Abrasive particle jet assisted ultrahard fine abrasive material grinding wheel ultraprecise grinding method

A technology of superabrasives and abrasive jets, which is applied in the direction of grinding workpiece supports, grinding/polishing equipment, and machine tools suitable for grinding the edge of workpieces, etc. Field limitations and other issues, achieve the effect of simple grinding equipment and process, realize sharpening and contour dressing, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

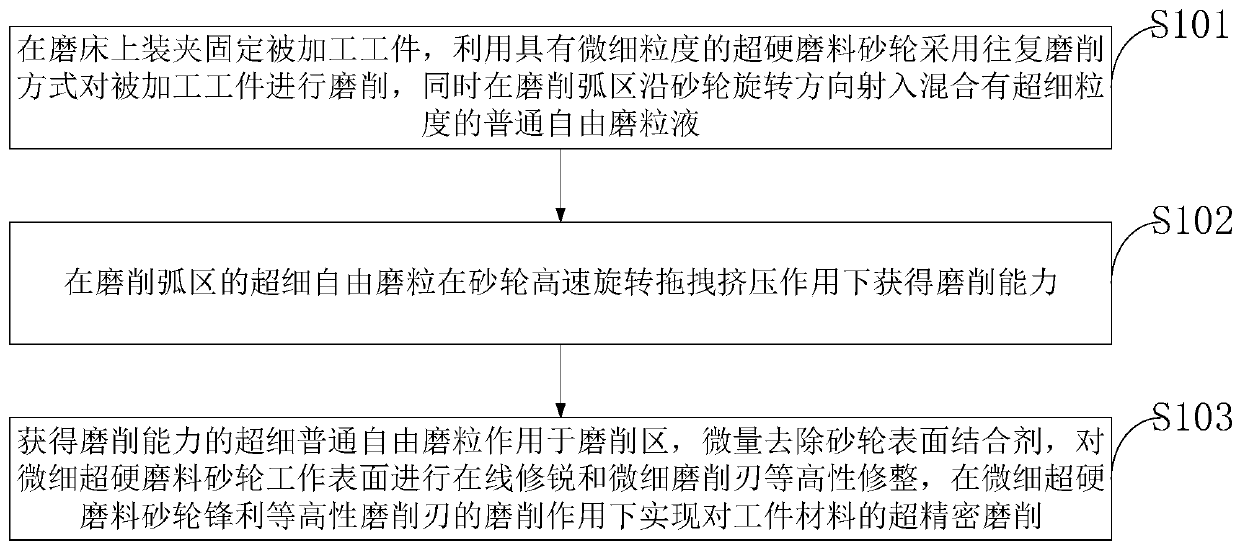

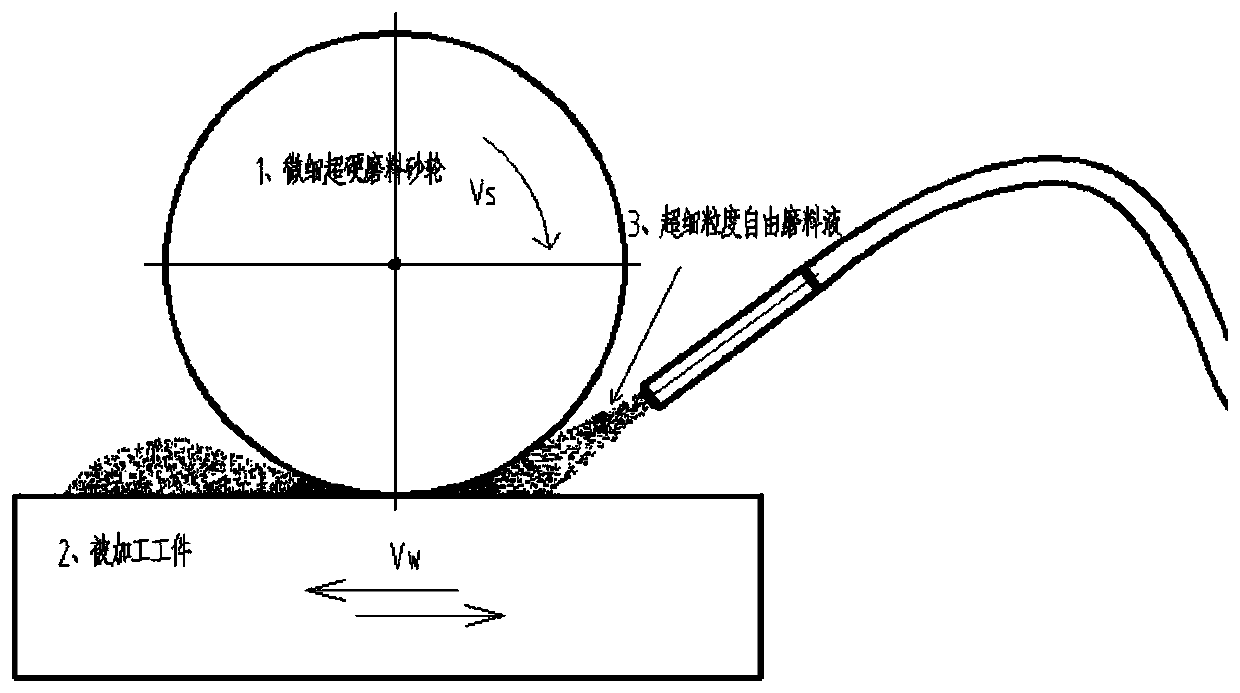

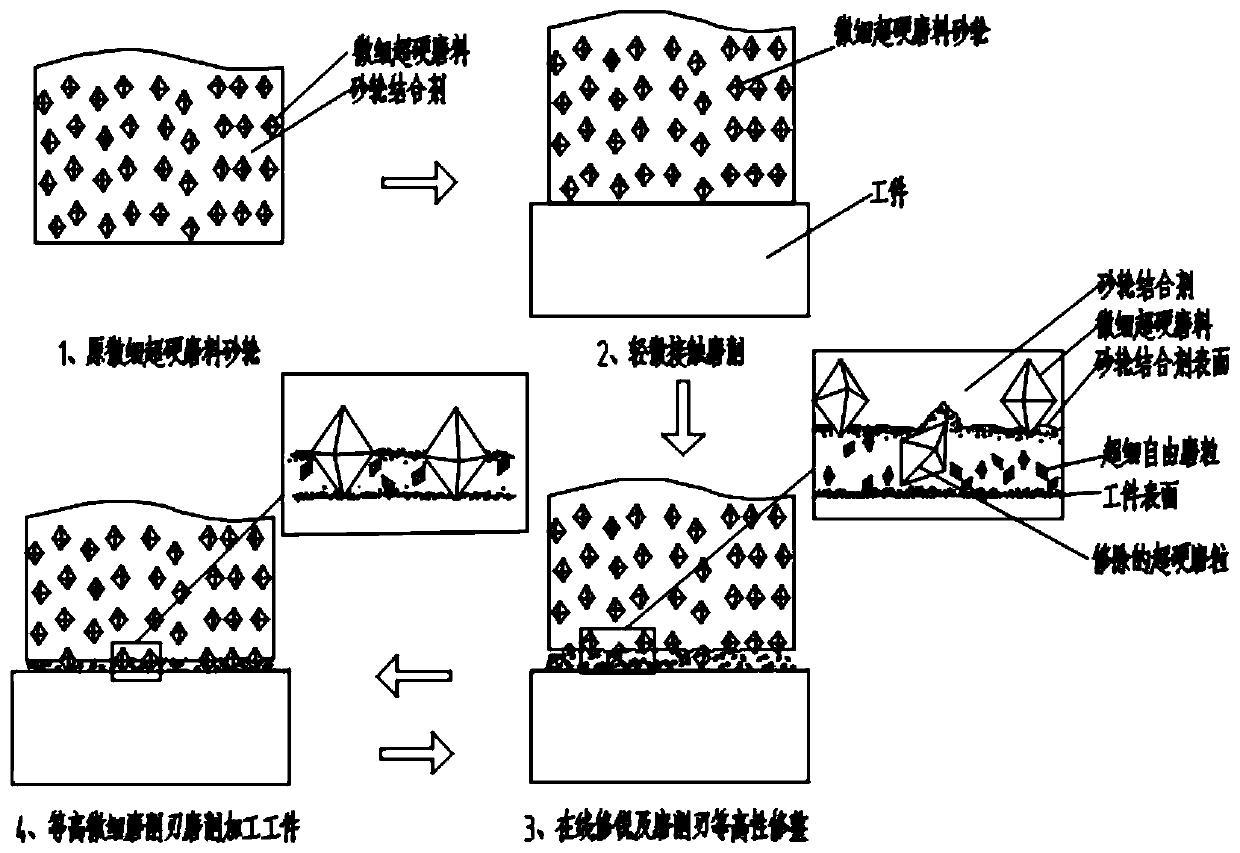

[0049] Ultra-fine abrasive jet assisted ultra-fine super-abrasive grinding wheel ultra-precision grinding method and principle such as figure 2 As shown, the fine superabrasive grinding wheel 1 is a ceramic, resin or metal bonded superabrasive grinding wheel, which is a bonded abrasive tool made of fine superabrasives and bonds, with a particle size range of w15-w0.5. The workpiece 2, that is, the workpiece to be processed, can be made of metal or ceramics. The ultra-fine ordinary free abrasive liquid 3 is a water-based grinding coolant containing ultra-fine silicon carbide or corundum abrasives and added with a dispersant, and the particle size range of the ultra-fine ordinary free abrasive particles is within the range of the fine superabrasive grinding wheel 1 / 5-1 / 3 times of the superabrasive particle size, the abrasive particle concentration range in the abrasive liquid is 2-20% of the volume ratio, determined according to the required grinding conditions.

[0050] The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com