Patents

Literature

35results about How to "Good centering performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

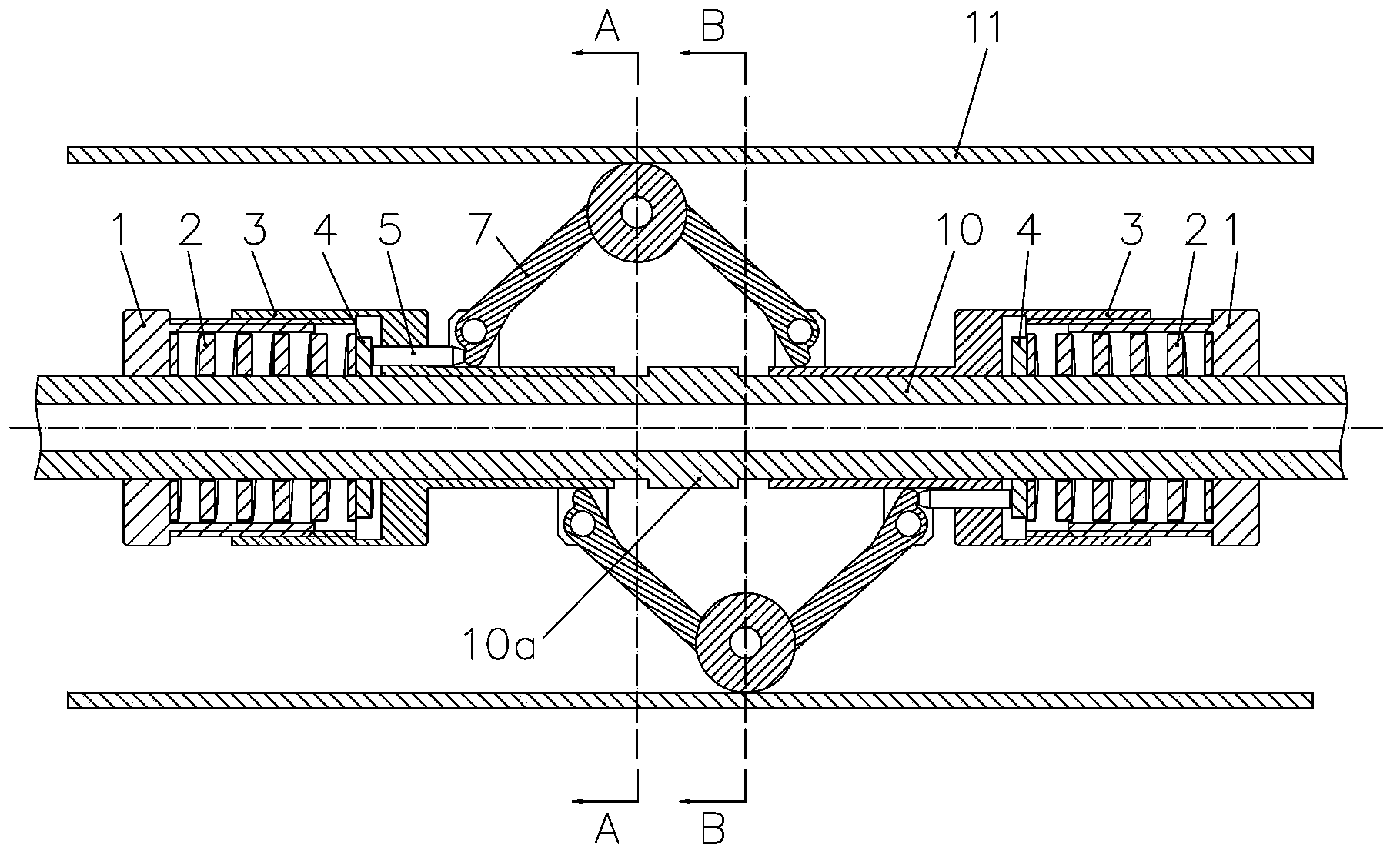

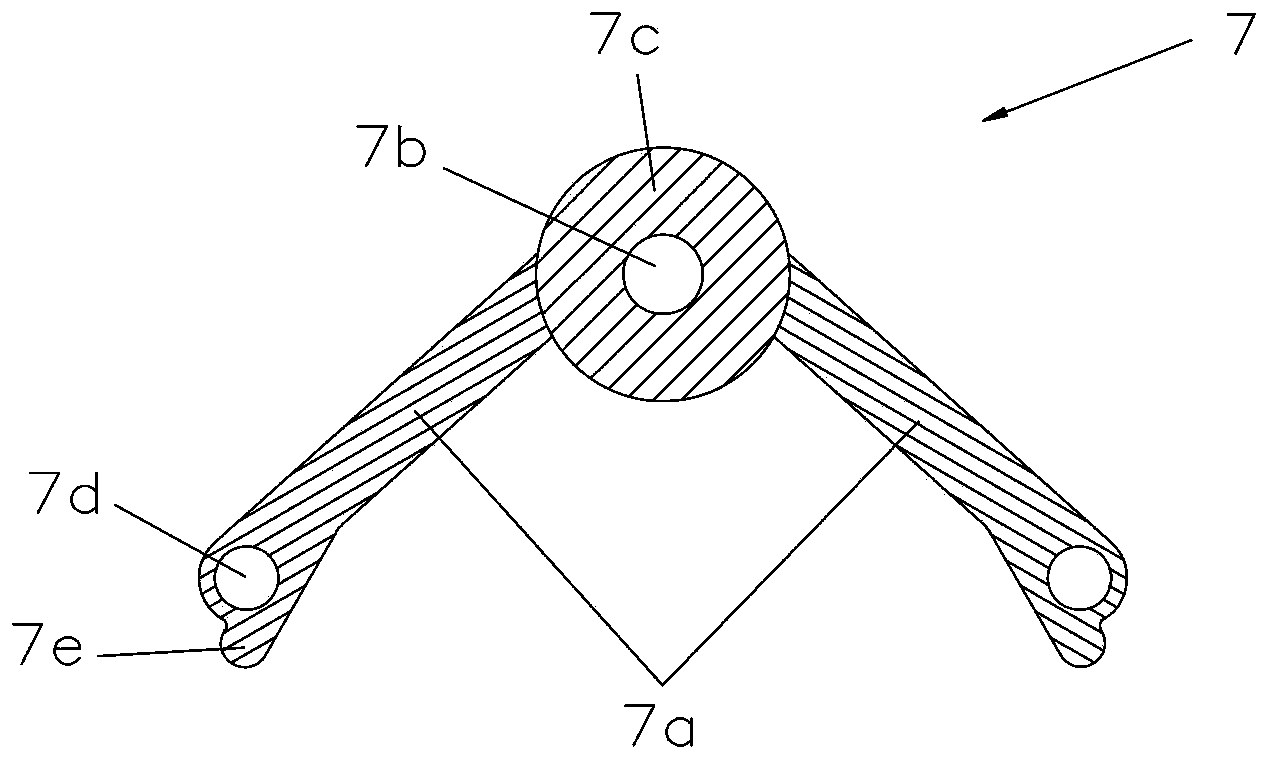

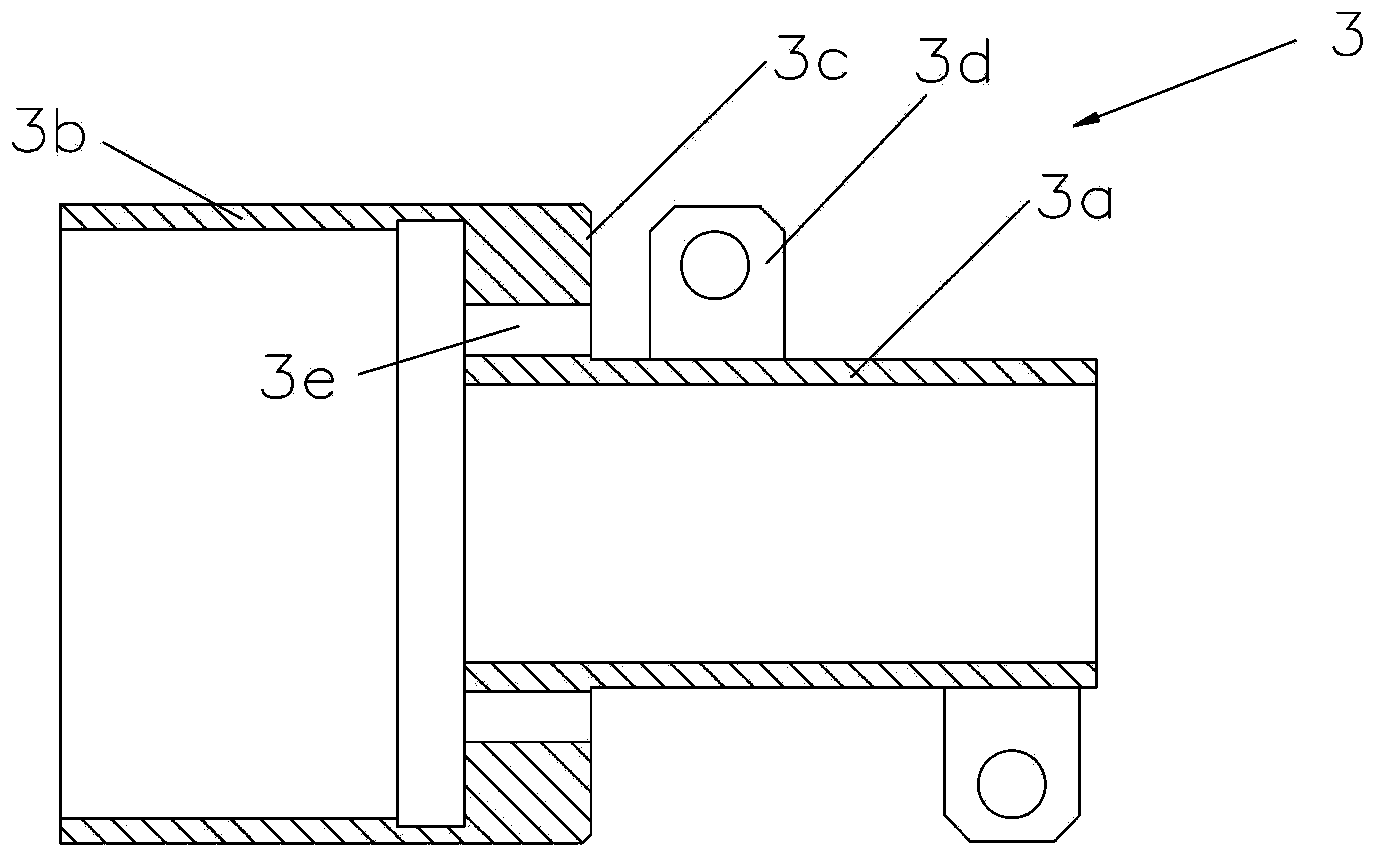

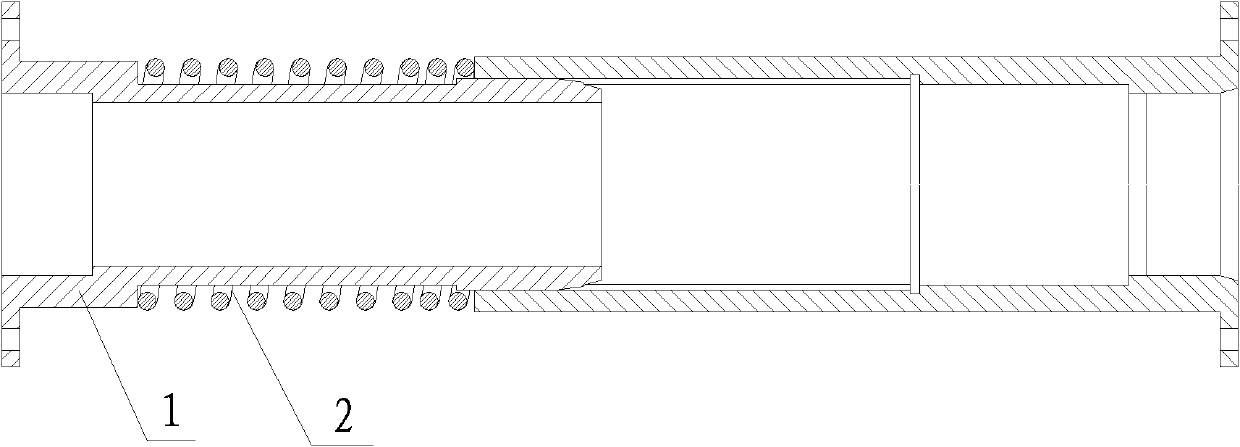

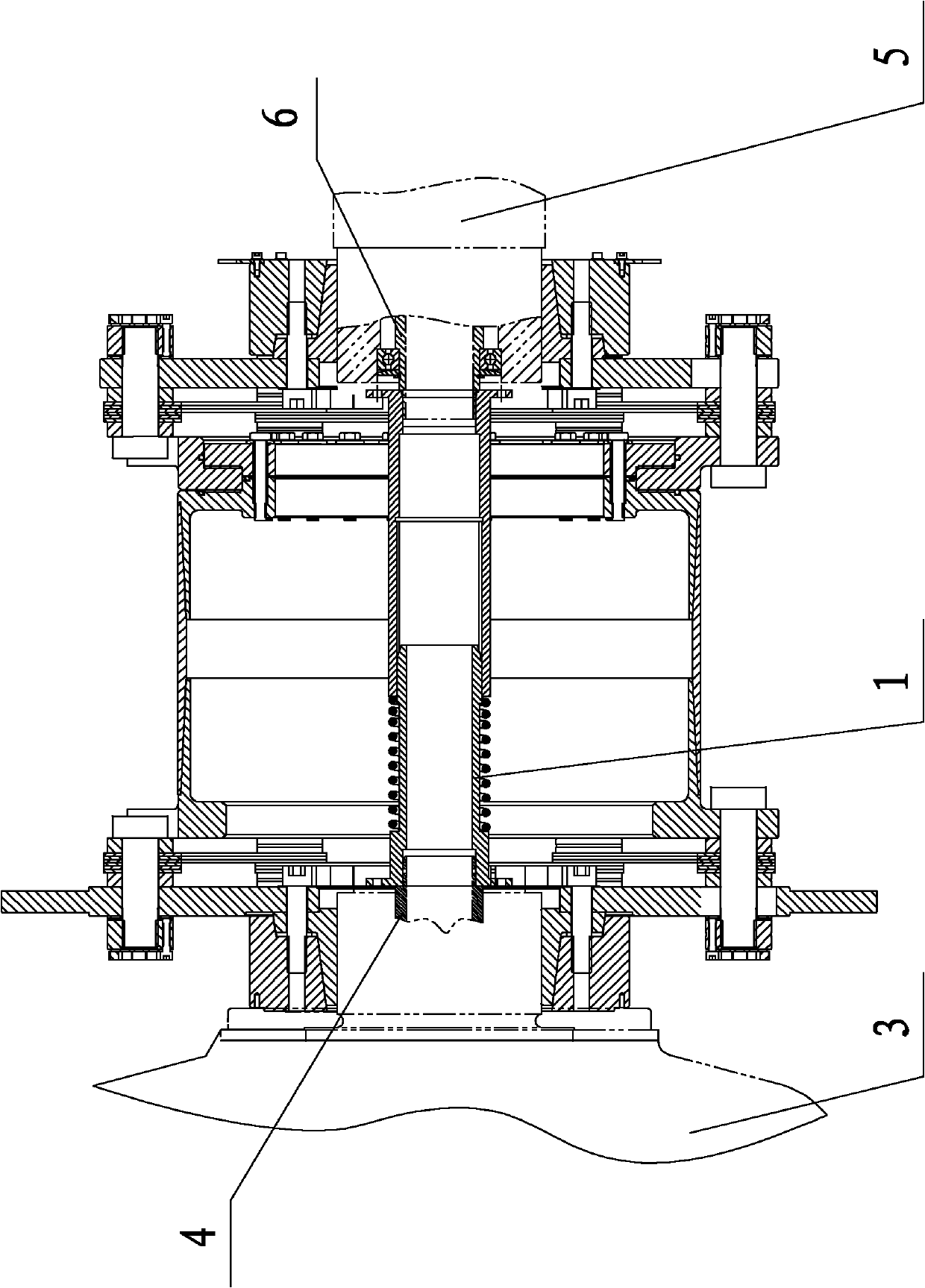

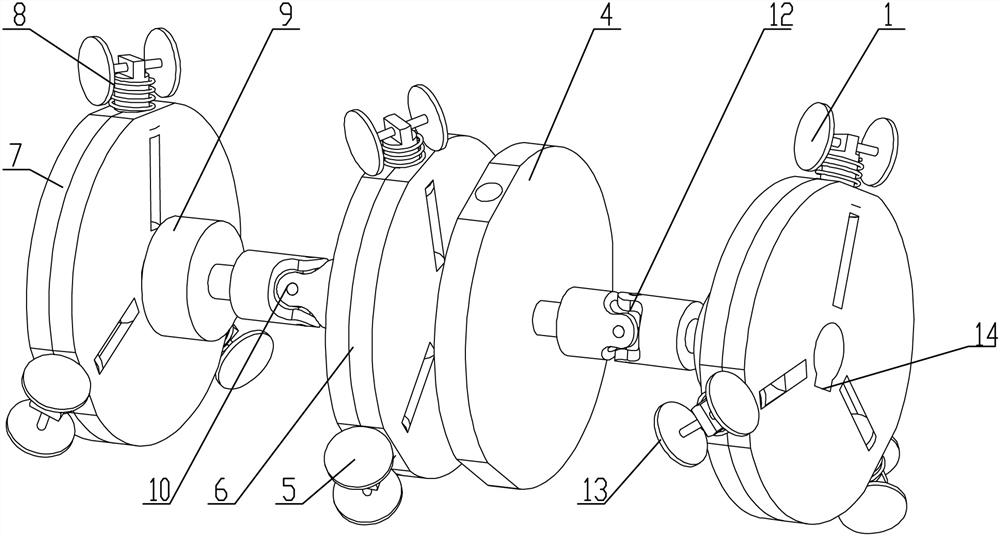

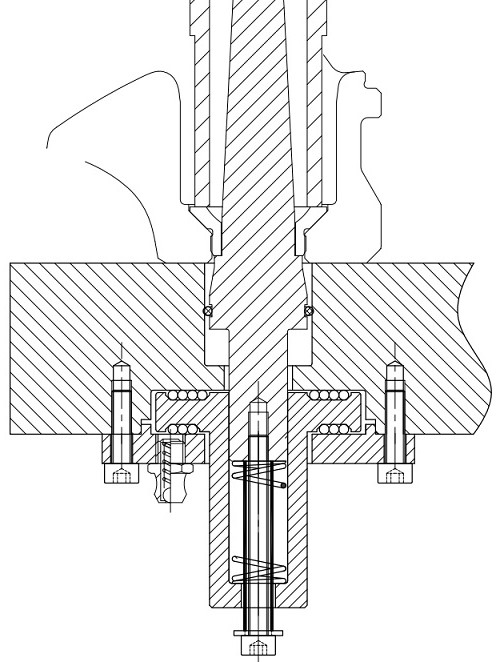

Dislocated support-type centering guide for cased well logger

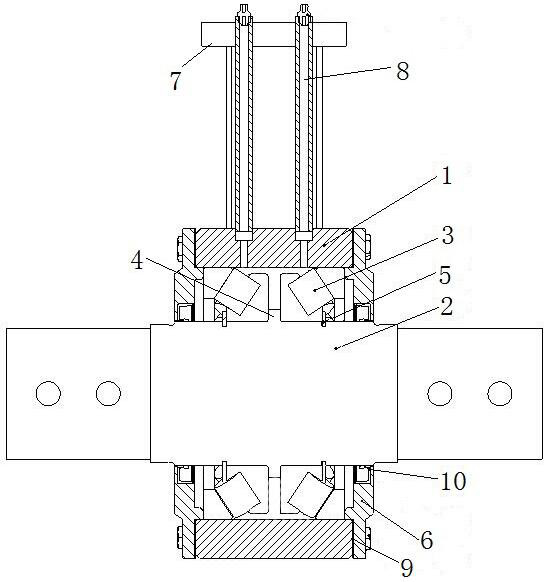

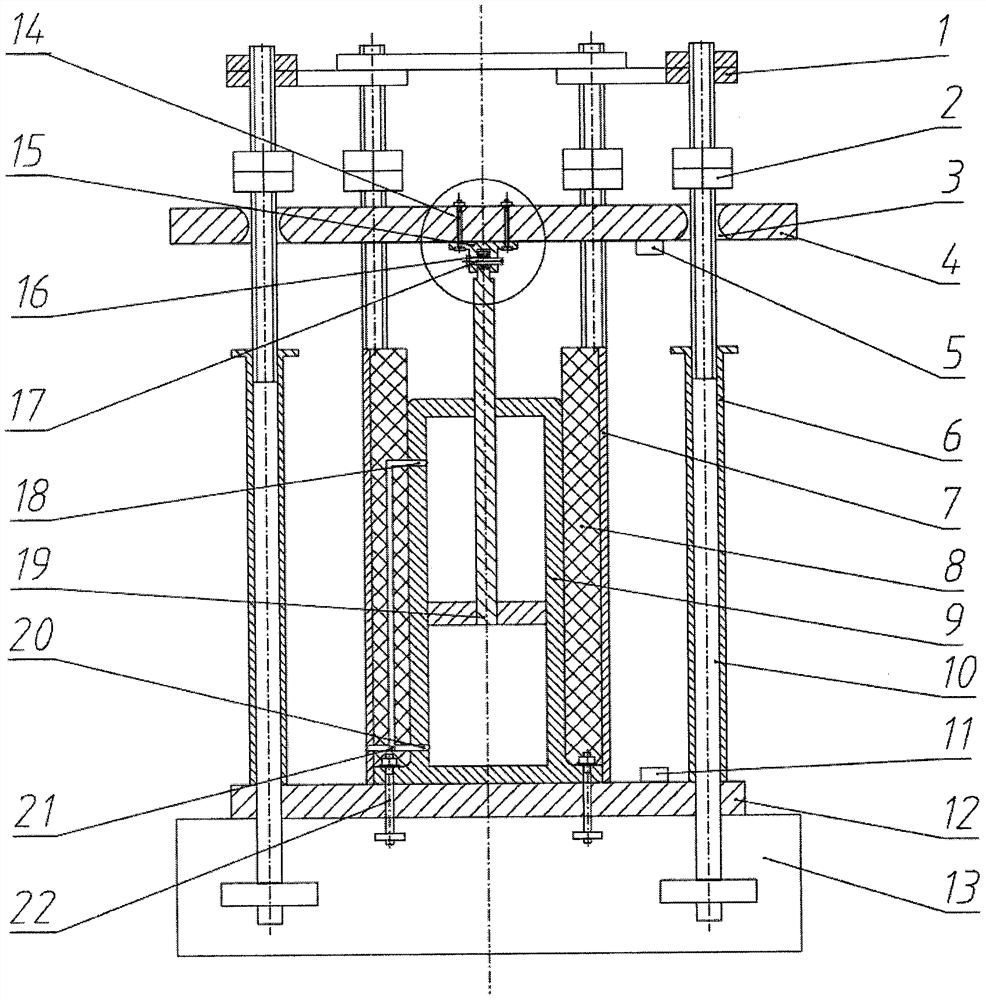

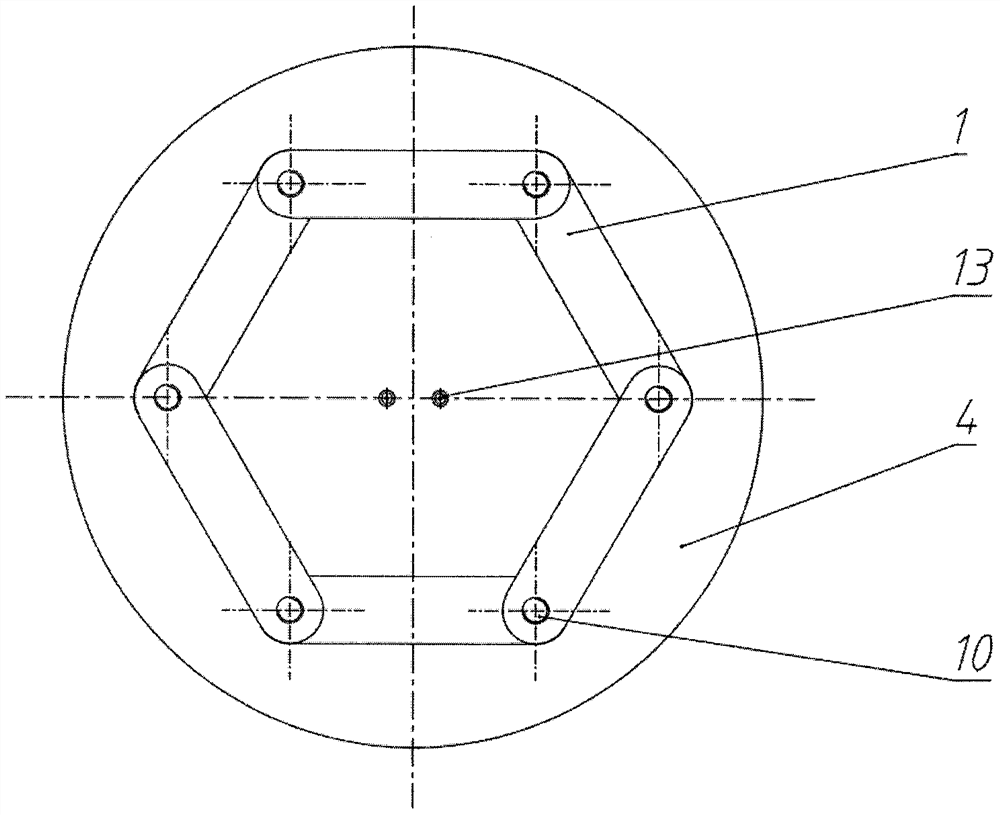

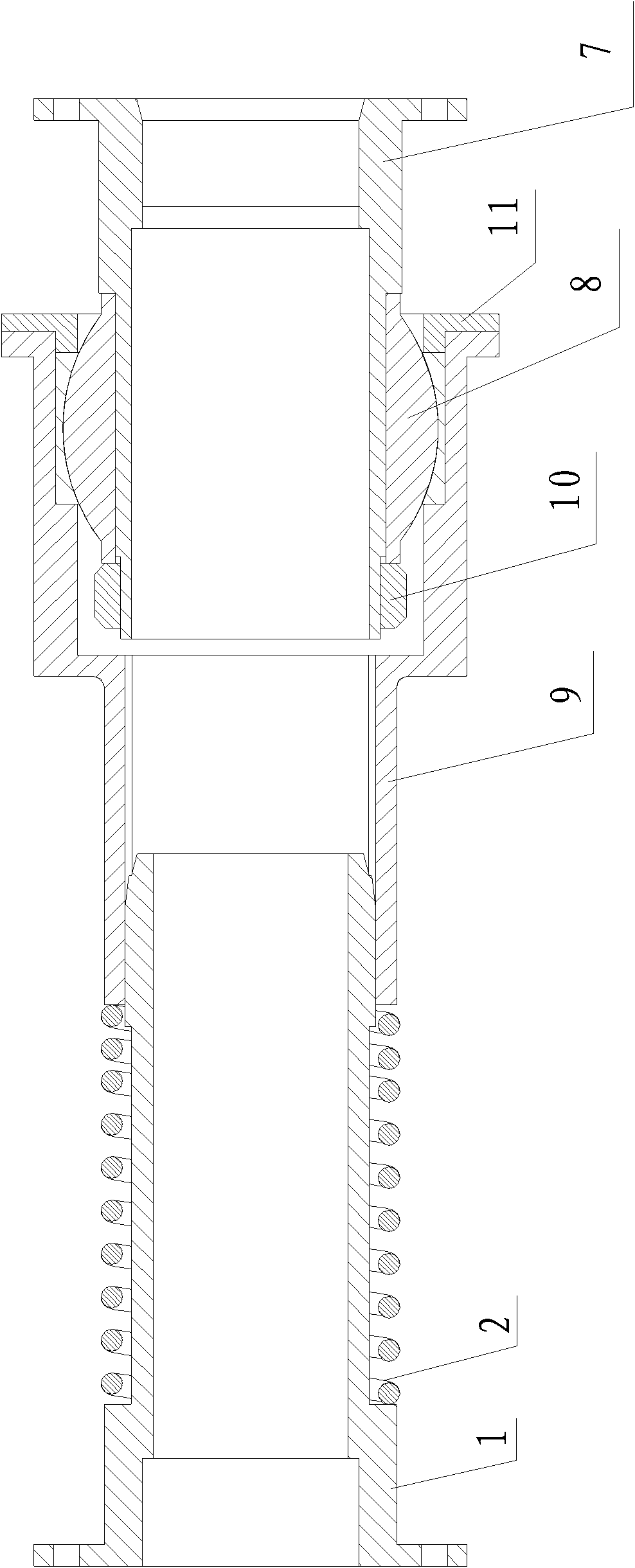

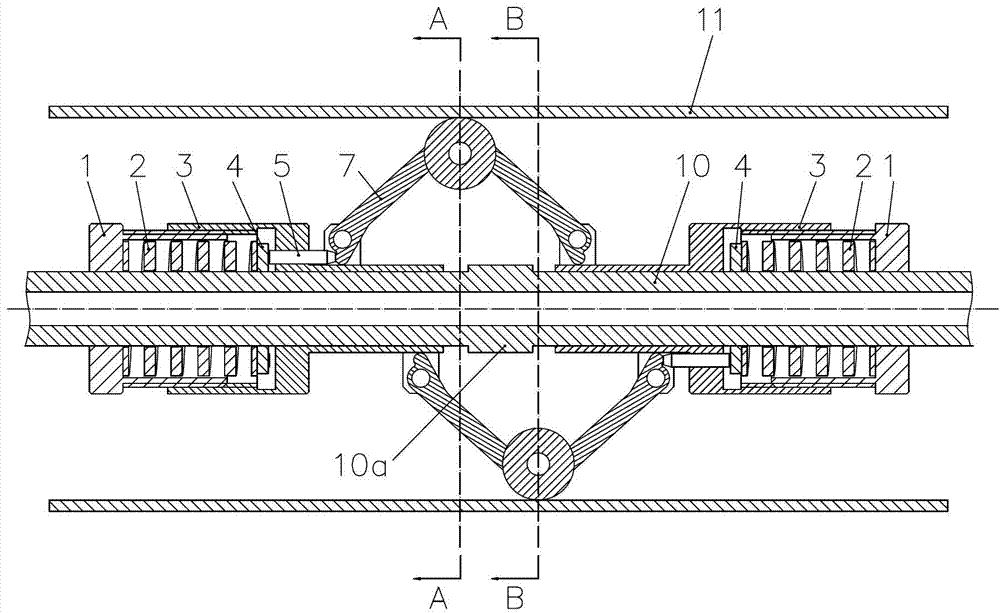

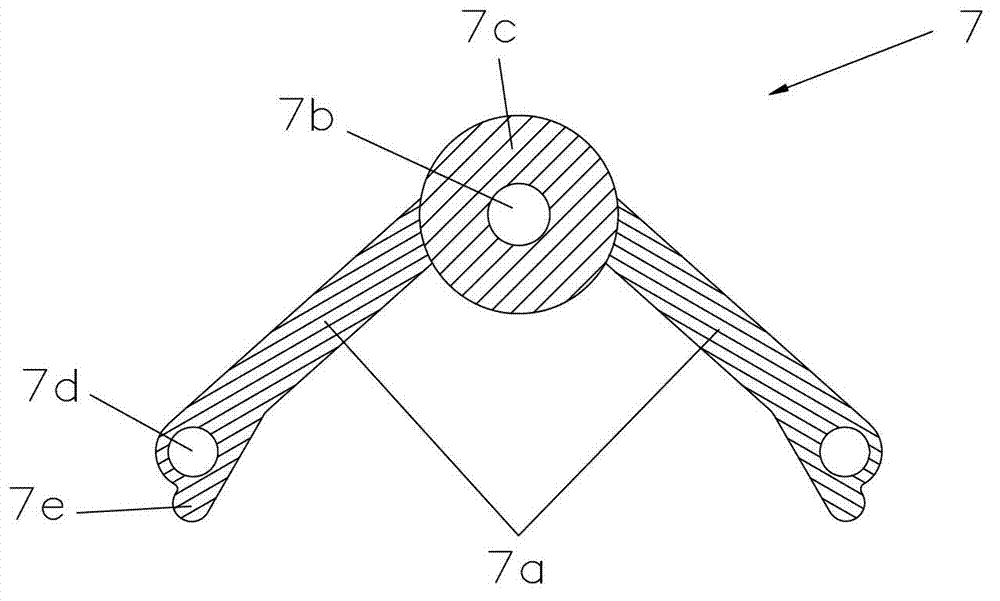

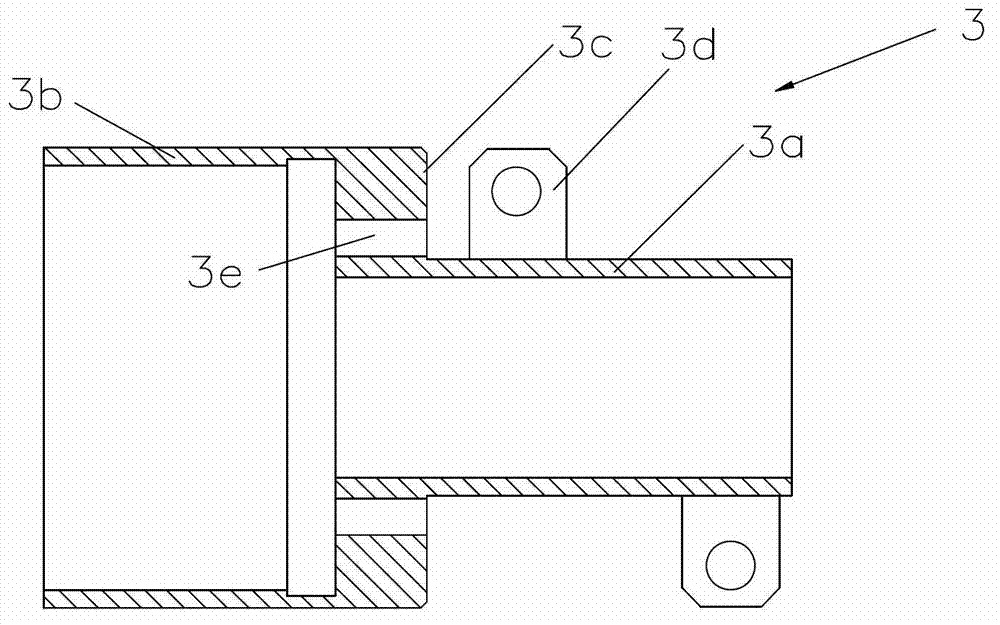

The invention discloses a dislocated support-type centering guide for a cased well logger. The dislocated support-type centering guide for the cased well logger is characterized in that support arms, ejector rods, springs and socket sleeves are adopted to form a lever structure. When the inner diameter of a casing pipe is slightly changed, the support arms rotate, forces received by the springs are not changed much, and moment arms of the springs are nearly unchanged, so that support forces of rollers are nearly unchanged by the buffering and the compensation of lever mechanisms; all rollers are centripetally arranged, so that the centering performance of the centering guide is better; two sets of centering arms are dislocated in an axis direction, so that the centering guide is more stable, and can more easily overcome obstacles. A positioning boss located on a center rod is capable of preventing the phenomenon that the support arms at both sides of each roller are damaged due to the fact that the support arms are excessively close, and meanwhile, the positioning boss also plays a role of limiting the sliding socket sleeves. The dislocated support-type centering guide for the cased well logger disclosed by the invention is suitable for casing pipes of various specifications. By rotating threads between glands and slide carriages, the length of an inner gap between each socket sleeve and the corresponding gland is adjusted to control magnitudes of the forces of the springs, and therefore, the magnitudes of the support forces can be adjusted according to the size of the inner diameter of the casing pipe in actual logging operations.

Owner:WUHAN HAIWANG MECHANICAL & ELECTRICAL ENGTECH

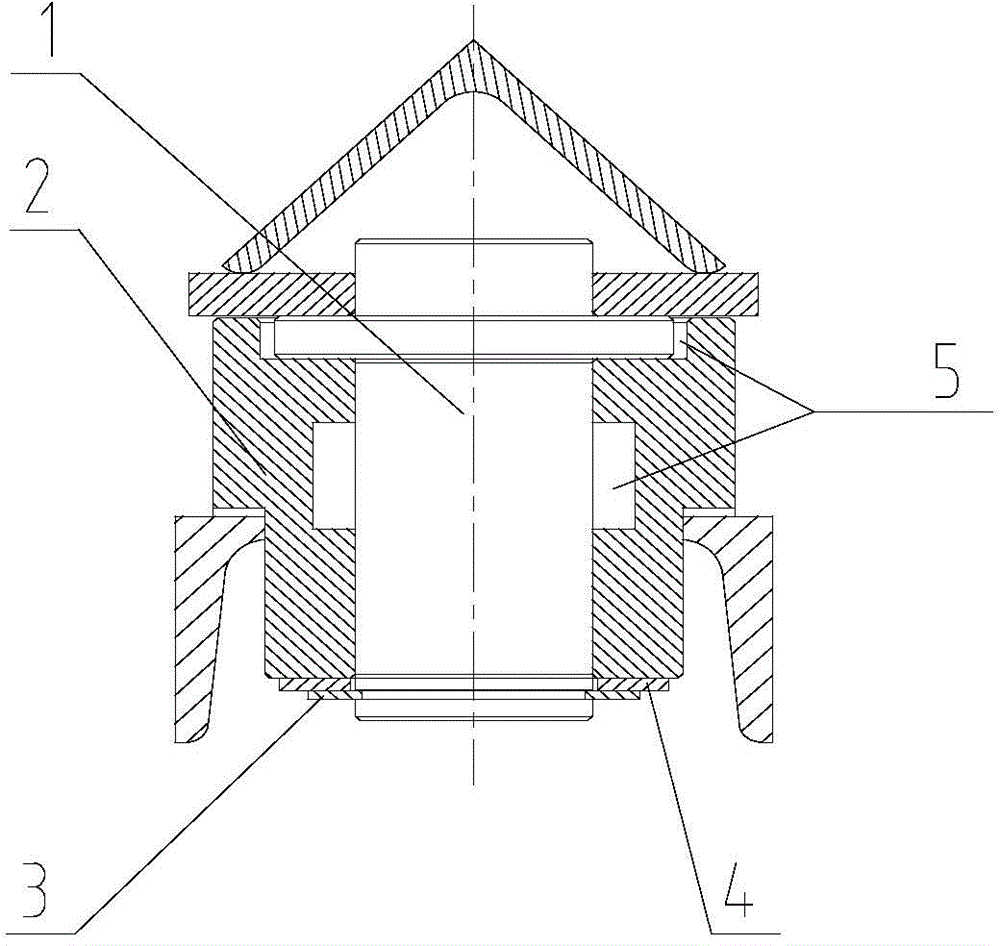

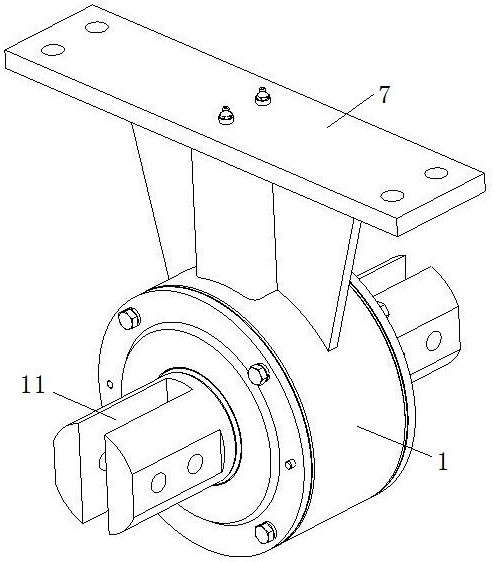

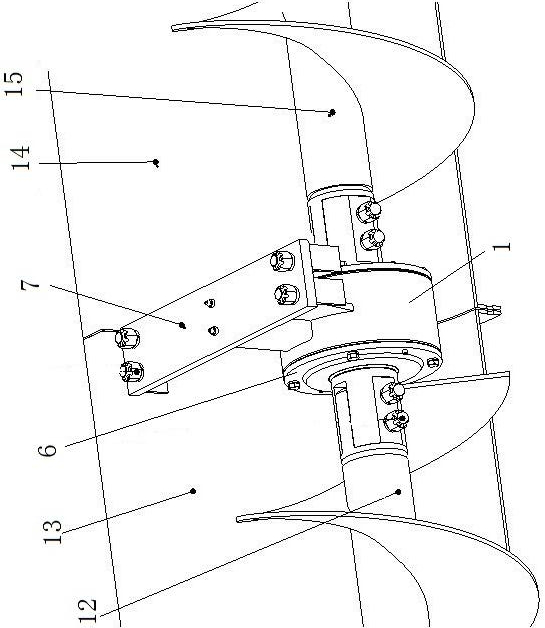

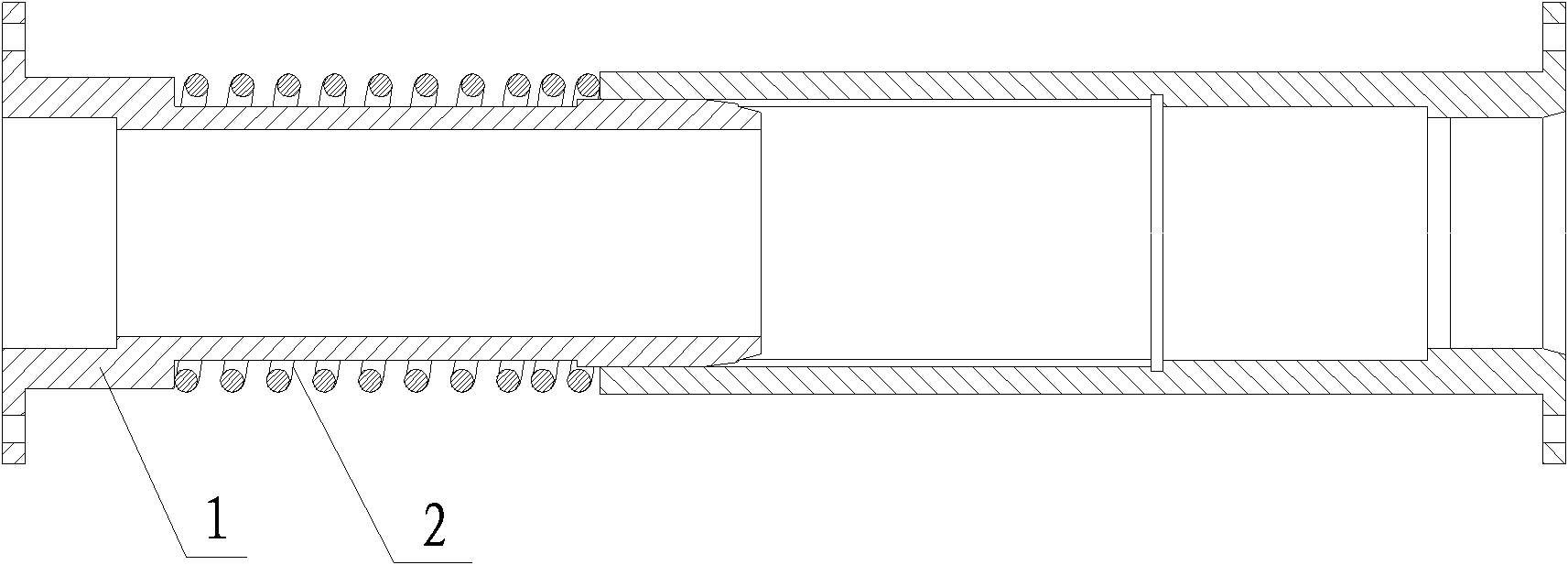

Threading tube coupler of wind generating set

