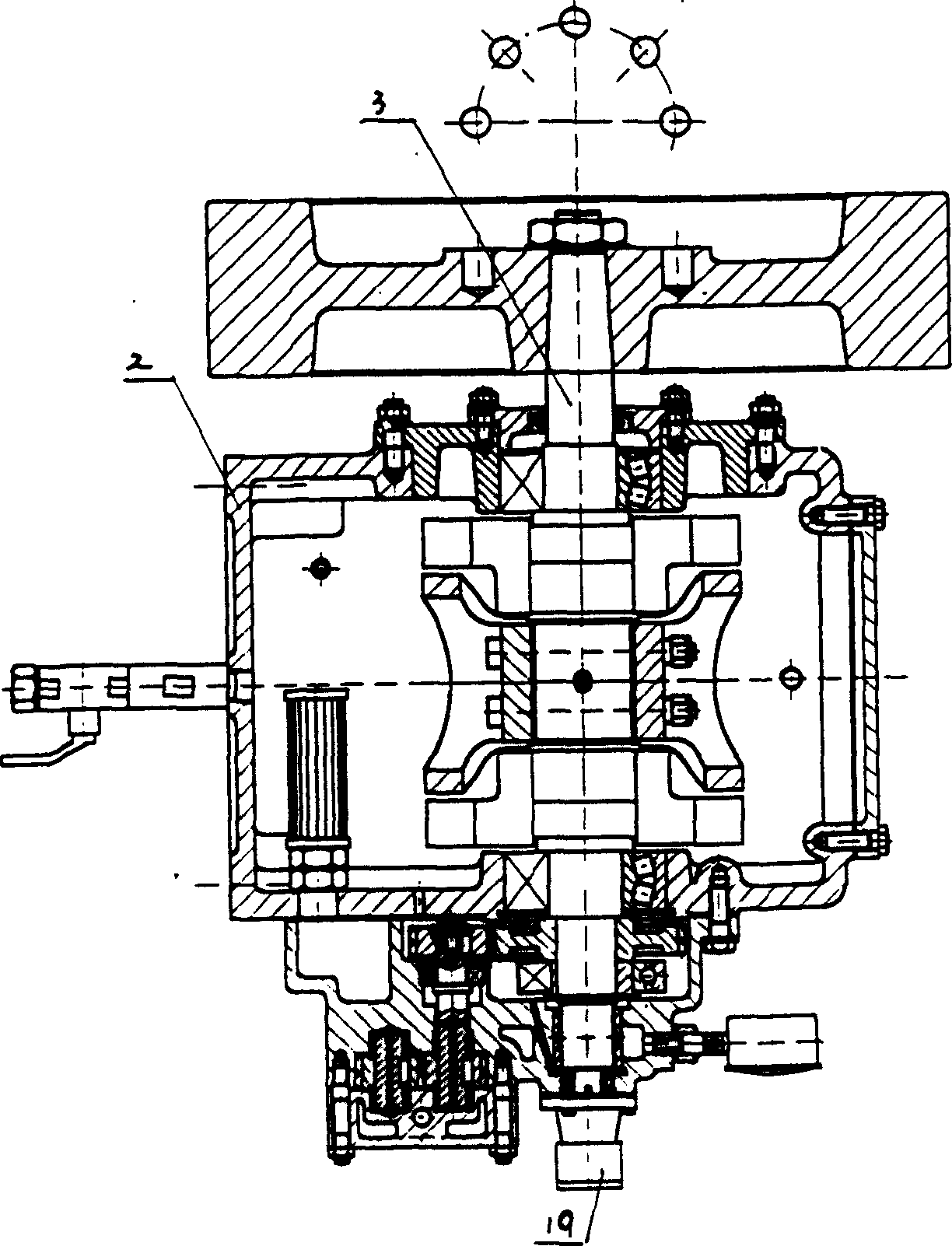

Overlap type large-displacement diaphragm compressor

ActiveCN105804976AReduce thicknessAvoid different status quoPositive displacement pump componentsFlexible member pumpsFuel tankOil distribution

The invention discloses an overlap type large-displacement diaphragm compressor. The overlap type large-displacement diaphragm compressor comprises a cylinder body and a cylinder cover installed on the cylinder body. At least two sets of compressing mechanisms which are mutually overlapped are arranged in the cylinder body. Each set of compressing mechanism comprises oil distribution discs and gas distribution discs. A diaphragm is arranged between the oil distribution disc and the gas distribution disc in each pair. A piston is arranged in the cylinder body. The power end of the piston is connected with a flywheel through a crank-link mechanism. An oil supply plunger pump is arranged on one side of the flywheel. Each oil distribution disc is provided with an oil supply inlet and an overpressure overflow hole. The oil supply plunger pump is connected to the oil supply inlets. Outlets of the overpressure overflow holes are connected with an oil tank. The gas distribution discs are provided with gas inlets and gas outlets. By the adoption of the structure, the thickness of the gas distribution discs and the thickness of the oil distribution discs can be decreased, and the overlap type large-displacement diaphragm compressor has a positive effect on saving materials and lowering the machining difficulty; in addition, the production cost is further reduced by increasing or decreasing the overlap number; and the situation that the diaphragms corresponding to oil guide holes, the gas inlets and the gas outlets are damaged is avoided.

Owner:包头盈德气体有限公司

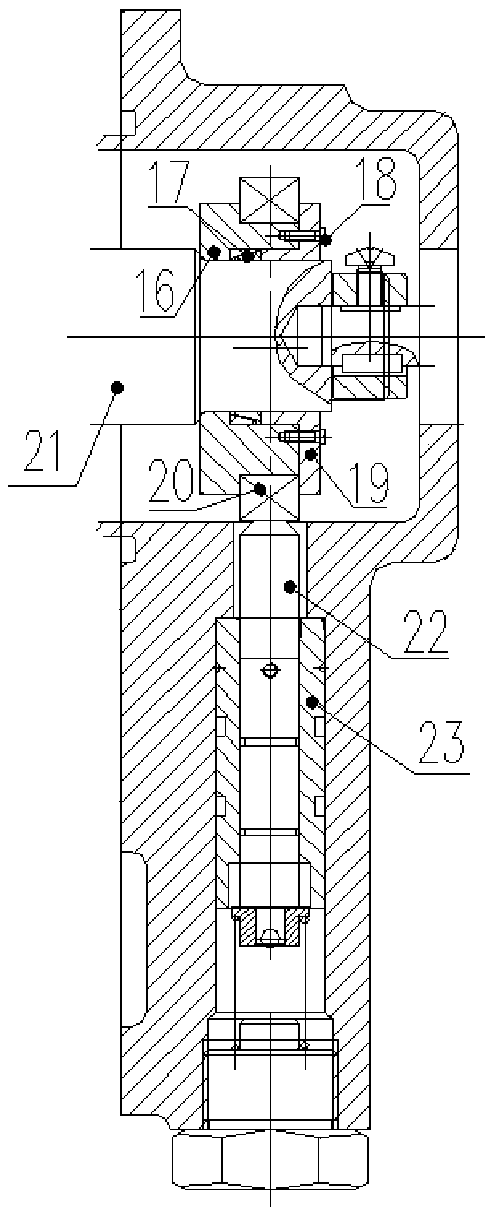

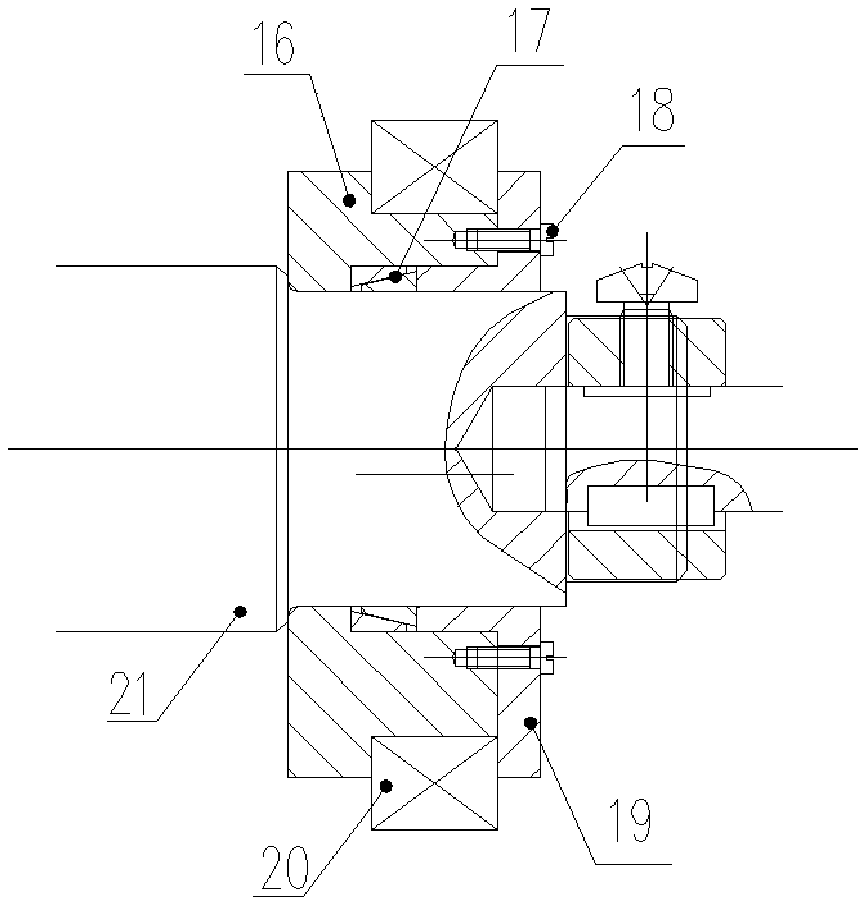

Diaphragm compressor and flow regulating method thereof

ActiveCN109209844ASolve the problem of not being able to inhale gas anymoreRealize stepless adjustmentFlexible member pumpsPump controlHydraulic cylinderGear pump

The invention discloses a diaphragm compressor and a flow regulating method thereof. The diaphragm compressor comprises a cylinder component comprising a diaphragm, a hydraulic cylinder, a cover plateand a support plate, wherein the periphery of the diaphragm is fastened between the cover plate and the support plate to form a membrane chamber and oil chamber; the support plate and the diaphragm enclose a hydraulic cylinder; a crankcase, wherein the upper case of the crankcase is connected with a cylinder component; a gear pump, which is arranged on one side of the crankcase and connected witha lower tank body of the crankcase through an oil suction pipe; and at least one plunger pump, which is disposed outside the gear pump and connected with the gear pump through an oil passage. The oiloutlet of the plunger pump is connected to the hydraulic cylinder through an oil replenishing pipeline to supplement oil for the oil chamber. Stepless adjustment of the gas flow rate of the diaphragmcompressor during the operation of a machine can be realized by adjusting the oil replenishing time of the plunger pump, thereby solving the problem of insufficient air suction at the time of oil replenishing of an existing diaphragm compressor. The diaphragm compressor is more convenient and economical, and energy consumption is also reduced.

