Patents

Literature

79results about How to "Overcome deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

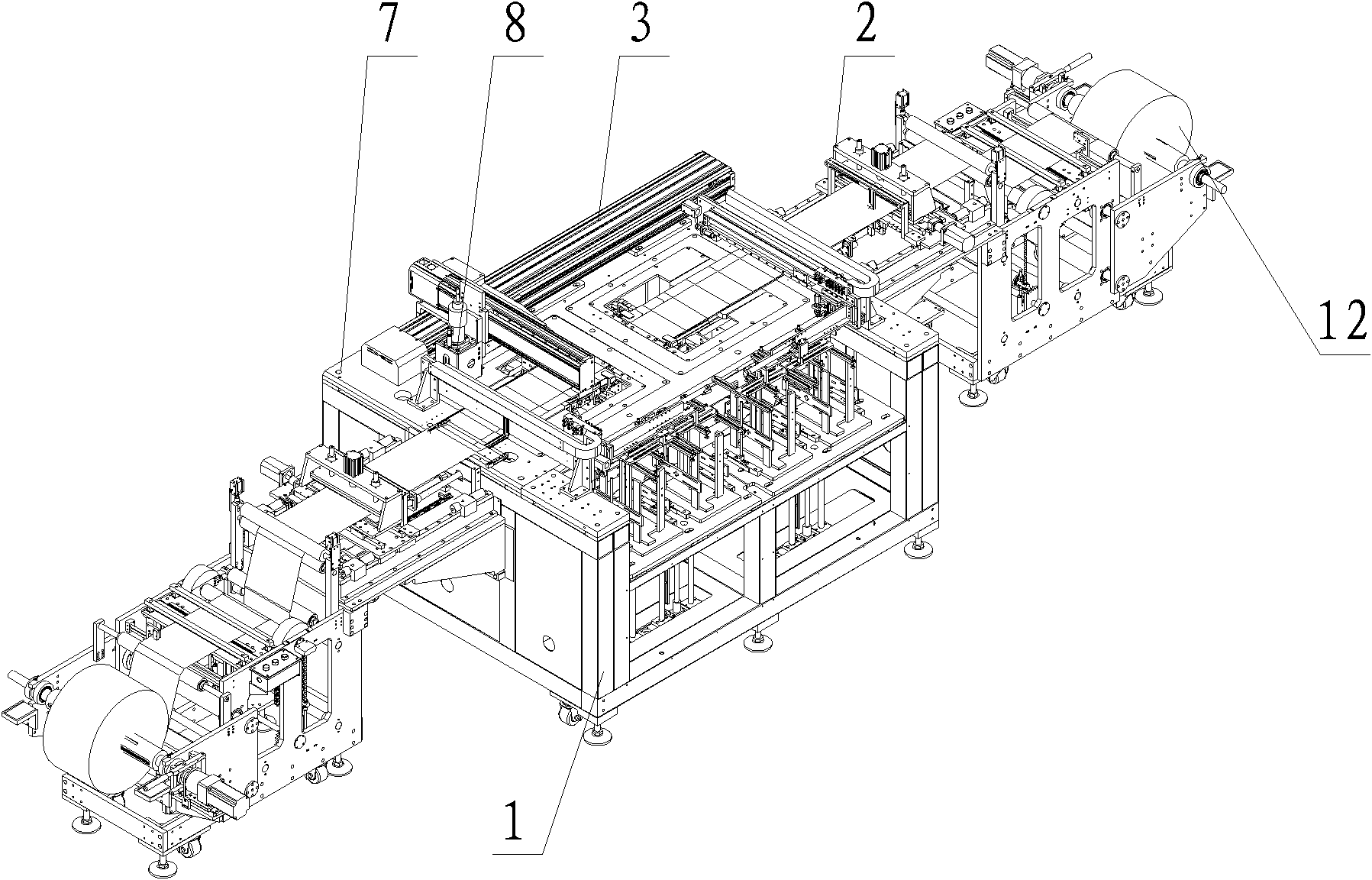

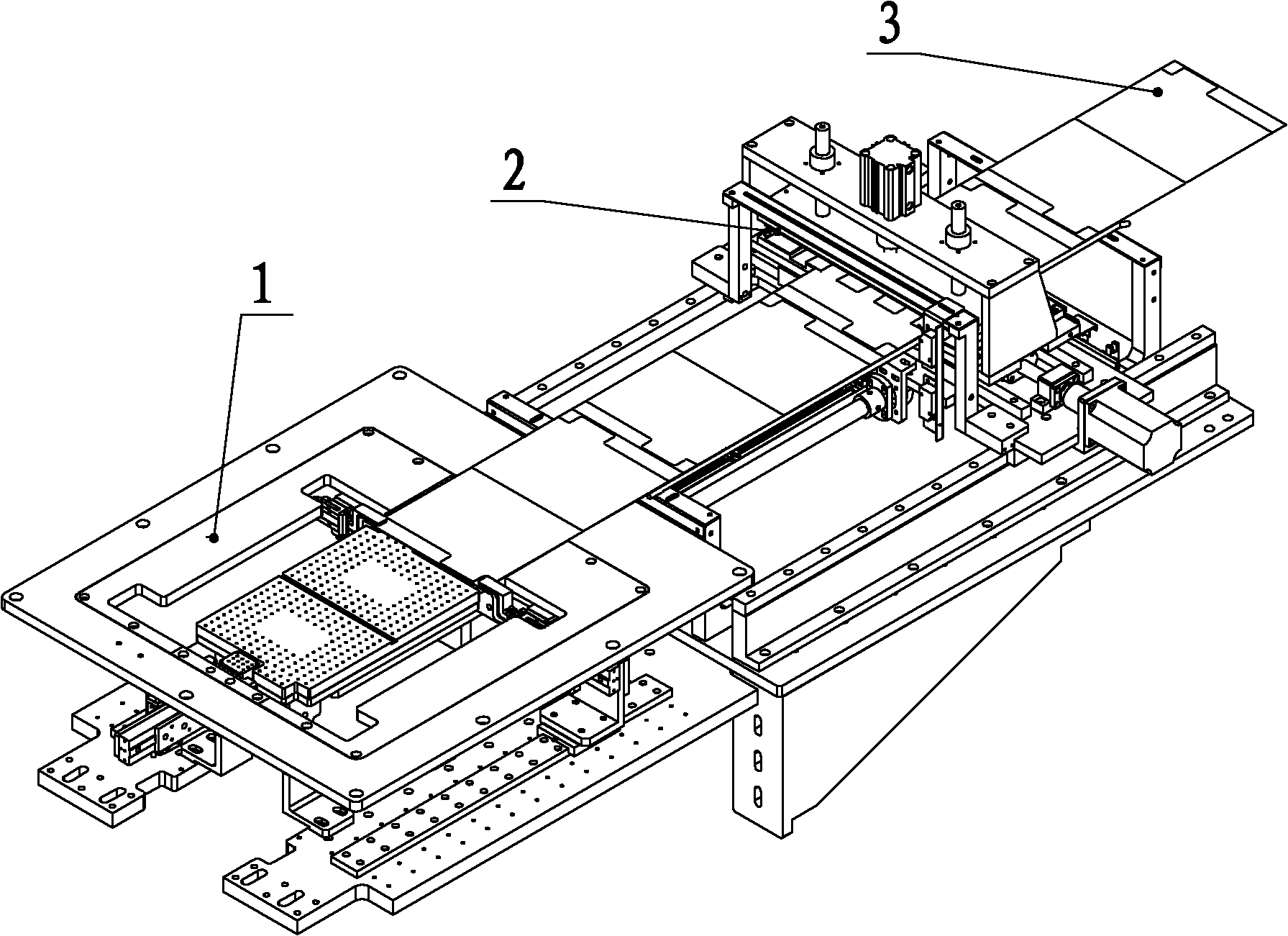

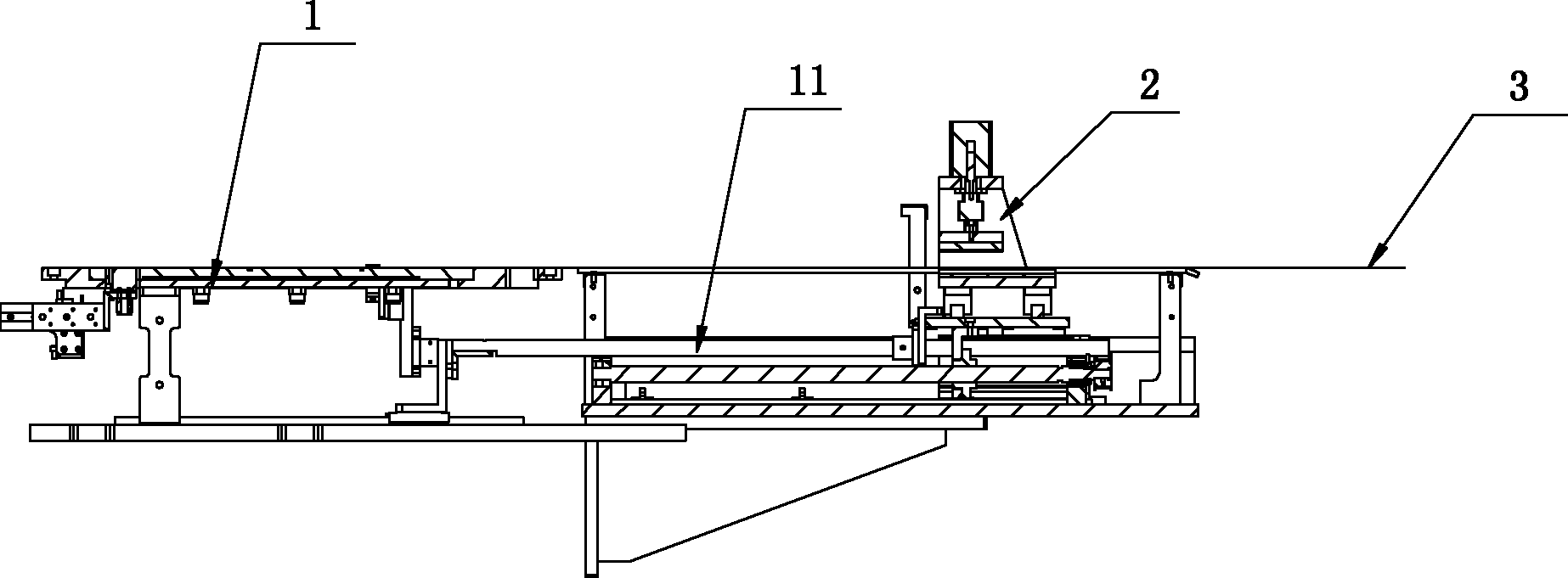

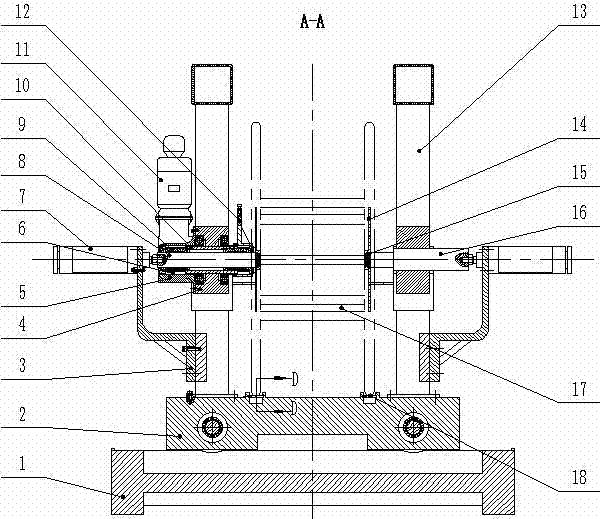

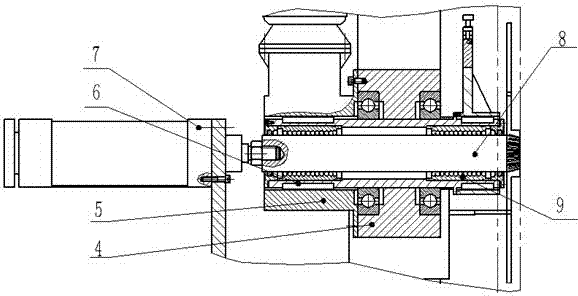

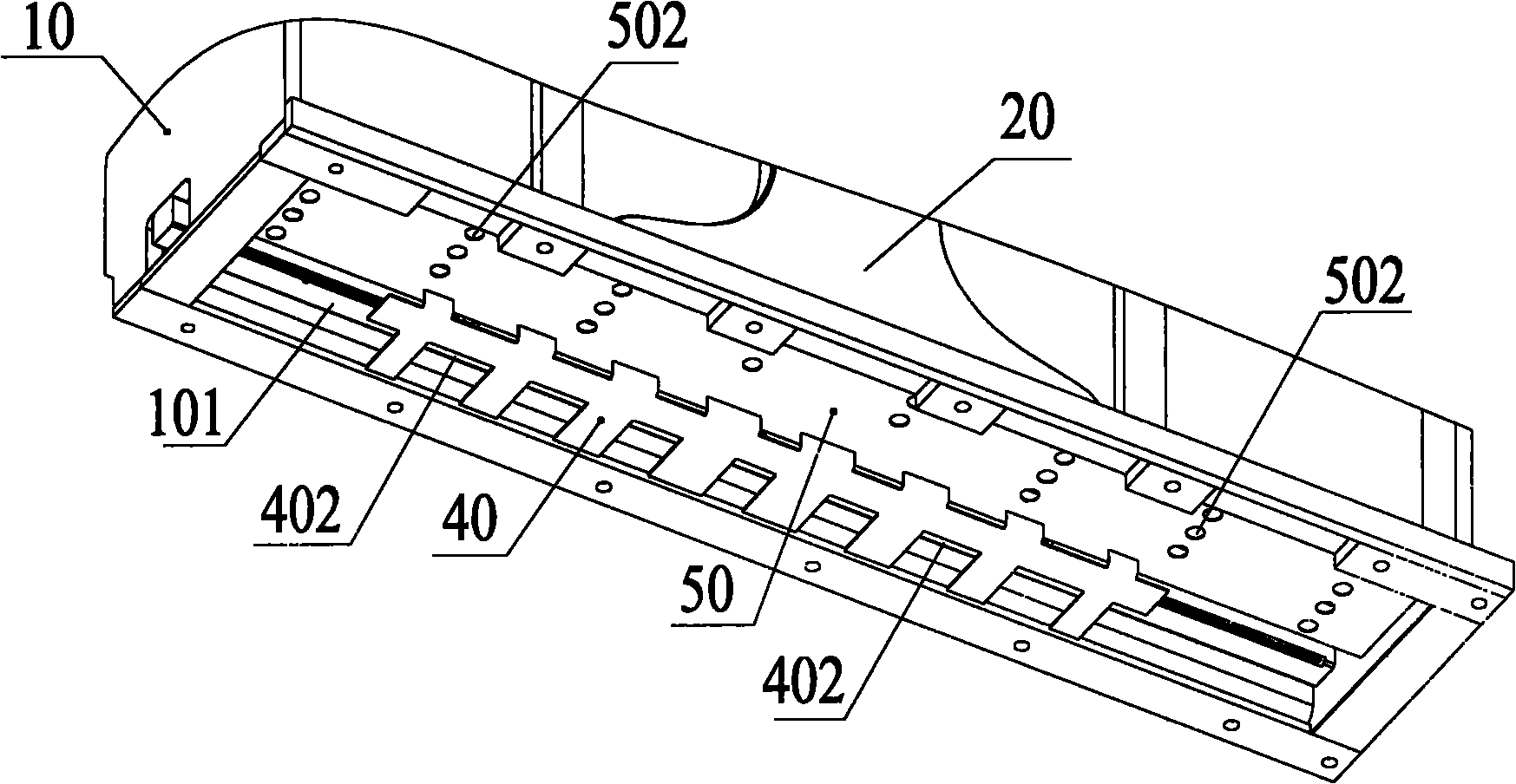

Pole piece laser cutting machine

ActiveCN102642089AOvercome deformationSmall size errorProgramme-controlled manipulatorElectrode manufacturing processesCapacitanceLaser technology

The invention discloses a pole piece laser cutting machine. The machine comprises a base frame part, a laser cutter, a cutting manipulator part, a control system and at least a piece feeding component, wherein the cutting manipulator part is used for driving the laser cutter; each piece feeding component comprises a material clamping manipulator part, a feeding fixed-length part and an emptying part; the cutting manipulator part and the material clamping manipulator part are installed on the base frame part; the feeding fixed-length part is arranged between the material clamping manipulator part and the emptying part; and the control system is connected with the cutting manipulator part, the material clamping manipulator part and the feeding fixed-length part. The machine has the following beneficial effects: the machine realizes the piece preparation processes of the lithium ion batteries or super capacitors by adopting the laser technology, can solve the problem that the pole pieces are easy to deform and have bigger burrs as the traditional cutting processes are adopted in the prior art, simultaneously improves the piece preparation process quality under the control of the control system and increases the yield.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

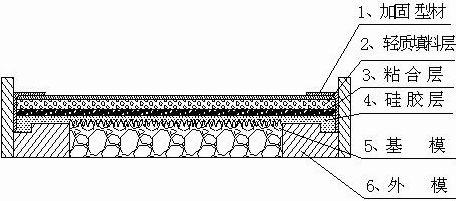

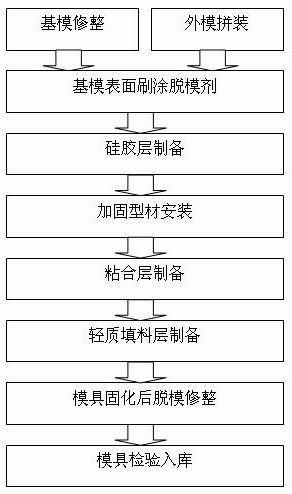

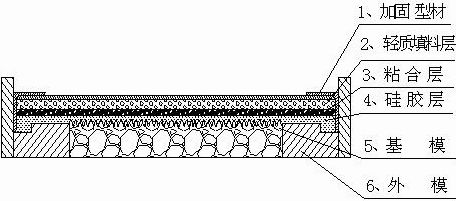

Die for building materials products and preparation method thereof

The invention discloses a die for building materials products and a preparation method thereof. The die provided by the invention contains a preformed female die and is prepared by the following steps of: cleaning the female die by an air pump, coating a mold releasing agent on the surface of the female die, uniformly laying a silica gel surface layer on the surface of the female die coated with the mold releasing agent to form a nonstick material surface layer, placing a bar of angle iron at each long side of the die; successively laying a silica gel bonding coat and a layer of gauze on the silica gel surface layer after its gelation, laying an epoxy resin bonding layer and a layer of glass fiber grid cloth after coagulation of the silica gel bonding layer to form a bonding layer; laying an insulation plate and flat iron on the bonding layer, pressing tightly by using a steel plate and simultaneously installing seal section bars at the four corners of the die; laying epoxy resin mortar on the surface of the insulation plate to form a light filling layer; laying a layer of glass fiber biaxial cloth on the light filling layer, and laying an epoxy adhesive coat on the glass fiber biaxial cloth to form a hard base material. The die provided by the invention has a simple structure, is easy to demould, and can be used to effectively guarantee the quality of moulded products. In the meantime, the preparation method provided by the invention is convenient to operate, requires low cost, and is easy to maintain.

Owner:ENERGY EFFICIENCY TECH

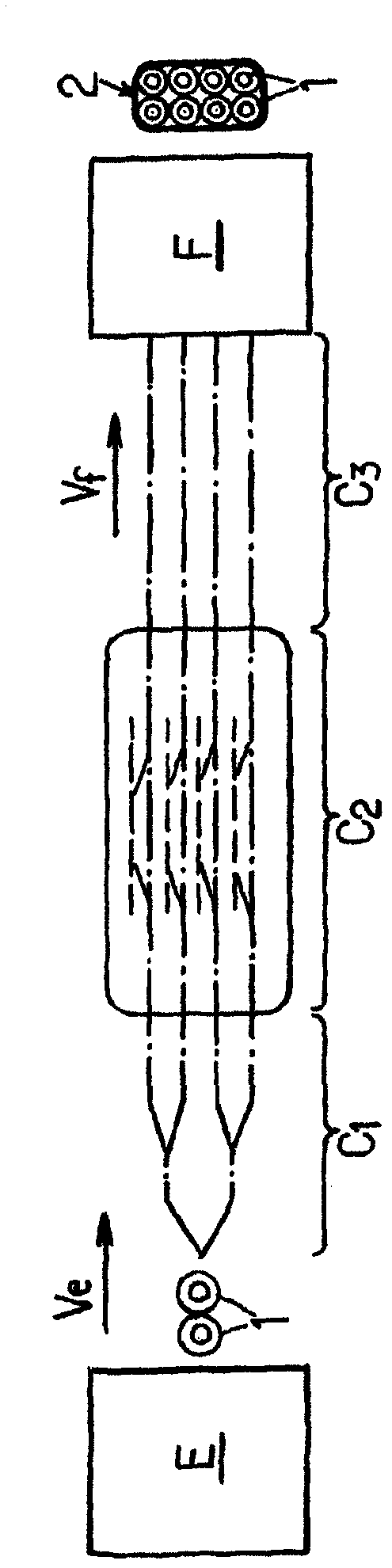

Modified high-speed steel roller and preparation method thereof

InactiveCN101797630AImprove wear resistanceShorten the production cycleRollsProcess efficiency improvementDuctile ironFerrochrome

The invention discloses a modified high-speed steel roller and a preparation method thereof. The modified high-speed steel roller is formed by adopting a centrifugal composite casting method and has a roller outer layer of high-speed steel and a roller inner layer of ductile iron or high-strength cast iron. The preparation method comprises the following steps of: forming the roller outer layer on a centrifugal casting machine; then, filling a static roller core with melted iron; and casting into a high-speed steel composite roller. The roller outer layer of the high-speed steel roller is prepared from raw materials in percentage by weight: 60-65 percent of M2 high-speed waste steel (W6Mo5Cr4V2), 1.0-1.4 percent of metal aluminum, 5.0-5.5 percent of boron iron, 9.2-9.4 percent of carbon ferrochrome iron, 0.2-0.4 percent of titanium iron, 1.0-1.2 percent of nickel-magnesium alloy and 18-23 percent of waste steel Q235. The roller can be produced by utilizing an electric furnace, has high hardness, simple and convenient process, low production cost and favorable wear resistance without adding noble iron alloy or quenching treatment and can have favorable economic benefits by popularization and use.