ActiveCN102168725AAvoid twistingEasy to install and removeYielding couplingWind energy generationElectric generatorEngineering

The invention relates to a threading tube coupler of a wind generating set, which is provided with a left joint, a spring and a right part joint, wherein the end part of the front end of the left joint is in clearance fit connection with the end part of the rear end of the right part joint; the periphery of the left joint is provided with a stepped clamping groove; the spring is mounted in the stepped clamping groove; a blocking surface at the front end of the stepped clamping groove is lower than that at the rear end of the stepped clamping groove; one end of the spring is pressed against the blocking surface at the rear end of the stepped clamping groove; the other end of the spring is pressed against the end surface of the rear end of the right part joint; the outer periphery of the end part of the front end of the left joint is provided with a sliding key; and the inner peripheral surface of the right part joint is provided with a key slot matched with the sliding key. The threading tube coupler is expandable, so an input shaft of an electric generator and an output shaft of a speed increasing gearbox are convenient to install and disassemble by the coupler. The threading tubecoupler allows a left threading tube and a right threading tube to have certain eccentricity and higher eccentricity.

Owner:JIANGSU NEW UNITED HEAVY IND SCI & TECH +1

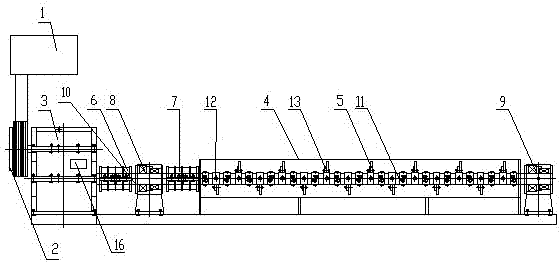

Variable speed control method for cooling table output roller beds

InactiveCN107600960AUniform drag forceTroubleshootingAC motor controlControl devices for conveyorsFrequency conversionWorking environment

The invention discloses a variable speed control method for cooling table output roller beds. The cooling table output roller beds are sequentially grouped when conveying towards cold shears, and a control circuit of each group of roller beds is provided with a controller used for controlling the operation speed of a roller bed motor. The principle is simple, the transform difficulty is low, the cost is low, the labor intensity is small, the control way for the cooling table output roller beds is changed through frequency conversion, grouping and PLC analog quantity control technology, the control performance for the cooling table output roller beds is improved, the noise in the working environment is lowered, energy conservation and environmental protection are achieved, the improved cooling table output roller beds are stable and reliable in operation, and production efficiency is high.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