Owner:XI AN JIAOTONG UNIV +1

High temperature gas-cooled reactor helium purification regeneration system and regeneration method

ActiveCN105006264AEfficient regenerationGuaranteed uptimeRadioactive decontaminationMolecular sieveActivated carbon

The present invention relates to a high temperature gas-cooled reactor helium purification regeneration system and a regeneration method. The regeneration system comprises a diaphragm compressor, an electric heater, a water / helium cooler 1, a gas / water separator, an auxiliary water adsorption bed, and a vacuum device with a built-in discharge pipeline. A bypass is further disposed at the auxiliary water absorption bed. All the devices form: a regeneration loop of a copper oxide bed of a helium purification system, a regeneration loop of a molecular sieve bed of the helium purification system, a regeneration loop of an auxiliary water adsorption bed, and a regeneration loop of a low-temperature activated carbon bed of the helium purification system; and an oxygen injecting device is disposed on the regeneration hoop of the copper oxide bed. Through the four regeneration loops, high-efficient regeneration is achieved for the copper oxide bed, the molecular sieve bed, and the low-temperature activated carbon bed of the helium purification system; a problem of freeze-blockage in a cryogenic helium / helium heat exchanger of the helium purification system is solved; the runtime of the high temperature gas-cooled reactor helium purification system is prolonged; and high-efficient operation of the high temperature gas-cooled reactor helium purification system is ensured.

Owner:CHINERGY CO LTD

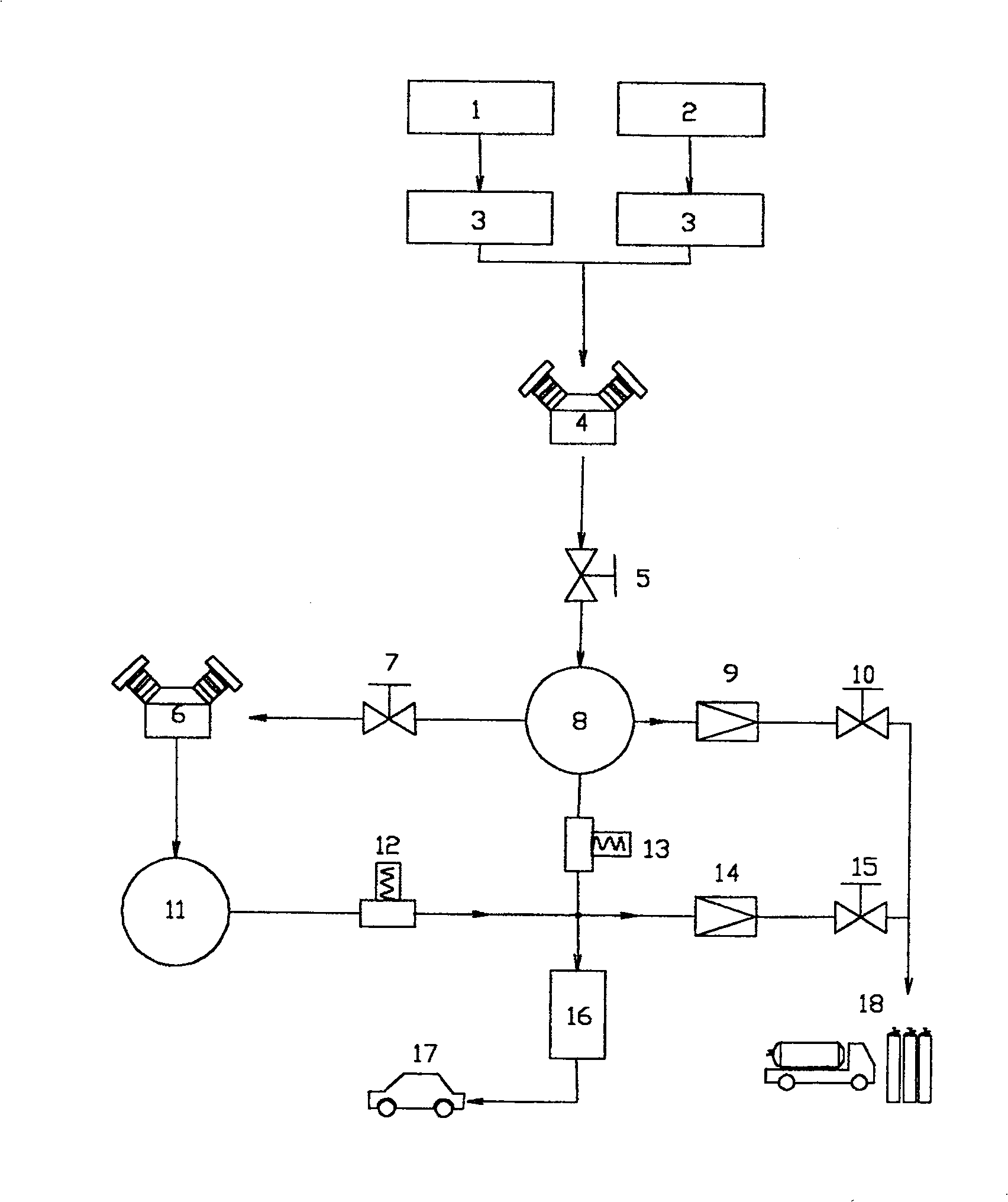

Hydrogen generating and refilling system and method capable of refilling hydrogen fast

InactiveCN100534840CIncrease profitEnsure safetyVehicle servicing/repairingContainer filling under pressureHigh energyHydrogen pressure

The hydrogen generating and refilling system and method capable of refilling hydrogen fast belongs to the field of regenerable clean energy source technology. The system includes water electrolyzing and natural gas reforming hydrogen-making equipment, hydrogen purifying equipment, hydrogen pressure raising equipment, hydrogen storage tank and hydrogen refilling equipment. The fast hydrogen refilling process includes making hydrogen via electrolyzing water and reforming natural gas; purifying hydrogen to eliminate O2, CO, sulfide and water; compressing hydrogen in a diaphragm hydrogen compressor; and refilling hydrogen via the hydrogen refilling equipment to fuel cell or hydrogen-burning internal combustion engine in automobile. The present invention has the advantages of high hydrogen refilling efficiency, high energy source utilization rate and high safety.

Owner:北京飞驰绿能电源技术有限责任公司

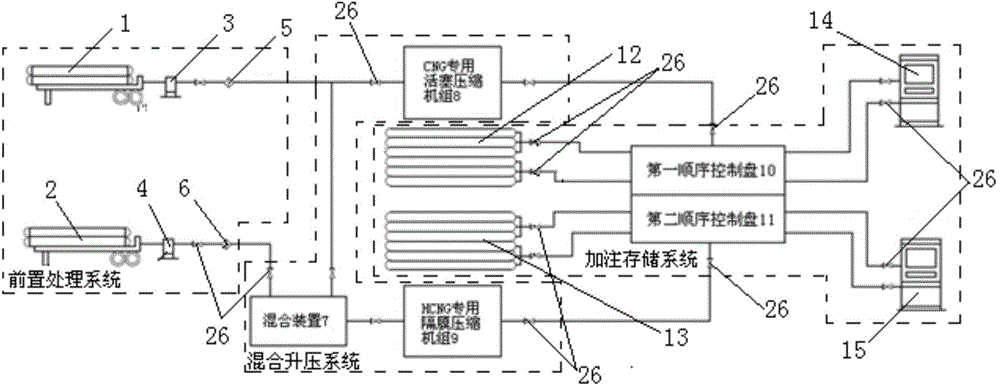

CNG and HCNG mixing and refilling device and method

ActiveCN104534271AHelp drive adoptionLow costContainer discharging methodsContainer filling under pressureHydrogenProcess engineering

The invention relates to a CNG and HCNG mixing and refilling device and a CNG and HCNG mixing and refilling method. The device comprises a prepositioned treatment system, a mixing and pressurizing system and a filling and storing system, wherein the prepositioned treatment system is connected with the filling and storing system by the mixing and pressurizing system; the prepositioned treatment system comprises a pipe bundle CNG conveying trailer, a pipe bundle hydrogen gas conveying trailer, a CNG unloading column, a hydrogen gas unloading column, a CNG purifier and a hydrogen gas purifier; the mixing and pressurizing system comprises a mixing device, a CNG special piston compressor set and an HCNG special diaphragm compressor set; a gas inlet of the CNG special piston compressor set is connected with a gas outlet of the CNG purifier; the gas outlet of the CNG special piston compressor set is connected with the filling and storing system; a hydrogen gas inlet pipeline of the mixing device is connected with the gas outlet of the hydrogen gas purifier; a CNG inlet pipeline is connected with the gas outlet of the CNG purifier; an HCNG outlet pipeline is connected with the gas inlet of the HCNG special diaphragm compressor set; and the gas outlet of the HCNG special diaphragm compressor set is connected with the filling and storing system. The CNG and HCNG mixing and refilling device and the CNG and HCNG mixing and refilling method can be widely applied to gas stations of HCNG cars and CNG cars.

Owner:TSINGHUA UNIV

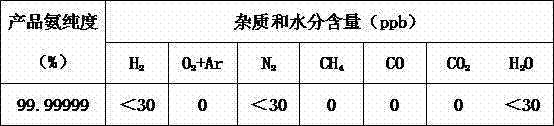

Method for recovering and reutilizing waste ammonia gas in LED (light-emitting diode) manufacturing through compression method

ActiveCN102963910ASolve the reuse problemSignificant energy saving benefitsAmmonia preparation/separationEnvironmental engineeringWater cooling

The invention discloses a method for recovering and reutilizing waste ammonia gas in LED (light-emitting diode) manufacturing through a compression method, which comprises the following steps of: performing negative-pressure intake on waste ammonia gas discharged in the LED manufacturing process with a diaphragm compressor, then performing pressurized compression, and condensing with cooling water to obtain liquid ammonia, thus achieving the purpose of recovering the waste ammonia gas; and then performing secondary rectification and separation on the cooled and recovered liquid ammonia to remove impurities, thus purifying the liquid ammonia, wherein the purified liquid ammonia can achieve ultra pure ammonia quality of 7N content and can be further used in the LED manufacturing circularly. The whole process is pollution-free, thereby thoroughly solving the problem that pollution is caused by the discharge of waste ammonia gas in the LED manufacturing process at present. Besides, the recovery investment is low, the recovery and purification cost is far lower than that of a method of manufacturing ultra pure ammonia for an LED from industrial liquid ammonia, and the LED manufacturing cost is greatly reduced.

