Patents

Literature

66results about How to "Lift freely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

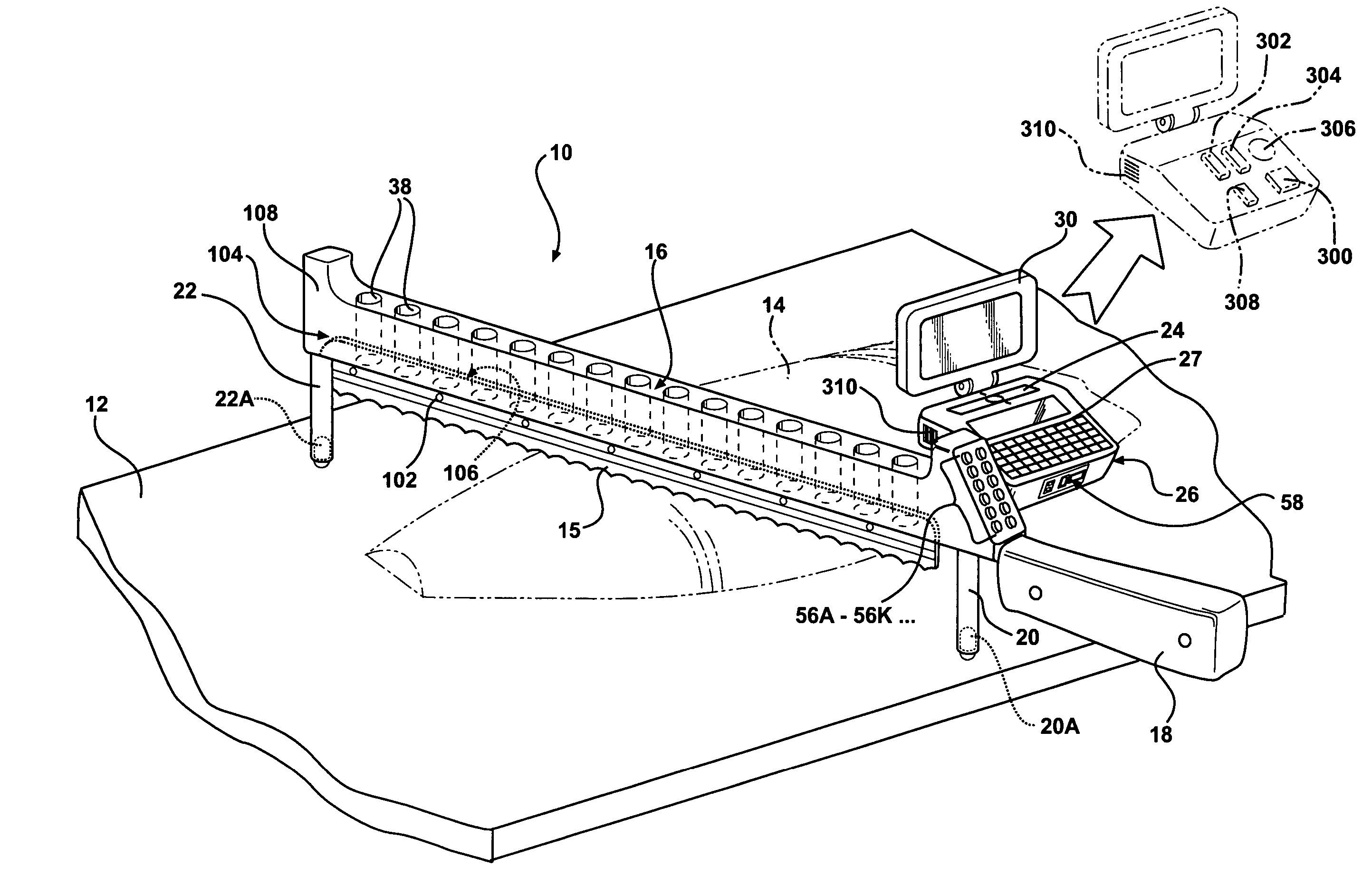

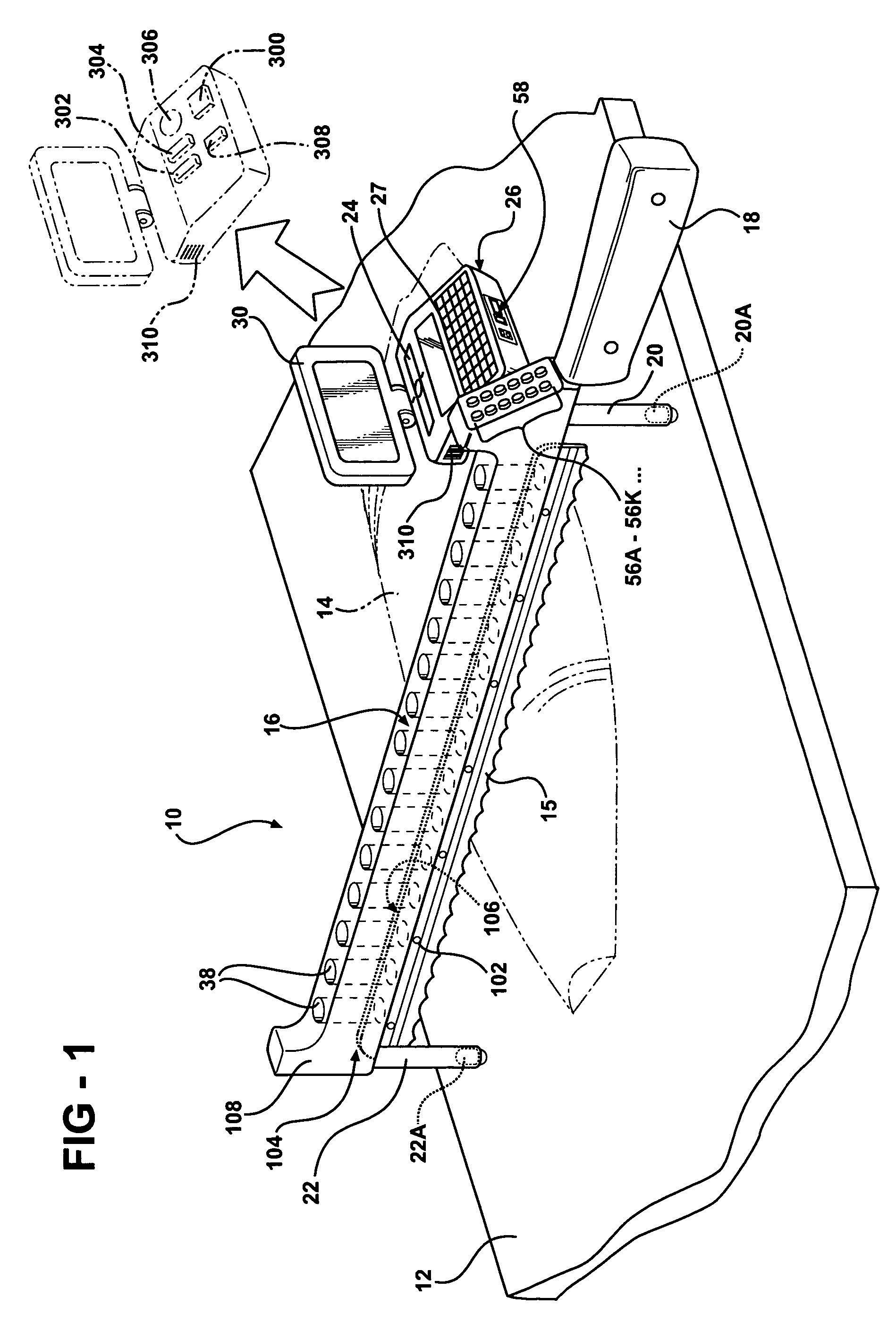

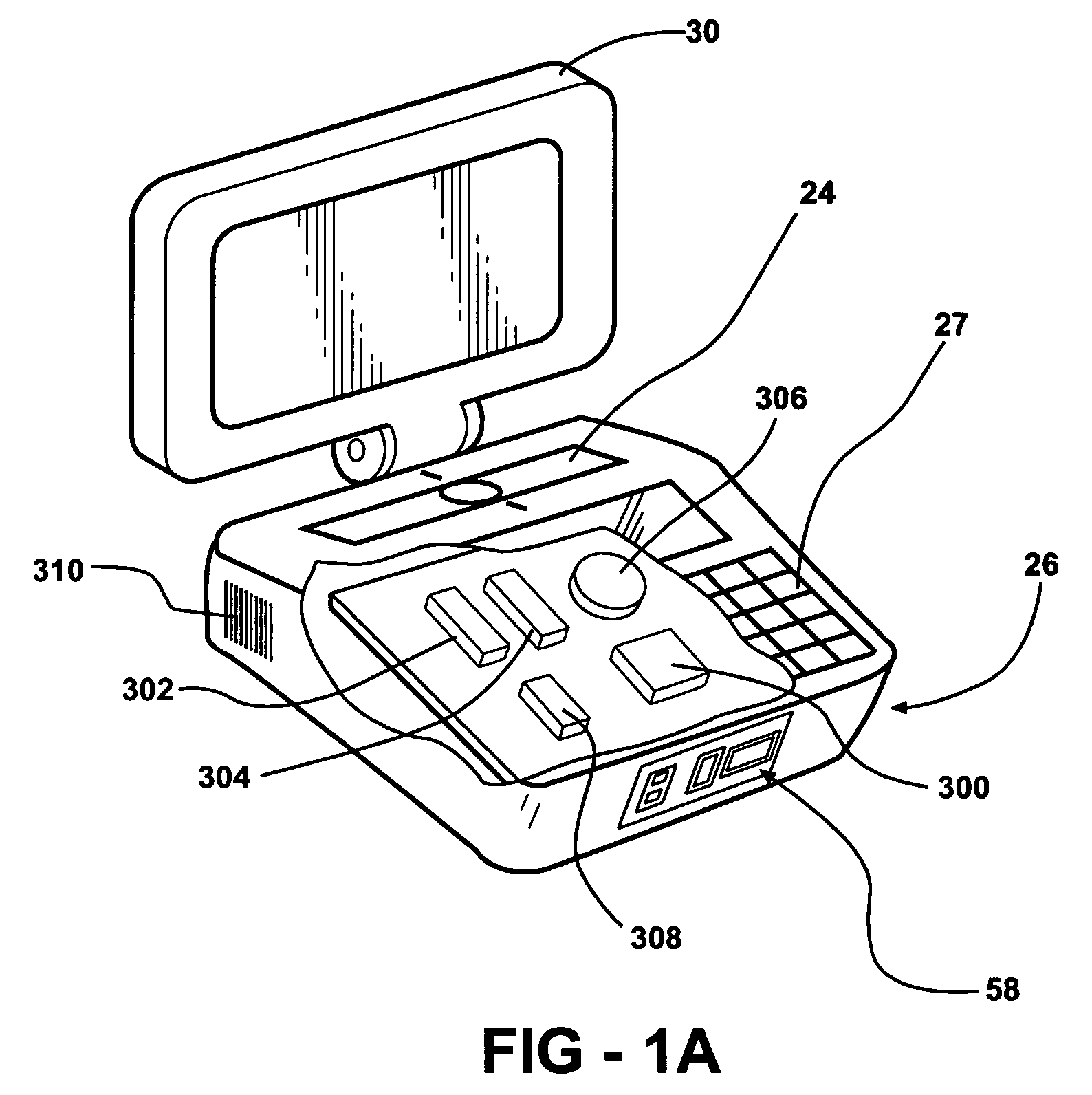

Apparatus and method for displaying numeric values corresponding to the volume of segments of an irregularly shaped item

ActiveUS7158915B2Low costFast and accurate determinationMeat holding apparatusFeeler-pin gaugesNumeric ValueWeight value

An apparatus and method for displaying the weight or cost of segments of an irregularly shaped item involves passing a sensor bar supported above a supporting surface over the item lying on the surface. A compact hand-held embodiment of the sensor bar enables the operator to move the sensor bar in various linear or non-linear motions over the item surface as the sensor bar moves laterally across the item surface while the sensor bar support posts remain in constant contact with the supporting surface. The sensor bar contains one or more sensors which generate signals corresponding to the height of the item as the sensor bar traverses the item. At the same time, a displacement detector arrangement generates signals corresponding to displacement of the sensor bar relative to the support surface. These signals are processed in a signal processor to determine the volume of an uncut segment of the item lying behind the sensor bar at successive positions. Each of these cumulative volume determinations may be continuously converted into numeric weight values based on the density factor for the particular type of item, whereby numeric weight and cost values (based on weight) are continuously displayed as the sensor bar is stroked over the item, thus enabling the operator to accommodate an on-looking consumer's specific requests as per the particular portion desired based on the physical appearance, weight, and cost of an item before the item is cut.

