Tank body multi-angle polishing grinding machine

A multi-angle, polishing technology, used in grinding/polishing equipment, grinders, belt grinders, etc., can solve the problems of inconvenient operation, high cost, long processing time, etc., to reduce equipment investment, fine crystal size, Good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

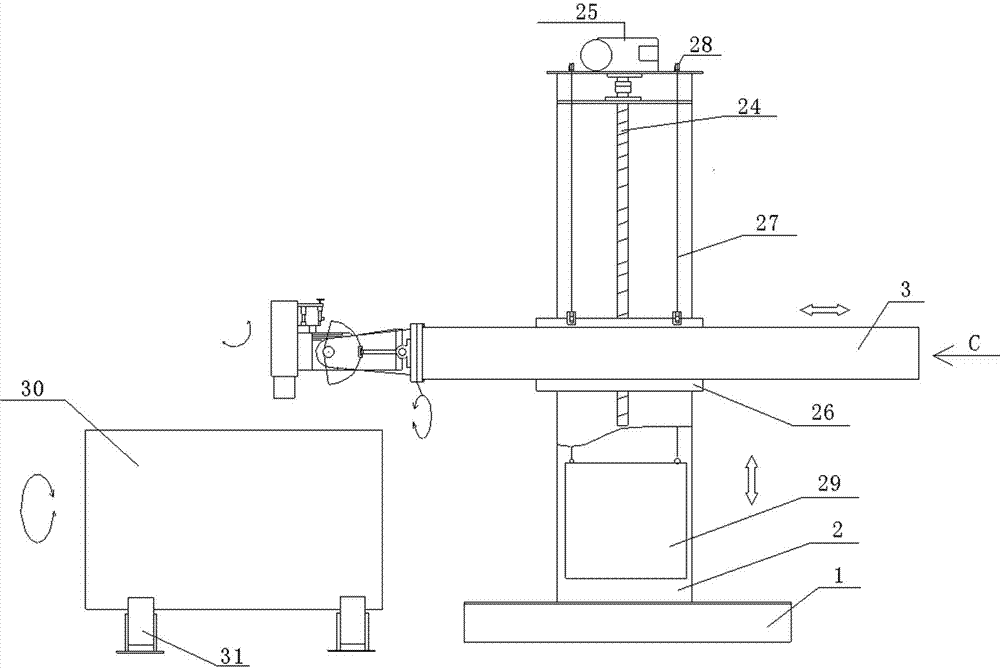

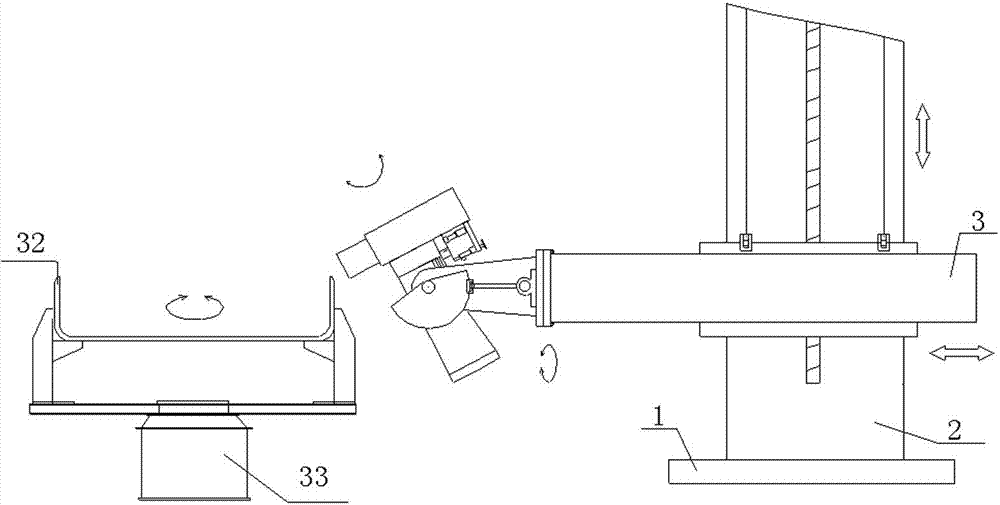

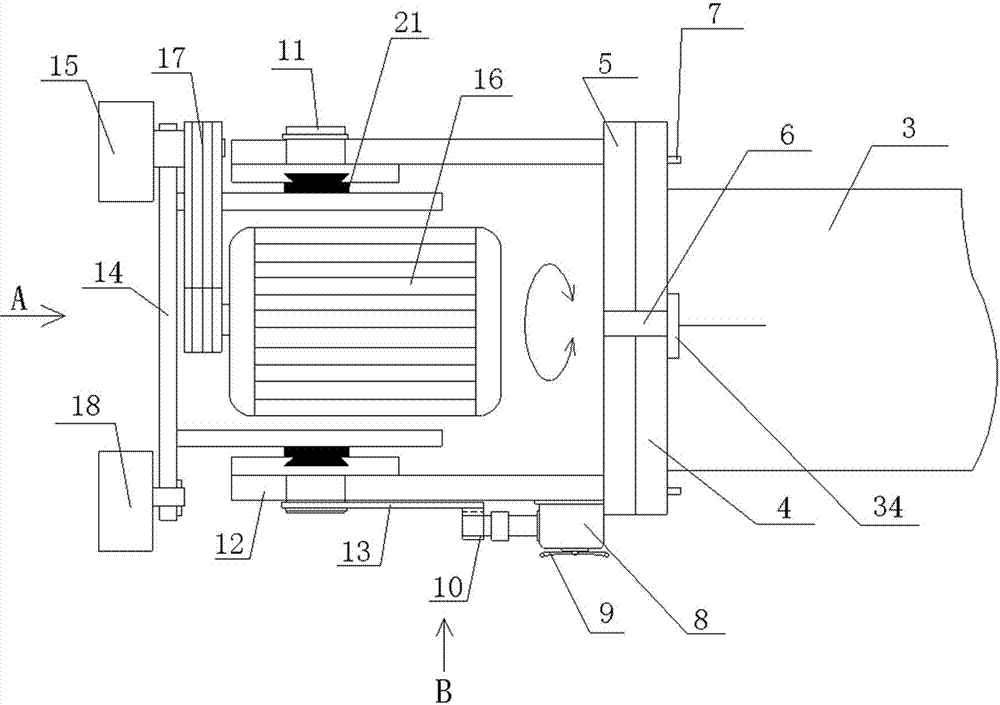

[0031] Such as figure 1 , 2 , 3, 4, 5, 6, 7 and 8, the present invention includes a base 1, the base 1 is provided with a vertical column 2, the column 2 is provided with a horizontal cross arm 3, and the cross arm 3 passes through the lifting device along the The column 2 lifts up and down, and the cross arm 3 moves left and right along the column 2 through the left and right moving device. The left end of the cross arm 3 is provided with an abrasive belt grinding head mounting seat (not marked in the figure); the abrasive belt grinding head mounting seat passes through the first rotating shaft 6 It is rotatably connected with the cross arm 3, and the abrasive belt grinding head mounting seat rotates around the circumference of the cross arm 3; the abrasive belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com