Owner:SUZHOU JINHONG GAS CO LTD

Method for extracting angelica oil from angelica

InactiveCN102911783AImprove solubilityGood solvent propertiesFatty-oils/fats productionEvaporationSight glass

The invention discloses a method for extracting angelica oil. The method is mainly characterized by comprising the following steps of: (1) firstly screening the angelica raw material, cleaning and drying until the water content is less than or equal to 13%, and grinding to 40-60 meshes by a grinder; (2) putting the dried and ground angelica into an extraction kettle, vacuumizing until the pressure is below 1*10<4>Pa, and exhausting the air in the extraction kettle; (3) leading a tetrafluoroethane solution into the extraction kettle by a plunger pump until the angelica raw material is submerged by the liquid level according to the observation through a sight glass; (4) heating and stirring, and starting extraction, wherein the extraction pressure is 0.8-1.5MPa, the extraction temperature is 35-40 DEGE C, each extraction process lasts for 45min, and the extraction is performed twice; (5) performing reduced-pressure heating evaporation and separation in a separation kettle, heating and keeping the separation temperature at 45-50 DEG C, and pumping the negative pressure by a diaphragm compressor to gradually reduce the pressure to 5*10<-2>Pa, wherein each separation process lasts for 30min, and the separation is performed twice; and (6) after the subcritical extraction is over, merging the angelica oil obtained by the extraction twice, performing centrifugal separation by a high-speed centrifuge, and filtering to obtain the final angelica oil product. According to experimental verification, the final yield of the angelica oil under the technological conditions is 2.0%, the content of ligustilide is 62.16%, and the appearance quality of the product is good.