Owner:WARGON KENNETH

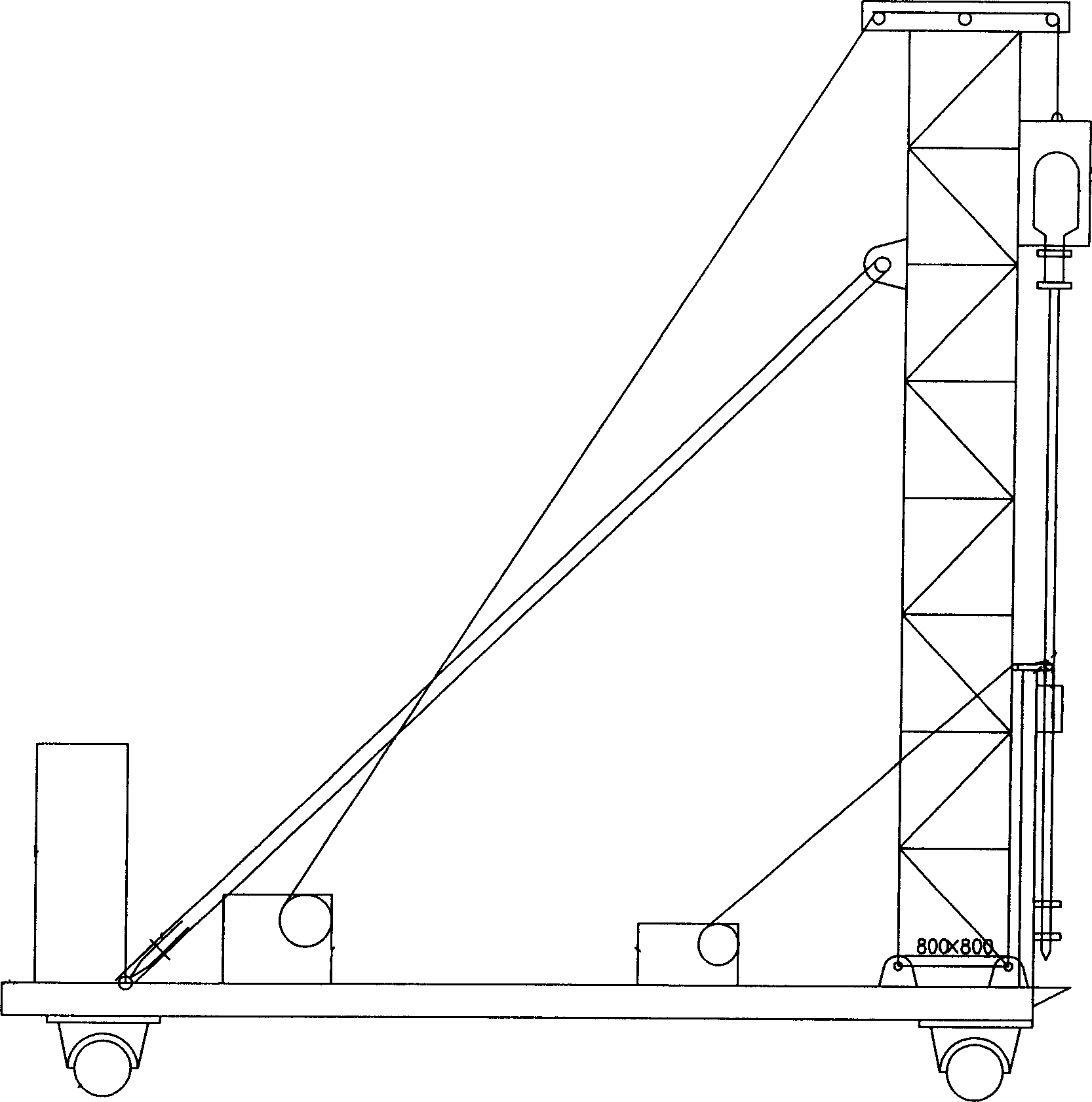

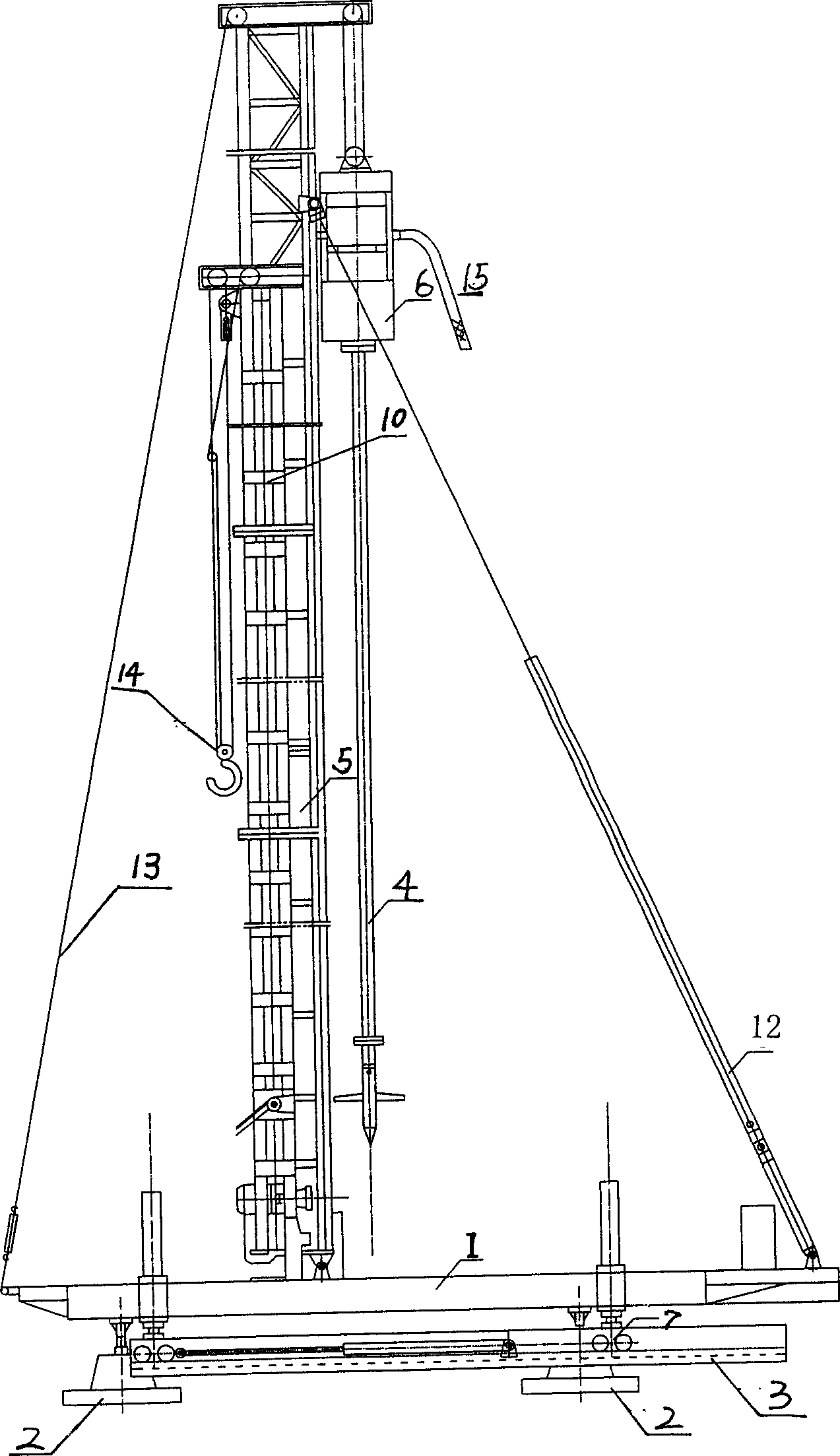

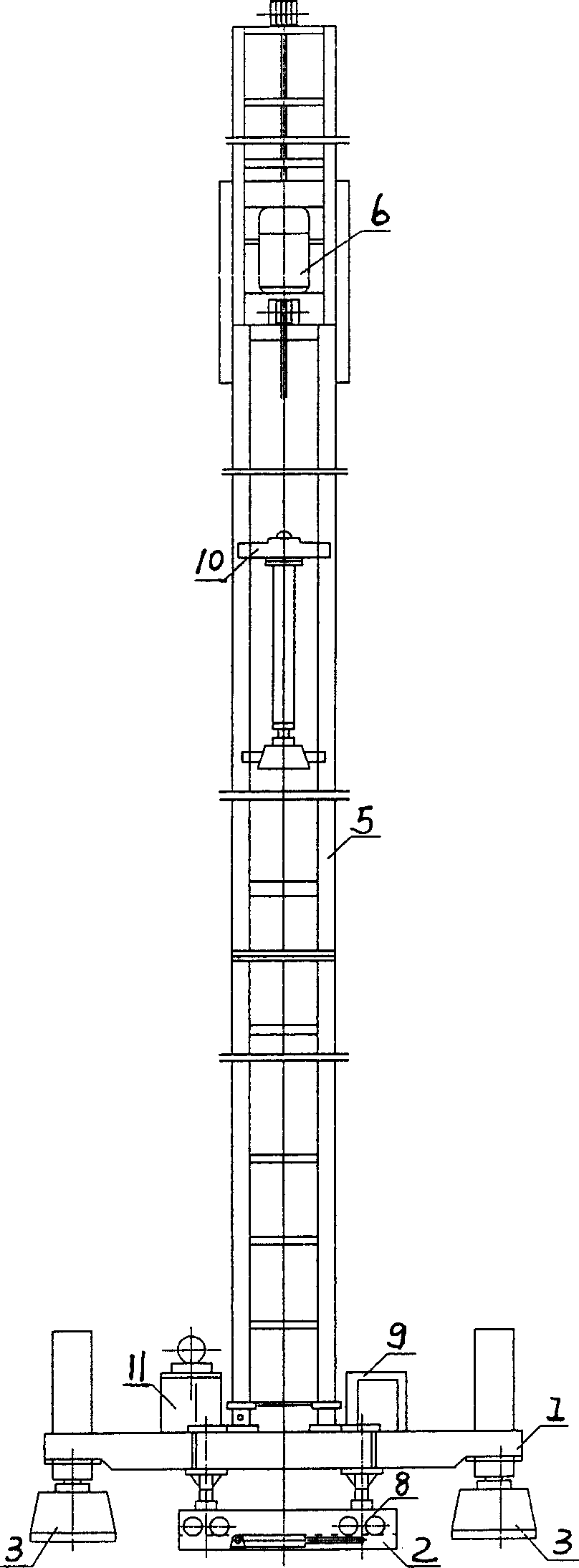

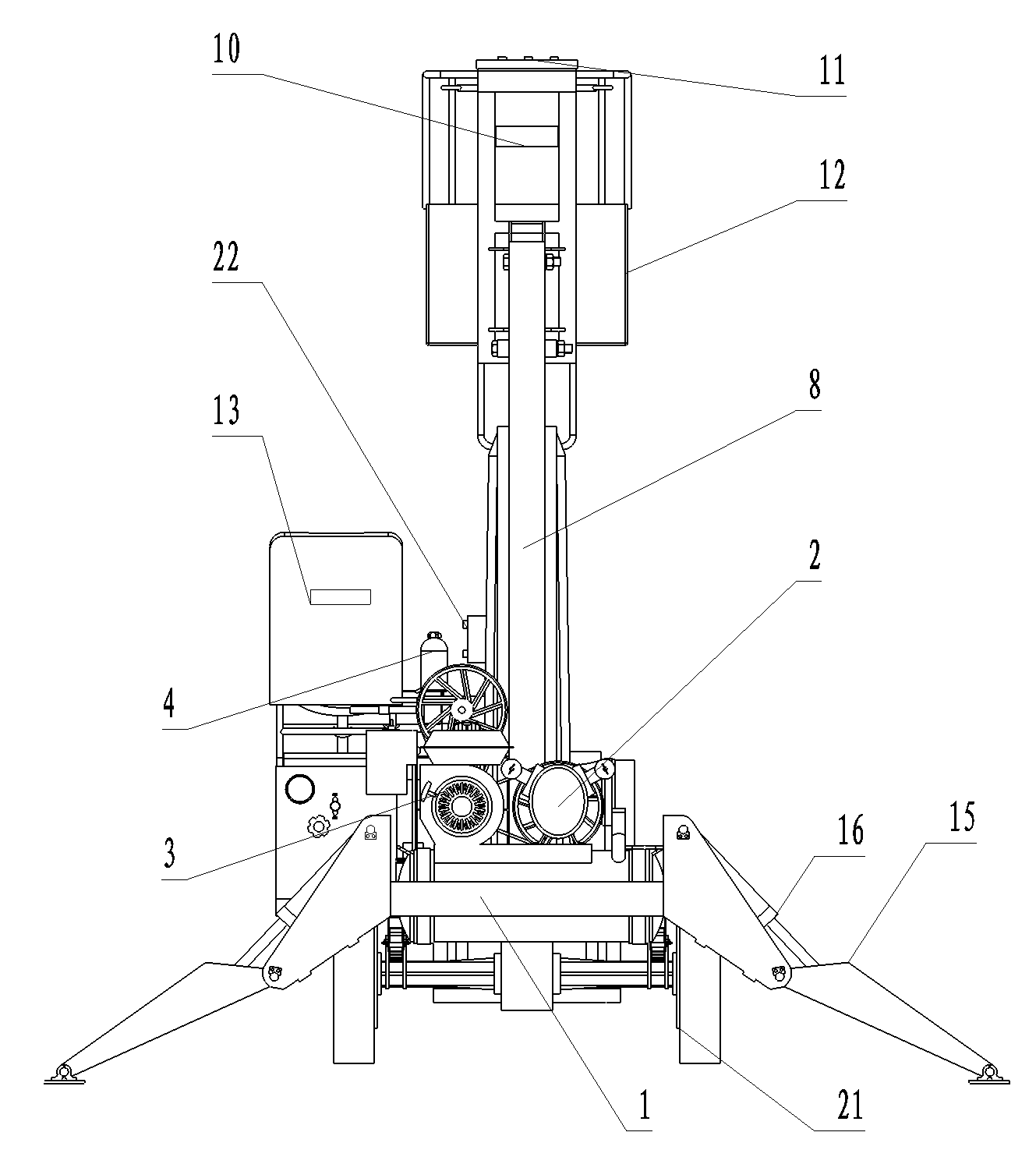

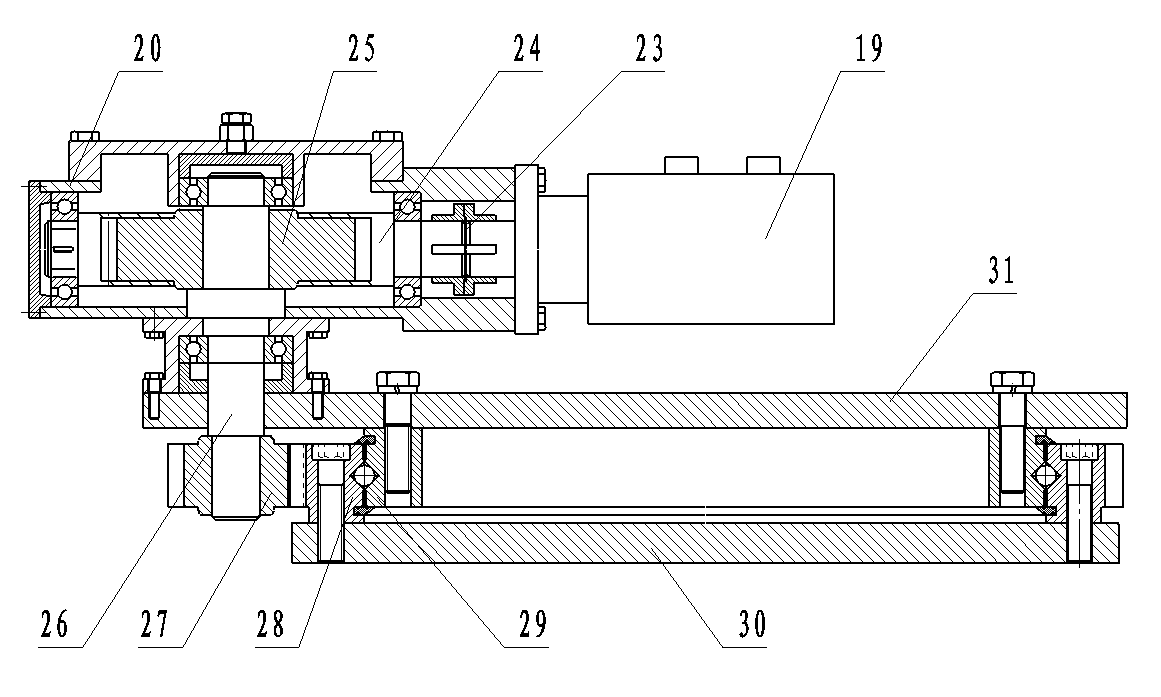

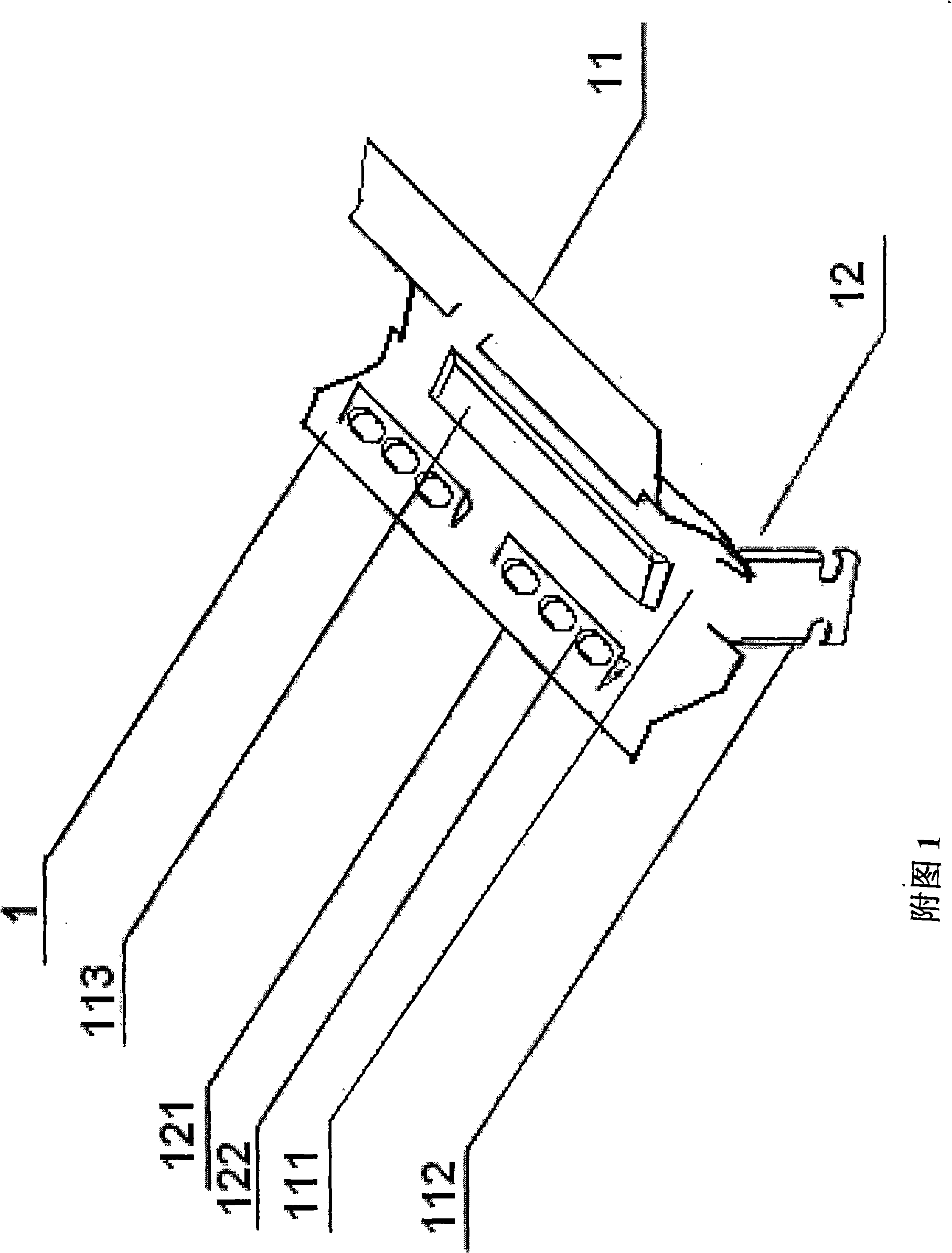

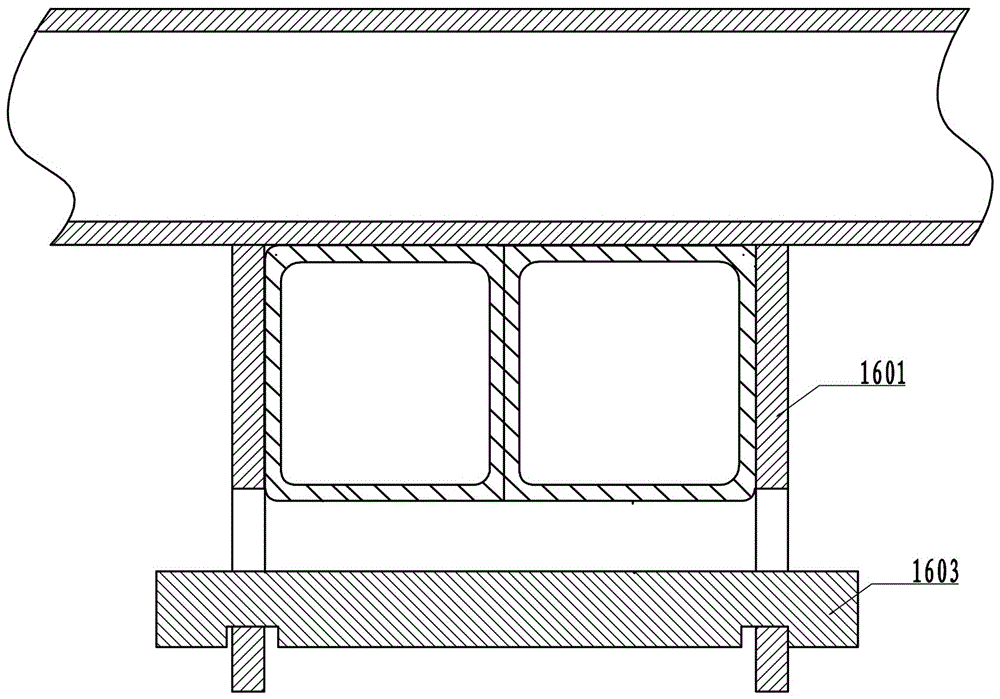

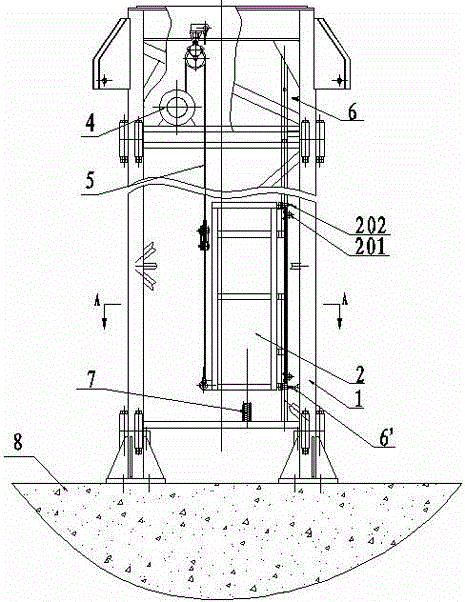

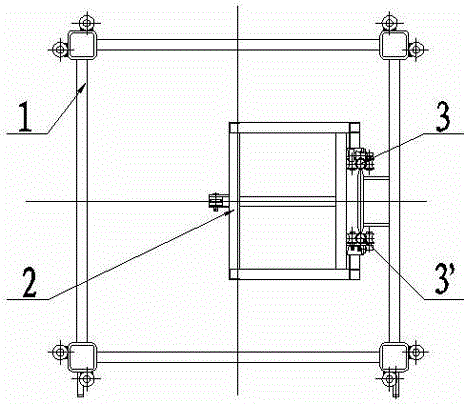

Concrete core cement soil stirring pile machine and its construction technological method

InactiveCN1718938AAvoid Weaknesses of Poor Fighting AbilityGuaranteed alignmentBulkheads/pilesHydraulic pumpArchitectural engineering

The present invention discloses a concrete core cement earth stirring pile machine and its construction process and method. The bottom portion of said pile machine is equipped with hydraulic walking system, including machine frame, base seat, hydraulic pump station, longitudinal and transverse moving beams, longitudinal and transverse roller supporting frames, guideway, deep stirring machine head, drilling machine, drill bit, slurry pump, distribution box and hydraulic pile-pressing system.

Owner:NANJING UNIV

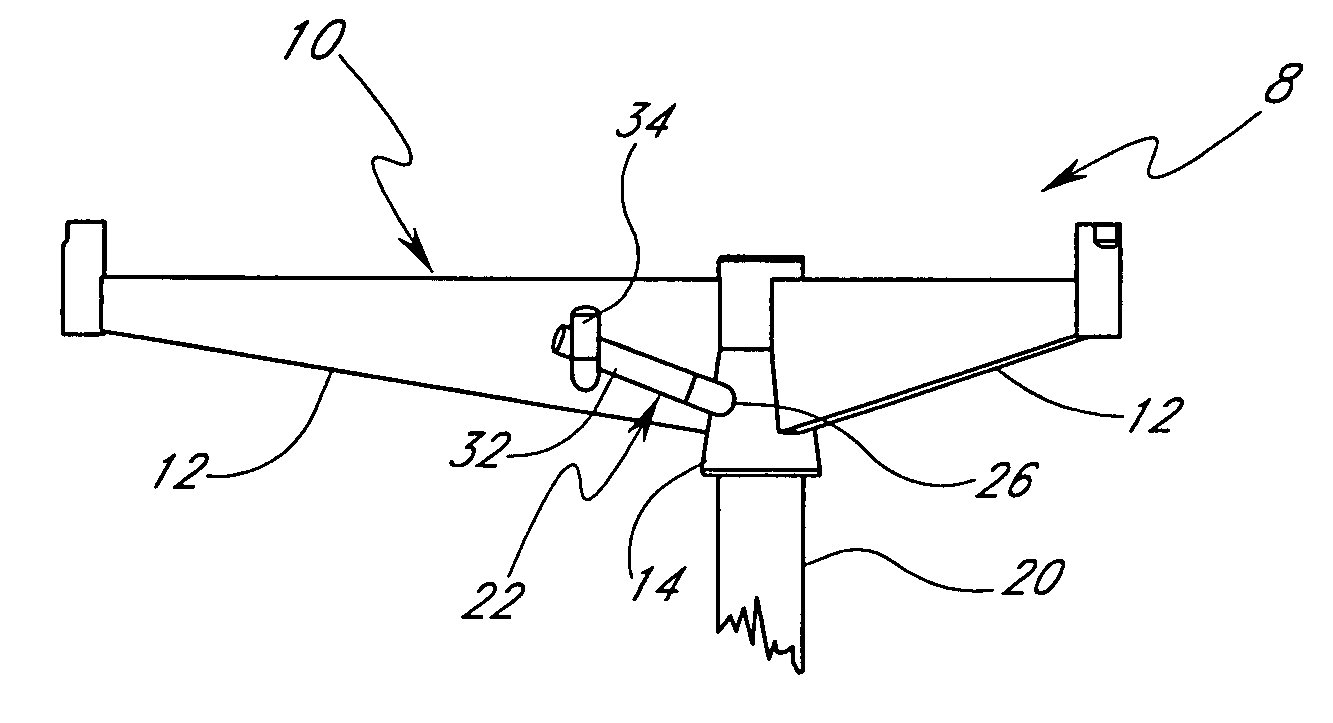

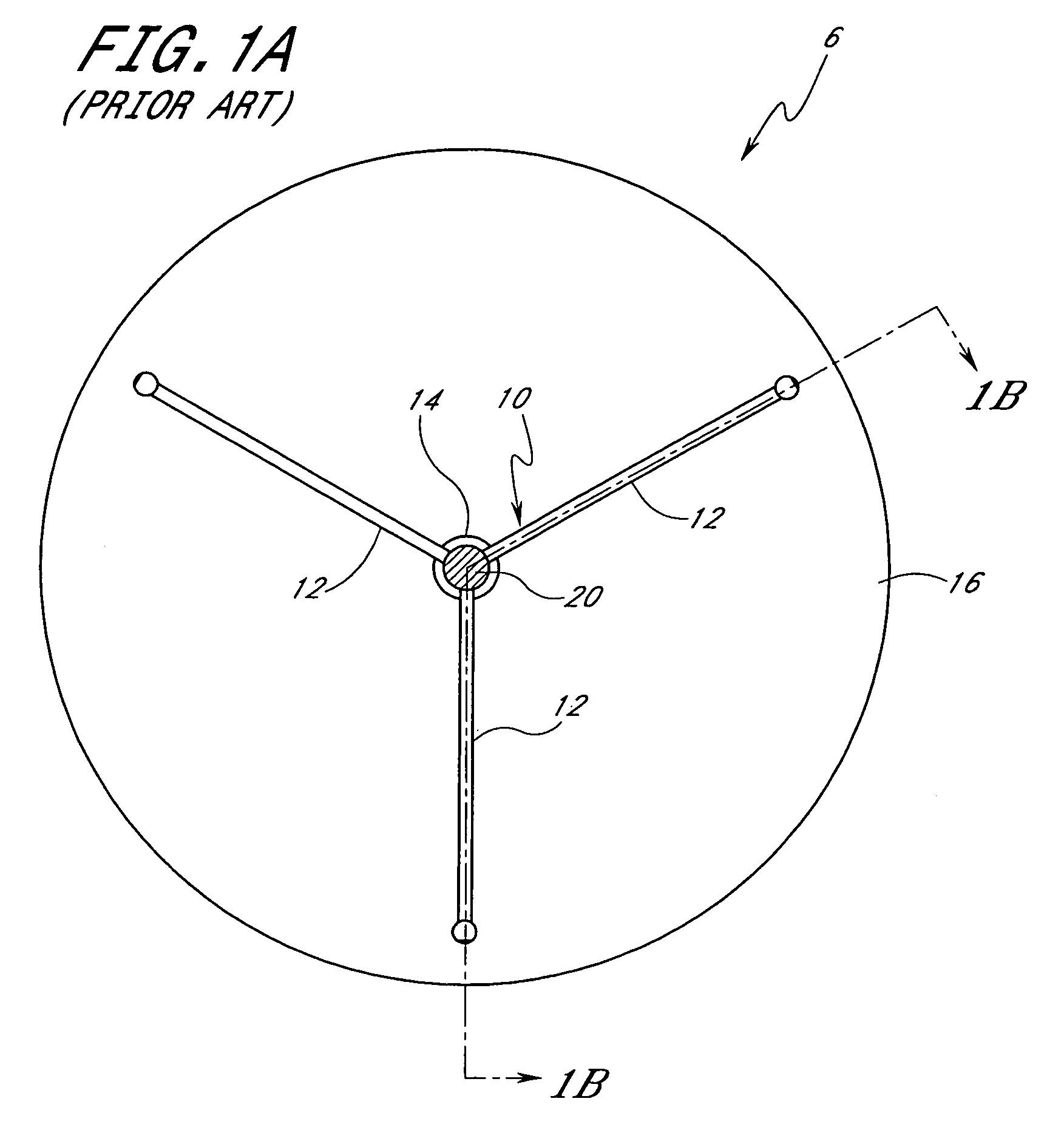

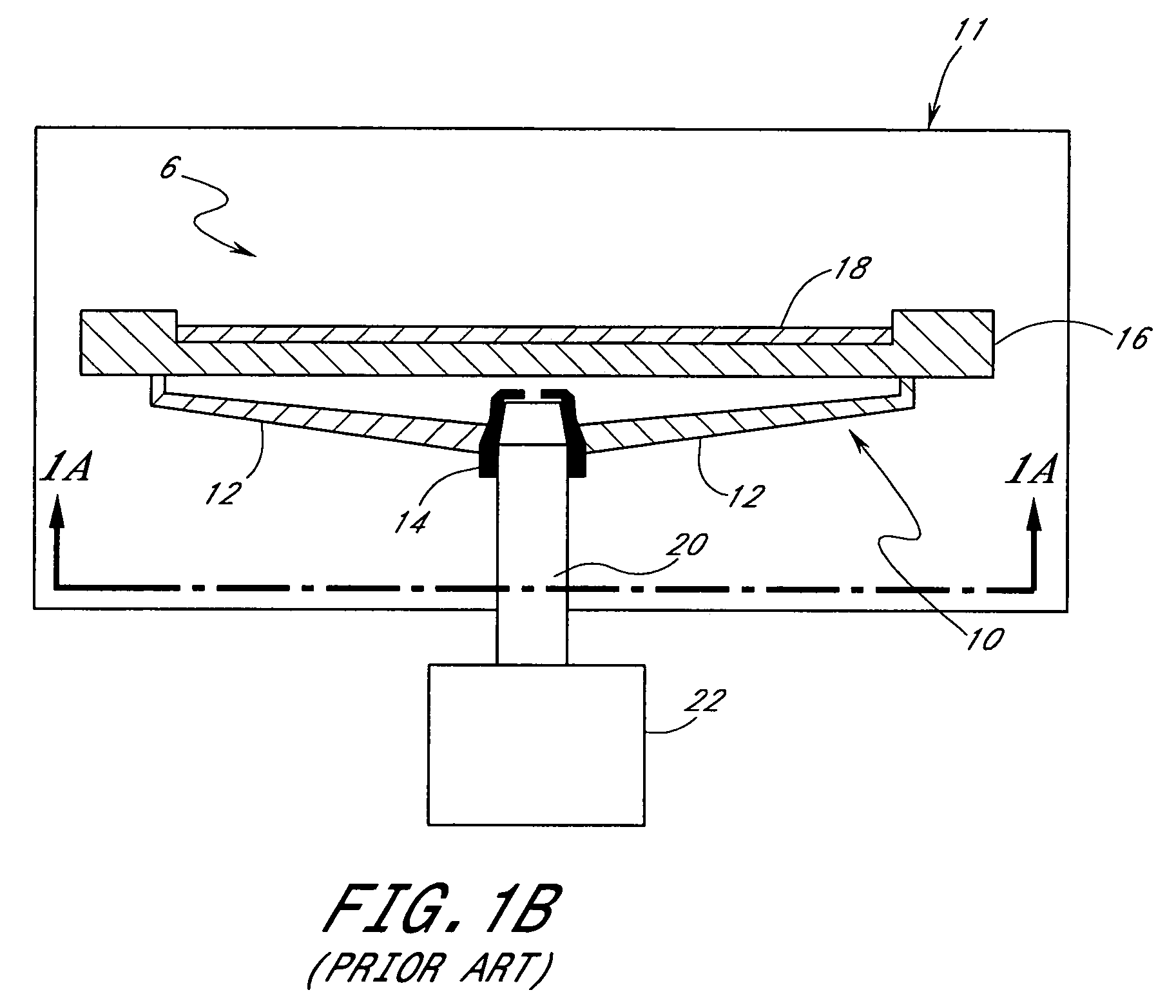

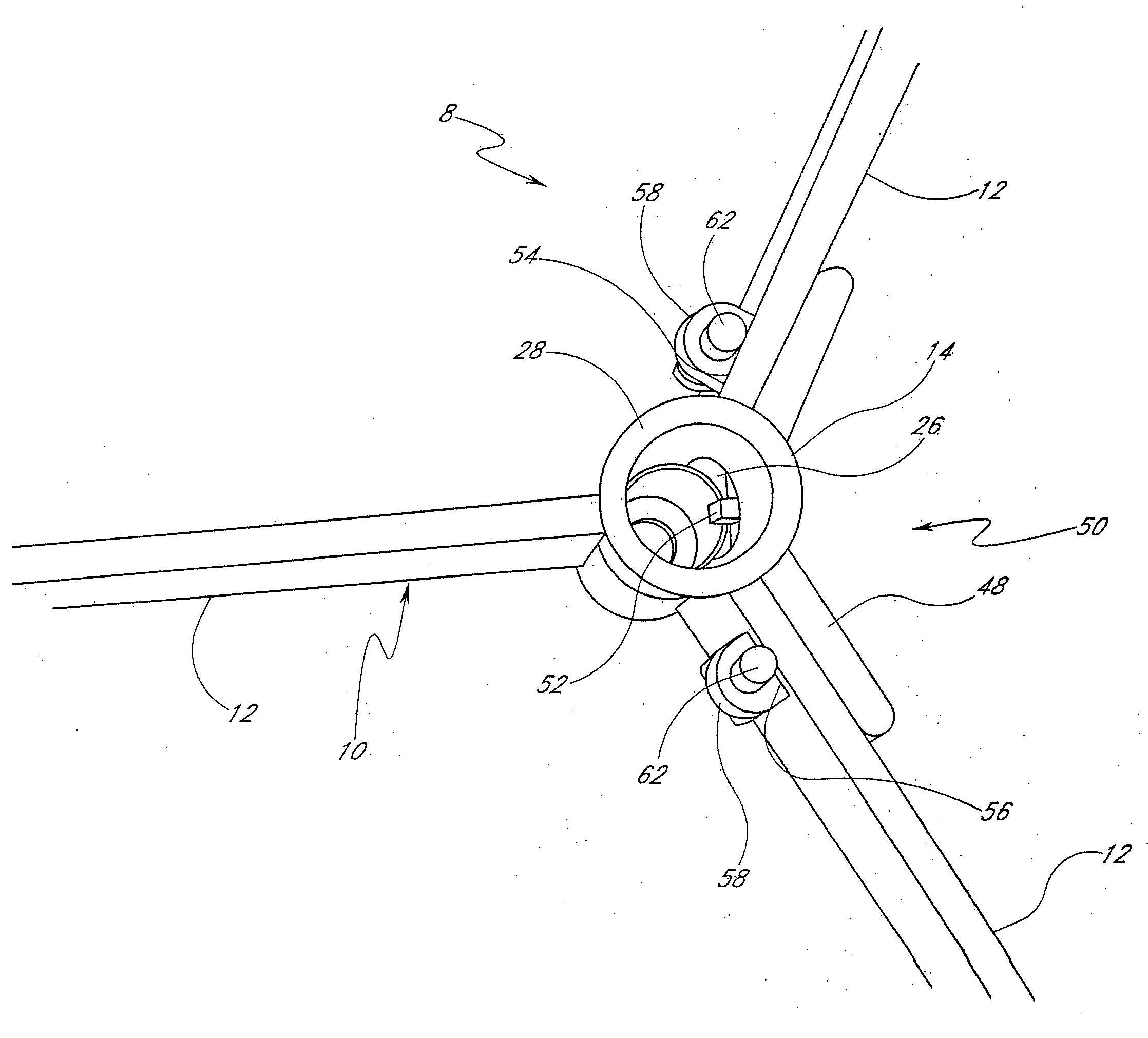

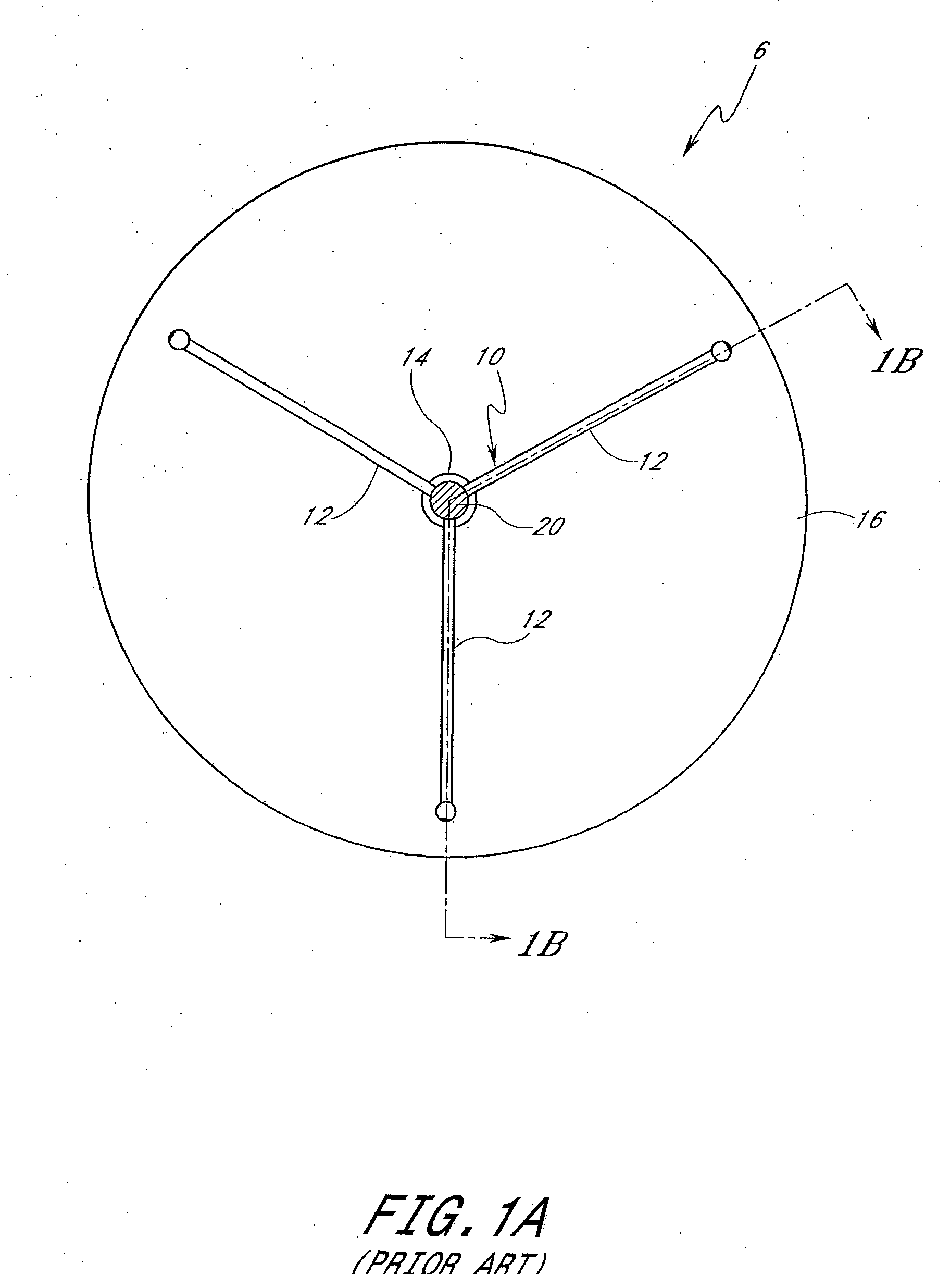

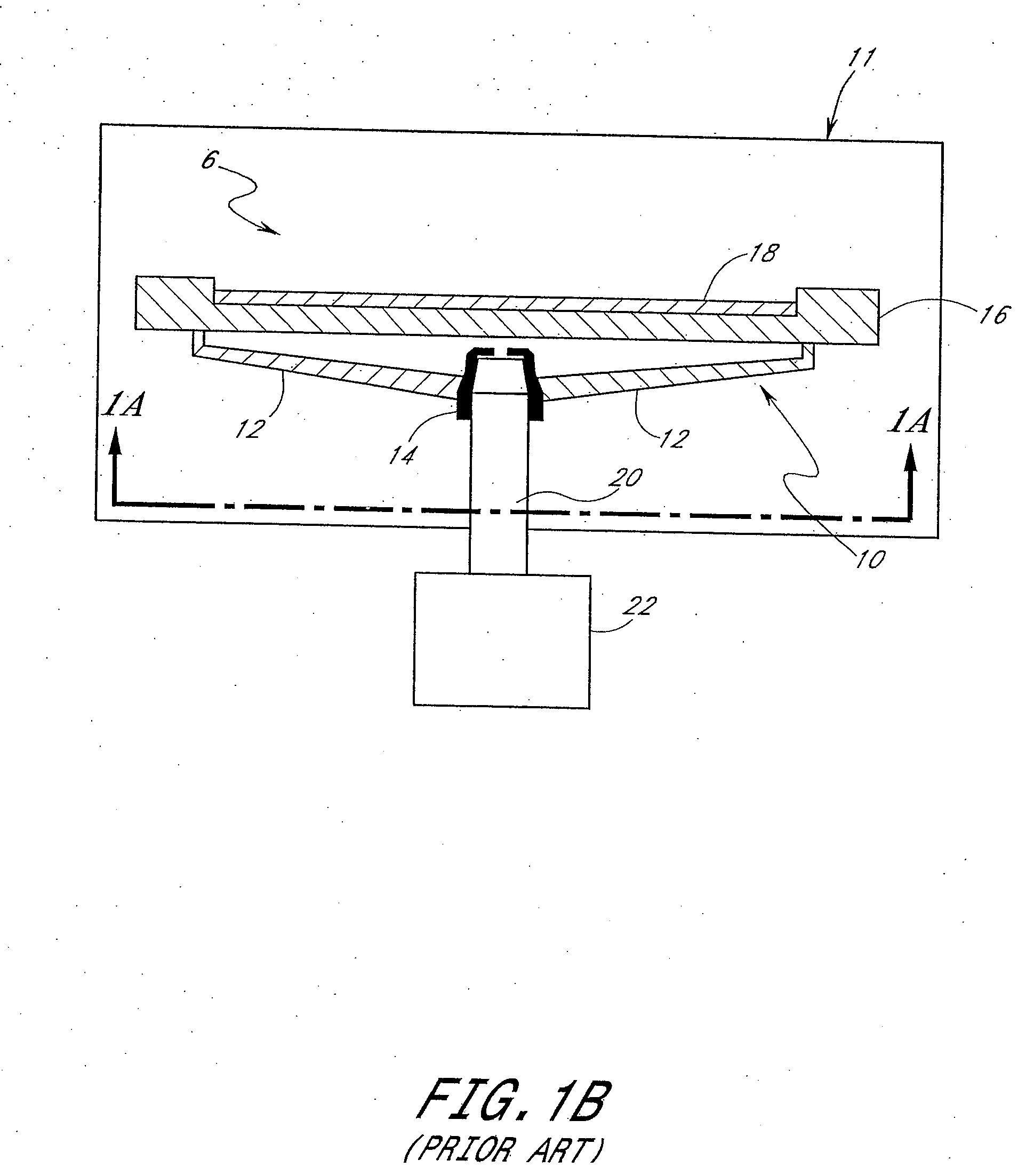

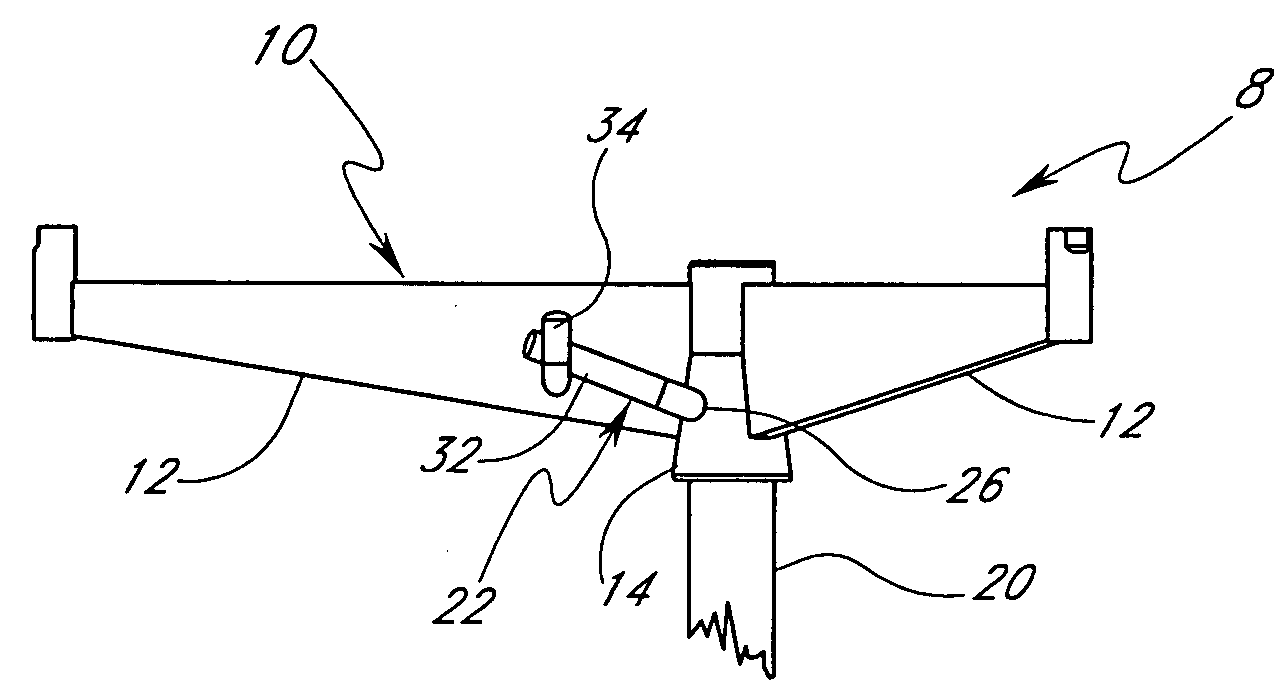

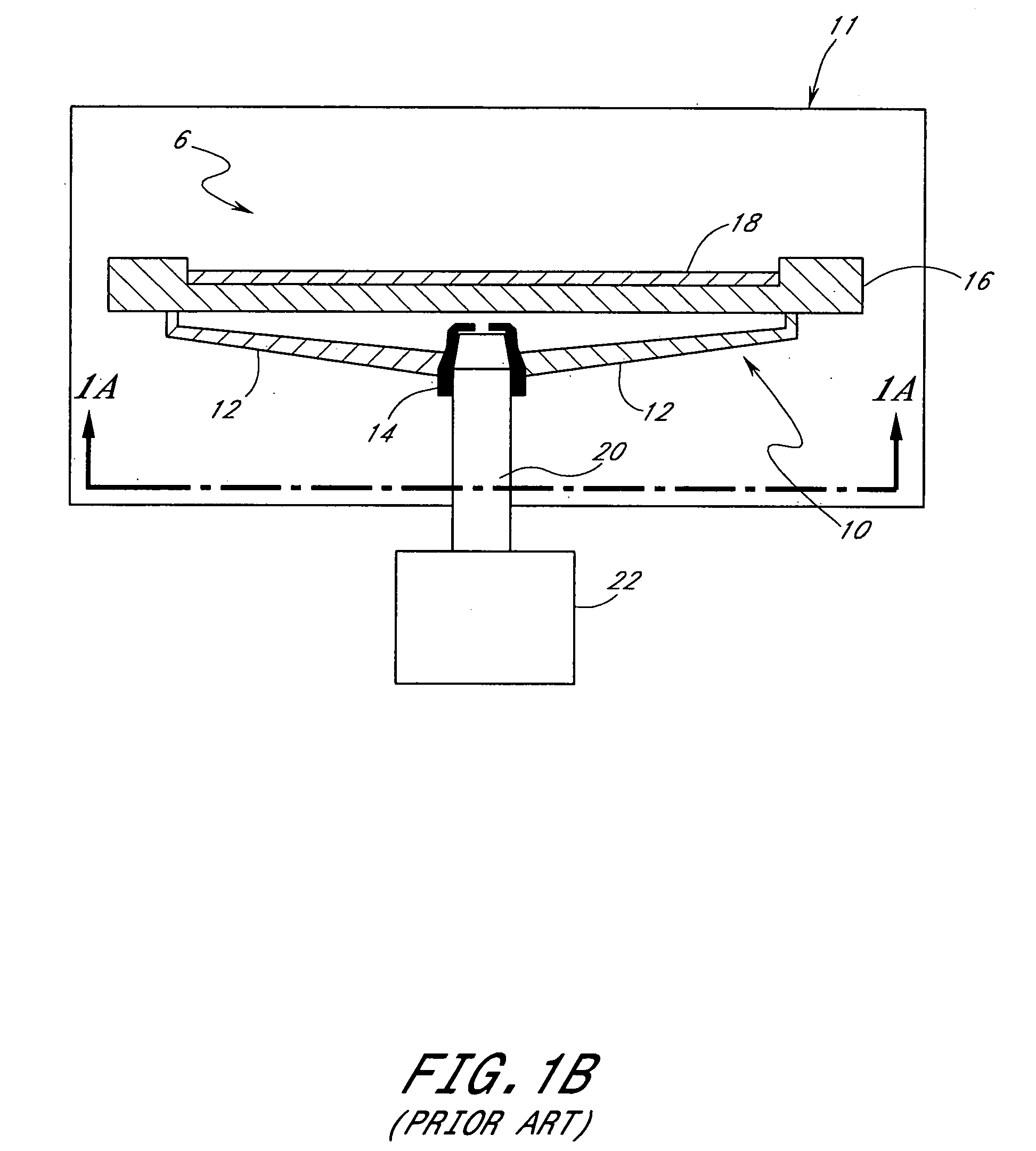

Apparatus and methods for preventing rotational slippage between a vertical shaft and a support structure for a semiconductor wafer holder

