Overlap type large-displacement diaphragm compressor

A diaphragm compressor, large displacement technology, applied in the direction of liquid displacement machinery, mechanical equipment, variable displacement pump components, etc., can solve the problems of easy damage, increased production cost and difficulty, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

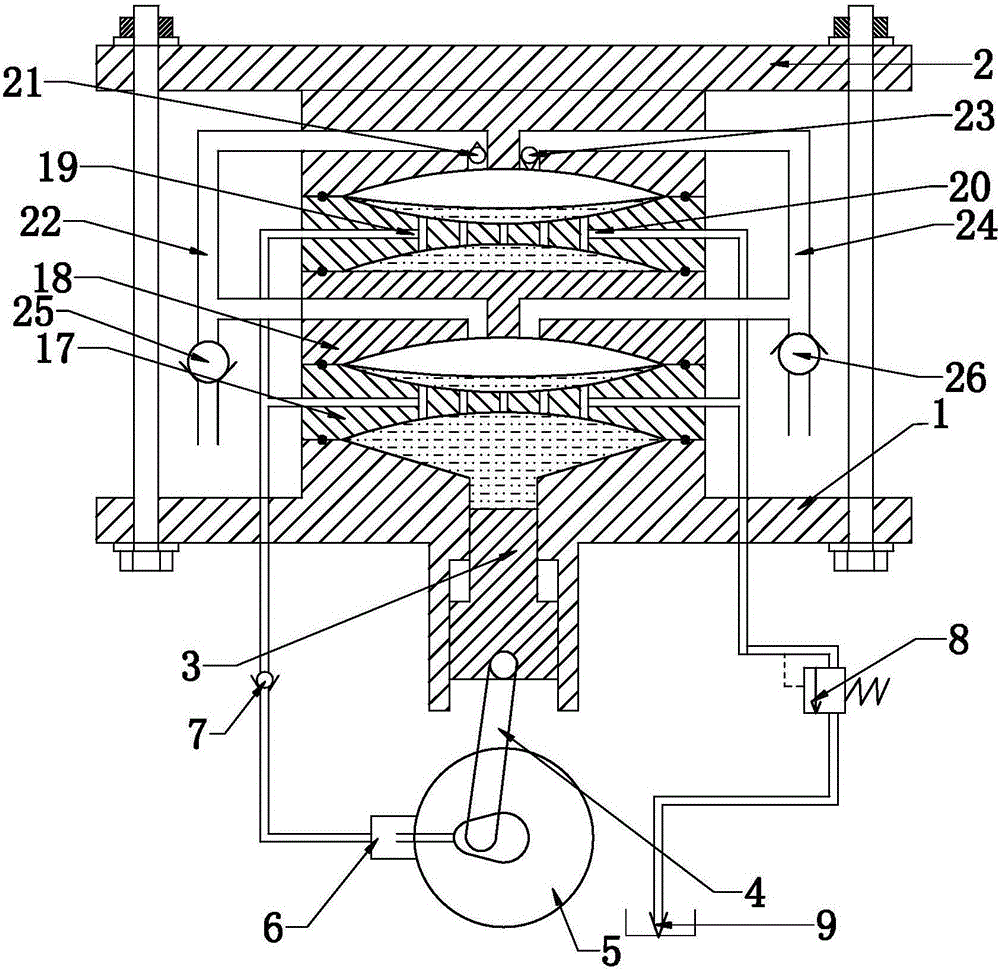

[0014] The superimposed large-displacement diaphragm compressor of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

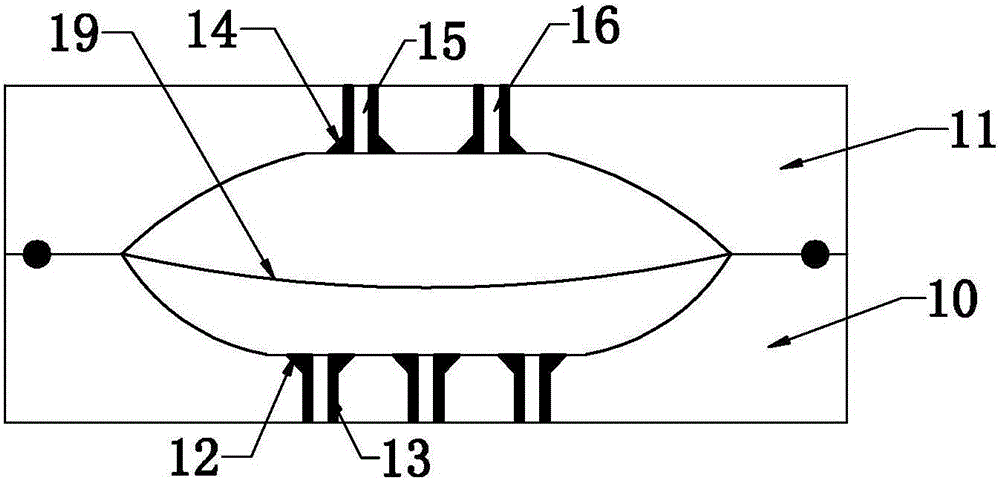

[0015] As shown in the figure, the superimposed large-displacement diaphragm compressor of the present invention includes a cylinder body 1, a cylinder head 2 installed on the cylinder body, and at least two groups of mutual Superimposed compression mechanisms. In this embodiment, there are two sets of compression mechanisms superimposed on each other. The cylinder body 1 and the cylinder head 2 are fixedly connected by fasteners and the compression mechanisms are pressed therein. Each set of compression mechanisms includes a component For the set oil distribution plate 17 and air distribution plate 18, a diaphragm 19 is arranged between each pair of oil distribution plate 17 and air distribution plate 18, and the side of the diaphragm 19 near the oil distribution plate is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com