Low wind speed large-sized double-fed half direct-drive main bearing mechanism

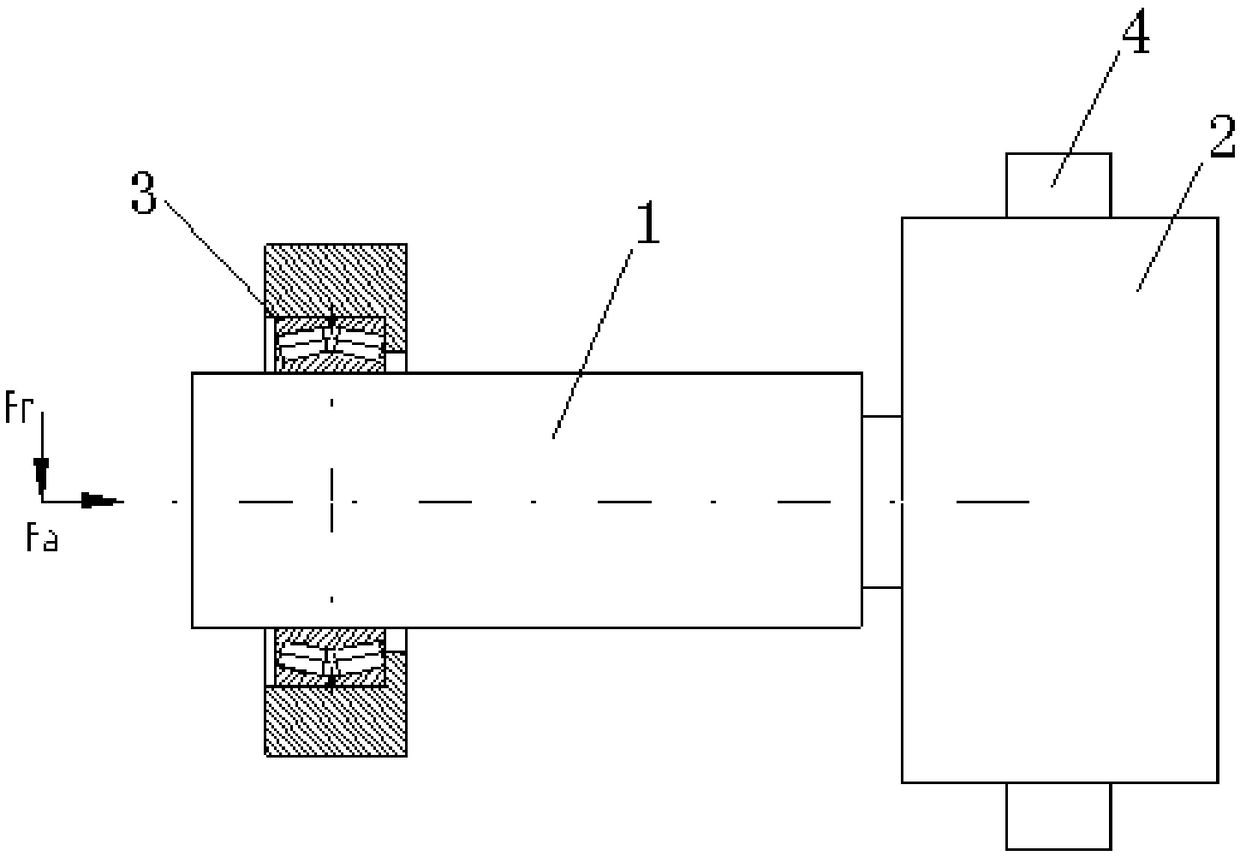

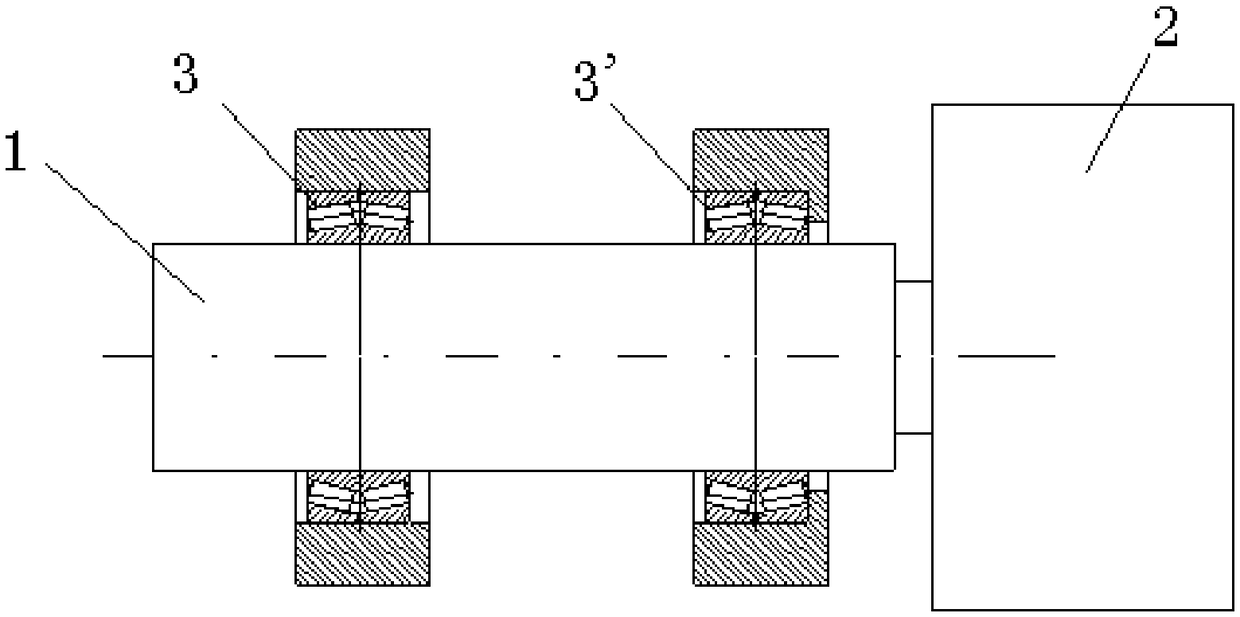

A semi-direct drive, low wind speed technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the requirements of high axial bearing capacity of bearings, insufficient axial bearing capacity of main bearings, and axial bearing capacity. The problem that the force cannot be amplified in one direction can achieve the effect of facilitating sampling and manual grease injection operation, ensuring power generation and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

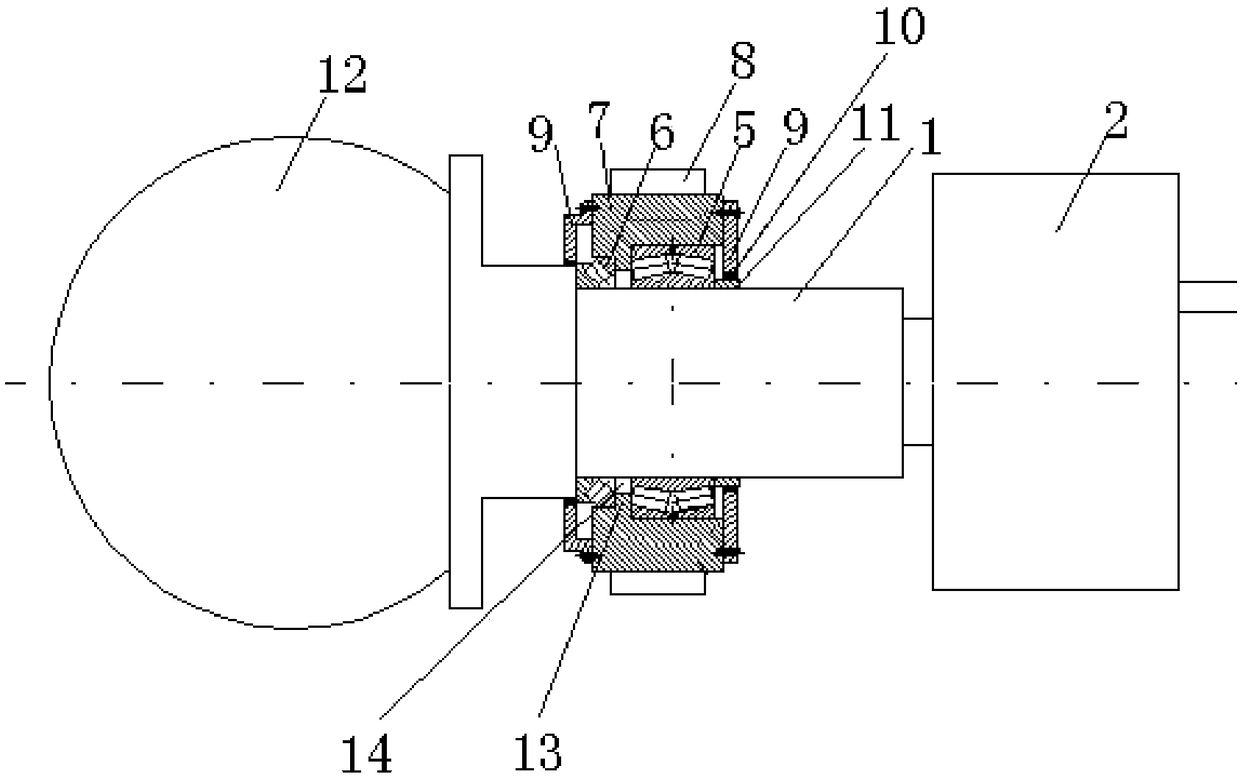

[0029] Refer to attached image 3 As shown, the main bearing mechanism of the wind turbine in this embodiment includes a floating bearing 5 and a thrust bearing 6 arranged outside the main shaft 1 . Specifically, the floating bearing 5 adopts any existing bearing structure such as double-row spherical roller bearing, double-row tapered roller bearing or double-row cylindrical roller bearing, and is mainly used to bear the radial load transmitted by the impeller 12 . The thrust bearing 6 adopts a thrust self-aligning roller bearing, which has good self-aligning performance, and overcomes the disadvantages of the long length of the main shaft 1 and the large load that is easily deformed, and the thrust self-aligning roller bearing has no axial play , has a strong axial bearing capacity, and can well withstand all axial loads transmitted by the impeller 12.

[0030] In this embodiment, the floating bearing 5 and the thrust bearing 6 share a bearing seat 7, and the bearing seat 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com