Engine cylinder head robot automatic burr removal workstation

A technology of engine cylinder head and robot, which is applied in the direction of grinding automatic control device, manufacturing tool, grinding workpiece support, etc., can solve the problems such as difficult to guarantee the quality of burr removal, low burr efficiency, and affecting the tact and efficiency of the whole line processing, etc. To achieve the effect of ensuring product consistency, improving product quality, and recovering equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

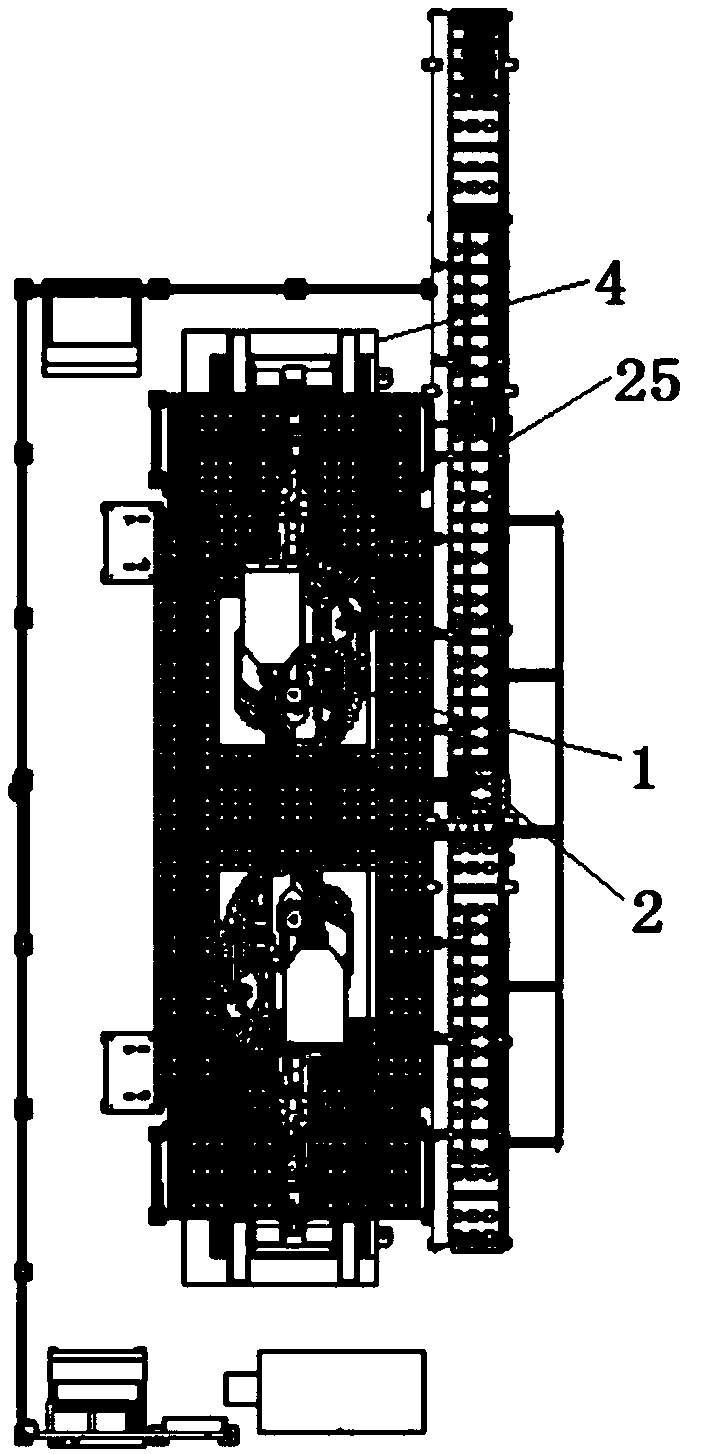

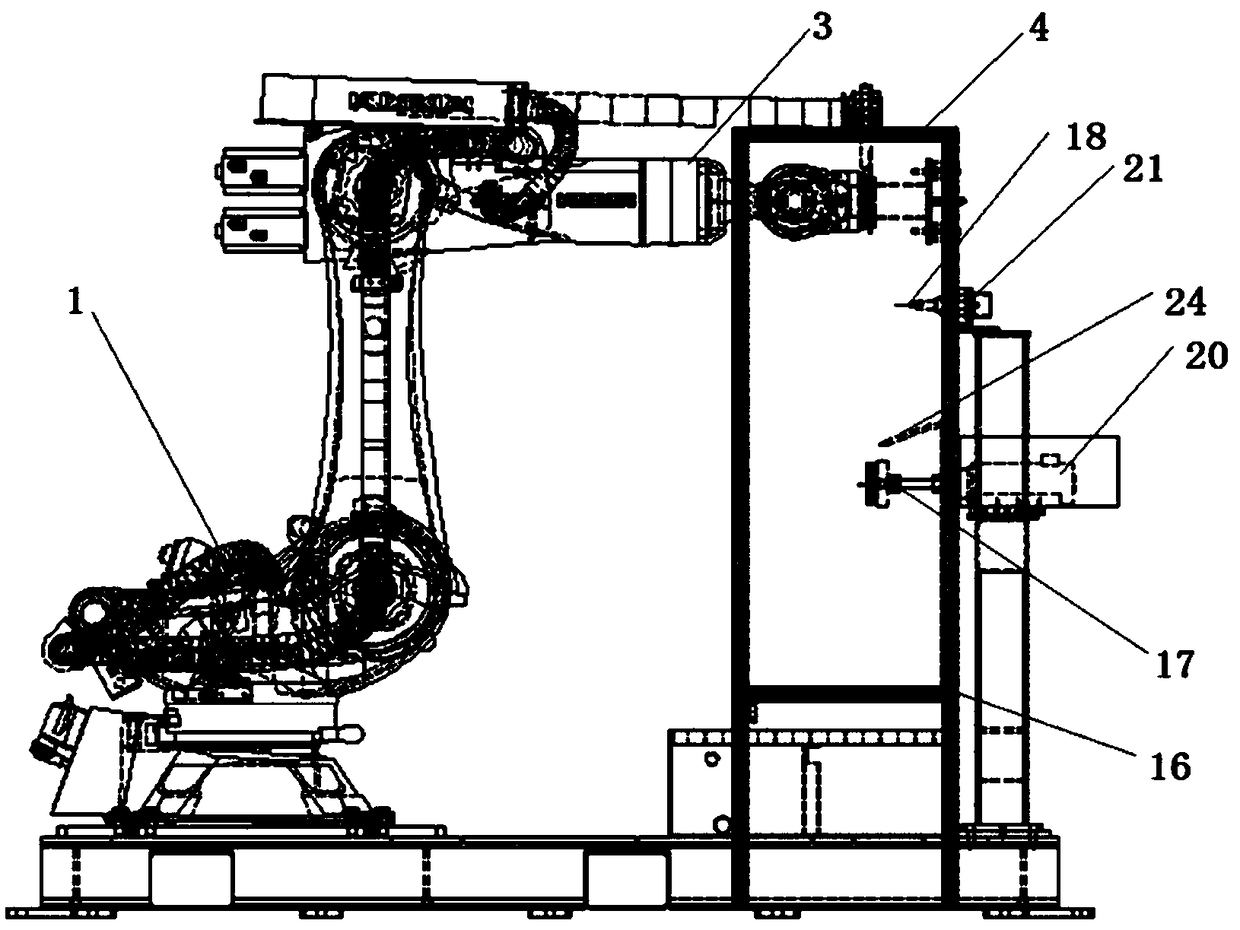

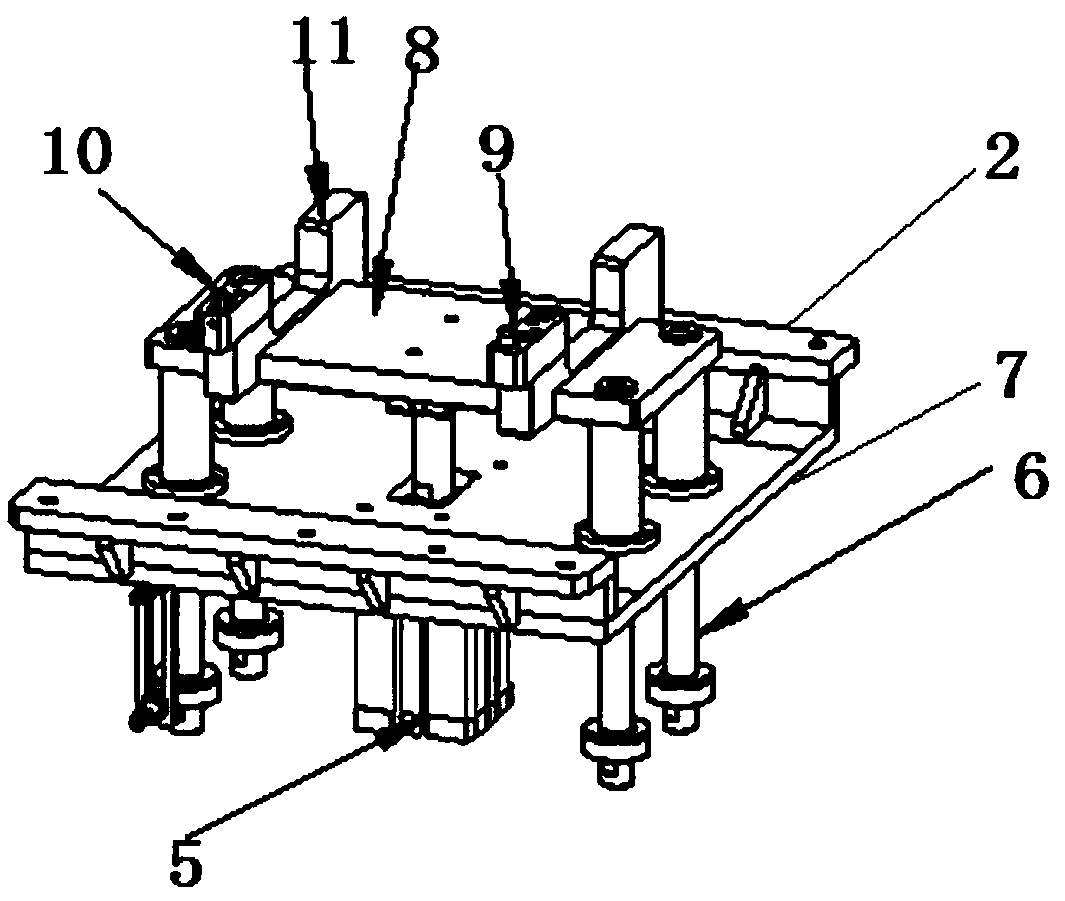

[0055] In a preferred embodiment, the engine cylinder head robot automatic deburring workstation includes two robots 1 , a jacking positioning device 2 , two cylinder head gripper assemblies 3 and two deburring tool assemblies 4 .

[0056] In a preferred embodiment, the control system is connected with the jacking cylinder 5 for controlling the lifting of the jacking cylinder 5; the control system is also connected with the workpiece sensor 15, the tension pin 13, the robot 1, the first electric spindle 20, and the floating spindle respectively. 21. The second electric spindle 22 is connected, and is used for shrinking the tension positioning pin 13 when the workpiece sensor 15 senses that there is no cylinder head on the cylinder head gripper assembly 3; it is also used to control the first electric spindle 20, the floating spindle 21, The second electric spindle 22 and the robot 1 use the disc brush 17, the rotary file 18 and the brush 19 to deburr the cylinder head.

[0057...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com