High temperature gas cooled reactor tritium-contained wastewater optimization collection system and technology

A high-temperature gas-cooled reactor and collection system technology, which is applied in the field of nuclear reactors, can solve the problem that tritium-containing wastewater cannot be collected in a molecular sieve bed, and achieve the effect of maintaining efficient operation and prolonging operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 An optimized collection system for high-temperature gas-cooled reactor tritium-containing wastewater

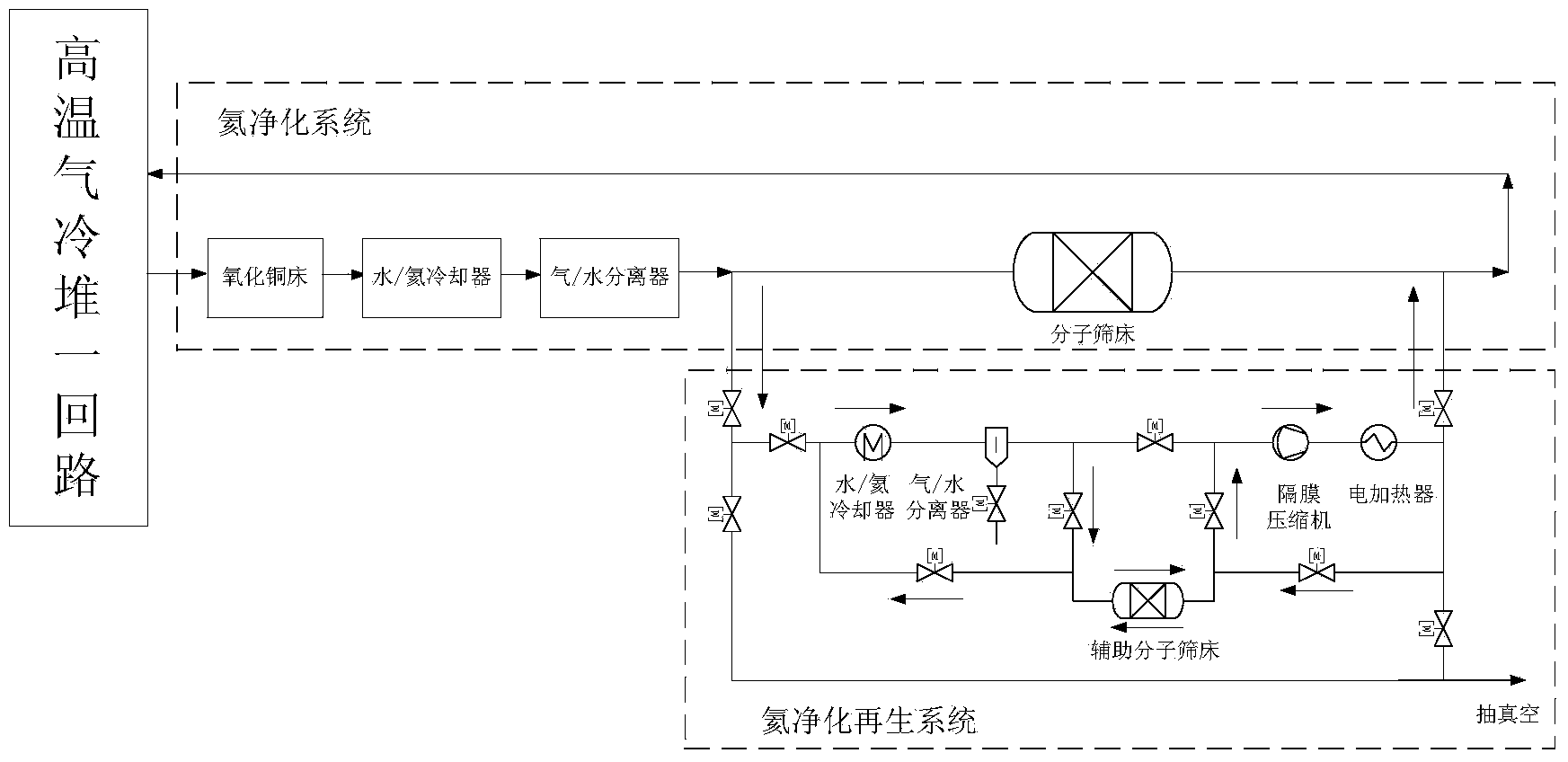

[0029] An optimized collection system for high temperature gas-cooled reactor tritium-containing wastewater, such as figure 1 As shown, it consists of the first closed loop system and the second closed loop system; where,

[0030] The first closed loop system consists of diaphragm compressor of helium purification and regeneration system, electric heater of helium purification and regeneration system, molecular sieve bed of helium purification and regeneration system, water / helium cooler of helium purification and regeneration system, gas / water separator of helium purification and regeneration system, auxiliary Molecular sieve beds are connected sequentially;

[0031] The second closed loop system is composed of diaphragm compressor of helium purification and regeneration system, electric heater of helium purification and regeneration system, auxiliary molec...

Embodiment 2

[0034] Example 2 An optimized collection process for high-temperature gas-cooled reactor tritium-containing wastewater

[0035] The collection system of the present invention is used to transform the helium purification and helium auxiliary system of the 10MW high temperature gas-cooled experimental reactor. The optimized collection process of tritium-containing wastewater after transformation includes the following steps:

[0036] 1) Use the first closed-circuit circulation system to transfer the tritium-containing wastewater in the molecular sieve bed of the helium purification system to the gas / water separator and the auxiliary molecular sieve bed of the helium purification regeneration system;

[0037] The specific steps are: fill the first closed-circuit circulation system with helium to low pressure, start the diaphragm compressor of the helium purification regeneration system, and the helium gas enters the helium purification regeneration system through the diaphragm com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com