Owner:甘肃省轻工研究院有限责任公司

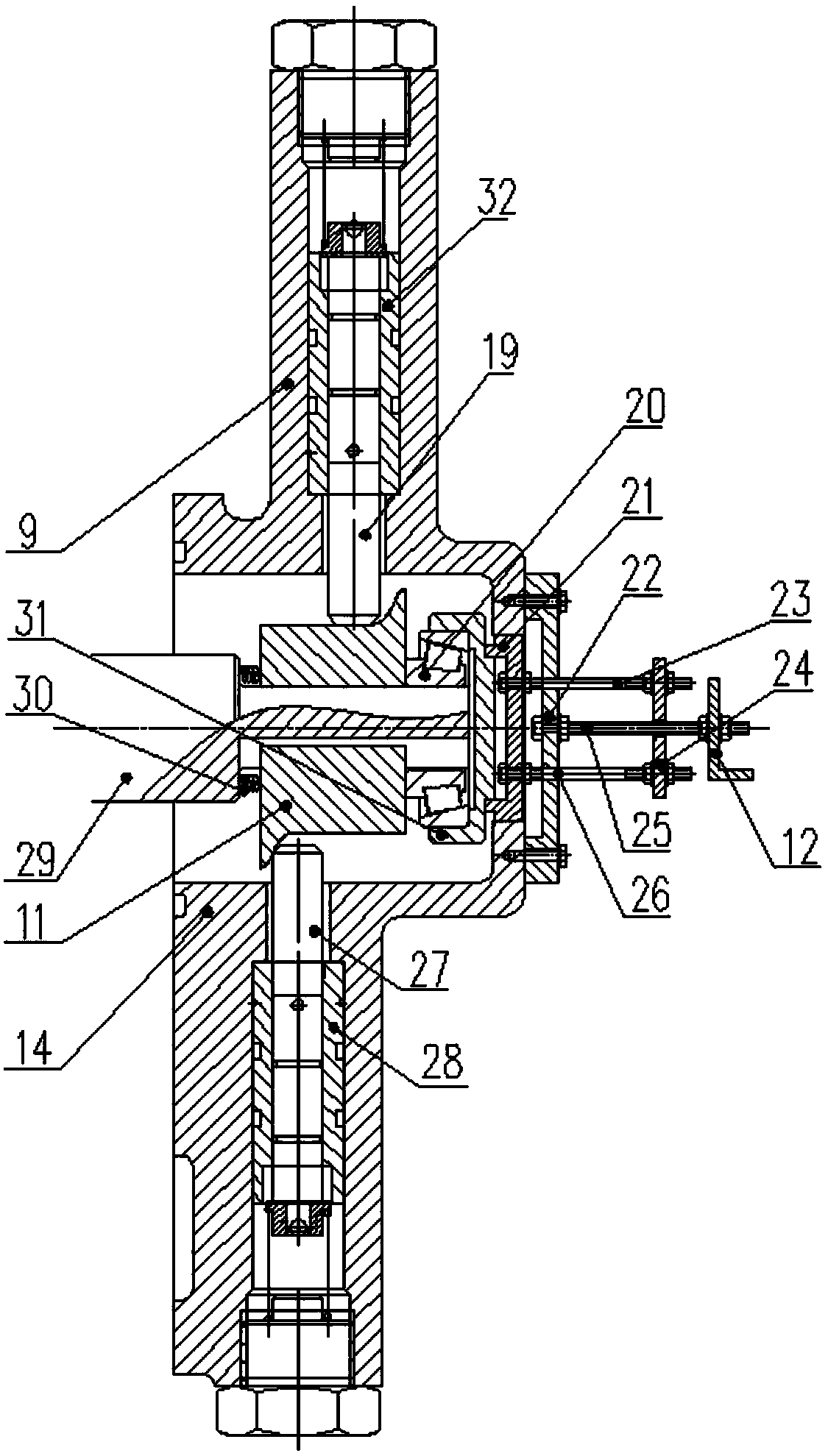

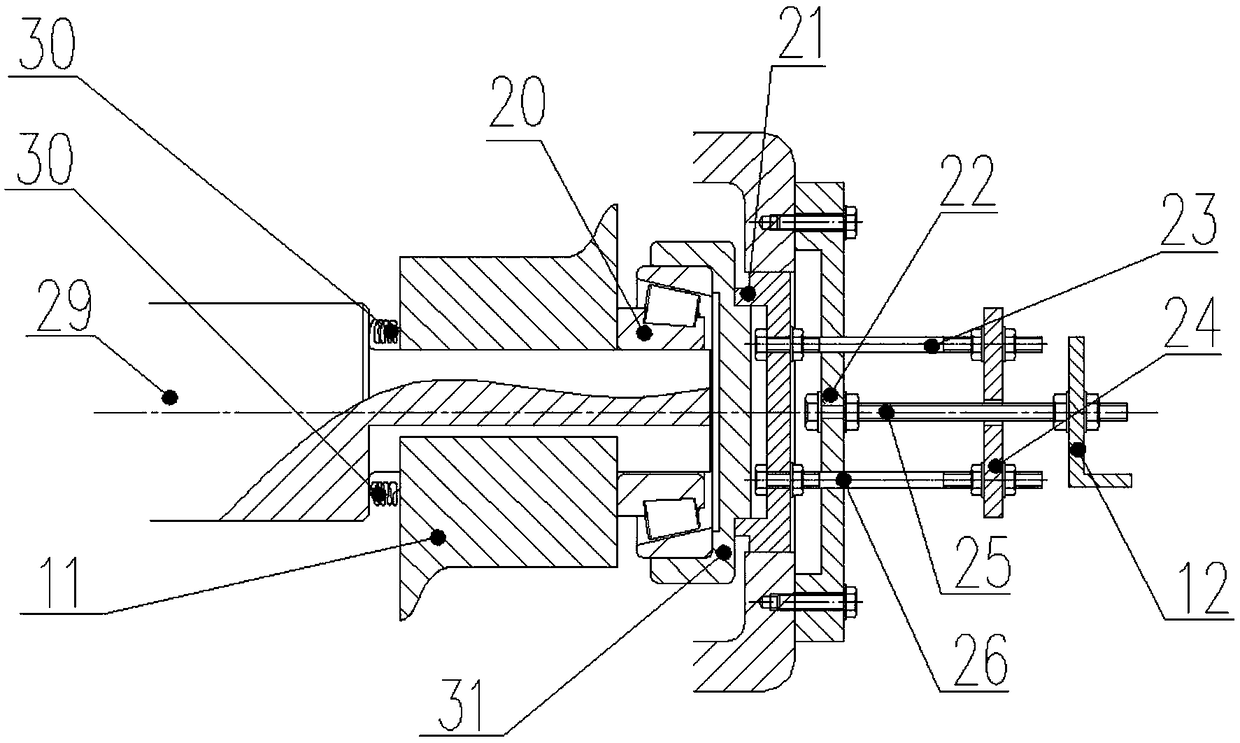

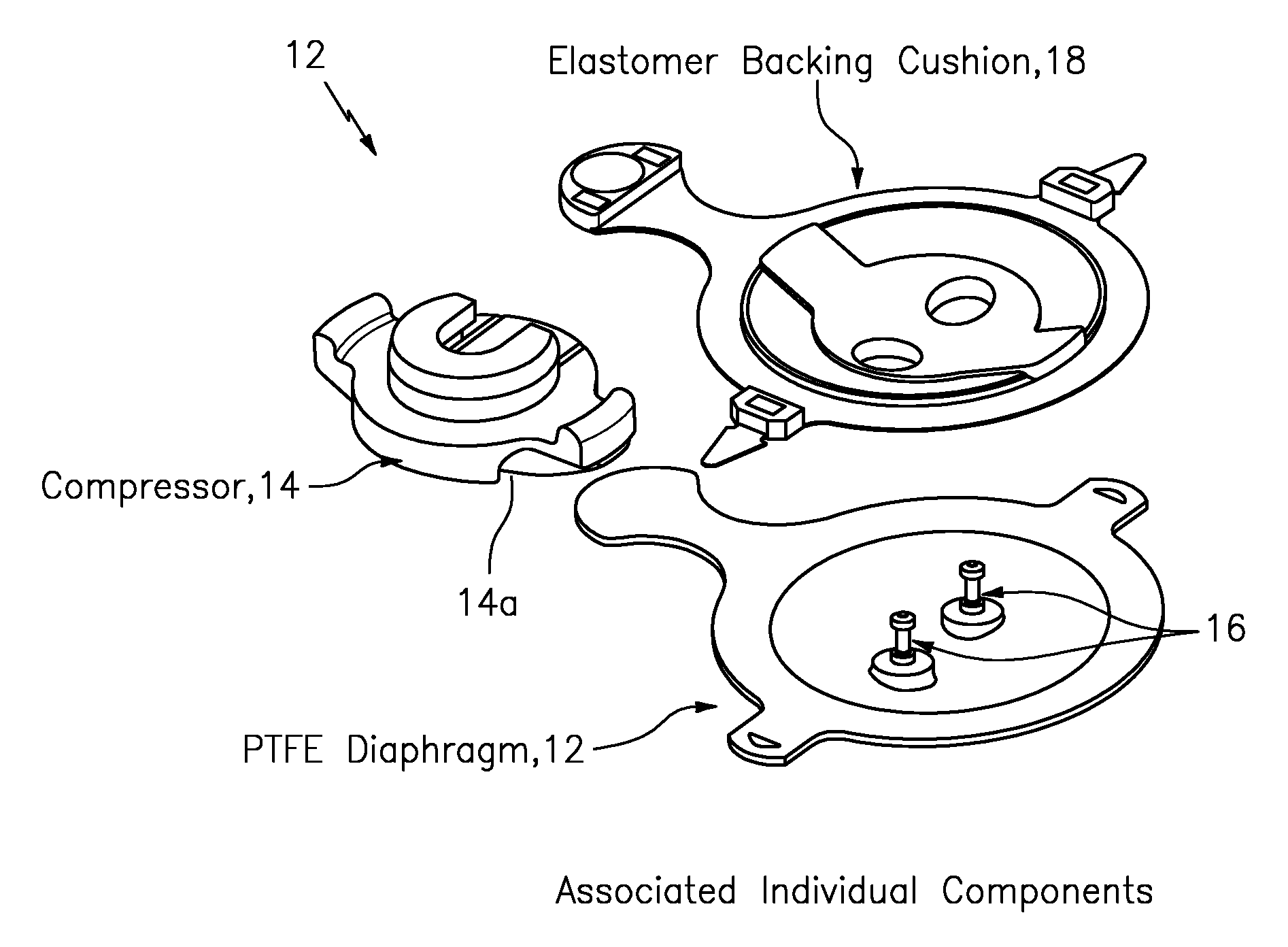

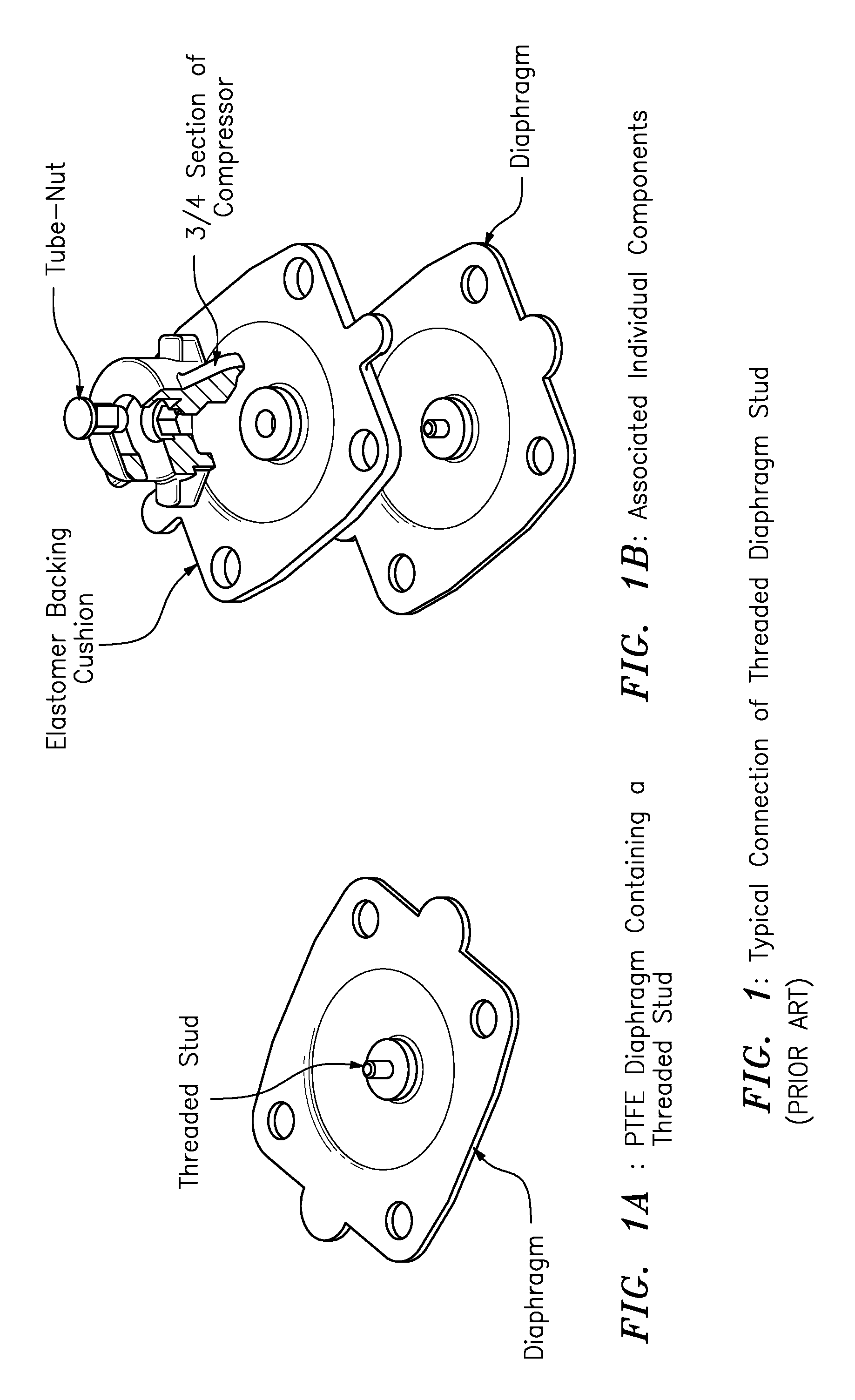

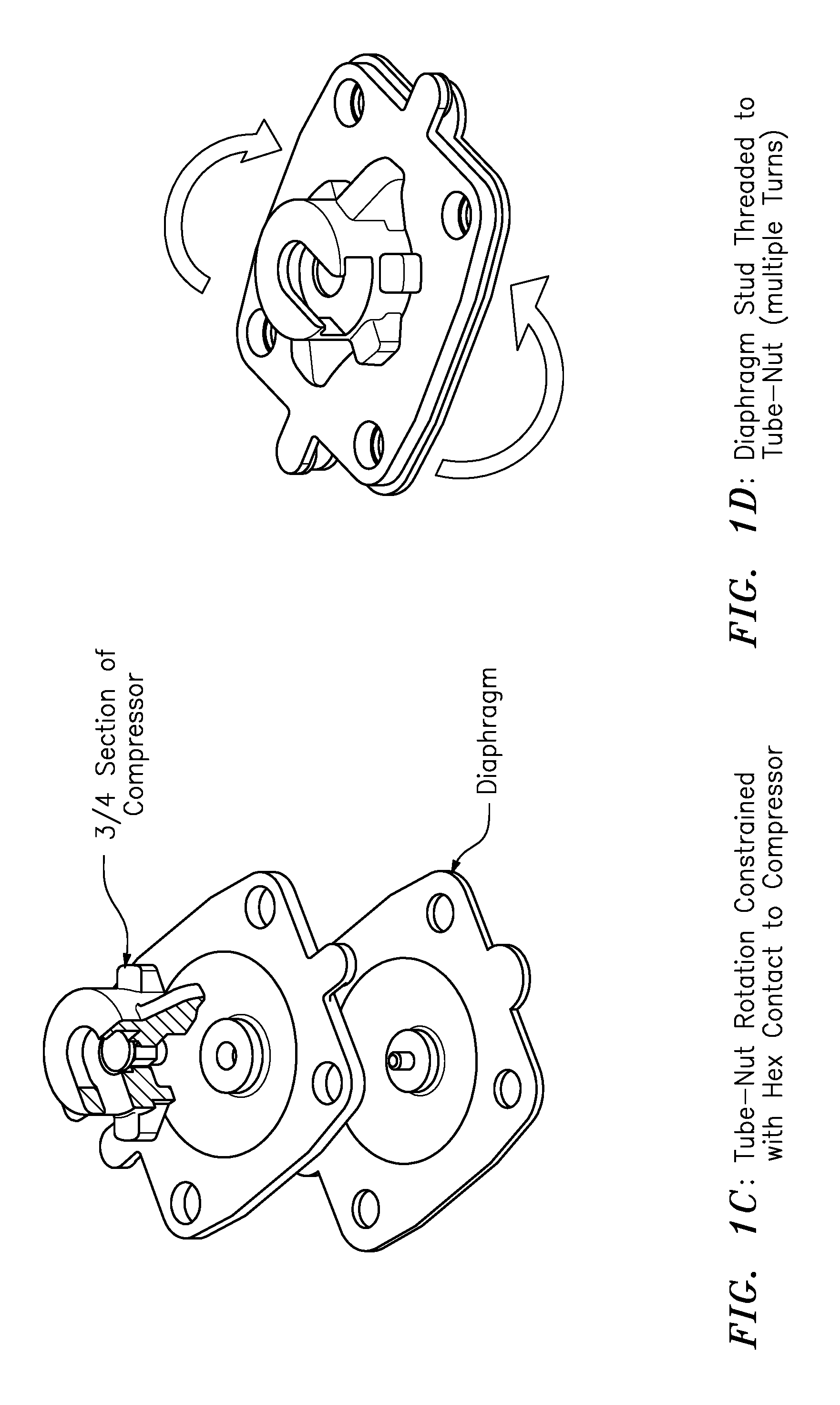

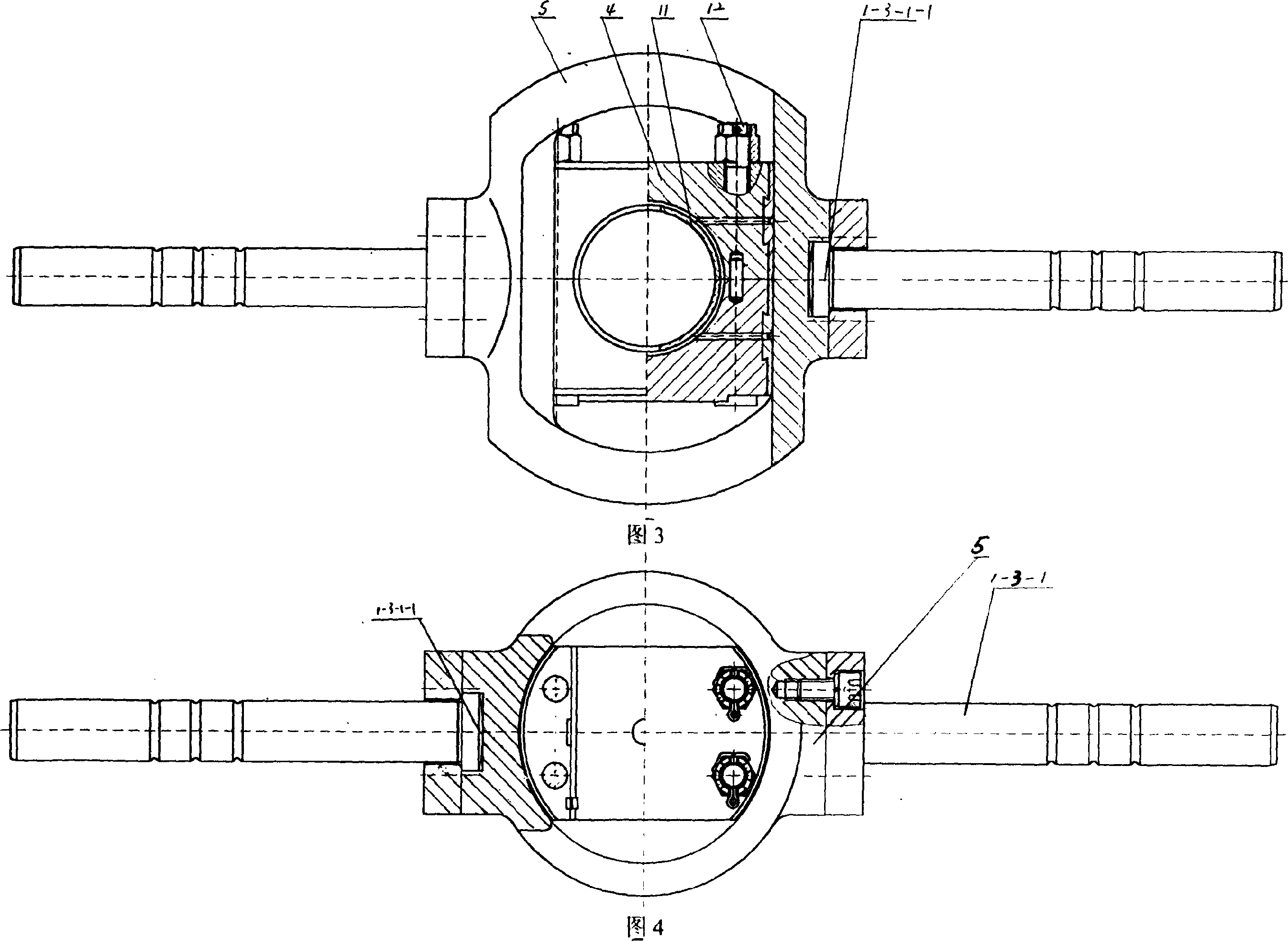

Valve having at least one hourglass studs for coupling to diaphragm and compressor/spindle components

Apparatus, including or forming part of a diaphragm valve, features a diaphragm; a compressor or spindle component; and at least one hourglass-stud having a head configured to couple to the compressor or spindle component, having a lower shaft configured to couple to the diaphragm, and having an upper shaft configured to couple together the head and the lower shaft, the head having opposing curved surfaces configured and dimensioned with a width so as to be substantially the same as the diameter of the lower shaft, the upper shaft having a diameter configured and dimensioned so as to be smaller, including slightly smaller, than the width of the opposing curved surfaces of the head.

Owner:ITT MFG ENTERPRISES LLC

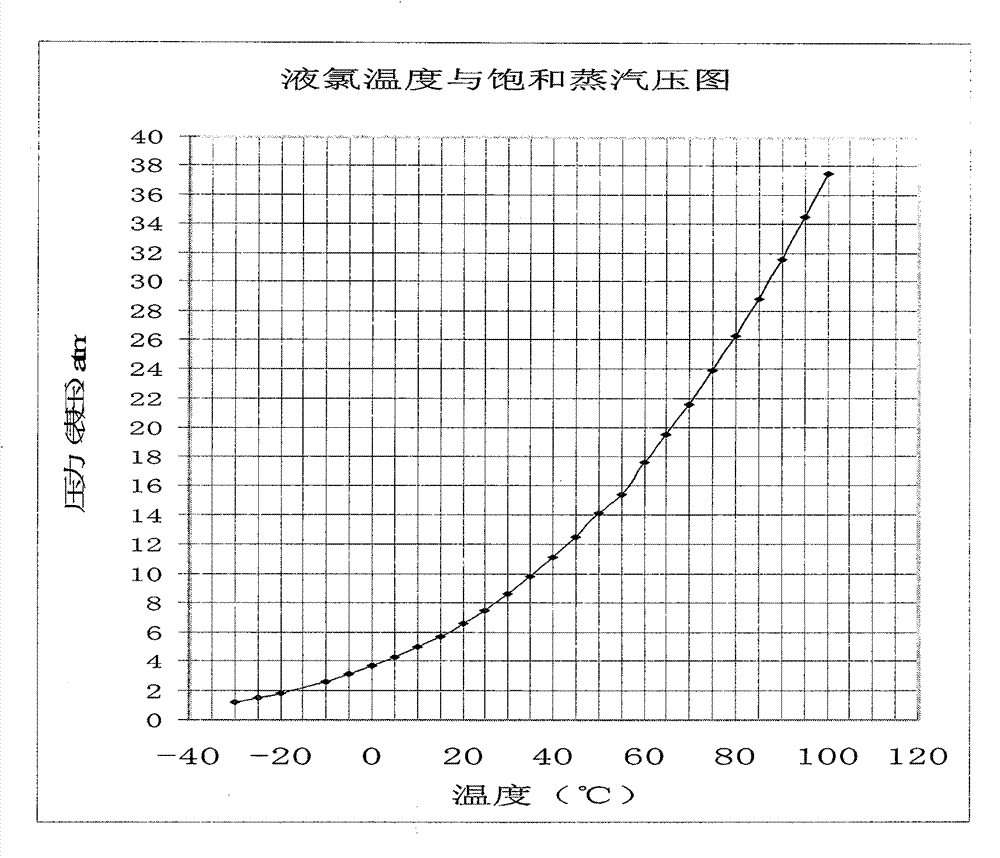

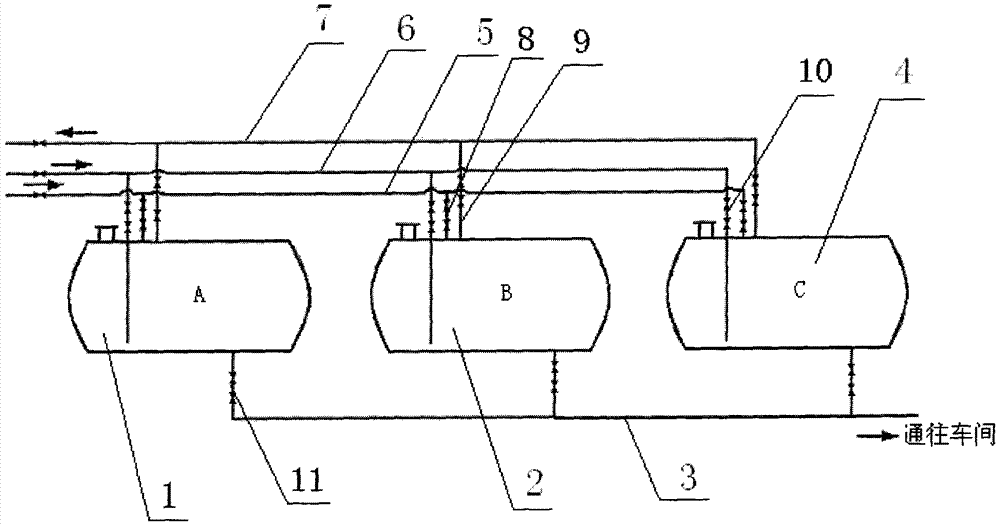

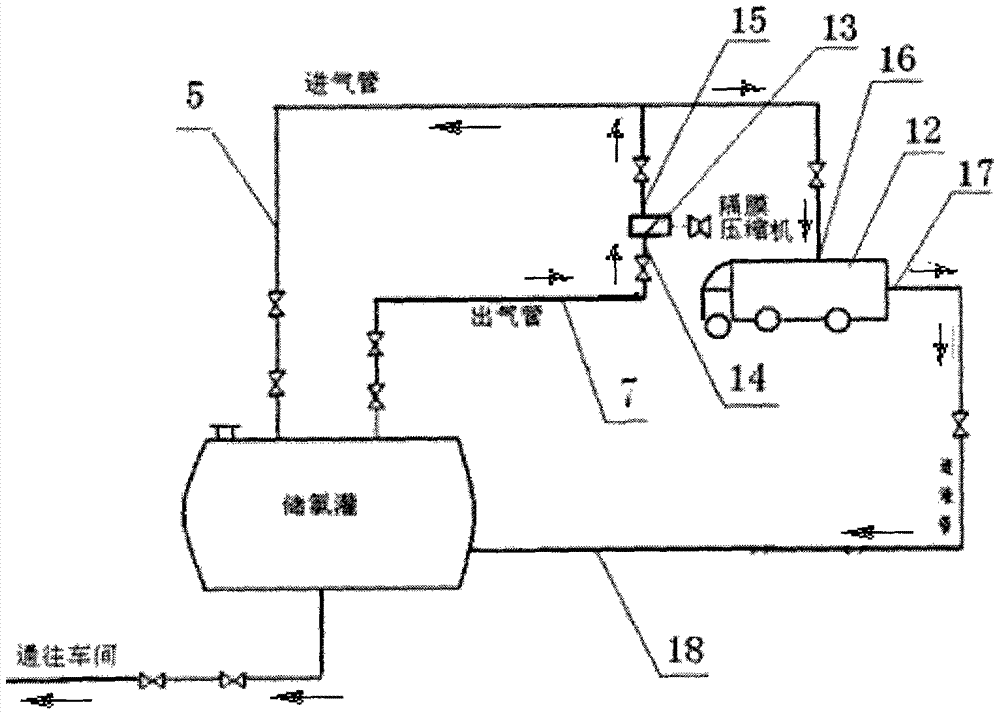

Liquid chlorine delivery system for producing chlorinated polyethylene