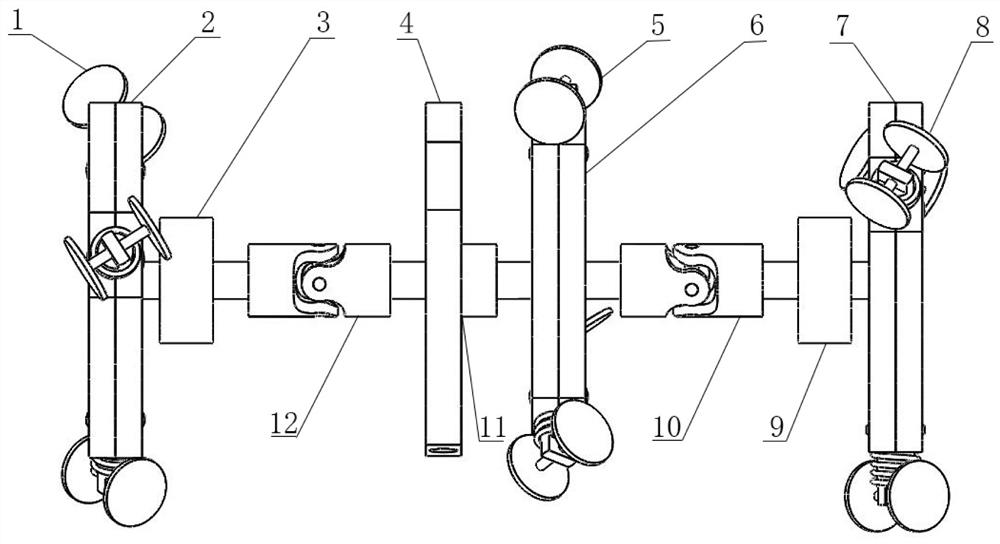

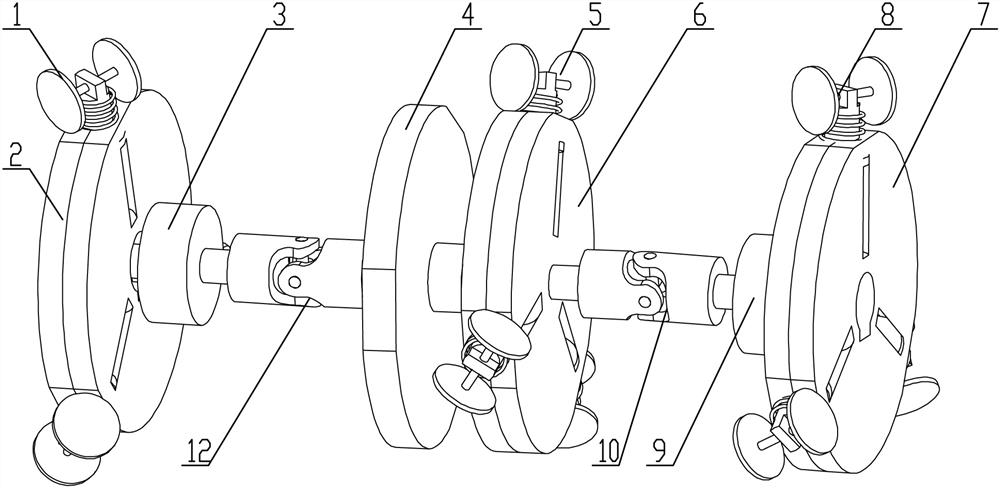

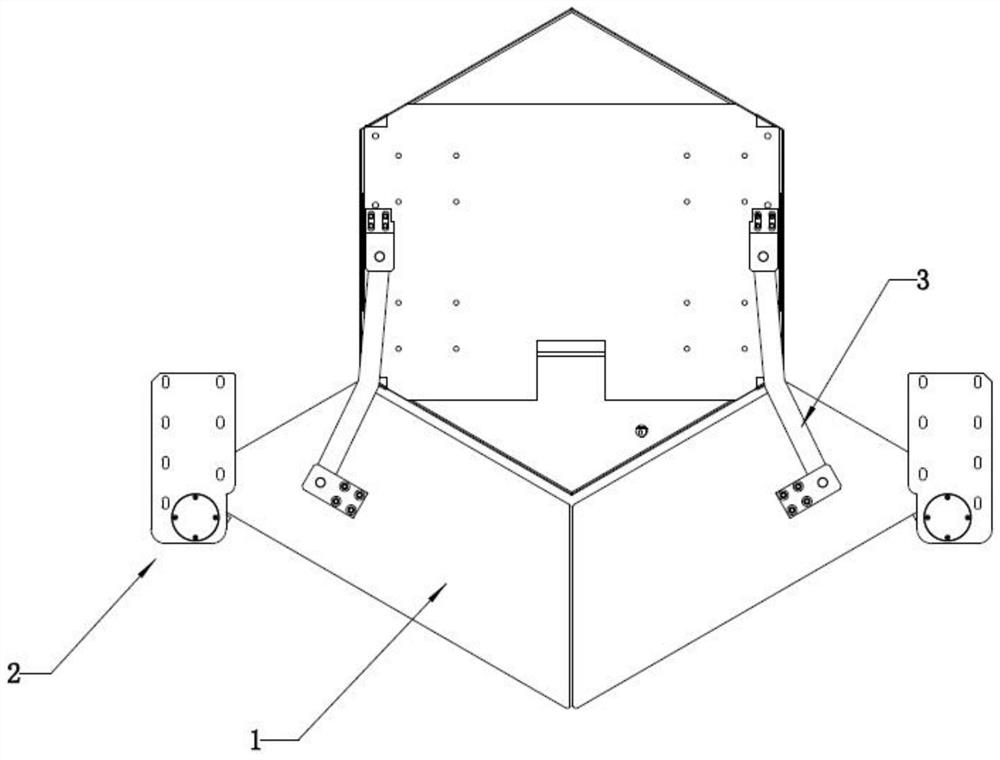

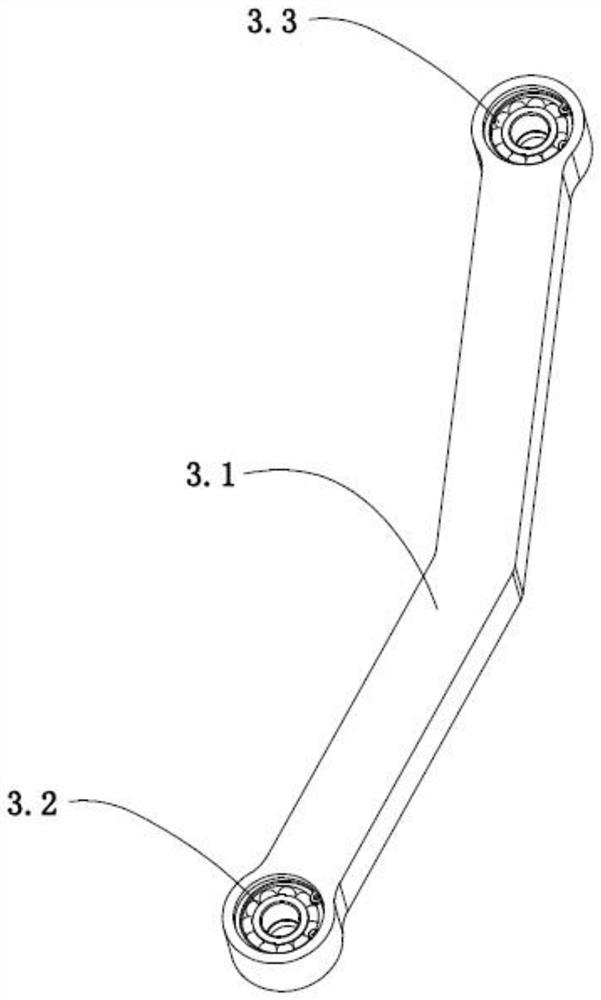

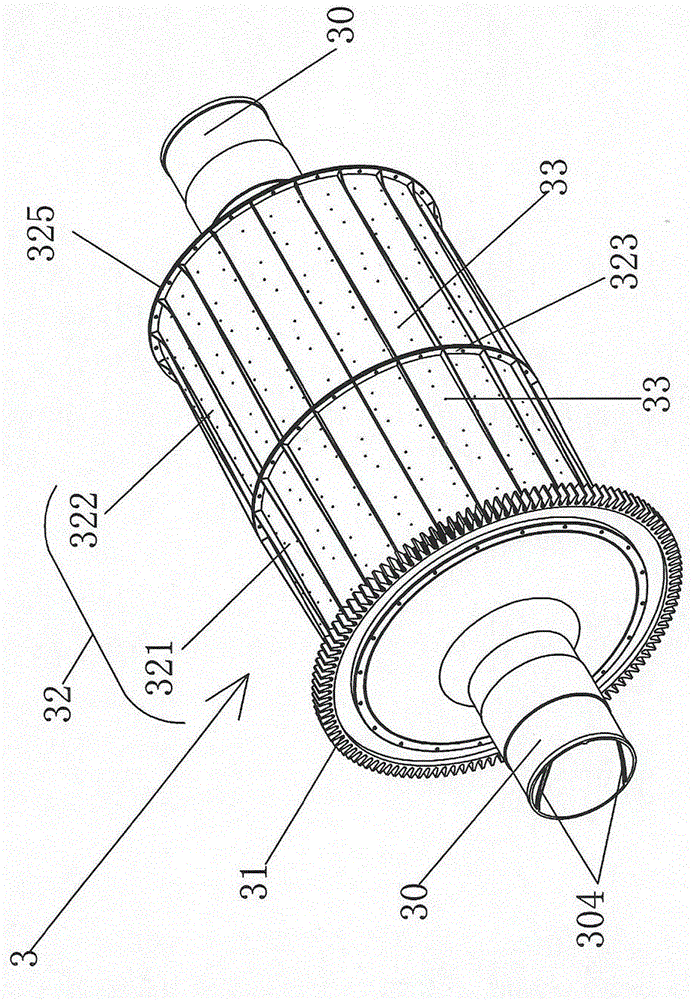

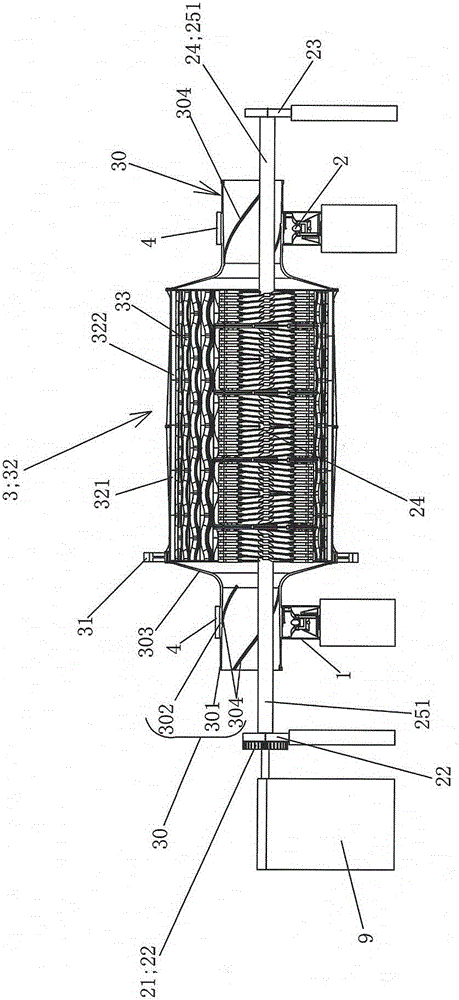

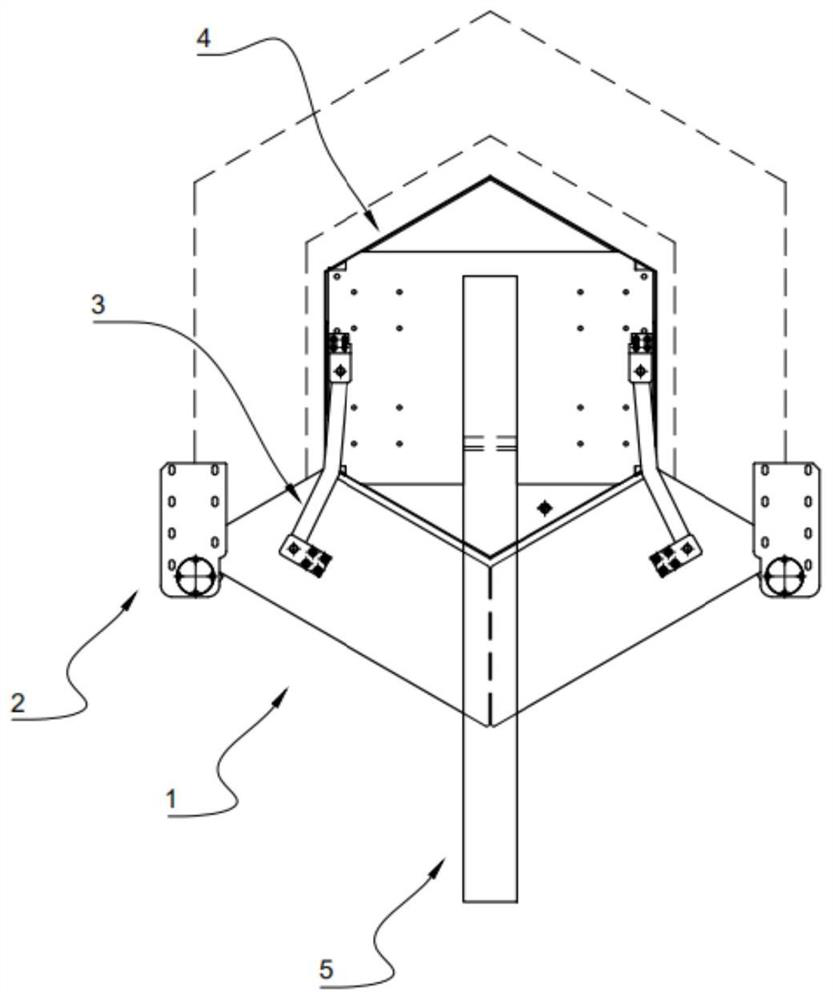

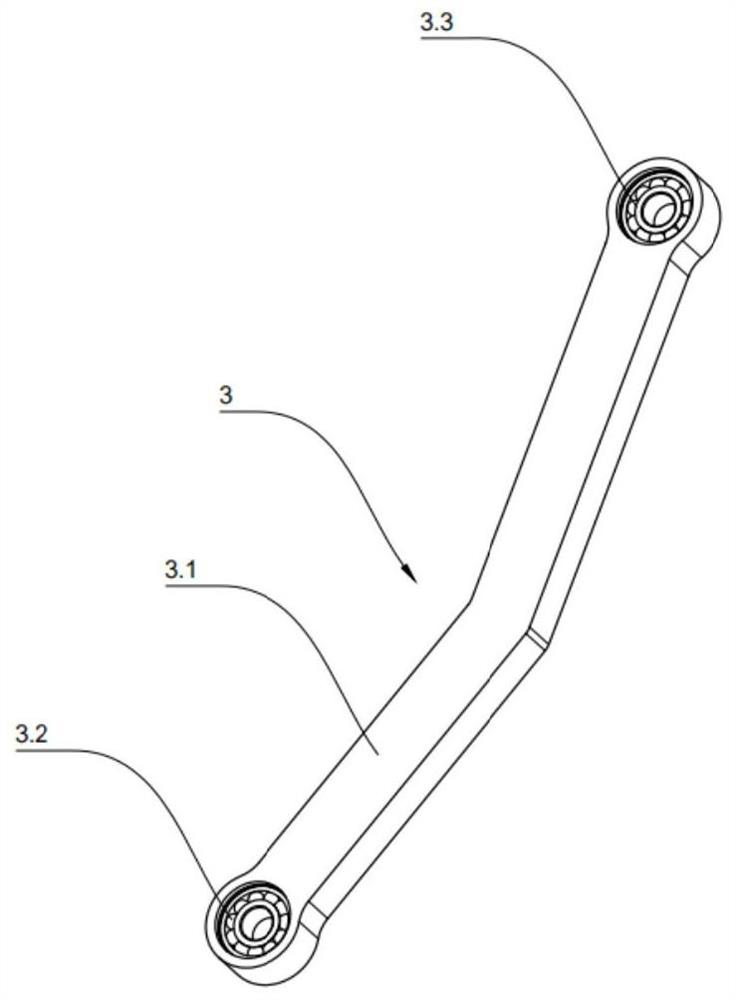

Novel spiral wheel type miniature pipeline detection robot and using method

The invention provides a novel spiral wheel type miniature pipeline detection robot and a using method. The novel spiral wheel type miniature pipeline detection robot comprises a robot body, and the robot body is of a sectional structure and comprises a front axle drive, a supporting part, a detection part and a rear axle drive; and the front axle drive is hinged to the detection part through a second universal joint coupler, the detection part is fixedly connected with the supporting part, and the supporting part is hinged to the rear axle drive through a first universal joint coupler. The detection robot is simple and reliable in structure and convenient to use, exploration work in a pipeline can further be completed, and problems existing in the pipeline can be detected in time.

Owner:CHINA THREE GORGES UNIV

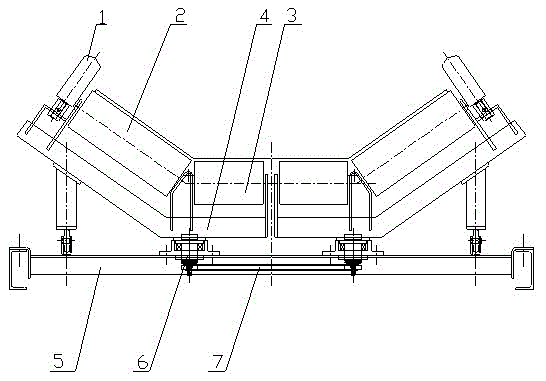

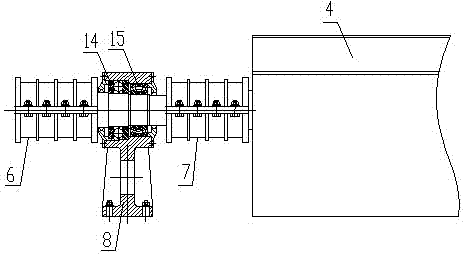

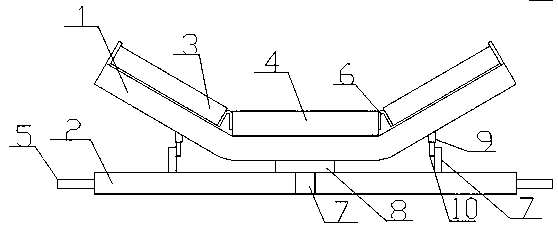

Full-automatic reversible conveying belt aligning idler

InactiveCN104418036AGood centering effectSmall turning radiusConveyorsRollersEngineeringFour-bar linkage

The invention relates to a full-automatic reversible conveying belt aligning idler. The full-automatic reversible conveying belt aligning idler comprises an upper beam (4), a lower beam (5), rotating shafts (6) and a four-connecting bar mechanism (7), the upper beam (4) and lower beam (5) are connected through the rotating shafts (6), vertical rollers (1) are arranged at the top of the upper beam (4), baffle rollers (2) are arranged at the middle, idlers (3) are arranged at the lower part, the vertical rollers (1), baffle rollers (2), idlers (3), upper beam (4) and rotating shafts (6) are symmetrically arranged in the horizontal direction in a mode of using the vertical central line of the lower beam (5) as a symmetrical axis, and the bottoms of two rotating shafts (6) are connected through the four-connecting bar mechanism (7). When the belt deviates on the idler, the full-automatic reversible conveying belt aligning idler drives the upper beam to rotate by a certain angle, and reverse rotating force is exerted to the idlers at the two sides by means of the rotating shafts so as to enable the deviated belt to return to the original position.

Owner:JIANGYIN BOFAN MACHINERY MFR

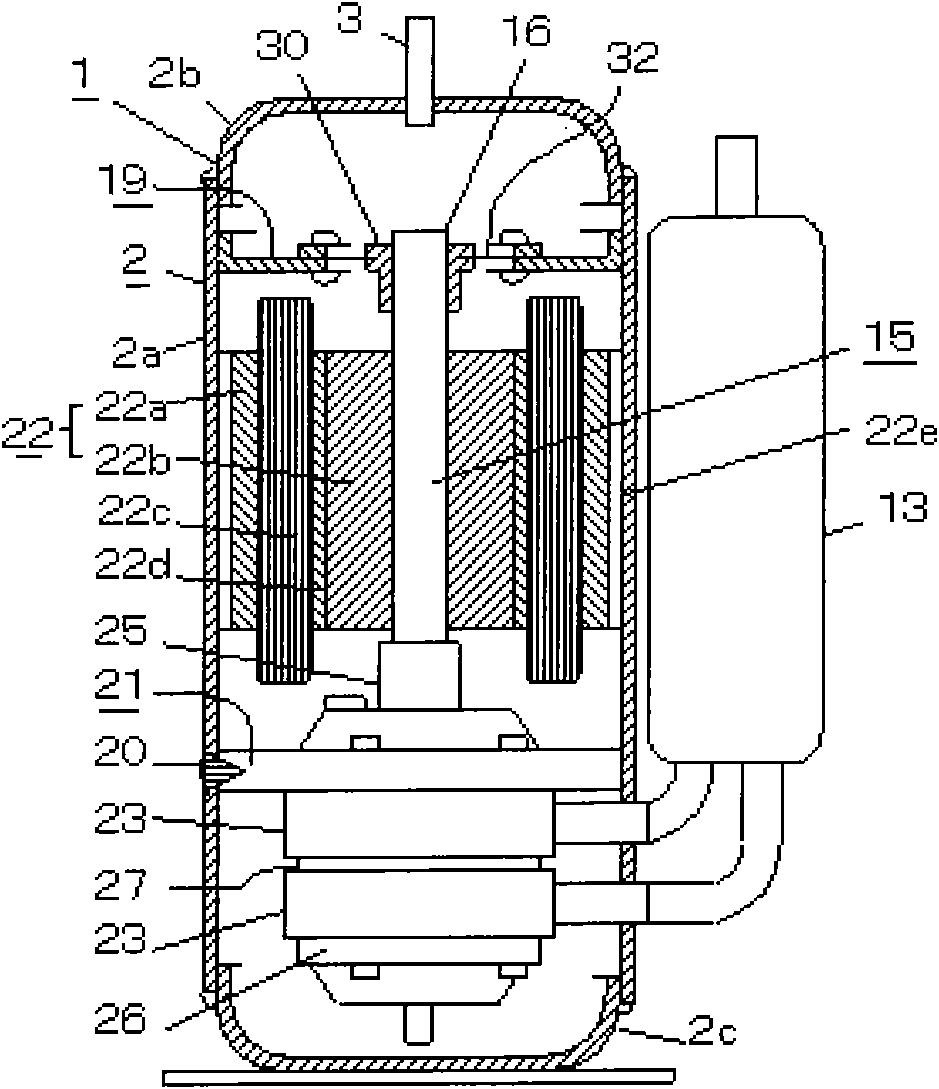

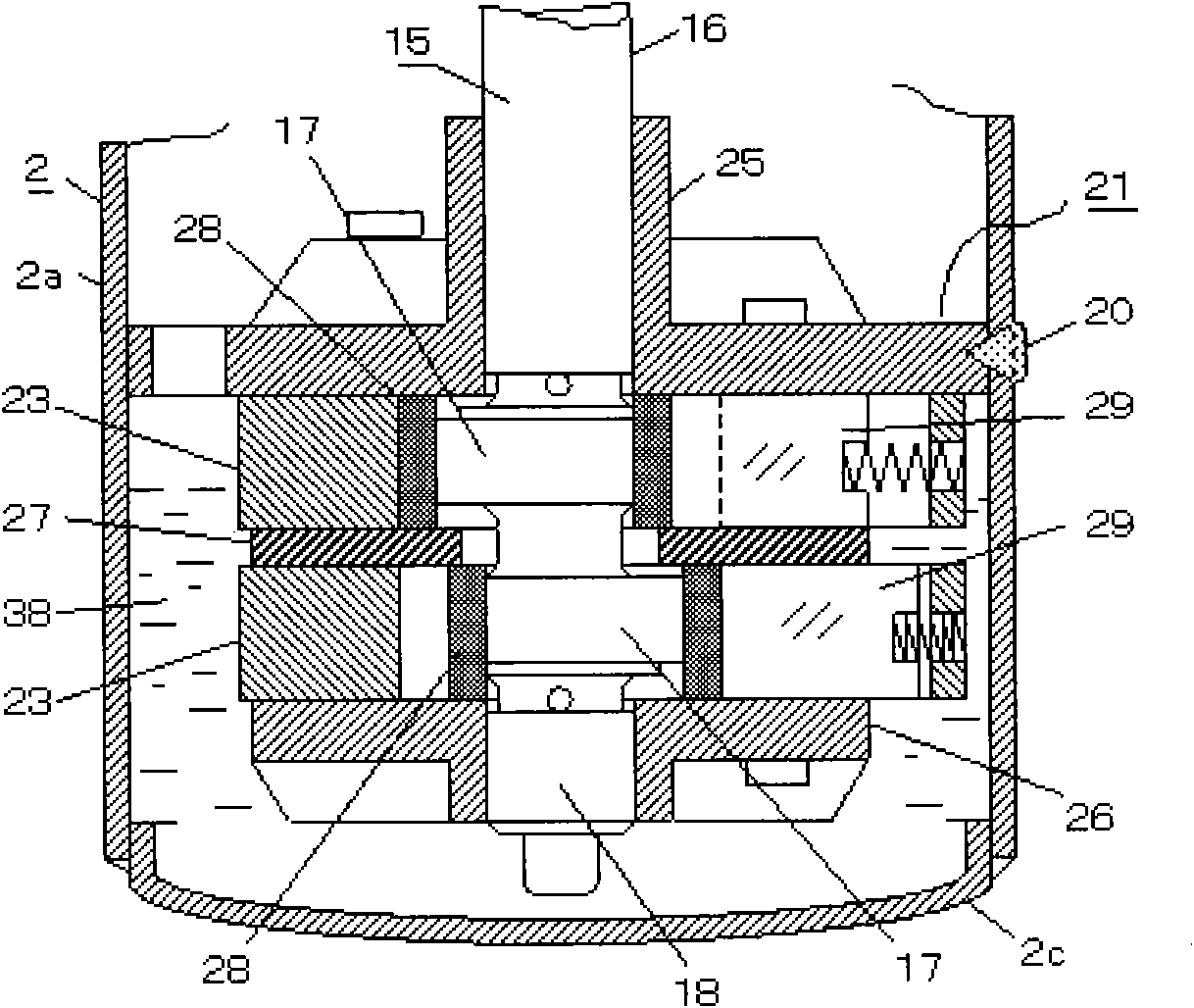

Rotary type compressor

InactiveCN102644595ASmall amount of deformationSimple structureRotary/oscillating piston combinations for elastic fluidsMachines/enginesReciprocating motionCrankshaft

The invention provides a rotary type compressor. A closed shell is internally provided with a compression mechanism and a motor, wherein the motor comprises a stator and a rotor; the compression mechanism comprises an air cylinder, an eccentric crank shaft and a slide sheet, wherein an air cylinder compression chamber is arranged in the middle of the air cylinder; the eccentric crank shaft drives a piston to do eccentric rotation in the air cylinder compression chamber; the slide sheet moves back and forth through the eccentric rotation of the piston; the eccentric crank shaft is composed of a main shaft, a secondary shaft and an eccentric shaft; a first bearing and a second bearing which are used for respectively supporting the main shaft and the secondary shaft of the eccentric crank shaft are arranged on the air cylinder; a third bearing is arranged at the opposite side of the first bearing by being separated from the motor; the third bearing comprises a bearing bracket which is arranged on the inner wall of the closed shell, a center bearing for supporting the main shaft of the eccentric crank shaft and an elastic plate which is arranged between the bearing bracket and the center bearing; and the elastic plate is used for elastically supporting the center bearing. The rotary type compressor not only can be suitable for the rotary type compressor but also can be suitable for a scroll compressor; and the rotary type compressor has the advantages of good centering effect, low abrasion rate and wide application range.

