Novel energy-saving mixer-mill

A mixed mill, a new type of technology, is applied in the direction of mechanical equipment, bearings, bearing components, etc., which can solve the problems of high maintenance costs, poor fine grinding ability, and high energy consumption in operation, and achieve large bearing capacity, good centering performance, The effect of low energy consumption in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

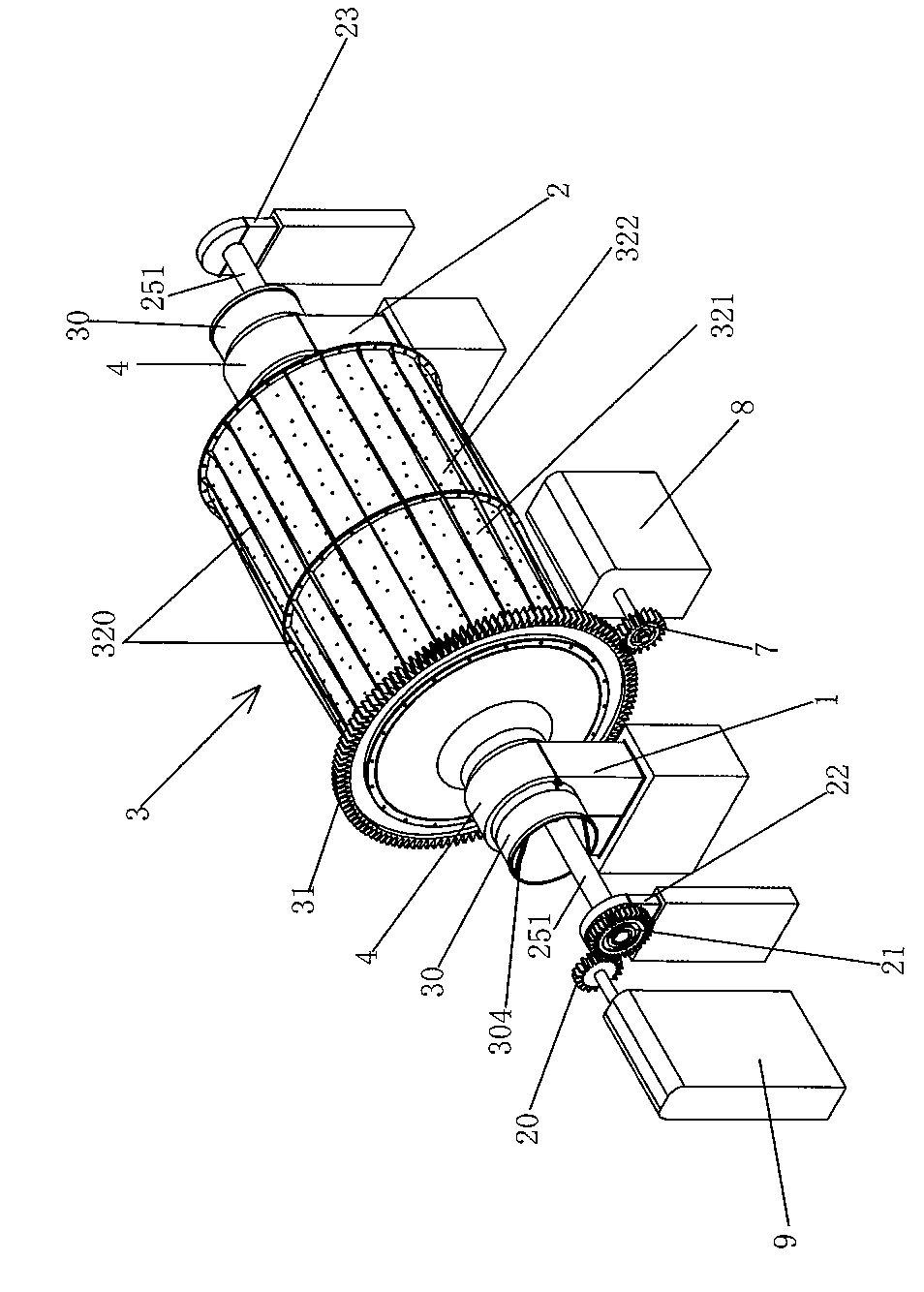

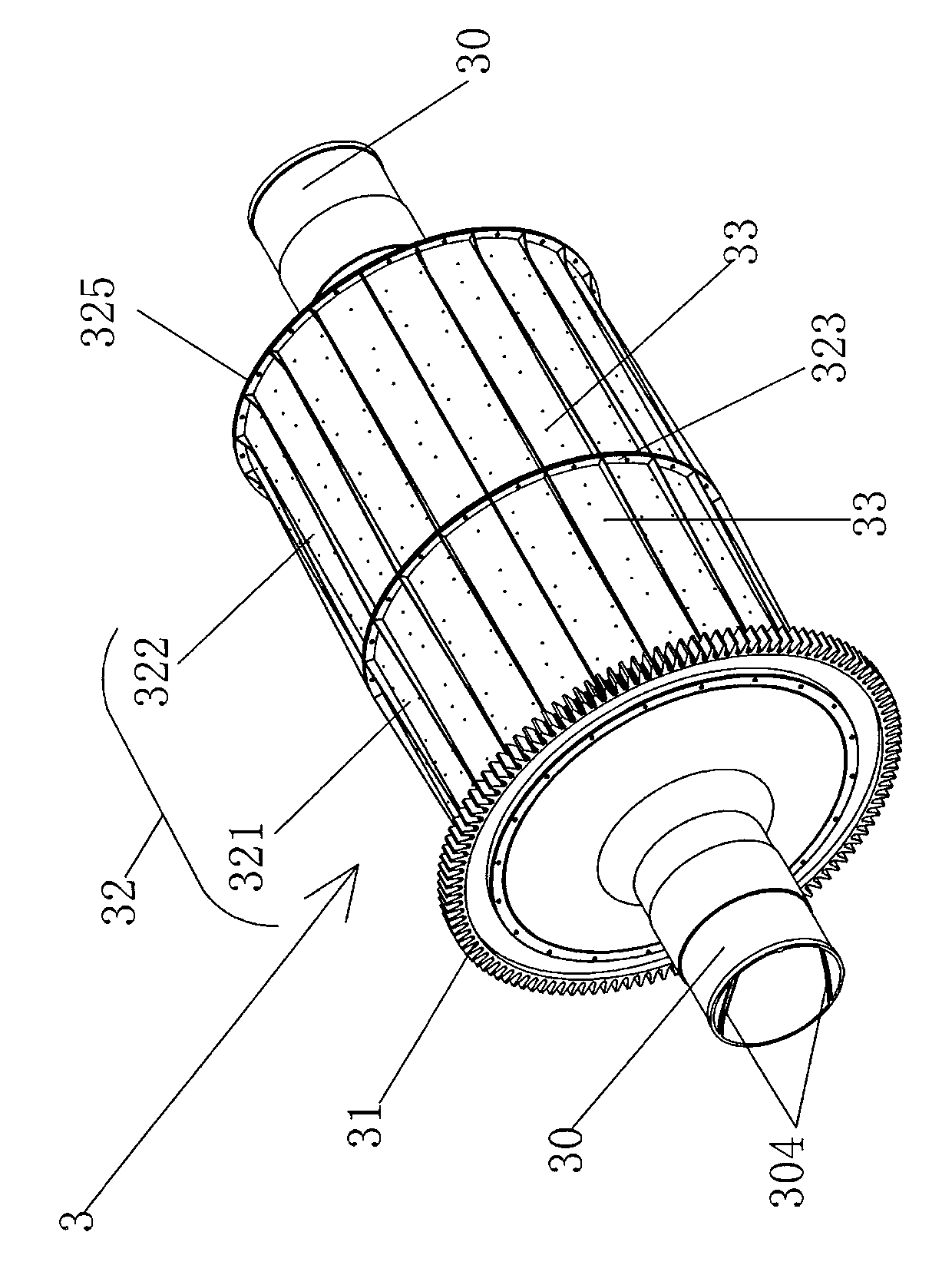