Owner:BEIJING UNIV OF TECH

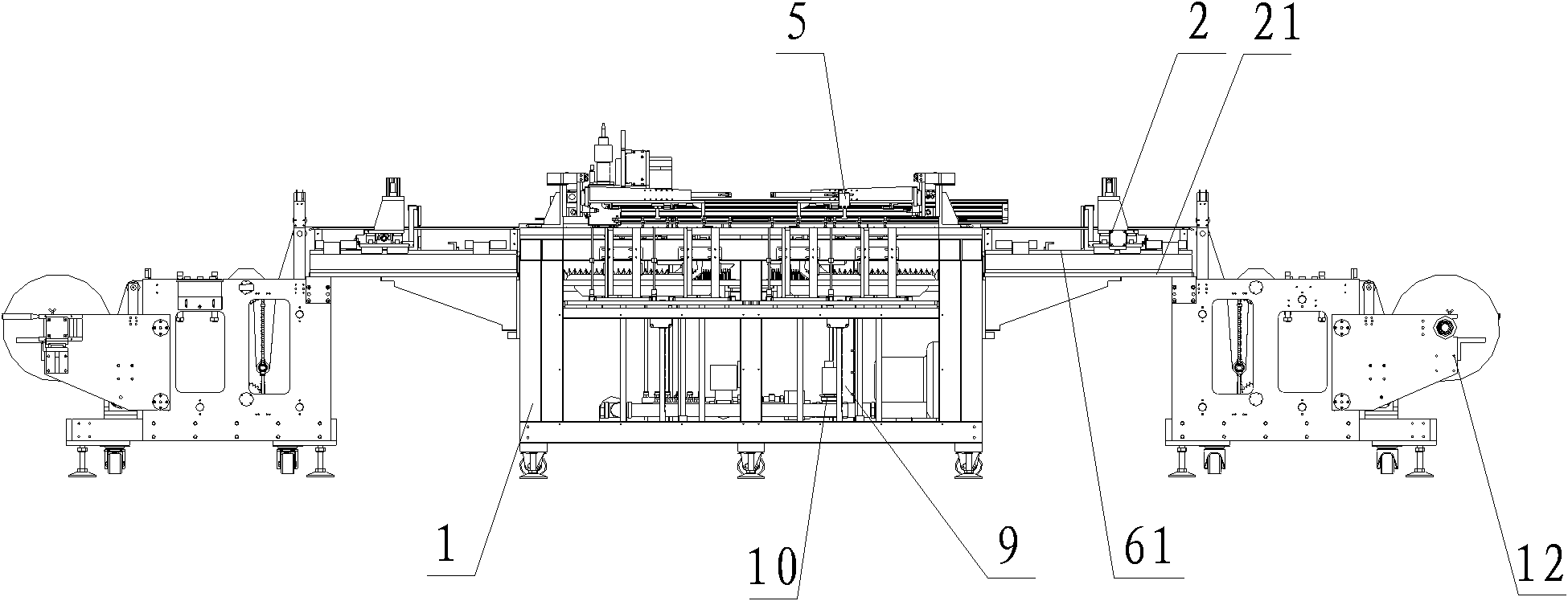

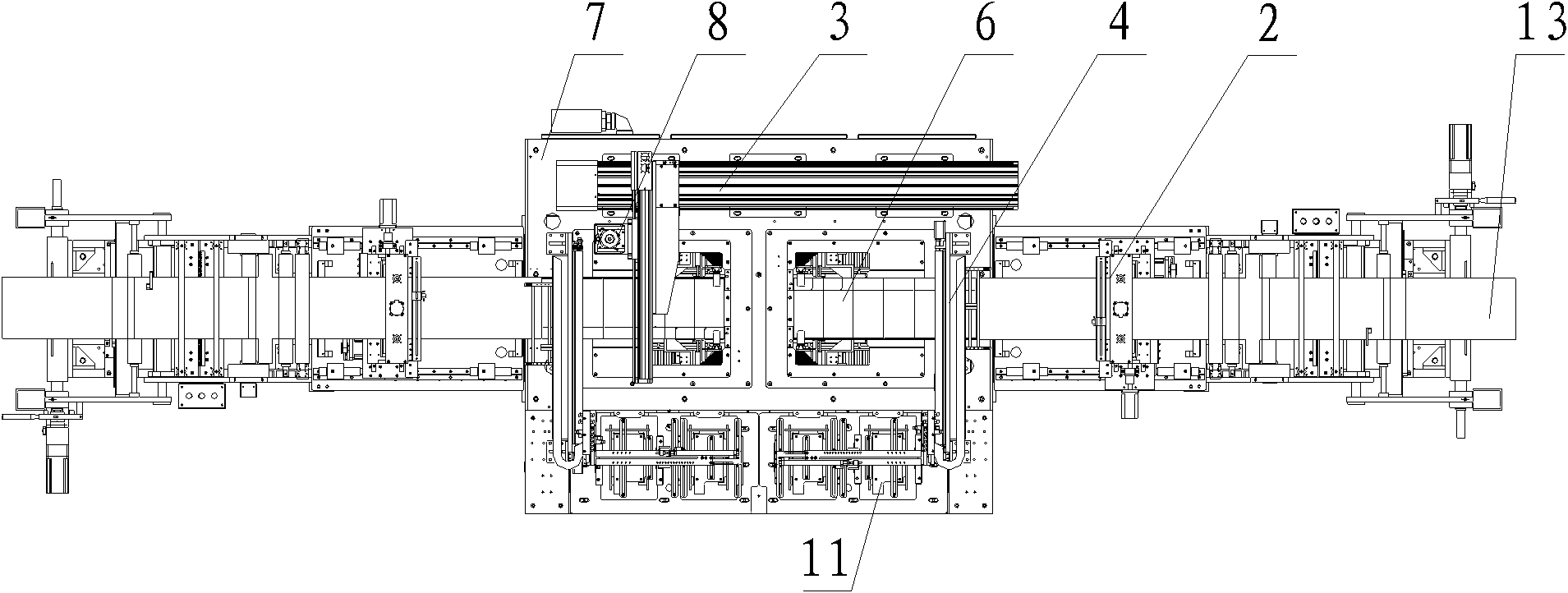

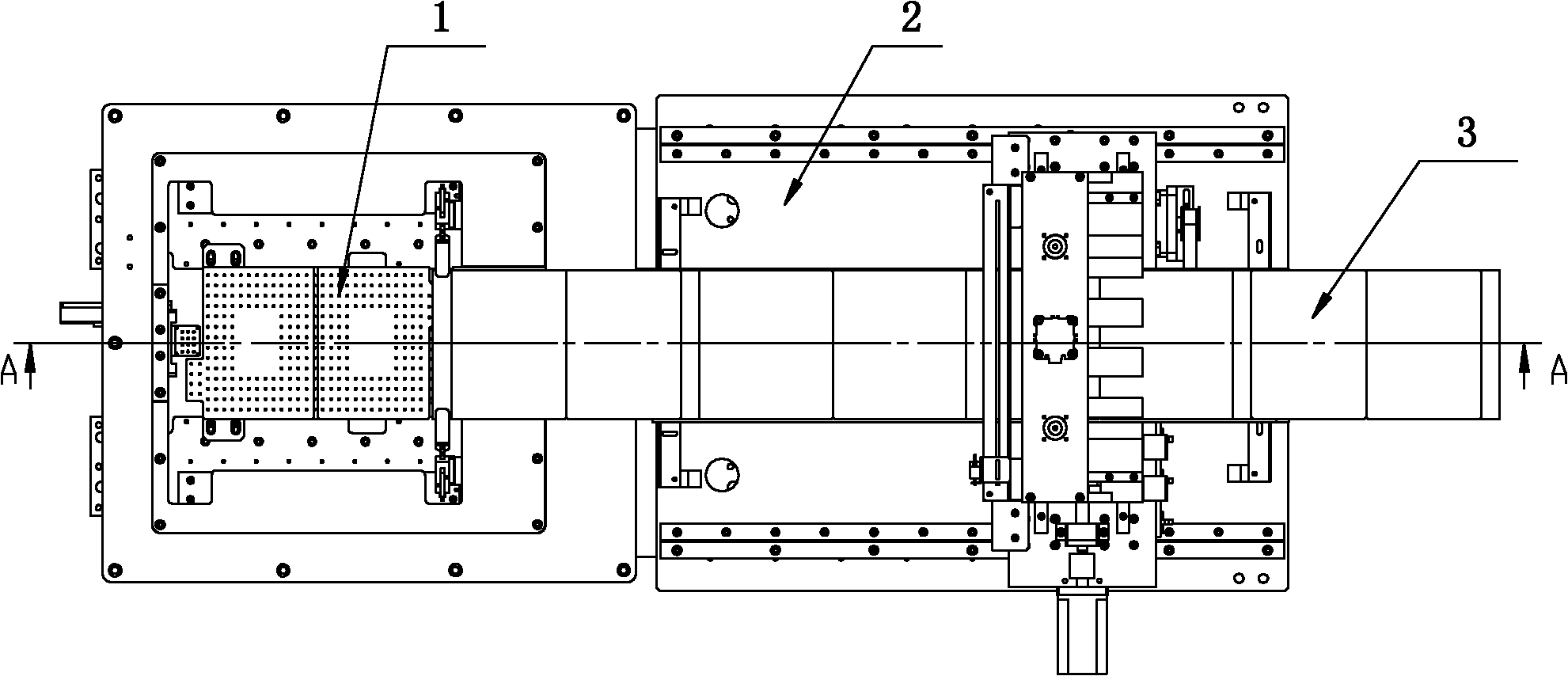

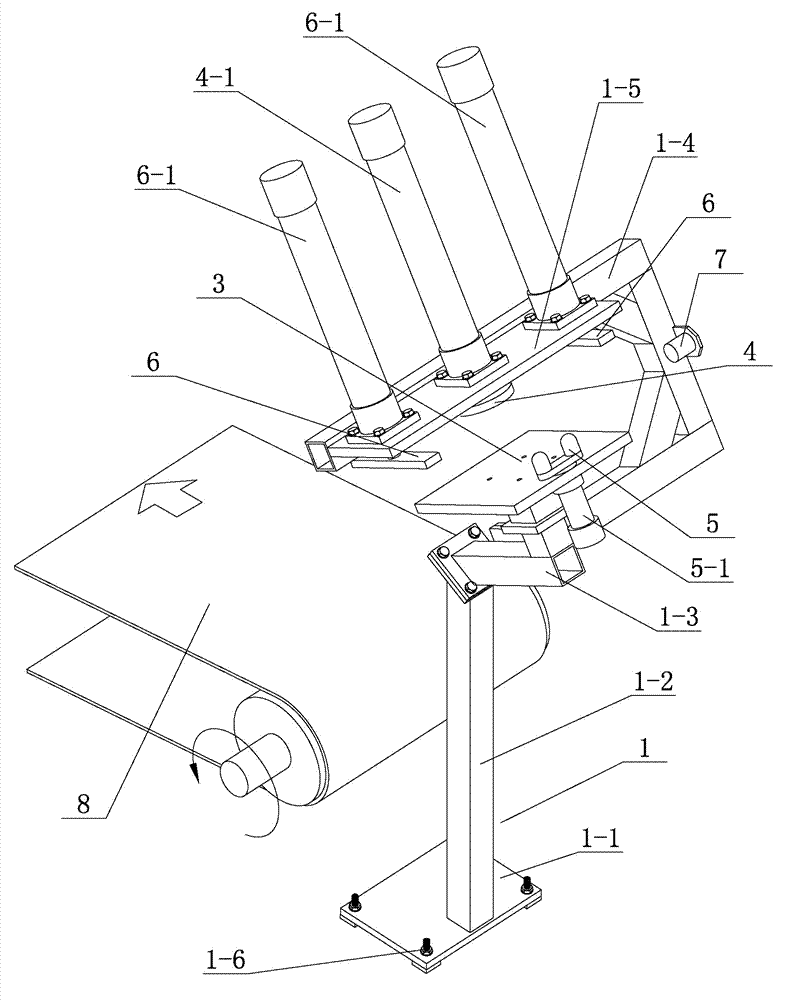

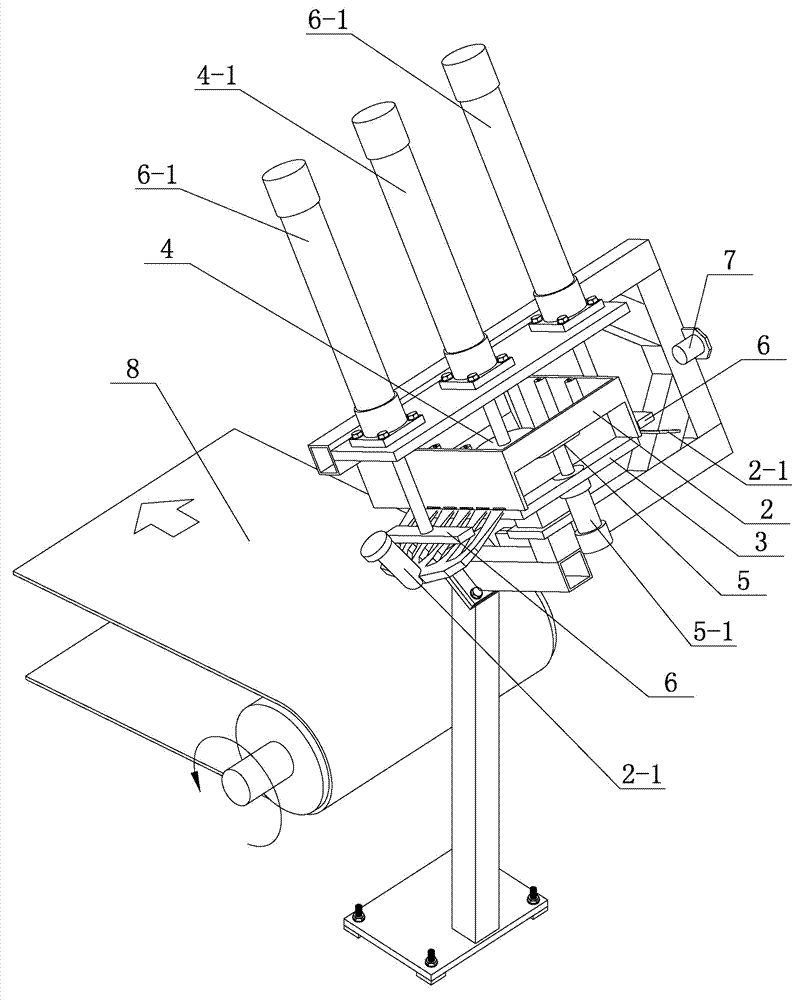

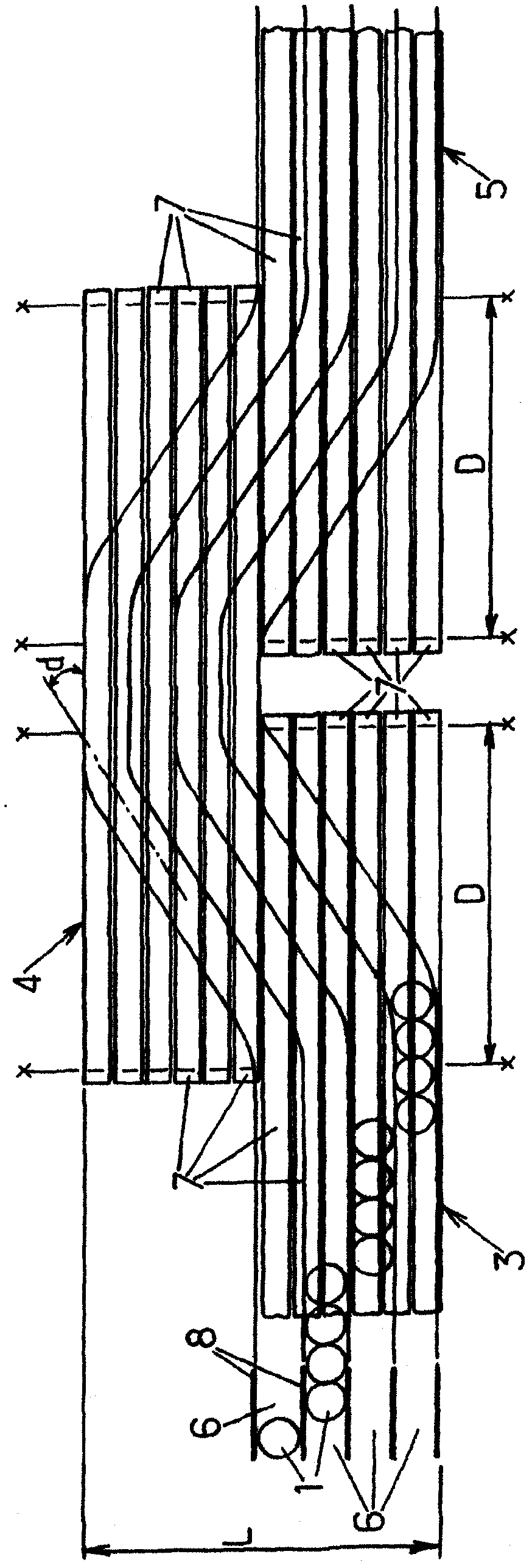

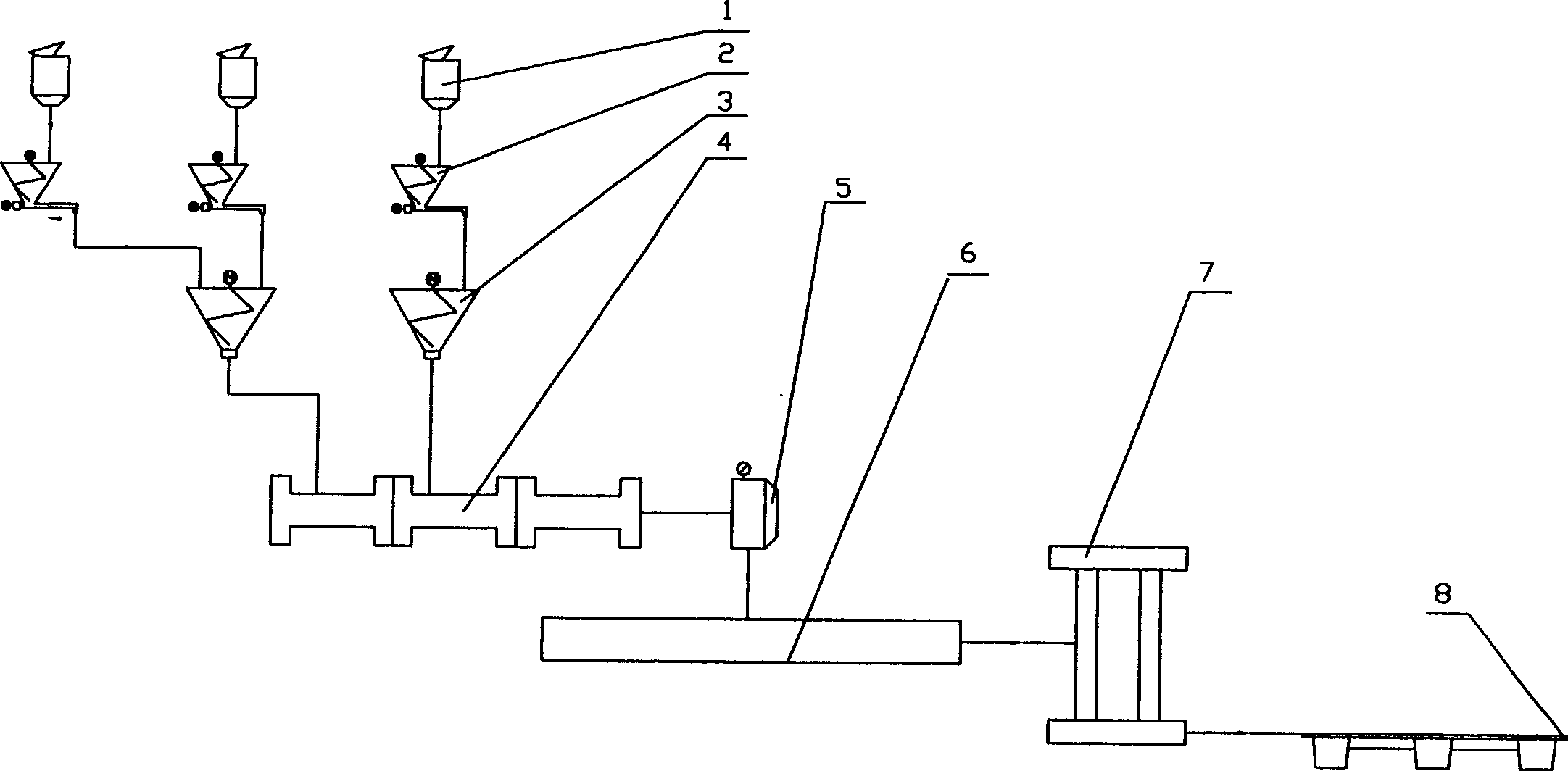

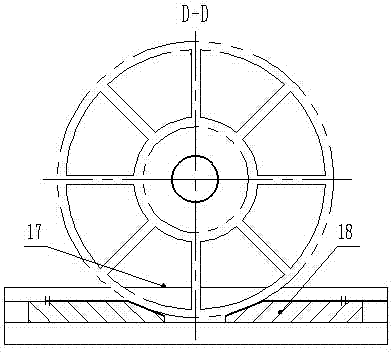

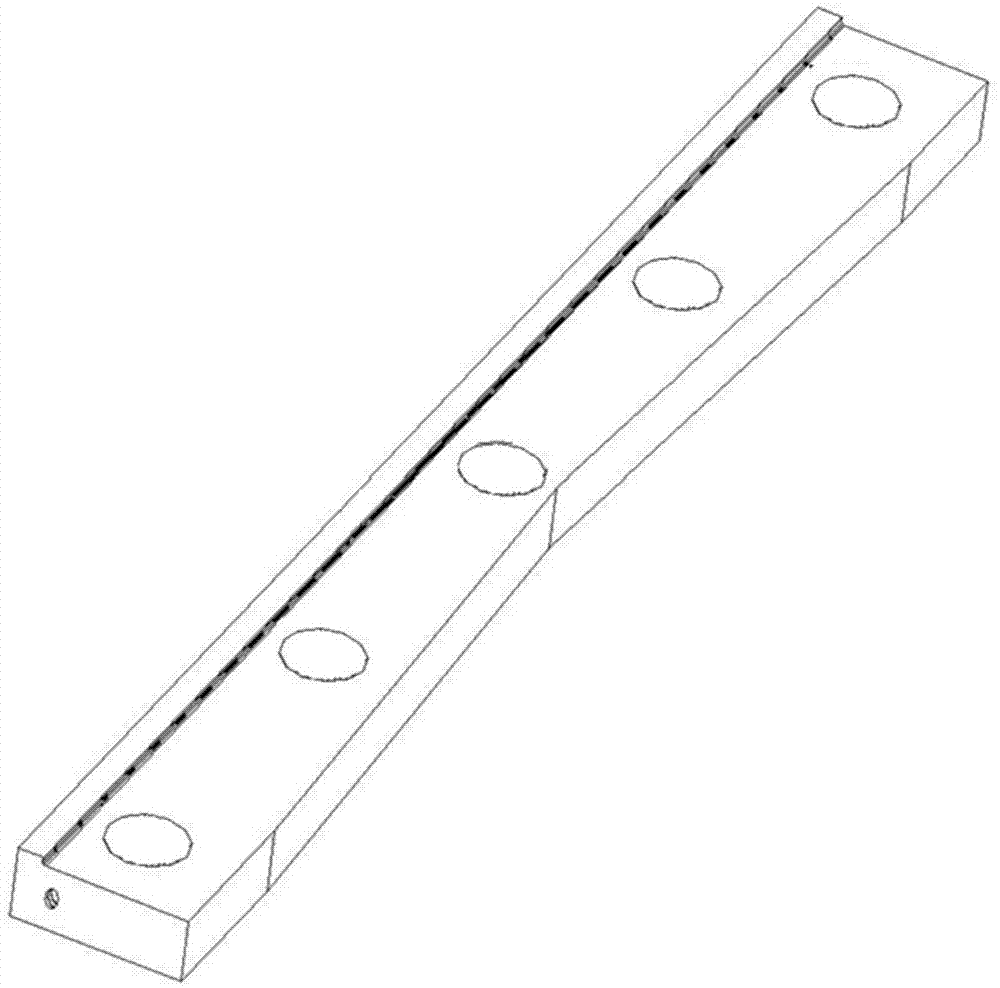

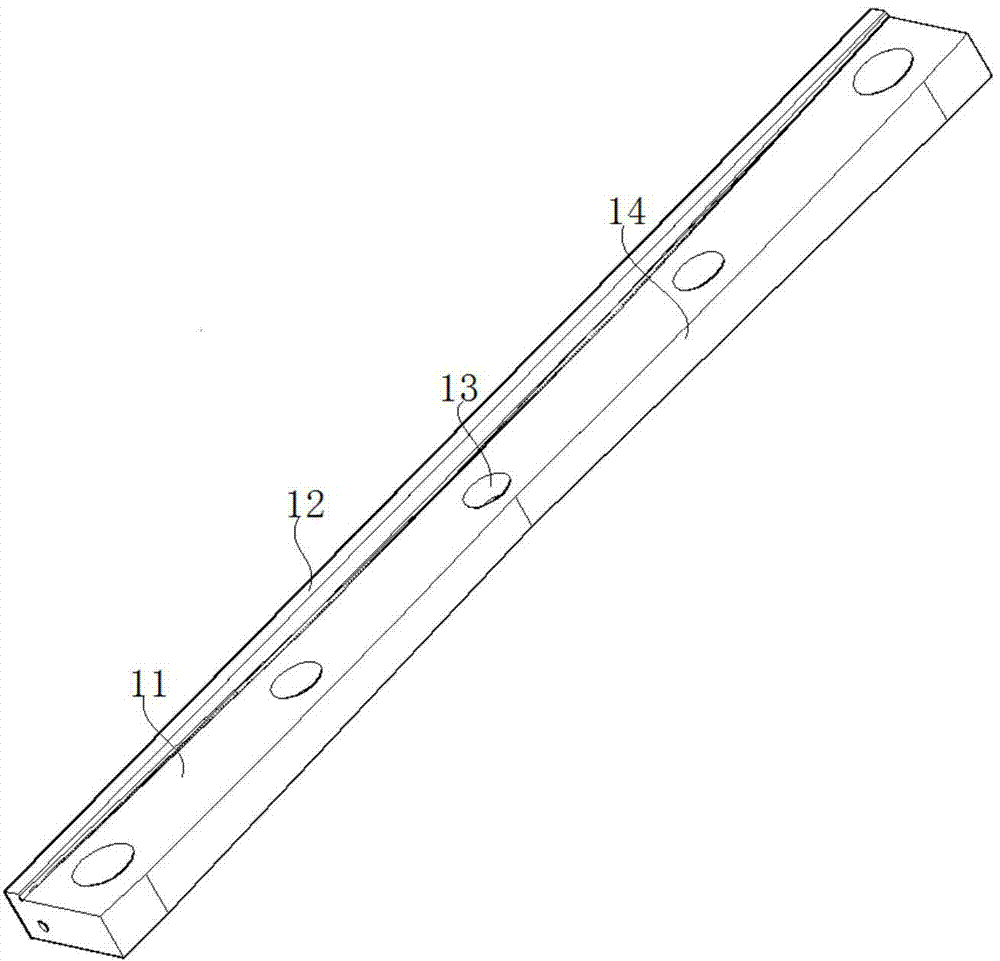

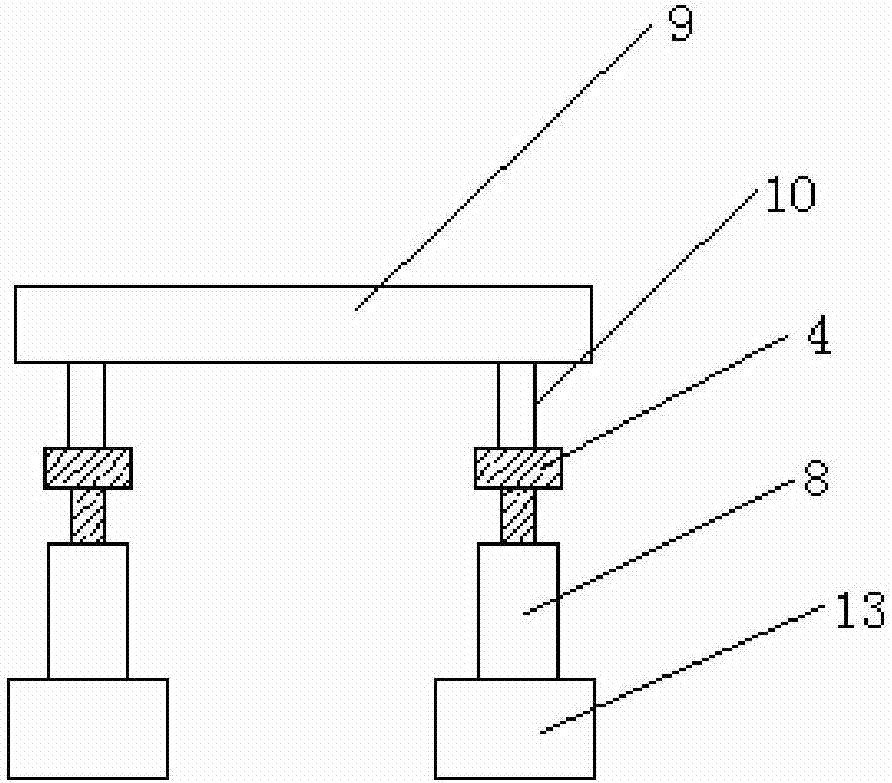

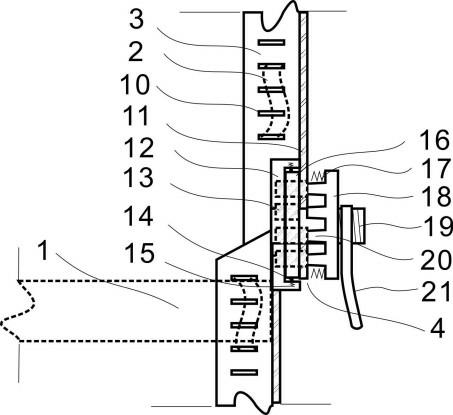

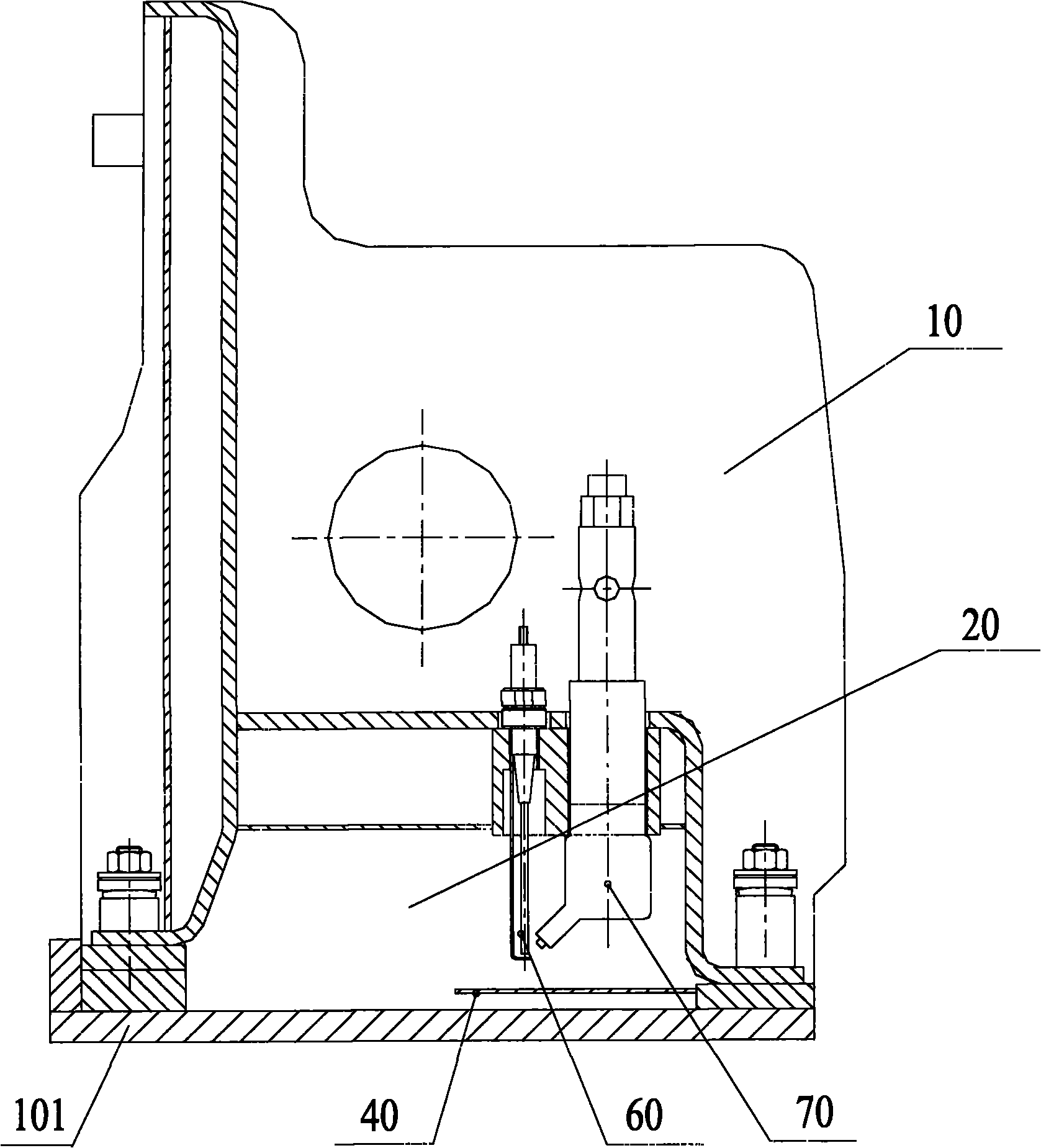

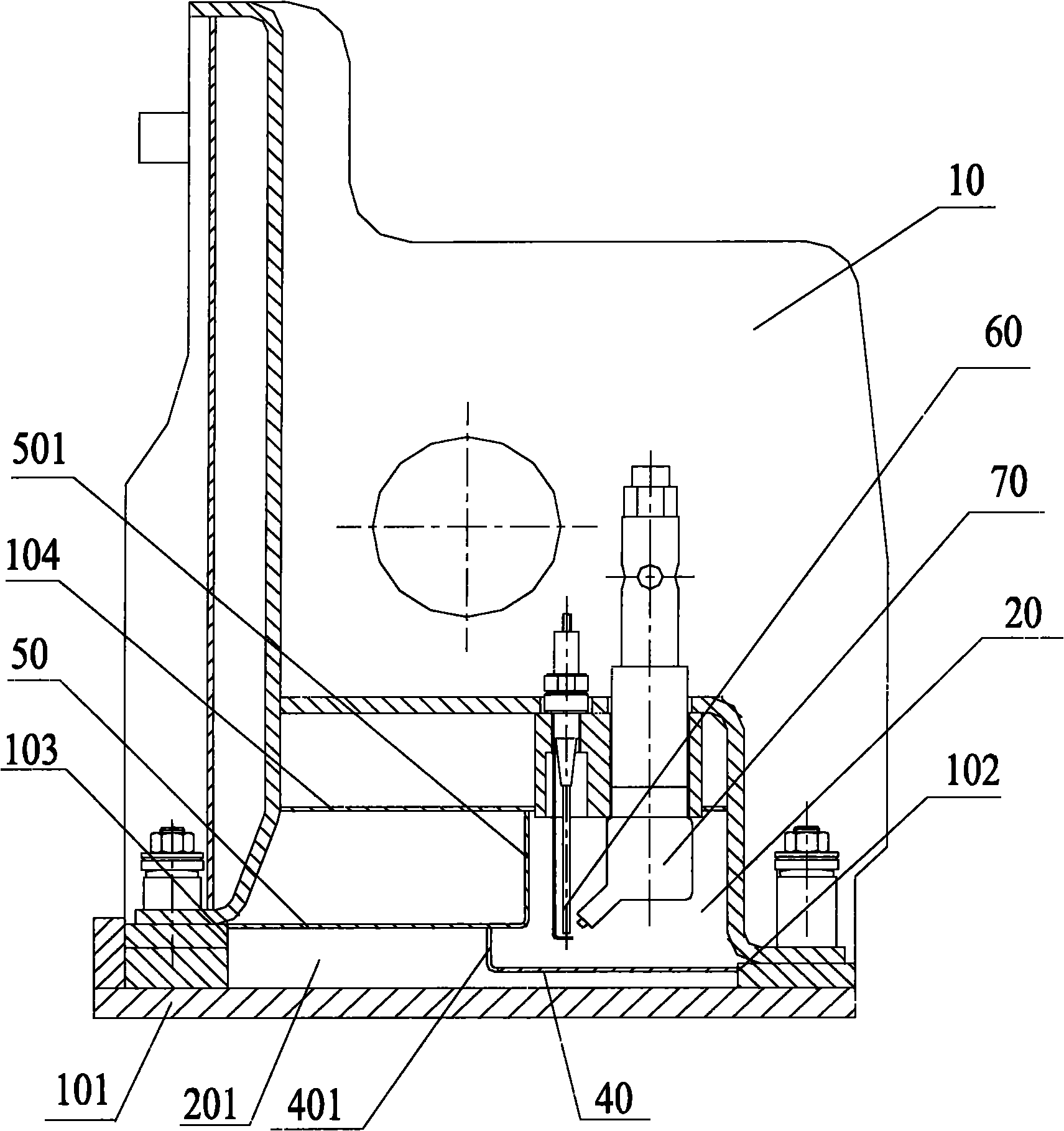

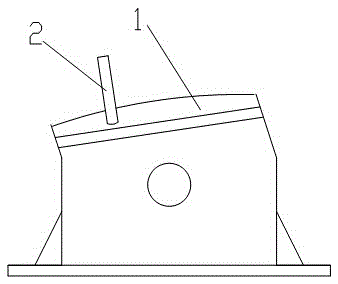

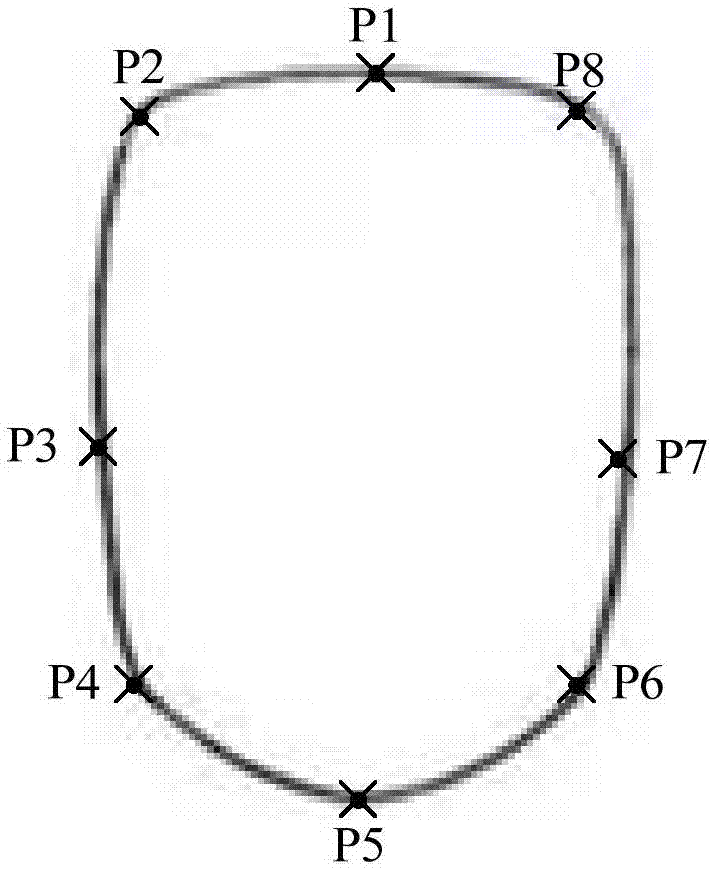

Pole piece feeding device

ActiveCN102642150AOvercome deformation and wrinklingAvoid left and right offsetMetal working apparatusManipulatorEngineering

The invention discloses a pole piece feeding device. The device comprises a material clamping manipulator part and a feeding fixed-length part, wherein the material clamping manipulator part comprises push rods and a first material clamping mechanism for clamping the front part of a pole piece; the feeding fixed-length part comprises a second material clamping mechanism for clamping the middle part of the pole piece and a feeding mechanism for driving the second material clamping mechanism to move back and forth; the first material clamping mechanism is installed at the front ends of the push rods; and the second material clamping mechanism is installed at the rear ends of the push rods. The device can be widely used for conveying and cutting such pole pieces as battery pole pieces and super capacitor pole pieces, can solve the problem that the pole pieces are easy to deform