Owner:GUANGDONG MEIZHI COMPRESSOR

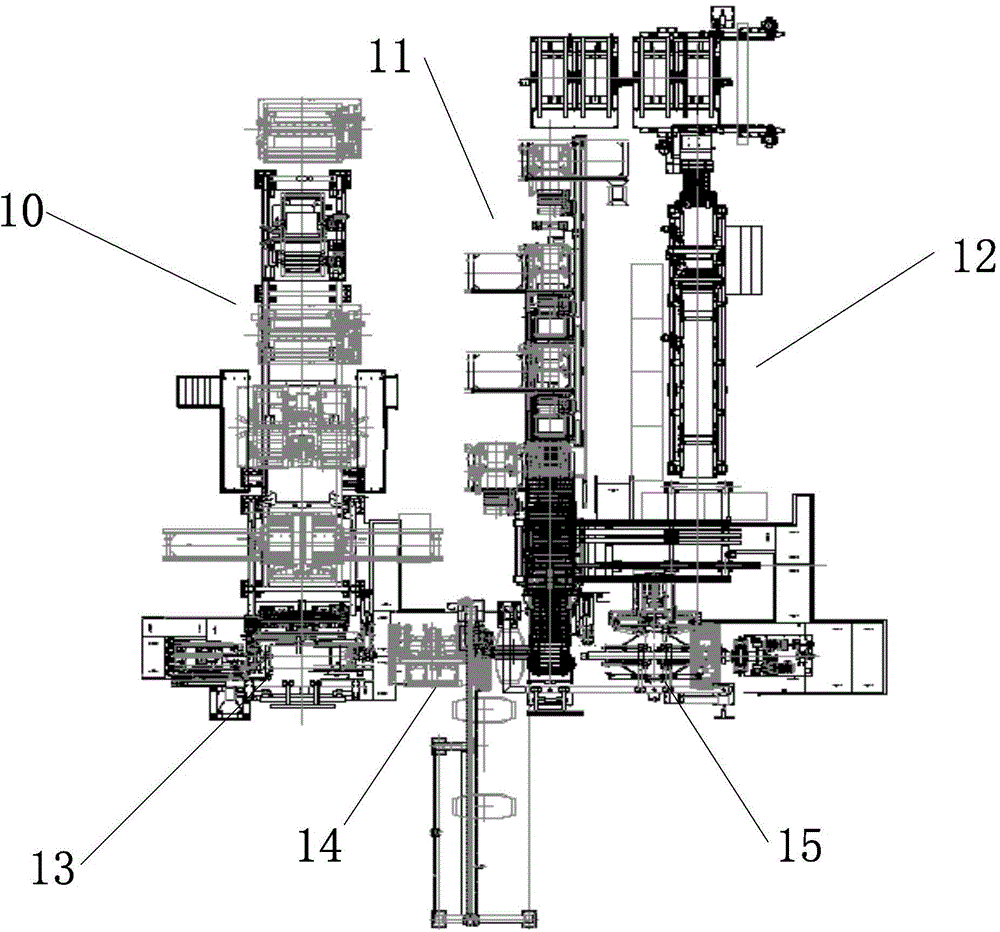

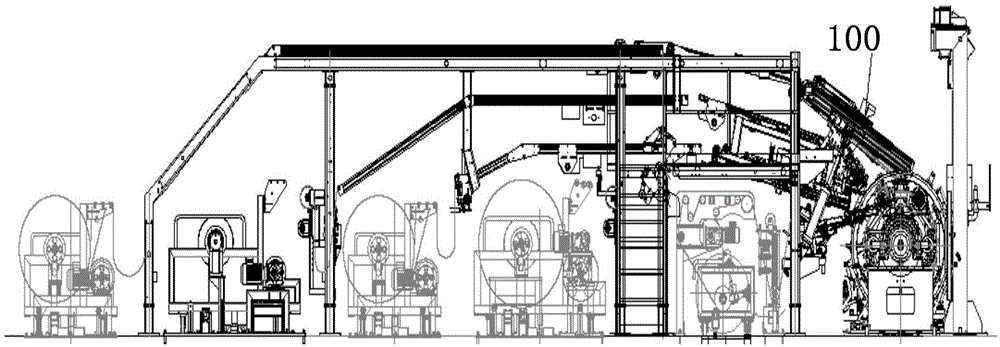

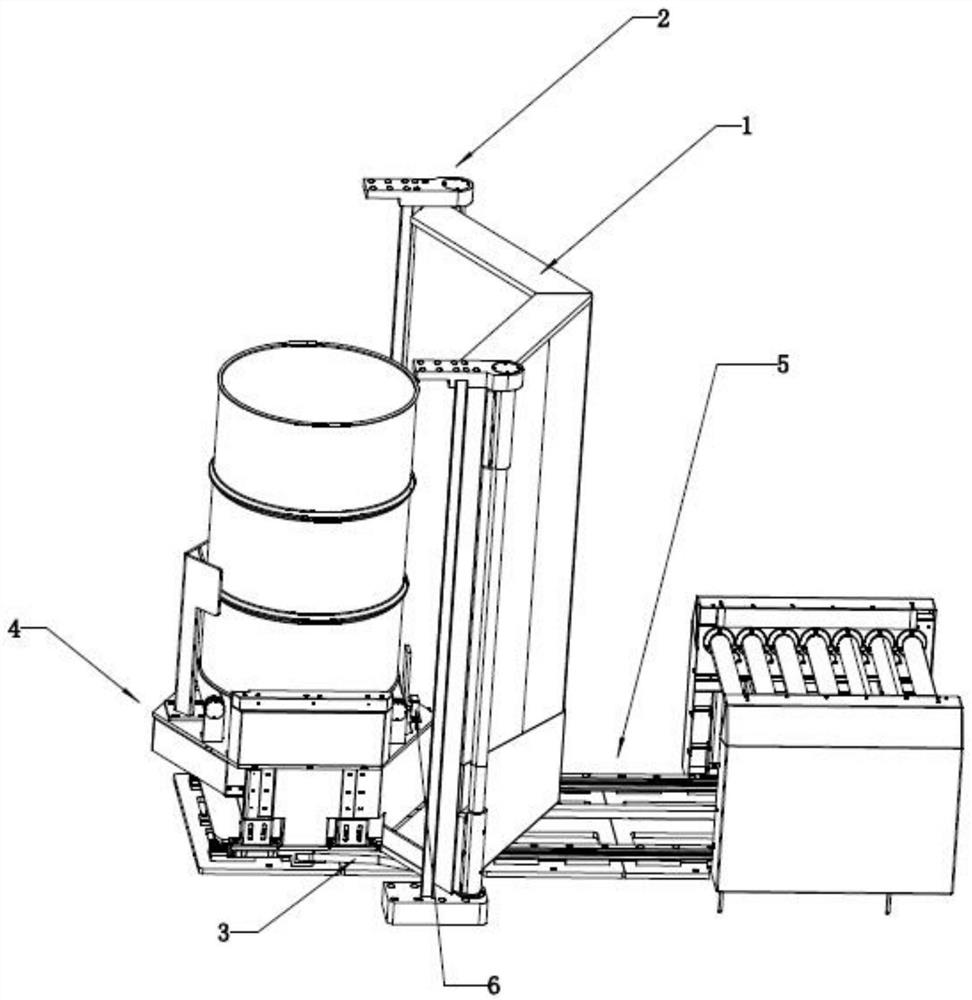

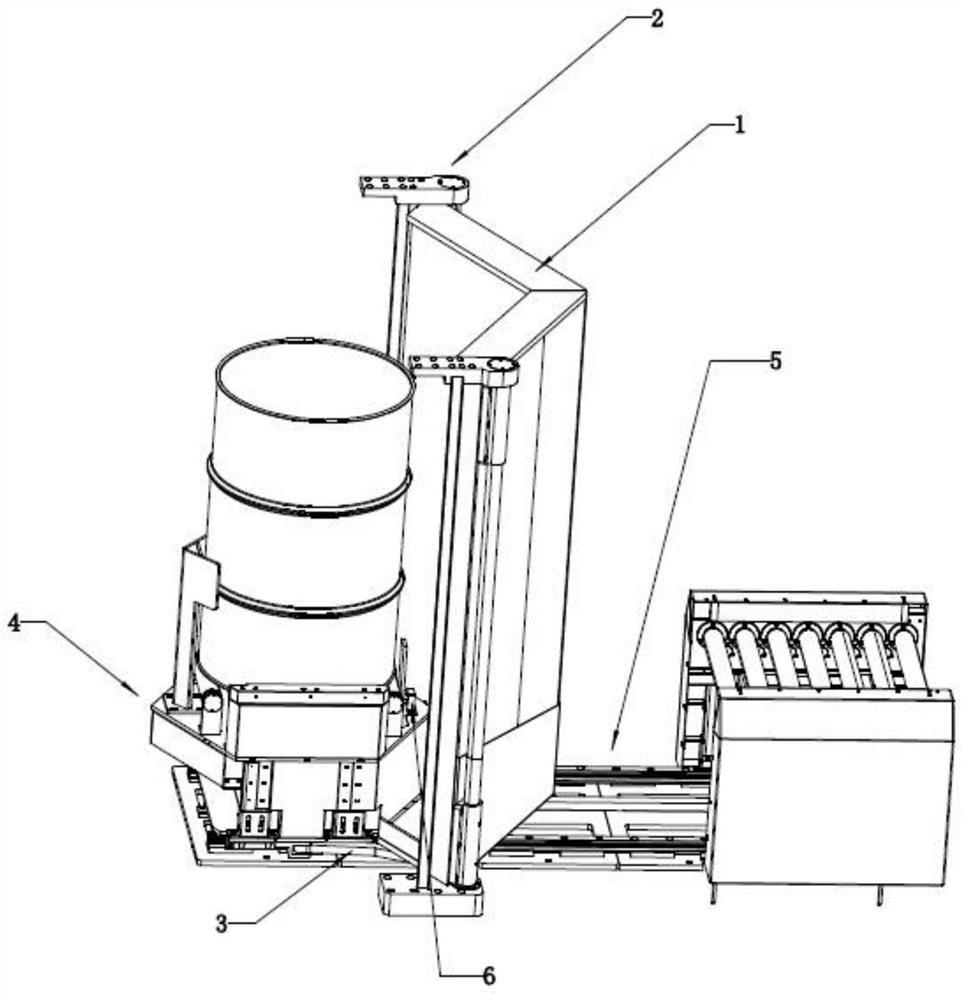

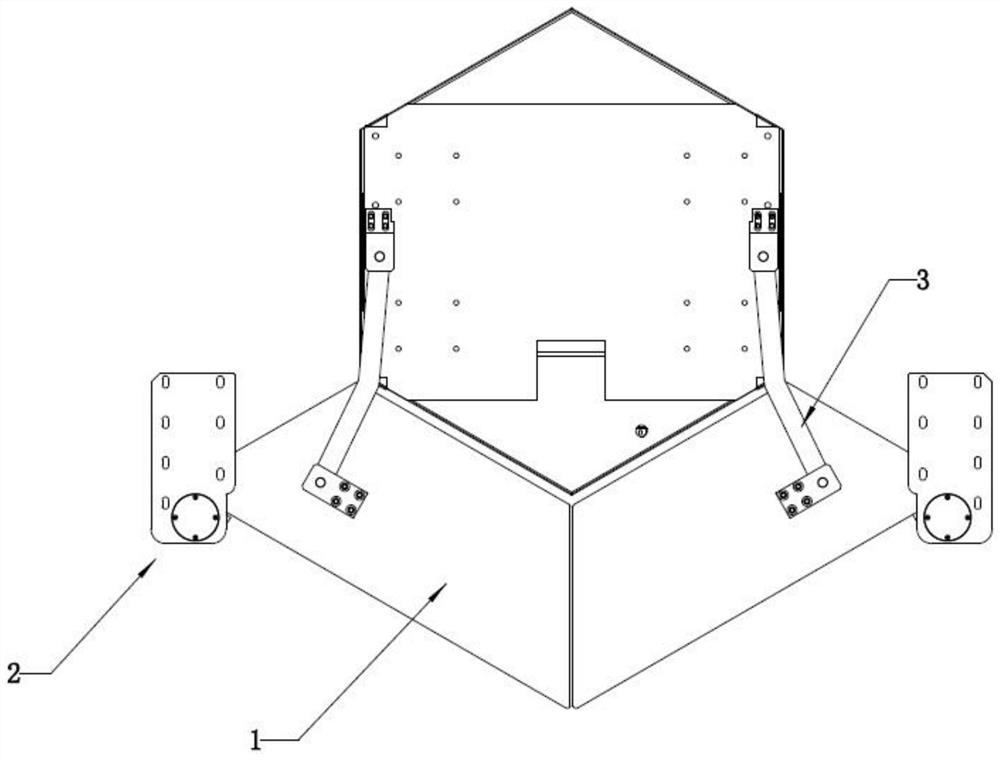

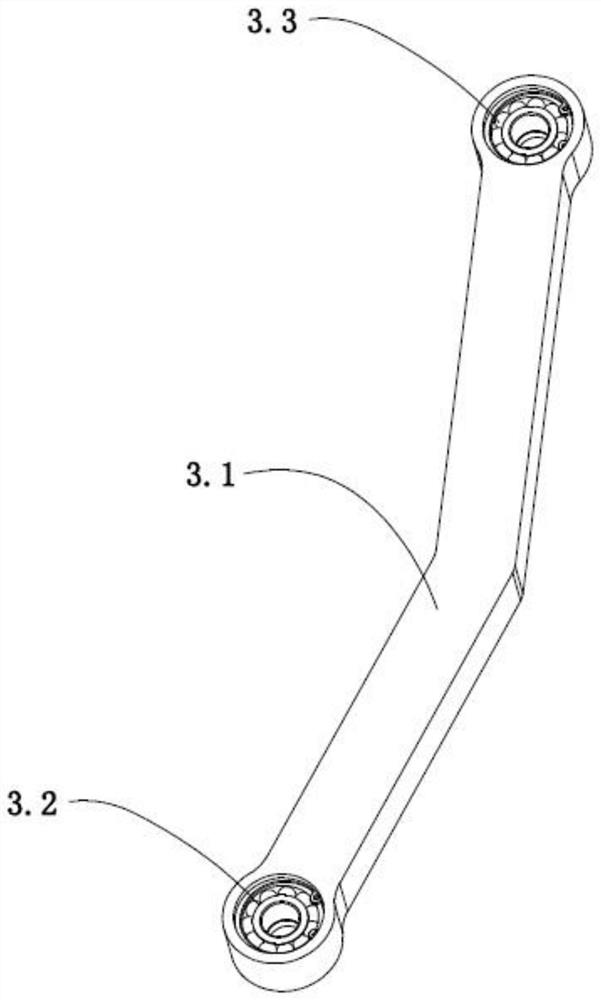

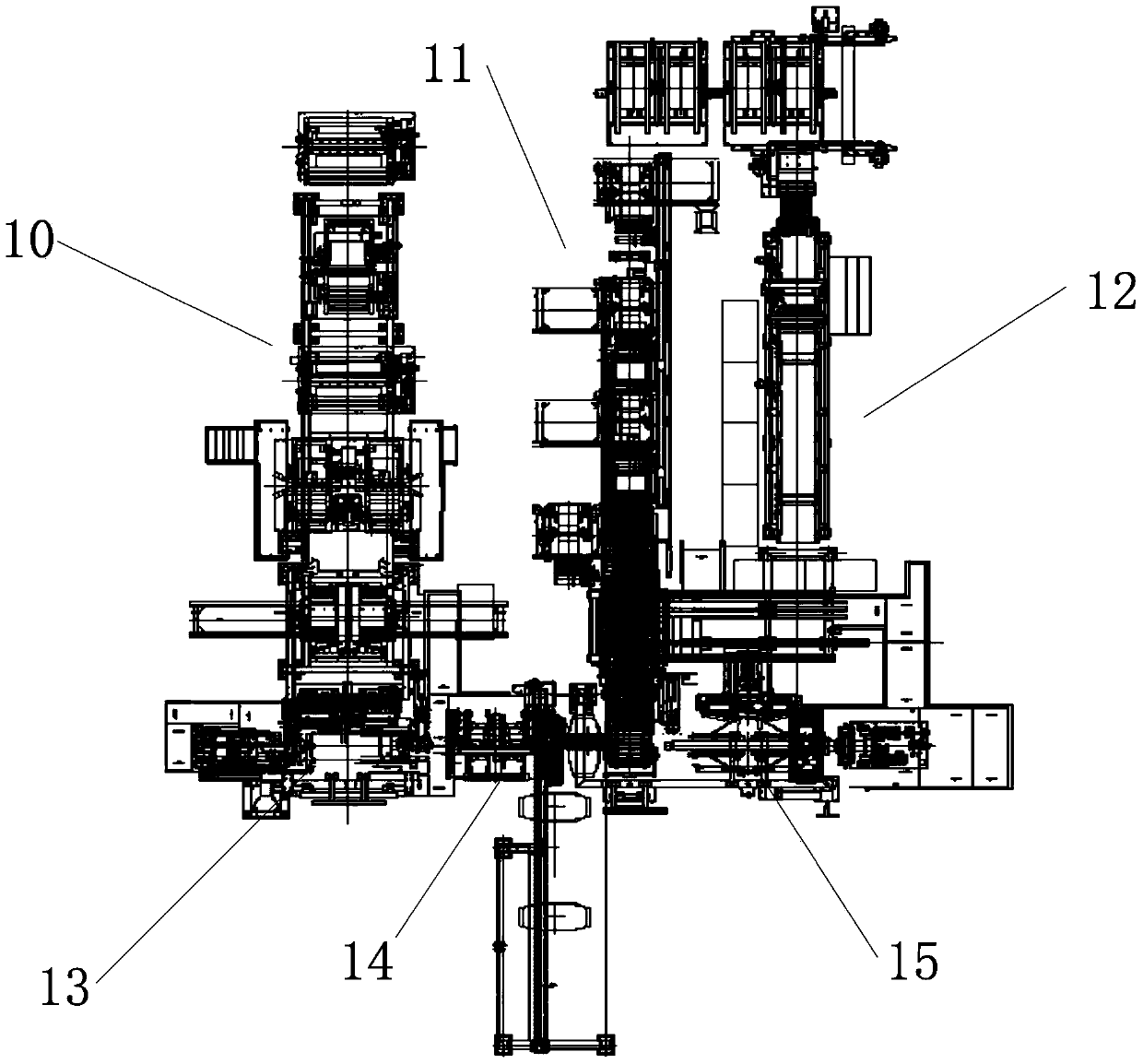

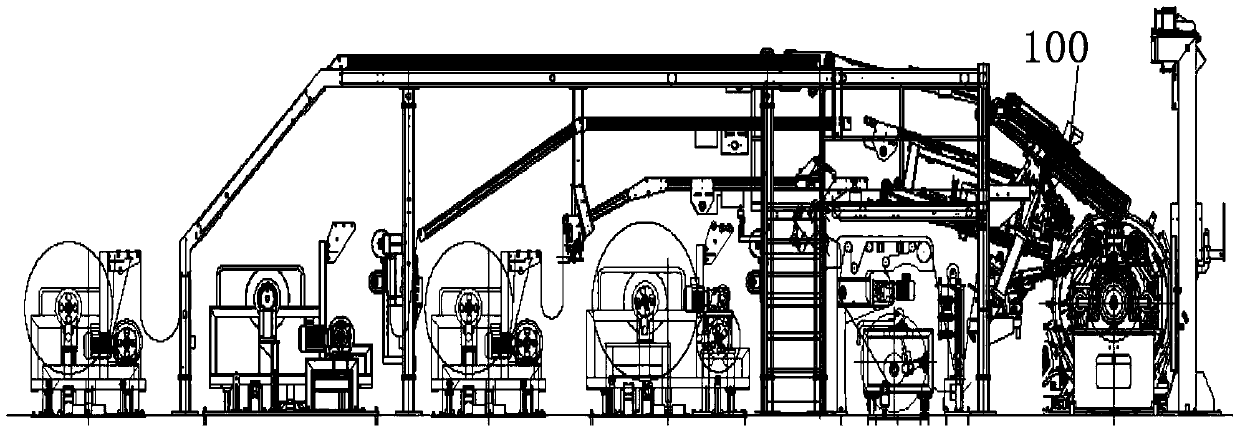

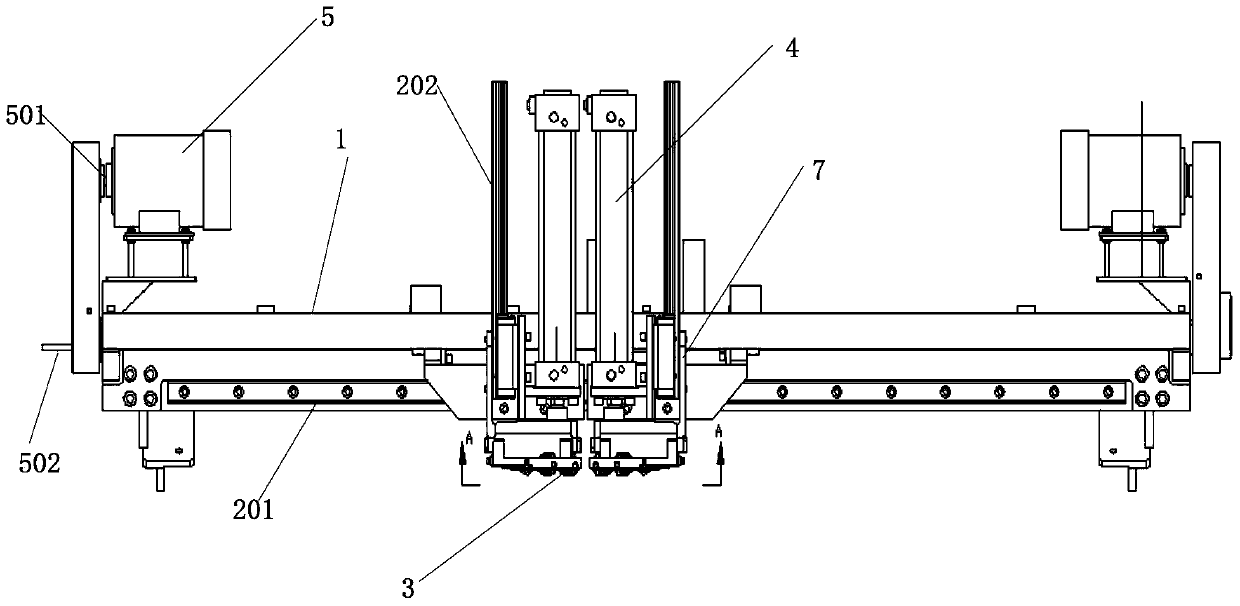

Automatic one-time all-steel forming machine

The invention provides an automatic one-time all-steel forming machine which comprises a main unit and an auxiliary unit.The main unit comprises a tire body drum, a belt drum and a forming drum, the belt drum is arranged between the tire body drum and the forming drum, centers of the tire body drum, the forming drum and the belt drum are positioned on a same straight line, transferring rings are arranged by taking the straight line as a center line, and tire bodies reciprocate through the transferring rings.The auxiliary unit comprises a main feeding frame, a belt feeding frame and a tread feeding frame, the main feeding frame, the belt feeding frame and the tread feeding frame are connected to the tire body drum, the belt drum and the forming drum respectively, and the belt feeding frame and the tread feeding frame are positioned on the same side of the belt drum.The automatic one-time all-steel forming machine is high in production efficiency, and overall output per manshift is more than 170 and reaches a domestic leading and international advanced level; the machine is high in automation degree, the tire body drum and the belt drum only require one operator, full-automatic forming is realized at the forming drum, high product quality is achieved, and the automatic one-time all-steel forming machine is widely applicable to forming procedures of all-steel-cord radial tires.