The invention discloses a liquid chlorine delivery system for producing chlorinated polyethylene. The liquid chlorine delivery system comprises a chlorine storage tank A, a chlorine storage tank B, a chlorine storage tank C and a membrane air compressor, and is characterized in that the top faces of the chlorine storage tank A, the chlorine storage tank B and the chlorine storage tank C are respectively provided with a gas inlet pipe, a gas outlet pipe and a liquid chlorine inlet pipe, the bottom faces of the chlorine storage tanks are respectively provided with a liquid chlorine outlet pipe, the gas outlet pipes of the chlorine storage tanks are connected to a total gas outlet pipe, the gas inlet pipes are connected to a total gas inlet pipe, the liquid chlorine inlet pipes are connected to a total liquid chlorine inlet pipe, the liquid chlorine outlet pipes are connected to a total liquid chlorine outlet pipe, and the pipes of each tank are provided with valves for control respectively. When the chlorinated polyethylene is produced, the total gas outlet pipe is connected with a gas inlet of the membrane air compressor, the total gas inlet pipe is connected with a gas outlet of the membrane air compressor, and the total liquid chlorine outlet pipe is connected with a workshop reaction kettle; when the liquid chlorine delivery system is used for liquid chlorine tank car unloading, the total gas outlet pipe is connected with the gas inlet of the membrane air compressor, the gas outlet of the membrane air compressor is connected with a compressed air opening of a tank car, and a liquid chlorine outlet of the tank car is connected with the liquid chlorine inlet pipes of the chlorine storage tanks.