and wrinkle in the conveying process in the prior art, simultaneously avoids feeding fixed-length out of tolerance and left and right offset through fixed-length feeding and rectification control, reduces the size error of the pole piece and obviously improves the quality of the pole piece feeding process.

Owner:GEESUN AUTOMATION TECH

Device and method for automatically removing sprue

The invention relates to a device and a method for automatically removing a sprue. The sprue is removed on an automatic production line, wherein the sprue is generated when a workpiece is cast. The device comprises a working table with an inclined angle, a workpiece chuck, a positioning head, a punching hammer and a grating sensor, wherein the grating sensor is used for detecting whether the workpiece is arranged on the working table; the workpiece is arranged on the working table by using a mechanical arm and is positioned on the working table by using the positioning head; the workpiece chuck is used for chucking the workpiece on the working table; the punching hammer is used for punching and removing the sprue of the workpiece; and the workpiece of which the sprue is removed is conveyed to a next working procedure by a conveyer belt. The device has the beneficial effects that a fracture surface is high in consistency after the sprue of a product is removed, thereby being beneficial for a follow-up machining procedure; a robot can be used for stabilizing and controlling an operation process; compared with a manual removing mode, the method has higher working efficiency and security; and the device for automatically removing the sprue is used, so that full-process automation of product machining is beneficially achieved.

