Lifting clamping device for automobile window glass

A clamping device and window glass technology, which is applied in the installation of window glass, windshield, windows, etc., can solve the problems of high cost, complicated process, and difficult installation, and achieve low manufacturing cost, soft clamping force, and easy installation. The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a further description of the specific implementation with reference to the accompanying drawings:

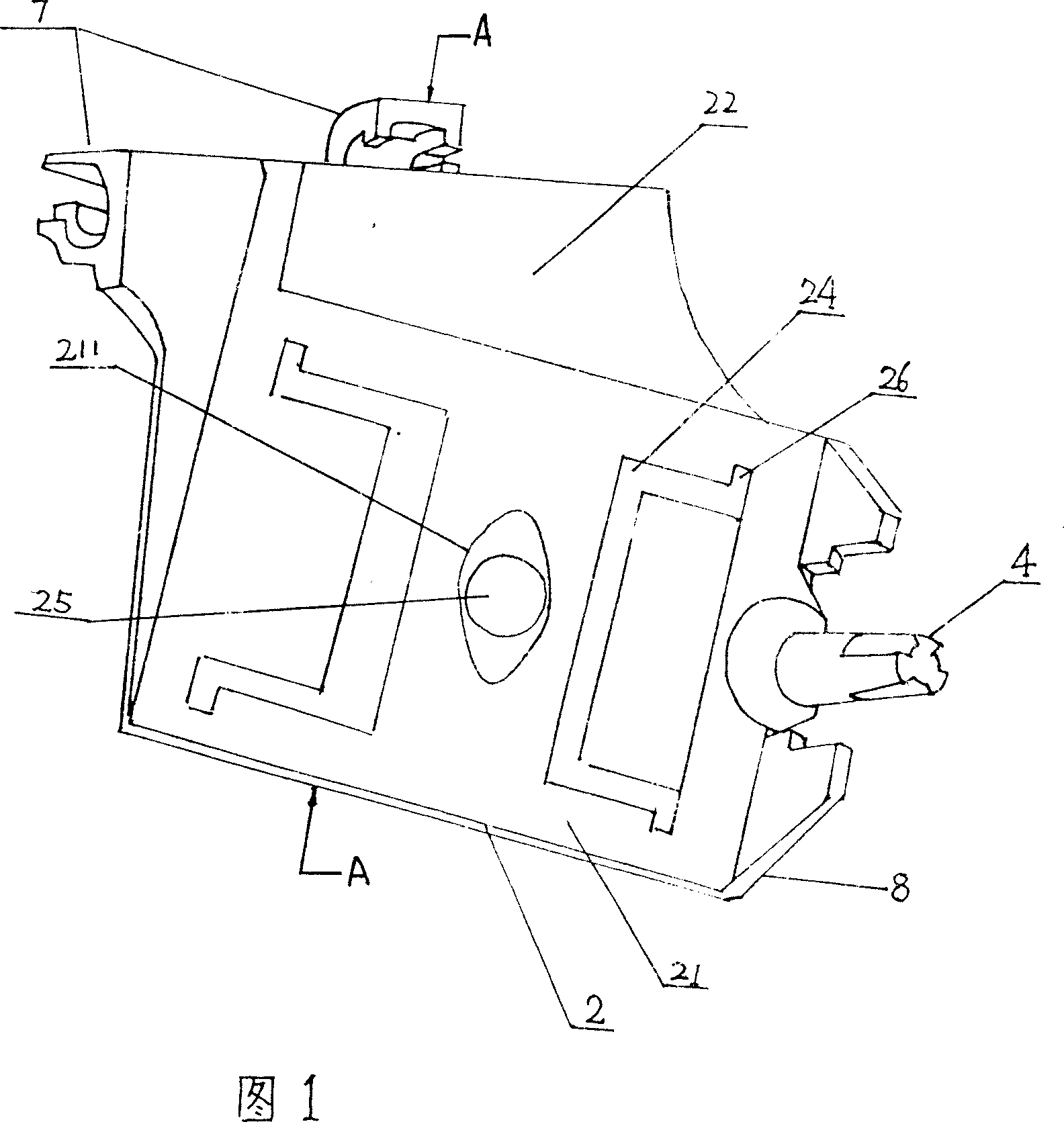

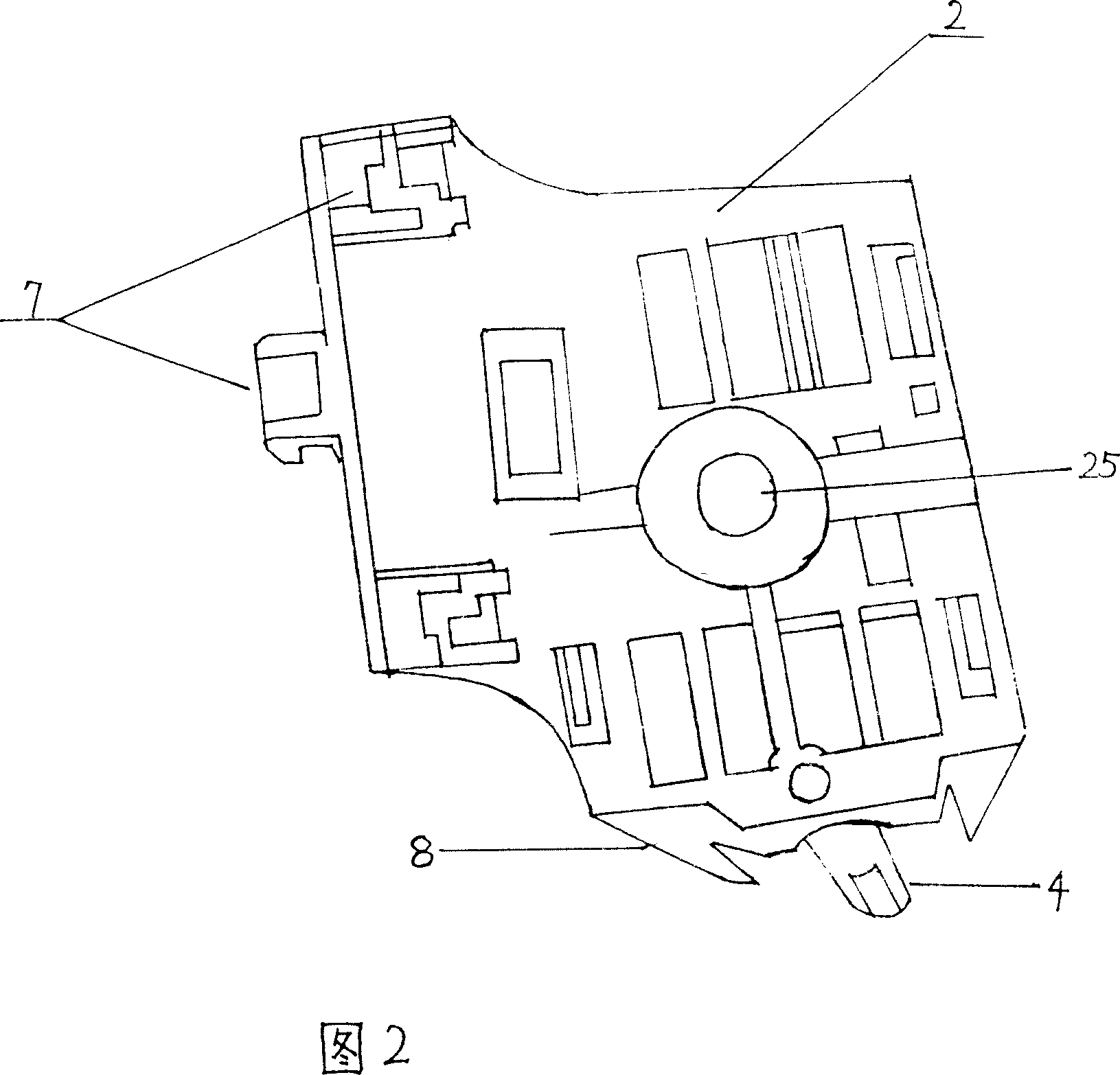

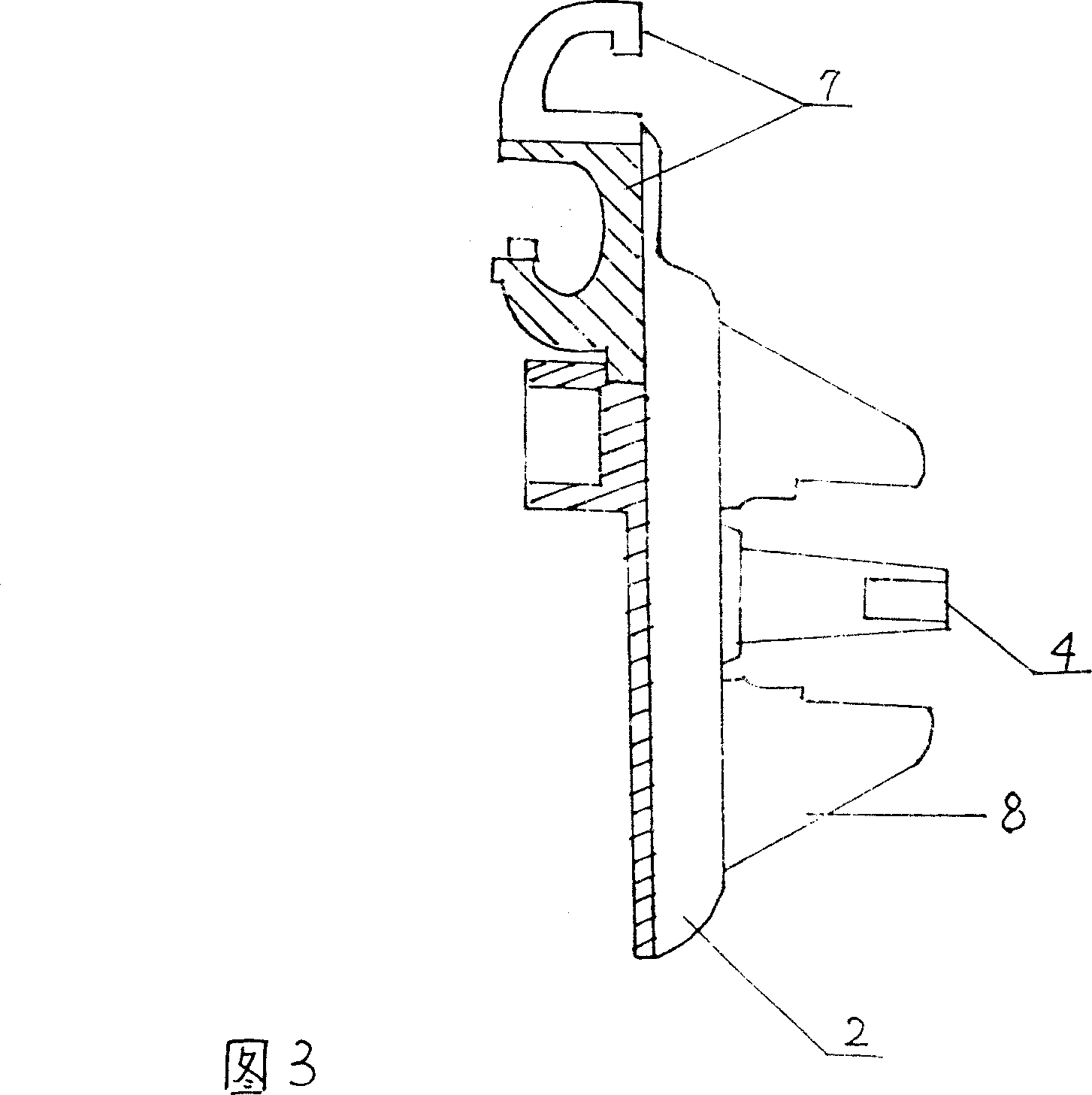

[0019] As shown in Figures 1, 2 and 4, the automotive window glass lifting and clamping device 1 includes a tray 2, a splint 3, two plastic clips 21, 31, and the middle part of the tray 2 is provided with a through hole 25. The bottom of the holding surface 22 is provided with a bracket hook 8 and a spline rod 4, and a draw-in groove 24 for installing the plastic clip 21 is also provided on the holding surface 22, on the side and the side opposite to the holding surface 22 A hook 7 connected with the lifting mechanism is provided;

[0020] A splint, the middle part of the splint 3 is provided with a screw hole 35 matching the through hole 25 on the tray 2, and a hook groove 10 matching the bracket hook 8 on the tray 2 is provided at the bottom of the clamping surface 32 The spline hole 9 matching the spline rod 4 on the tray 2 is also provided with a slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com