Expansion graphite base compound material dual-pole board and its making method

A technology of expanded graphite and composite materials, used in battery electrodes, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as unsatisfactory interface bonding, affecting fuel cell performance, and easy layer-to-layer detachment, achieving excellent Corrosion resistance and oxidation resistance, overcoming the effects of poor mechanical properties and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: adopt natural flake graphite to intercalate by chemical method (impregnated in H 2 SO 4 、HNO 3 In the mixed solution of H 2 SO 4 80% by volume, HNO 3 The volume percentage is 20%, stirred, and reacted for 30 minutes), filtered, washed with water to a pH value of 5-6, and dried to obtain expandable graphite. The expandable graphite is extruded at a high temperature of 1000°C to obtain worm-like graphite with an expansion factor of 240; add worm-like graphite to the mold, and press at 8MPa at room temperature to form a prefabricated expanded graphite plate with a thickness of 0.7mm.

[0020] The above two expanded graphite prefabricated plates and the carbon cloth (thickness 0.4mm, porosity 50%) put into the polyvinylidene fluoride / N, N-dimethylformamide solution with a solid content of 40wt% were impregnated, Dry at room temperature, then heat treat at 160°C for 2 hours.

[0021] The two impregnated expanded graphite prefabricated plates and carbon cl...

Embodiment 2

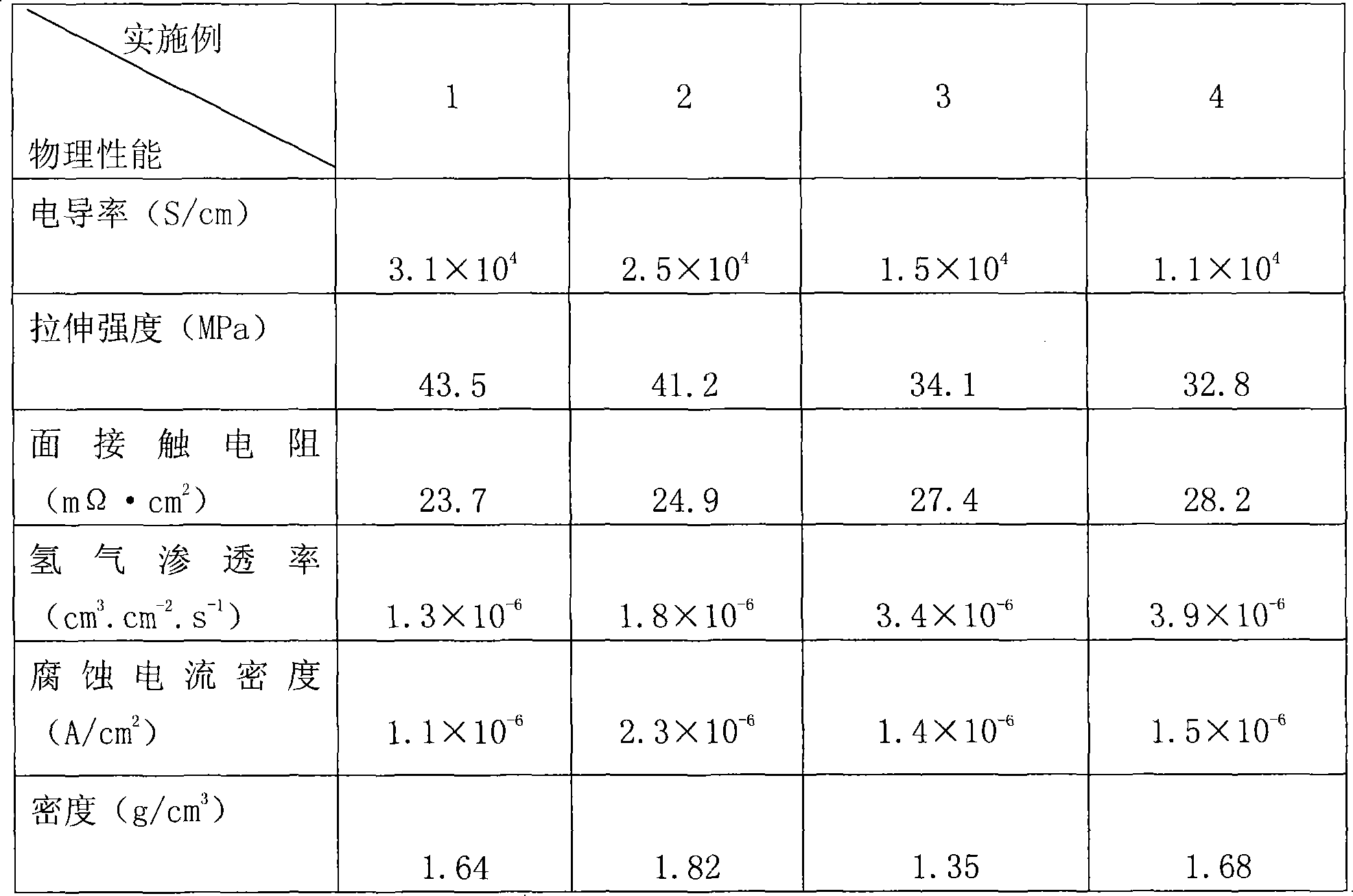

[0022] Embodiment 2: The preparation method is the same as that of Embodiment 1, except that the soaking liquid is replaced with polytetrafluoroethylene emulsion with a solid content of 50 wt%. The test results of its basic physical properties are shown in Table 1.

Embodiment 3

[0023] Embodiment 3: The preparation method is the same as in Embodiment 1, and the carbon cloth is replaced with carbon paper. The test results of its basic physical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com