Owner:ALTEAMS SUZHOU DIE CASTING ELECTRONICS TECH

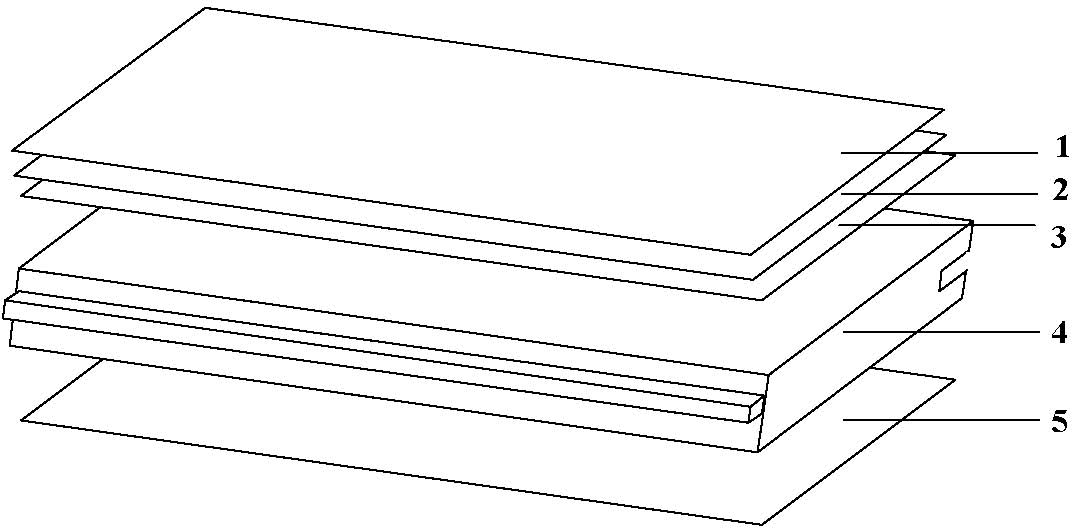

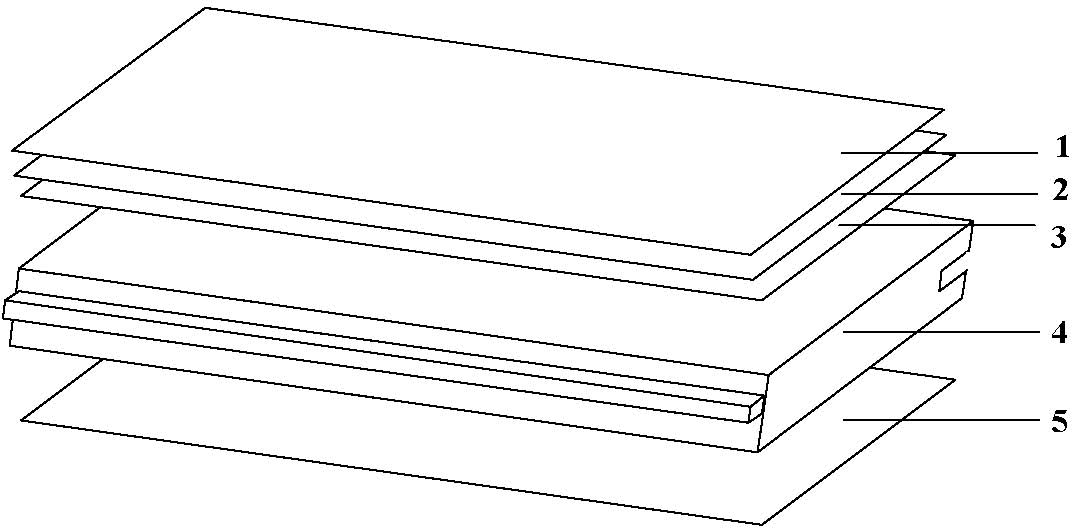

Wear-resisting anti-flaming poplar solid flooring and preparation method thereof

The invention provides a wear-resisting anti-flaming poplar solid flooring which is mainly composed of a modified solid flooring billet layer, and a preparation method of the wear-resisting anti-flaming poplar solid flooring; the wear-resisting anti-flaming poplar solid flooring sequentially comprises a balance moisture-proof layer, the modified solid flooring billet layer, a color blending layer, an ultrathin natural veneer decoration layer and a wear-resisting layer from bottom to top. The method comprises the steps of preparing a composite modified impregnation liquid and performing technologies of vacuum pressurization dipping treatment, drying, assembling and pressing and the like on woods. A composite modification processing technique of the invention enables the strength of poplar to be increased, the stability of the poplar to be enhanced, and enables the poplar to have properties of wear resistance, flame retardant, mildew prevention and anticorrosion and the like, so that the utilization value of artificial poplar is improved greatly. The method is simple and easy; and the wear-resisting anti-flaming poplar solid flooring processed by the method has the advantages of scratch resistance, wear resistance, flame retardant, mildew prevention, anticorrosion, easiness in maintenance, natural textures, comfort, environmental protection and high cost performance.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

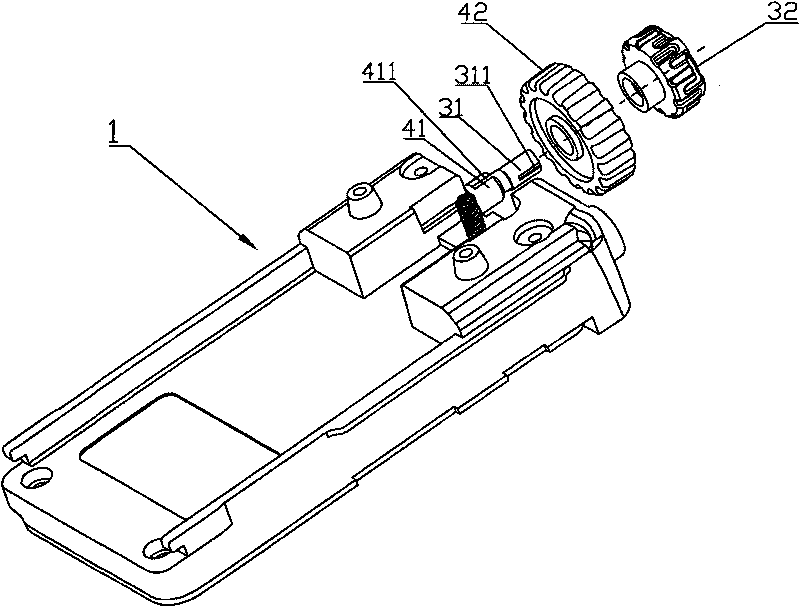

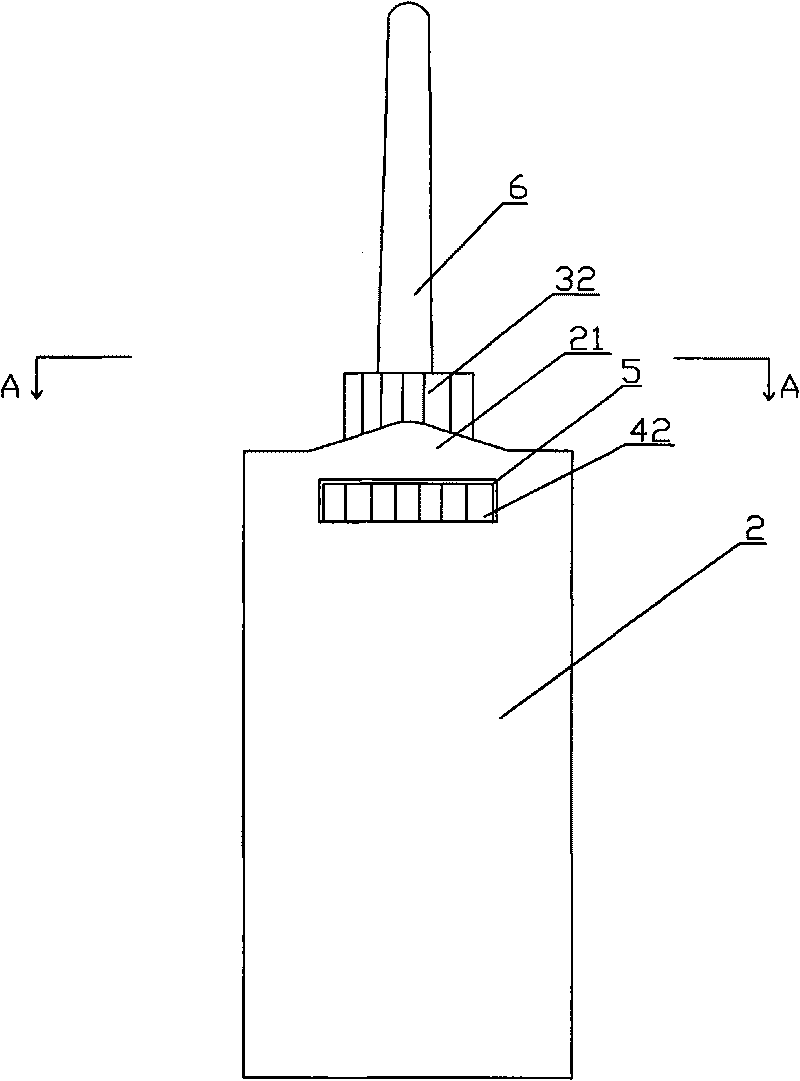

Interphone having modified adjusting knob

The invention relates to an interphone having a modified adjusting knob, which comprises an interphone body and a plastic shell covered on the interphone body. The interphone body is at least connected with two adjusting knobs which are on the same central line; and at least one of the adjusting knobs is positioned inside the plastic shell. By effectively modifying the adjusting knobs, the shortcomings that the adjusting knob of the traditional interphone is easy to bend and the error operation is easy to occur are overcome.