Owner:青岛海琅智能装备有限公司

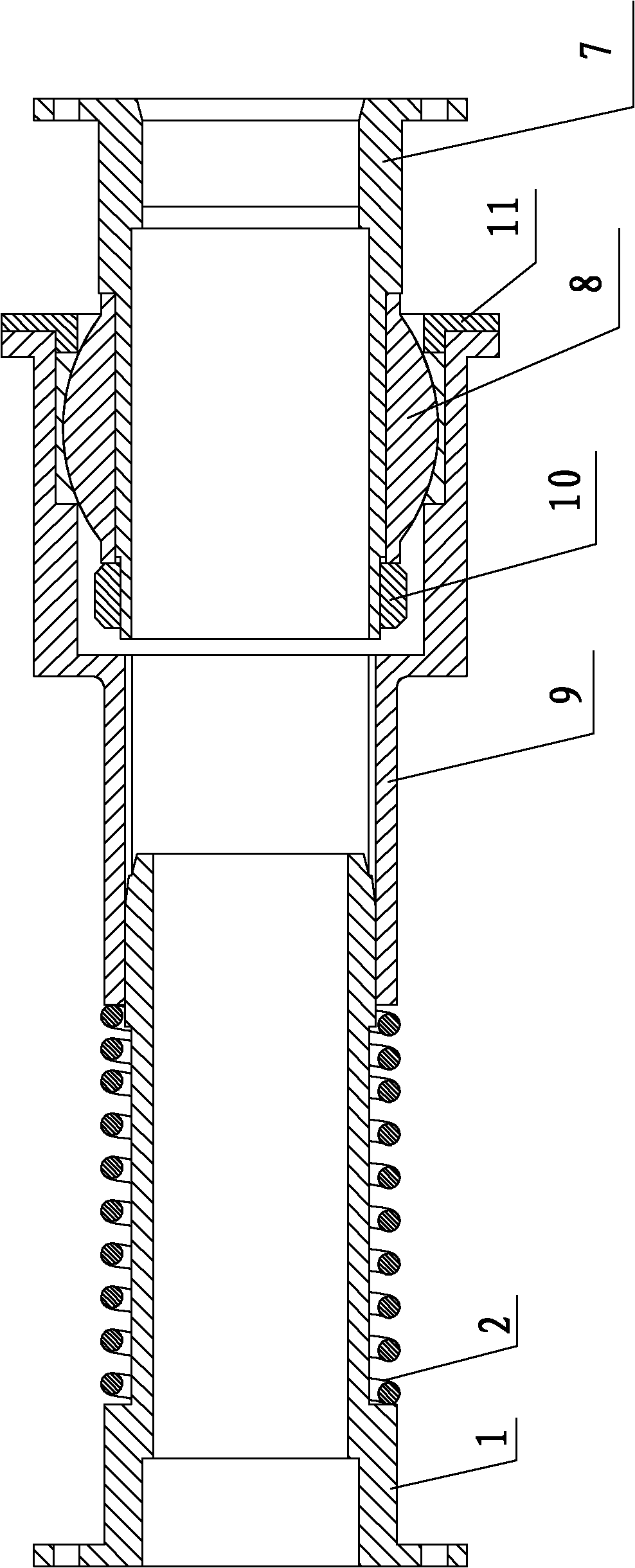

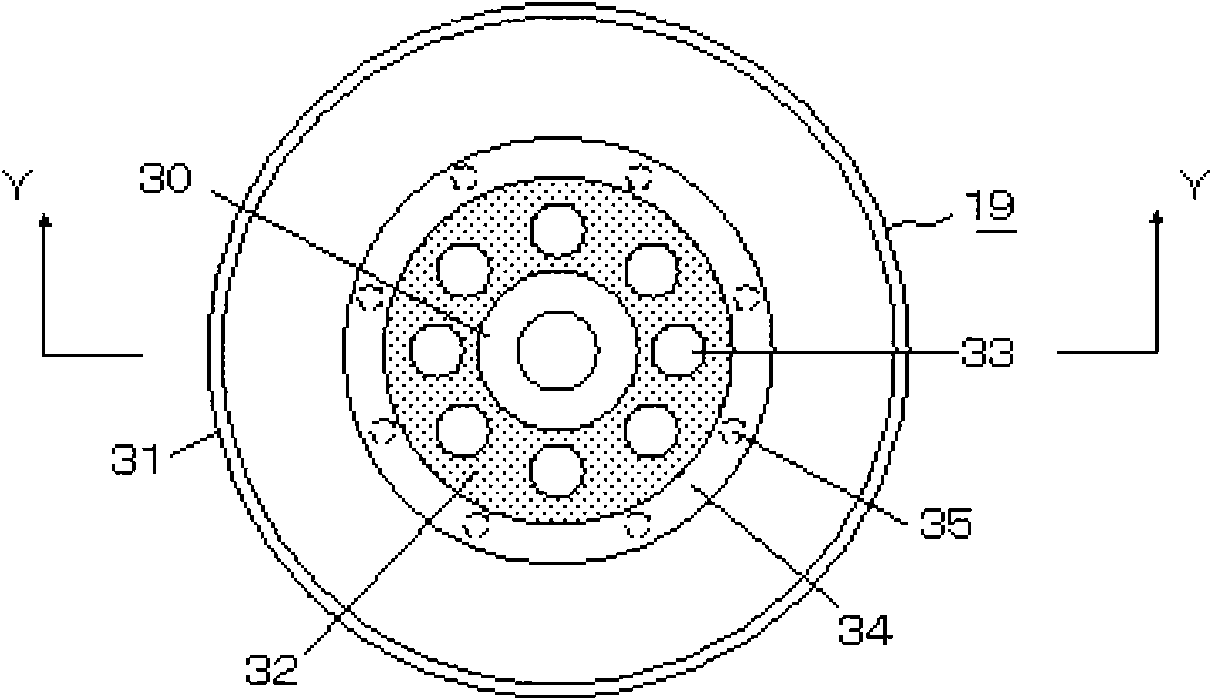

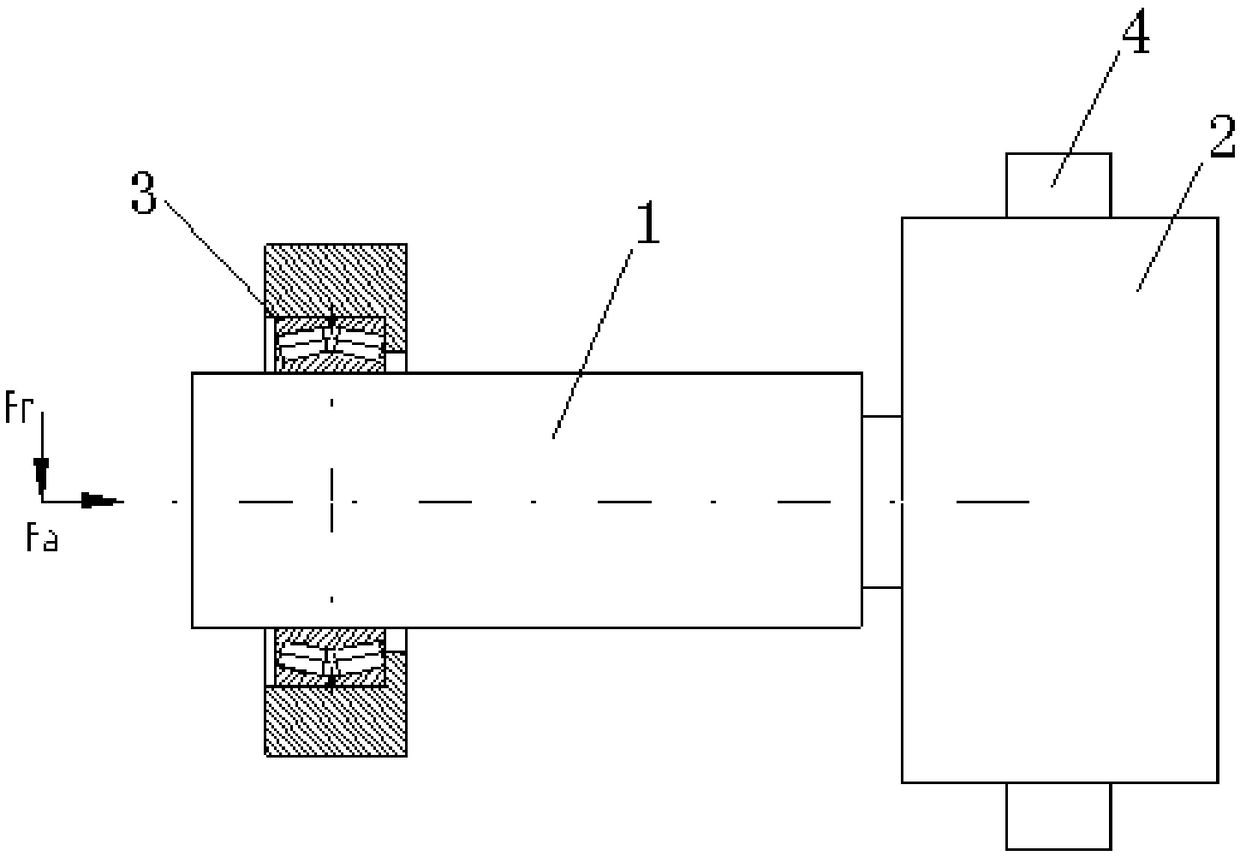

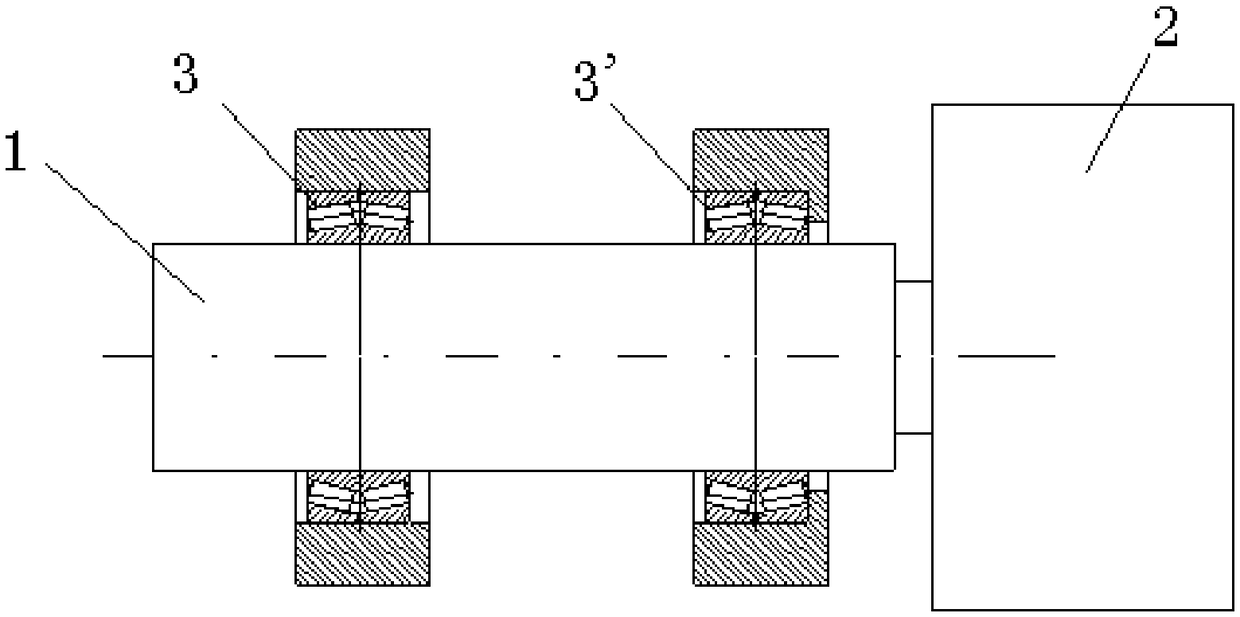

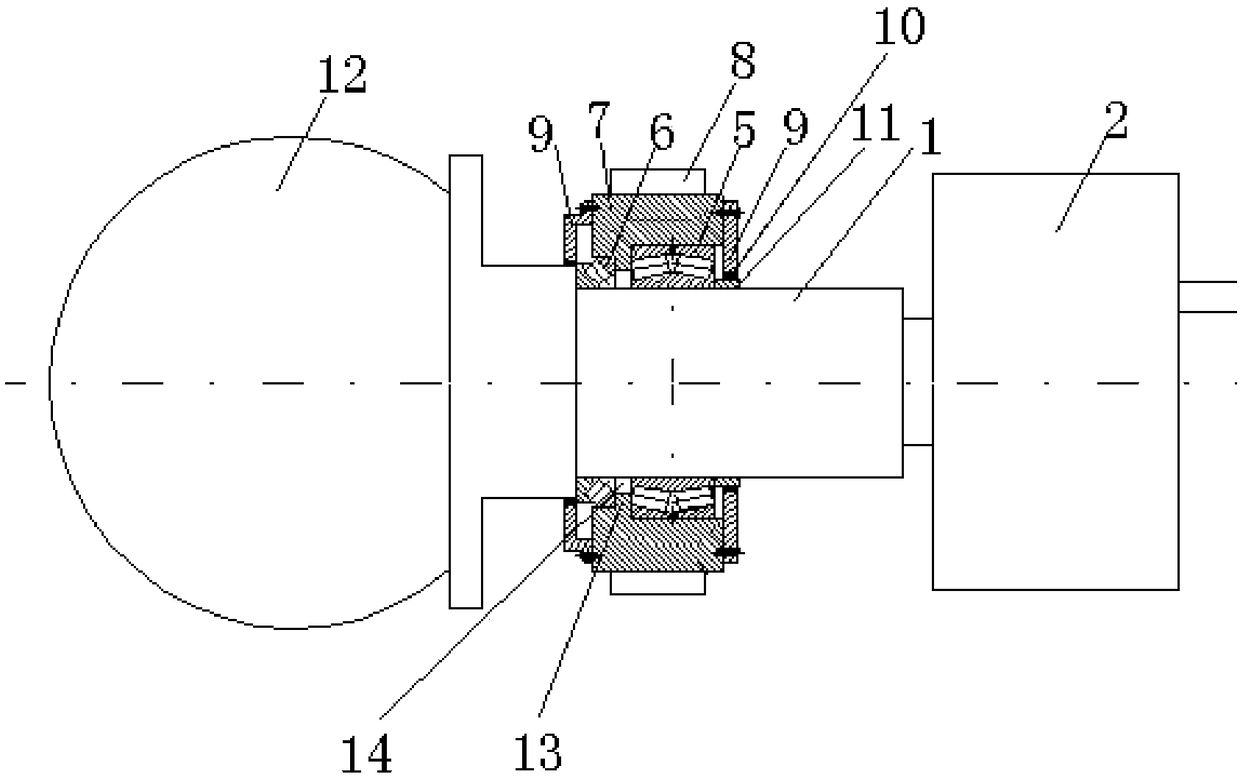

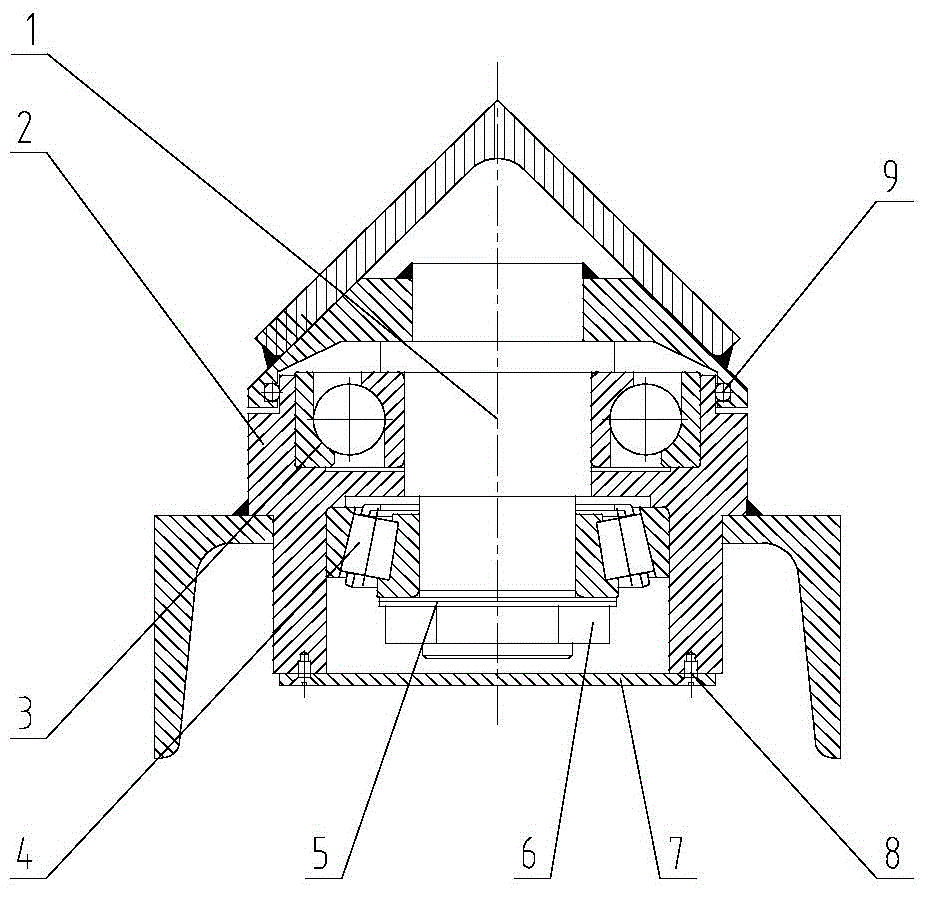

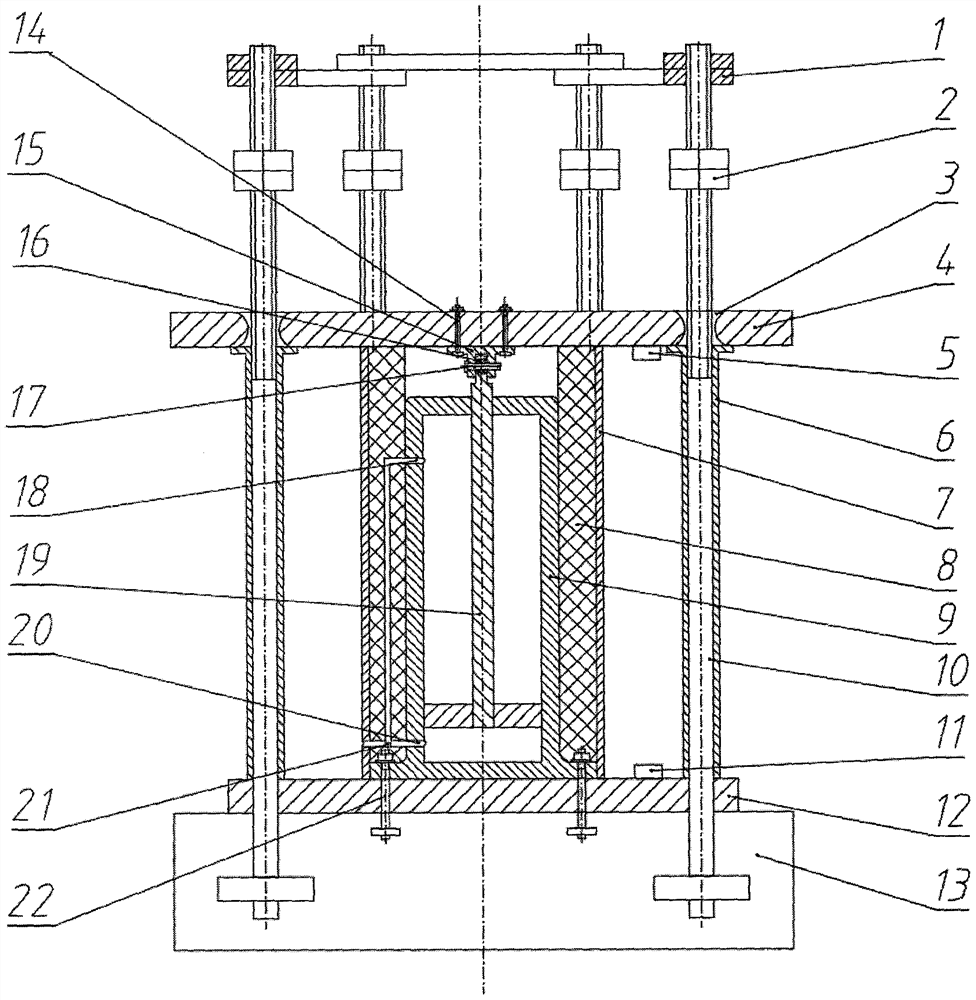

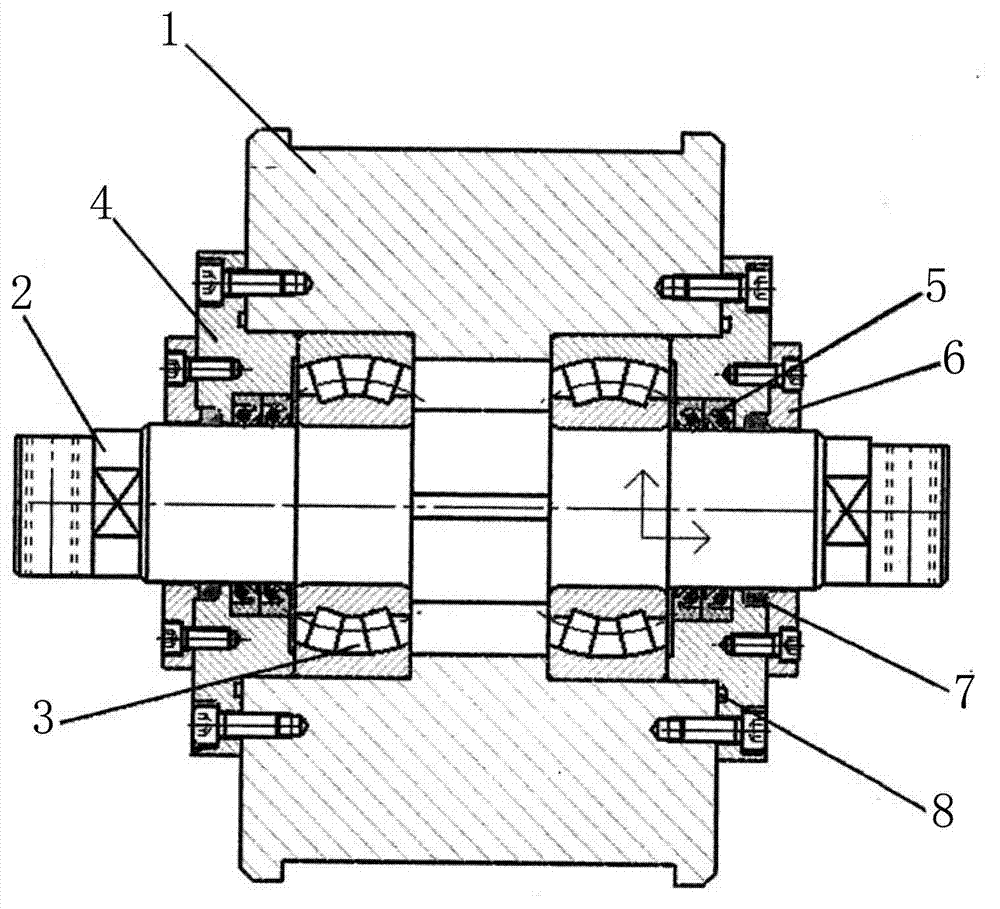

Low wind speed large-sized double-fed half direct-drive main bearing mechanism

PendingCN109139718AOvercome deformationGood centering performanceBearing unit rigid supportImpellerElectricity

The invention discloses a low wind speed large-sized double-fed half direct-drive main bearing mechanism. The low wind speed large-sized double-fed half direct-drive main bearing mechanism comprises afloating bearing and a thrust bearing, wherein the thrust bearing adopts a thrust self-aligning roller bearing; the floating bearing and the thrust bearing share one bearing block; a spigot ring is arranged on the inner side of the bearing block; the floating bearing and the thrust bearing are respectively arranged on two sides of the spigot ring; a gap is reserved between the spigot ring and theouter side of a main shaft; inner rings of the floating bearing and the thrust bearing are both in interference fit with the main shaft; outer rings of the floating bearing and the thrust bearing areboth in interference fit with the inner side of the bearing block; in addition, a gap between the floating bearing and the bearing block is smaller than that between the thrust bearing and the bearing block. According to the low wind speed large-sized double-fed half direct-drive main bearing mechanism disclosed by the invention, by adopting the thrust self-aligning roller bearing as the thrust bearing, all axial loads transmitted by an impeller can be borne and the problem that the main shaft is easy to deform can be solved. By adopting a bearing combined structure, the coaxiality of the twobearings is ensured; in addition, inner cavities of the two bearings are enabled to be communicated, so that convenience in maintenance is realized, the reliability of a main bearing and a wind generation set is improved, and the service life of the main bearing mechanism is prolonged.

