Apparatus and methods for preventing rotational slippage between a vertical shaft and a support structure for a semiconductor wafer holder

a technology of vertical shaft and support structure, which is applied in the direction of coating, metallic material coating process, chemical vapor deposition coating, etc., can solve the problems of shaft and spider socket not being precisely aligned, surface slippage with respect to one another, and deformation of mating surfaces, etc., to prevent rotational slippage, prevent rotational slippage of susceptor holder, prevent the effect of rotational slippage of the substrate holder suppor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

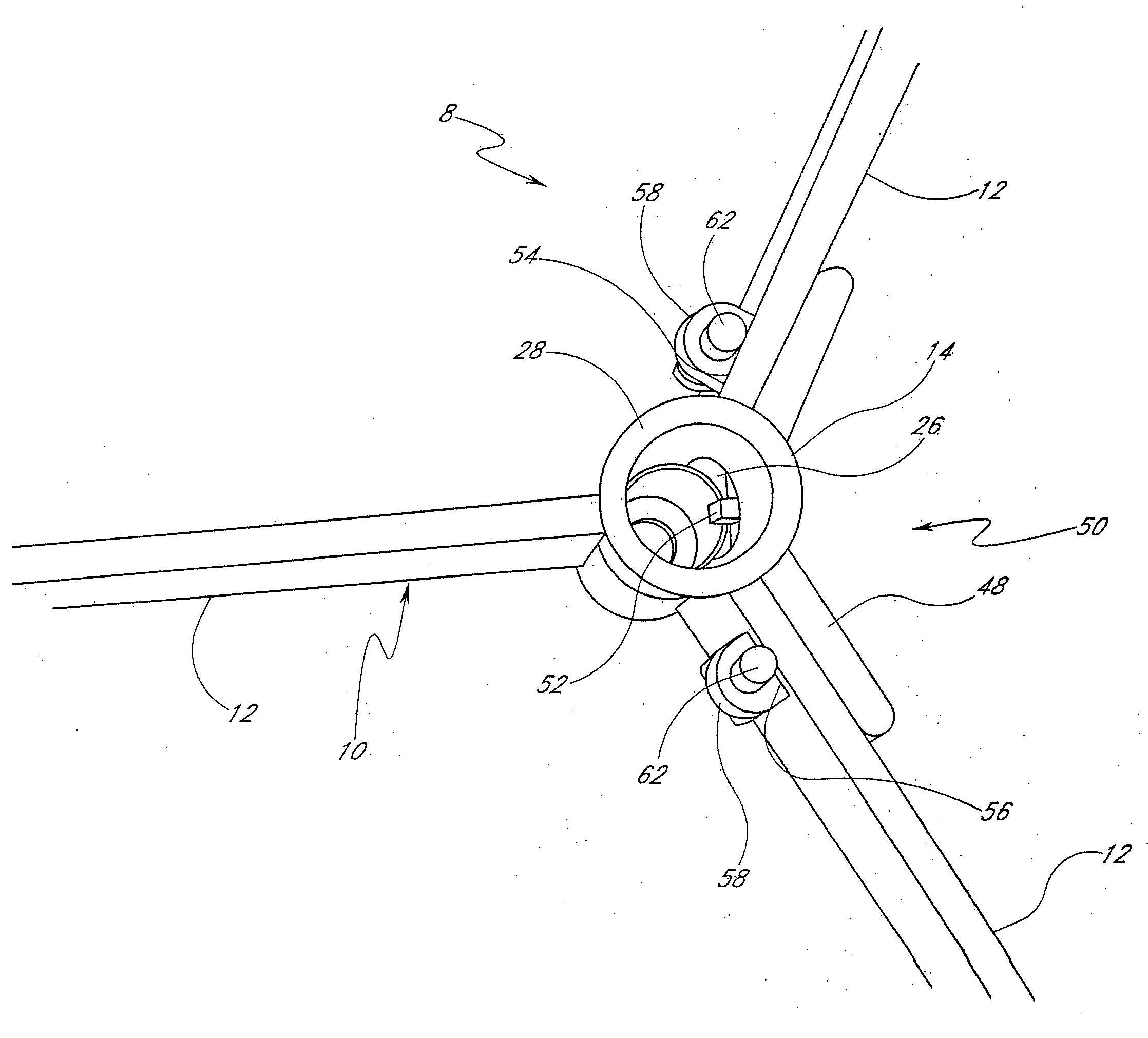

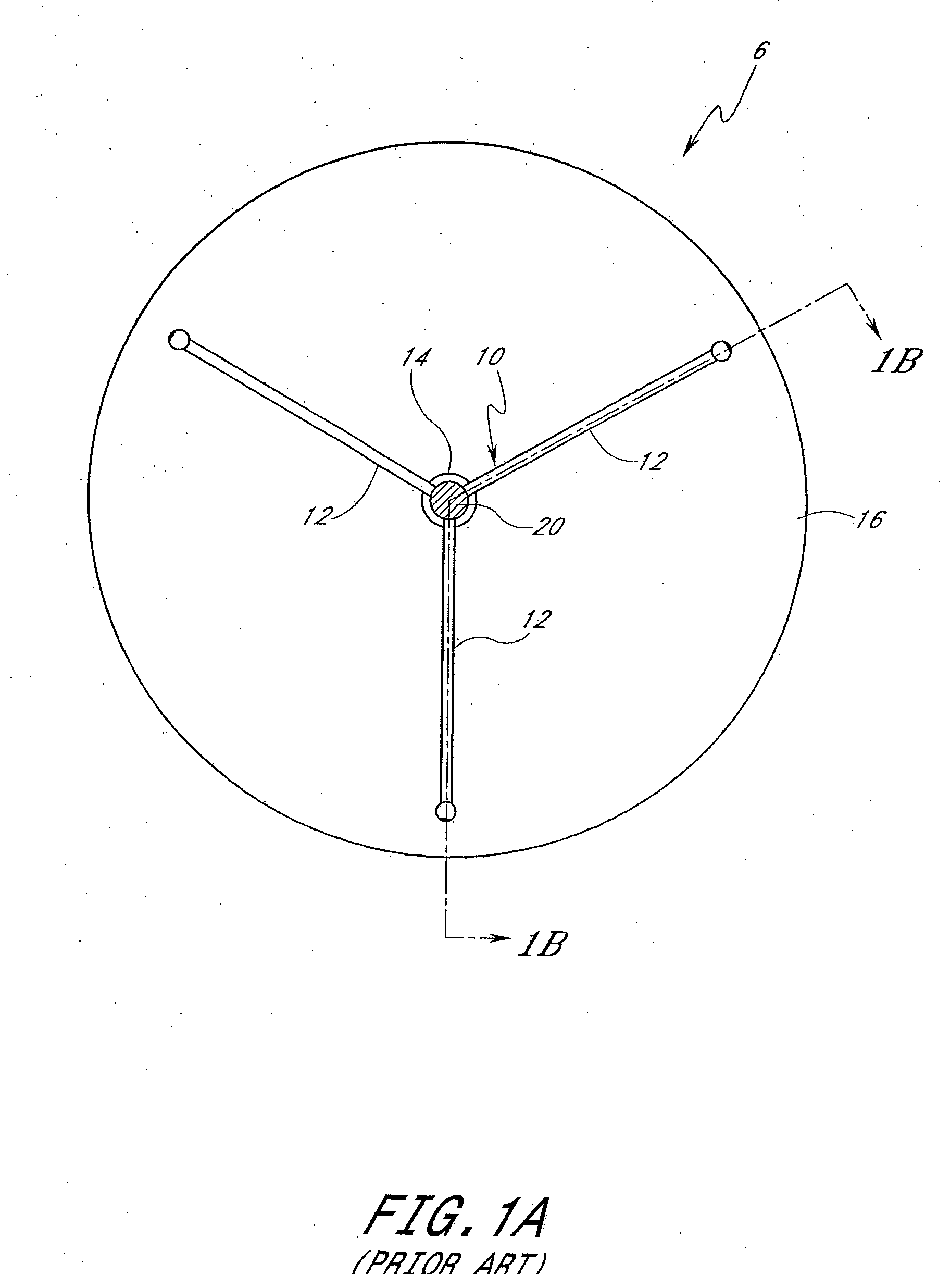

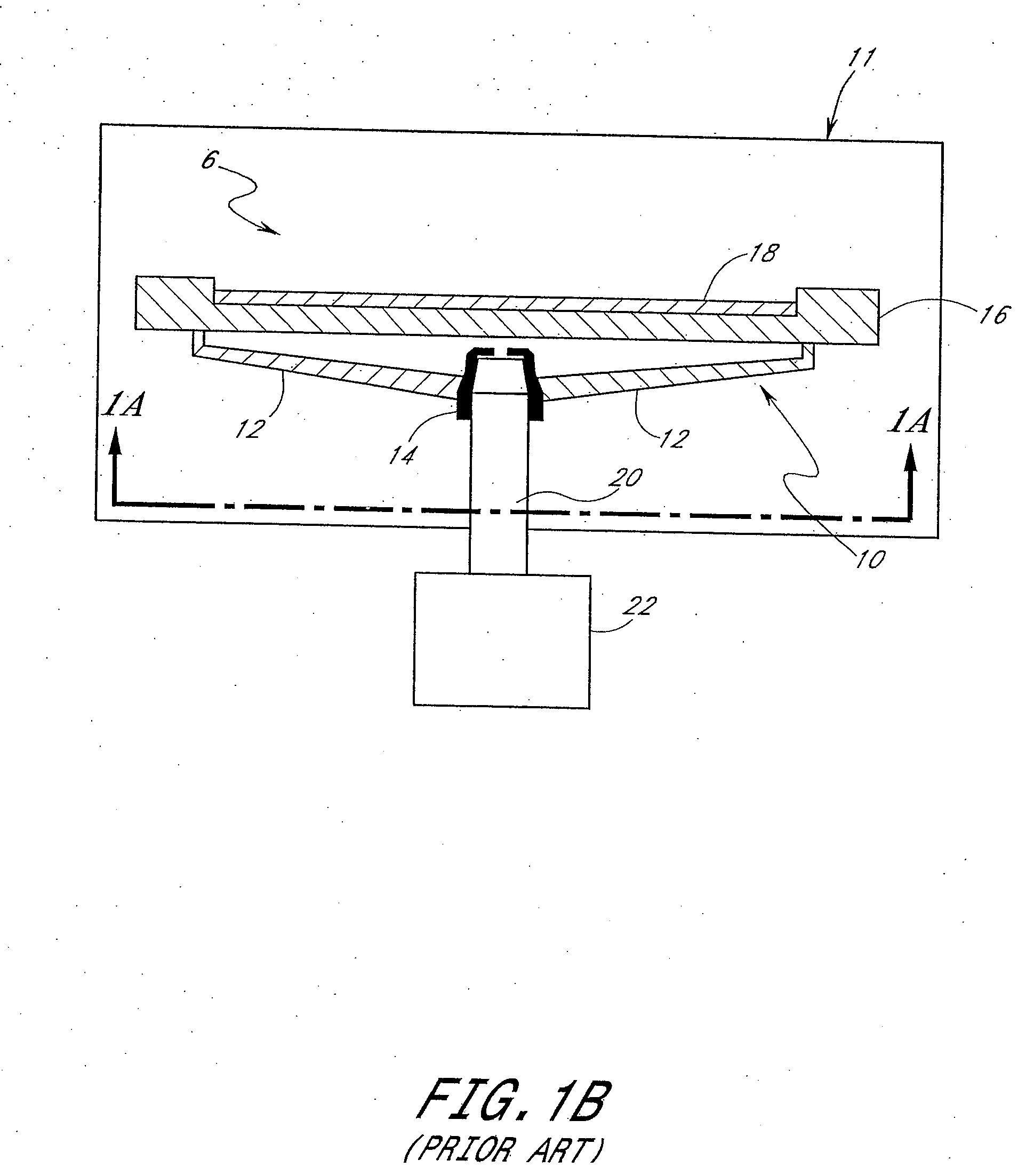

[0042]FIGS. 1A and 1B are schematic depictions of a support assembly 6 of the prior art. A substrate (or wafer) holder support, or spider 10, is shown in a reaction chamber 11. The spider 10 has a plurality of support arms 12 extending radially outward and upward from a central socket 14 to support the underside of a substrate holder 16, such as a susceptor. The substrate holder 16 rests upon the support arms 12 and is configured to hold a substrate or wafer 18. Underneath the spider 10, an elongated shaft 20 is mated with the spider socket 14, providing a coupling that allows the spider 10 to be rotated when the elongated shaft 20 is rotated by a motor 22. As explained above in the Background section, this coupling does not satisfactorily prevent relative rotation between the shaft 20 and the socket 14, particularly when the mass of the system has increased by movement from 200 mm wafers to 300 mm wafers. Also, as the mating surfaces rub against one another and deform, wobbling of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radiant energy | aaaaa | aaaaa |

| rotation | aaaaa | aaaaa |

| deposition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com