Owner:FUJIAN NANAN QUANSHENG ELECTRONICS

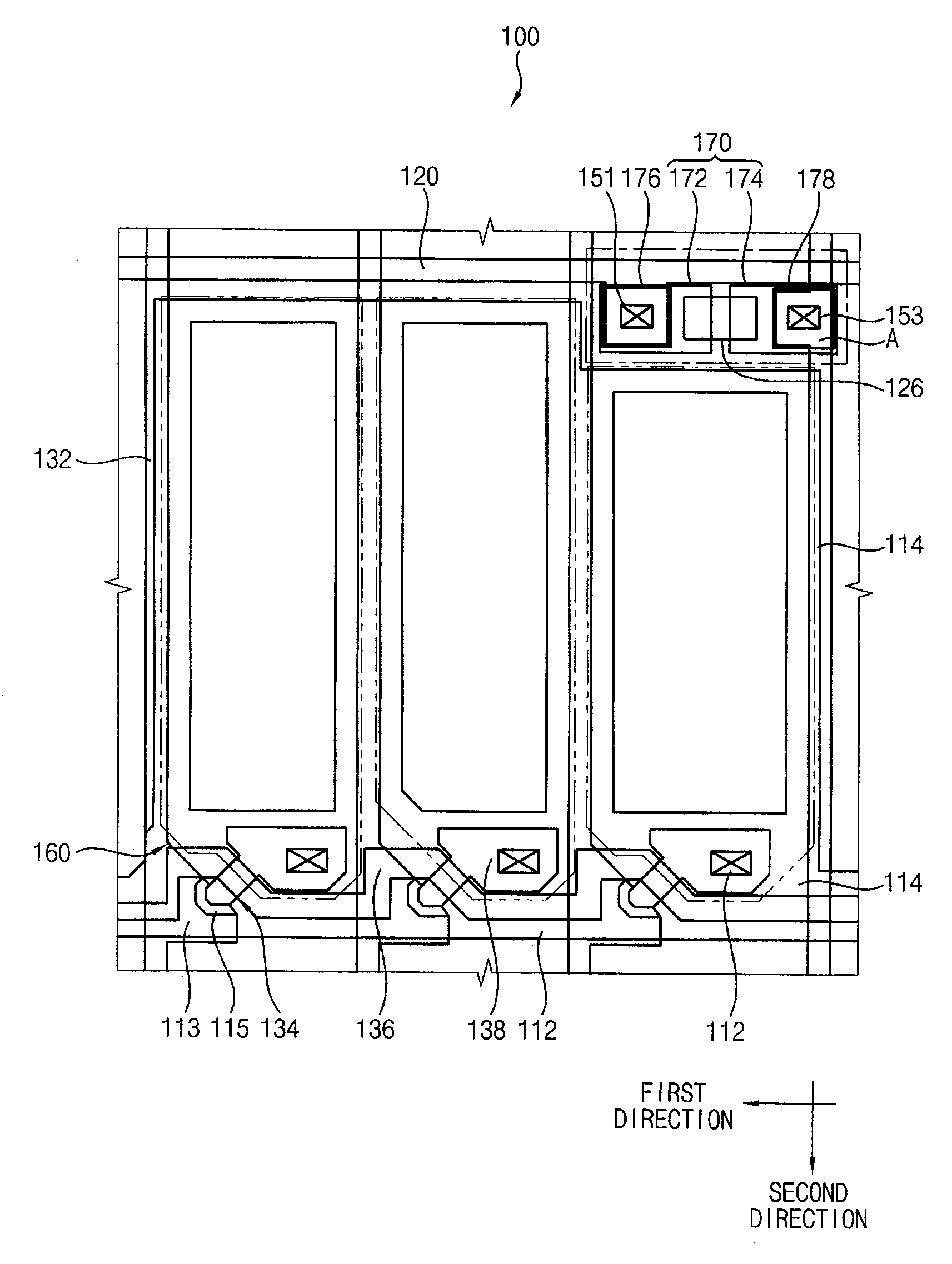

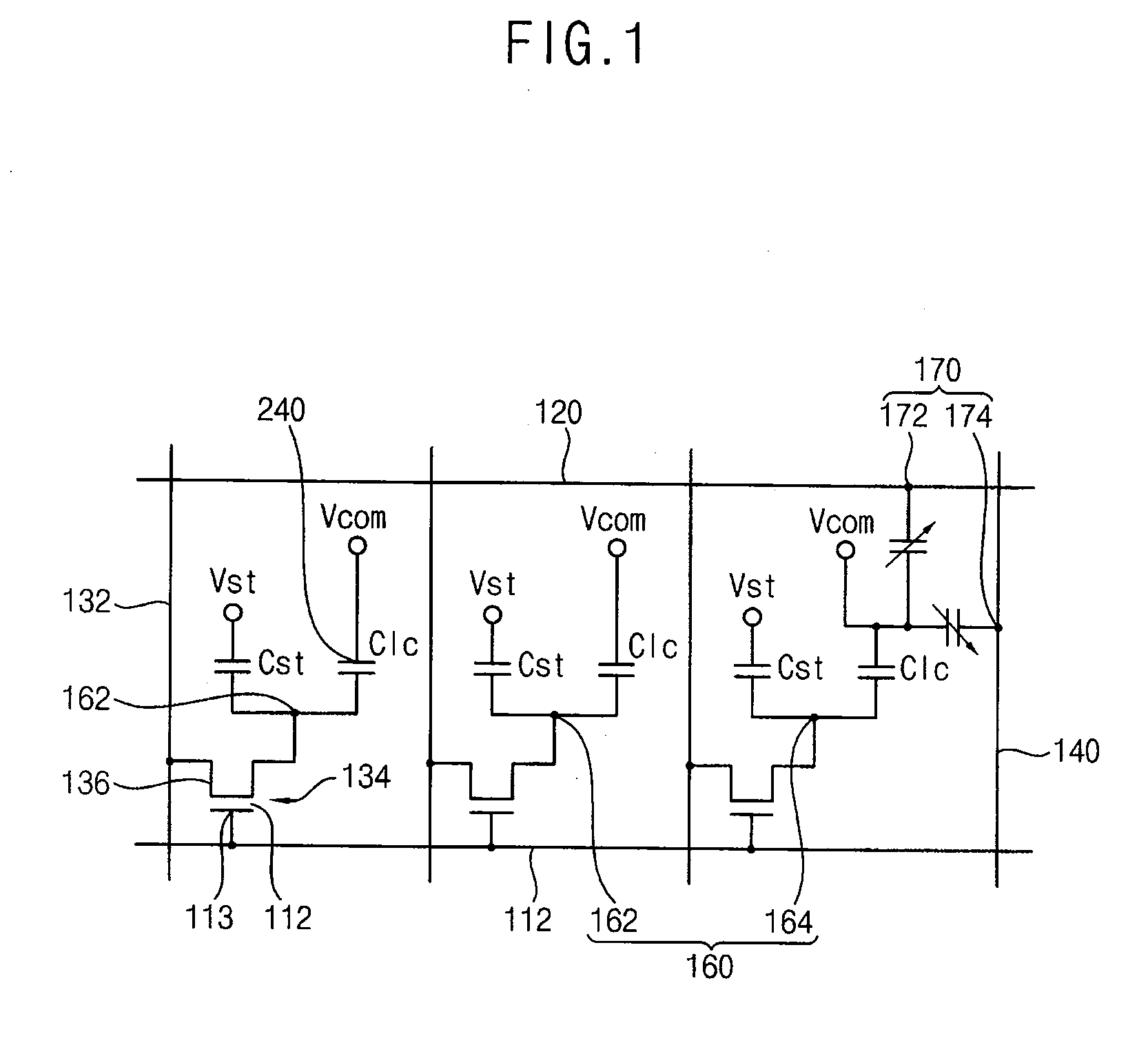

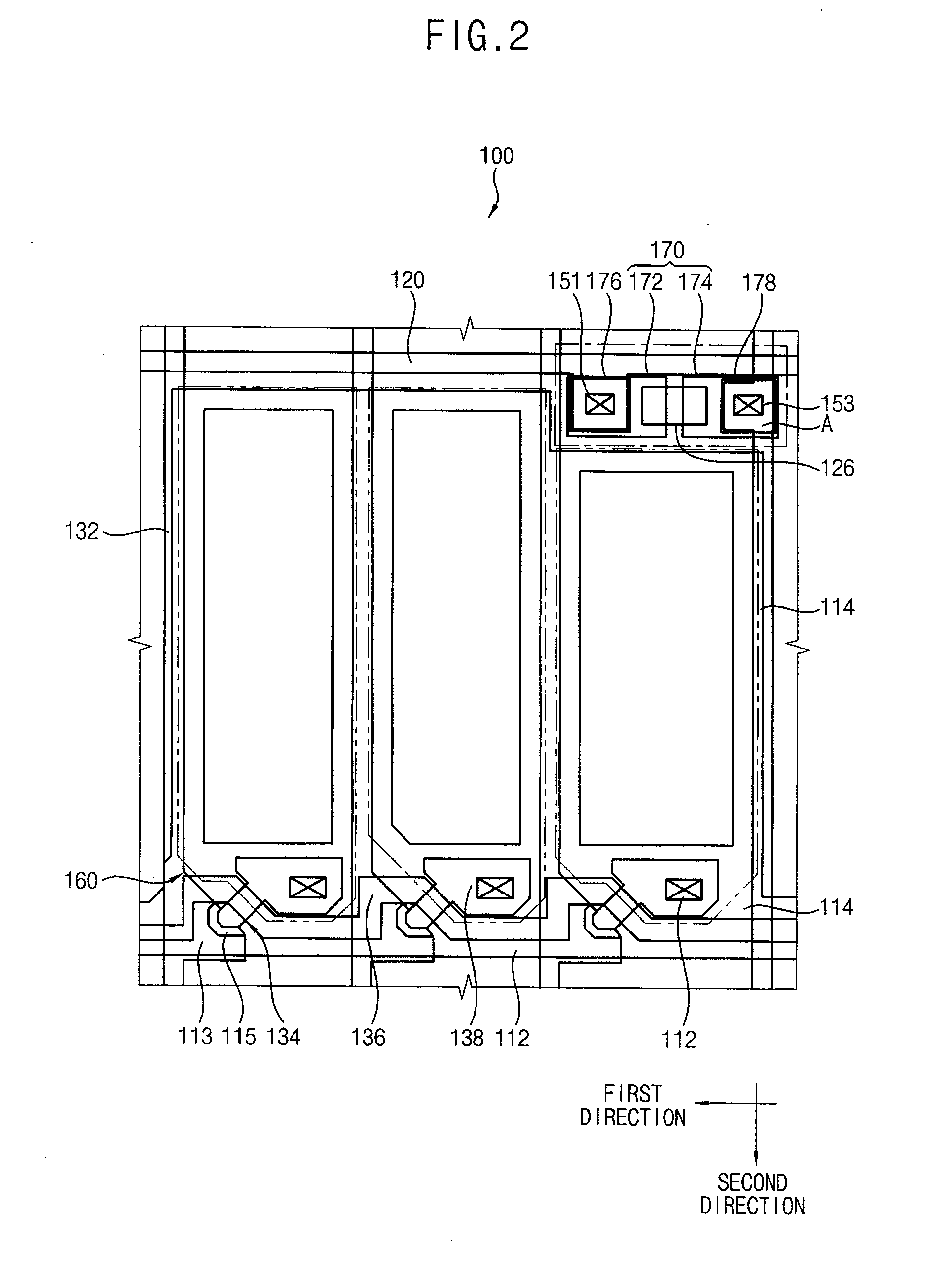

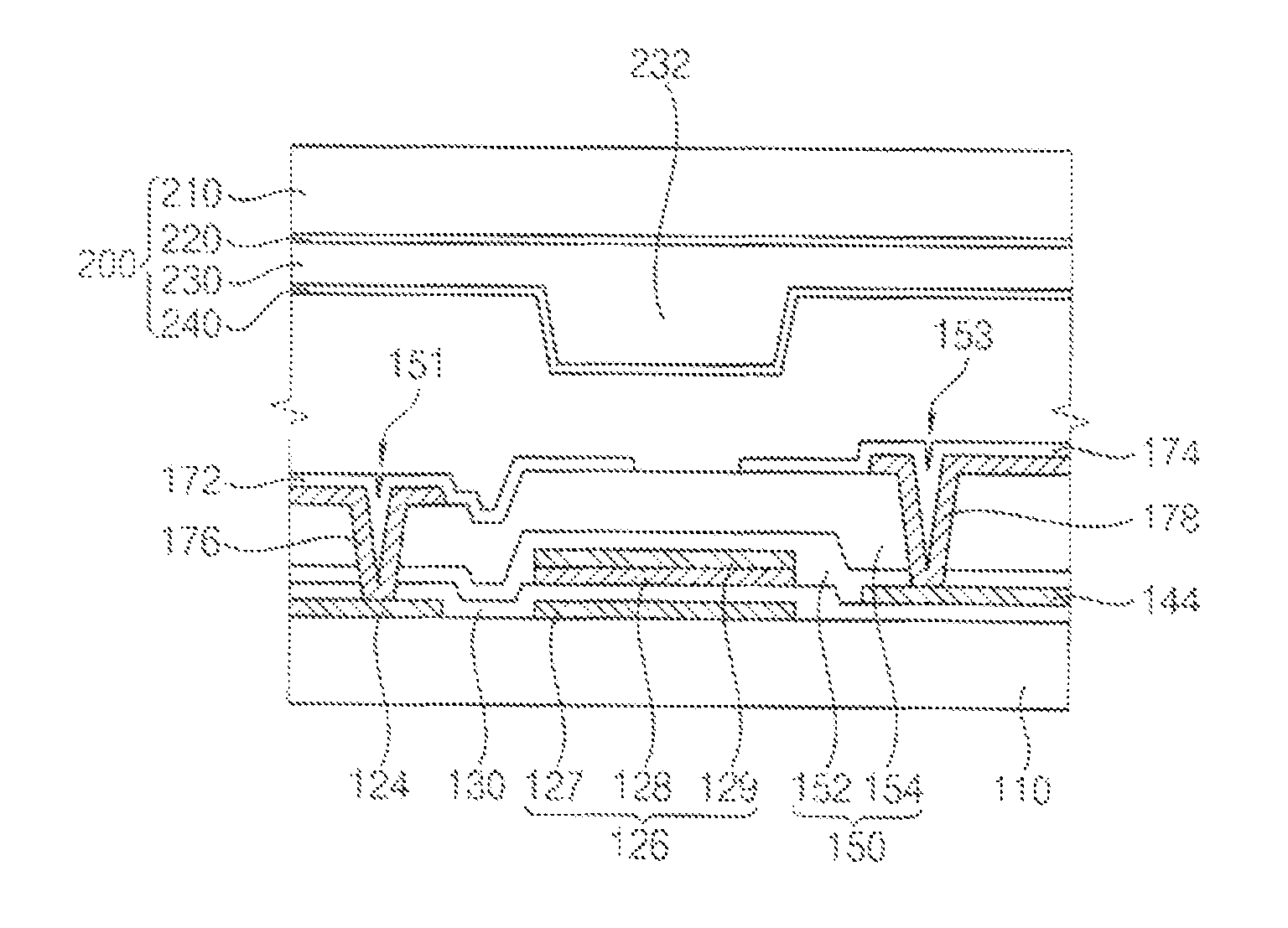

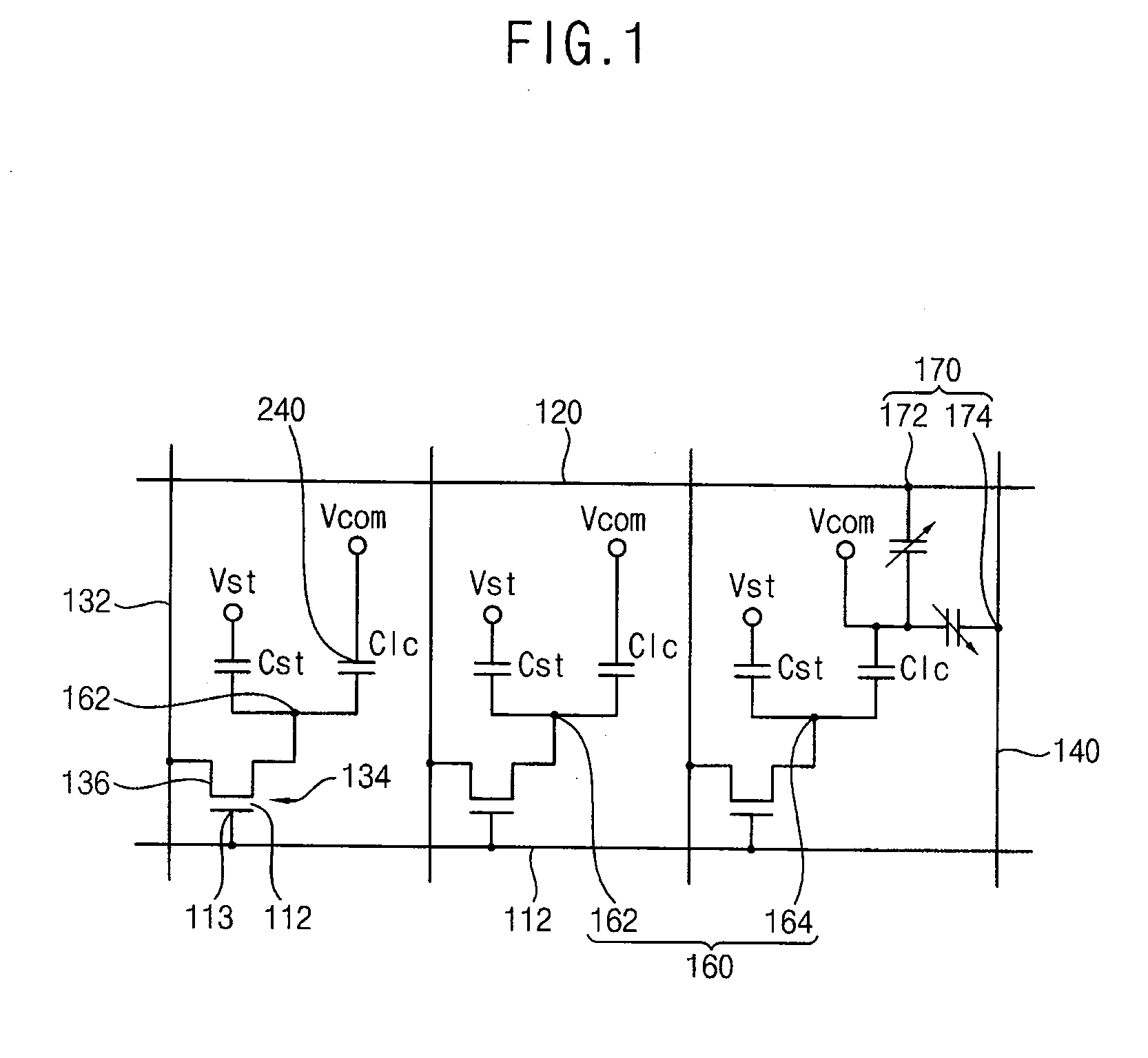

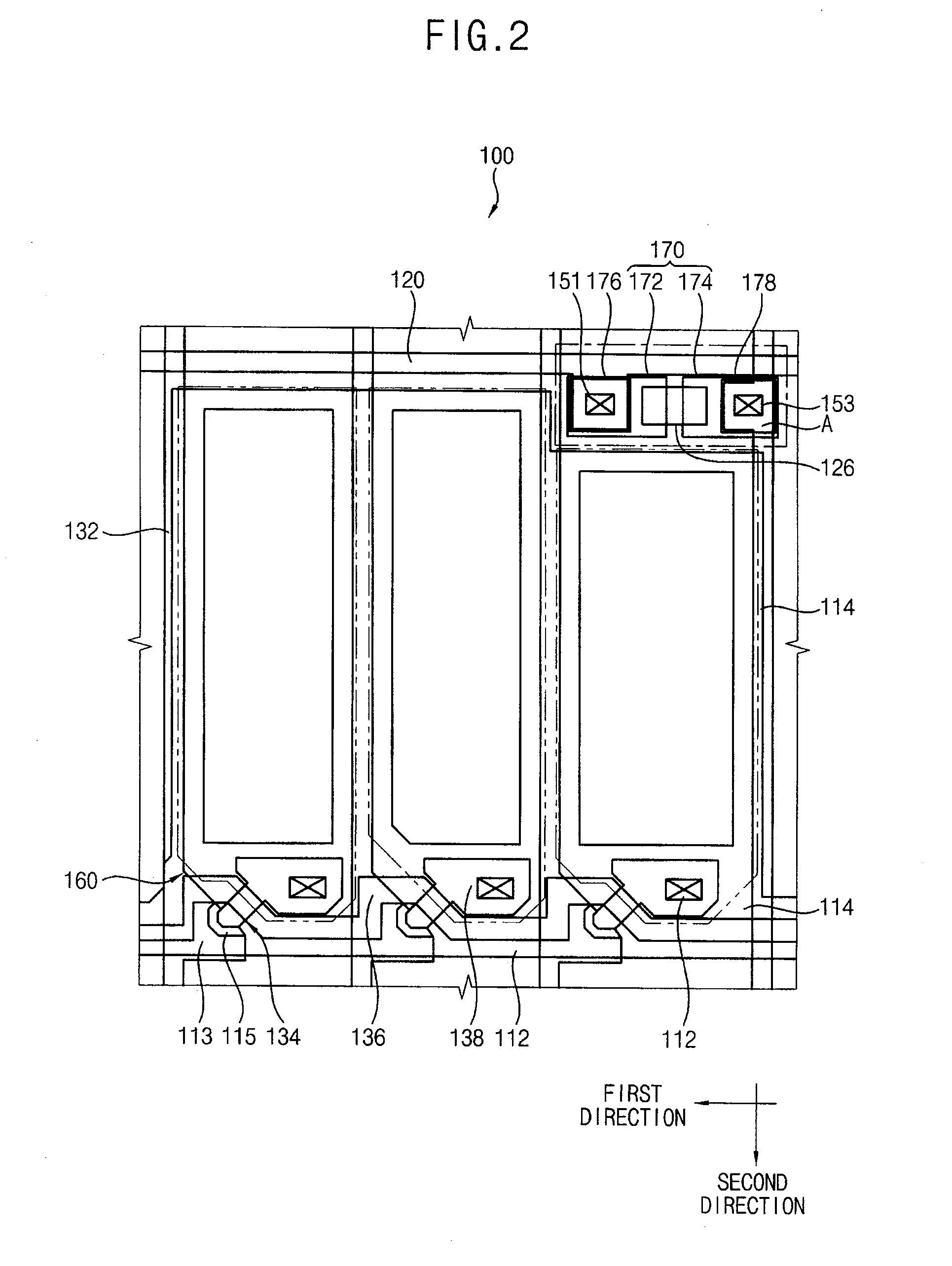

Thin film transistor substrate, display device having the same and method of manufacturing the same

ActiveUS20090091698A1Overcome elastic deformationOvercome pressure deformationStatic indicating devicesSolid-state devicesElectricityDisplay device

A display substrate includes a first sensor line substantially parallel with the gate line or the data line, a first protrusion portion protruded from the first sensor line, and a first sensor electrode electrically connected to the first protrusion portion. The first sensor electrode includes a malleable metal. The malleable metal can overcome pressure and elastic deformation. Thus, the sensor electrode made from the malleable metal is not easily damaged by pressing the sensor electrode repeatedly.

Owner:SAMSUNG DISPLAY CO LTD

Thin film transistor substrate, display device having the same and method of manufacturing the same

ActiveUS8345173B2Overcome deformationOvercome pressureSolid-state devicesNon-linear opticsDisplay deviceEngineering

A display substrate includes a first sensor line substantially parallel with the gate line or the data line, a first protrusion portion protruded from the first sensor line, and a first sensor electrode electrically connected to the first protrusion portion. The first sensor electrode includes a malleable metal. The malleable metal can overcome pressure and elastic deformation. Thus, the sensor electrode made from the malleable metal is not easily damaged by pressing the sensor electrode repeatedly.

Owner:SAMSUNG DISPLAY CO LTD

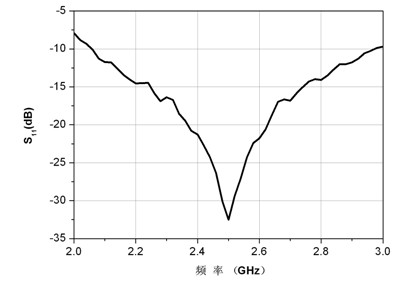

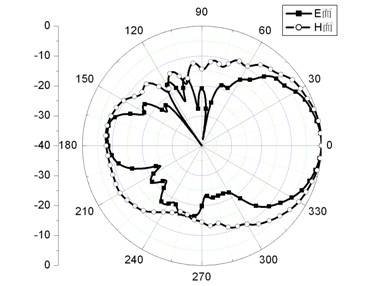

Dual-probe reverse phase feeding microstrip antenna

InactiveCN102637957APromote polarizationImprove featuresRadiating elements structural formsMechanical engineeringPhysics

The invention discloses a dual-probe reverse phase feeding microstrip antenna, which comprises a first medium substrate, a second medium substrate and a ground level, wherein the first medium substrate is parallel to the ground level; the second medium substrate penetrates through the ground level vertically; the upper end of the second medium substrate is adjacent to the lower surface of the first medium substrate; the first medium substrate is provided with a microstrip patch; a first L-shaped probe strip and a second L-shaped probe strip are arranged symmetrically on the second medium substrate; the first L-shaped probe strip is formed by connecting a first coupling exciting strip which is parallel to the ground level and a first feeding strip which is vertical to the ground level; the second medium substrate is partitioned into an upper area and a lower area by an intersection line between the second medium substrate and the ground level; an area of the second medium substrate, which is positioned on the lower side of the intersection line, is provided with a microstrip power divider in two penny; one path of the microstrip power divider is connected with the first feeding strip through an inverter; and the other path of the microstrip power divider is directly connected with the second feeding strip.

Owner:SOUTHEAST UNIV

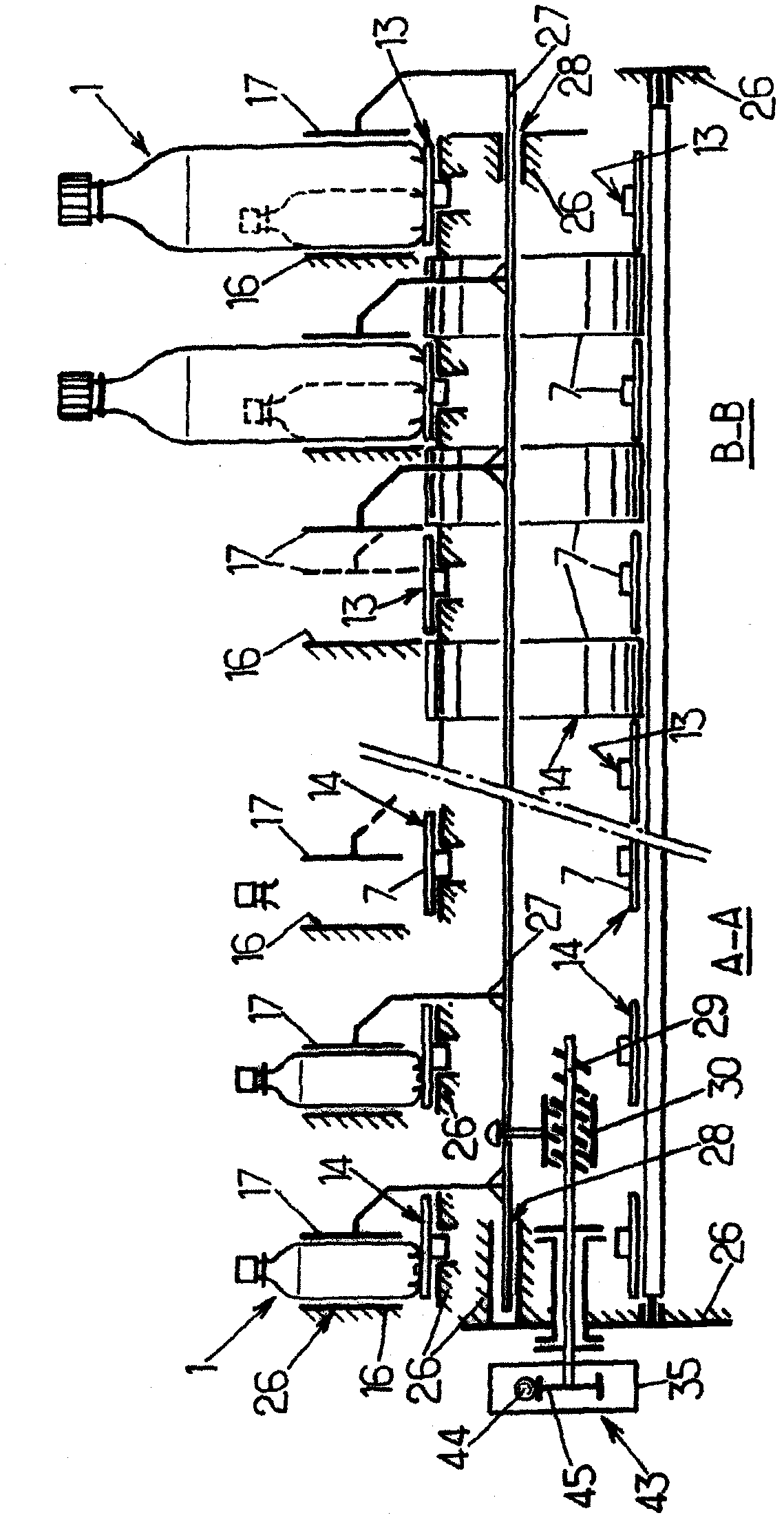

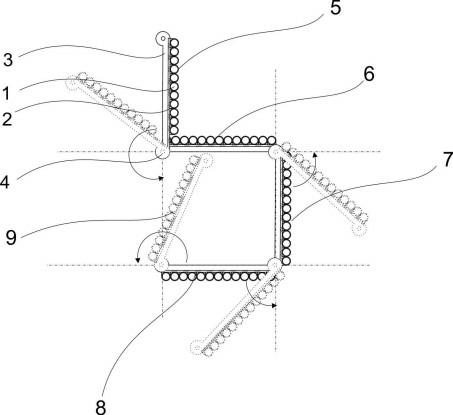

Multipath conveyor installation

ActiveCN102083716AOvercome deformationOvercoming distractionsConveyorsConveyor partsEngineeringBottle

A conveyor installation makes it possible to control the speed of items of the bottle (1) type dispatched in several trains distributed across various paths in the form of single-file lanes (11). The lanes are delimited by a pair of walls (16, 17) which are arranged in an omega shape over a base plate made up of several juxtaposed conveyors (13, 14, 15). Each lane (11) may comprise a fixed wall (16) acting as a reference, and a moving wall (17) that can be adjusted according to the dimensions of the items that are to be conveyed.

Owner:GEBO PACKAGING SOLUTIONS FRANCE SAS

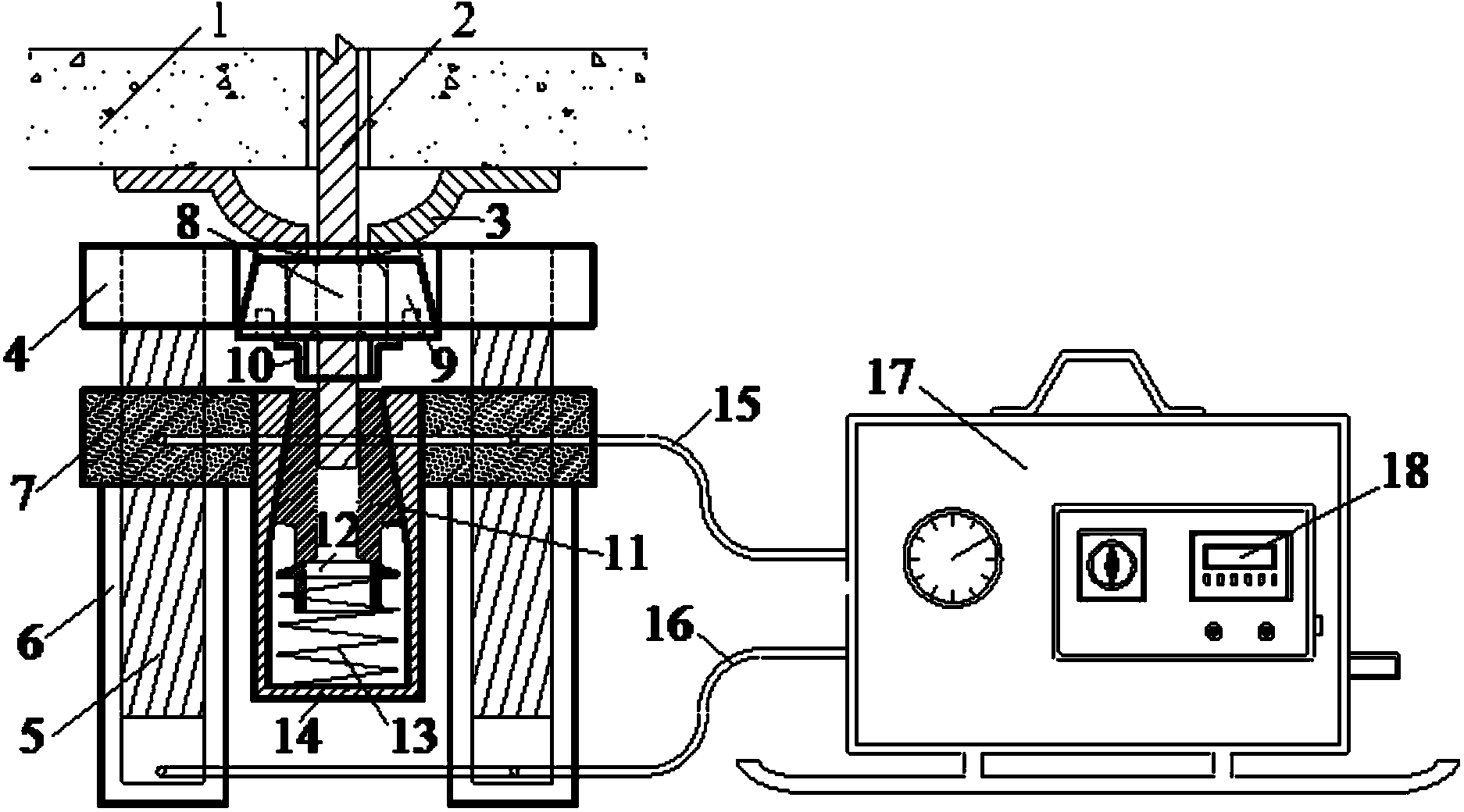

Full-thread anchor rod pre-tightening force exerting device capable of achieving automatic anchor unloading and operation method

ActiveCN103590842AOvercoming low torque conversion coefficientOvercome large thread pitchAnchoring boltsScrew threadRock bolt

The invention discloses a full-thread anchor rod pre-tightening force exerting device capable of achieving automatic anchor unloading and an operation method. The full-thread anchor rod pre-tightening force exerting device comprises a front transverse beam, a rear transverse beam and an anchor unloading device for clamping and releasing an anchor rod, the front transverse beam and the rear transverse beam are respectively connected with two hydraulic telescopic oil cylinder supporting columns, the middle of the front transverse beam is provided with a cone-shaped nut, and the end portion of the cone-shaped nut is provided with a sleeve which is movably matched with the anchor unloading device; the front transverse beam is attached to a tray of the anchor rod; the rear transverse beam is matched with the anchor unloading device; the middle of the rear transverse beam is matched with the anchor unloading device, the telescopic oil cylinder supporting columns are driven by a pneumatic oil pressure pump, and the output end of the pneumatic oil pressure pump is connected with a controller. The full-thread anchor rod pre-tightening force exerting device achieves automatic anchor unloading, is convenient to operate and use, high in pre-tightening force exerting efficiency, and beneficial to giving full play to supporting potential of the high-strength full-thread anchor rod, and guarantees safe and efficient production of coal mine enterprises.