ActiveUS7169234B2Reduce the possibilityMaintaining productive lifeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

A substrate support assembly positively secures a substrate holder support to a rotation shaft with respect to rotationally applied forces. A substrate holder support is configured to have an opening in a socket into which, when aligned with an indentation in the rotational shaft to form a passage, a retaining member is removably inserted to engage both the socket opening and the shaft indentation. Methods of rotating a substrate while minimizing rotational slippage of the substrate holder support with respect to the shaft are also provided.

Owner:ASM IP HLDG BV

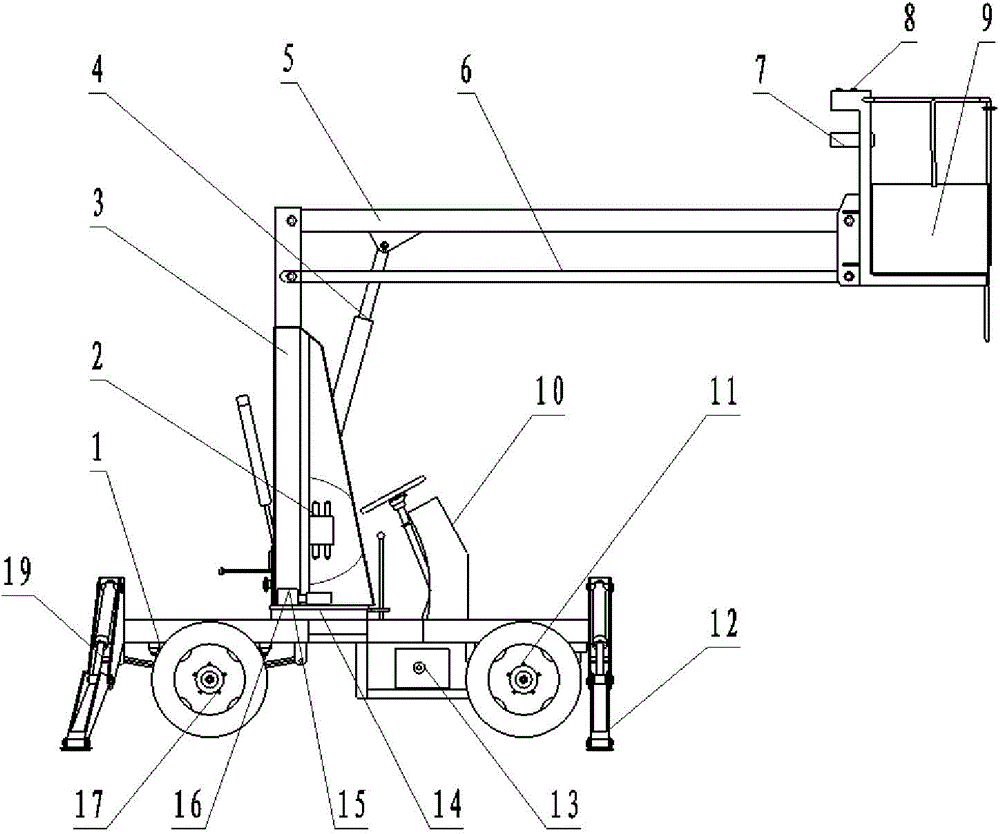

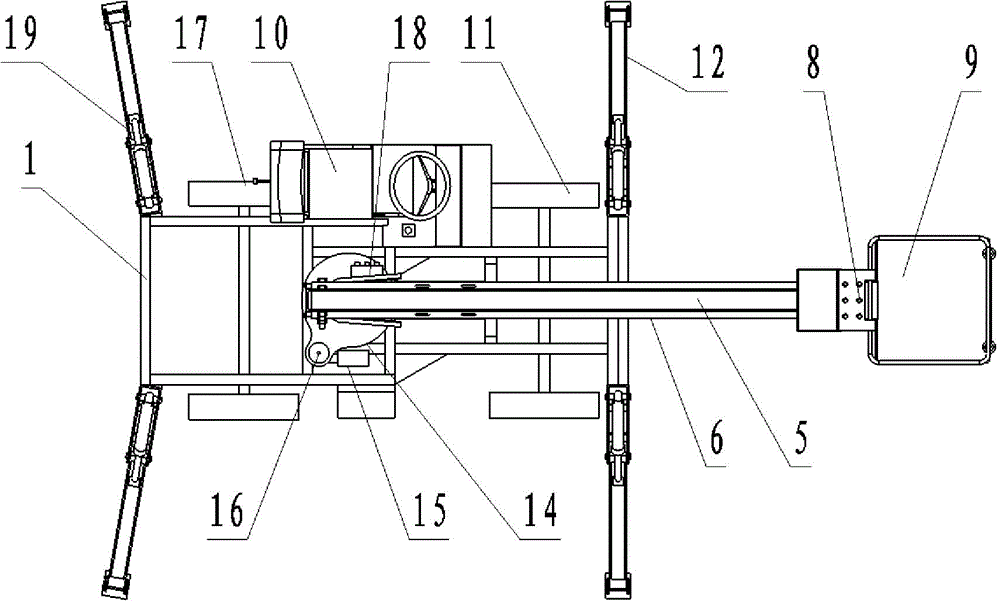

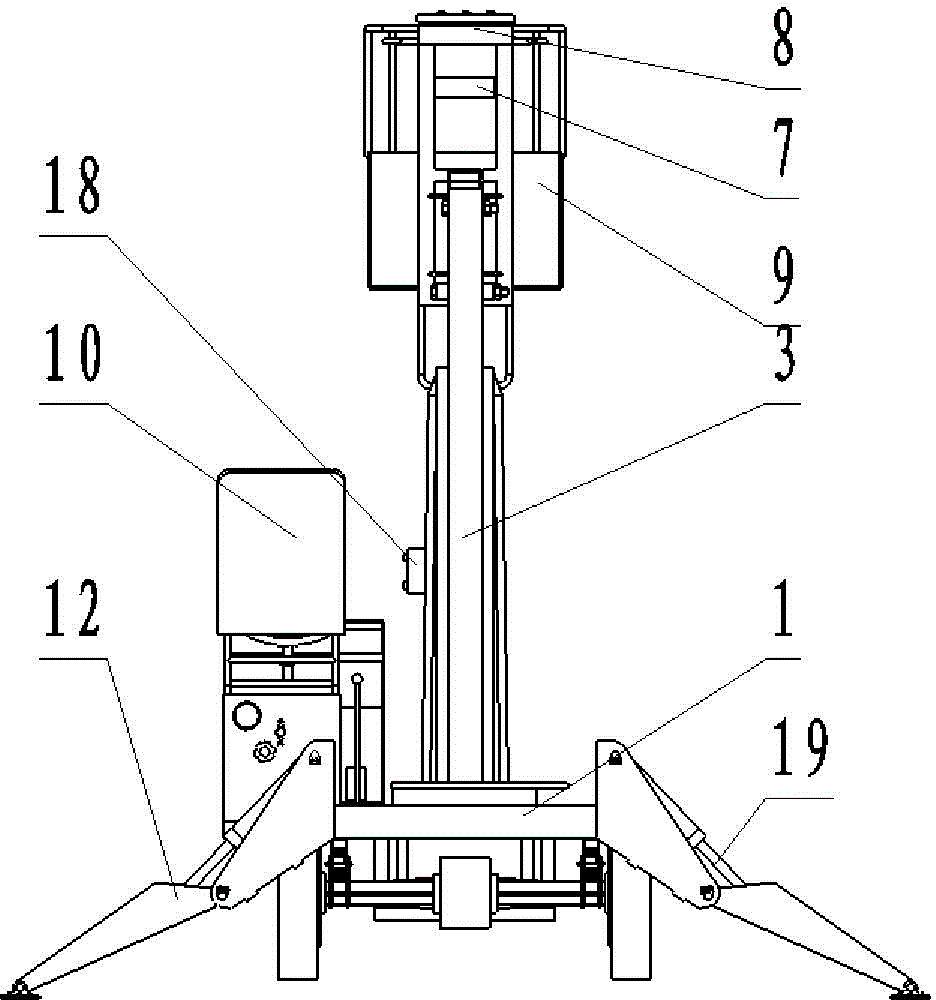

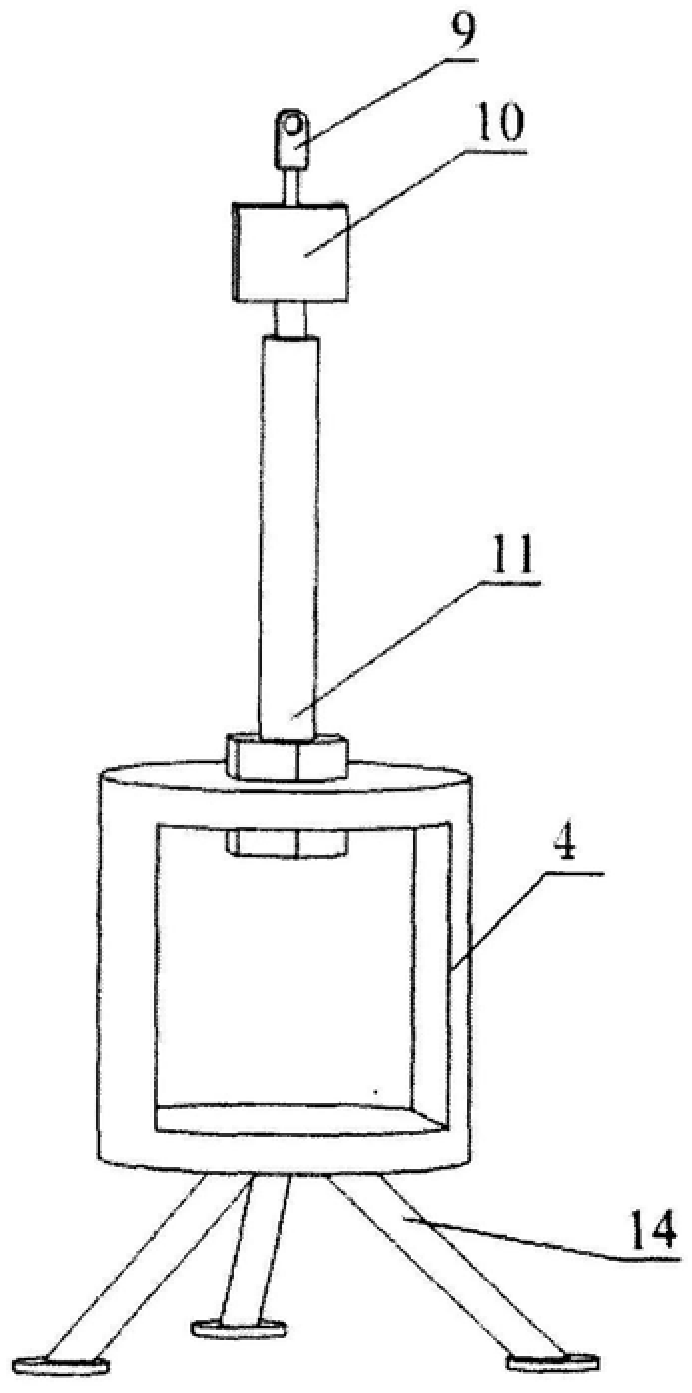

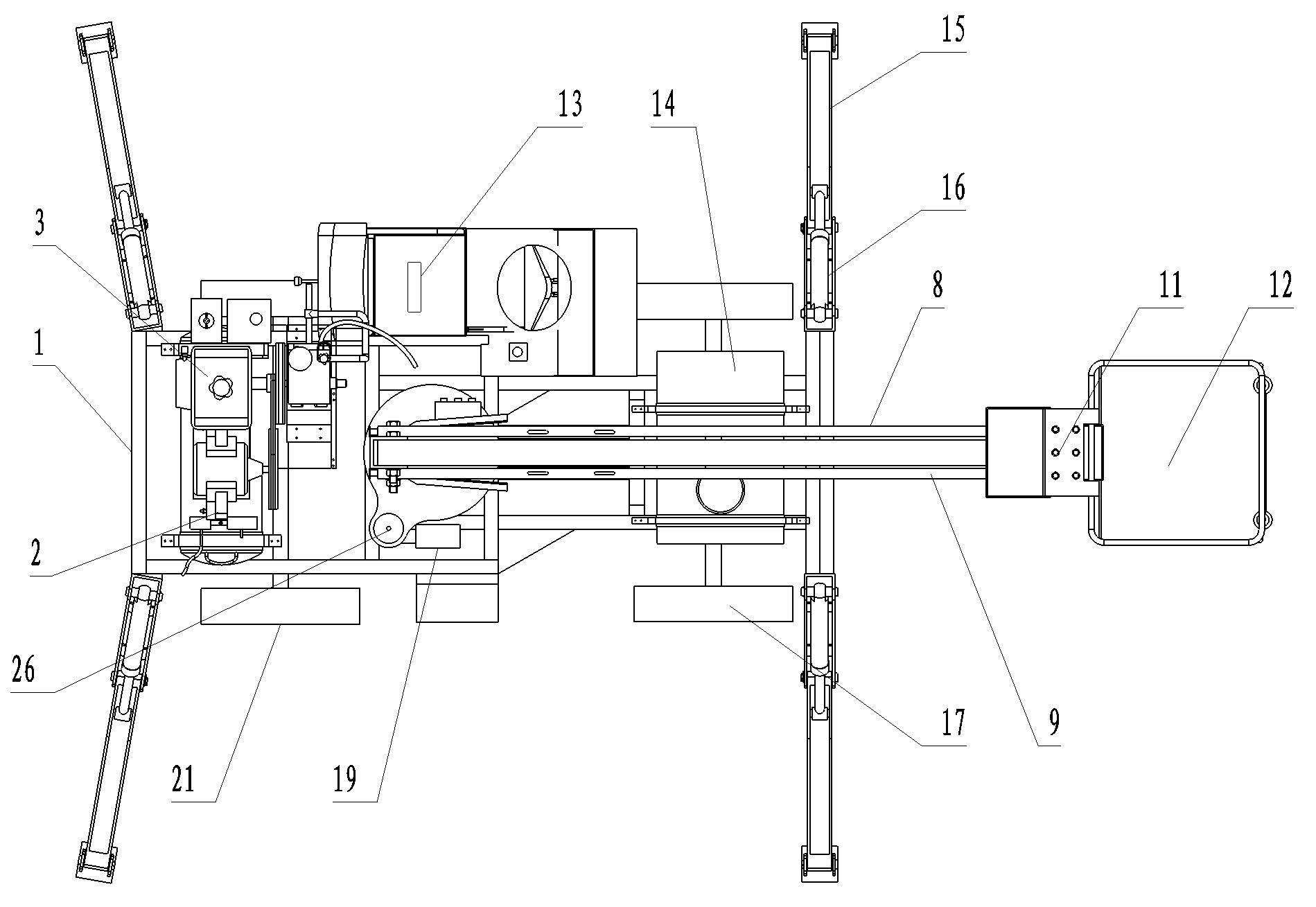

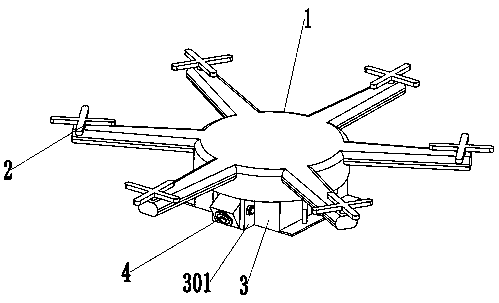

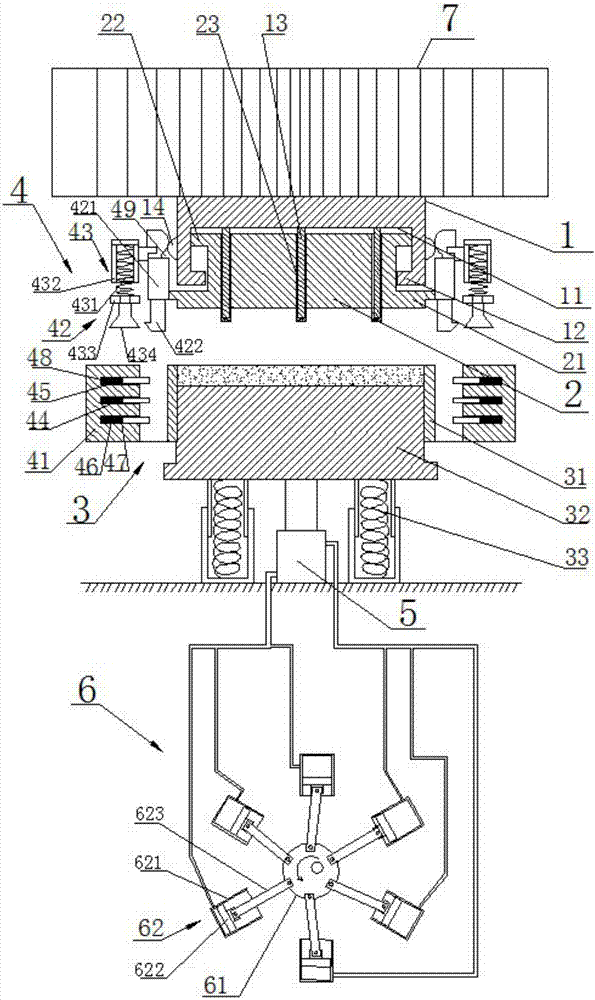

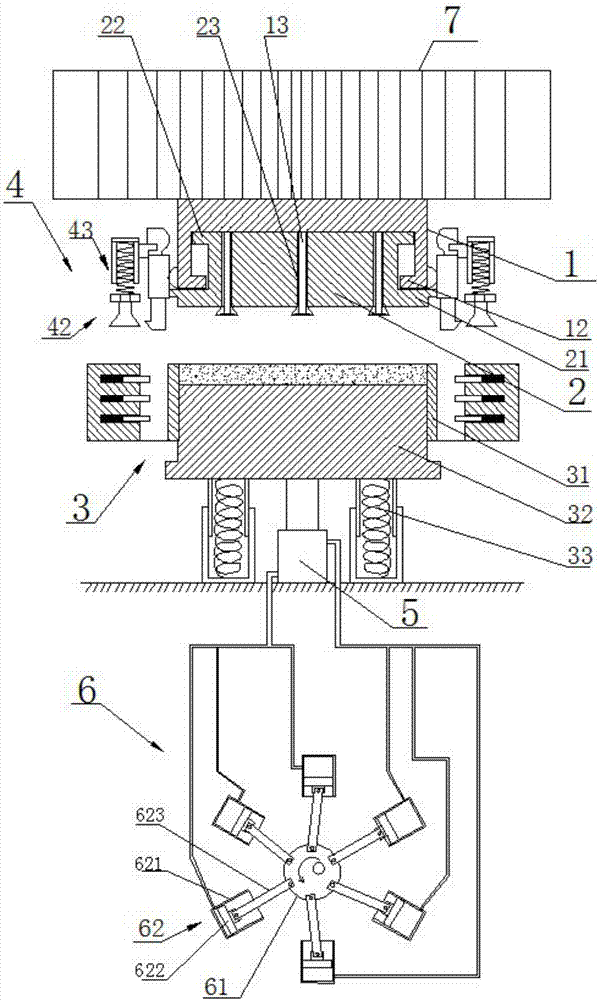

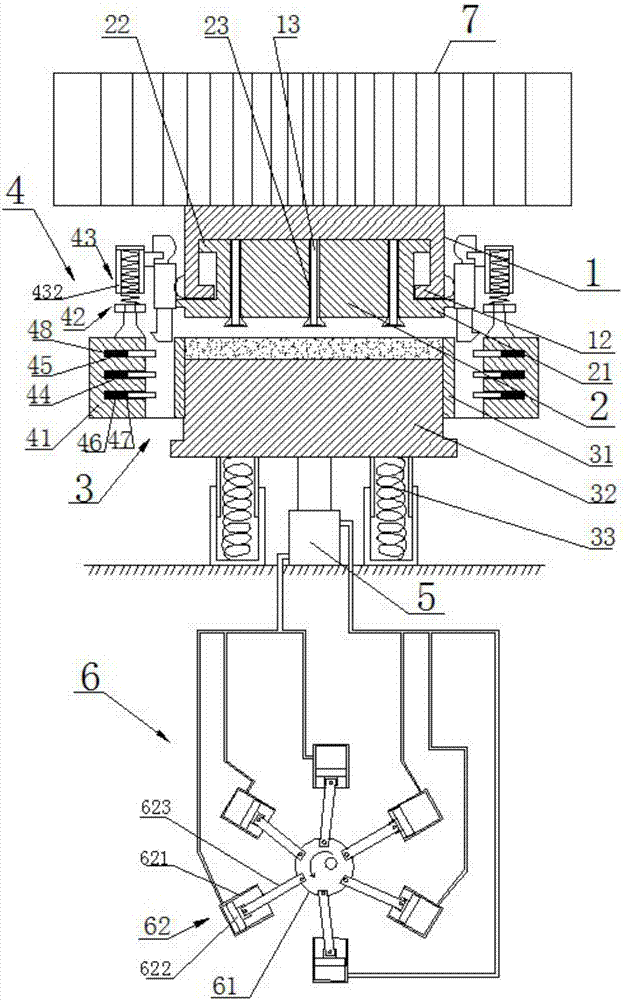

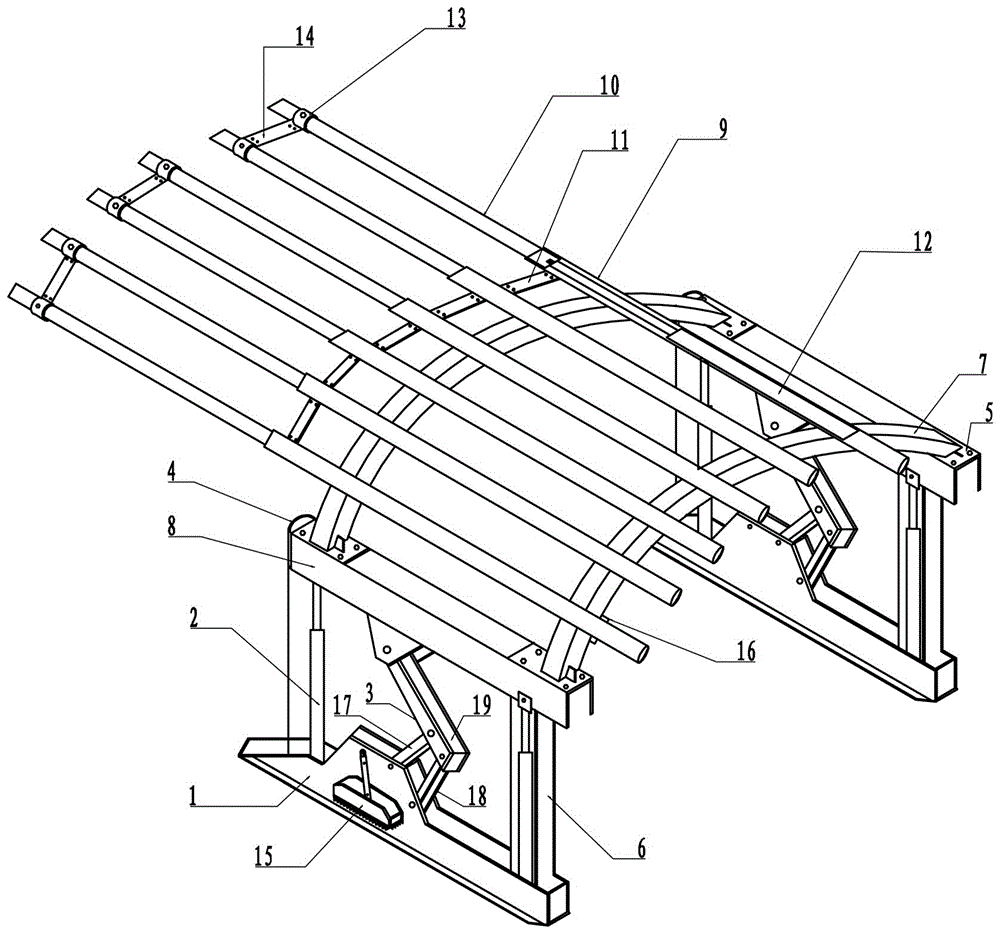

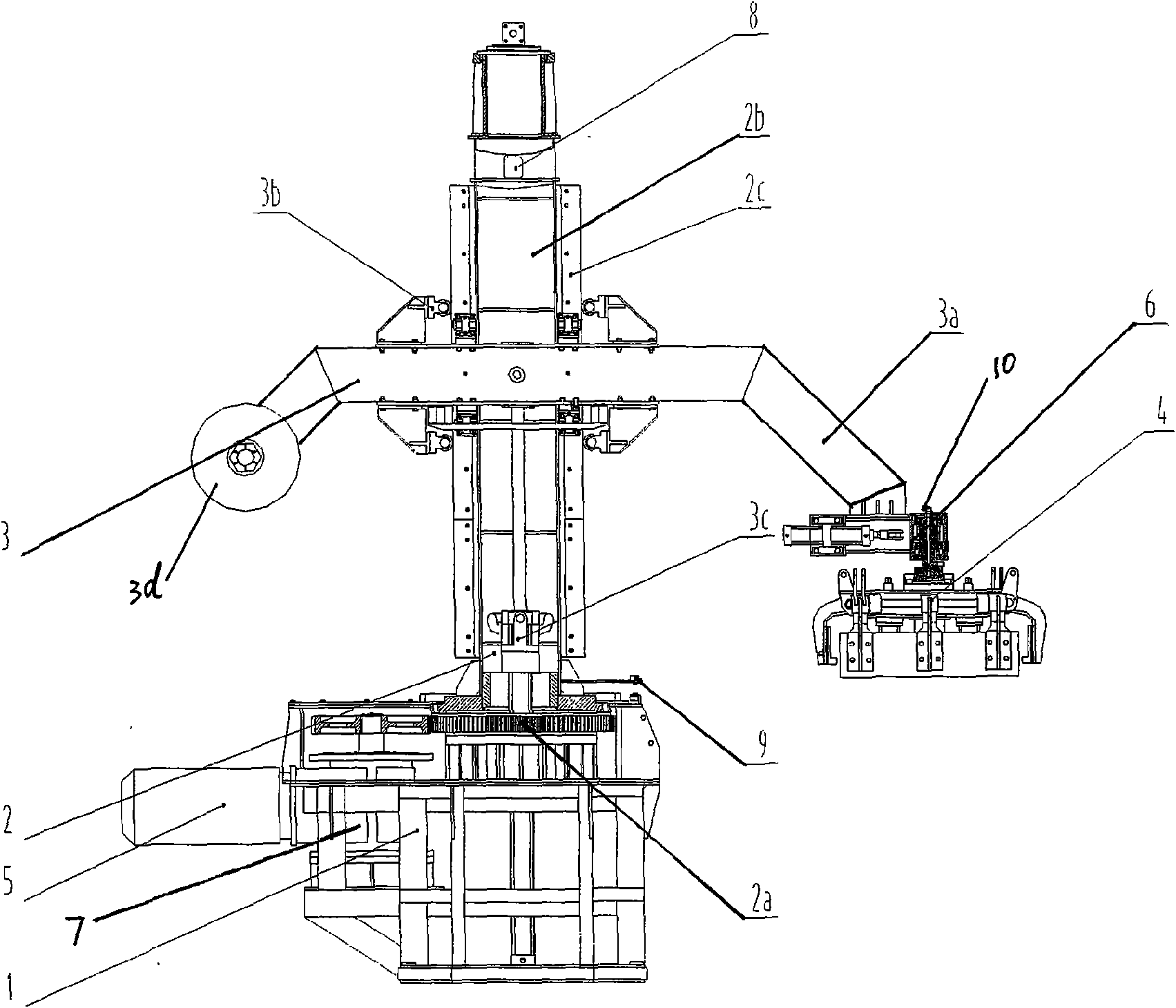

Orchard self-propelled lifting operation platform

The invention discloses an orchard self-propelled lifting operation platform which comprises a hydraulic system, a traveling mechanism and an engine (13). The orchard self-propelled lifting operation platform is characterized by being provided with a rotary device, a lifting device, an operating platform and an operation table. The rotary device comprises a rotary component and a rotary upright column (3), the rotary component comprises a hydraulic motor (15), a worm and gear reducing mechanism (16) and a slewing ring bearing (14), and the rotary upright column can perform a 360-degree stable rotation on a base plate through the slewing ring bearing. The lifting device comprises a support arm (6), a lifting arm (5) and a lifting oil cylinder (4), and the operation table (9) can ascend or descend in a range from 1m to 6m. Each of the four corners of the base plate is respectively provided with a support leg (12) and a support leg controlling oil cylinder (19). The orchard self-propelled lifting operation platform has the advantages of being flexible in moving and traveling, free in lifting and rotating, and convenient and safe to operate.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

