Framework landing self-moving type front telescopic advanced supporting device

An advanced support and self-moving technology, which is applied in the direction of hoisting devices, mine roof supports, mining equipment, etc., can solve the problems of cumbersome installation of advanced support, high labor intensity of workers, and high safety hazards, so as to reduce the danger of workers climbing high , Self-moving takes up less space and reduces the accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

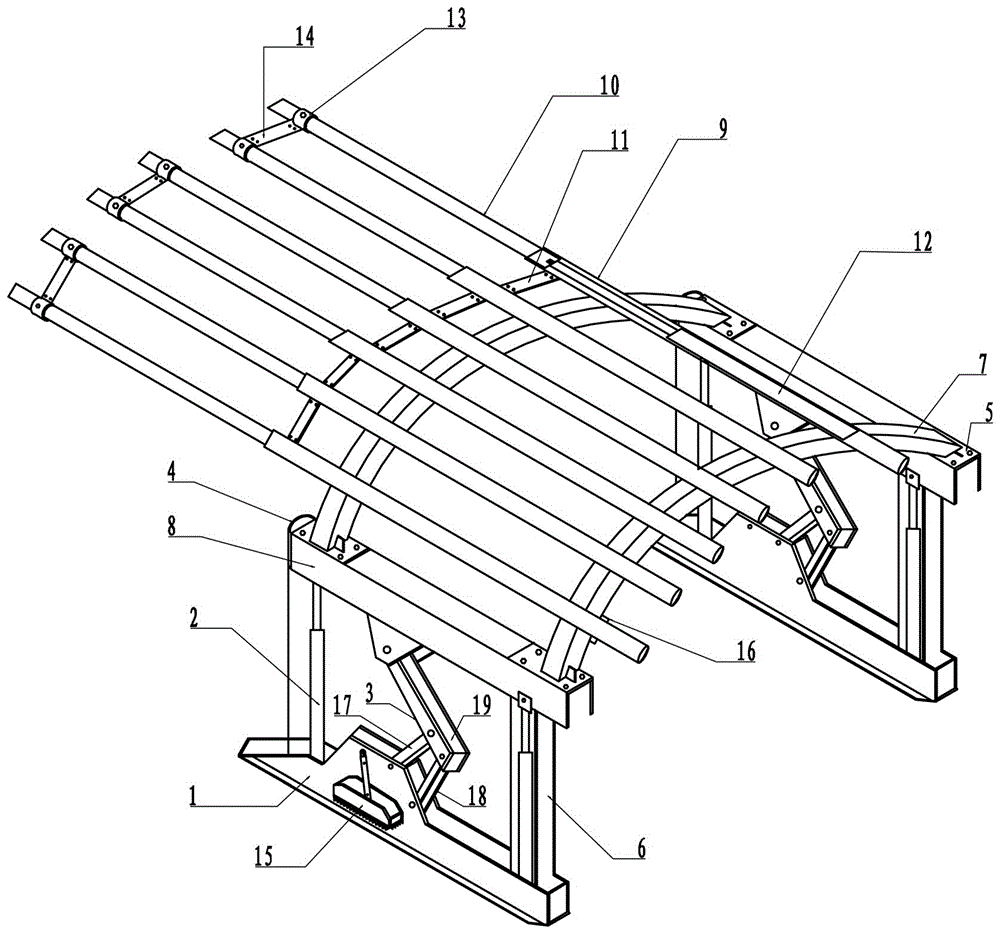

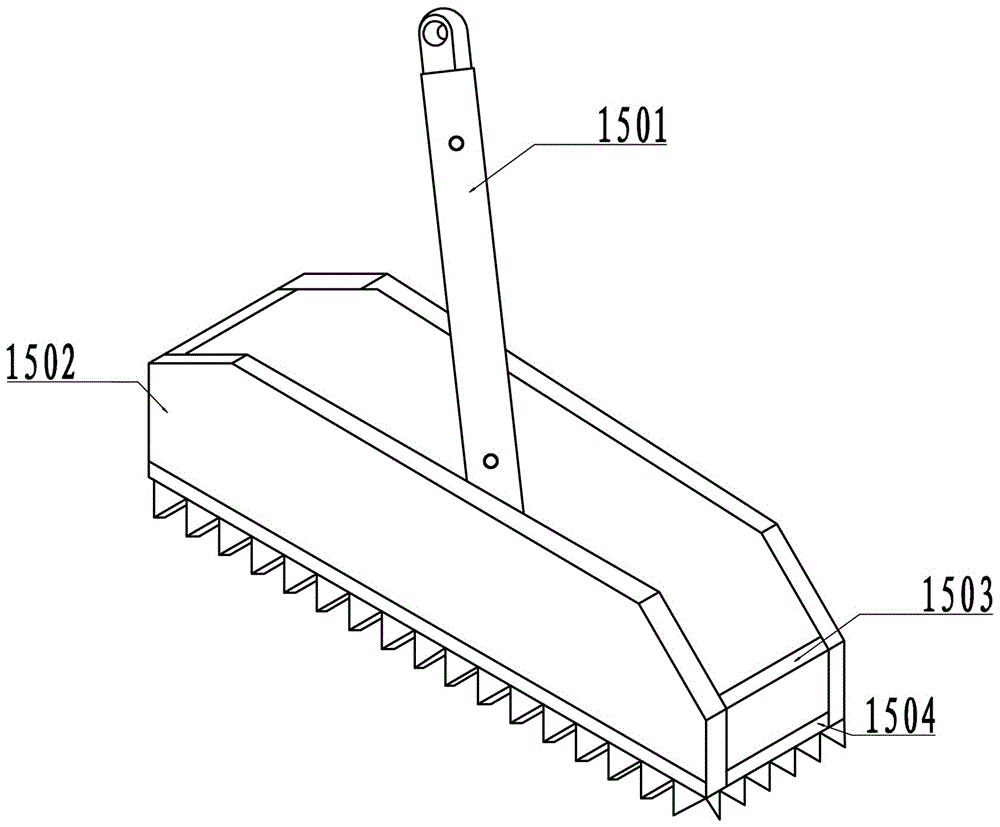

[0022] A frame landing self-moving front telescopic advance support device, such as figure 1 Shown among them includes: lifting base 1, lifting middle beam 8, stabilizing device 3, lifting oil cylinder 2, arched upper beam 7, self-moving device 15.

