Opposed diaphragm compression engine capable of auto-regulating coaxial degree of bar piston and plunger case

An automatic adjustment and plunger sleeve technology, applied in the field of compressors, can solve problems such as contact friction, increased wear, difficulty in ensuring coaxiality, and large installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

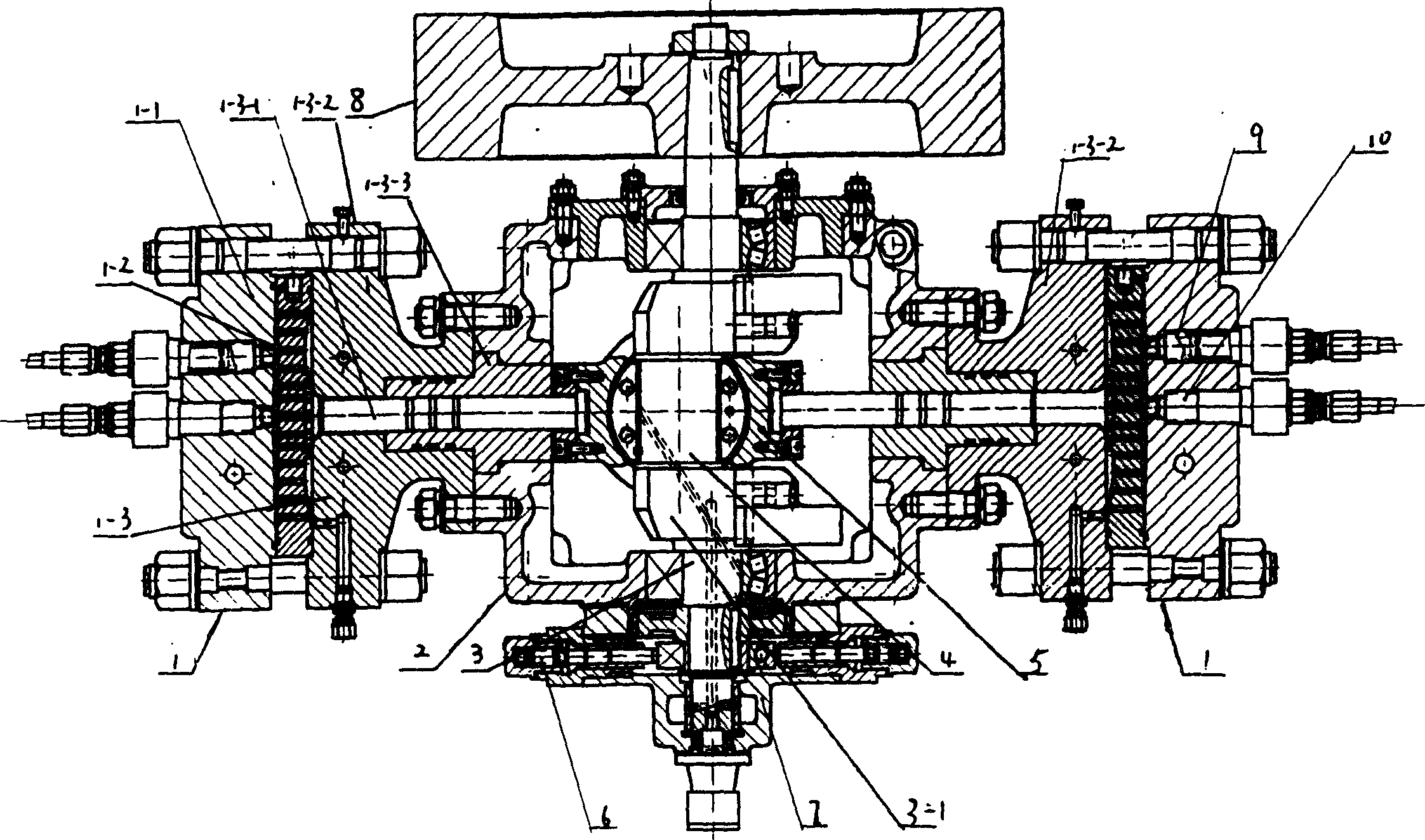

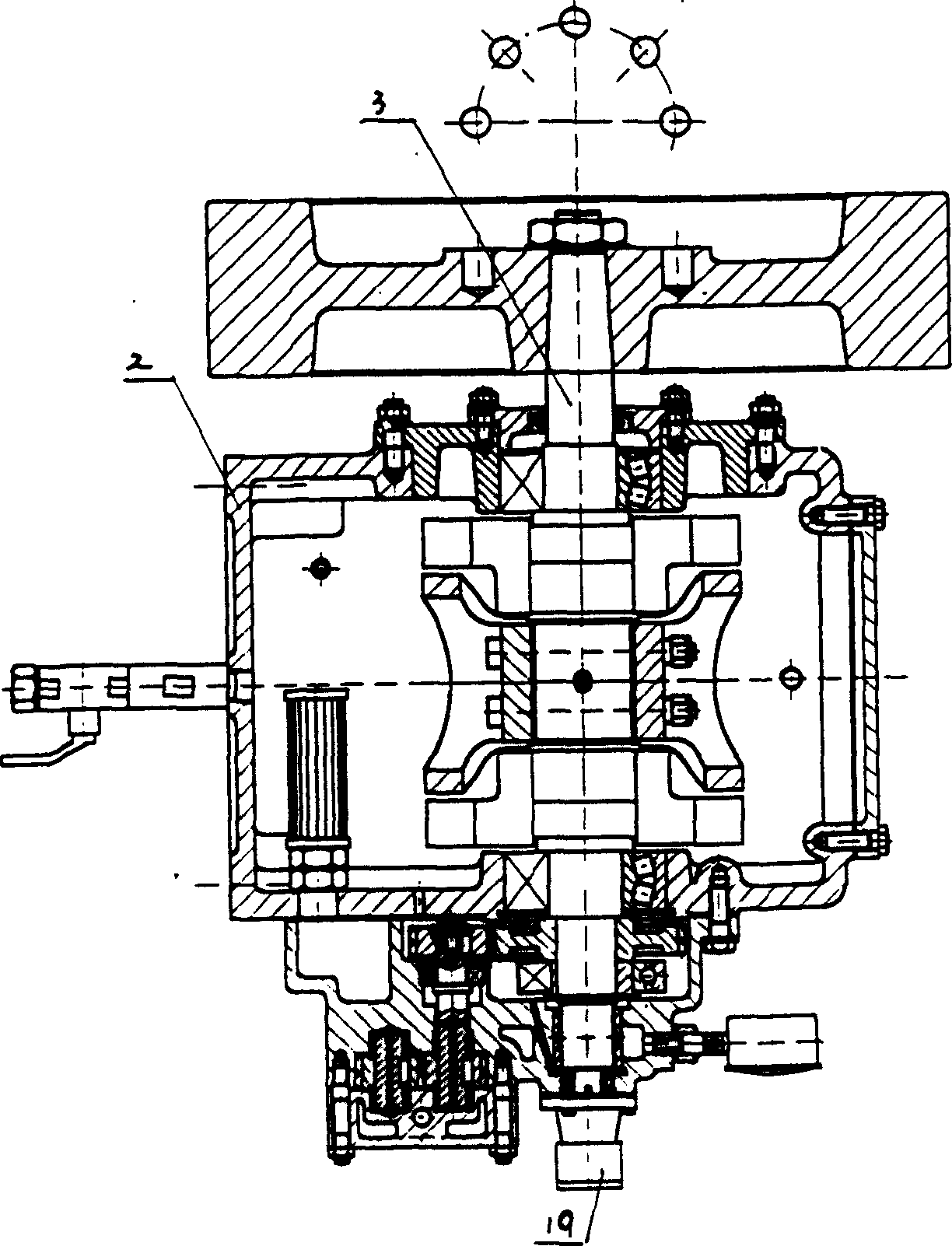

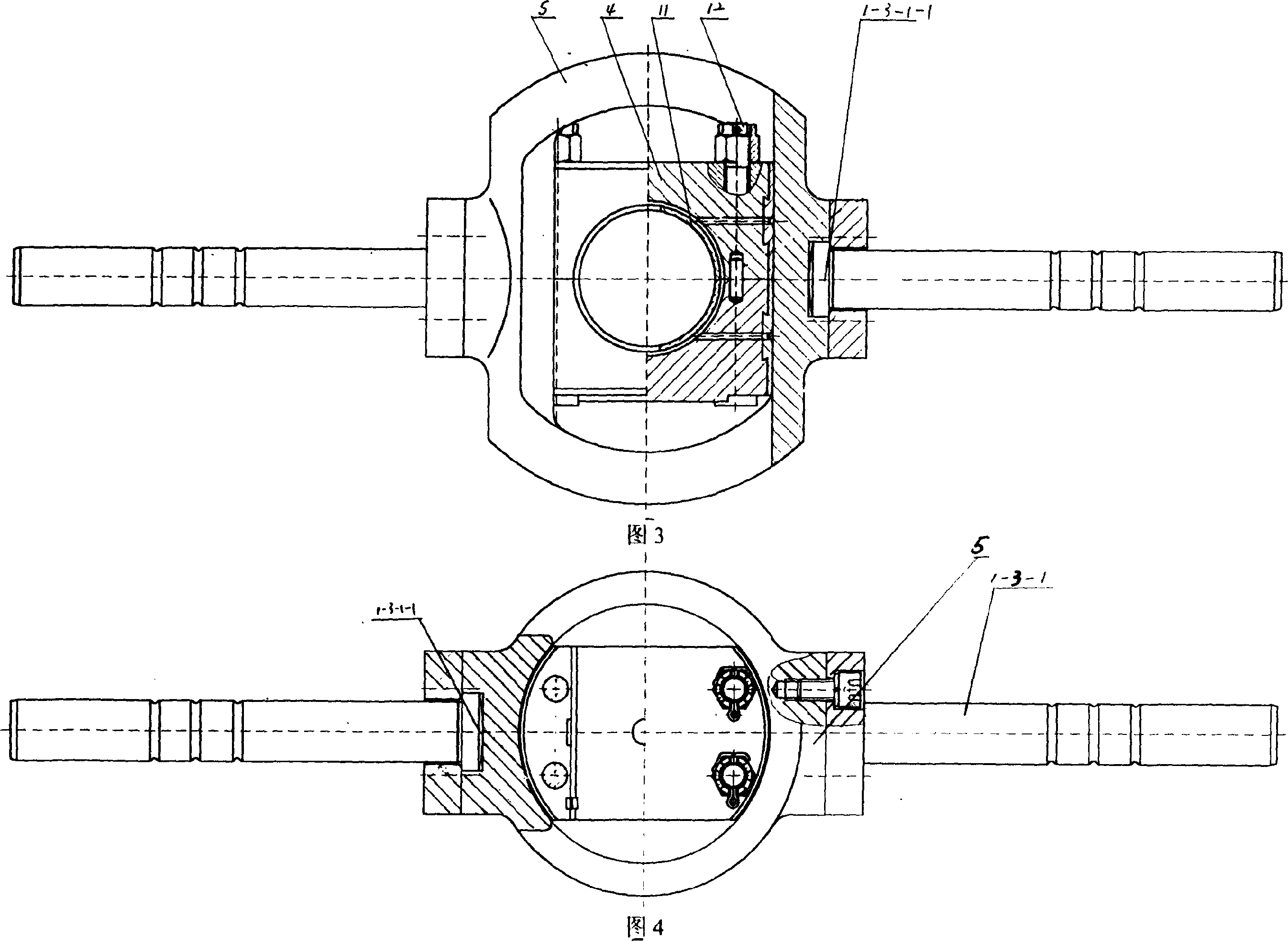

[0011] like Figure 1~2 , the present invention is an opposed diaphragm compressor capable of automatically adjusting the coaxiality of the plunger and the plunger sleeve, mainly composed of a crankcase 2, a crankshaft 3, a slider 4, a sliding sleeve 5, left and right working cylinders 1, an oil pump 7. It is composed of charge pump 6, flywheel 8, suction and exhaust valves 9, 10, and gas pipeline system and oil pipeline system. The crankshaft 3 is placed in the crankcase 2 . The slider 4 is equipped with a shaft hole, which is an upper and lower two-lobe structure. It is connected with 4 bolts 12 and placed on the crankshaft 3 crankshaft 3-1 through the bearing bush 11, and 5 sets of sliding sleeves are placed on the slider 4 (such as Figure 3, 4). Working cylinder 1 is divided into two parts by diaphragm 1-2, one is oil cylinder 1-3, the other is cylinder 1-1, and oil cylinder 1-3 includes cylinder body 1-3-2, plunger 1-3- 1 and plunger set 1-3-3 (such as Figure 5 ). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com