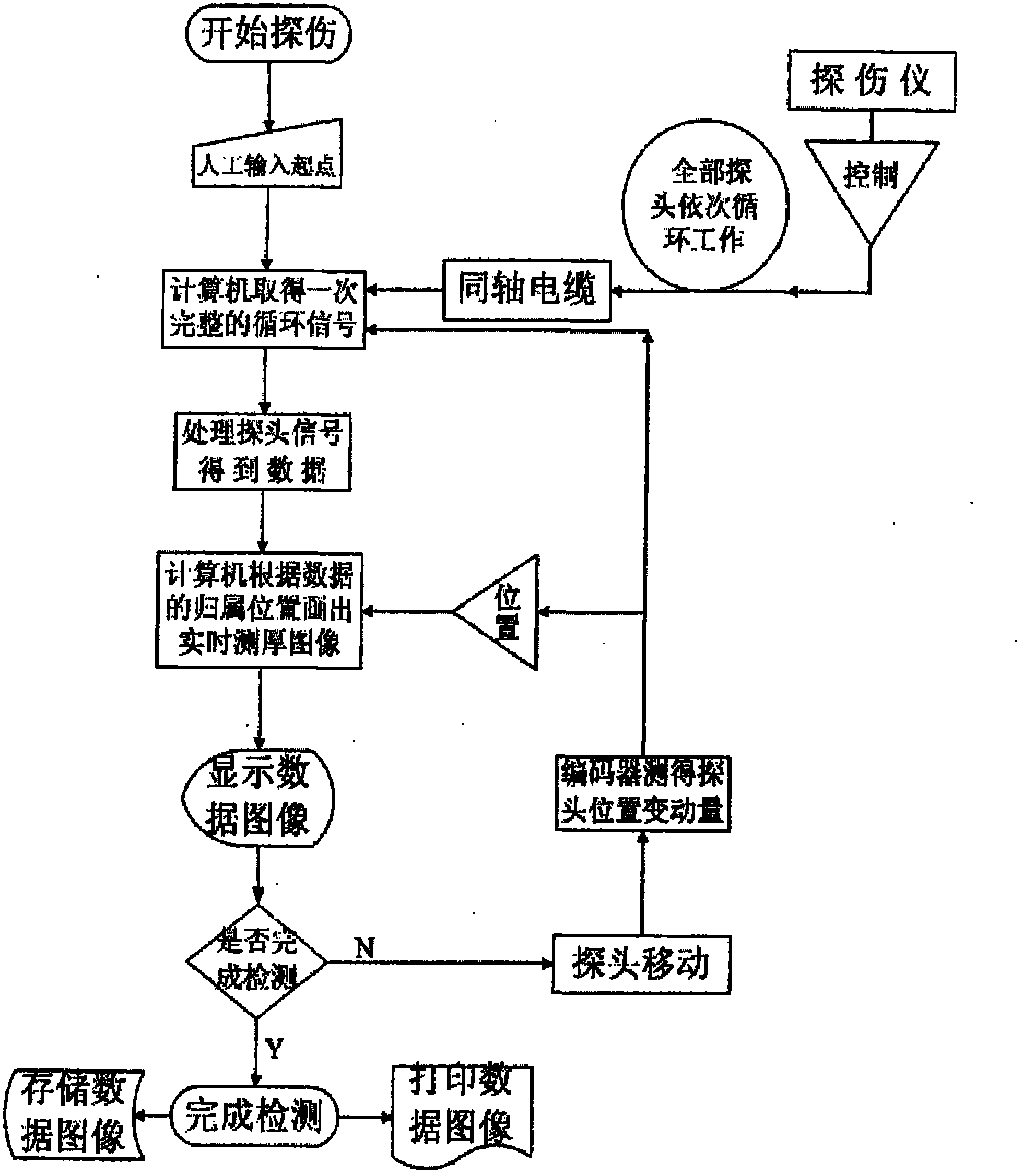

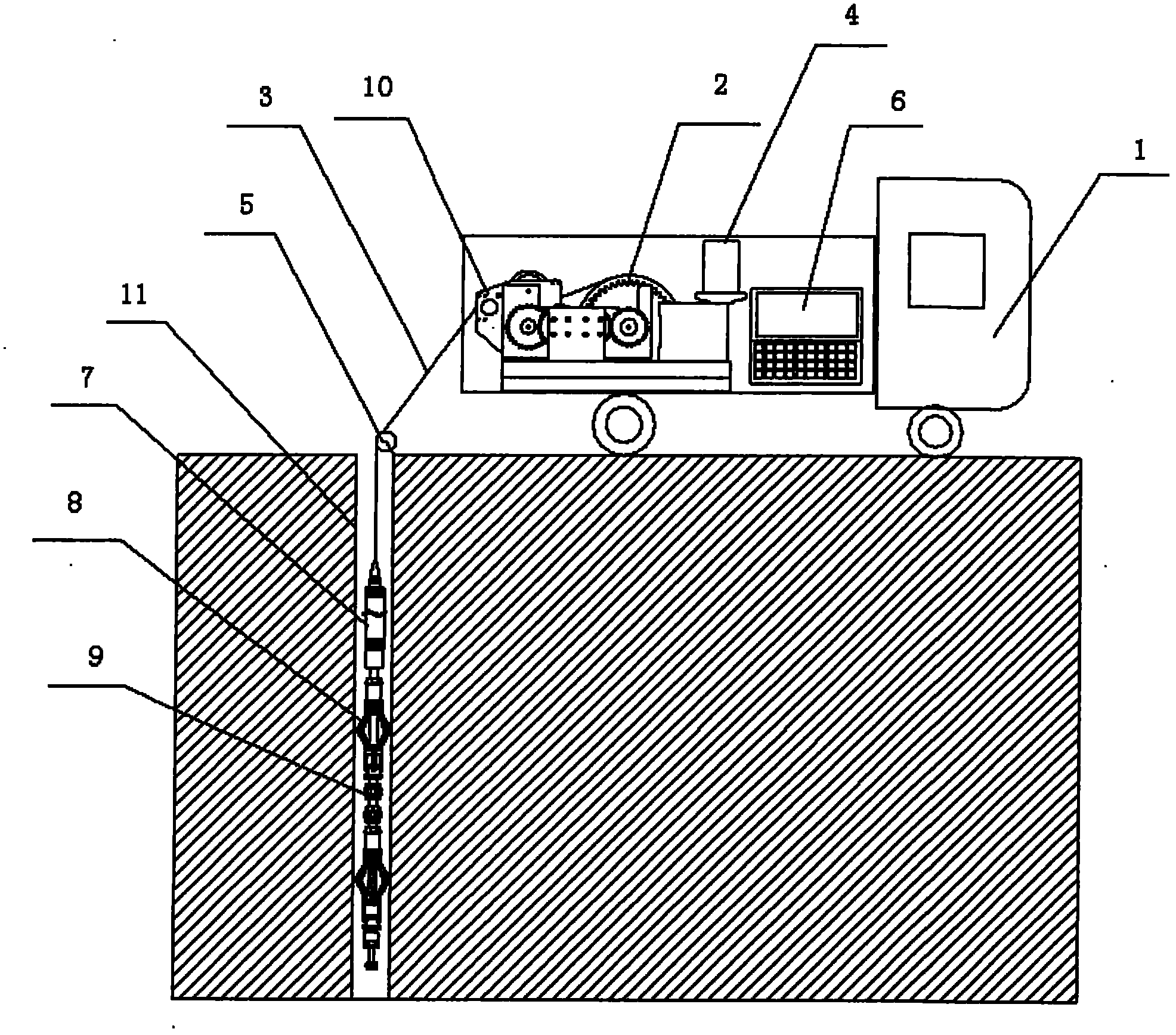

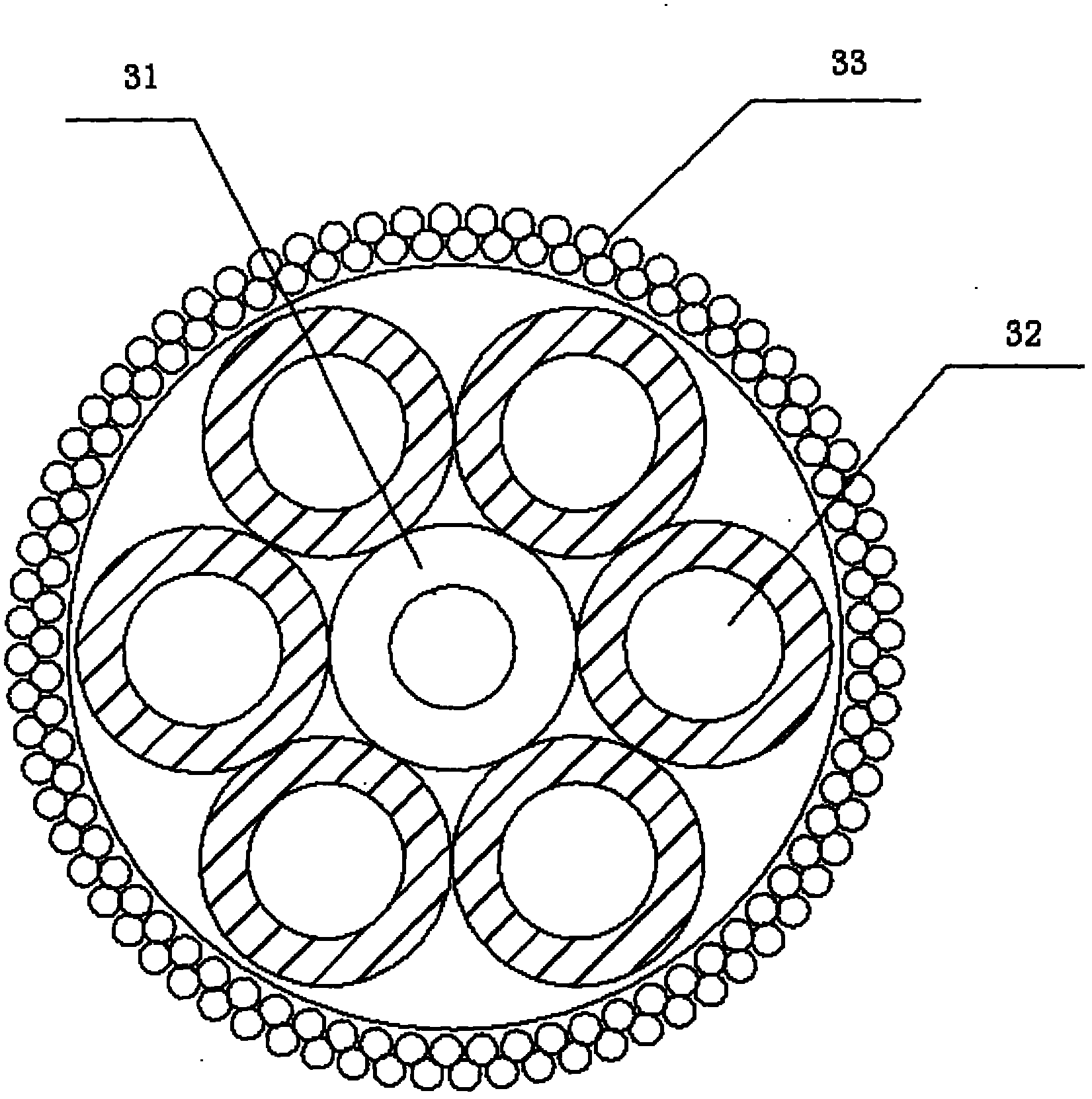

Improved system and method for detecting wall thickness and corrosion of well casing of gas storage well

InactiveCN102072714ALift freelyFirmly connectedWeather/light/corrosion resistanceUsing subsonic/sonic/ultrasonic vibration meansWater immersionEngineering

The invention discloses an improved system and method for detecting wall thickness and corrosion of a well casing of a gas storage well. The system comprises an overground signal processing part and an underground signal receiving and transmitting part arranged inside the gas storage well, wherein the overground part is provided with a mobile detection device connected with the underground part through an armored composite wire, and the detection device is provided with a dragging part and a control terminal; a coaxial cable in the armored composite wire inputs a plurality of collected analog probe signals into a computer, and the computer finishes digital conversion of analog signals and processing of data signals; the signal processing part moves up and down on the inner wall of the well casing through a centralizer; an annular water immersion analog probe array is also arranged; and the armored composite wire is manufactured by winding the coaxial cable for signal transmission with an underground instrument power cord layer by layer and winding a steel wire at the outermost layer, and the coaxial cable and the power cord share one multi-core waterproof seal joint. An encoder is directly installed at the wire swinging part in front of a roller, and the joint of encoder and the computer are in fixed connection. The system disclosed by the invention has stronger reliability and better vibration resistance, and can operate for a long time without faults.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

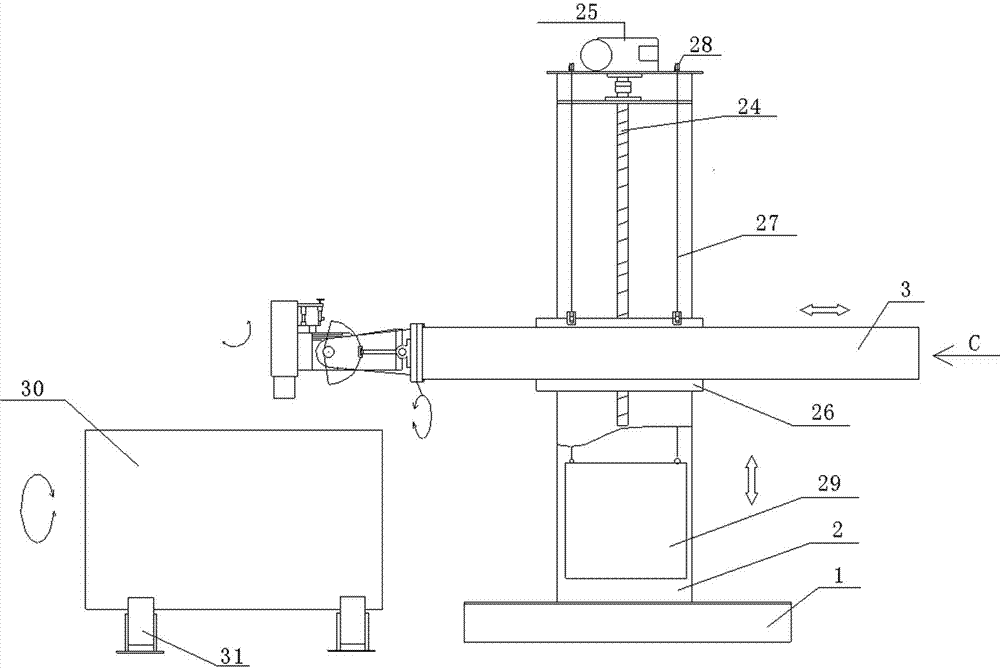

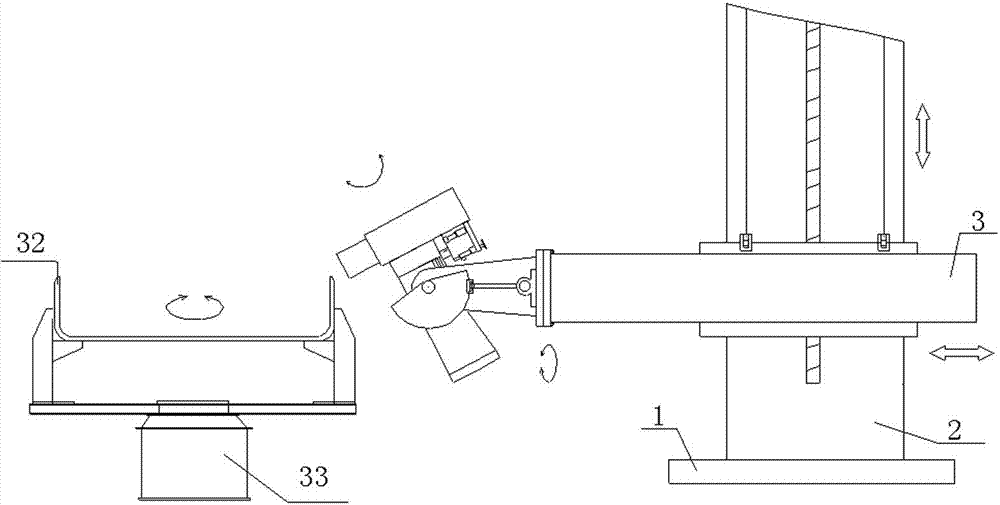

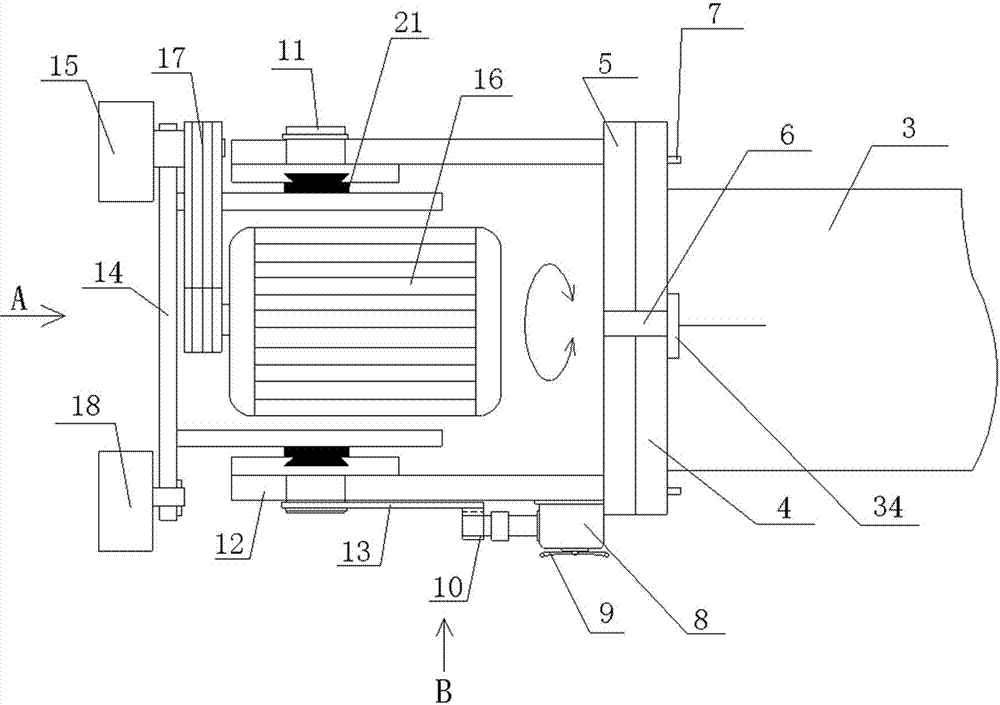

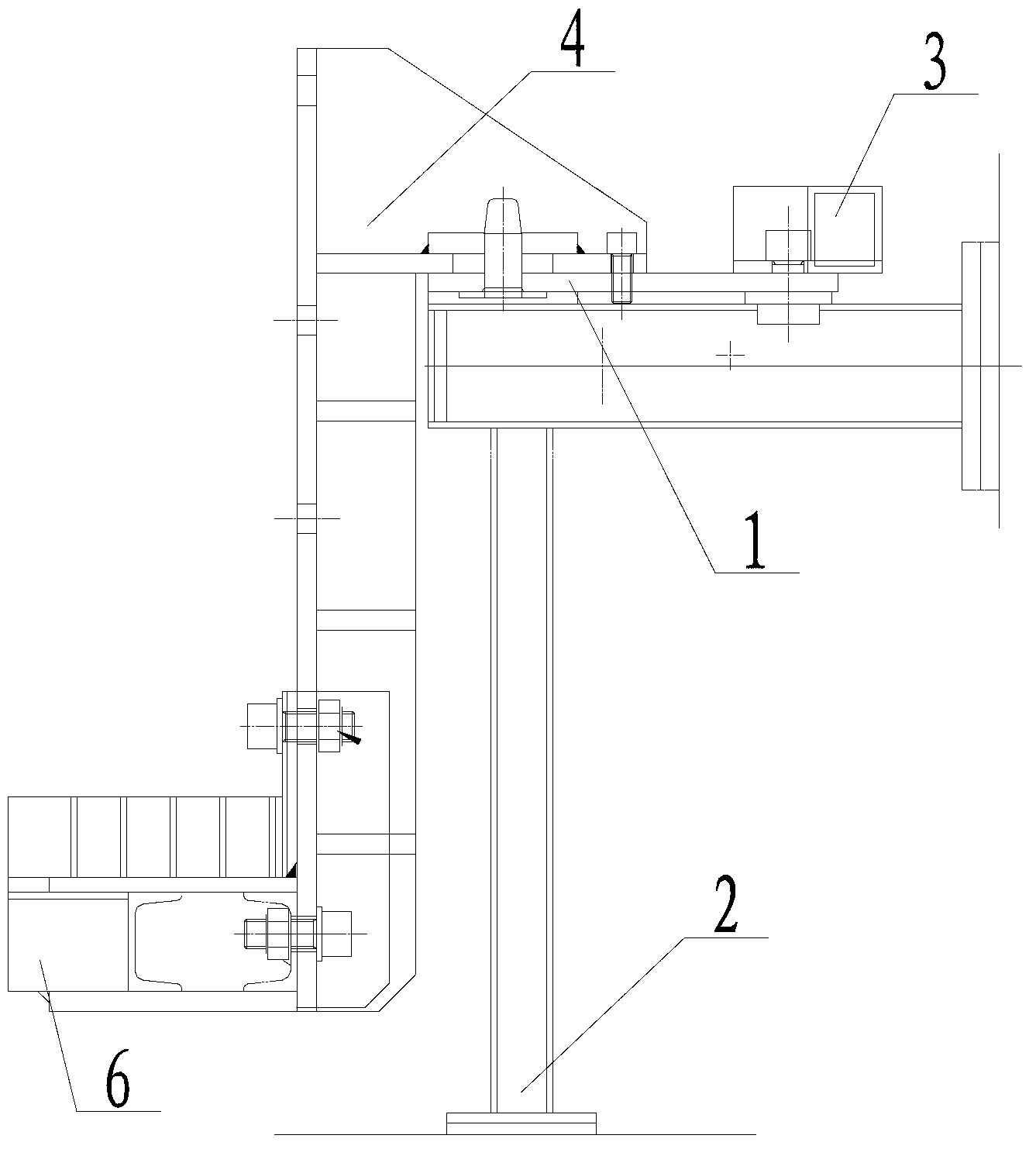

Tank body multi-angle polishing grinding machine

PendingCN106985038AImprove grinding abilityImprove toughnessBelt grinding machinesRotational axisElectric machinery

The invention discloses a tank body multi-angle polishing grinding machine. A stand column is arranged on a base. A cross arm is arranged on the stand column, goes up and down along the stand column through a lifting device and moves left and right along the stand column through a left-right movement device. An abrasive belt grinding head mounting base is arranged at the left end of the cross arm and rotationally connected with the cross arm through a first rotary shaft. The abrasive belt grinding head mounting base rotates around the cross arm. An abrasive belt grinding head is arranged on the abrasive belt grinding head mounting base and rotationally connected with the abrasive belt grinding head mounting base through a second rotary shaft peripherally. The central line of the first rotary shaft is perpendicular to the central line of the second rotary shaft. The abrasive belt grinding head swings around the second rotary shaft peripherally. The abrasive belt grinding head comprises a supporting base fixed to the second rotary shaft. An abrasive belt grinding polishing device and an abrasive belt driving device are arranged on the supporting base. A barrel and an end socket of a tank body can be ground and polished through one abrasive belt grinding head, the power of an adopted motor is low, the energy consumption is low, cost can be lowered, and the equipment investment can be reduced.

Owner:南阳龙腾专用车制造有限公司

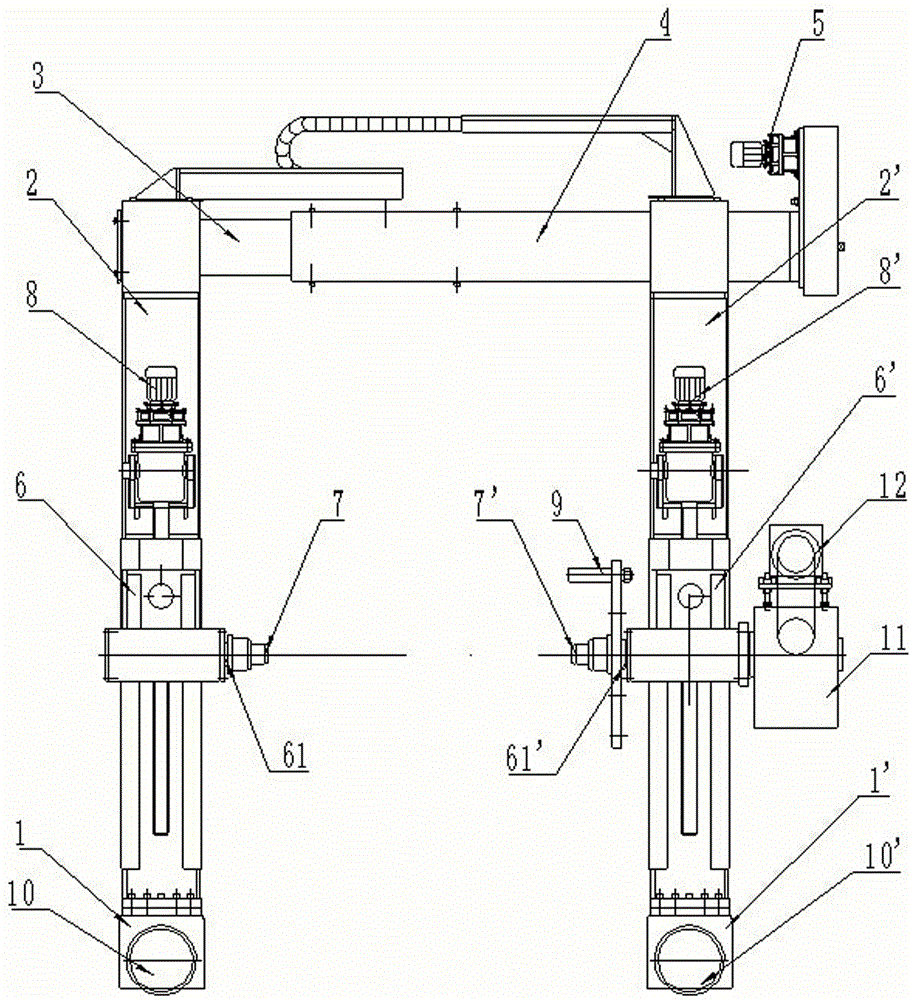

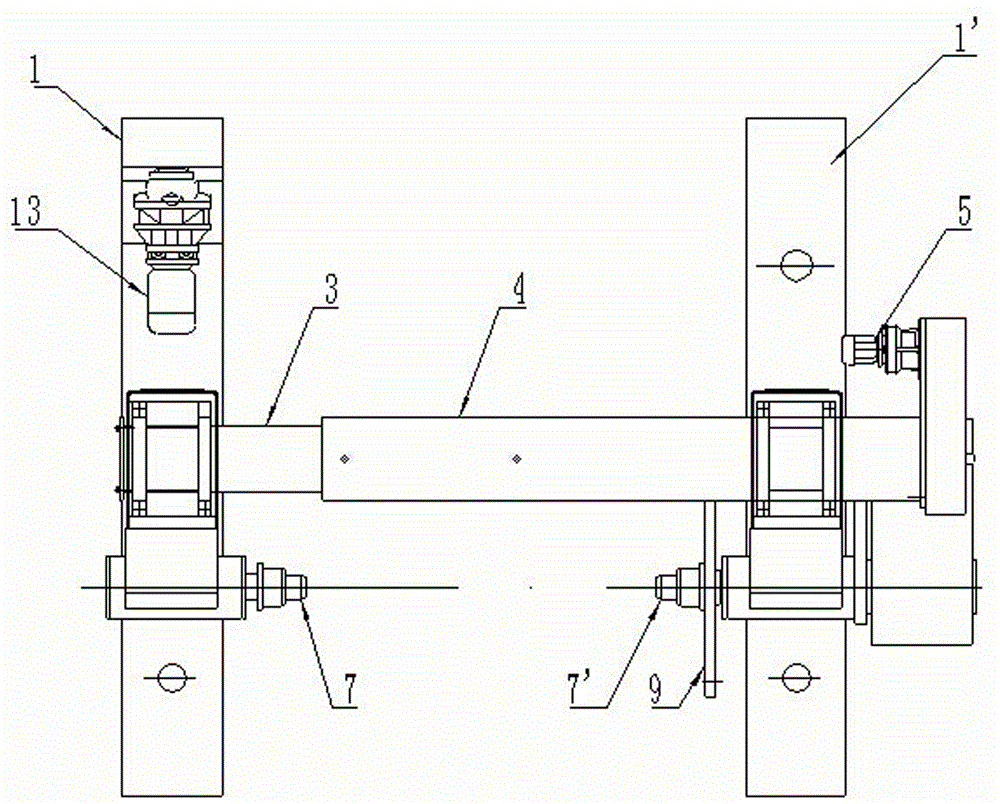

Walking type cable winding and arranging device for gantry ground rail

InactiveCN104609256AClamping freedomReasonable structural designFilament handlingCable trayElectric machine

The invention discloses a walking type cable winding and arranging device for a gantry ground rail. The walking type cable winding and arranging device comprises a left ground beam, a right ground beam, a left vertical column and a right vertical column, wherein the left vertical column and the right vertical column are arranged on the left ground beam and the right ground beam. A left idler wheel and a right idler wheel are arranged on the left ground beam and the right ground beam. An inner sleeve is arranged at the top of the left vertical column. An outer sleeve is arranged at the top of the right vertical column. The inner sleeve is sleeved with the outer sleeve. A gear motor is arranged at the upper portion of the outer sleeve. A left bracket and a right bracket are installed on the left vertical column and the right vertical column. A left bracket shaft and a right bracket shaft are arranged on the left bracket and the right bracket. A left tip cone and a right tip cone are arranged at one end of the left bracket shaft and one end of the right bracket shaft. A left motor and a right motor are arranged on the left vertical column and the right vertical column. A pulling pin is arranged at one end of the right bracket shaft, and a gearbox is arranged at the other end of the right bracket shaft and connected with a direct current motor. The walking type cable winding and arranging device has the advantages of being reasonable in structural design, free in cable tray clamping, convenient to use and large in application range, and is widely applied to winding, arrangement, cable defense and equipment matching for a crosslinking unit, an extrusion unit, a continuous curing unit, a cabling unit, an armoring unit, a tray dumping unit and other units of manufacturers for various cables such as wires, electric cables, optical cables and communication cables.