Owner:山东泓利化学有限责任公司

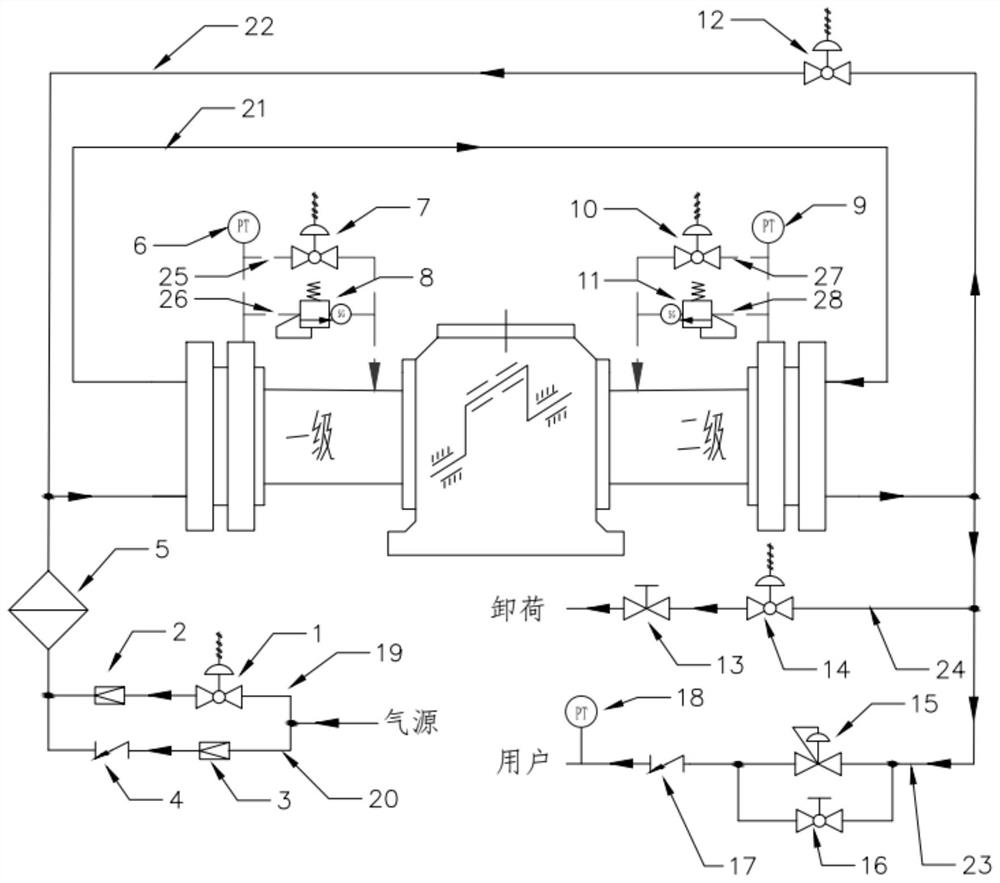

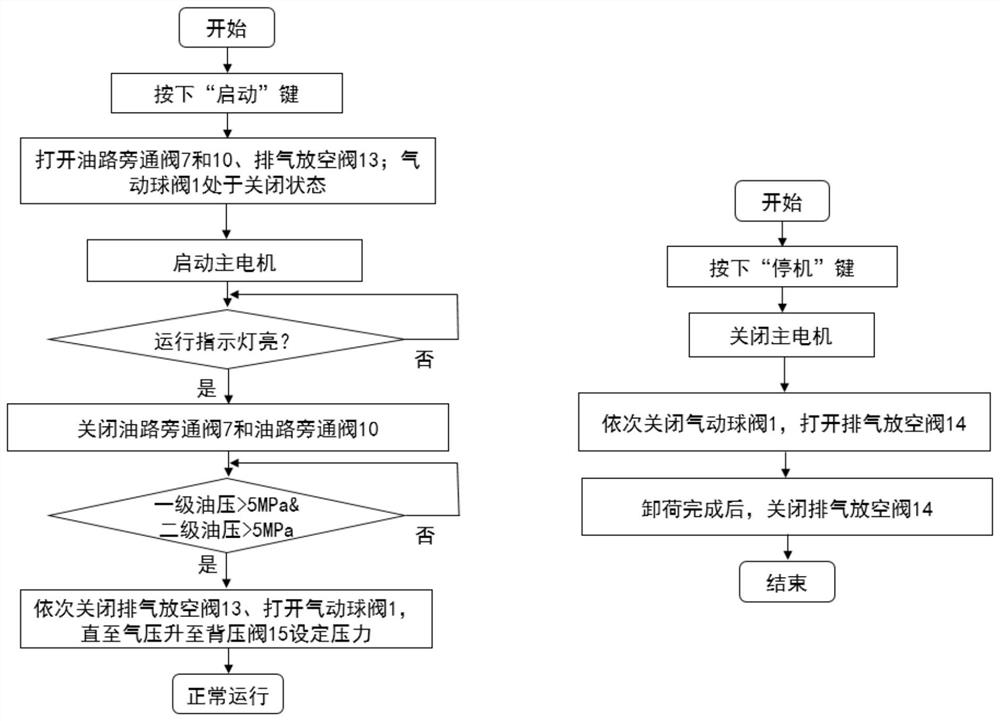

Full-automatic start-stop control system of diaphragm compressor

ActiveCN113107821ARealize fully automatic start and stop controlImprove reliabilityPump testingPositive displacement pump componentsThermodynamicsAutomatic control

The invention relates to the technical field of diaphragm compressors, in particular to a full-automatic start-stop control system of a diaphragm compressor. The full-automatic start-stop control system of the diaphragm compressor comprises an air inlet pipeline, an interstage pipeline and an exhaust pipeline. The air inlet pipeline and the exhaust pipeline are connected with the air inlet end and the exhaust end of the diaphragm compressor respectively, the interstage pipeline is arranged between all stages of air cavities of the diaphragm compressor, and each stage of the diaphragm compressor is provided with an oil overflow pipeline; and an oil overflow valve is arranged on the oil overflow pipeline to ensure that the oil pressure in the oil cavity does not exceed a set value. Full-automatic control over starting and stopping of the diaphragm compressor can be achieved, and the problems that the control process of the diaphragm compressor is complex, and field manual control is needed are solved. Meanwhile, micro-positive pressure protection of a gas path system can be achieved, and the situation that negative pressure is caused in the starting stage to cause failure of a sealing piece, and gas leakage is caused is avoided; and after shutdown unloading, the micro-positive pressure can prevent air from leaking and being mixed with compressed gas (such as hydrogen), and safety accidents are avoided.

Owner:康姆凯思新能源技术(上海)有限公司

Balanced dual rocking piston pumps

Piston assemblies for rocking piston compressors, diaphragm compressors and vacuum pumps wherein the overall mass of each piston assembly is identical to that of the other assembly despite having rod tops, retainers and diaphragms of different diameters and therefore different capacities. Each piston assembly includes a connecting rod connected to a rod top that supports a cup seal and a retainer or retainer plate. The mass of each rod is equal to that of the other rod despite the differing geometries. The mass of each retainer is the same as that of the other retainer despite the differing geometries. The overall length and stroke length of each piston assembly is the same. As a result, centers of gravity of the piston assemblies are continuously balanced on either side of the drive shaft in terms of distance from the drive shaft and in absolute value.

Owner:GAST MFG

Diaphragm compressor and gas flow adjusting method thereof

PendingCN109404267ASolve the problem of not being able to inhale gas anymoreRealize stepless adjustmentFlexible member pumpsPump controlReciprocating motionPhase difference

The invention discloses a diaphragm compressor and a gas flow adjusting method thereof. After relative positions of an eccentric block and a main shaft are adjusted, the difference of a phase at the beginning of oil replenishment and a phase at the moment when a diaphragm arrivesat a limiting position is accordingly fixed. A compression screw on an expansion sleeve compression component is tightened, so that the relative positions of the eccentric block and the main shaft and the phase difference of oil replenishment are able to be kept fixedthrough an expansion sleeve. A plunger piston is driven to do a reciprocating motion by a bearing matchedthe eccentric block when the main shaft rotates, so that a plunger pump is able to be replenished once with the oil at a certain position after themain shaft rotates by a circle. According to the diaphragm compressor and the gas flow adjusting method, stepless adjustment of gas flow of the diaphragm compressor is achieved by adjusting oil replenishment time of the plunger pump, so that a problem of insufficient gas suction during oil replenishment of an existing diaphragm compressor is able to be solved, and meanwhile, the compressor and the method are more economical, thereby reducing energy consumption.

Owner:XI AN JIAOTONG UNIV

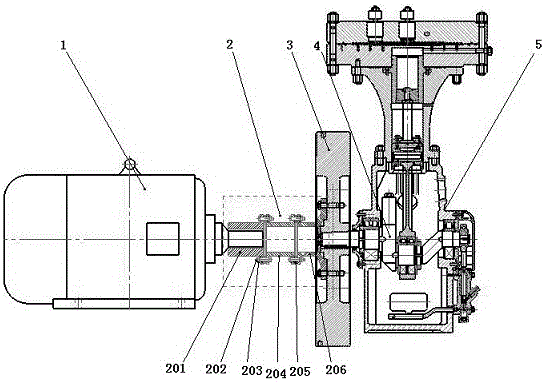

Motor direct driven diaphragm compressor

InactiveCN106762578AHigh concentricityImprove transmission efficiencyFlexible member pumpsPositive-displacement liquid enginesElectric machineCoupling

The invention relates to the manufacturing field of electrical equipment, in particular to the manufacturing field of compressors, and specifically provides a motor direct driven diaphragm compressor. The motor direct driven diaphragm compressor is composed of a motor, a coupler, a compressor airplane and a crankshaft box. A motor shaft of the motor is connected to one end of the coupler, and the other end of the coupler is connected to the compressor airplane through a flange. A crankshaft connecting rod system in the crankshaft box is connected with the compressor airplane through a key joint. The axis of the motor, the axis of the coupler, the axis of the compressor airplane and the axis of the crankshaft box are located on the same straight line. According to the motor direct driven diaphragm compressor, the loss of intermediate transmission energy is reduced, the transmission efficiency is high, the reserve capacity is large, and the compressor saves more energy; during running, the vibration and impact resistance of the compressor is small, and the compressor can also normally work in a relatively hostile working condition environment; and the number of equipment accessories connected by an ordinary belt is reduced, the intermediate links of the compressor are reduced, the probability of failures is reduced, and the running cost and the maintenance cost are reduced.