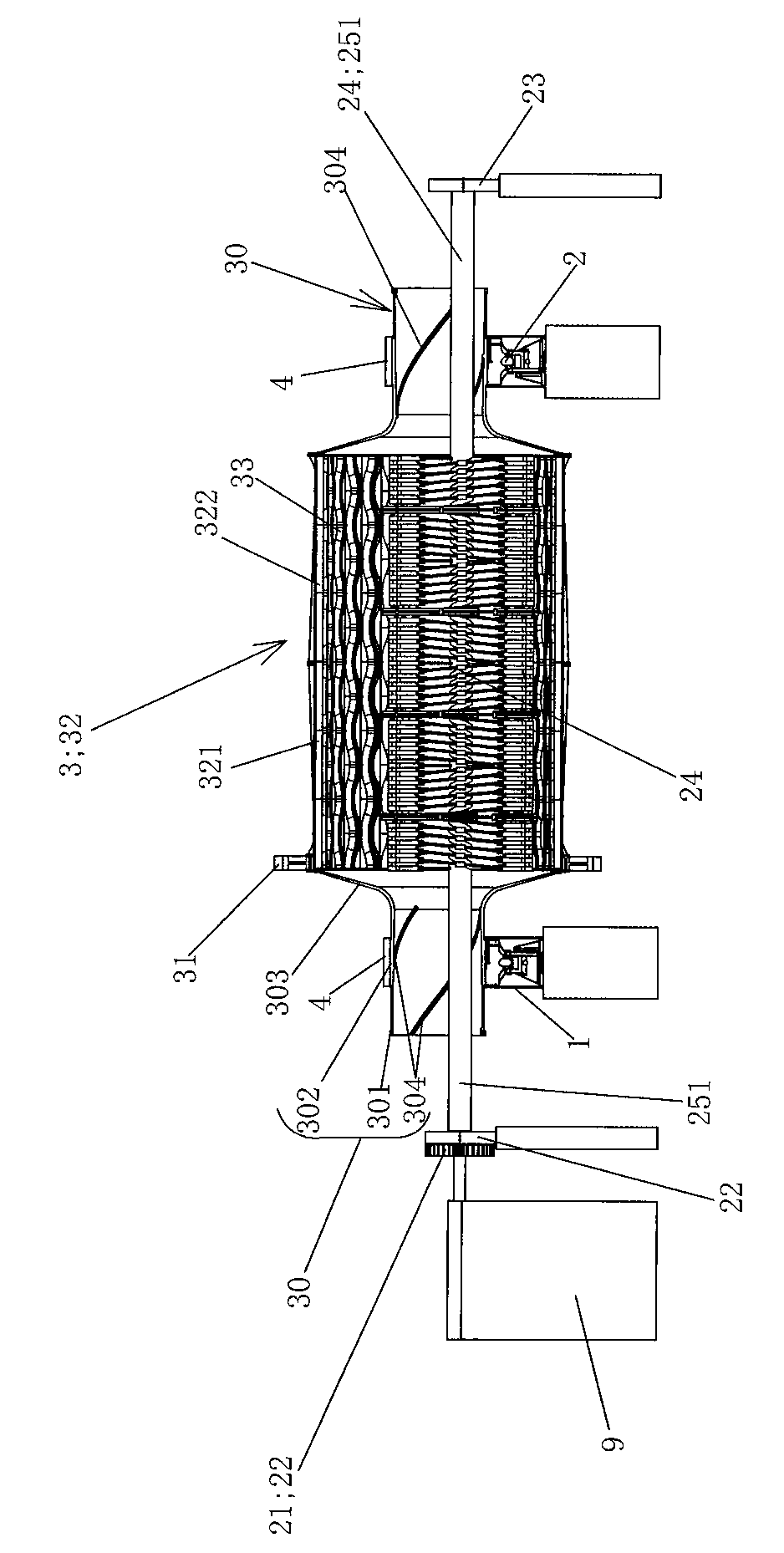

[0057] see figure 1 , figure 2 , image 3 and Figure 33 Shown, the present invention is made up of the first hydrostatic bearing 1, the second hydrostatic bearing 2, the revolving body 3, two hydrostatic bearing sealing covers 4, the first partial dust collector 5, the second partial dust collector 6, the first The gear 7, the first transmission system 8, the second transmission system 9, the third gear 20, the fourth gear 21, the first rolling bearing and its support 22, the second rolling bearing and its support 23, and the grinding part 24 are composed of two rotating bodies. The journals 302 of the hollow shaft 301 at the end are respectively placed on the first hydrostatic bearing 1 and the second hydrostatic bearing 2, and are respectively covered with two hydrostatic bearing sealing covers 4; the first gear 7 and the first transmission train 8 The output shaft of the cylinder 32 is connected with the output shaft, and the left end of the cylinder body 32 is pierced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com