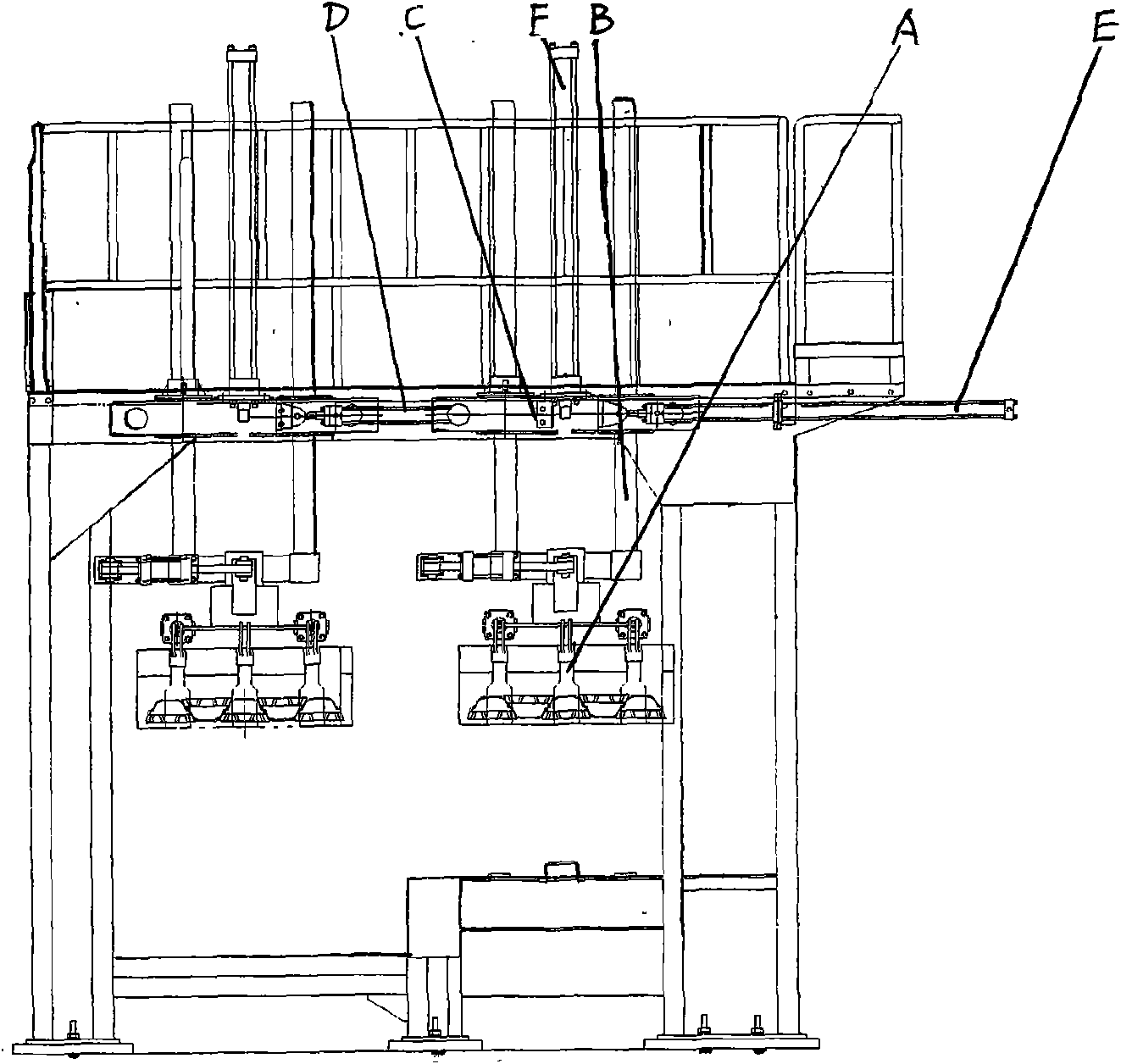

Jib type stacking device

A swivel-arm type stacking technology, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve problems such as difficult to control the movement of trolleys stably, and achieve high-speed operation, reduce operation inertia, and stack The effect of stack stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