Owner:GUODIAN UNITED POWER TECH

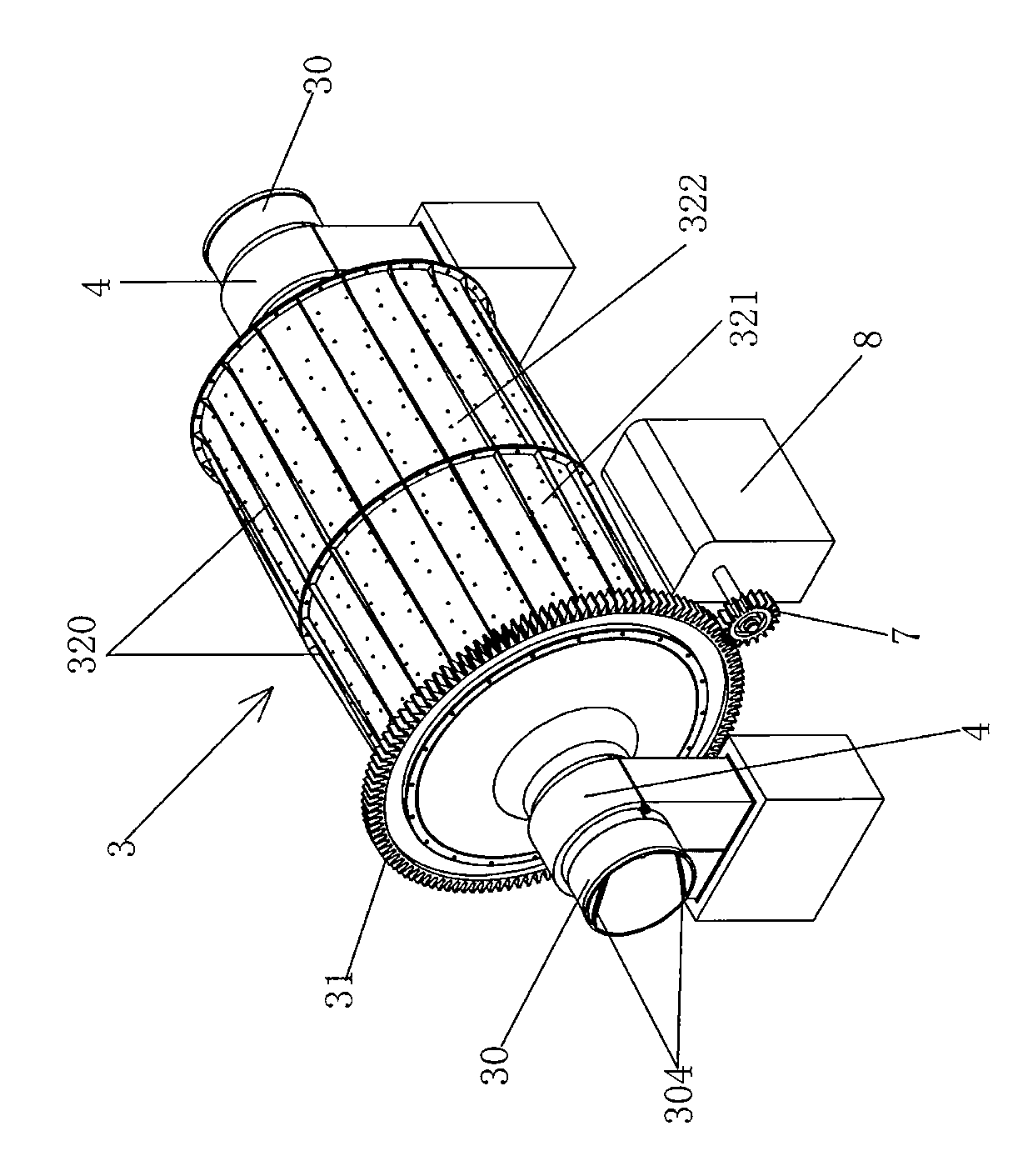

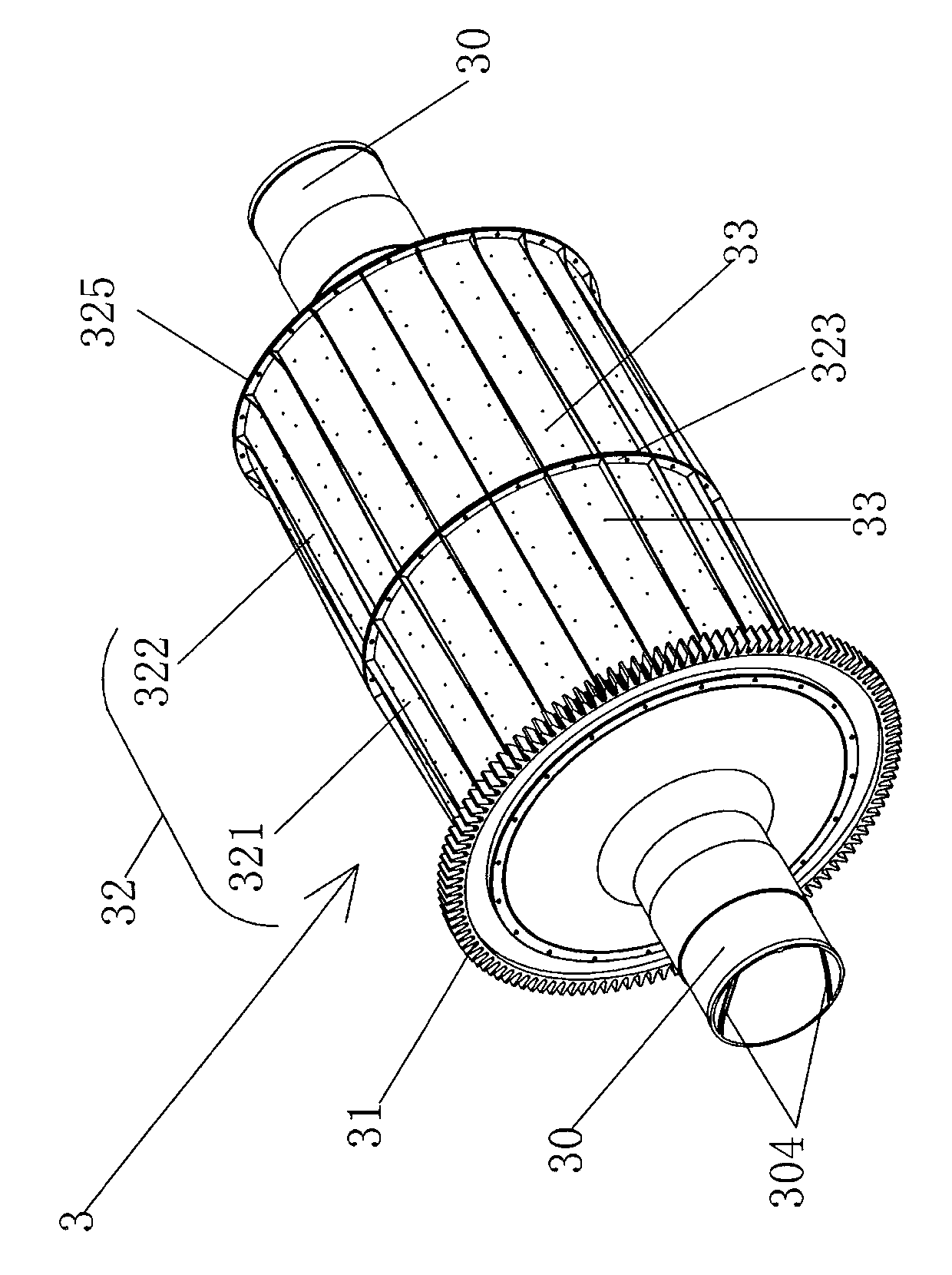

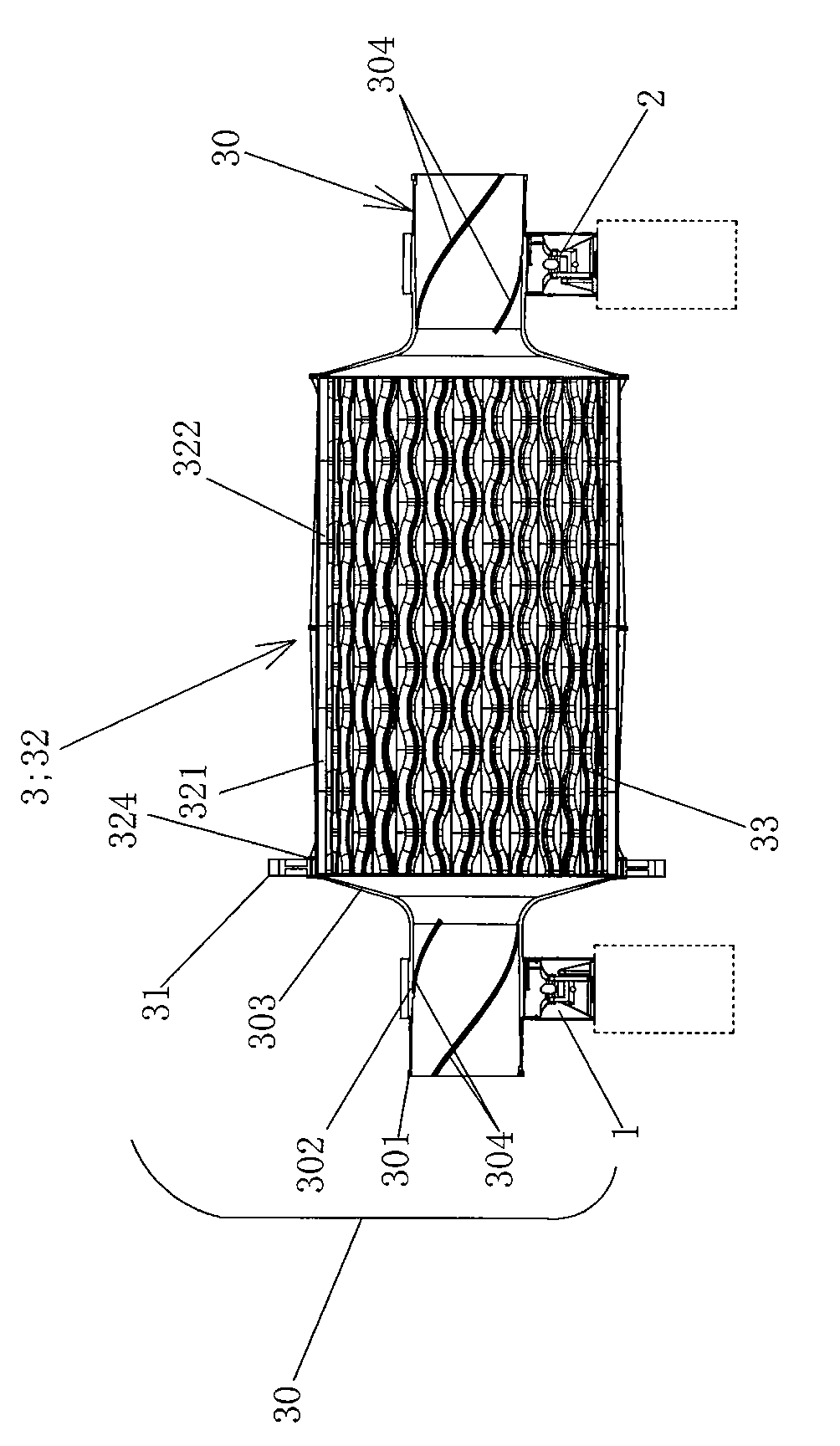

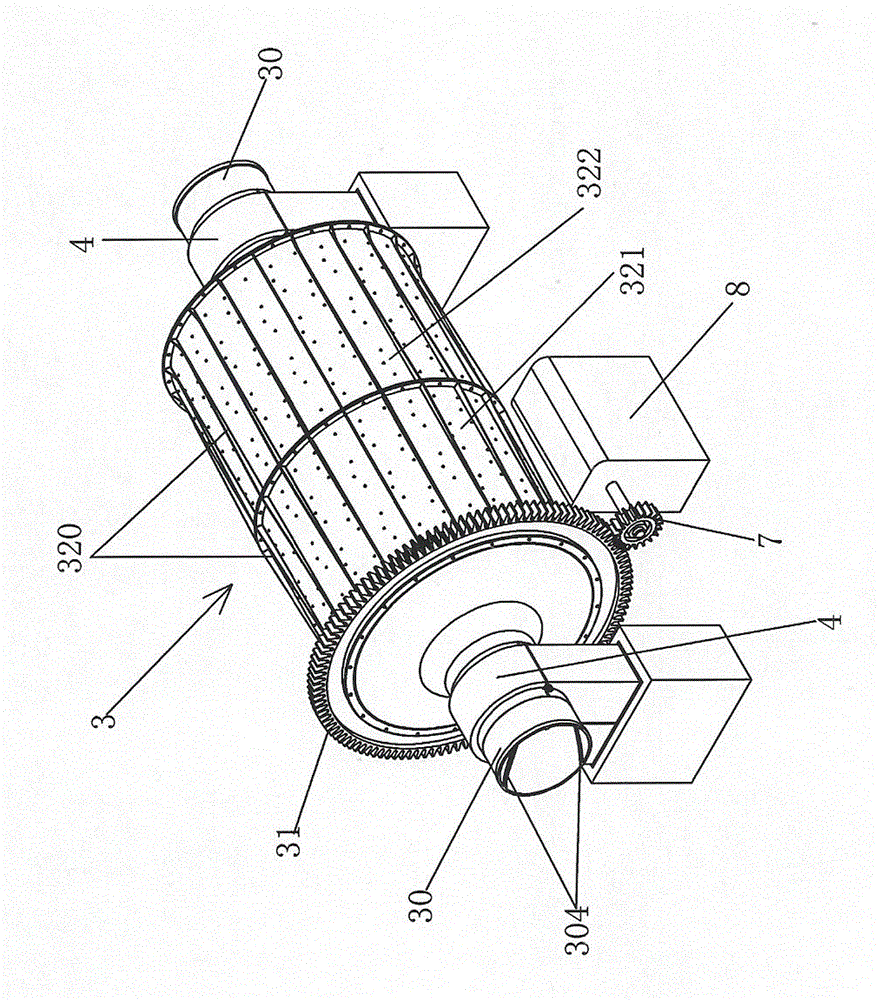

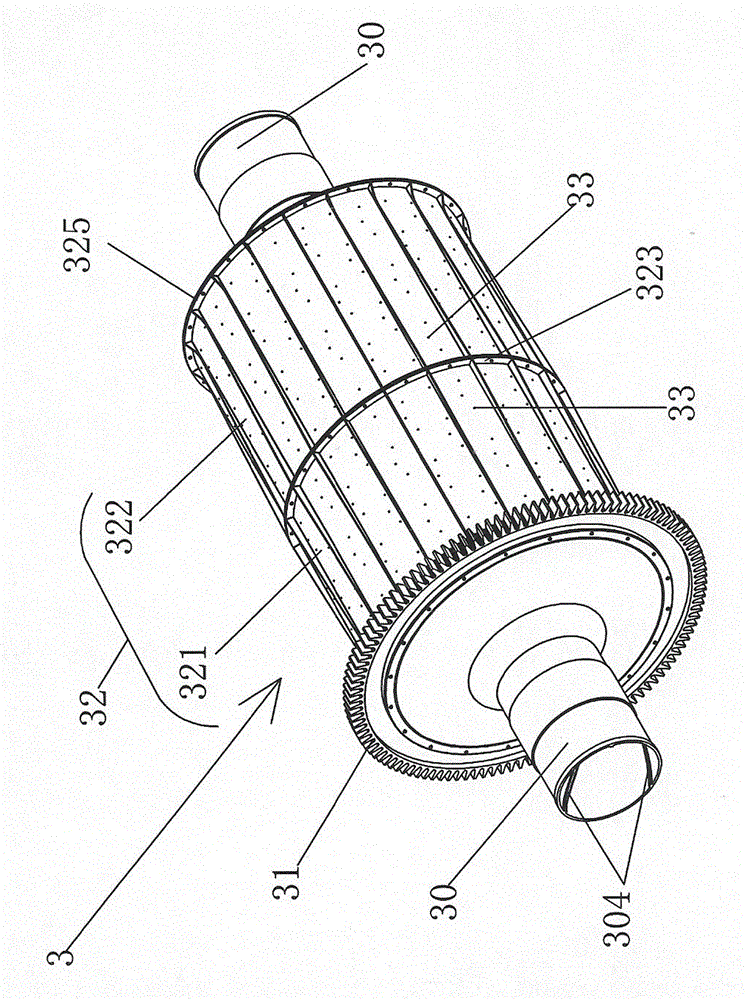

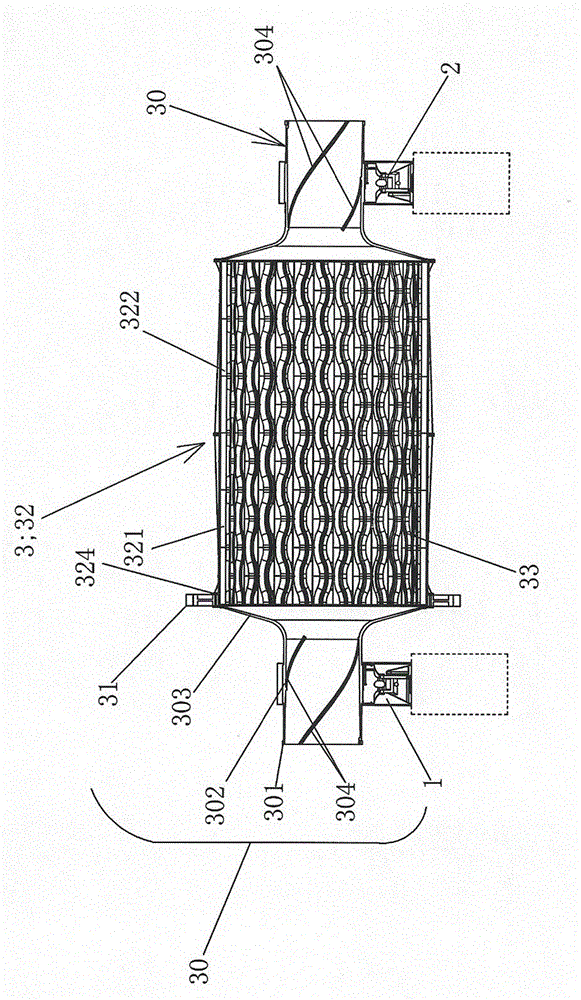

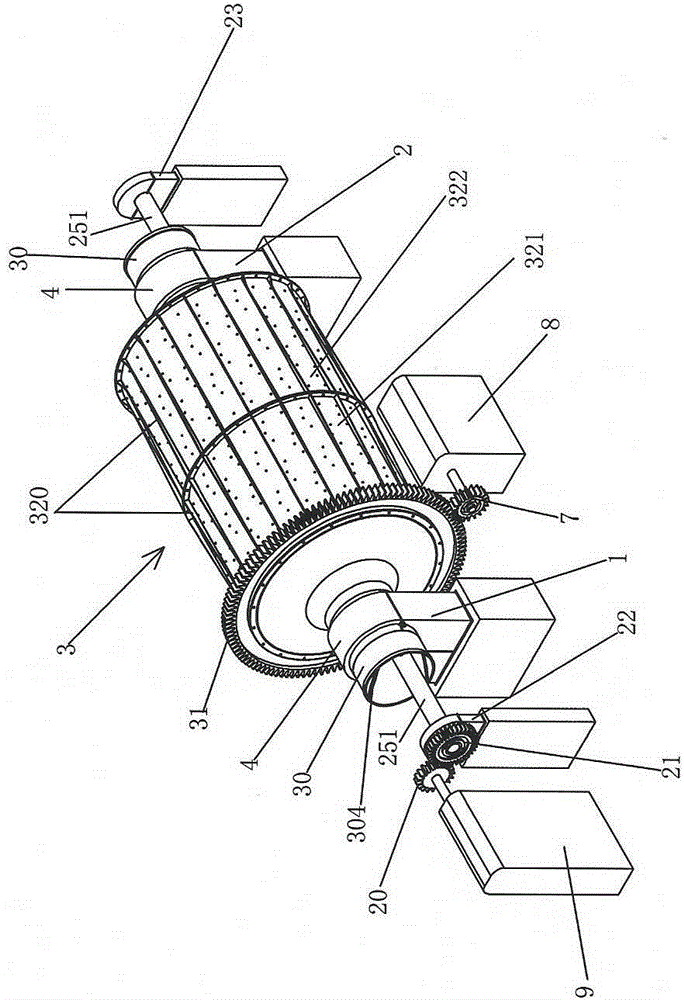

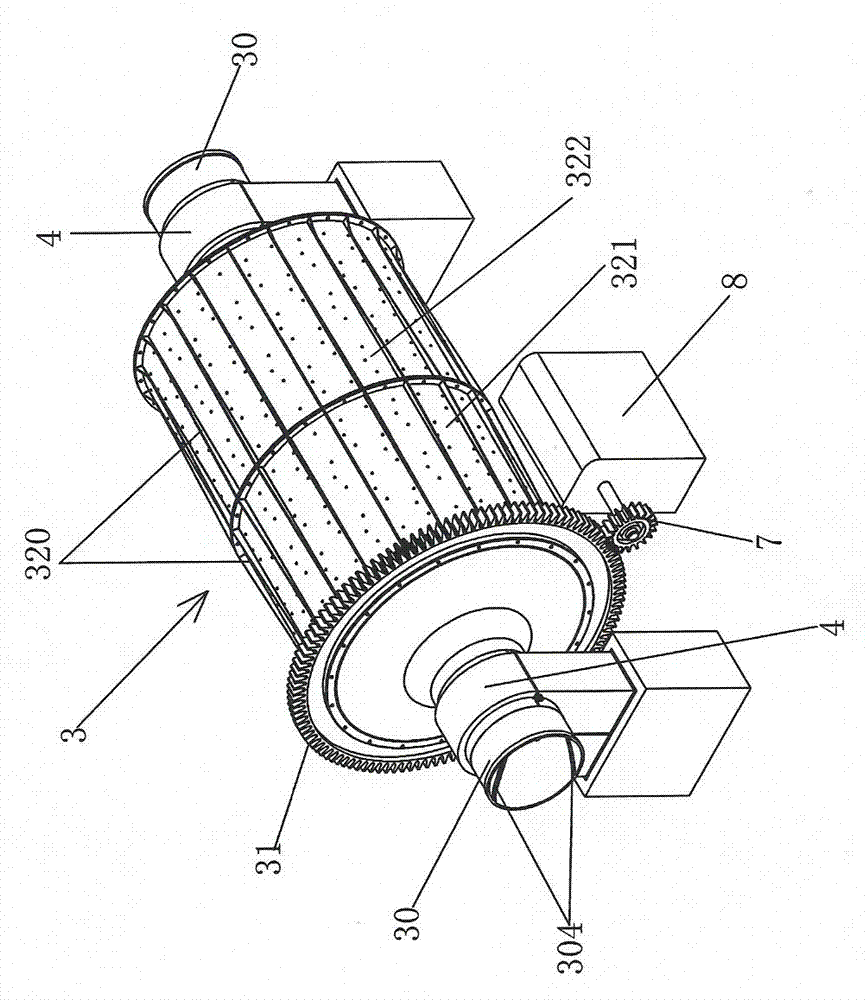

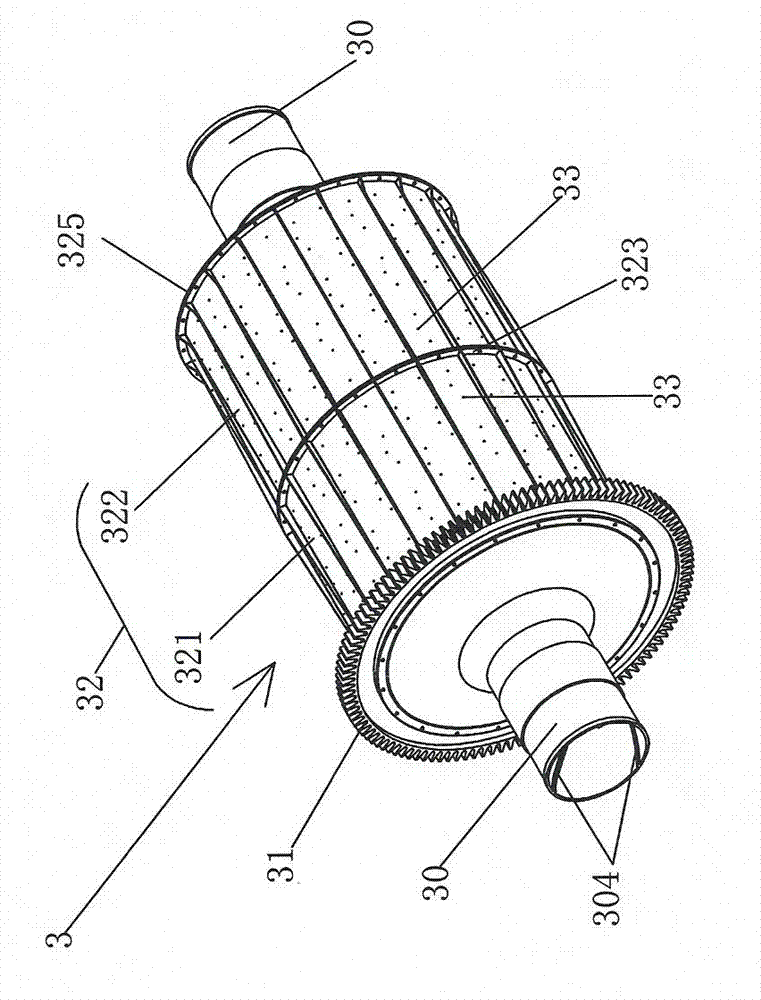

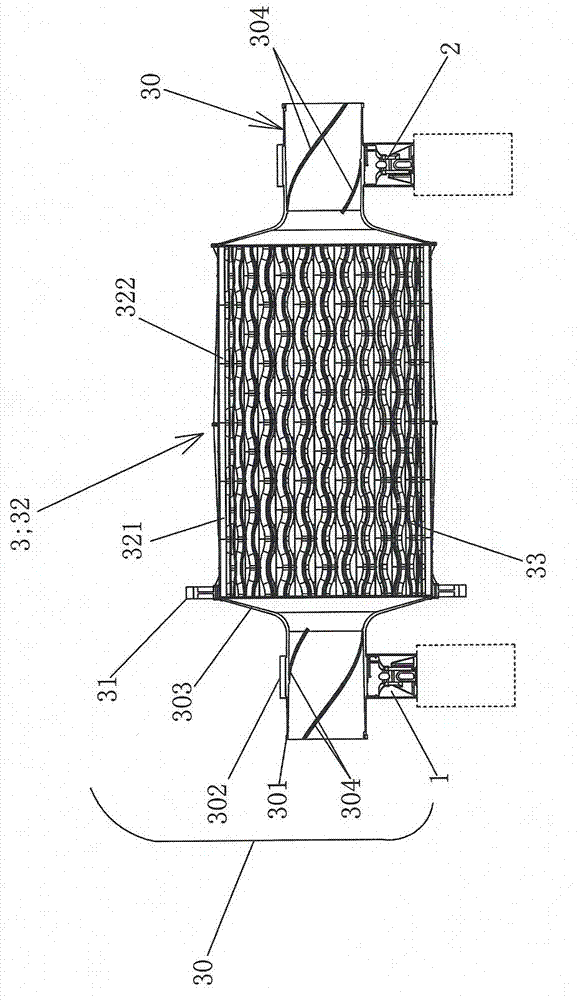

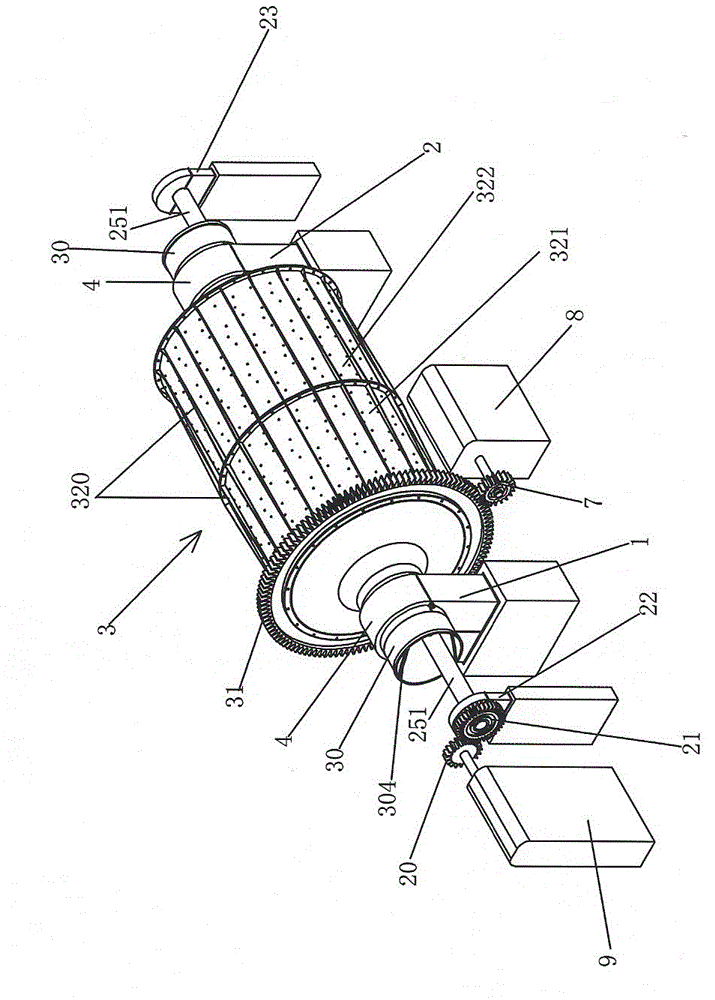

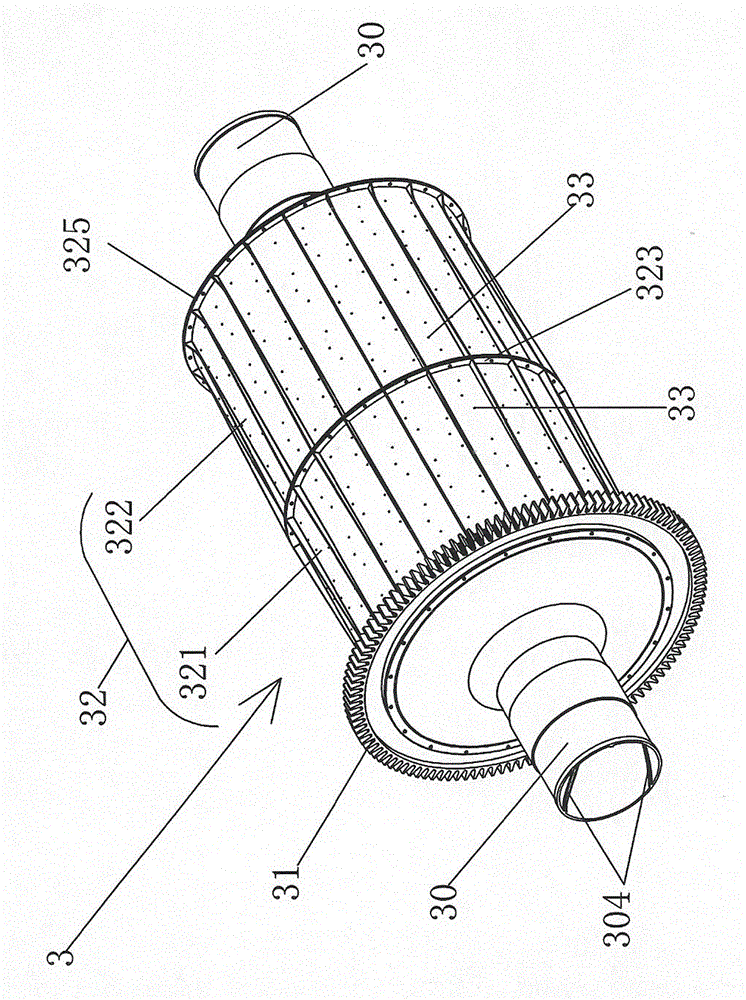

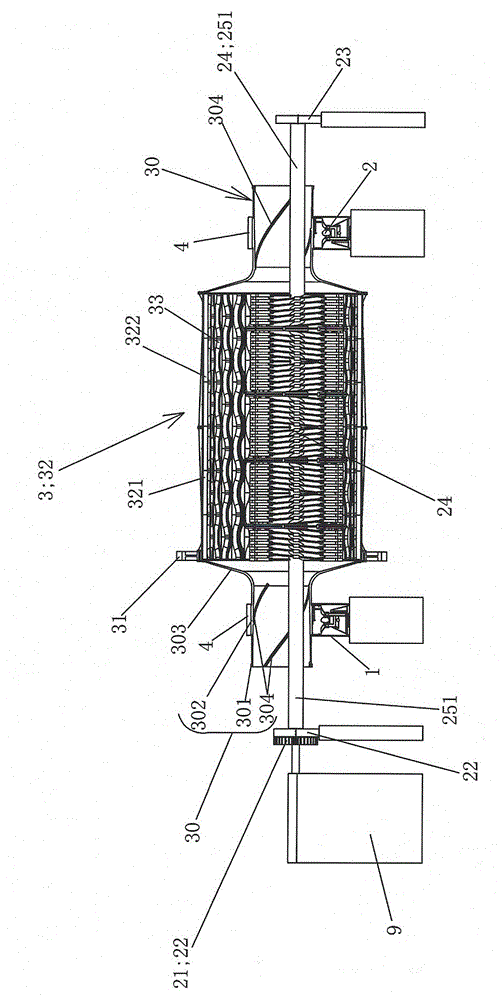

Energy-saving ball mill

InactiveCN103230817AImprove carrying capacityReduce energy consumptionGrain treatmentsHigh pressurePinion

The invention discloses an energy-saving ball mill which consists of a first hydrostatic bearing, a second hydrostatic bearing, a rotating body, hydrostatic bearing sealing covers, a local dust collector, a pinion and a transmission system, wherein hollow shafts at two ends of the rotating body are respectively arranged on the first hydrostatic bearing and the second hydrostatic bearing and are respectively covered by the two hydrostatic bearing sealing covers; the periphery of the rotating body is provided with a gearwheel meshed with the pinion; high pressure oil forms a lubricating oil film among the first hydrostatic bearing, the second hydrostatic bearing and the shaft neck of the hollow shaft of the rotating body, the rotating body can float, the lubricating oil film can be kept complete, and the liquid lubrication is completely realized; the bearing has high bearing capacity; when the rotating body generates small elastic bending deformation, the bearing bodies of the first hydrostatic bearing and the second hydrostatic bearing relatively rotate by a small angle around first pin shafts respectively, so that the thickness of the oil film is basically invariable along the axial direction; according to the corrugated lining plate in the rotating body, the abrasive action between the abrasive medium and mineral aggregate and between the mineral aggregate is enhanced; and moreover, according to the sealing covers and the local dust collector, the dust particles in the ball mill operating environment can be efficiently prevented from entering the operating space of the hydrostatic bearings.