Owner:安徽普瑞斯电工机械有限公司

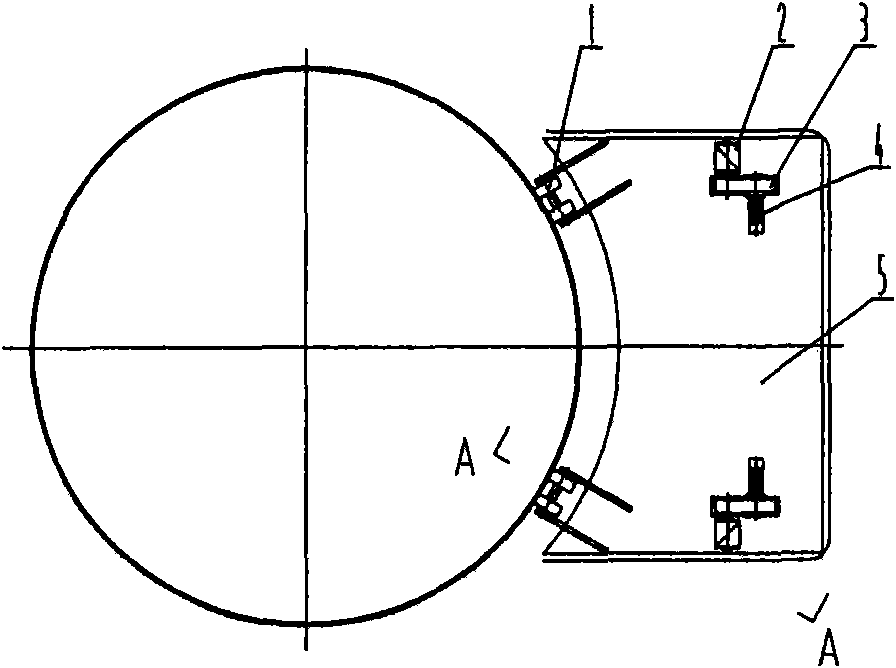

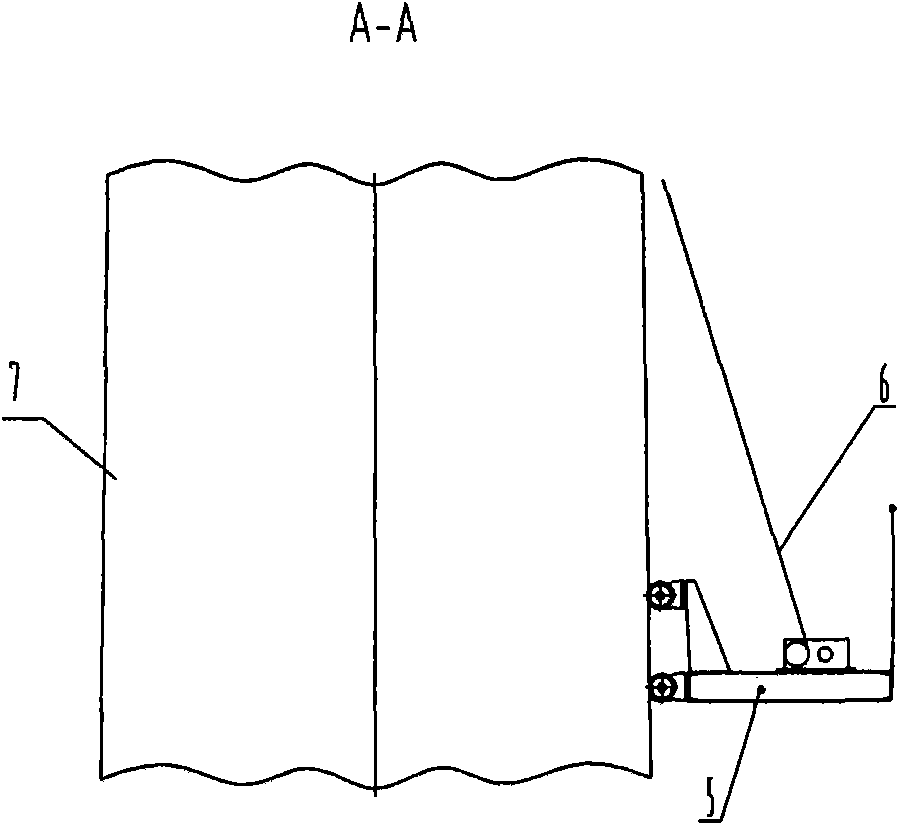

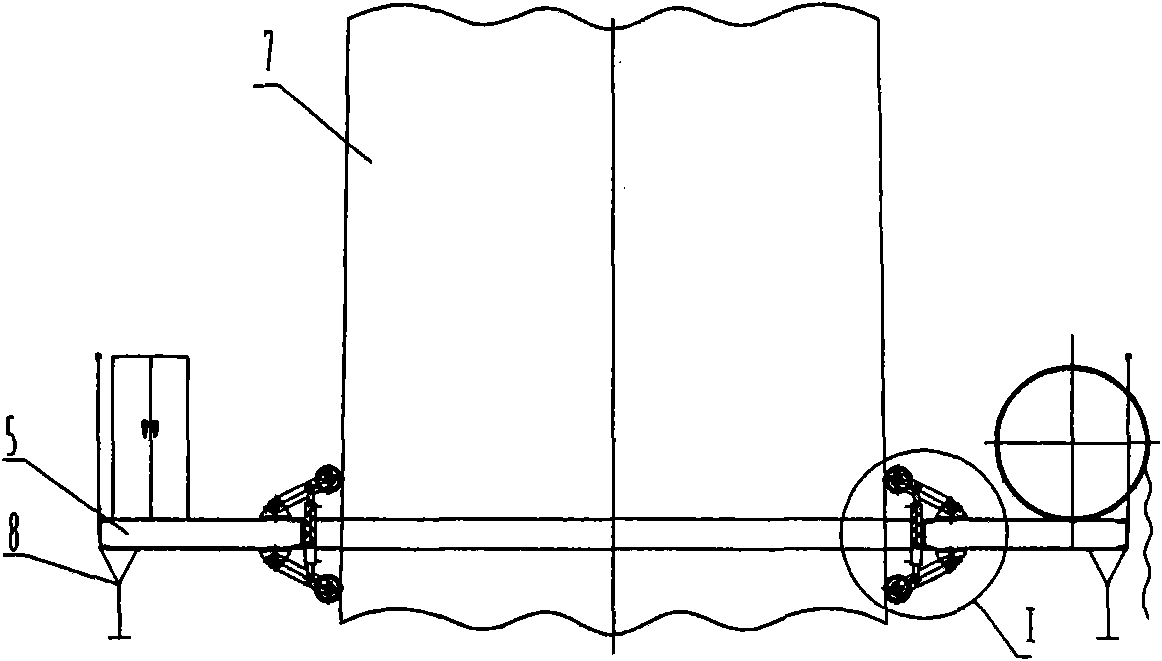

Large-diameter cylinder body outer wall climbing device

The invention relates to a large-diameter cylinder body outer wall climbing device, in particular to a lifting device. The device solves the problems of the existing large-diameter cylinder body outer wall climbing device using a steel wire rope reel mechanism: a steel wire rope is easily polluted, a cylinder body is damaged, the steel wire rope is hard to fix, and a platform is unstable when being lifted. The device comprises a motor installed on the platform, a speed reducer and roller wheels installed on the platform closely to the outer wall of the cylinder body, wherein the two roller wheels are symmetrically arranged on the platform by movable brackets; a support oil cylinder is installed between the two movable brackets; the motor drives the speed reducer to lead the roller wheels to roll up and down along the cylinder wall by chains; a brake skid shoe is arranged under the platform by a skid shoe bracket, and a brake oil cylinder is positioned between the skid shoe bracket and the platform; and the platform is also provided with a hydraulic station, an electrical system, an electrical cabinet and a cable drum device. The device is applicable to overhauling, maintaining, washing and the like of a large-diameter cylinder body outer wall.

Owner:TAIYUAN HEAVY IND

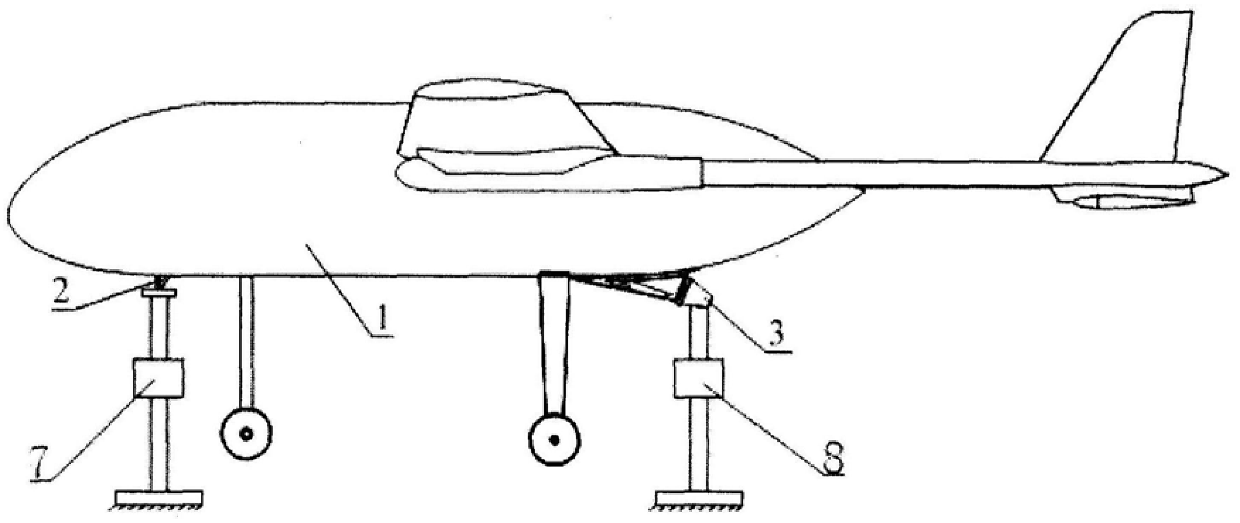

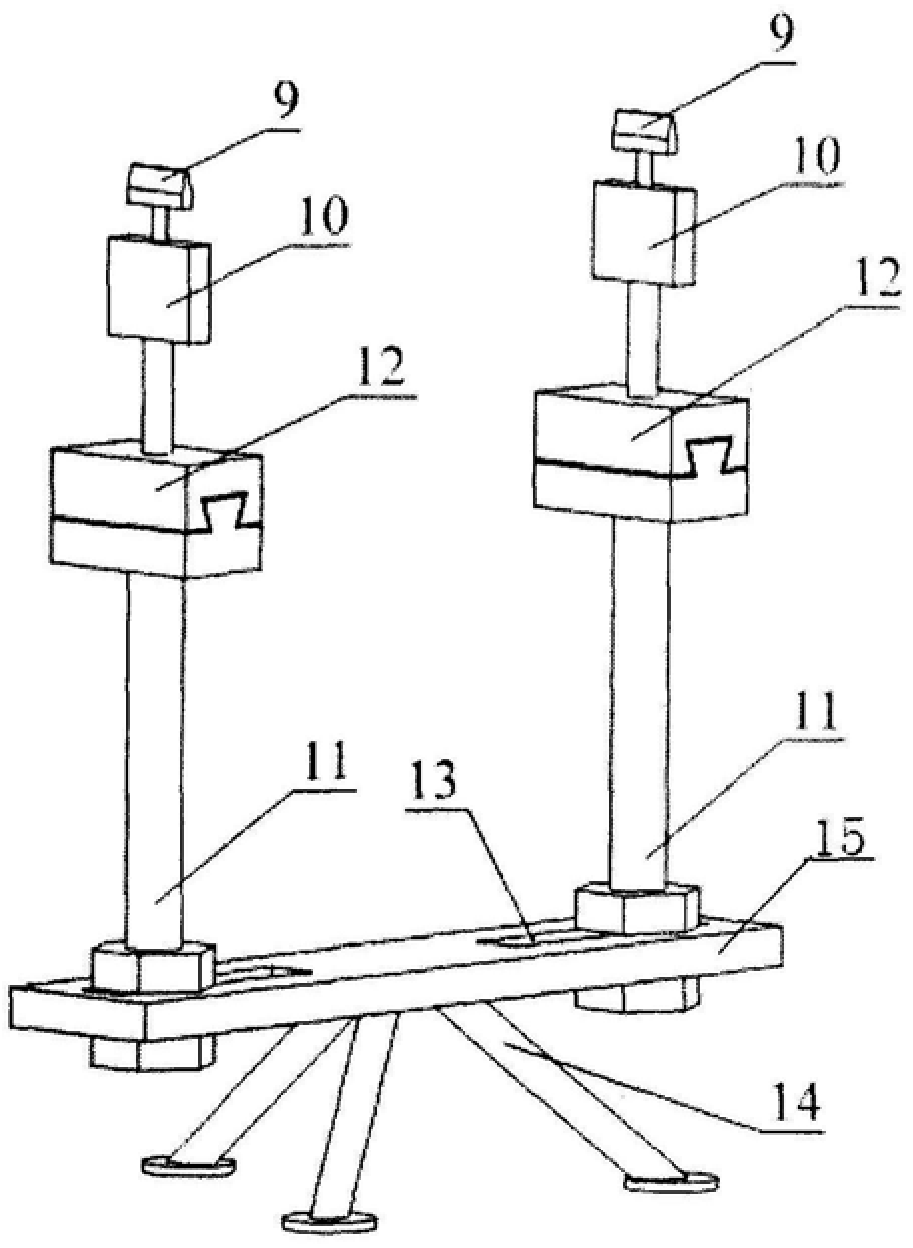

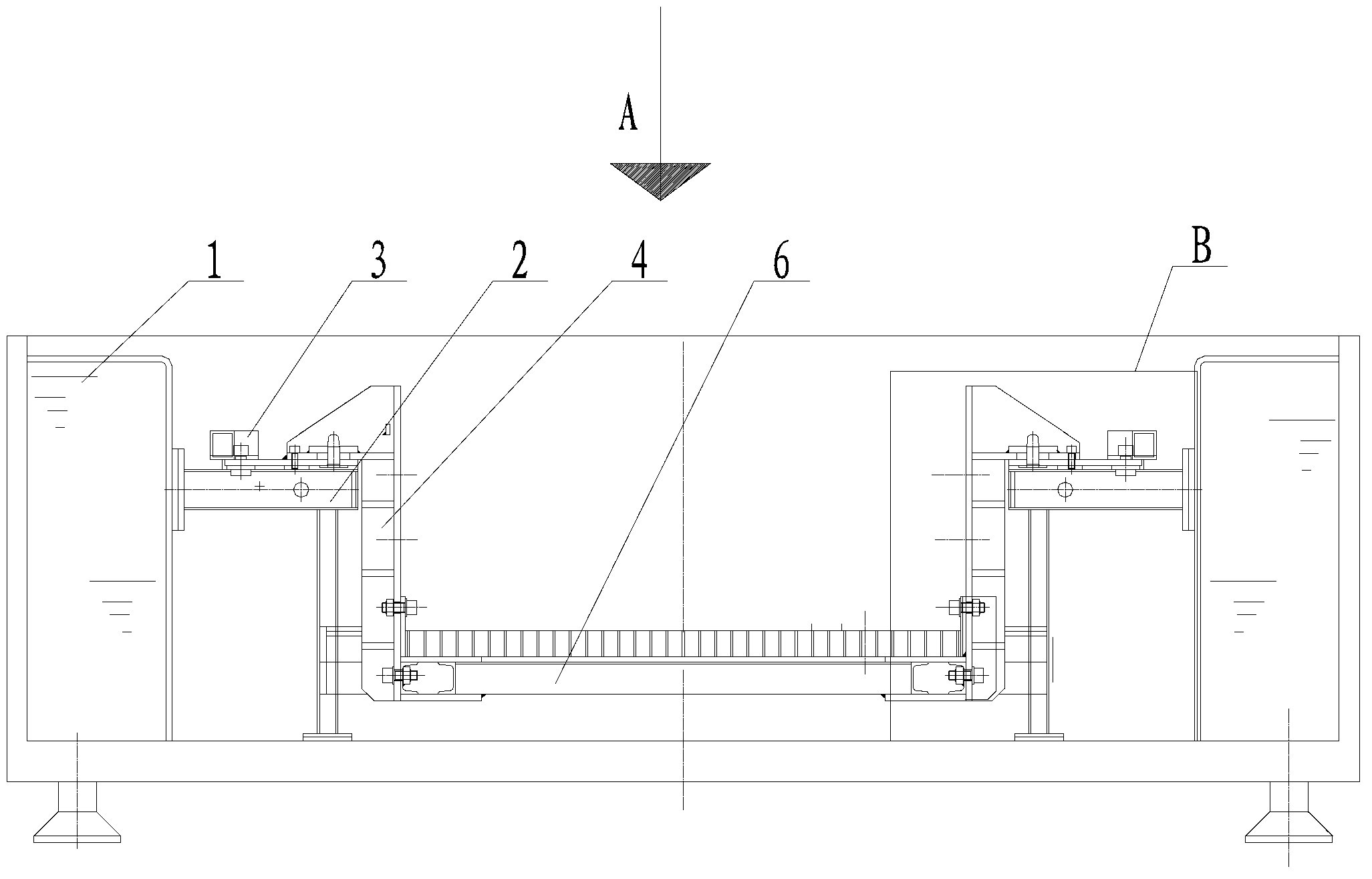

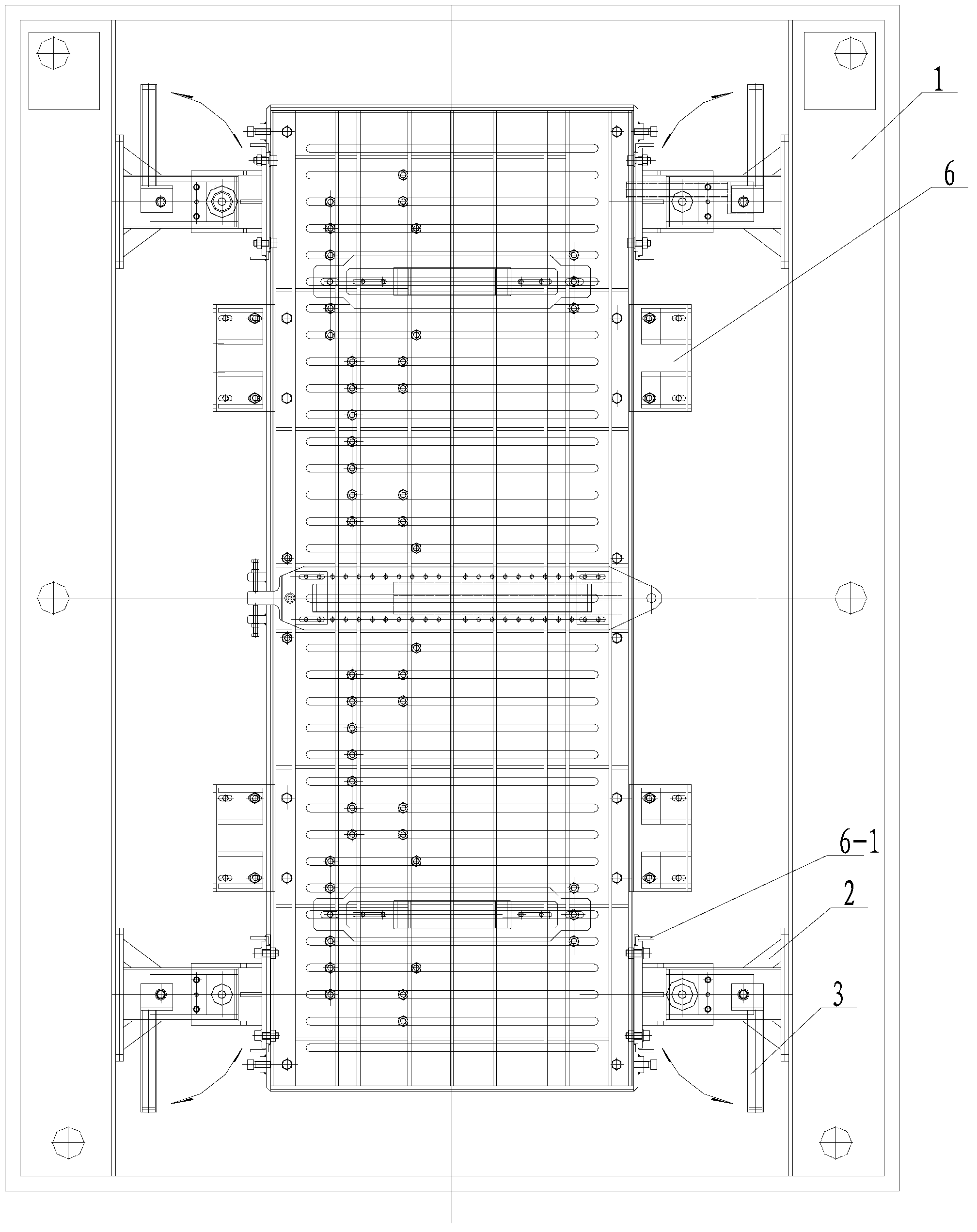

Analyzing the Method of Hanging Weighing Aircraft to Determine the Center of Gravity and the Compound Weighing Device

ActiveCN106507918BSimple weighing methodImprove efficiencySpecial purpose weighing apparatusAirplaneTilt sensor

The present invention proposes a method for determining the position of the center of gravity of an analytically hanging weighing aircraft and its compound weighing device. By using the compound analytical weighing method of the present invention in combination with the hanging weighing method and its compound weighing device, it is only necessary to One time of horizontal weighing and one time of hanging, the position of the center of gravity of the aircraft in three directions can be obtained. The present invention is achieved through the following technical solutions. Use the compound weighing device with three-dimensional adjustable three-point support to adjust the plane level, and pass the known coordinates of the front support and the rear support, through the pressure sensors of the front scale and the rear scale on the compound weighing device From the readings, the position of the center of gravity of the aircraft heading is calculated. Suspend the aircraft on the truss by a sling, install an inclination sensor between the sling and the rear support, and measure the relative angle between the axes of the above sling and the rear support in the pitch and yaw directions through the inclination sensor; according to "Aircraft Calculate the position of the center of gravity of the aircraft in the vertical direction and yaw direction by using the drawing method in the Design Manual.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

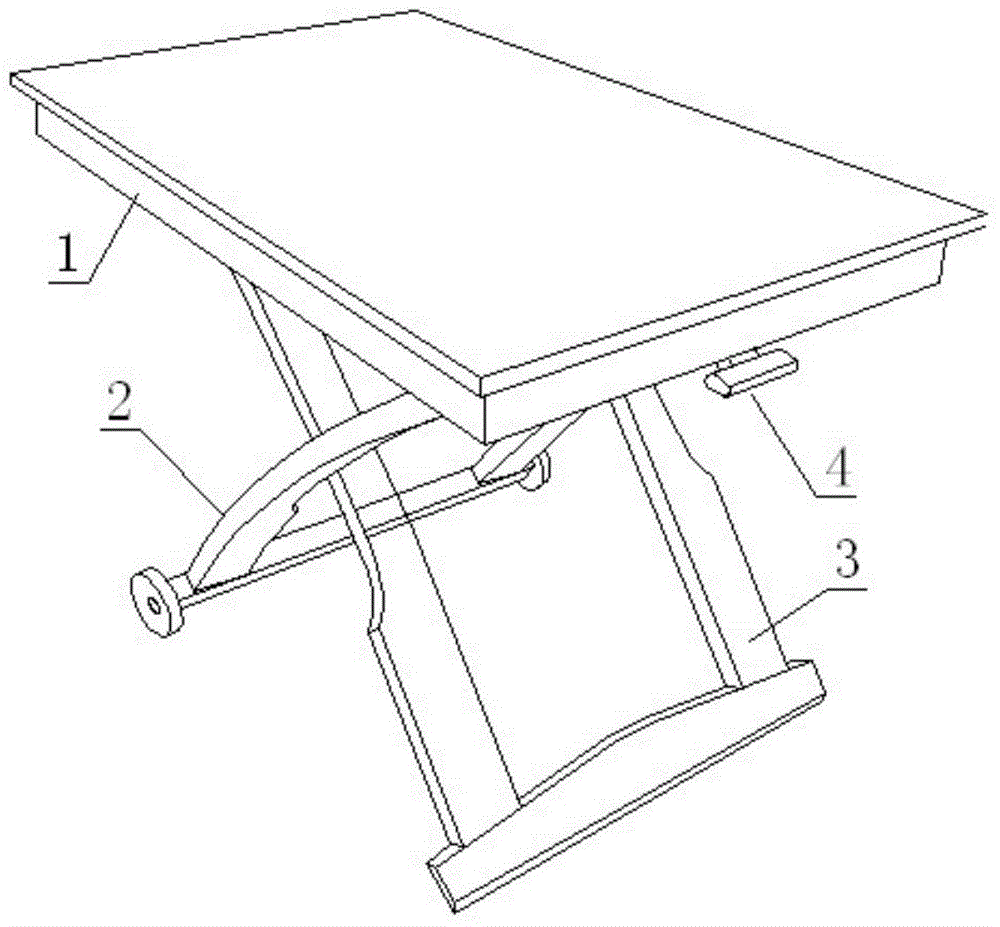

Self-locking height adjustable table

InactiveCN104643571AChange heightAvoid direct contact with frictionServing tablesVariable height tablesAir springSelf locking

The invention discloses a self-locking height adjustable table which includes a table top, front supporting legs, back supporting legs and an adjustment device. The adjustment device includes a self-locking air spring, a sliding bar, a sliding sleeve sleeved on the sliding bar, and a cross rod with two ends hinged to the back supporting legs. The sliding rod is longitudinally arranged at the bottom of the table top. The self-locking air spring is arranged in the sliding rod, and includes a cylinder, a piston rod and a release pin arranged on the piston rod. The front end of the piston rod is fixed on the sliding rod, the cylinder is fixed on the sliding sleeve through a bolt, and an elongated through hole is formed in the corresponding position of the piston rod. The bolt can penetrate through the elongated through hole and can slide along a strip of the through hole. The self-locking height adjustable table is simple in structure and reasonable in design, can stop at any position in the stroke by aid of the self-locking air spring, accordingly can adjust the included angle formed by the front supporting legs and the back supporting legs, and correspondingly the height of the table top can change. The self-locking height adjustable table is convenient to use.