Owner:SHANDONG UNIV

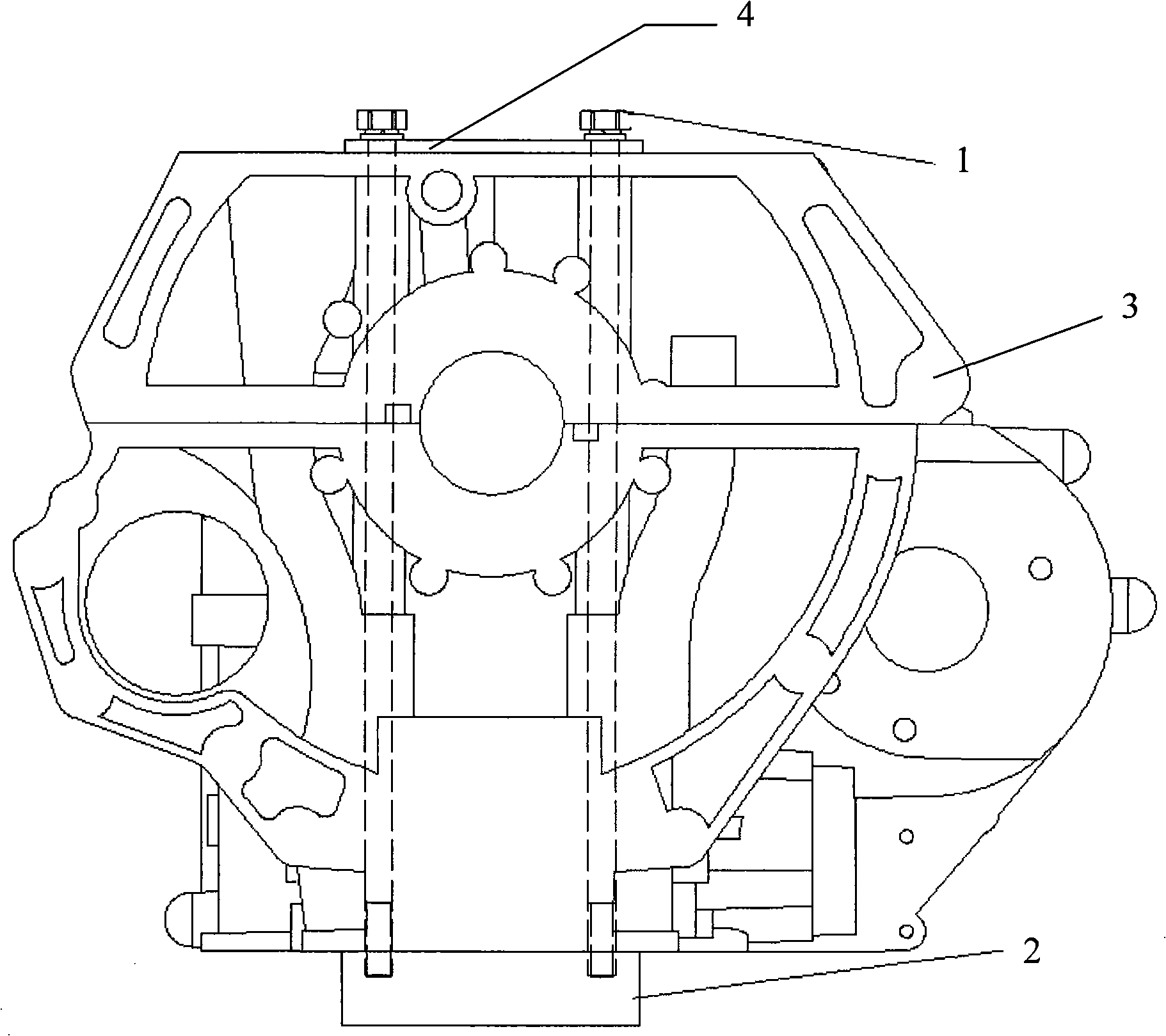

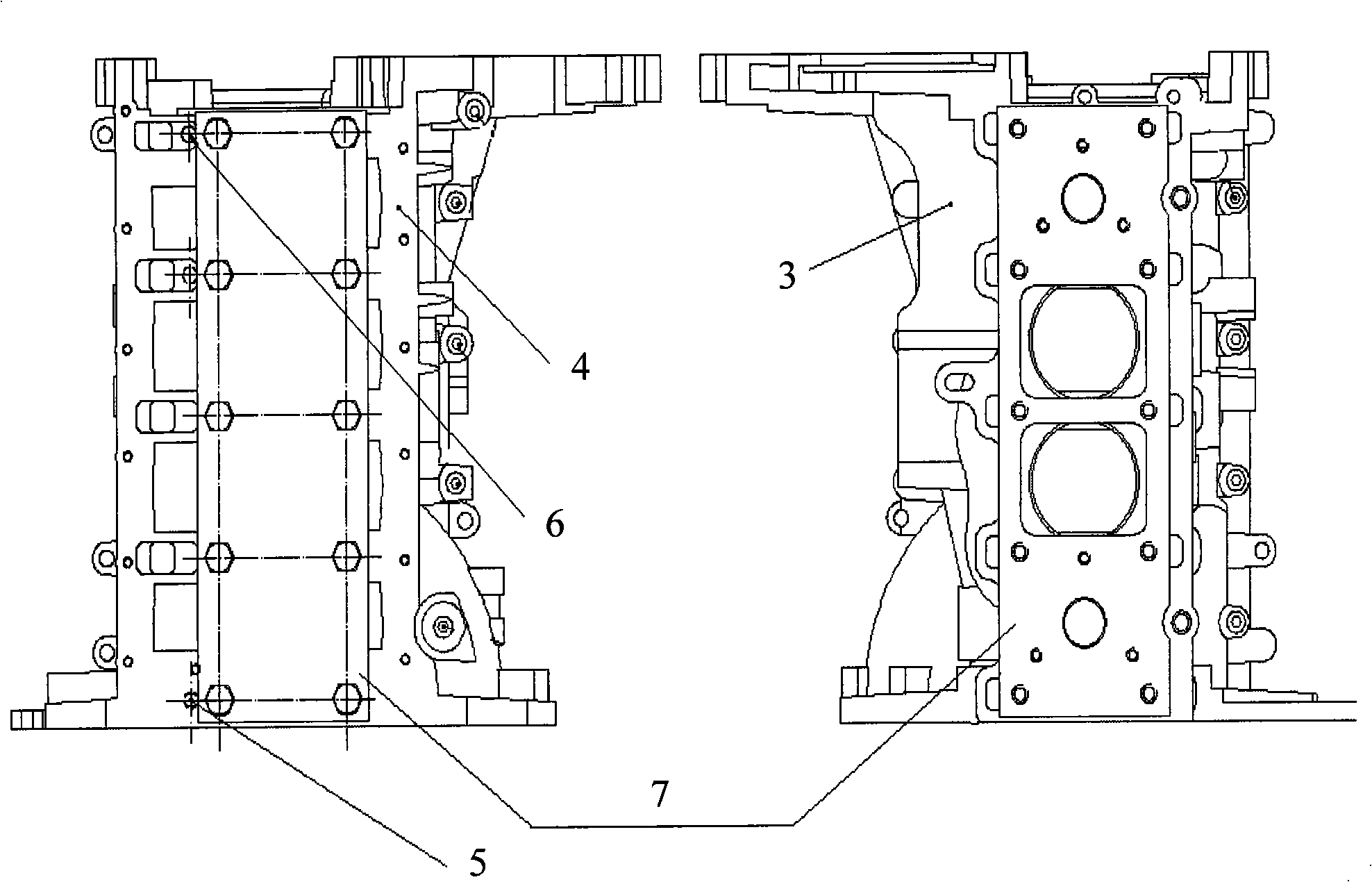

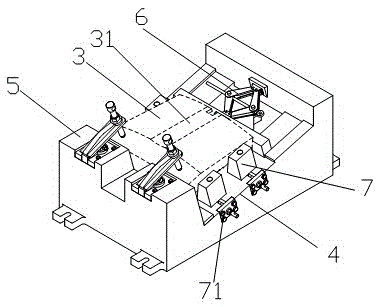

Assembly method and component for fine process of cylinder of diesel engine

InactiveCN101293286AOvercome deformationReduce processing difficultyMetal working apparatusBoring/drilling machinesCylinder headEngineering

The invention relates to an assembling method applied to fashioning a cylinder block of a diesel engine and assembling components thereof. The assembling method includes the following steps: a simulated cylinder head is designed and manufactured; the cylinder block is provided with a set pin, an engine seat aligns the set pin on the cylinder block so as to cause the engine seat to be installed in the cylinder block; the simulated cylinder head is connected with the cylinder block and the engine seat, and machining is carried out. The assembling components comprise a simulated cylinder head, a cylinder block and an engine seat, the simulated cylinder head, the cylinder block and the engine seat are connected in sequence. As the simulated cylinder head is designed and manufactured, in-and-out bolts are used for assembling the cylinder block, the simulated cylinder head and the engine seat for processing, thus overcoming the phenomenon that a spindle hole is deformed when the whole machine is assembled and processed, lowering the difficulty of processing and improving the precision and quality stability of the product.