Owner:JIANGSU PERMANENT MACHINERY

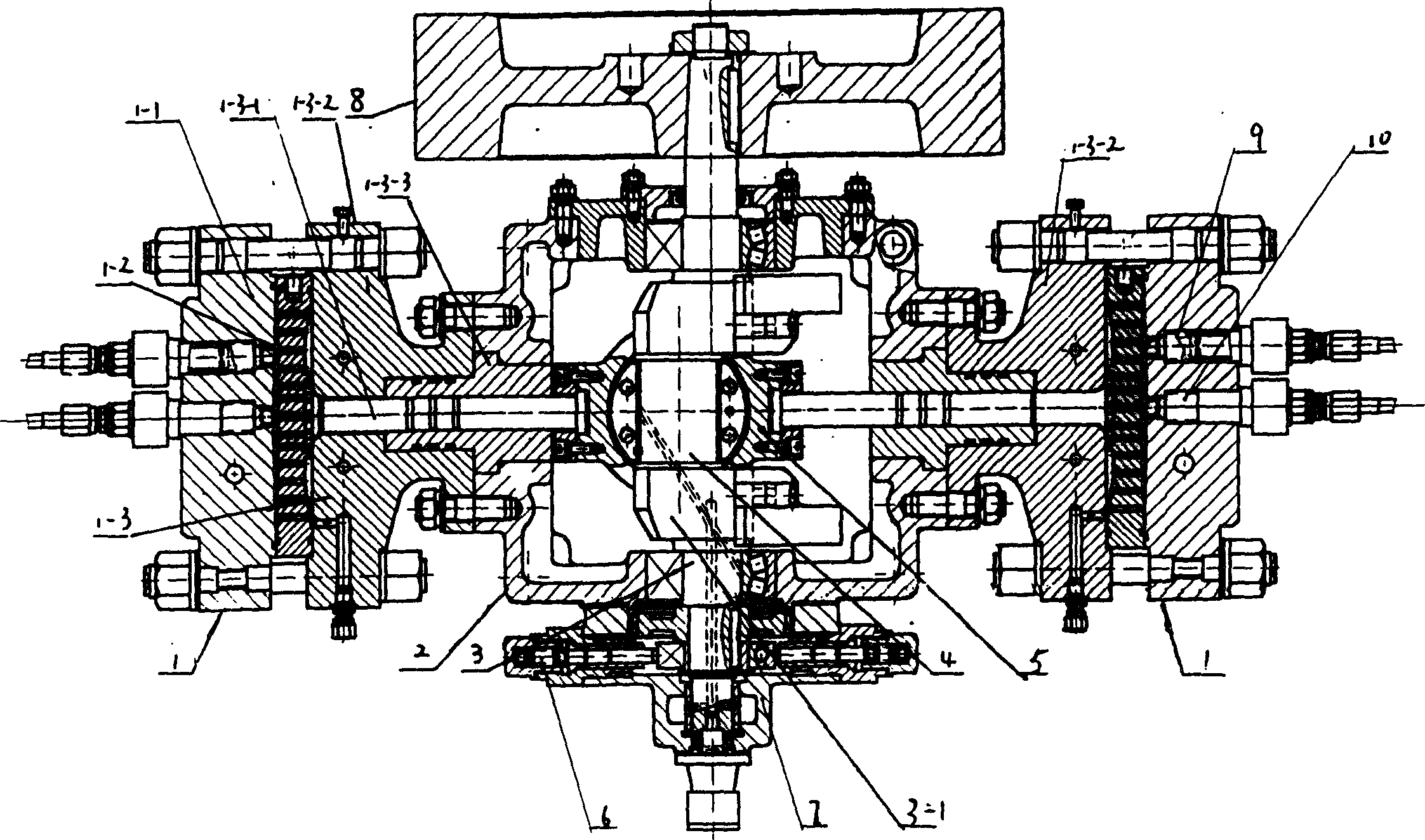

Opposed diaphragm compression engine capable of auto-regulating coaxial degree of bar piston and plunger case

InactiveCN1560475AReduce contact frictionReduce wearFlexible member pumpsPositive-displacement liquid enginesGas cylinderEngineering

The invention relates to opposed membrane compressor which can adjust the axiality of the pole cork and the cork cover automatically. It is mainly applied to compressing and transmitting purified air. It includes crank box, crank, sliding block, sliding cover and left and right working cylinders, the crank is arranged in the crank box, the sliding cover is arranged on the bellcrank of the crank, the sliding cover is covered out of the sliding block, the left and right working cylinders are separated into two parts with films 1-2, one is the oil cylinder, the other is a gas cylinder, the oil cylinder includes a cylinder, pole cork and cork cover, the cylinder is arranged on the lift and right sides of the crank box, the pole cork cover is embedded in the crank box and the cylinder, the pole cork is arranged in the cylinder and the pole cork cover, connected to the left and the right sides, the character is that the left and right sides of the sliding cover are arranged with slots, the connecting end of the pole cork and the sliding cover uses the ball head structure, the ball head structure is arranged in the slots, connected to the sliding cover. The axiality of the pole cork and the cork cover can be adjusted automatically; and reducing wear.