Owner:陈浠

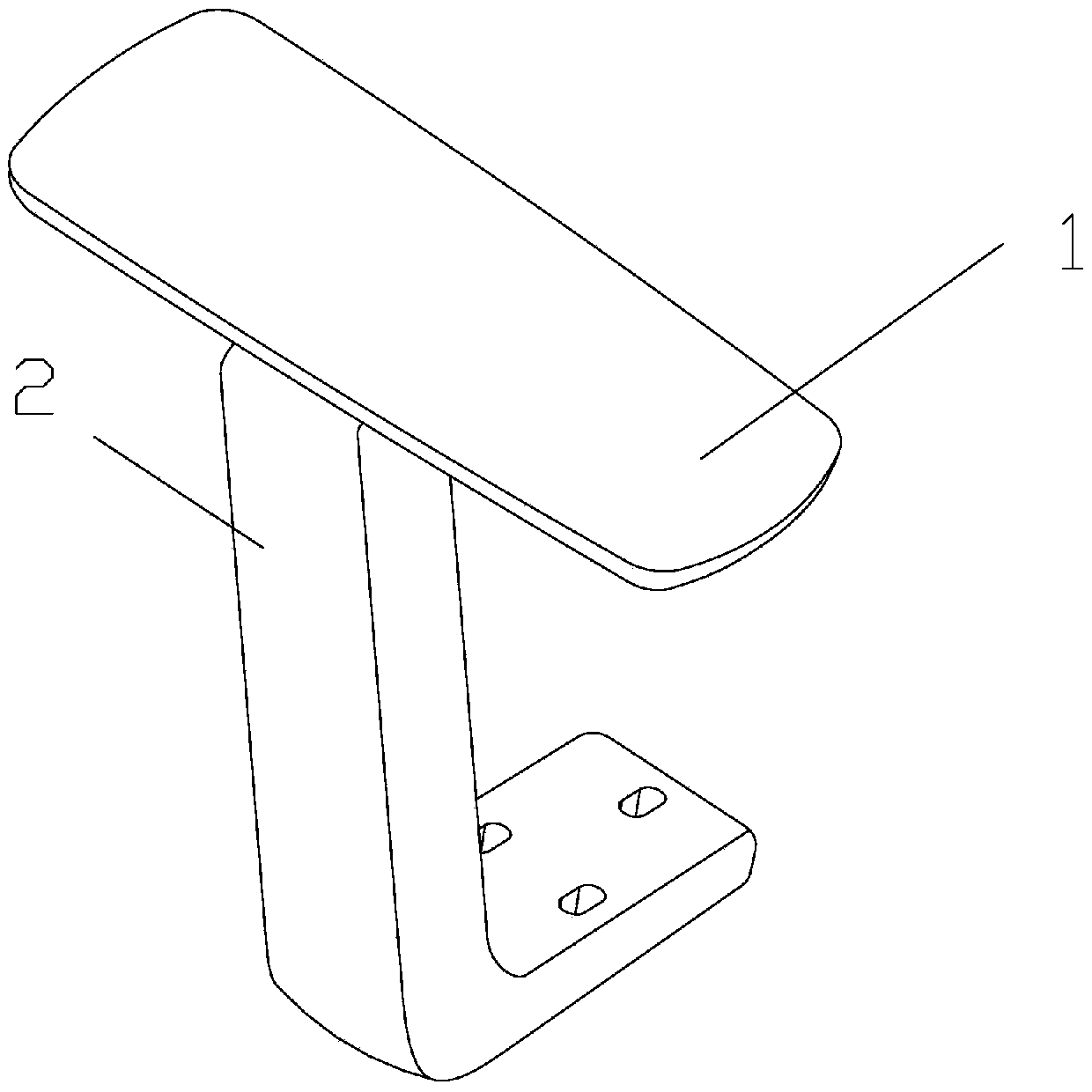

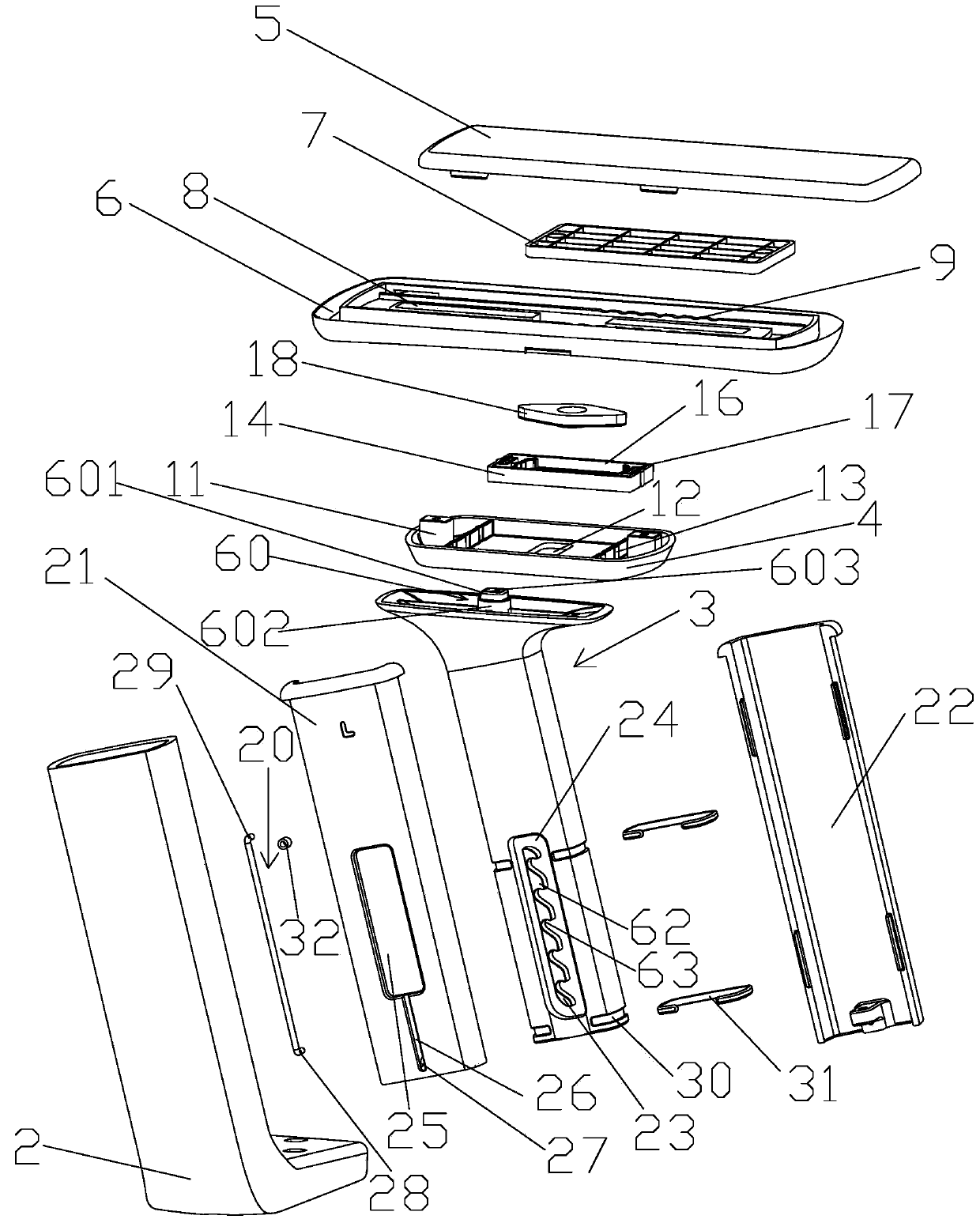

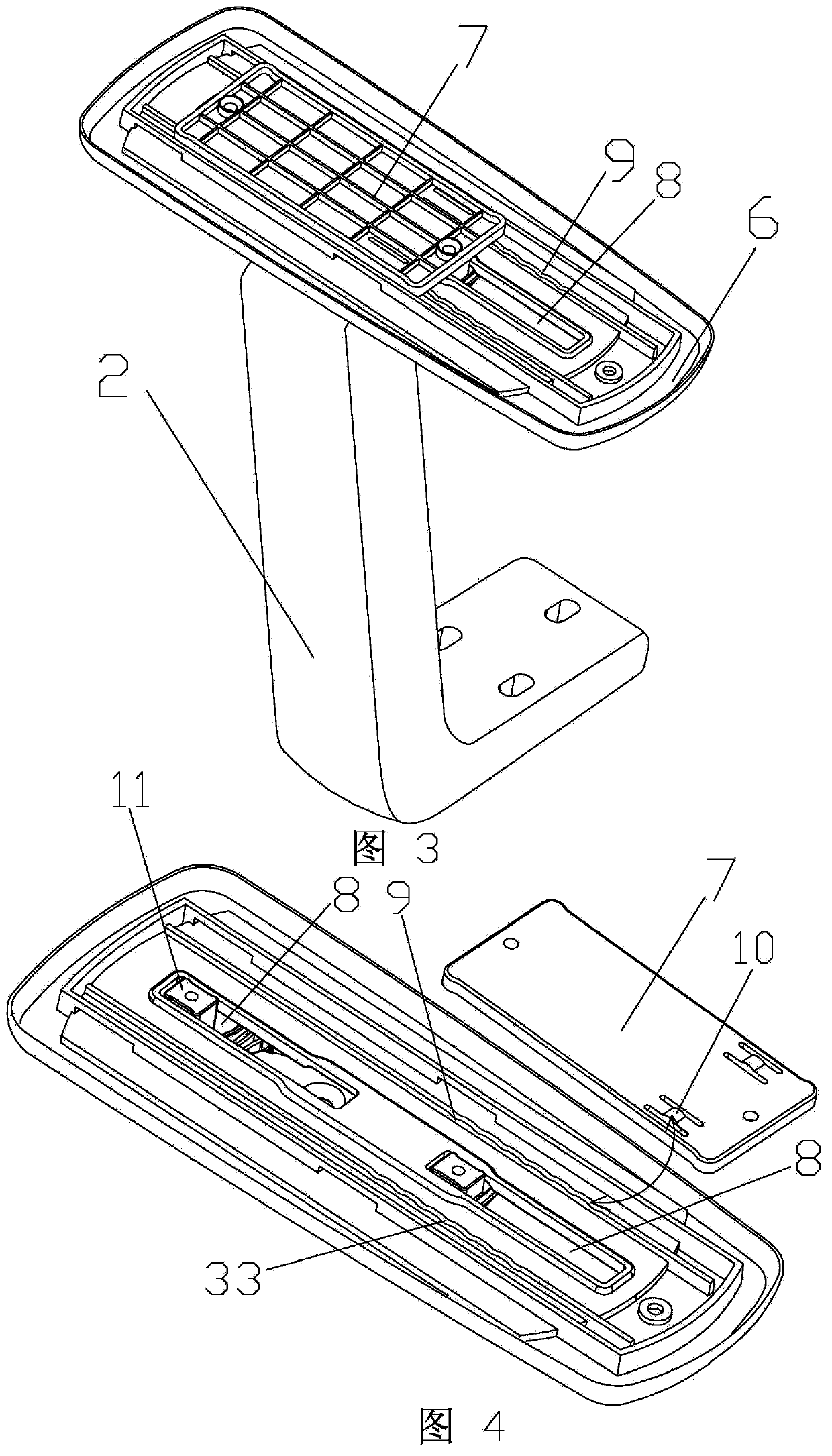

Multifunctional armrest

Owner:UE FURNITURE CO LTD

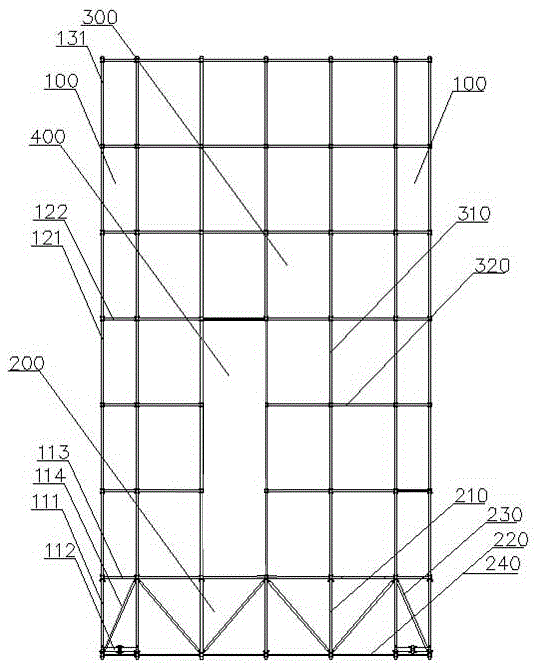

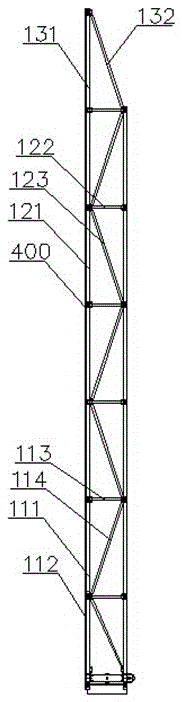

Attached lifting scaffold

InactiveCN105484485ALabor savingEasy to assembleScaffold accessoriesBuilding support scaffoldsFalseworkSafety net

The invention discloses an attached lifting scaffold which comprises a scaffold body, a protective safety net, a lifting mechanism, a lifting safety mechanism and a control system. Multiple bottom loading frames, bottom pedal frames, middle pedal frames, bottom pedals and upper pedals are prefabricated as a whole, and connection joints of multiple first vertical rods, the bottom loading frames, the bottom pedal frames, first diagonal bracings, second vertical rods, the middle pedal frames, second diagonal bracings, third vertical rods, third diagonal bracings, fourth vertical rods, fourth diagonal bracings, bottom pedals, fifth vertical rods and the upper pedals are provided with connection structures in advance. The scaffold is formed by splicing individual components, and the components are all all-steel components. During on-site installation, people only need to splice the components and the accessories according to a drawing to form the scaffold, a large amount of labor can be saved in the construction process, splicing is easy, and safety is also greatly improved.

Owner:ZHONGYIFENG CONSTR GRP

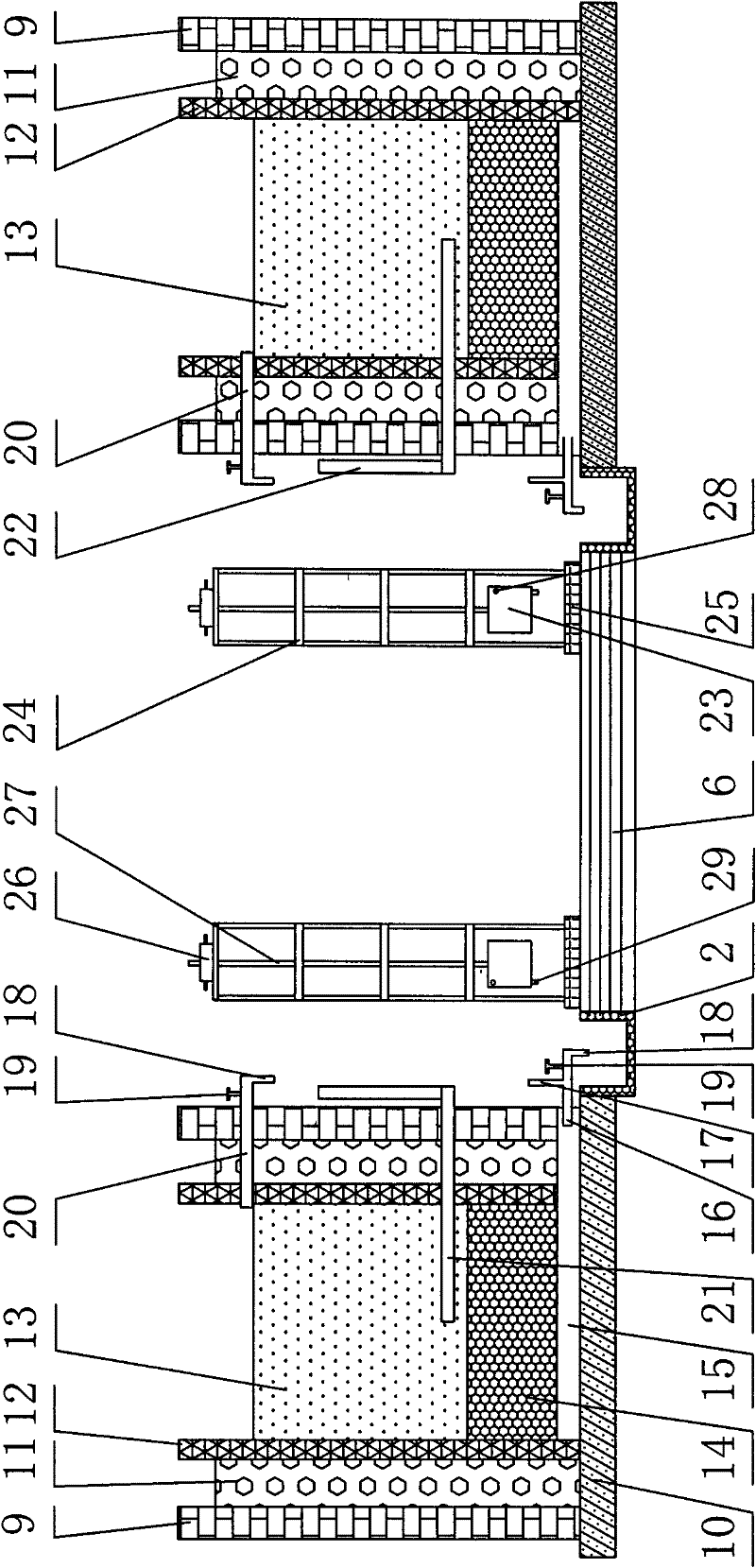

Waterlogging simulation test system for rainfed cropland

InactiveCN102047833AEliminate Boundary Temperature EffectsLift freelyConstructionsWatering devicesDitchWater storage tank

The invention relates to a waterlogging simulation test system for rainfed cropland, which belongs to the technical field of agricultural water and soil engineering. The waterlogging simulation test system comprises a water reservoir, a leaching pond group, water level control devices and the like, wherein the leaching pond group is composed of leaching pond units; an observation corridor and a gutter are arranged between the adjacent leaching pond units; the corresponding water level control device is arranged on one side of each leaching pond unit; and a tread is arranged at one end of the leaching pond group, and the water reservoir is arranged at the other end of the leaching pond group. The system is used for providing water for testing for the leaching pond group through a water conveying pipe and a water storage tank and can simulate a waterlogging environment of the cropland through drain pipes, irrigation and drainage dual-purpose pipes and the water level control devices and effectively perform irrigation and drainage control. The system can be used for solving the problems that the boundary conditions of the existing leaching pond testing and the crop growth environment are significantly different from the cropland, and the testing precision and the practicality of research results are affected. The system can be respectively used for creating the influences of rainfall as well as rivers, ditches and the like on the periphery of the cropland on soil water and underground water when the water level is too high, ensure that the testing can be carried out under the near-natural conditions. Furthermore, the structure is simple, and the construction cost is low and practical.

Owner:YANGTZE UNIVERSITY

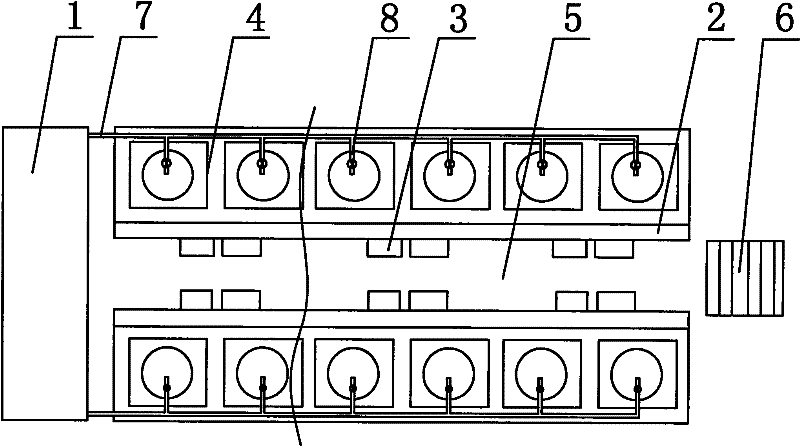

Multifunctional working machine for orchard

The invention provides a multifunctional working machine for an orchard. The multifunctional working machine comprises a working device and an operation platform. The working device is provided with a travelling device, a rotating device and a lifting device, wherein the travelling device can travel and divert freely. The rotating device can drive the operation platform and a working platform to steadily rotate at 360 degrees; the lifting device can drive the operation platform and the working platform to rise or fall between 1m to 6m. The working machine can perform pesticide spraying or pneumatic pruning. The multifunctional working machine has the advantages that the working machine can move and travel flexibly, can rise and fall freely, can rotate freely, is convenient and safe in operation and is multifunctional.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

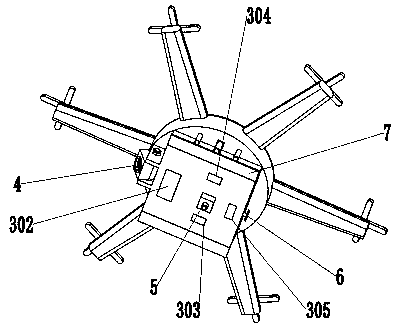

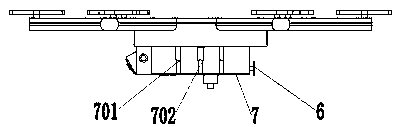

Unmanned aerial vehicle with riverway monitoring data collection sensing technology

InactiveCN110001947AQuick checkAccurate detectionAircraft componentsWithdrawing sample devicesElectricityWireless communication protocol

The invention discloses an unmanned aerial vehicle with riverway monitoring data collection sensing technology. The unmanned aerial vehicle with the riverway monitoring data collection sensing technology comprises an unmanned aerial vehicle body, a floating box, a detection system and a ground control base station, rotor wings used for flying are uniformly arranged on the periphery of the unmannedaerial vehicle body, a detachable lithium battery is arranged in the unmanned aerial vehicle body, the floating box is arranged below the unmanned aerial vehicle body, and supporting plates used forlanding supporting are arranged on the two sides of the floating box. The detection system comprises a data processor, a storage, cameras, sensors and a wireless module, the data processor is separately and electrically connected with the storage, the cameras, the sensors and the wireless module, the data processor, the storage and the wireless module are arranged in the unmanned aerial vehicle body, the sensors and the cameras are arranged on the floating box, and the wireless module is connected with the ground control base station through wireless communication protocol.

Owner:广西圣尧智能科技有限公司

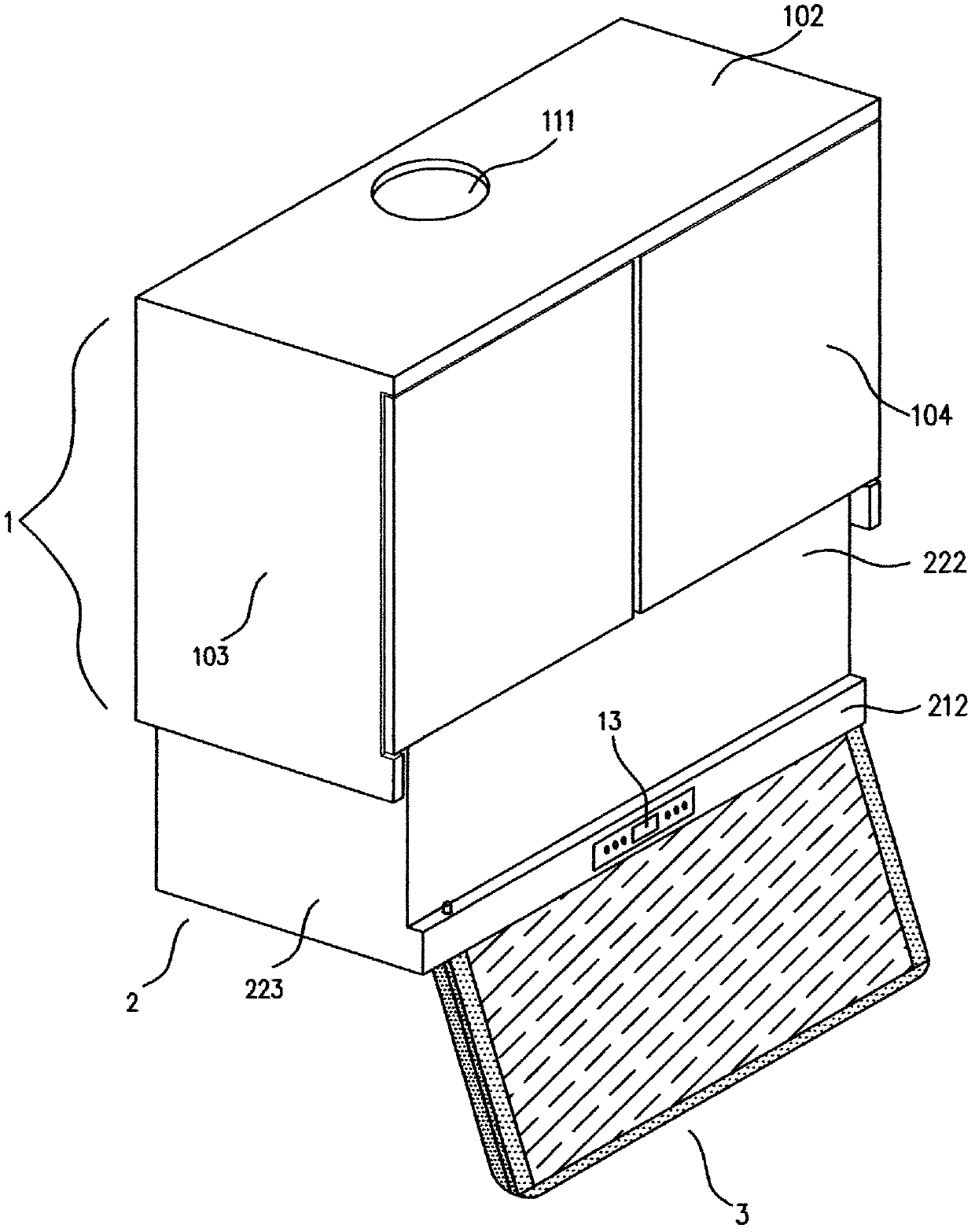

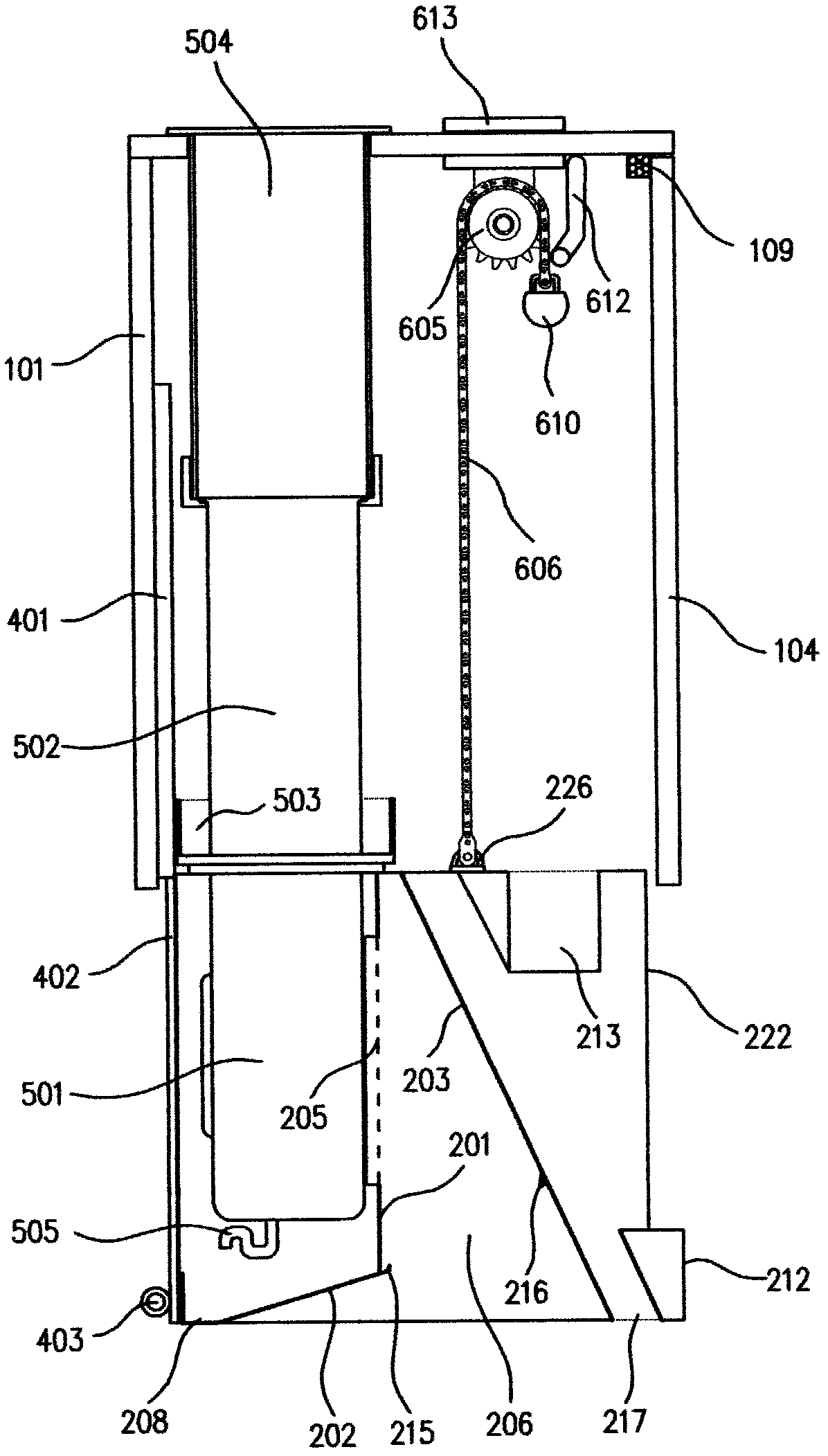

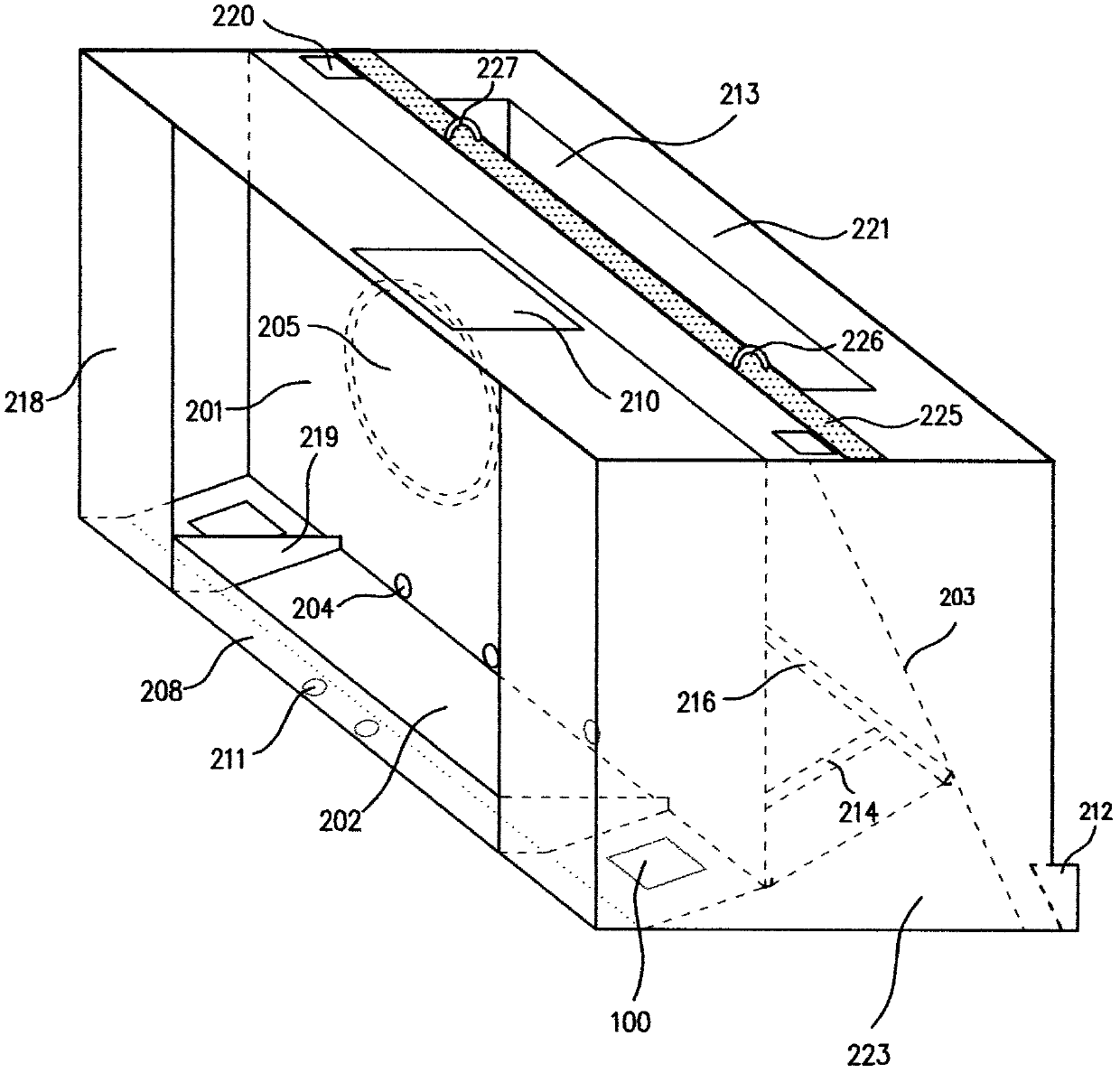

Motor-driven lift-type cabinet-shaped protecting range hood

InactiveCN102434904AFree from pollutionAvoid pollutionDomestic stoves or rangesLighting and heating apparatusStructural engineeringClockwise

The invention discloses a power-driven lift-type cabinet-shaped protecting range hood and belongs to the field of rang hoods. The technical scheme is as follows: the range hood comprises a cabinet shell, an air cabinet and a protection plate and is characterized in that the air cabinet is arranged in the cabinet shell; the back vertical board of the air cabinet is provided with a guide rail A and is connected with the inner surface of the back plate of the cabinet shell through the guide rail A; a power-driven lifting device A is arranged between the cabinet shell and the air cabinet and enables the air cabinet to go up and down along the clockwise rotation or reversion of the power-driven lifting device A in the cabinet shell; an air exhaust device is arranged in the air cabinet; the inner interlayer of the air cabinet is provided with the protection plate which is driven to lift by a power-driven lifting device B; the lower part of the front surface of the air cabinet is provided with an oblique pipe which is provided with a power switch panel; and the bottom of the air cabinet is provided with a floodlight and the front vertical plate of the air cabinet is provided with a video device and an audio device.