Owner:GUANGXI YUCHAI MASCH CO LTD

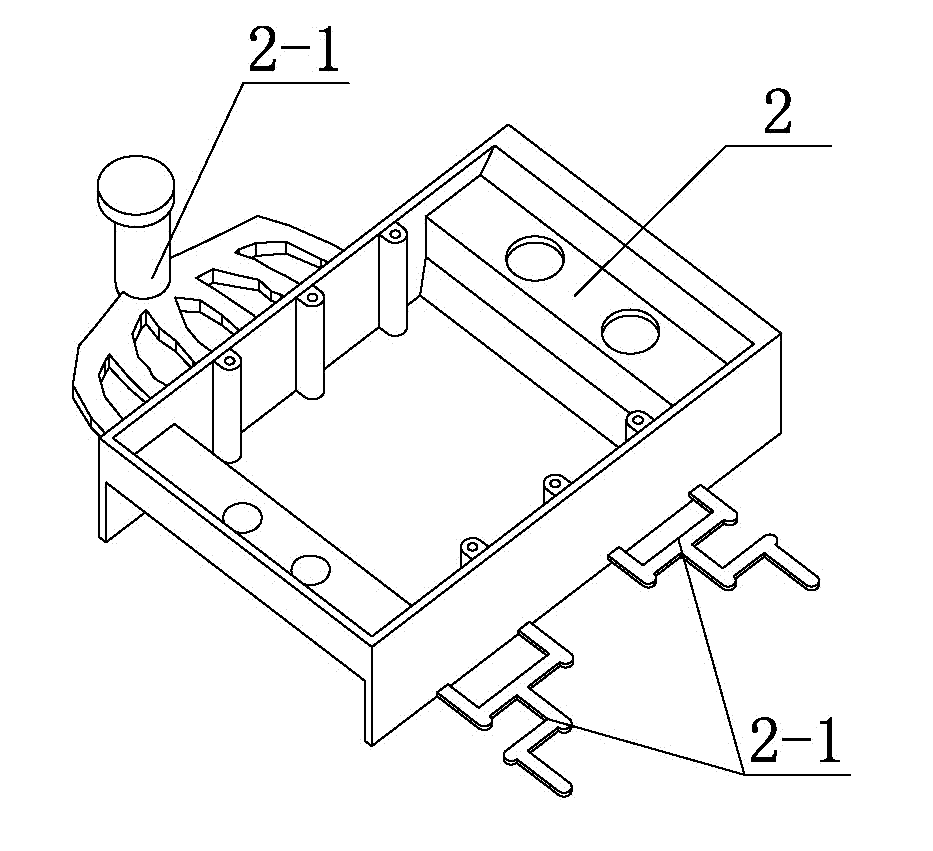

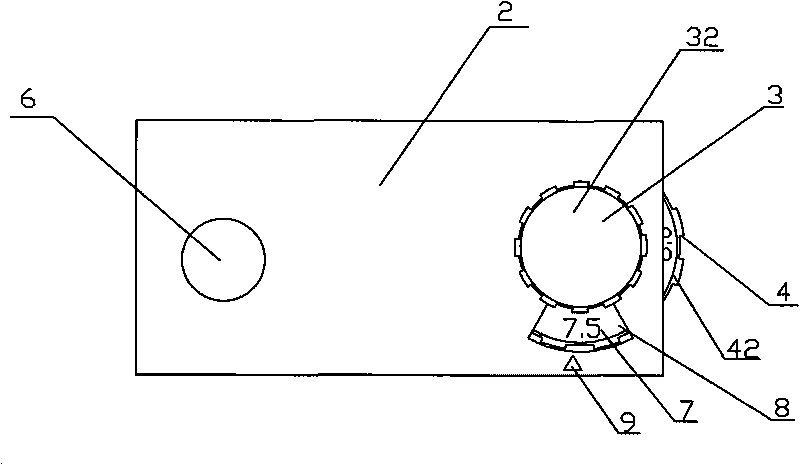

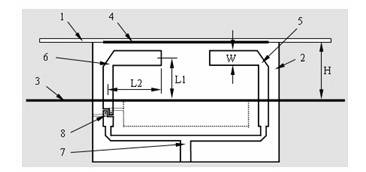

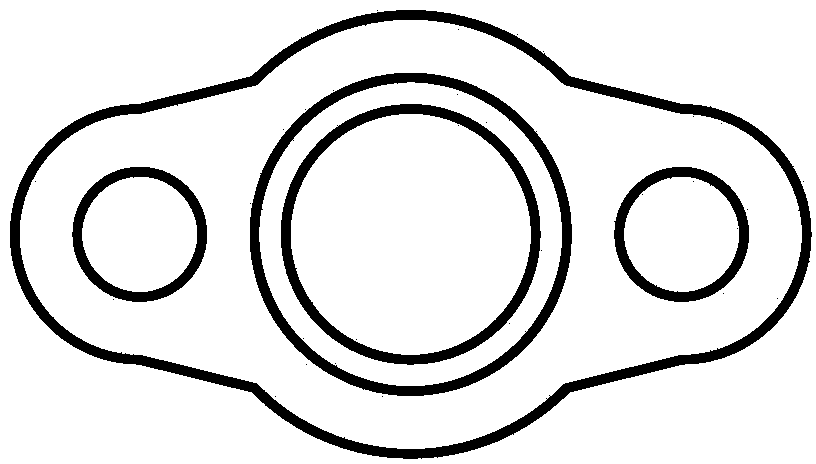

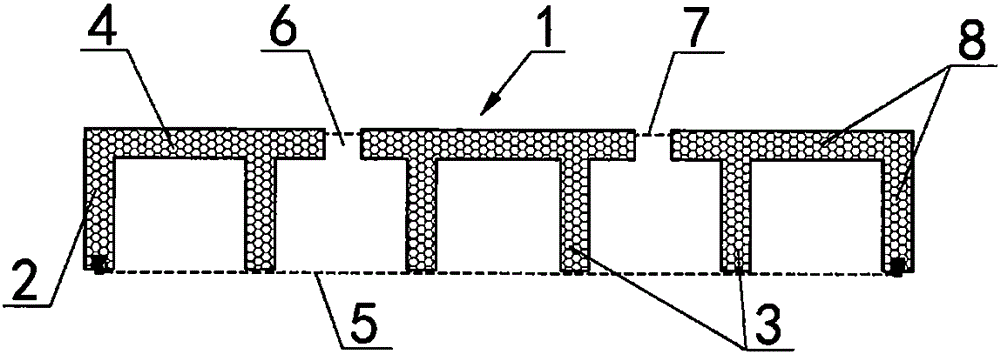

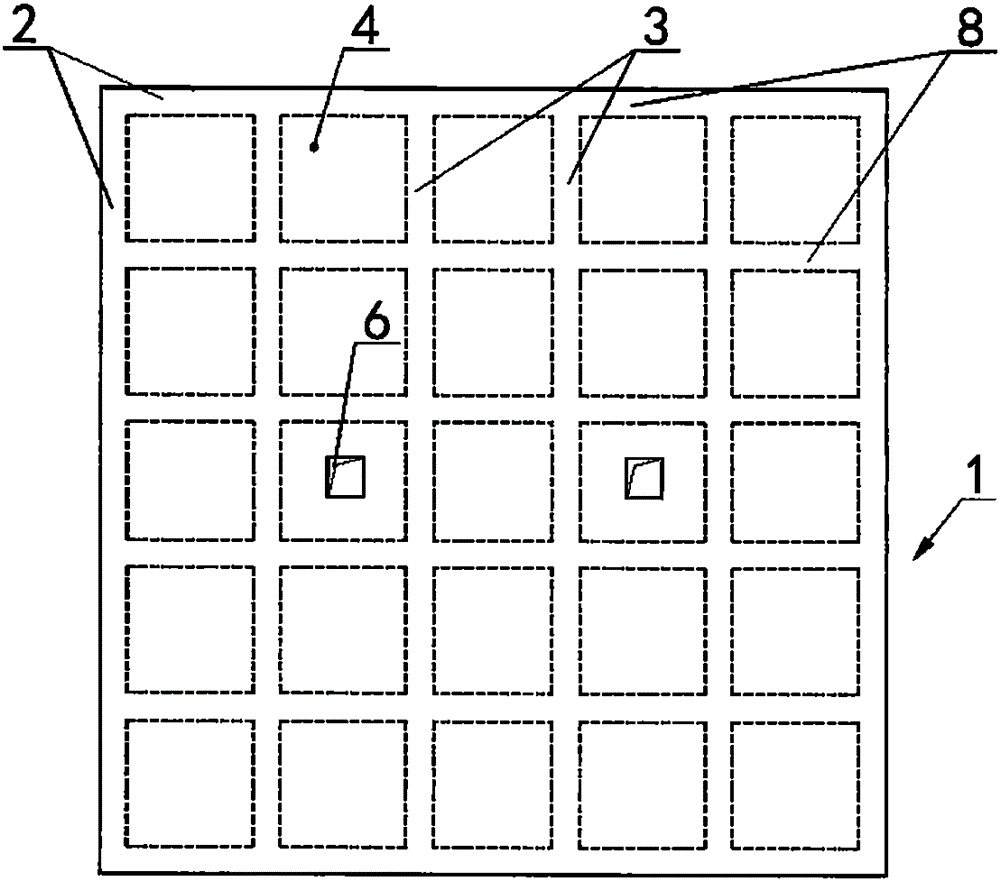

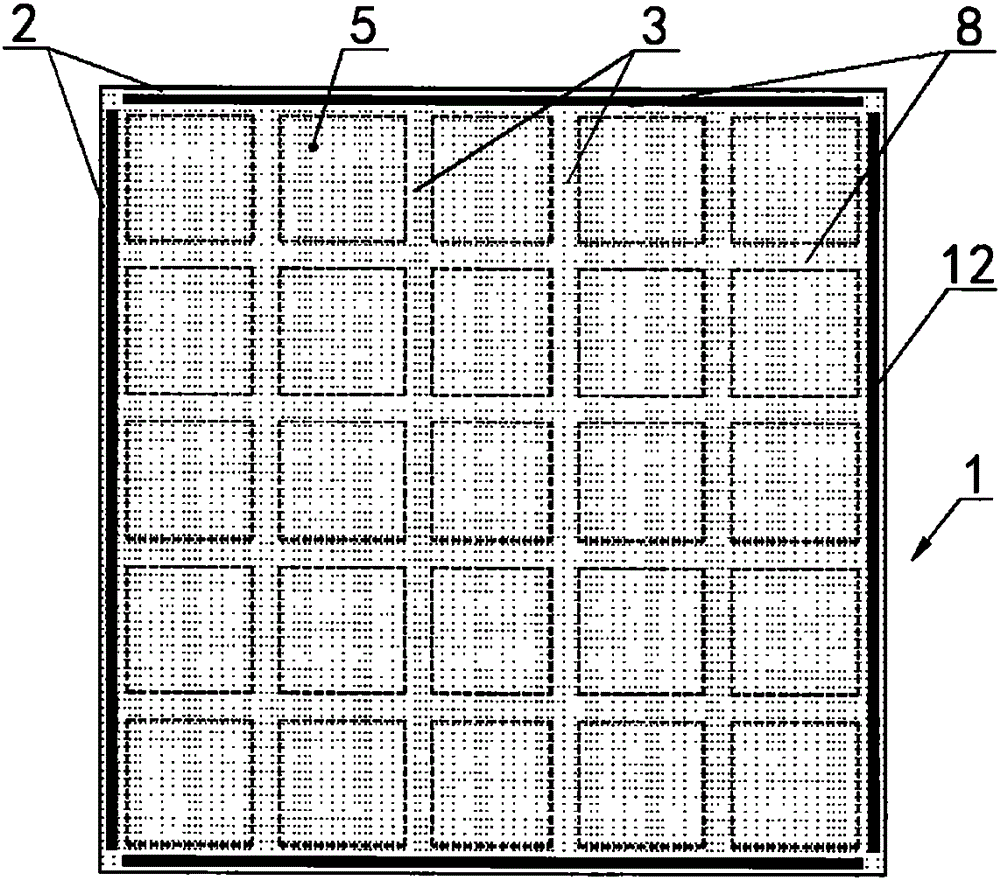

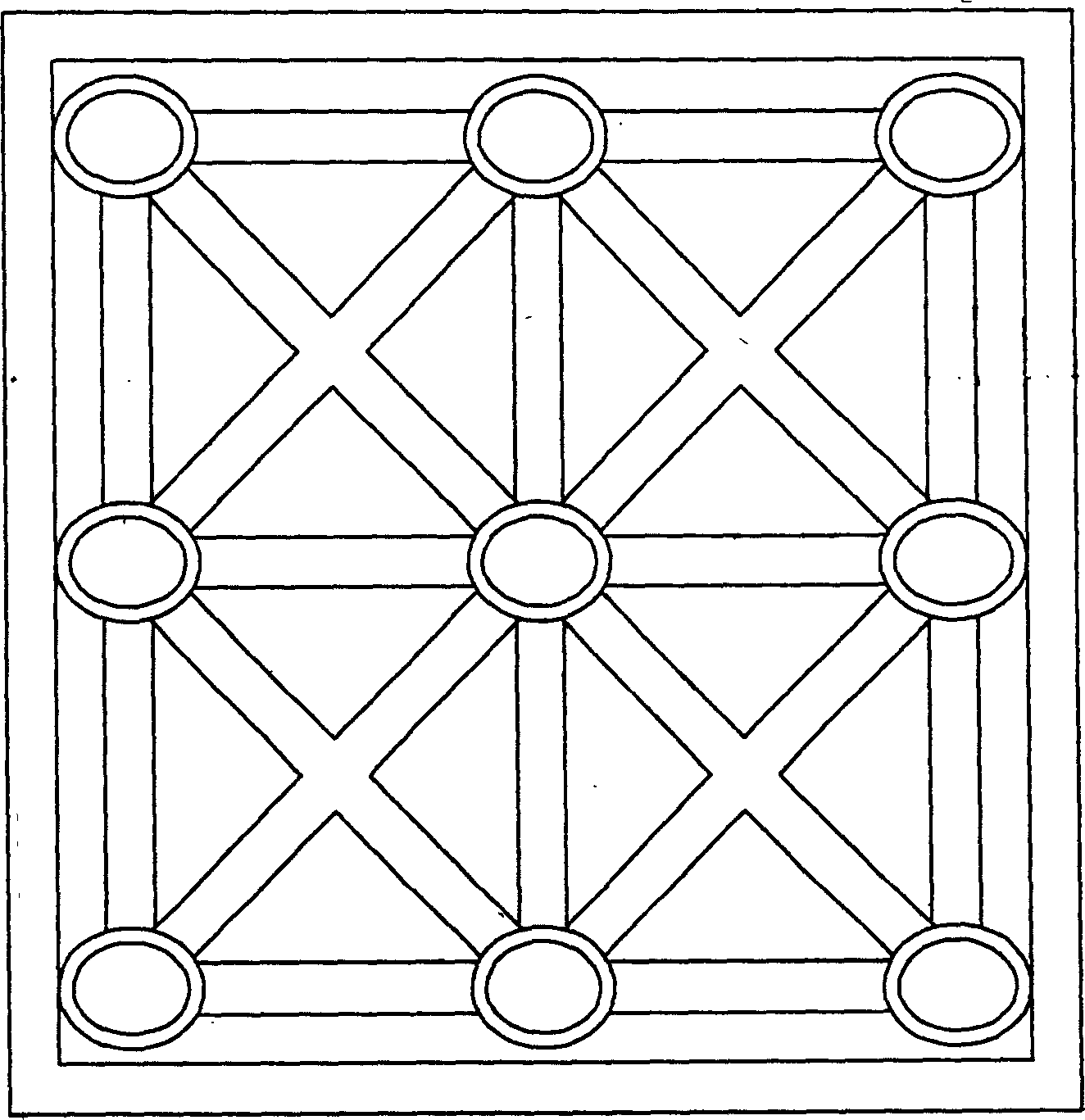

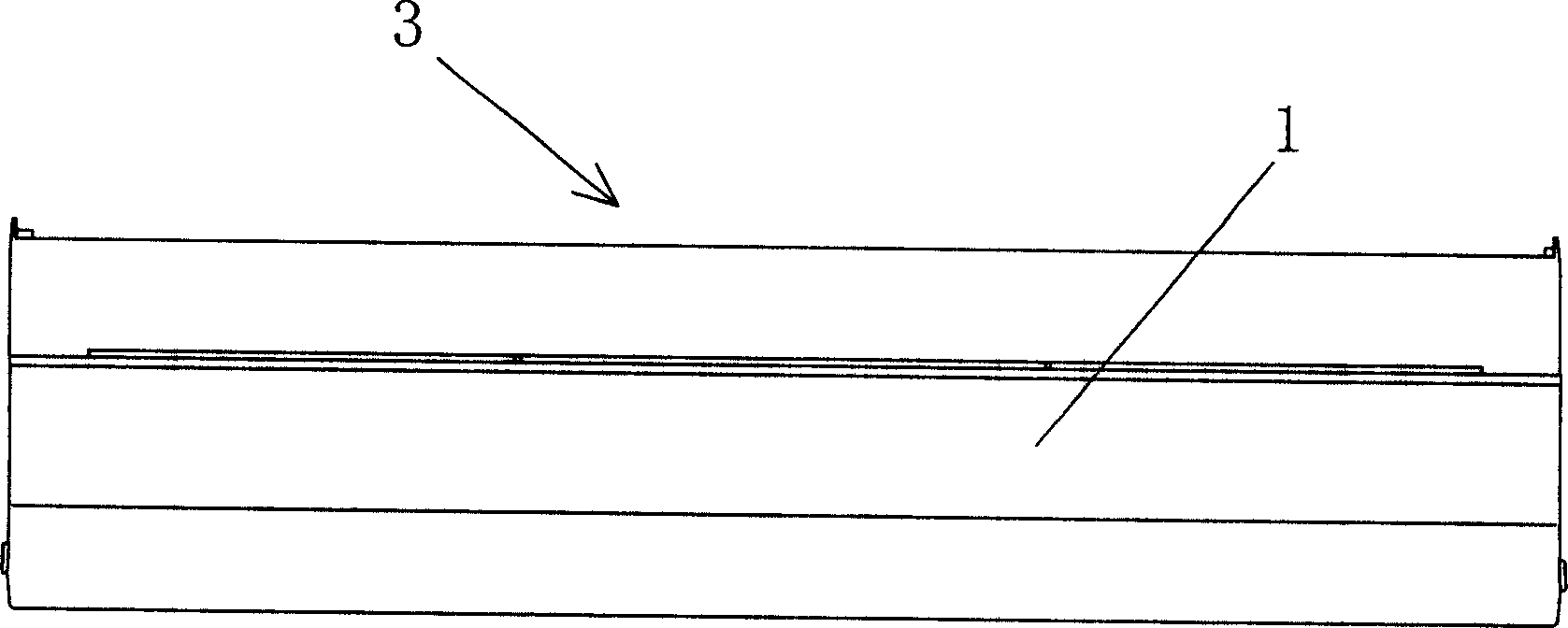

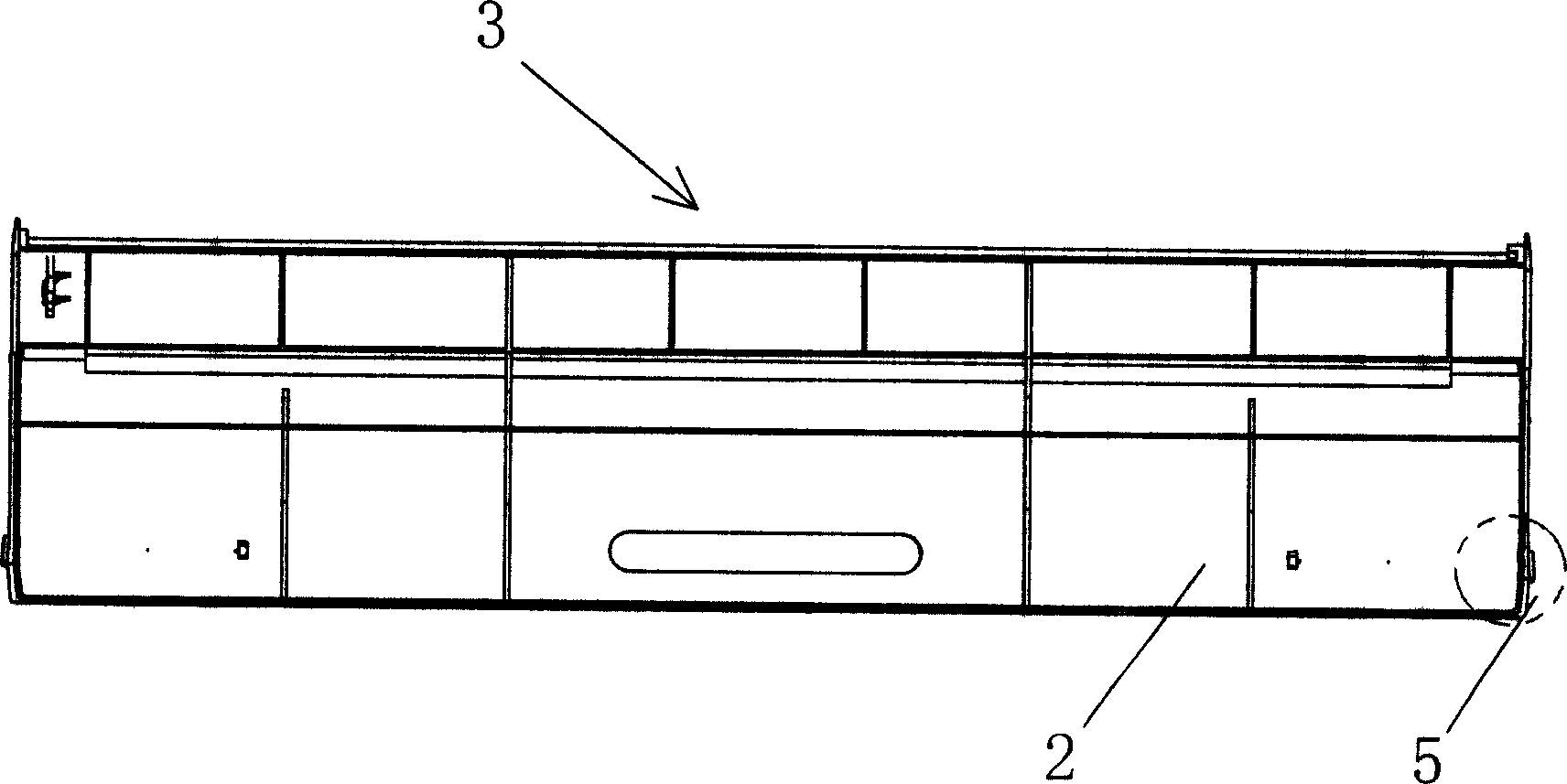

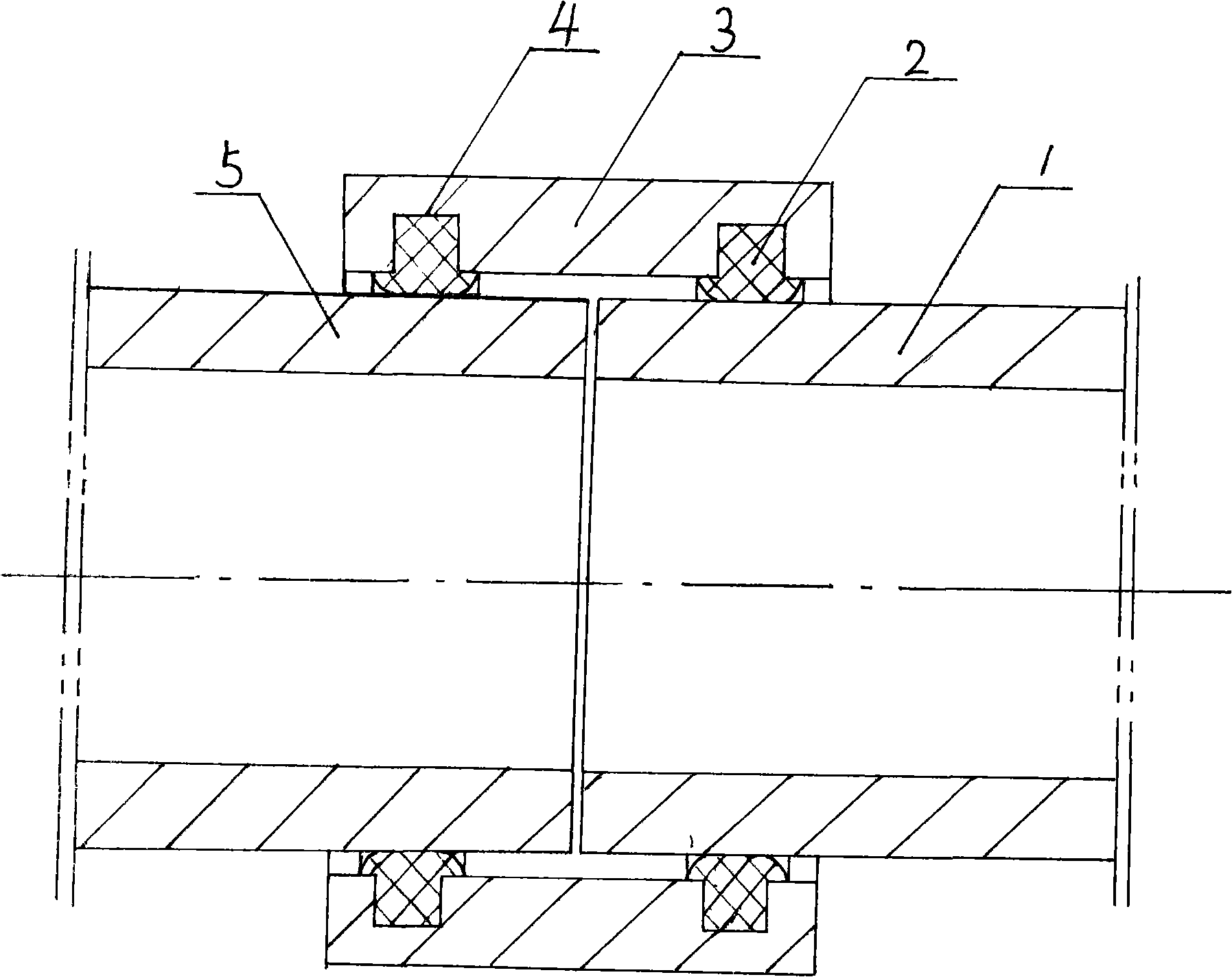

Filling box with bottom ventilation net and upper part exhaust holes

The invention relates to a filling box with a bottom ventilation net and upper part exhaust holes and a manufacturing method of the filling box, and belongs to the field of building construction. The filling box (1) comprises side frame plates (2), stiffening inner plates (3), a top cover plate (4) and the ventilation net (5), wherein the four side frame plates (2) in end-to-end connection define a rectangular plane; more than one stiffening inner plate is at least arranged in each direction; the stiffening inner plates in different directions are in mutual orthogonality; at least one exhaust hole (6) is formed in the top cover plate; an exhaust net (7) is arranged in each exhaust hole; the top cover plate, the stiffening inner plates and the side plate plates made of nonmetallic materials form a box-shaped structure (8) with an open bottom surface together; the ventilation net is fixed on the bottom of the box-shaped structure in various connecting modes; and the ventilation net and the exhaust nets are made of metal or plastic materials. The filling box provided by the invention has the advantages that the production, the transportation and the installation are very convenient; the mechanical property is good; and a hollow floor slab formed by the product has high reliability, good earthquake-resistant performance and good anti-crack performance.

