A labor-saving device for disassembling and assembling the main transformer clamp and its application method

A main wire and wire clip technology, applied in transportation and packaging, thin material handling, conveying filamentous materials, etc., can solve the problems of force on the removal bolts, difficult to remove, time-consuming and labor-intensive, etc., to ensure stability, convenient operation, The effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

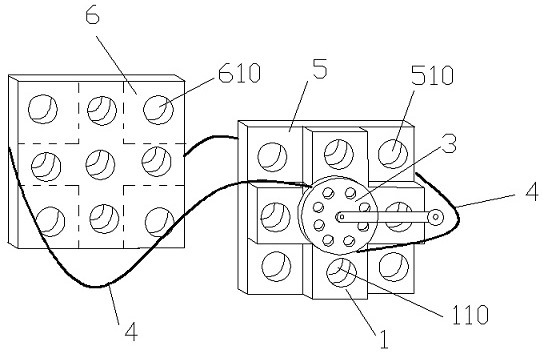

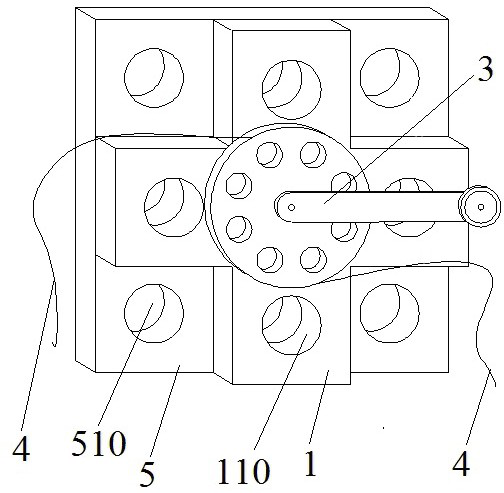

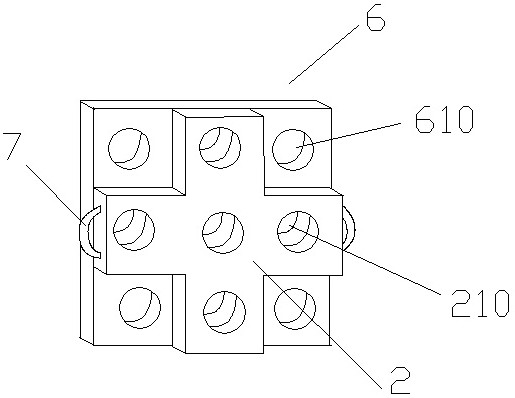

[0020] Embodiment 1: as Figure 1~7 As shown, in this embodiment, a labor-saving device for disassembling and assembling the main transformer clamp is provided, which includes a pair of steel plates, which include a first steel plate 1 fixed on the main clamp 5 and a first steel plate 1 fixed on the side clamp 6 The second steel plate 2 of the first steel plate is provided with a hand-operated take-up wheel 3 in the middle of the first steel plate, and the hand-operated take-up wheel is provided with steel plates extending to both sides of the second steel plate and fixedly connected to both sides of the second steel plate. Line 4.

[0021] In this embodiment, the first steel plate 1 has several evenly distributed first through holes 110, and the main clamp 5 has several evenly distributed first threaded holes 510 corresponding to the first through holes, and the bolts are sequentially The main clamp is fixedly connected with the first steel plate through the first through ho...

Embodiment 2

[0029] Embodiment 2: On the basis of Embodiment 1, in order to make the device safer to use, a retractor can also be provided inside the hand-cranked reel, and one end of the steel rope can be connected to the output end of the retractor. , is the prior art, referring to a retractor with an emergency locking function, which is mainly used in automobile safety belts.

[0030] The retractor used in this device can give full play to the emergency locking function of the retractor, which greatly improves the safety performance of the device. Such a setting can prevent the winding pressure of the main line clamp and the side line clamp from being too large, causing the hand-cranked line to recycle. The speed of the bullet is too fast, which may cause injury; when paying off the line, the retractor can limit the speed of the line, and when the pressure of the line is too high and the speed cannot be controlled, the hand-cranked take-up wheel will be blocked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com