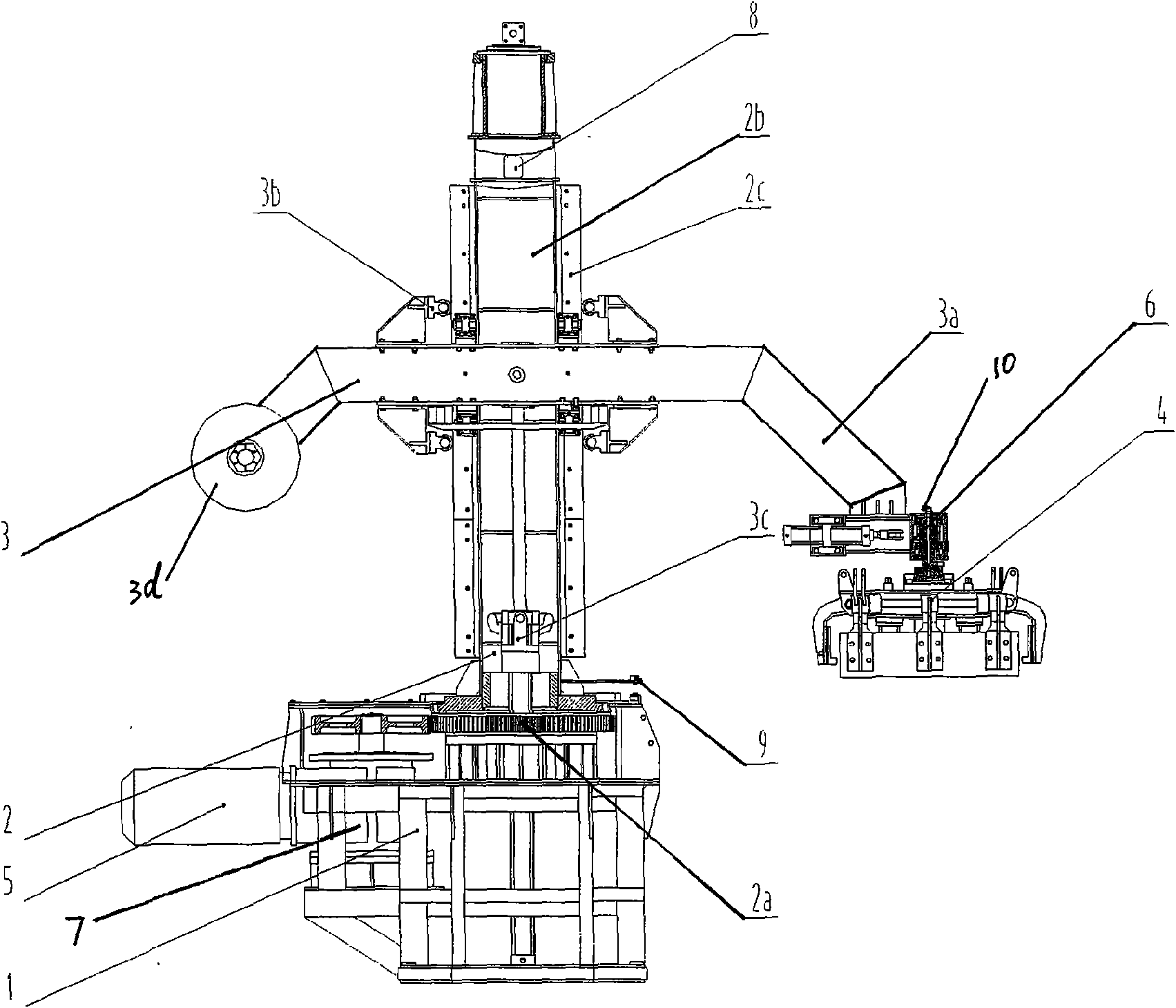

[0015] like figure 2 As shown, the present invention includes a base 1, a slewing guide rail assembly 2 mounted on the base, a lifting arm assembly 3 installed on the slewing guide rail assembly 2, and a clamp assembly 4 installed on the front end of the lifting cantilever 3a through a rotating member 6 to drive the slewing guide rail Drive mechanism 5 of assembly 2. The drive mechanism 5 is an asynchronous servo motor. The slewing guide rail assembly 2 includes a guide rail frame 2b rotatable along the slewing center 2a, and a guide rail 2c installed along the longitudinal direction of the guide rail frame. The lifting arm assembly 3 includes a lifting cantilever 3a laterally installed on the guide rail frame 2b, a roller group 3b installed on the lifting cantilever beam, and a driving cylinder member 3c connected with the lifting cantilever beam. The driving cylinder member 3c is controlled by a hydraulic proportional valve. High speed cylinder. In order to maintain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com