Owner:吴小国

Apparatus and methods for preventing rotational slippage between a vertical shaft and a support structure for a semiconductor wafer holder

InactiveUS20070056150A1Reduce the possibilityMaintaining productive lifeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

A substrate support assembly positively secures a substrate holder support to a rotation shaft with respect to rotationally applied forces. A substrate holder support is configured to have an opening in a socket into which, when aligned with an indentation in the rotational shaft to form a passage, a retaining member is removably inserted to engage both the socket opening and the shaft indentation. Methods of rotating a substrate while minimizing rotational slippage of the substrate holder support with respect to the shaft are also provided.

Owner:ASM AMERICA INC

Apparatus and methods for preventing rotational slippage between a vertical shaft and a support structure for a semiconductor wafer holder

ActiveUS20050166849A1Prevent spinning and slippingReduce the possibilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

A substrate support assembly positively secures a substrate holder support to a rotation shaft with respect to rotationally applied forces. A substrate holder support is configured to have an opening in a socket into which, when aligned with an indentation in the rotational shaft to form a passage, a retaining member is removably inserted to engage both the socket opening and the shaft indentation. Methods of rotating a substrate while minimizing rotational slippage of the substrate holder support with respect to the shaft are also provided.

Owner:ASM IP HLDG BV

Water-cutter cutting forming assembly for elbow workpiece

ActiveCN102794711APrecise positioningNovel structureBlast gunsAbrasive machine appurtenancesThermal deformationHigh pressure water

The invention discloses a water-cutter cutting forming assembly for an elbow workpiece, which comprises a working water tank, at least one pair of fixing supports, rotary supporting legs, pothooks and plate racks, wherein the fixing supports are symmetrically arranged in the working water tank; the rotary supporting legs are rotatably arranged on the fixing supports; the pothooks are fixedly arranged on the fixing supports through base plates; the plate racks are arranged on the pothooks; pothook slide chutes which are connected with the plate racks are arranged on the pothooks; and the plate racks vertically slide along the pothooks through the pothook slide chutes. The water-cutter cutting forming assembly for the elbow workpiece has the advantages: when a water cutter is used for cutting, the assembly provided by the invention is used for basically ensuring that a position plane of a longitudinal rough edge allowance cutting wire of a cut elbow is parallel to a X-Y two-dimensional motion plane of a cutting gun head of the water cutter, the positioning fixing of the elbow workpiece meets the technical demands on the cutting shape and size of the elbow workpiece, and the practical demands on free lifting of platforms and convenience in operation are met. Under the working condition of high-pressure water jet cold-cutting, the material of a titanium elbow workpiece is prevented from oxidized metamorphosis, the secondary thermal deformation of the workpiece is not generated and the cutting efficiency is high.

Owner:NANJING BAOSE

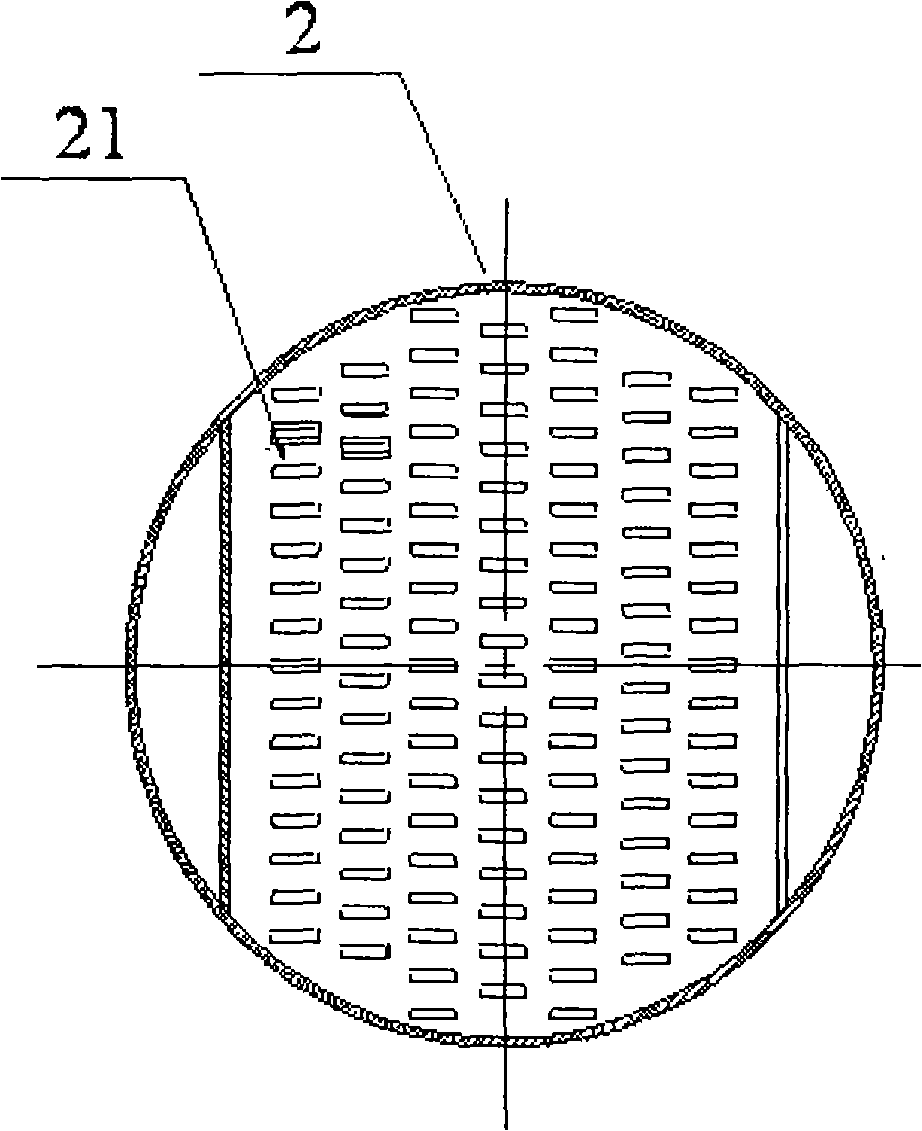

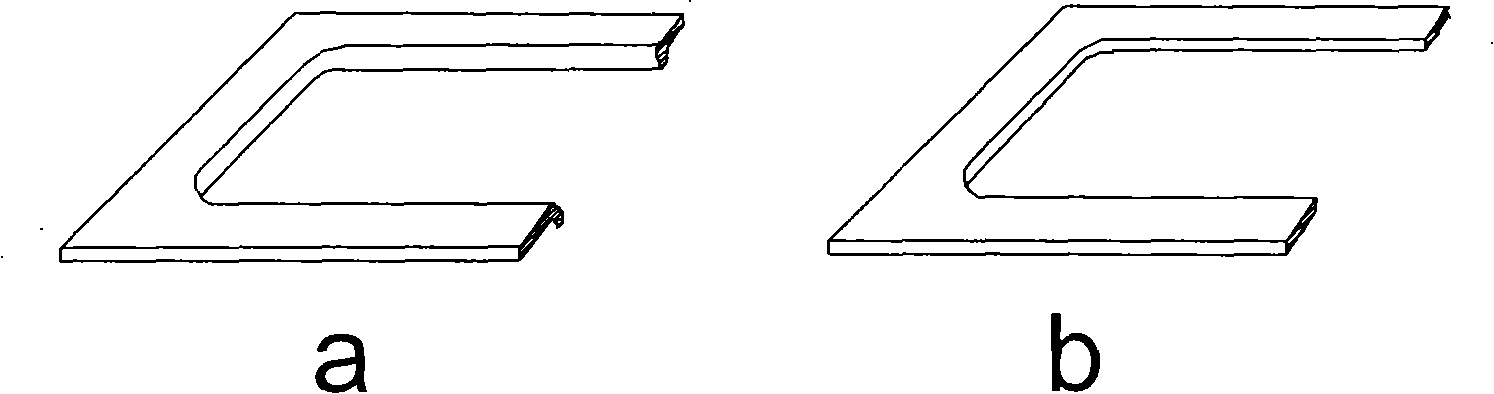

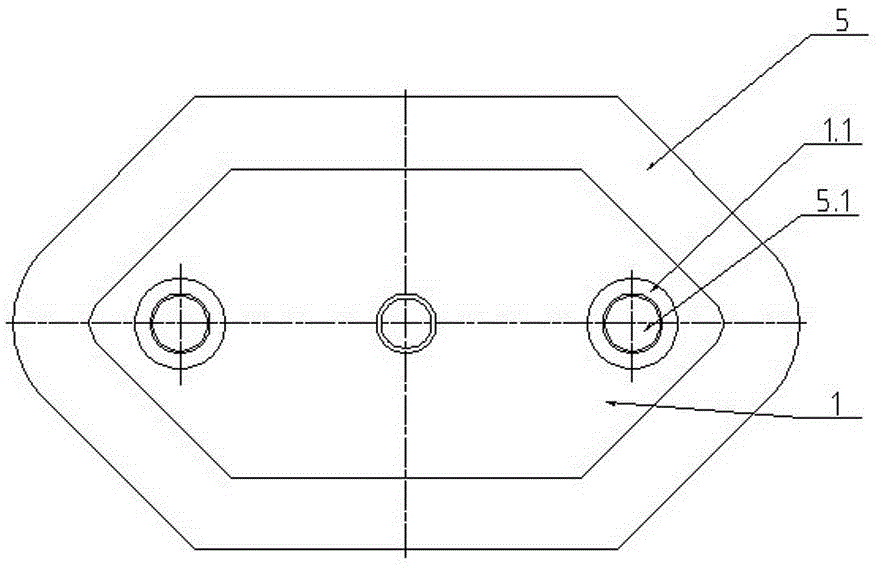

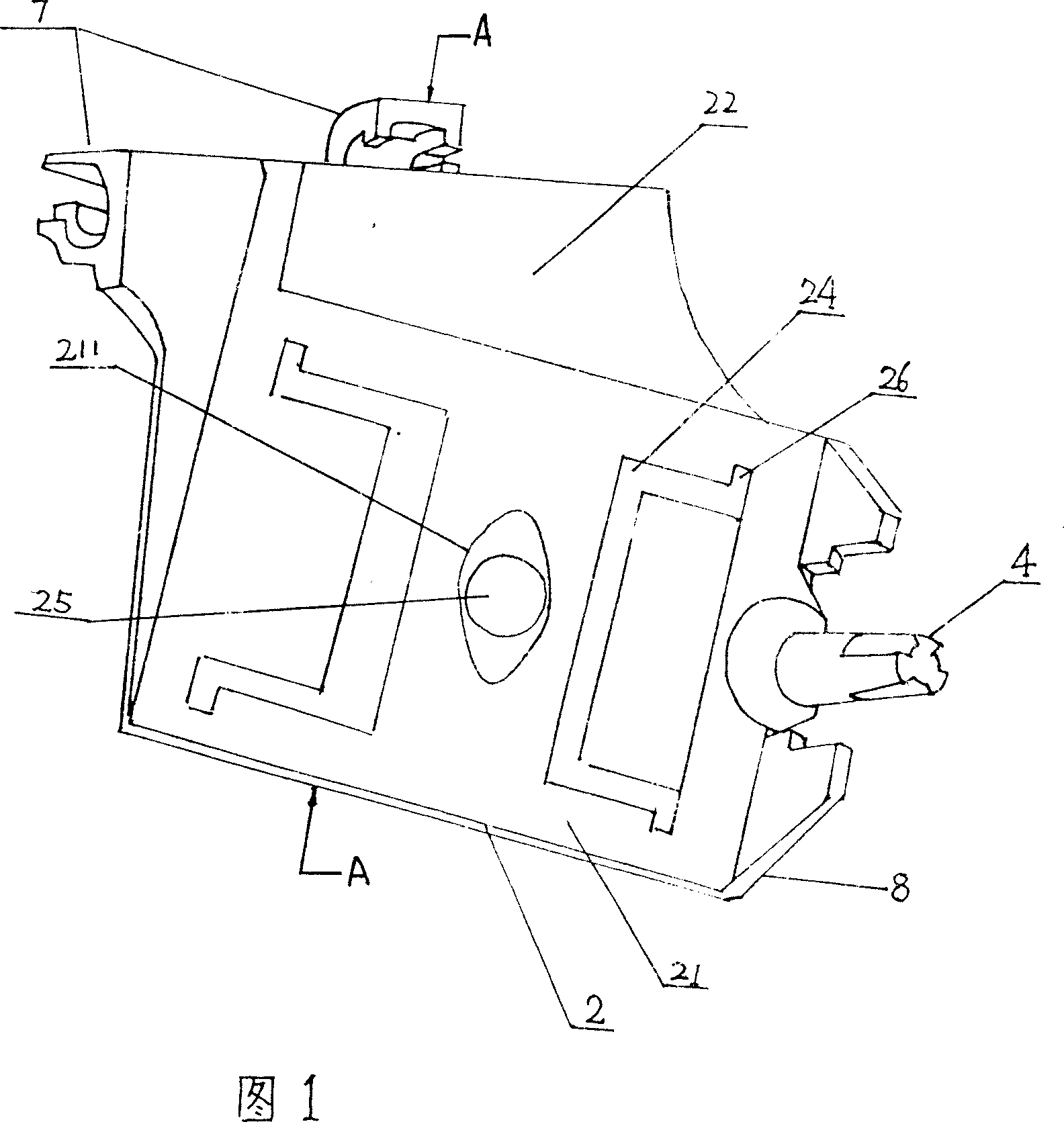

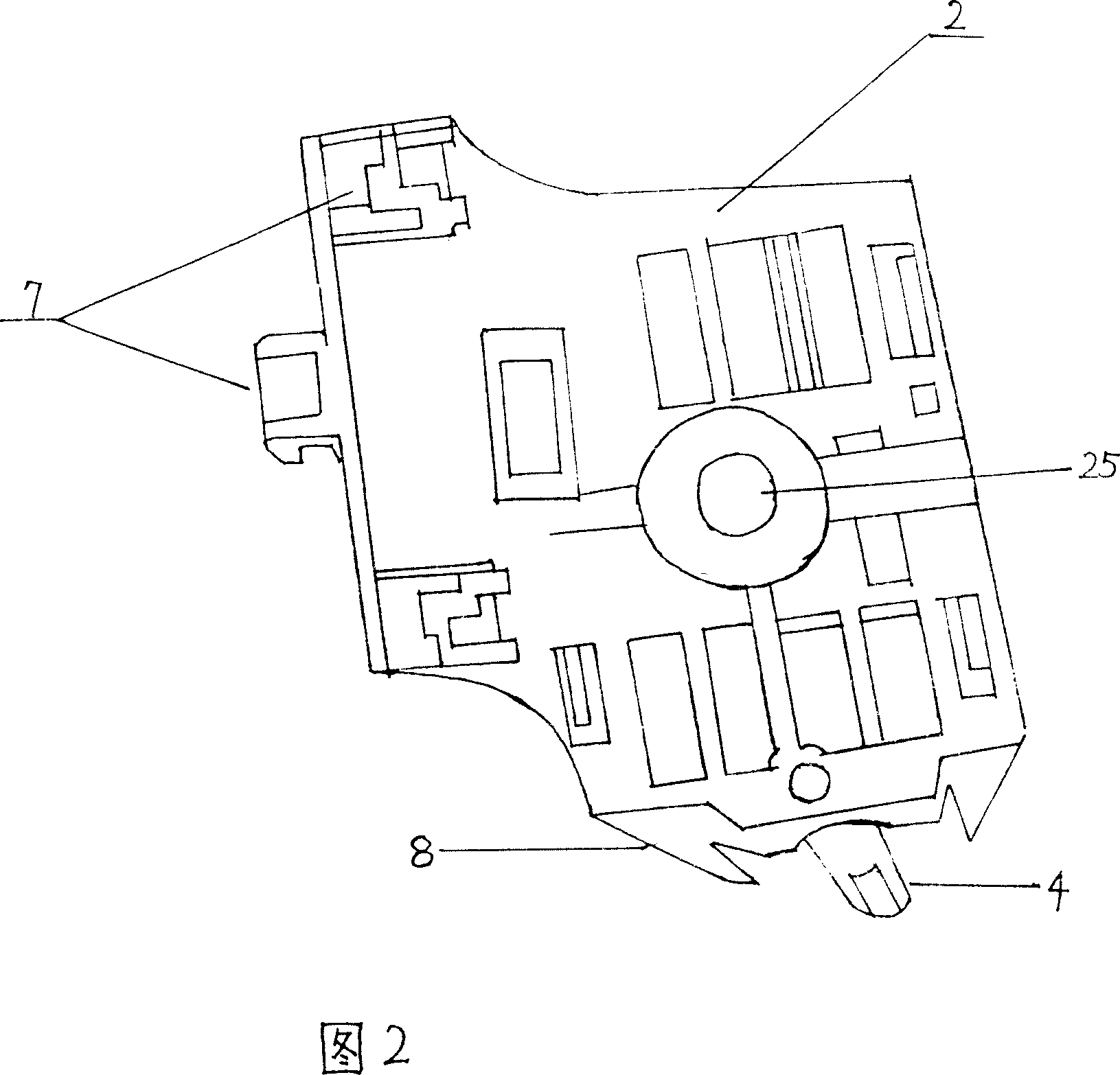

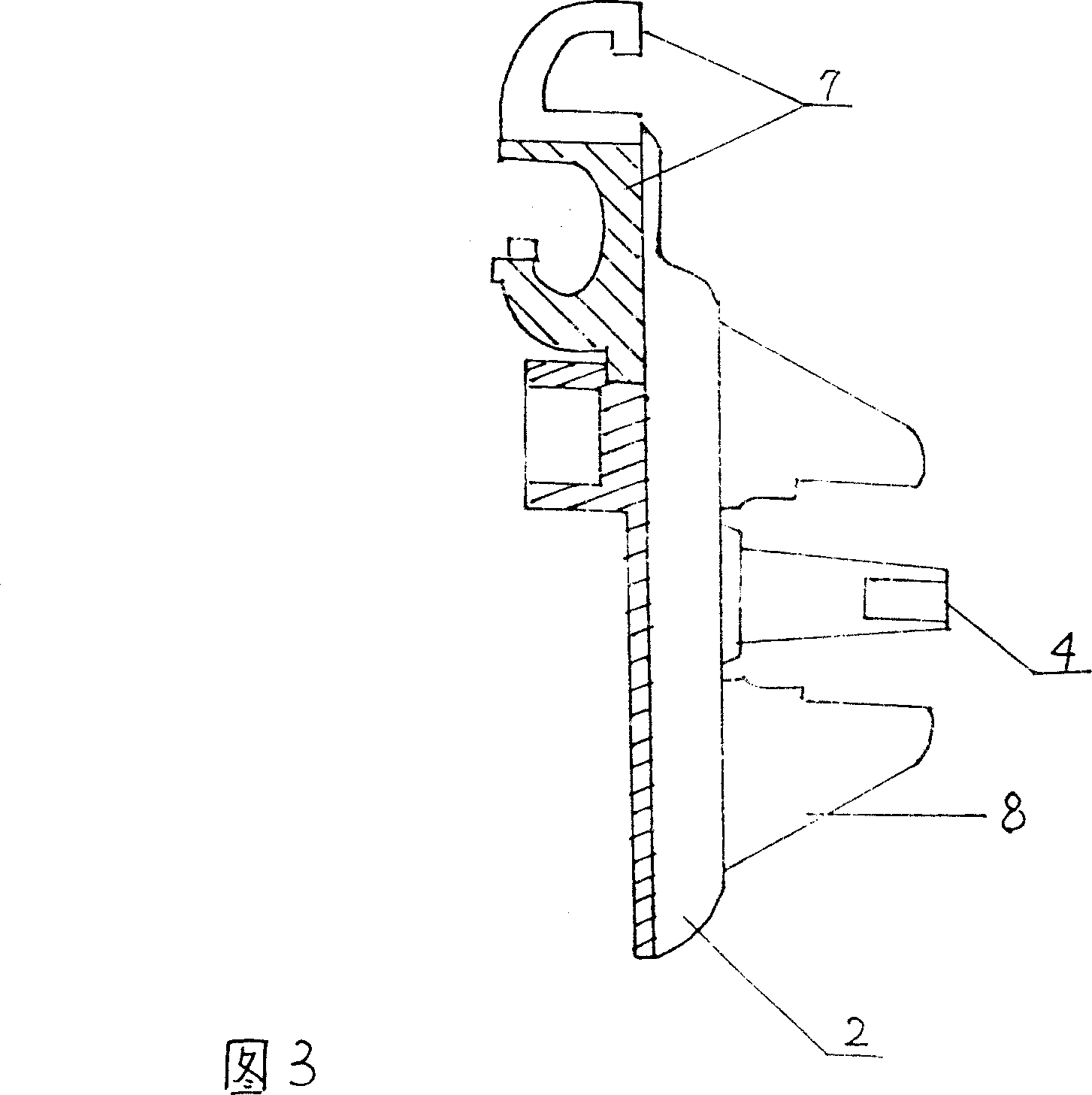

A packing float valve plate

InactiveCN101279143AReduce leak rateIncrease contact areaFractional distillationPressure systemLow voltage

The invention relates to a stuffing floating valve tray which consists of a floating valve (1) and a tray (2). The floating valve (1) is installed in a valve opening (21) and is hung at the tray (2). The stuffing floating valve tray is characterized in that the floating valve (1) has a rectangle structure formed by a valve body (11) and a stuffing part (12); the valve body (11) consists of a valve plate (111) and a valve leg (112); the stuffing part (12) is positioned at the upper part of the valve body (11), and is connected with the valve body (11). Compared with the prior art, the stuffing floating valve tray integrates the characteristics of the floating valve tray and that of the stuffing, thus not only having the advantages of large stuffing interface contact area, comparatively low voltage drop and comparatively high tray efficiency, but also being characterized in that the floating valve tray has large operation flexibility and high processing ability. The stuffing floating tray is applicable to regular type gas-liquid tower devices and ultra-large type gas-liquid tray devices with normal pressure system and pressurized system.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

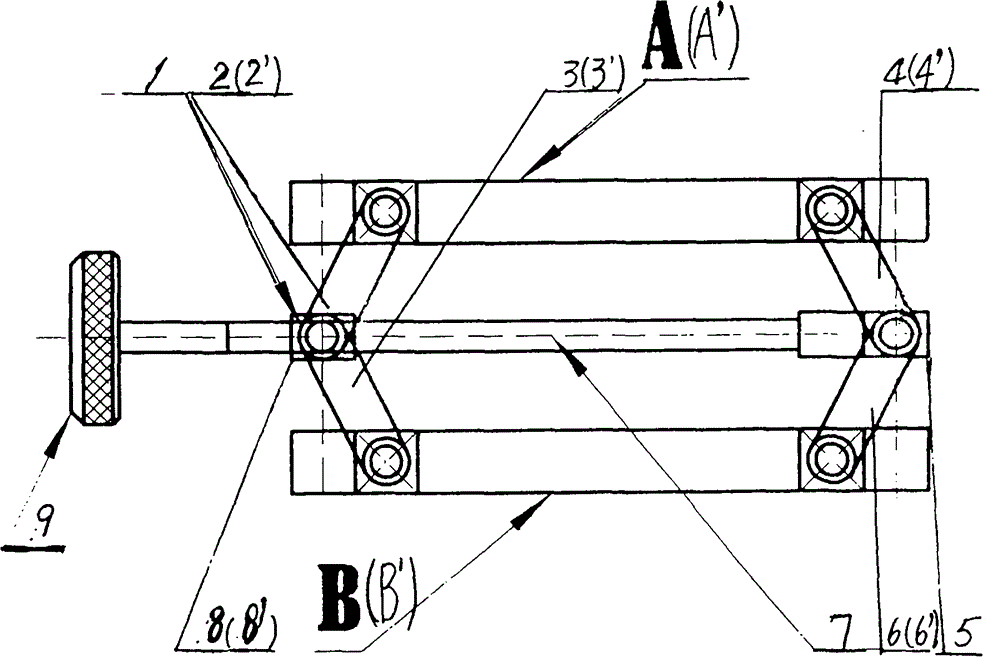

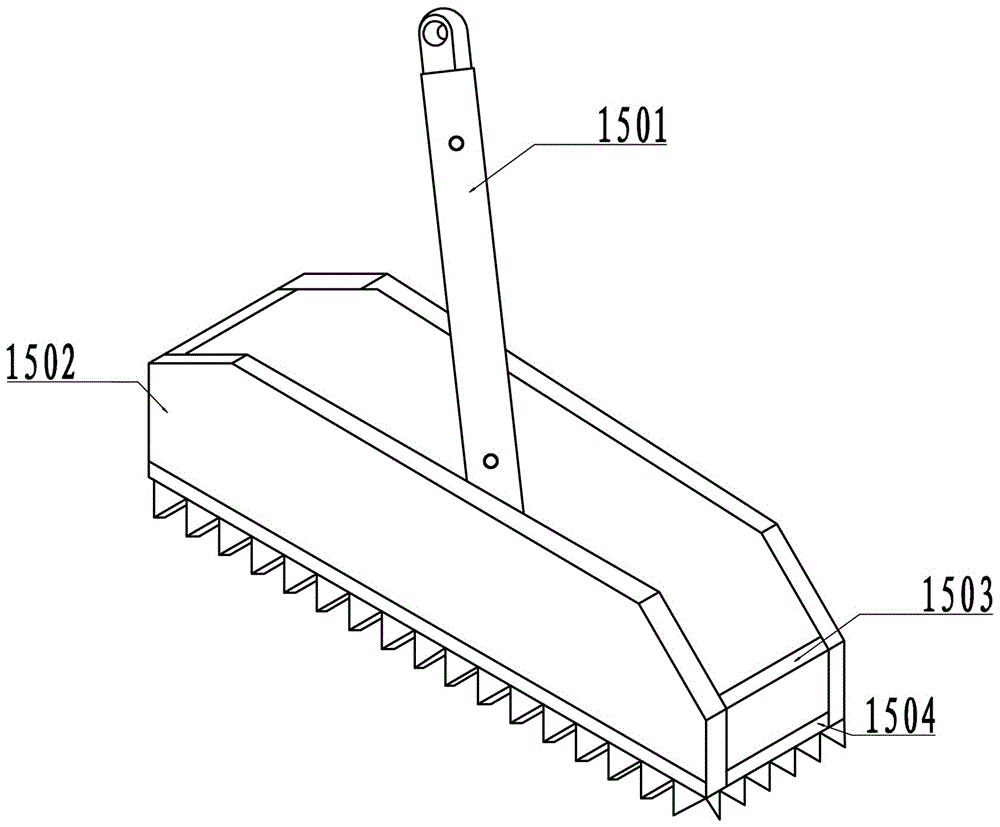

Mechanical type height regulating device of tea bud picking machine

A mechanical type height regulating device of a tea bud picking machine solves the defect that the quality of tea buds picked by a current tea bud picking machine is difficult to guarantee. The mechanical type height regulating device is characterized in that one end of a hinge 2 and one end of a hinge 3 are hinge-connected with the end head of a longitudinal supporting strip 8; the other ends of the hinge 2 and the hinge 3 are hinge-connected with a transverse upper supporting strip A and a transverse lower supporting strip B respectively; one end of a hinge 4 and one end of a hinge 6 are hinge-connected with the end head of a longitudinal supporting strip 5; the other ends of the hinge 4 and the hinge 6 are hinge-connected with the transverse upper supporting strip A and the transverse lower supporting strip B; one end of a hinge 2' and one end of a hinge 3' are hinge-connected with the other end head of longitudinal supporting strip 8; the other ends of the hinge 2' and the hinge 3' are hinge-connected with a transverse upper supporting strip A' and a transverse lower supporting strip B'; one end of a hinge 4' and one end of a hinge 6' are hinge-connected with the other end head of the longitudinal supporting strip 5; the other ends of the hinge 4' and the hinge 6' are hinge-connected with the transverse upper supporting strip A' and the transverse lower supporting strip B', respectively; and a regulating bolt 9 penetrates through the longitudinal supporting strip 8 and the longitudinal supporting strip 5. The mechanical type height regulating device has the advantage of being free in lifting.