Owner:江阴开益特种压缩机有限公司

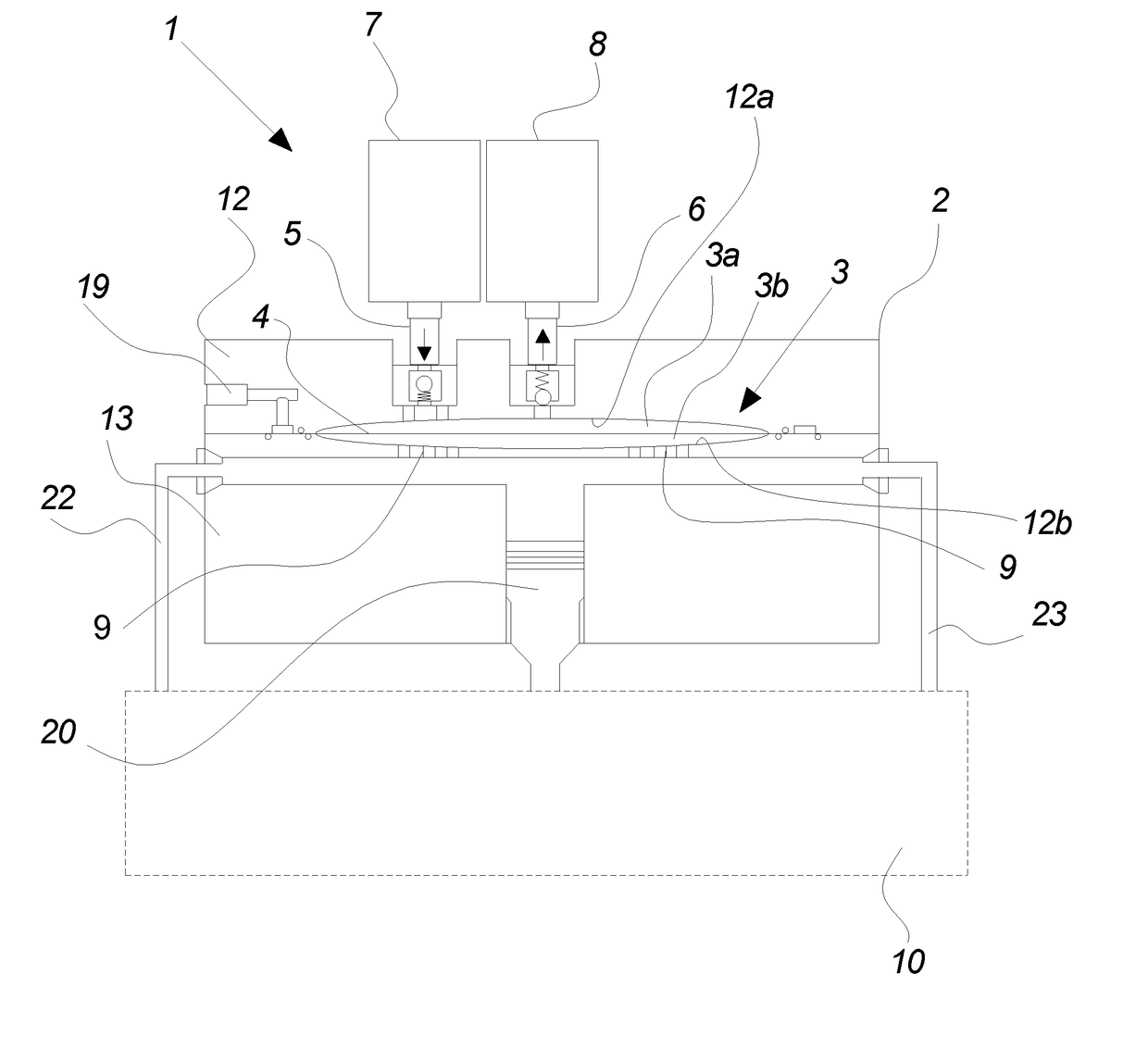

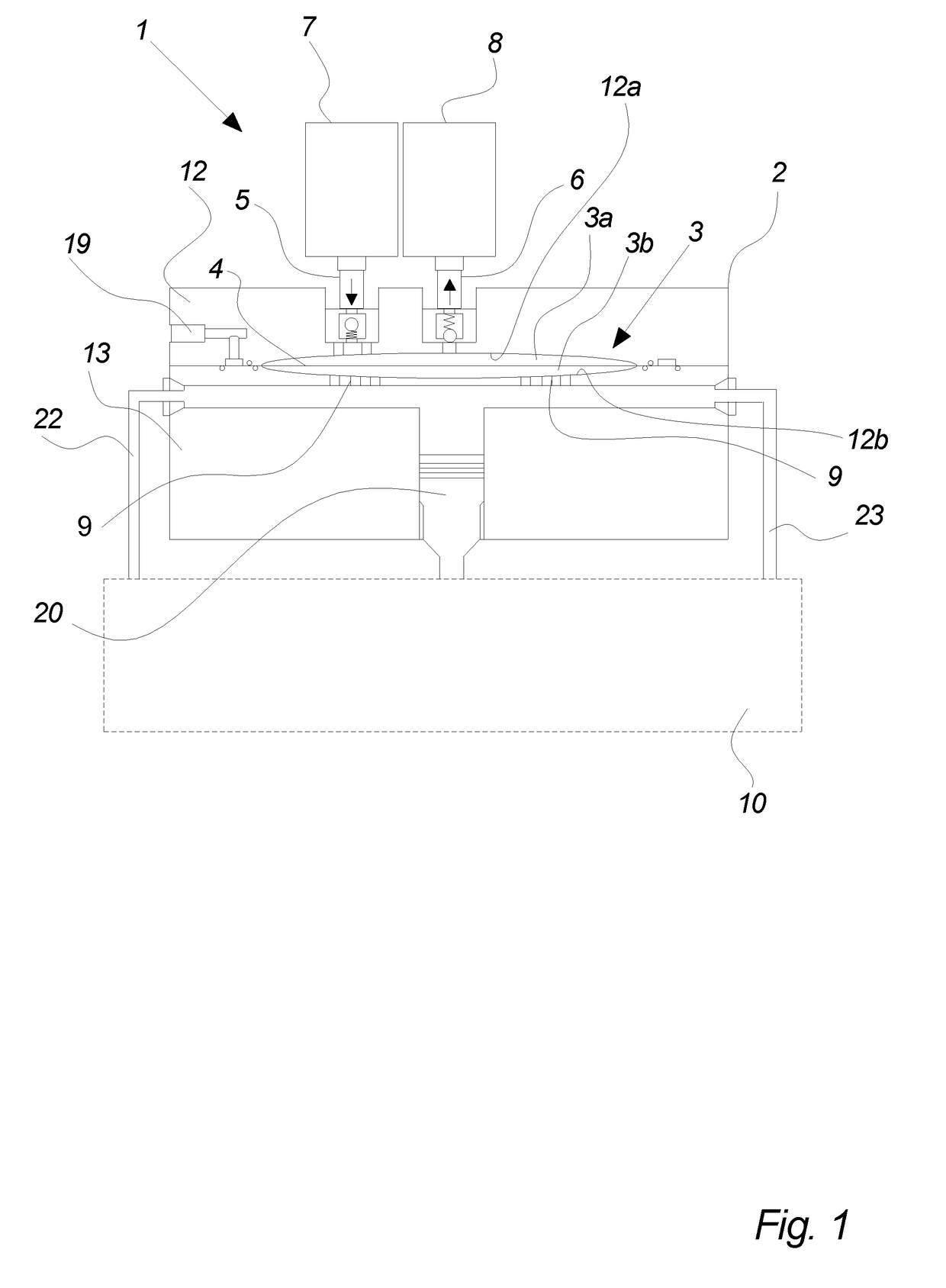

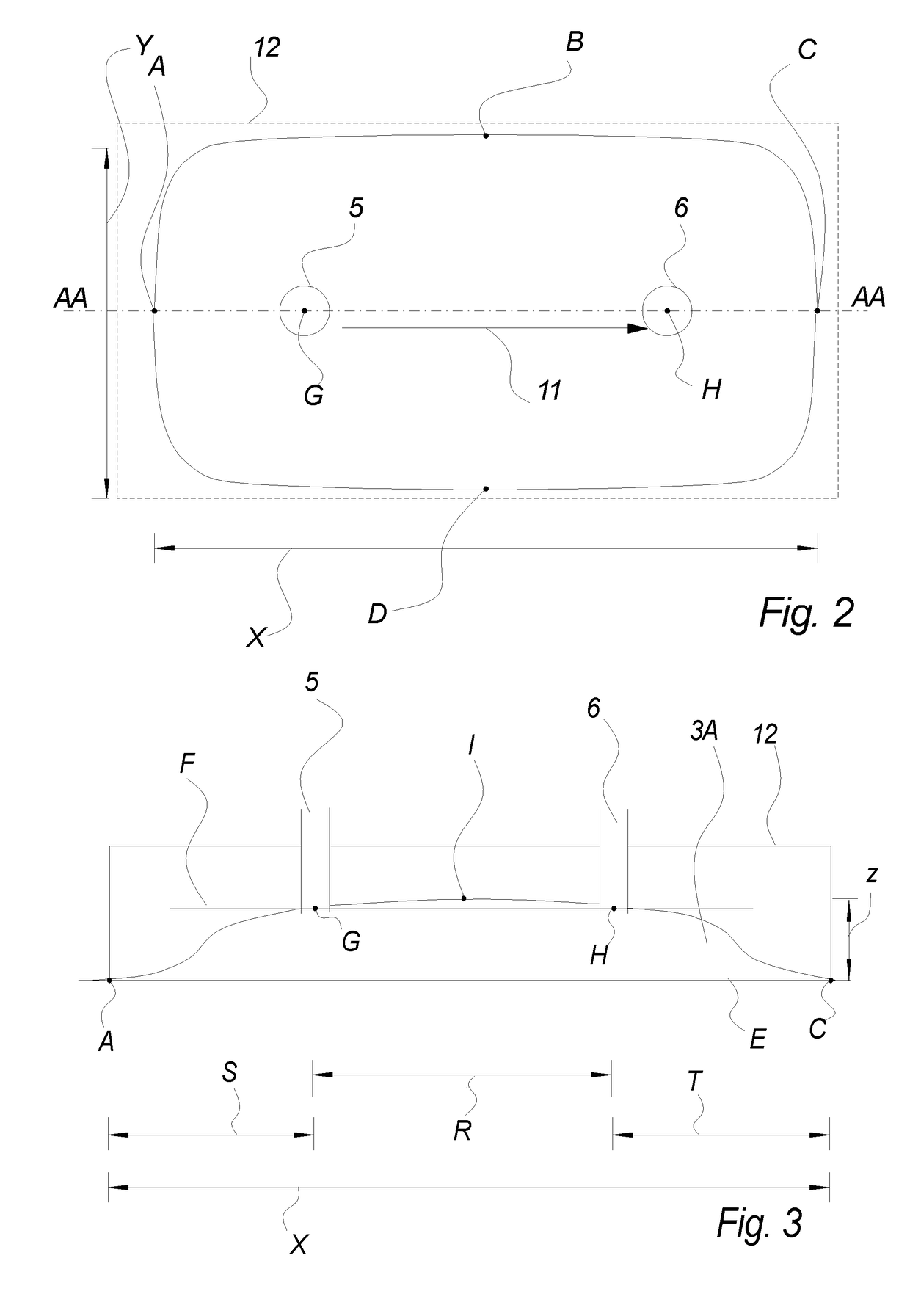

Diaphragm compressor with an oblong shaped chamber

PendingUS20180135616A1Reduce wearRelieve pressurePositive displacement pump componentsContainer filling methodsEngineeringHigh pressure

The invention relates to a high pressure diaphragm compressor for pressurizing a gaseous fluid to a pressure of at least 10 MPa, the compressor including a compressor head having an oblong shaped chamber.

Owner:NEL HYDROGEN AS

Totally-enclosed parallel apparatus of production and dosage

InactiveCN102327760AReasonable structureEasy to installMixer accessoriesFeed devicesEngineeringMechanical engineering

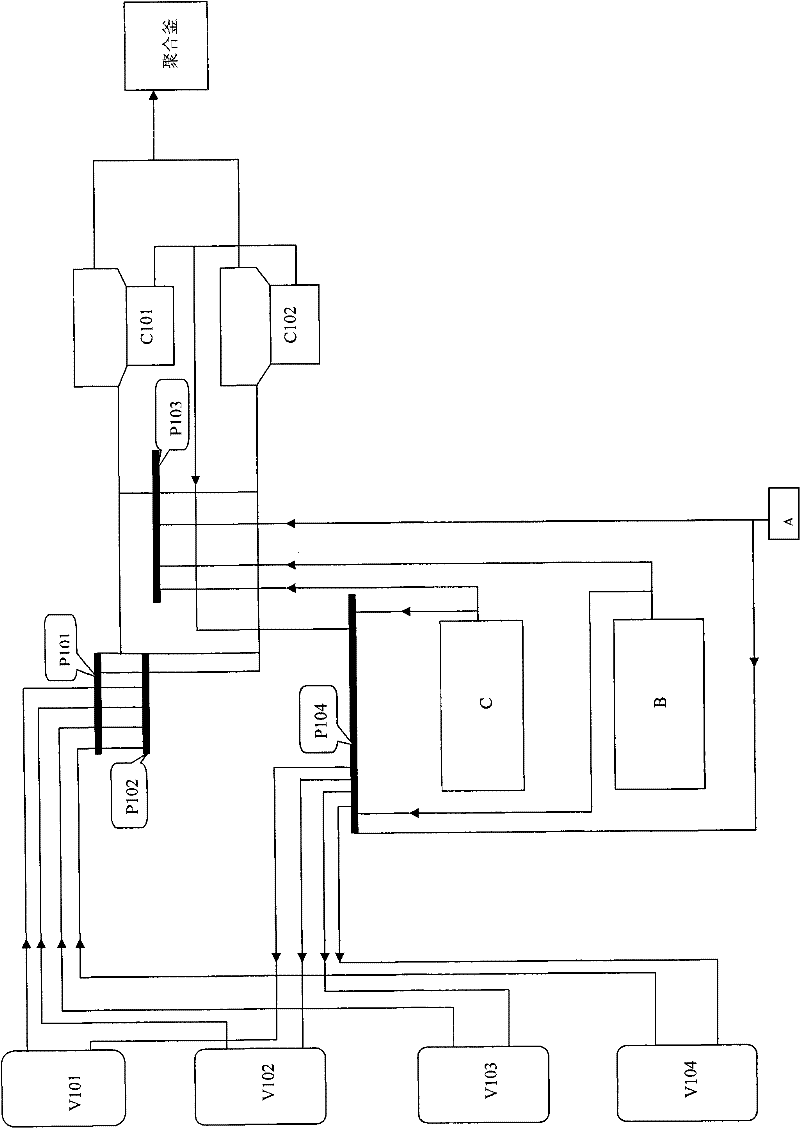

The invention discloses a totally-enclosed parallel apparatus of production and dosage. The apparatus is characterized in that: the apparatus comprises a dosage bunker, an addition bunker, a first seal cylinder, a second seal cylinder, a third seal cylinder, a fourth seal cylinder, a first diaphragm compressor, and a second diaphragm compressor; the dosage bunker is connected with the second seal cylinder through a pipeline, the discharge hatch of the first seal cylinder is connected with the second diaphragm compressor through a pipeline, the output terminal of the second diaphragm compressor is connected with the fourth seal cylinder through a pipeline, the fourth seal cylinder is connected with the dosage bunker through a pipeline, and raw materials are added to the second diaphragm compressor through the third seal cylinder; and the output terminal of the addition bunker is connected with the first seal cylinder through a pipeline, the output terminal of the first seal cylinder is connected with the first diaphragm compressor through a pipeline, and the output terminal of the first diaphragm compressor is connected with a polymerization kettle. The apparatus of the present invention has the advantages of reasonable structure, easy arrangement, low cost, convenient operation, no leakage, and safety and reliability.

Owner:JIANGSU HUAAO COATING CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com