Owner:KUNMING UNIV

Novel rotating base

InactiveCN104609129AFlexible rotationImprove sealingConveyorsRollersTapered roller bearingRoller bearing

The invention discloses a novel rotating base which comprises a shaft and a base. The shaft is connected with an upper cross beam of an alignment carrier roller in a welded mode, the base is connected with a lower cross beam of the alignment carrier roller in a welded mode, an angular contact bearing and a conical roller bearing are arranged between the shaft and the base in a vertically spaced mode, the upper portion of the base is nested in the lower portion of an opening hole in the upper cross beam, an O-shaped seal ring is arranged between the base and the nesting position of the upper cross beam, the part, on the lower end face of the conical roller bearing, of the shaft is sleeved with a gasket, the gasket is tightly pressed to the lower end face of the conical roller bearing through a nut, and a base end cover is connected to the bottom face of the base through fixing parts. The novel rotating base has the advantages that the angular contact bearing and the conical roller bearing are arranged between the shaft and the base, so that the shaft and the base are rotated flexibly; the O-shaped seal ring is arranged between the base and the upper cross beam, the seal performance is good, the alignment effect is good, and the service life is long.

Owner:天津三岛输送机械有限公司

Differential reducer

The invention discloses a differential reducer, and belongs to the technical field of reducers. The differential reducer includes a box body, a gear reduction system and a lubrication system, whereinthe gear reduction system includes an intermediate shaft assembly, an input shaft assembly, a low speed output shaft assembly and a high speed output shaft assembly, a transmission gearwheel in the intermediate shaft assembly is partially placed in lubricating oil, the lubrication system includes a thin oil lubricating station, an oil distributor and a connector seat, the thin oil lubricating station is connected with the bottom of the box body and the oil distributor, oil outlets of the oil distributor communicate with the joints between each assembly and the box body and the connector seat correspondingly, and perforated oil tubes on the connecting seat are placed above gears on the low speed output shaft assembly and the high speed output shaft assembly. According to the differential reducer, the thin oil lubricating station provides fast circulating fluidity for the lubricating oil, the transmission gearwheel drives the lubricating oil to splash while stirring the lubricating oil,thus the heat dissipation performance of the differential reducer is improved, and the oil temperature can be effectively lowered.

Owner:CSR ZIYANG TRANSMISSION

Material conveying mechanism

ActiveCN112850106AReduce failure rateReduce manufacturing costPower-operated mechanismConveyor partsEngineeringLarge Calorie

The invention relates to a material conveying mechanism. The mechanism comprises a linkage opening and closing door mechanism, a conveying line and an automatic stopping mechanism. The linkage opening and closing door mechanism comprises an opening and closing door, a rotating shaft part, a material carrier and a connecting rod part; the opening and closing door is mounted through the rotating shaft part and can rotate around a rotating shaft of the rotating shaft part; the connecting rod part comprises a connecting rod; and the two ends of the connecting rod are connected to the material carrier and the opening and closing door correspondingly so that the opening and closing process of the opening and closing door and the in-out process of the material carrier can be linked. The two ends of the connecting rod are connected to the material carrier and the opening and closing door through self-aligning roller bearings respectively. The material carrier moves out of the opening and closing door and then is in butt joint with the conveying line so as to transfer the materials to the conveying mechanism. The automatic stopping mechanism is arranged on the material carrier and / or the conveying line so as to stop or allow conveying of the materials. The material conveying mechanism has the beneficial effects that opening and closing doors actions and feeding or discharging of the materials can be achieved through one driving device, the manufacturing cost is saved, and the fault occurrence rate of the mechanism is reduced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

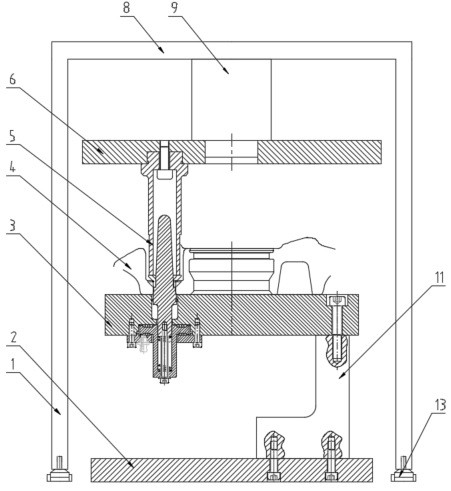

Suspended degassing device

The invention provides a suspended degassing device which is high in structural stability, has small vibration amplitude during the running process, effectively avoids sloshing of molten aluminum and guarantees the refining quality. The suspended degassing device comprises a frame, a graphite rotor, a gas blowpipe and a rotor driving device, wherein the graphite rotor is connected with the gas blowpipe through a connecting sleeve. The suspended degassing device is characterized by further comprising a guide rail, a lifting platform, a guide pillar and a lifting driving device, wherein a plurality of cross beams are arranged on the frame; the guide rail and the guide pillar are parallel to each other and are supported by the cross beams; two ends of the lifting platform are connected with the guide rail and the guide pillar in a sliding way respectively; a bearing block is fixed at the lower part of the lifting platform; the gas blowpipe and the bearing block are mounted in a matching way; and a driven wheel and an elastic support piece are arranged on the lifting platform.

Owner:WUXI SHUANGQUAN MECHANICAL FACTORY

Stirrer

The invention discloses a stirrer which comprises a motor, a clutch, a reducer, a stirring box, a stirring shaft, stirring knife blades, a first clamp coupling, a second clamp coupling, a front link double bearing pedestal and a rear link double bearing pedestal, wherein the stirring shaft consists of a stirring short shaft and a stirring long shaft; one end of the stirring short shaft is connected with a slow-speed shaft of the reducer by the first clamp coupling; the other end of the stirring short shaft is connected with a bearing bore of the front link double bearing pedestal; one end of the stirring long shaft is connected with the bearing bore of the front link double bearing pedestal by the second clamp coupling; the other end of the stirring long shaft is connected with a bearing bore of the rear link double bearing pedestal; the stirring long shaft is sleeved with a threaded protective sleeve; a stirring knife holder is welded on the threaded protective sleeve; the stirring knife blades are fixed on the stirring knife holder by bolts. The stirrer adopts a broken shaft structure, so that the deflection of the stirring shaft can be reduced effectively, the stirring shaft can be prevented from bending deformation, a curing degree of a stirred material is ensured, and a brickmaking effect is improved.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

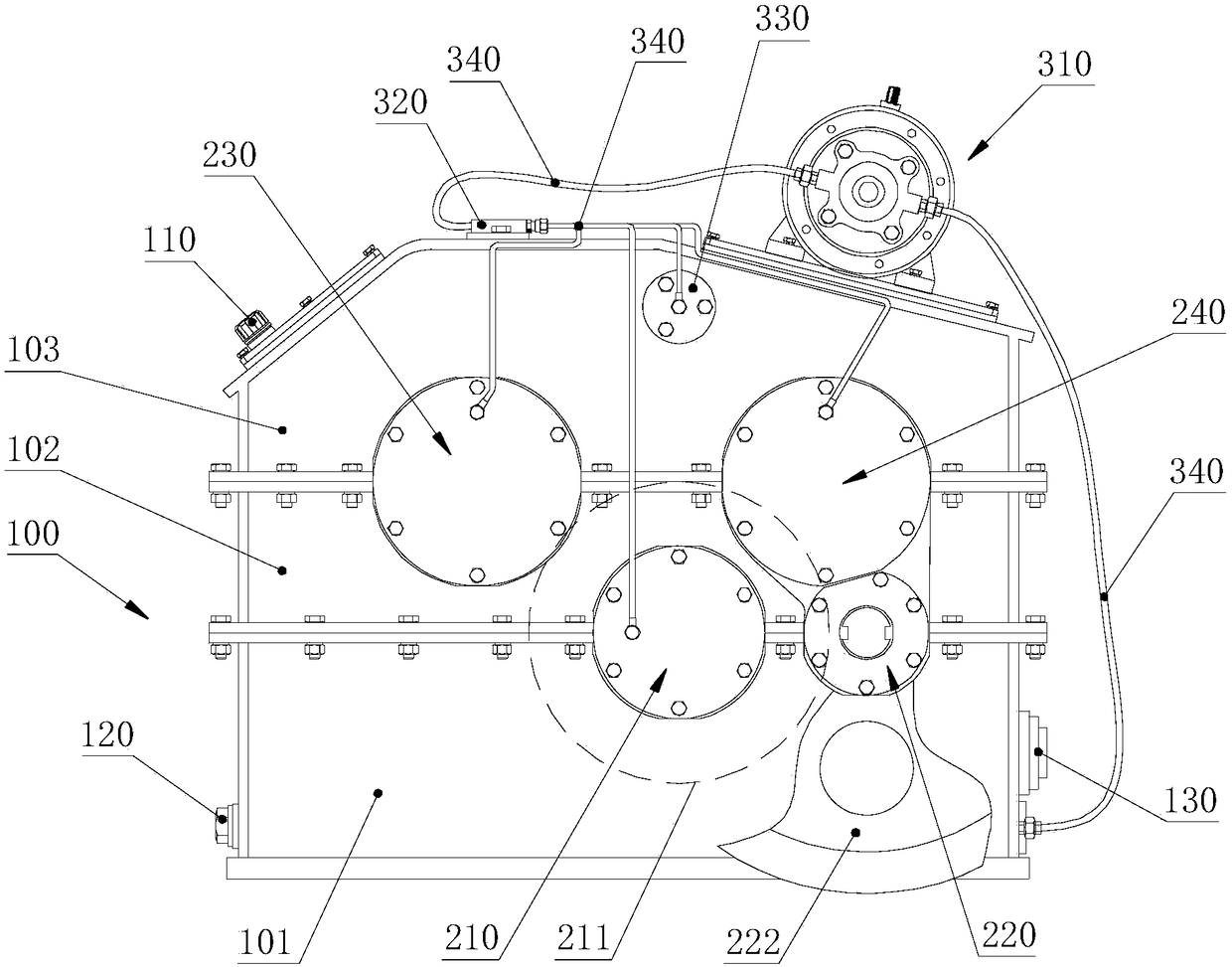

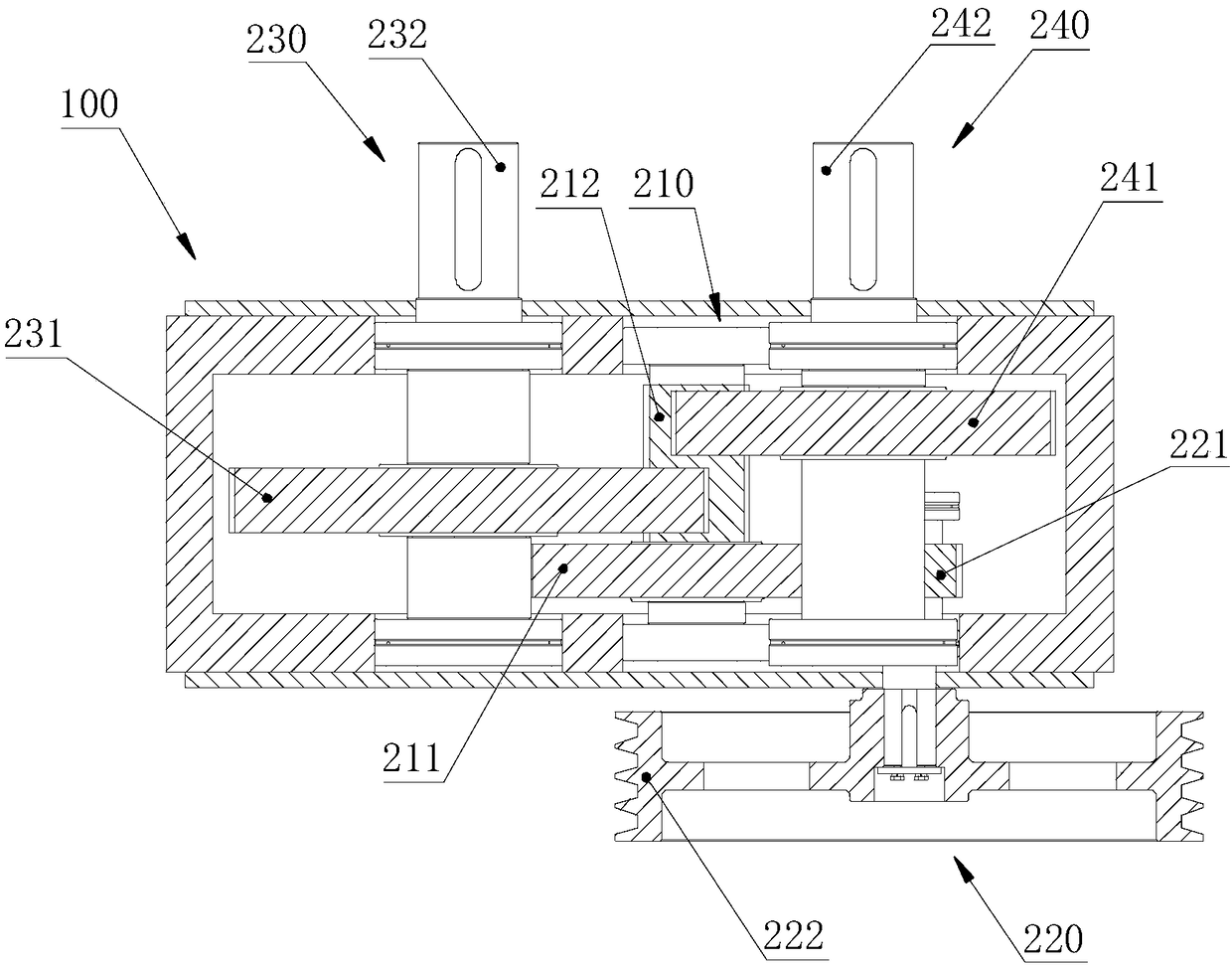

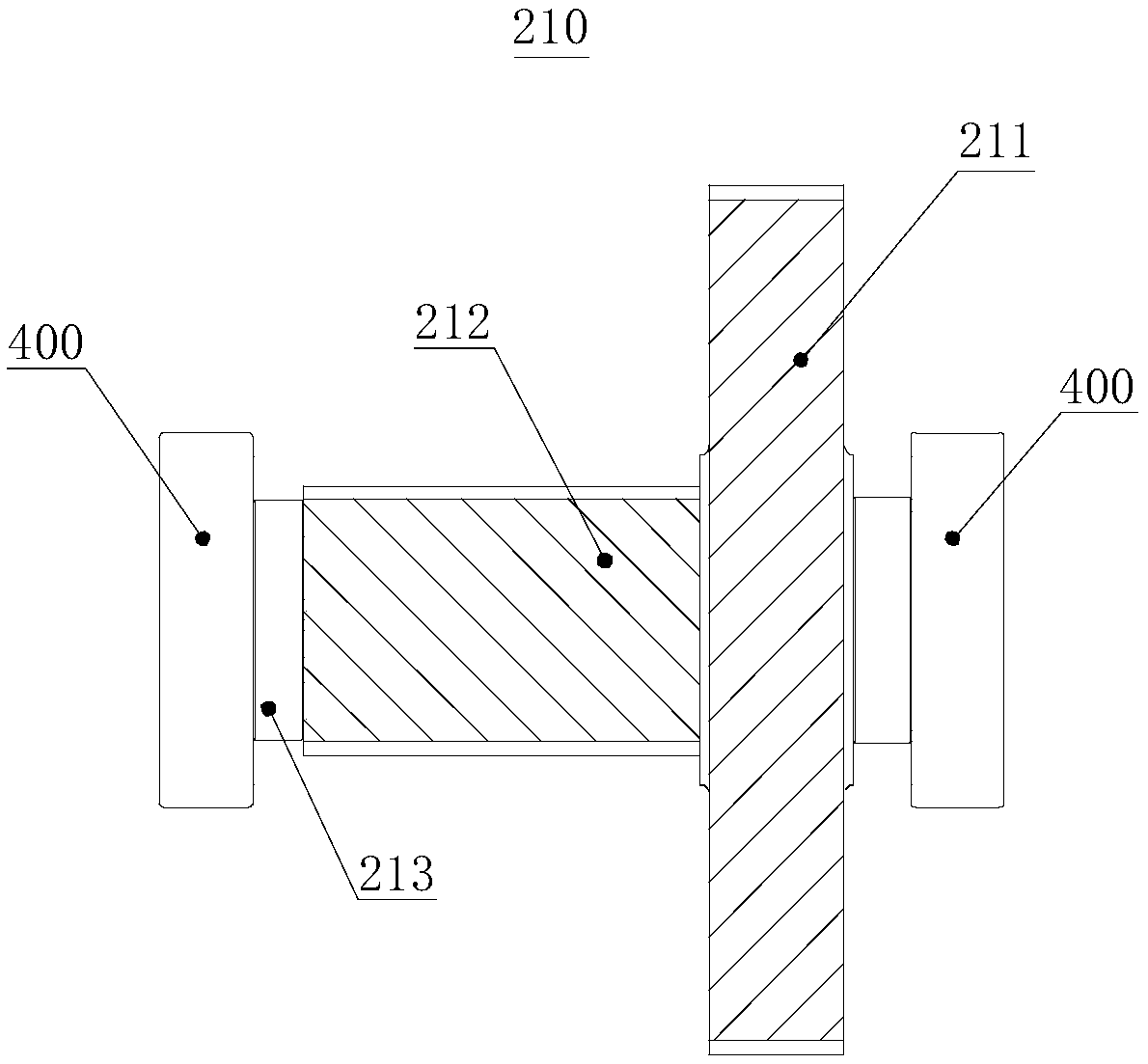

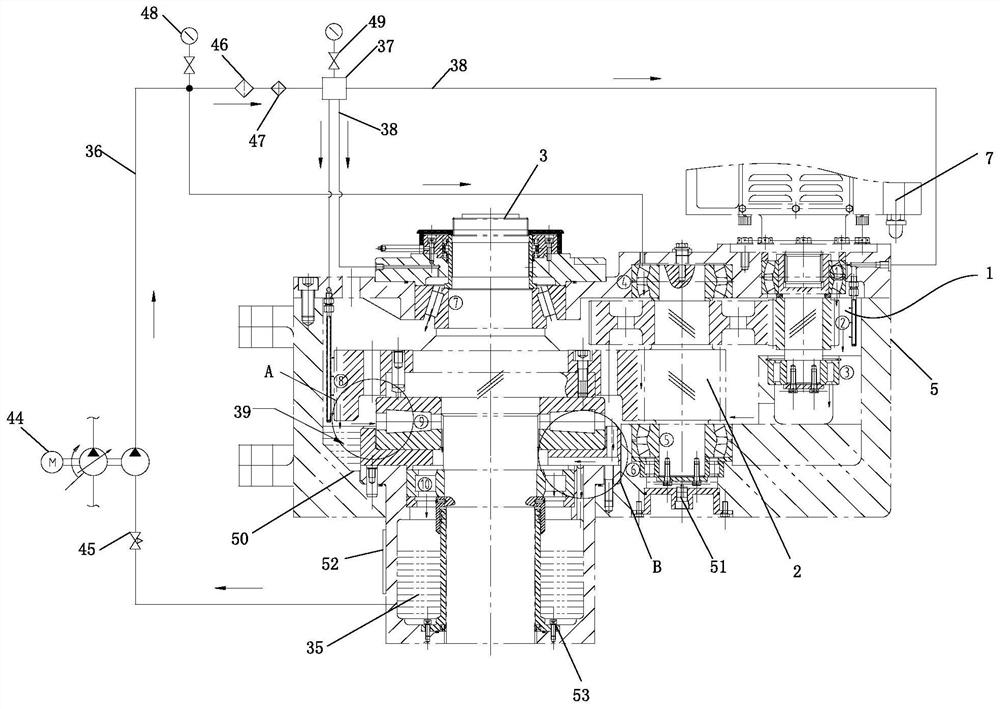

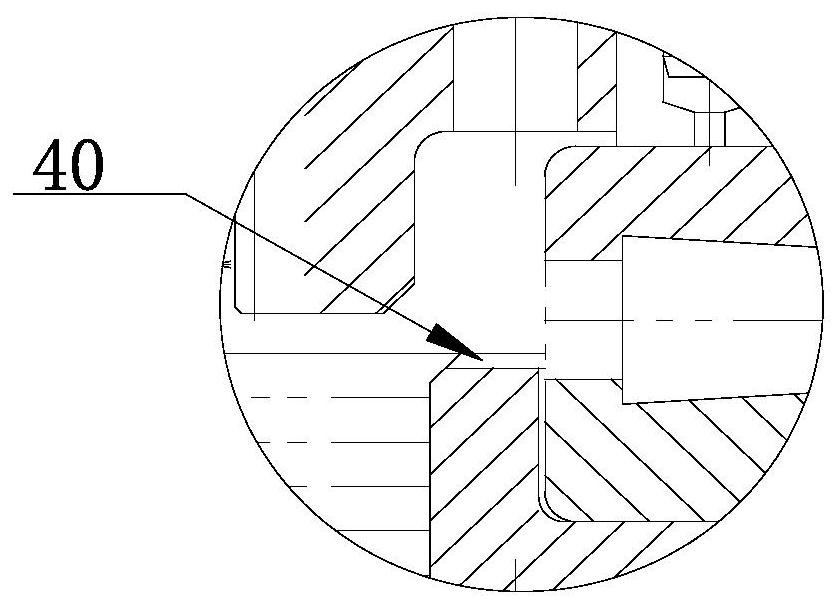

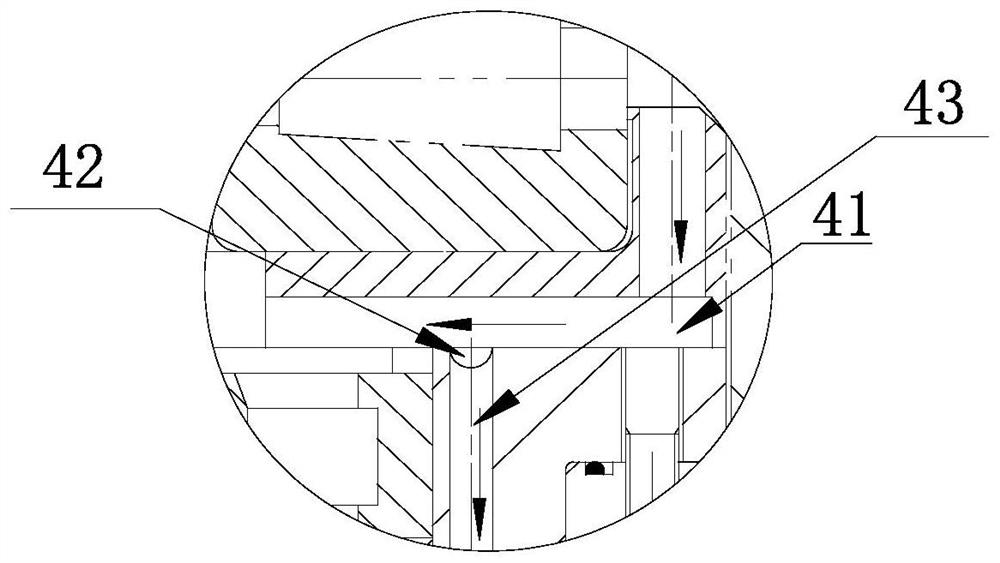

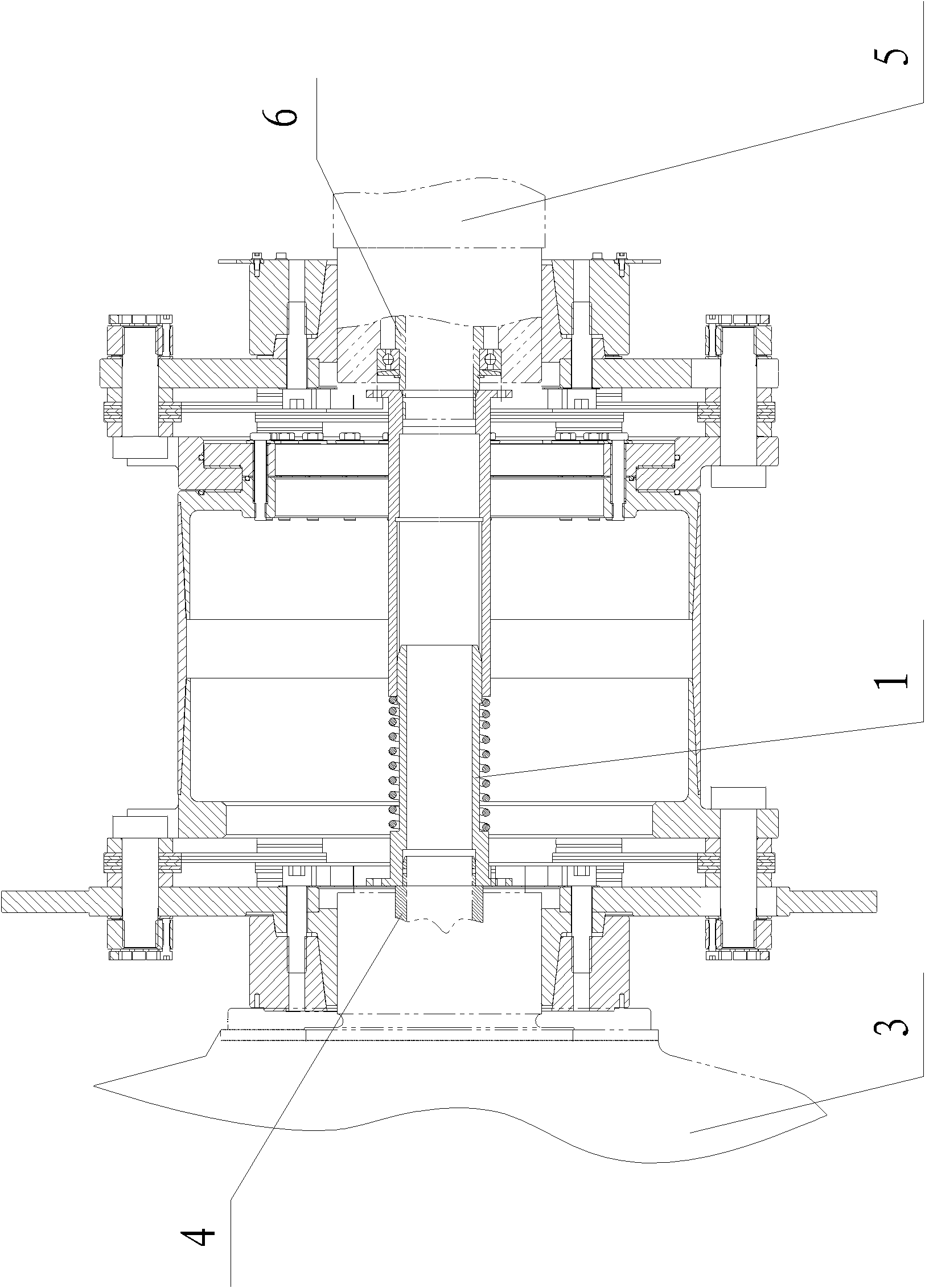

A control structure of a top drive device

ActiveCN112065265BImprove stressGood centering performanceGear lubrication/coolingBorehole drivesTop driveSprayer