Owner:安顺市晶英科技研发有限责任公司

Device and method for processing circular single dovetail grooves in back surfaces of ceramic tiles

InactiveCN107053432APrevent infiltrationSimple and effective pressure retentionDischarging arrangementShaping press ramPneumatic pressureCeramic tiles

The invention relates to a processing device and a processing method for a circular single dovetail groove on the back of a ceramic tile. The processing device includes a hollow pressure seat lifting cover fixed at the lower end of an air hammer and a pressure seat sliding sleeve matching with the pressure seat lifting cover. seat; the upper end of the lifting cover of the press seat is provided with a cover surface, and the lower end is provided with a lifting arm extending inward; And the lifted arm located in the cover of the pressure seat lifts; the lifted arm is limited and slid in the cavity formed by the cover surface and the lifting arm; the pressure seat is evenly distributed with a plurality of vertical hollow holes Cylinder; the upper end of the hollow cylinder is flush with the top of the press seat, and the lower end protrudes downward from the press seat, and the part protruding from the press seat is formed by sequentially overlapping a plurality of first fan-shaped pressing pieces that can be turned inside and outside; the The processing device and processing method for the circular single dovetail groove on the back of the ceramic tile can effectively, quickly and stably form the circular single dovetail groove.

Owner:郑小华

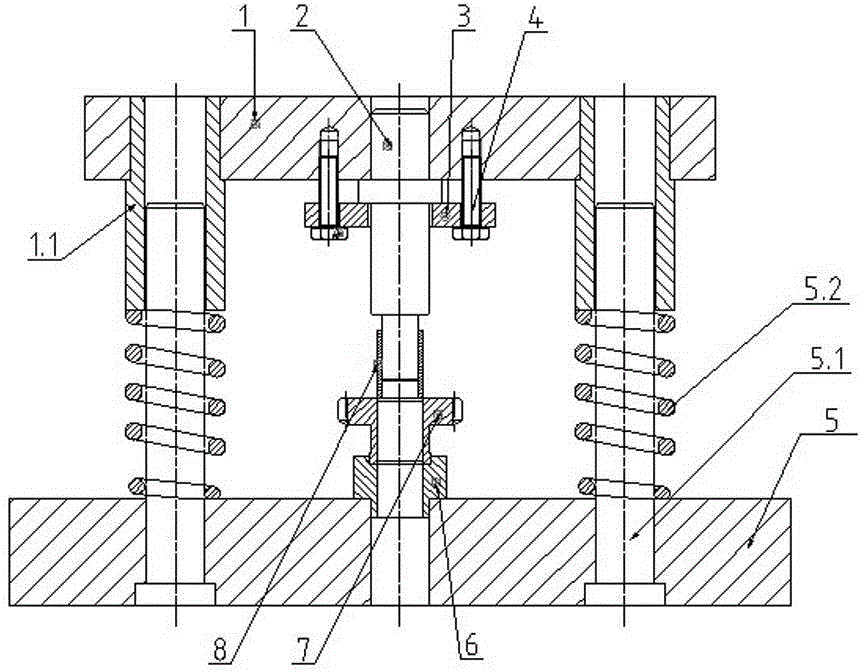

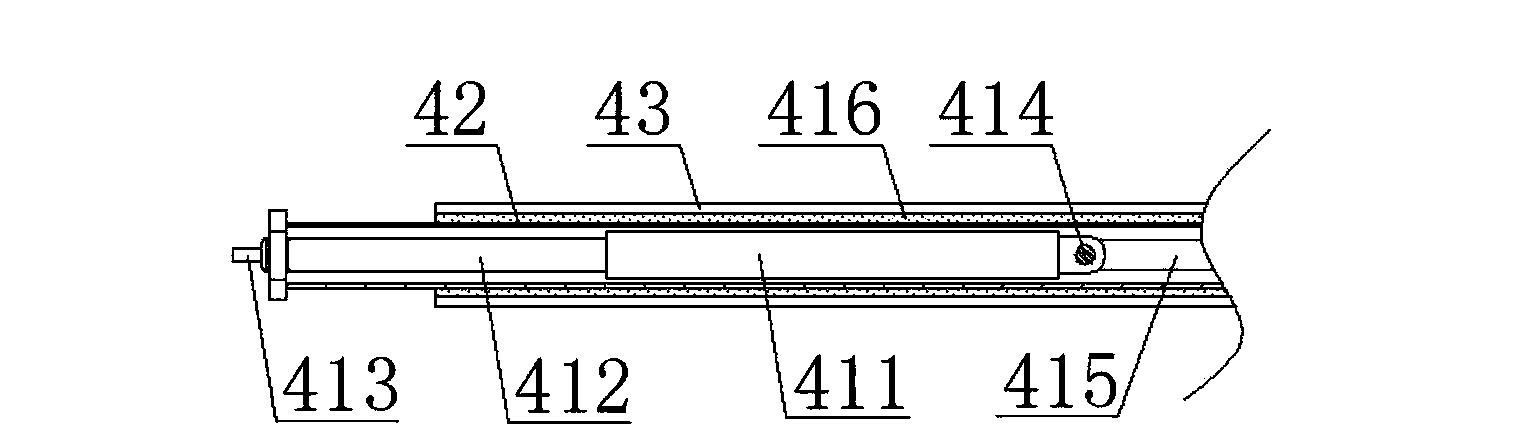

Positioning and pressing device for gear shaft hole lining thin-walled sleeve

ActiveCN103302474BSimple structureLift freelyWork holdersMetal working apparatusCopperMechanical engineering

Owner:JIANGSU PACIFIC PRECISION FORGING +1

Multifunctional stamping base

The invention discloses a multifunctional stamping base, which comprises a base body, and the base body includes a fixed base, a mounting frame, a movable base, a large disc, a tray, a fixing device, a baffle and an infrared alarm. The top of the base body is set as a big disc; the groove in the middle part of the big disc is a tray; a movable base is set under the big disc; a mounting frame is set under the movable base; the big disc The fixed base and the movable base are fixed on the installation frame through the fixing device; the fixed base is arranged around the installation frame; the outermost side of the upper end of the fixed base is provided with an infrared alarm; the outer layer of the infrared alarm is provided with a baffle. The invention has the advantages of reasonable structure, safety and reliability, free lifting, high efficiency, simple operation and the like.

Owner:如皋市明德包装有限公司

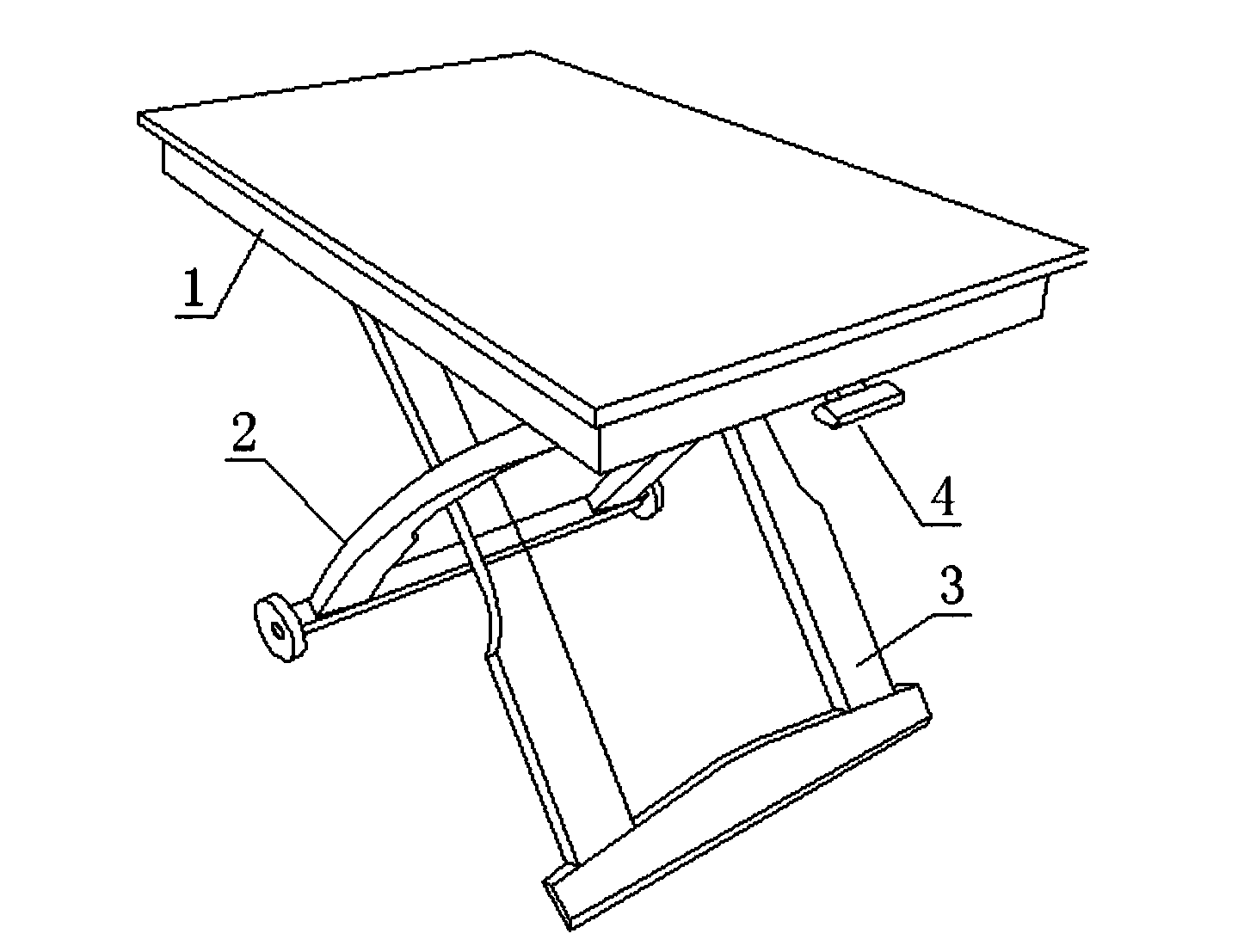

Lifting multipurpose dining table

InactiveCN103844594AChange heightAvoid direct contact with frictionFoldable tablesStowable tablesAir springSelf locking

The invention discloses a lifting multipurpose dining table which comprises a table top, front support legs, rear support legs and an adjusting device. The adjusting device comprises a self-locking air spring, a sliding rod, a sliding sleeve sleeving the sliding rod and a cross rod fixed on the sliding sleeve with two ends hinged to the rear support legs. The sliding rod is vertically arranged at the bottom of the table top, and the self-locking air spring is arranged in the sliding rod. The self-locking air spring comprises a cylinder body, a piston rod and a release pin arranged on the piston rod. The head end of the piston rod is fixed on the sliding rod, the cylinder body is fixed on the sliding sleeve through a bolt, and a long-strip-shaped through hole for the bolt to penetrate and slide along the long strip is formed in the piston rod at the corresponding position. The lifting multipurpose dining table is simple in structure and reasonable in design, the included angle between the front support legs and the rear support legs can be adjusted and fixed by ingeniously utilizing the fact that the piston rod of the self-locking air spring can stop at any position in a journey, the height of the table top can be changed with the include angle, and the dining table is convenient to use.

Owner:许俊荣

Lifting clamping device for automobile window glass

The invention relates to a lifting and holding device for auto glass, comprising pallet, of which in the middle there is a via hole; hook set at the bottom of holding face; spline bar; neck for installing plastic jaw, clamping hook connected with lifting mechanism, which is set on the face opposite to holding face and side face; splint, of which in middle there is a screw hole; hook groove and spline hole set at the bottom of holding face; clamping groove for installing plastic jaw, which is set at the holding face; waist-shaped hole set in the middle of two plastic jaws; reverse clamping hook set at the installing face of plastic jaw; spring clamp set at the side of holding face, which can clamp the auto glass. Above mentioned two plastic jaws are set on the pallet and the splint respectively and hook groove on the splint and spline hole are mated on the hook and the spline bar respectively so that bolt passes through the via hole in the middle of pallet and the waist-shaped hole in the middle of two plastic jaw and rotates into the screw hole in the middle of splint to make the pallet connect with the splint. The invention is provided with simply structure, low manufacturing cost, convenience installment and process.

Owner:上海海帕压铸件有限公司

Framework landing self-moving type front telescopic advanced supporting device

InactiveCN106593502AReduce the risk of climbingReduce accident rateLifting devicesMine roof supportsPetroleum engineering

Owner:枣庄联鑫实业有限责任公司

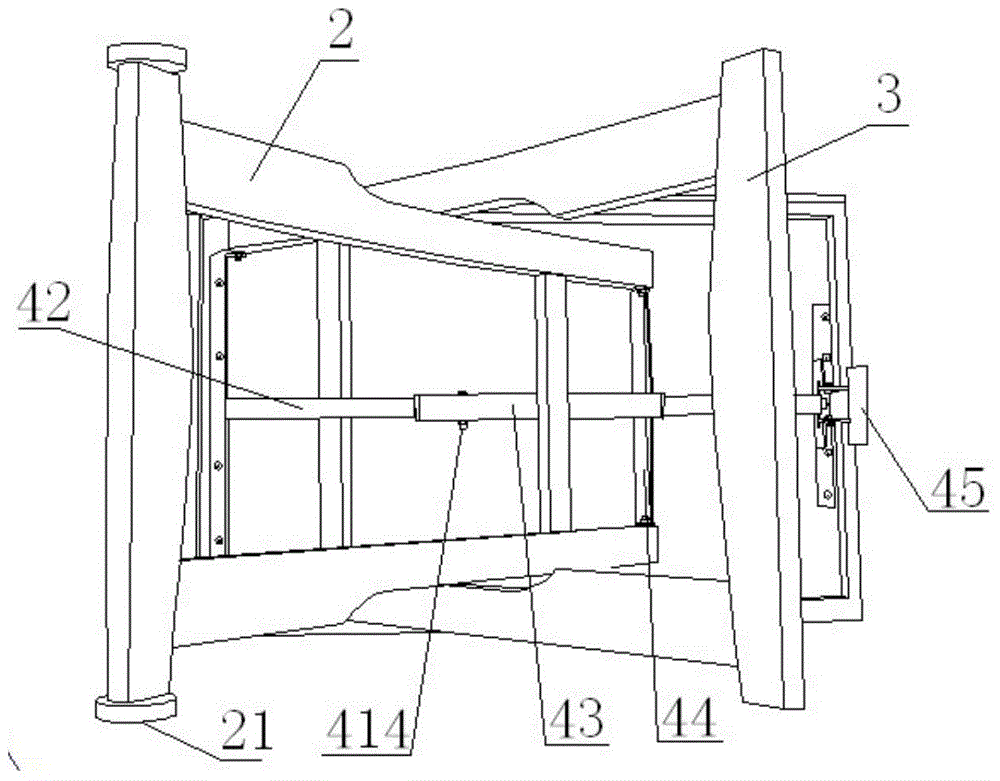

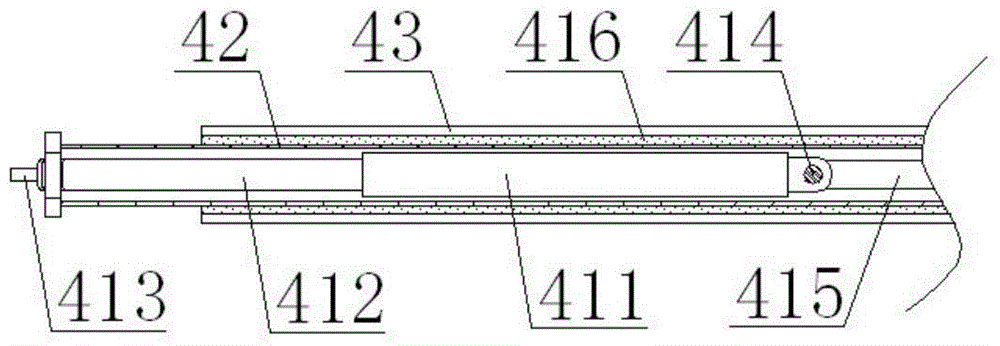

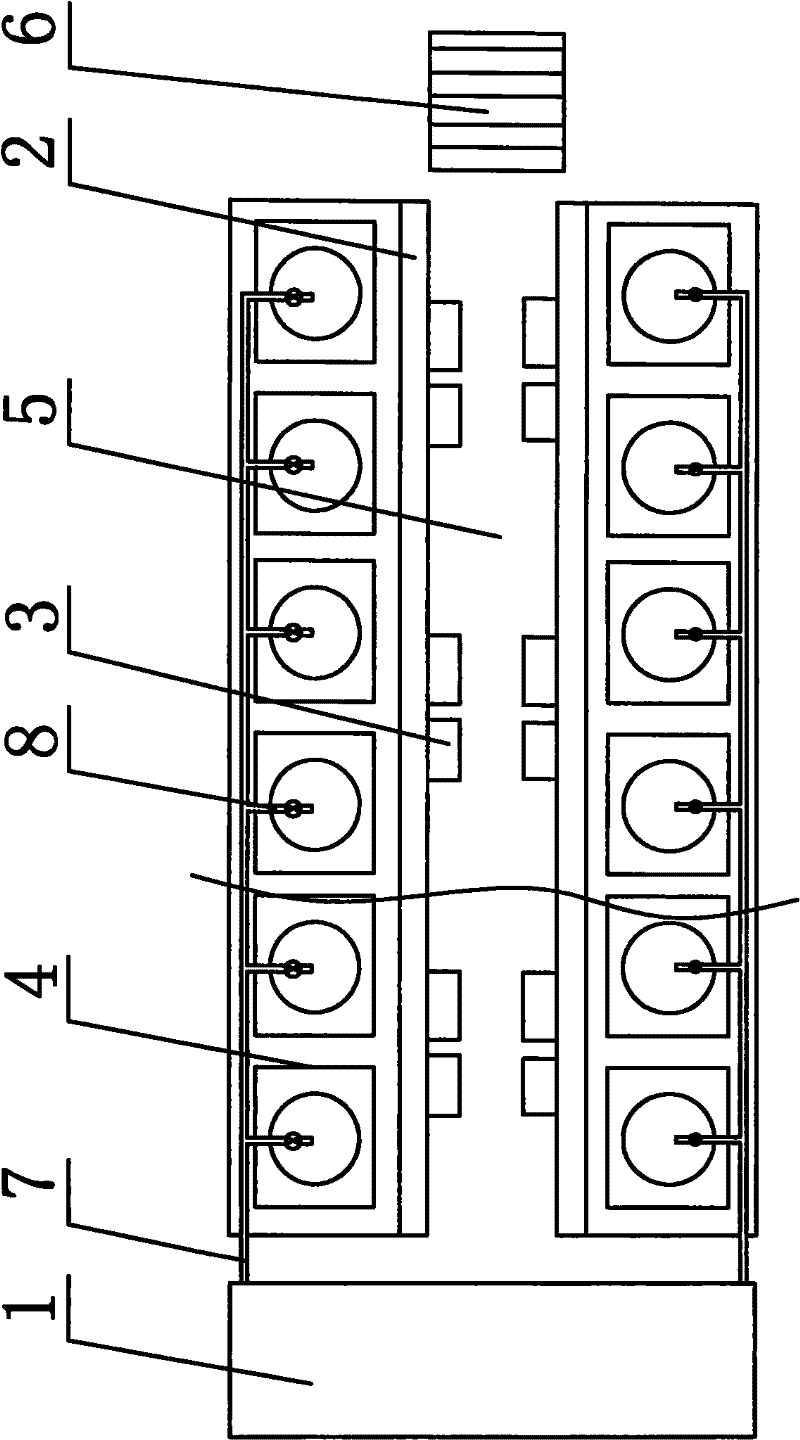

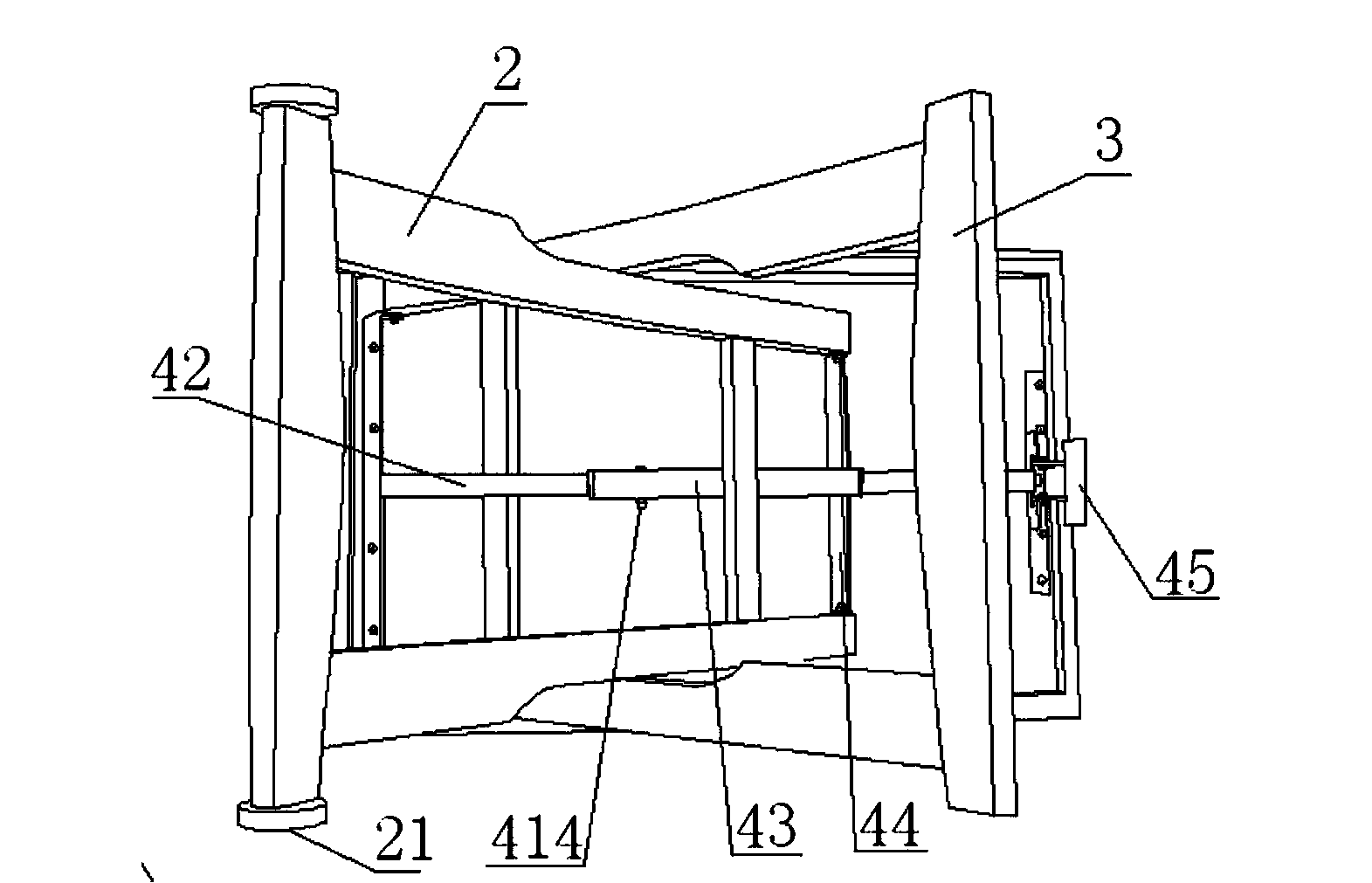

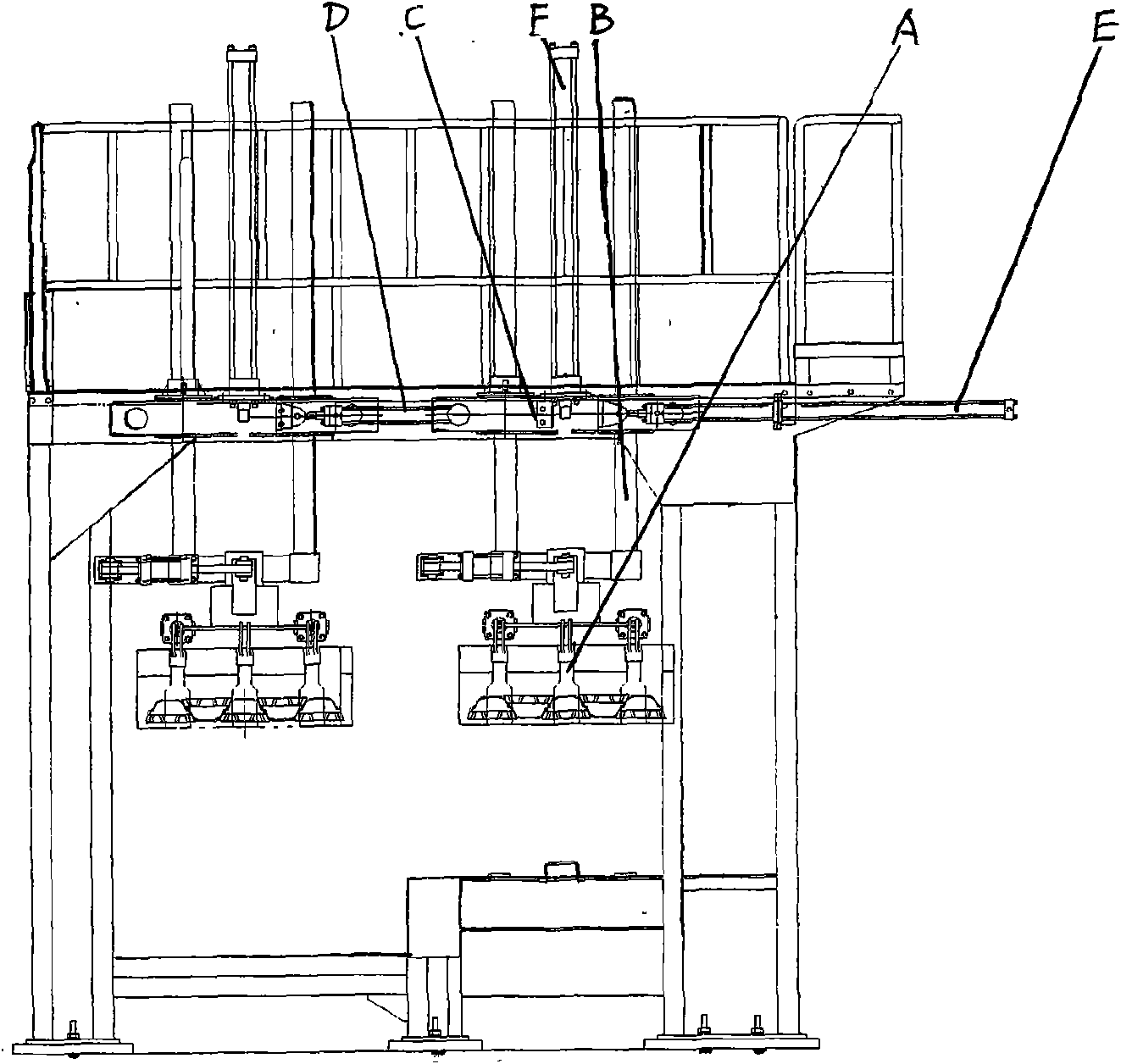

Jib type stacking device

InactiveCN101580181AStable structureGood rigidityStacking articlesDe-stacking articlesEngineeringCantilever

The invention provides a jib type stacking device, comprising a base (1), a revolving guide rail module (2) on the base, a lifting arm module (3) on the revolving guide rail module, a fixture module (4) on the lifting arm module, and a driving mechanism (5) for driving the revolving guide rail module, wherein, the revolving guide rail module includes a guide rail frame (2b) revolving along a revolving centre (2a), and a guide rail (2c) longitudinally arranged along the guide rail frame; the bottom end of the revolving centre (2a) is connected with the driving mechanism through a driving box (6); the lifting arm module includes a lifting cantilever (3a) transversely disposed on the guide rail frame (2b), a roller set (3b) installed on a cross beam of the lifting cantilever, and a driving cylinder component (3c) connected with the cross beam of the lifting cantilever; and the roller set (3b) is assembled and supported on the guide rail (2c). The invention has the advantages of stable structure, high stacking efficiency and flexibility.

Owner:KUNMING LISHEN HEAVY IND

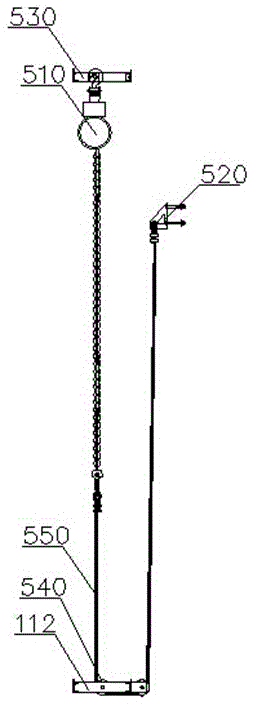

Building tower crane manned lifting basket

The invention relates to a building tower crane manned lifting basket which comprises a tower body, a manned basket body, two lifting guide columns and a winch. The two lifting guide columns are vertically fixed to one side of the interior of the tower body in parallel. The manned basket body is arranged in the tower body, holds the two lifting guide columns by means of multiple idler wheels arranged at one side outside the basket body, and the freedom degree of the basket body except vertical motion is limited. The winch is fixed to the upper portion of the tower body and fixedly connected with the manned basket body through connecting ends of steel wire ropes. According to the lifting basket, the winch drives the manned basket body to be lifted, climbing intensity of tower crane operators is eliminated, and the lifting basket is safe and fast to use. The lifting basket has the advantages of being reasonable in design, simple in structure and high in safety coefficient, and the lifting basket is lifted freely.

Owner:江苏锐凯机械有限公司

Method for arranging tomato cage in protected area

The invention relates to a method for arranging a tomato cage in a protected area, and belongs to the technical field of biological plantation. The method comprises the following steps of: arranging a load bearing steel cable for each tomato planting groove at a position which is 2.5-3 meters higher than the tomato planting groove in the protected area along the planting groove direction, and firmly fixing the two ends of each steel cable; manufacturing a double M-shaped yarn fixing device by using steel cable, wherein the middle of the yarn fixing device is wound with yarns for binding tomato stems, and the length of the yarns is determined by adding 3 to 5 meters to the estimated growth height of tomato plants; and when a tomato plant grows to the height of more than 30 centimeters and before the tomato plant begins to fall, putting the yarn fixing device on the load bearing steel cable above the plant, fixing the other end of a yarn to the stem base of the plant, winding the yarn around the plant by several circles, releasing the yarn along the growth of the plant to continuously wind the tomato stem so as to ensure that the tomato stem grows in a mode of moving in the horizontal direction, and removing old leaves on the base of the plant to make the positions of ripe fruits 1.5 meters away from the ground. The method has the advantages that: the method is simple and is favorable for growing tomato plants, and the fruits are convenient to pick.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com