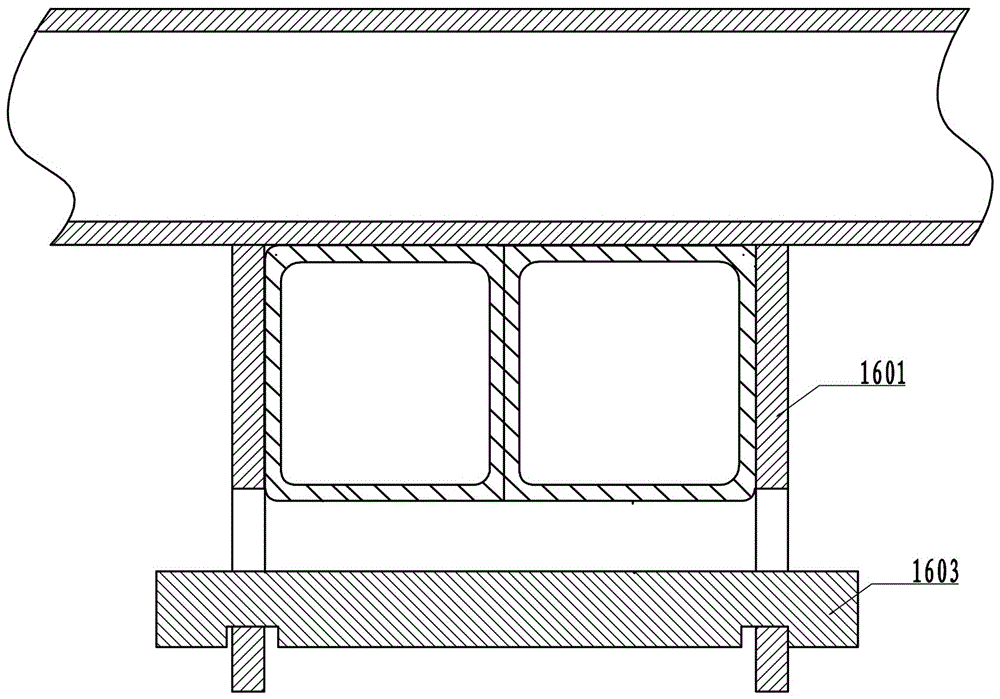

[0023] In this embodiment, the arched upper beam 7 is bolted to the bottom plate of the arched beam 5 and docked with the lifting middle beam 8. The two arched upper beams 7 are locked by the track tube 9 through the inclined brake structure 16, and the track tube 9 is installed inside. Telescopic oil cylinder 12, the connection of track pipe 9 is connected by rear balance plate 11, and telescopic oil cylinder 12 is controlled to connect telescopic arm 10.

[0024] In this embodiment, the front section of the telescopic arm 10 is connected between the two telescopic arms 10 by a balance plate 14 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com