The invention discloses a control structure of a top drive device, which mainly solves the problem of the short service life of the motor of the existing top drive device, the large space occupied by the shut-off mechanism of the remote control internal blowout preventer, the large span of the tilting oil cylinder of the lifting ring, and the large span of the hydraulic control pipeline. complicated question. The control structure of the top drive device includes the main motor input transmission mechanism, the intermediate shaft transmission assembly connected with the main motor input transmission mechanism, and the kelly driven by the intermediate shaft transmission assembly, which is used for remote control internal defense in the kelly The shut-off mechanism of the injector, and the lubrication system used to control the lubrication of the lubrication points of the bearings in the structure. The control structure of the top drive device of the present invention improves the main motor input transmission mechanism of the top drive device, the shut-off mechanism of the remote control internal blowout preventer in the kelly, and the lubrication system of the gear box, and extends the main power of the top drive device. The service life of the motor makes the hydraulic pipeline of the shut-off mechanism simpler, saves space to a large extent, and makes the overall structure more compact.

Owner:SICHUAN KUNLUN GASOLINEEUM EQUIP MFG

Energy-saving ball mill

InactiveCN103230817BSame intensityHigh strength to weight ratioGrain treatmentsGear wheelEngineering

Owner:KUNMING UNIV

Spiral conveyor hanging bearing

InactiveCN111997994AExtended service lifeHigh concentricityRoller bearingsBearing componentsAxial LoadingsEngineering

The invention relates to the technical field of material conveying equipment, in particular to a spiral conveyor hanging bearing. The hanging bearing comprises a bearing seat, a main shaft and two bearings; a shaft shoulder is arranged on the main shaft; the shaft shoulder is positioned at a central position on the bearing seat; the bearings are symmetrically distributed on two sides of the shaftshoulder; the bearings are tapered roller bearings; the shaft shoulder is used for spacing the two bearings and for bearing force exerted by the bearings in the axial direction; elastic check rings are further arranged on the main shaft and are for limiting inner races of the bearing; the elastic check rings are used for realizing axial limiting of the inner races of the bearings; and bearing endcovers are arranged on two sides of the bearing seat. The hanging bearing can better bear radial and axial load, rapid connection is realized, and service life of the hanging bearing is prolonged; andat the same time, the hanging bearing has good lubricating and sealing performance and prevents external materials from entering the inside of bearing covers.

Owner:SHANDONG KERUI MACHINERY MFG

Heavy-load type aligning carrier roller

PendingCN110745489APrevent fallingIncrease stiffnessConveyorsRollersHigh stiffnessMetallic materials

The invention provides a heavy-load type aligning carrier roller. The heavy-load type aligning carrier roller comprises an upper transverse beam and a lower transverse beam made of a high-strength metal material, the upper transverse beam is placed at the upper end of the lower transverse beam, the upper transverse beam is equally divided into three sections, auxiliary rotating devices are arranged on the inner sides of the lower ends of the sections, on the left side and the right side, of the upper transverse beam, a main supporting device is arranged in the middle of the lower end of the section, in the middle, of the upper transverse beam, the lower end of the main supporting device and the lower ends of the auxiliary rotating devices are connected with the lower transverse beam, friction rollers are arranged on the sections, on the left side and the right side, of the upper transverse beam, a common roller is arranged on the section, in the middle, of the upper transverse beam, and bolt fixing holes are formed in the left side wall and the right side wall of the lower transverse beam. The lower transverse beam is made of the high-strength metal material, so that the rigidity is improved, moreover, the two auxiliary rotating devices are arranged, so that the rigidity of the upper transverse beam during rotation is improved, the aligning effect during heavy load is also greatly improved, and the reliable operation of equipment is ensured.

Owner:WUHU CRANE & CONVEYOR

Anti-overturning jacking mechanism for power transmission line tower

The invention provides an anti-overturning jacking mechanism for a power transmission line tower. The anti-overturning jacking mechanism mainly comprises hydraulic cylinders, piston rods, U-shaped bolt plates, a jacking plate, a heat preservation layer, a limiting plate and a temperature sensor, wherein the hydraulic cylinders are installed on a bottom plate and a cement foundation through foundation bolts, the piston rods in the hydraulic cylinders are connected with the U-shaped bolt plates through cotter pins, the U-shaped bolt plates are connected with the jacking plate through bolts, and supporting legs of the power transmission line tower are installed on the jacking plate. When the power transmission line tower is inclined, the displacement of the supporting legs of the power transmission line tower is adjusted by adjusting the movement of the piston rods of the hydraulic cylinders. The mechanism acts on the bottoms of the four supporting legs of the power transmission line tower and solves the problem that the power transmission line tower cannot dynamically compensate or adjust itself when the foundation of the power transmission line tower is subjected to differential settlement at present.

Owner:CHANGAN UNIV

Threading tube coupler of wind generating set

ActiveCN102168725BLarge amount of heartGood centering performanceYielding couplingWind energy generationCouplingEngineering

The invention relates to a threading tube coupler of a wind generating set, which is provided with a left joint, a spring and a right part joint, wherein the end part of the front end of the left joint is in clearance fit connection with the end part of the rear end of the right part joint; the periphery of the left joint is provided with a stepped clamping groove; the spring is mounted in the stepped clamping groove; a blocking surface at the front end of the stepped clamping groove is lower than that at the rear end of the stepped clamping groove; one end of the spring is pressed against the blocking surface at the rear end of the stepped clamping groove; the other end of the spring is pressed against the end surface of the rear end of the right part joint; the outer periphery of the end part of the front end of the left joint is provided with a sliding key; and the inner peripheral surface of the right part joint is provided with a key slot matched with the sliding key. The threading tube coupler is expandable, so an input shaft of an electric generator and an output shaft of a speed increasing gearbox are convenient to install and disassemble by the coupler. The threading tubecoupler allows a left threading tube and a right threading tube to have certain eccentricity and higher eccentricity.

Owner:JIANGSU NEW UNITED HEAVY IND SCI & TECH +1

Dislocated support-type centering guide for cased well logger

Owner:WUHAN HAIWANG MECHANICAL & ELECTRICAL ENGTECH

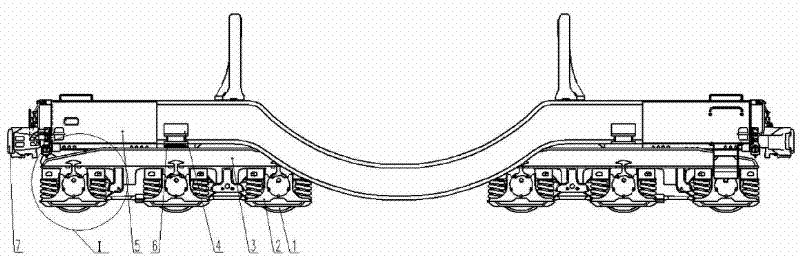

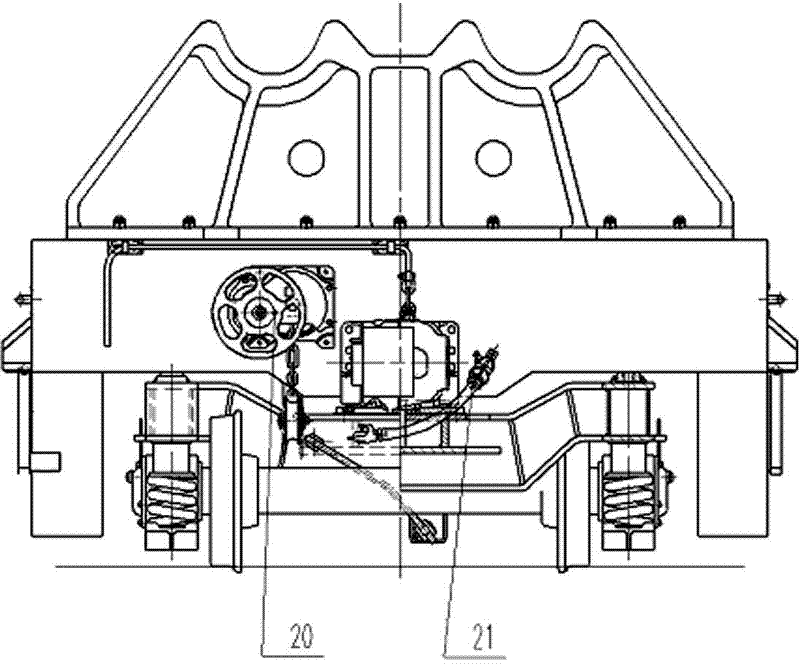

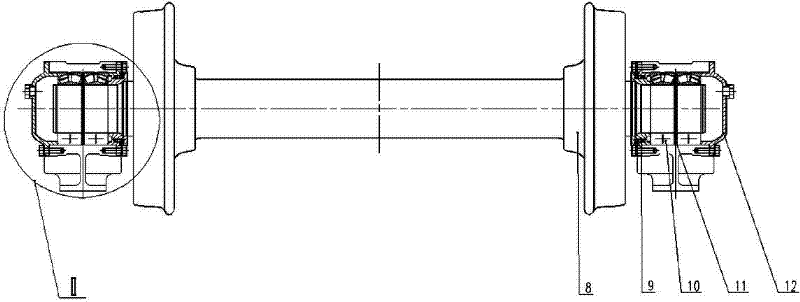

Open can type six-axis molten iron vehicle with load of 140 to 160t

The invention discloses a six-axis open can molten iron vehicle with load of 140 to 160t. The molten iron vehicle is characterized in that: the wheel set of a bogie is a special wheel set of the molten iron vehicle, an axle of the special wheel set of the molten iron vehicle is borne by two dual-aligning bearings arranged in parallel, and a space ring is arranged between the two dual-aligning bearings. A connecting device is arranged between the bogie and a vehicle body, and the connecting device encircles a connecting center disc of the bogie and the vehicle body and is arranged in parallel horizontal gaps of the vehicle body and the bogie. The special wheel set of the molten iron vehicle has good aligning performance, and can compensate coaxial error caused by bending deformation of theaxle, bear high axial load and improve the small-curve passing capability of the molten iron vehicle; and the axle load can reach 43t. The connecting device is non-contact, and does not affect the relative rotation between the vehicle body and the bogie; and when the vehicle needs rescue or the vehicle derails and needs reset, the vehicle body carrying the bogie is integrally hoisted under the action of other operating equipment so as to facilitate the operations such as vehicle maintenance, rescue and the like.

Owner:株洲新通铁路装备有限公司

An energy-saving mixer

InactiveCN103230824BSame intensityHigh strength to weight ratioBearing componentsGrain treatmentsRolling-element bearingEngineering

Owner:KUNMING UNIV

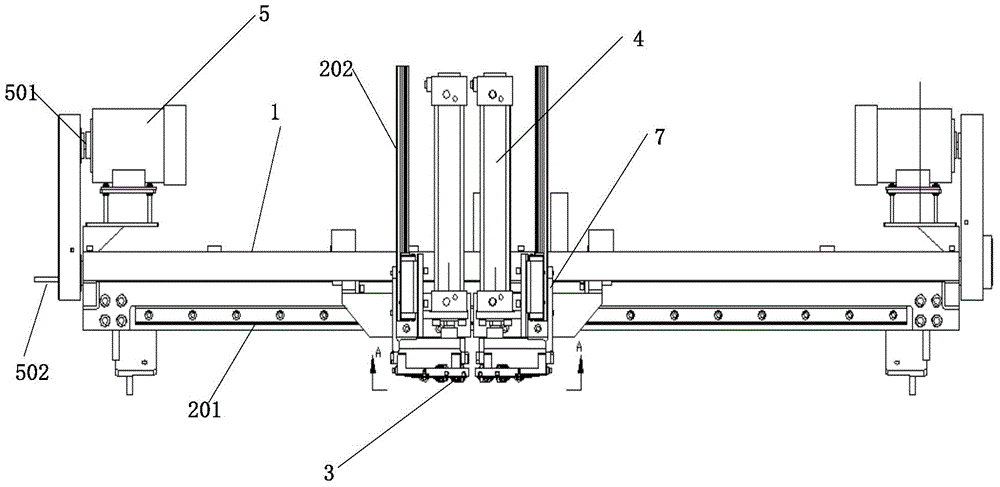

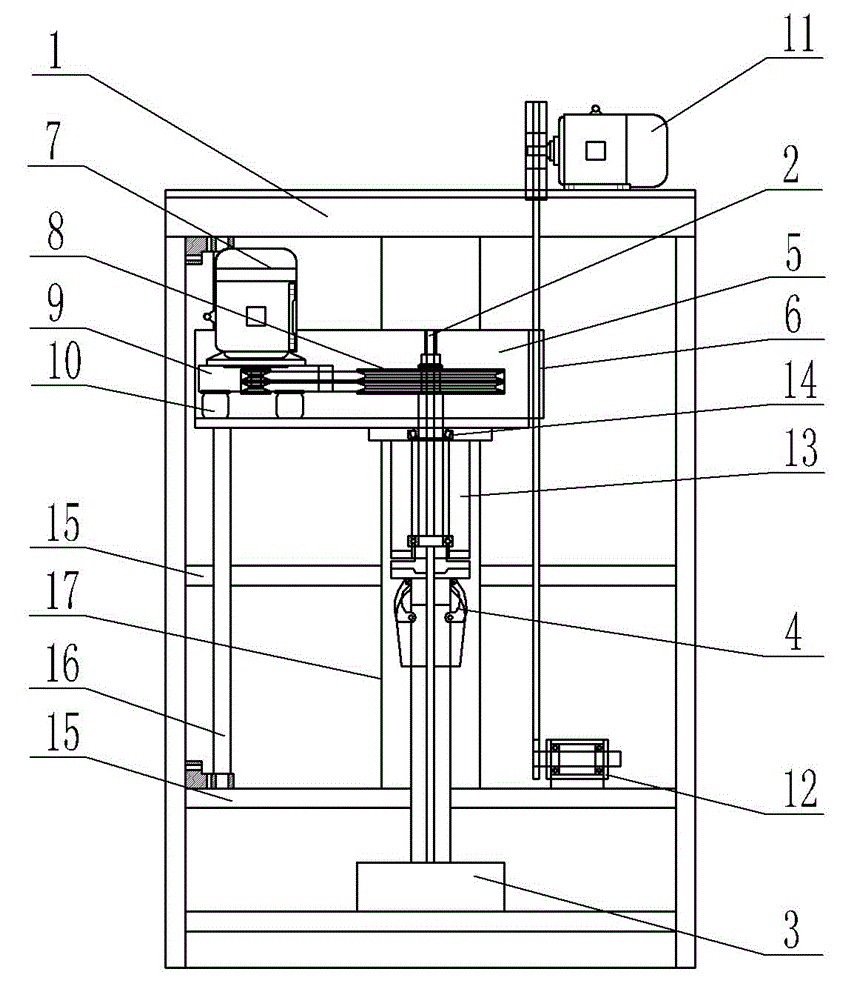

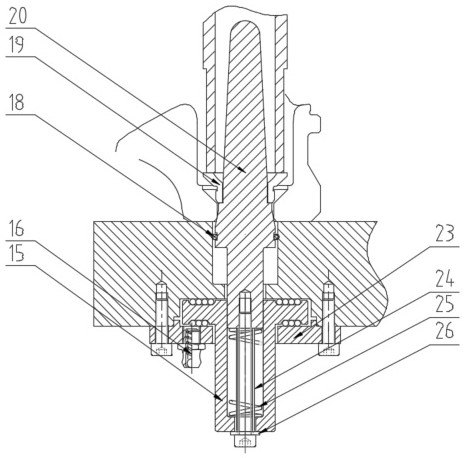

Self-centering device for pressing cylinder sleeve into wheel

PendingCN112475864AImprove center alignmentReduce wasteMetal working apparatusWaste productStructural engineering

The invention discloses a self-centering device for for pressing a cylinder sleeve into a wheel. The self-centering device for pressing the cylinder sleeve into the wheel comprises a rack; a bottom plate is arranged at the bottom of the rack; a top plate is arranged at the top of the rack; a flat plate is arranged on the bottom plate; a self-centering system is arranged on the flat plate; the self-centering system comprises a positioning column elastically connected to the flat plate; a hydraulic cylinder is arranged on the top plate; and a down-pressing hollow column is connected to a position, downward corresponding to a positioning column, at the output end of the hydraulic cylinder. According to the self-centering device for pressing the cylinder sleeve into the wheel in the scheme provided by the invention, the center centering performance when the cylinder sleeve is pressed into a wheel bolt hole can be improved, waste products generated by bolt hole material extrusion due to misalignment are reduced, and the press-fitting yield is increased.

Owner:CITIC DICASTAL

Linkage door opening and closing mechanism

PendingCN112854963AReduce failure rateReduce manufacturing costWing arrangementsSpecial door/window arrangementsStructural engineeringMechanical engineering

The invention relates to a linkage door opening and closing mechanism. The mechanism comprises an openable and closeable door, a rotating shaft part, a material carrier and a connecting rod part, wherein the openable and closeable door is installed through the rotating shaft part and can rotate around a rotating shaft of the rotating shaft part so that opening and closing of the openable and closeable door can be achieved; the connecting rod part comprises a connecting rod, and the two ends of the connecting rod are connected to the material carrier and the openable and closeable door correspondingly so that the opening and closing process of the openable and closeable door can be linked with the in-out process of the material carrier; and the two ends of the connecting rod are connected to the material carrier and the openable and closeable door through self-aligning roller bearings correspondingly so that self-aligning can be achieved under the condition that the rotating shaft part is bent under stress, and it is guaranteed that the openable and closeable door opens, closes and rotates smoothly and is closed tightly. The mechanism has the beneficial effects that door opening and closing actions and feeding or discharging of materials can be achieved through one set of driving device, the manufacturing cost is saved, and the fault occurrence rate of the mechanism is reduced. When the weight of the openable and closeable door is large, the openable and closeable door can still rotate smoothly and is closed more tightly even though the rotating shaft is bent under stress when the openable and closeable door rotates.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

A new type of energy-saving ball mill

InactiveCN103230818BSame intensityHigh strength to weight ratioBearing componentsGrain treatmentsNew energyWorking environment

The invention discloses a novel energy-saving ball mill. The novel energy-saving ball mill consists of a first hydrostatic bearing, a second hydrostatic bearing, a rotator, hydrostatic bearing sealing covers, a local dust collector, a small gear and a transmission system; the shaft journals of hollow shafts at the two ends of the rotator are respectively placed on the first hydrostatic bearing and the second hydrostatic bearing and are covered by the two hydrostatic bearing sealing covers respectively; a large gear which is engaged with the small gear is arranged on the periphery of the rotator; high-pressure oil forms a lubricating oil film among the first hydrostatic bearing, the second hydrostatic bearing and the shaft journals of the hollow shafts of the rotator, so that the rotator can float, the completeness of the lubricating oil film can be guaranteed and the complete liquid lubrication can be realized; the bearing capacity of the bearings is large; when the rotator generates the small bending elastic deformation, bearing bodies of the first hydrostatic bearing and the second hydrostatic bearing rotate at a small angle relatively around respective first pin shafts, so that the thickness of the oil film is not changed basically; the grinding effect between a grinding medium and a mineral aggregate and among the mineral aggregates can be enhanced because of a corrugated liner plate in the rotator; and the sealing covers and the local dust collector can effectively prevent dust particles in the working environment of the ball mill from entering the working space of the hydrostatic bearings.

Owner:KUNMING UNIV

Novel support roller apparatus

InactiveCN102852964AImprove carrying capacityGood centering performanceEngine sealsShaft and bearingsWorking environmentPulp and paper industry

The present invention discloses a novel support roller apparatus, which is characterized in that a support roller and a support roller shaft are connected by using a double row self-aligning roller bearing, support roller pressing covers are fixed on both end surfaces of the support roller through bolts, sealing of the support roller pressing covers and the support roller shaft is achieved through a polytetrafiuoroethylene filler and a filler pressing cover, the inner side wall of the support roller pressing cover is further provided with a skeleton type oil seal, double sealing of the support roller pressing covers and the support roller shaft is achieved, a fluorine rubber sealing ring is arranged between the support roller pressing cover and the support roller so as to achieve sealing of the support roller pressing cover and the support roller. With the arrangement, the novel support roller apparatus of the present invention is particularly suitable for complex work environments of rotation type sterilization kettles.

Owner:诸城市中泰机械有限公司

a material transport mechanism

ActiveCN112850106BReduce failure rateReduce manufacturing costPower-operated mechanismConveyor partsStructural engineeringMaterial transport

The invention relates to a material transportation mechanism, which includes a linkage door opening and closing mechanism, a transportation line and an automatic stop mechanism; the linkage opening and closing mechanism includes an opening and closing door, a rotating shaft part, a material carrier and a connecting rod part; the opening and closing door is installed through the rotating shaft part and can be wound around The rotating shaft of the rotating shaft part rotates; the connecting rod part includes a connecting rod; the two ends of the connecting rod are respectively connected to the material carrier and the opening and closing door to link the opening and closing process of the opening and closing door with the process of entering and exiting the material carrier; the two ends of the connecting rod They are respectively connected to the material carrier and the switch door through self-aligning roller bearings; after the material carrier moves out of the switch door, it is docked with the transportation line to transfer the material to the transportation mechanism; the automatic stop mechanism is set at on the material carrier and / or on the transport line to prevent or allow the transport of the material. The beneficial effects of the present invention are as follows: the present invention can realize the action of opening and closing the door and feeding or sending of materials through a set of driving devices, saving manufacturing costs and reducing the failure rate of mechanisms.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

All steel one-step automatic forming machine

The invention provides an all-steel one-step automatic forming machine, including a main machine and an auxiliary machine, the main machine includes a carcass drum, a belt drum, and a forming drum, and the belt drum is arranged between the carcass drum and the forming drum; The centers of the carcass drum, forming drum and belt drum are arranged on a straight line, and a transfer ring is set with the straight line as the center line, and the carcass moves back and forth through the transfer ring; the auxiliary machine includes the main feeding frame, the belt The layer feeding frame and the tread feeding frame are respectively connected to the carcass drum, the belt layer drum, and the building drum, and the belt layer feeding frame and the tread feeding frame are placed on the same side of the belt layer drum. The equipment has high production efficiency, with an output of more than 170 pieces per shift, reaching the domestic leading and international advanced level; the degree of automation is high, only one operator is required to work on the carcass drum and belt layer drum, and the forming drum can realize automatic forming. The product is of high quality and is widely used in the molding process of all-steel radial tires.

Owner:青岛海琅智能装备有限公司

Energy-saving mixer mill

InactiveCN103203274BSame intensityHigh strength to weight ratioGrain treatmentsEngineeringLubrication

Owner:KUNMING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com