Owner:北京东方京宁建材科技有限公司

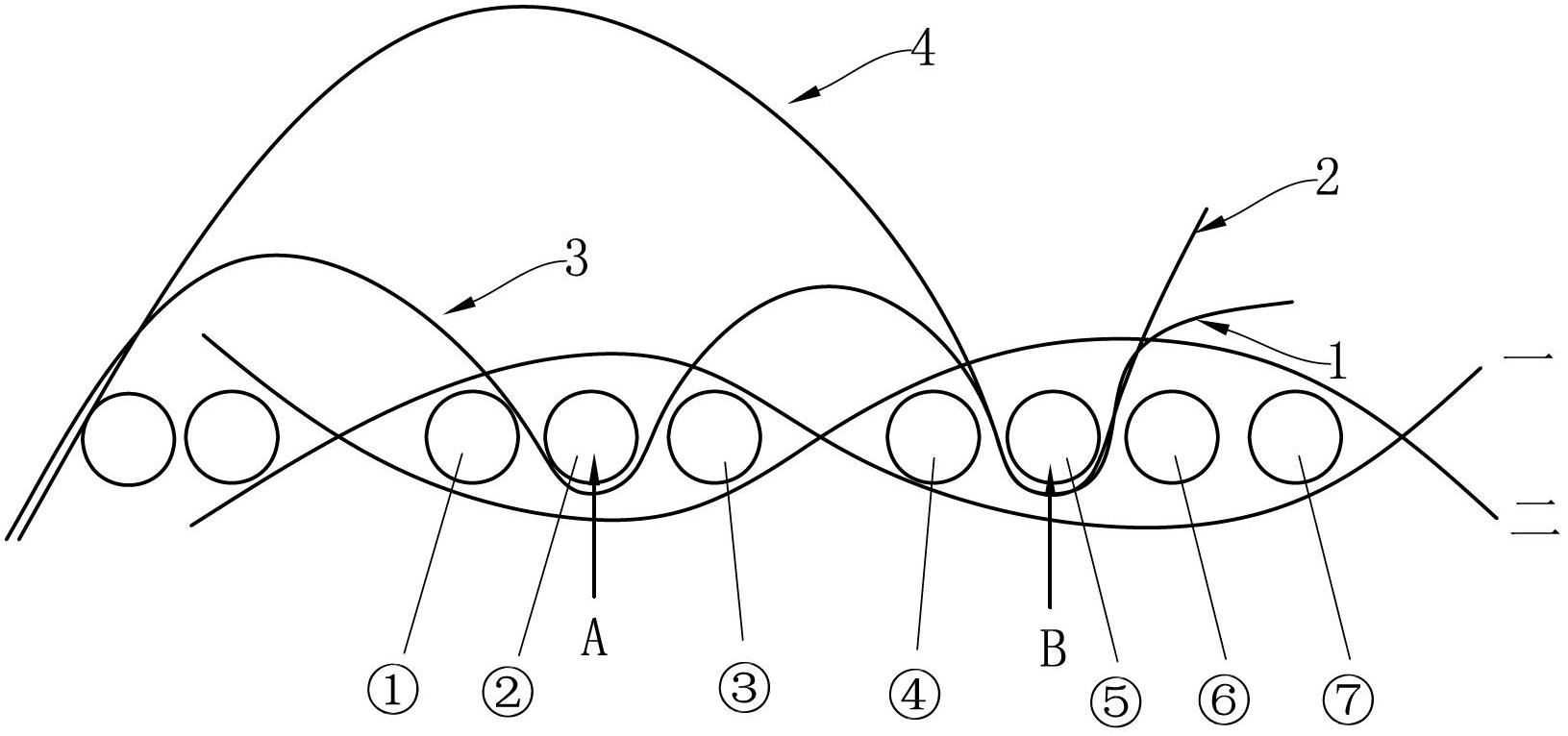

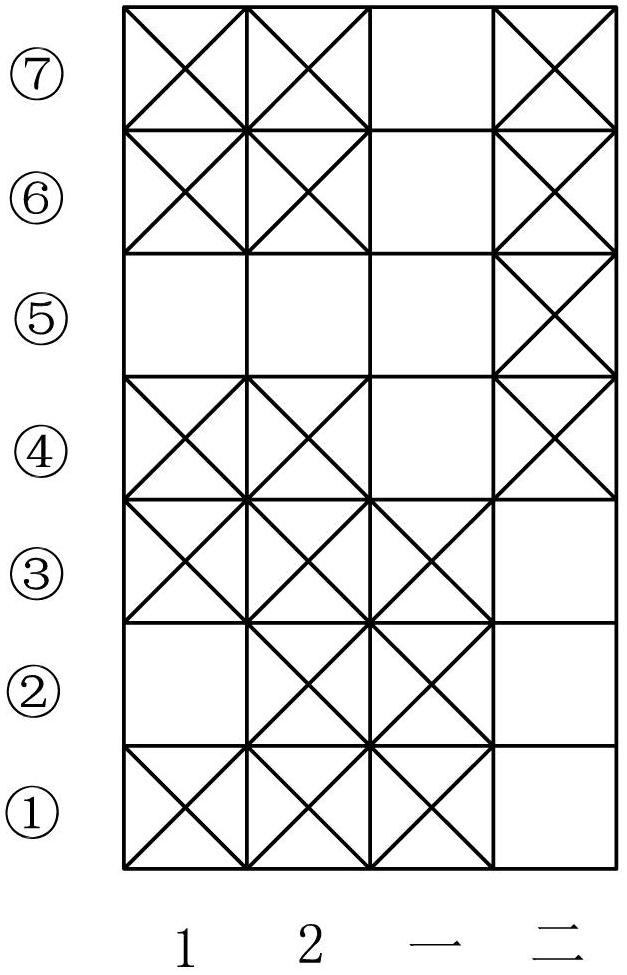

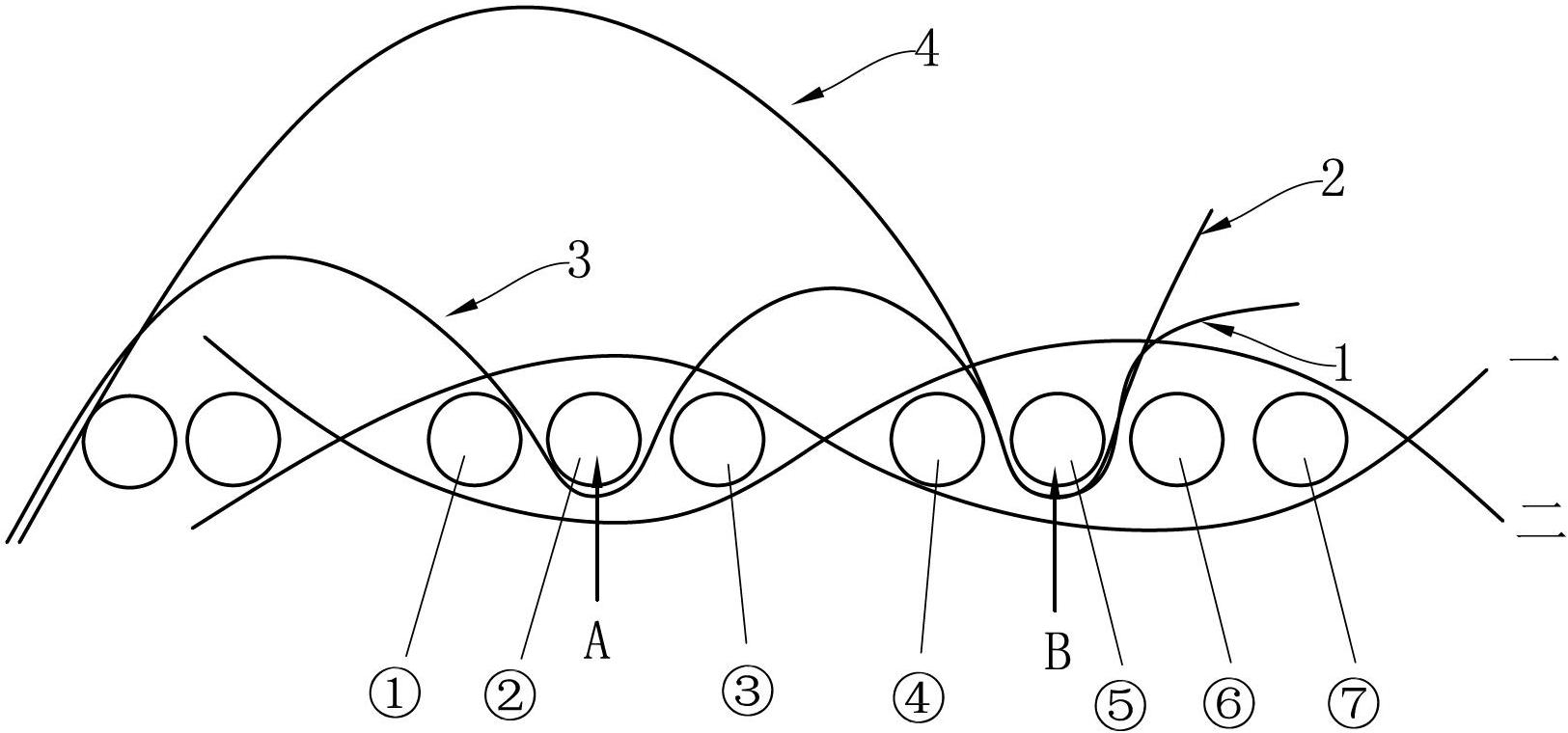

Pure cotton heavy bath mat weaving process

ActiveCN102691156AOvercome deformationOvercome elasticityBiochemical fibre treatmentBleaching apparatusYarnPulp and paper industry

The invention relates to a pure cotton heavy bath mat weaving process. Firstly fine staple cotton is spun into72.9tex of single yarns with the twist degree of 30-60 twists / 10cm, and then the single yarns are combined into four strands to make weak twist cone yarns with the twist degree of 15-25 twists / 10cm; then the weak twist cone yarns are warped and starched, and are woven into greige cloth by a variable-program beating-up loom with a specific fuzzing beating-up tissue; and the greige cloth is bleached through boiling, whitened, neutralized, softened, dried and sewed into a bath mat. According to the pure cotton heavy bath mat weaving process provided by the invention, pure cotton material is reasonably and effectively utilized in the field of bath mats, the defect that the bath mat made of the pure cotton material is deformed easily and has poor elasticity and poor durability, which can not be changed by technicists for a long time, are overcome, and the manufactured bath mat has the advantages of softness, comfort, good water absorbability, difficult generation of static electricity and the like of the pure cotton material, and can become a development trend of the bath mat weaving technology.

Owner:SUNVIM GROUP

Making process of mold composite material tray

The molded composite material tray of the present invention is produced with natural material, non-alkali glass fiber, plastic and other organic polymer. It is produced through molding, and during the production, plastic, wood dust, glass fiber and polymer additive are mixed homogeneously in material mixer and screw extruder, weighed, molded in mold and pressed with press. The tray has the advantages of light weight, high strength, high temperature resistance, high toughness, high corrosion resistance, etc. and may be used widely.

Owner:山东伟佳玻璃钢制品有限公司

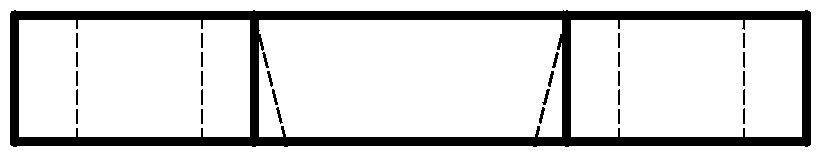

Automatic ground rail type steel wire rope winding machine without lifting device

InactiveCN104773606AThe overall structure is simpleReduce the incidence of complete machine failureFilament handlingWinding machineEngineering

Owner:UNIV OF JINAN

Pendulum-type concave-convex shear blade

Owner:MAANSHAN HENGLIDA MACHINE BLADE

Preparing method for aperture-controllable bacterial cellulose porous microspheres

The invention discloses aperture-controllable bacterial cellulose porous microspheres and a preparing method for the aperture-controllable bacterial cellulose porous microspheres. Bacterial cellulose is taken and dissolved in a solvent, a bacterial cellulose solution is obtained, template particles with different particle sizes are added in the bacterial cellulose solution, the mixture is put in an ultrasonic dispersing machine, the particles are evenly dispersed through ultrasonic treatment, and a dispersed solution is obtained; the dispersed solution and a surfactant are poured into an organic solvent for homogeneous emulsification, a w / o type bacterial cellulose emulsion is obtained, a precipitating agent is added in the bacterial cellulose emulsion and stirred, and microsphere suspension liquid is obtained; the microsphere suspension liquid is subjected to vacuum filtration, precipitate is collected and washed with n-butyl alcohol, acetone and acetone three times in sequence, the washed precipitate is then extracted with ethyl alcohol, precipitate is collected and subjected to frozen drying, and the aperture-controllable bacterial cellulose porous microspheres are obtained. The method has the advantages of being low in cost, simple in process, capable of facilitating industrialized production and the like, the stability and repeatability are good, the aperture of the bacterial cellulose porous microspheres ranges from 200 nanometers to 50 micrometers, and the bacterial cellulose porous microspheres are suitable for mass production.

Owner:陕西启悦医疗科技有限公司

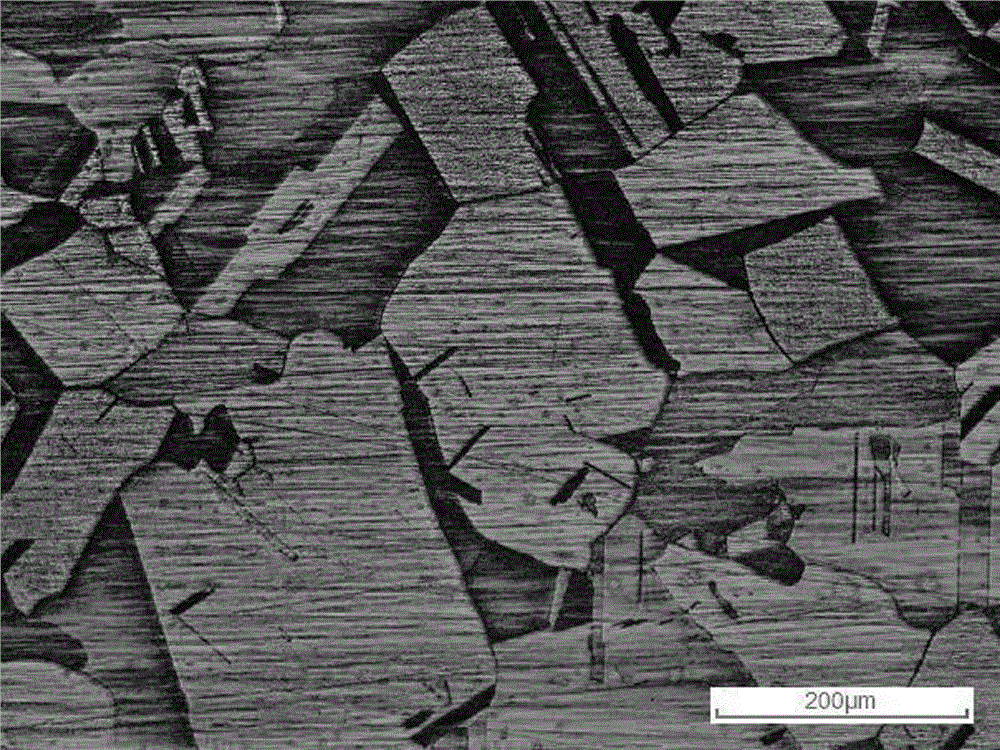

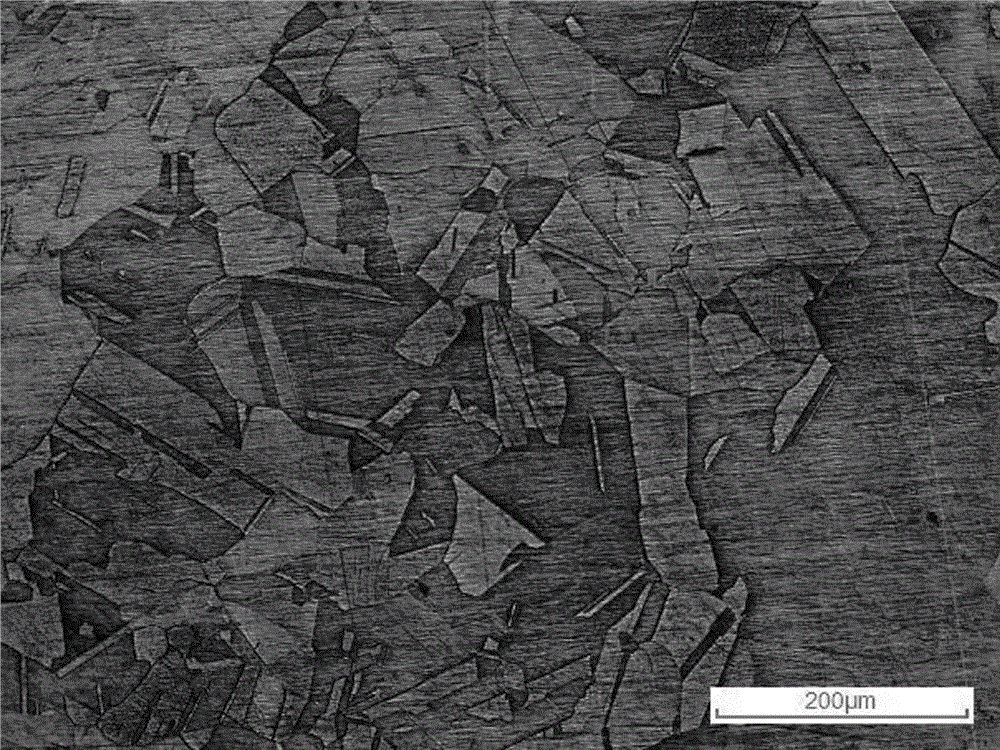

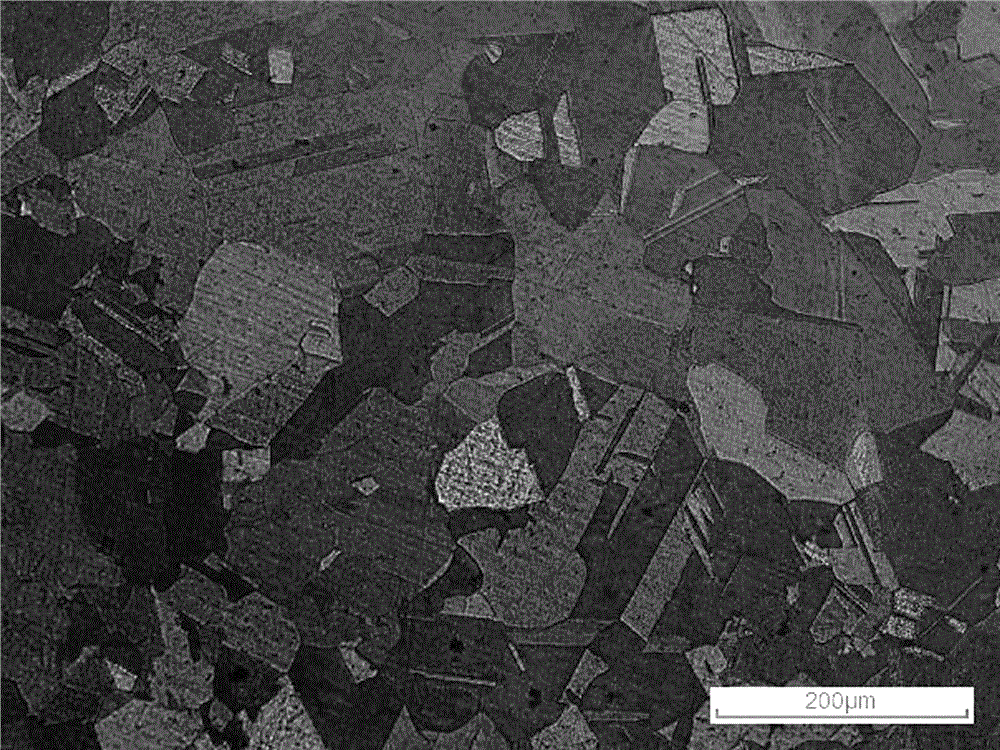

Preparation method of large-size high-pure copper flat target material

InactiveCN105887028AImprove compactnessAvoid too softVacuum evaporation coatingSputtering coatingDisplay deviceCopper

The invention belongs to the technical field of sputtering target materials and particularly relates to a preparation method of a large-size high-pure copper flat target material. The preparation method includes the steps that upsetting and drawing out are performed on a copper blank, the copper blank is forged into a cuboid copper forged blank, and annealing treatment is performed for the first time; and then hot rolling is performed, annealing treatment is performed for the second time, and the copper target material is obtained. The prepared copper target material is large in size, an internal structure is uniform and free of defects, the grain size is smaller than 100 microns, performance is excellent, and the copper target material can be widely applied to the field of flat panel displays.

Owner:LUOYANG SIFON ELECTRONICS

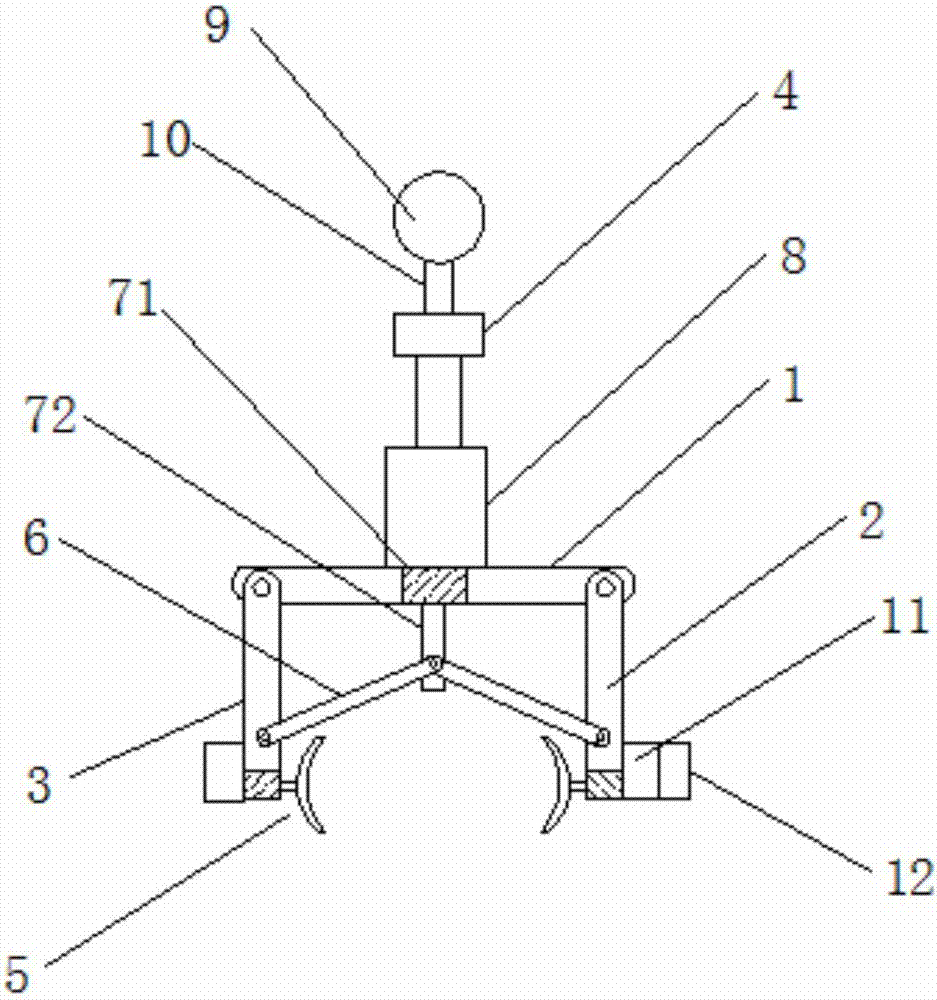

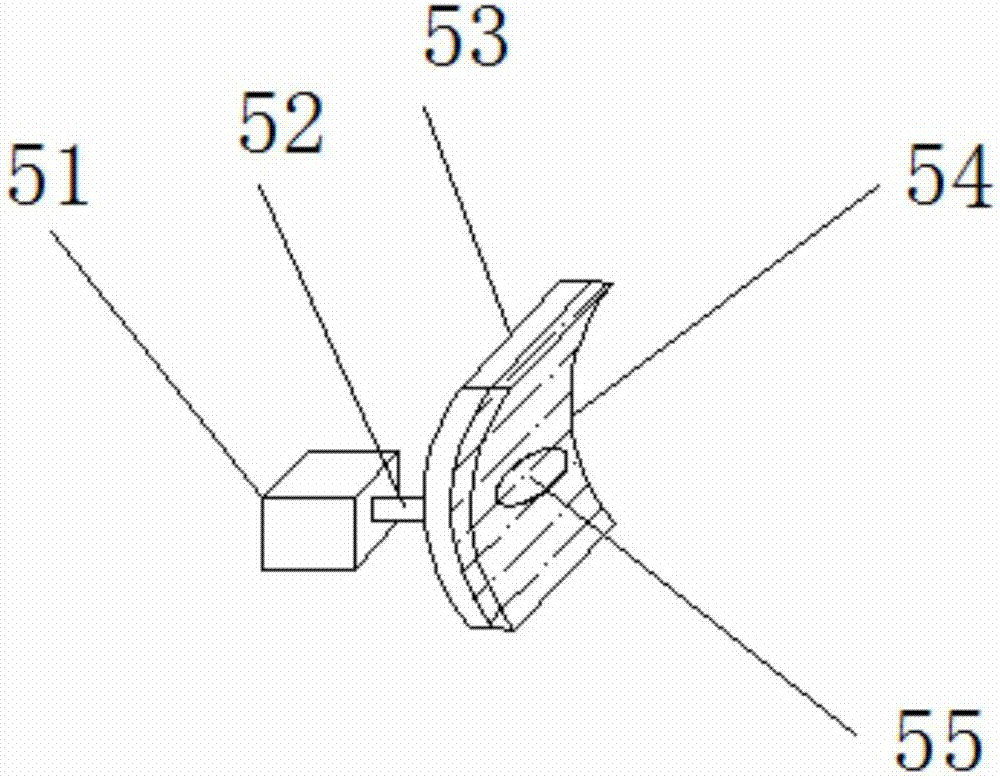

Manipulator

InactiveCN107214689AAvoid deformationOvercome deformationProgramme-controlled manipulatorGripping headsManipulatorPiston rod

The invention discloses a manipulator which comprises a supporting seat, fixing columns, rotating air cylinders, multistage air cylinders and grasping mechanisms. The multiple fixing columns are arranged on the lower surface of the supporting seat, and the rotating air cylinders, the multistage air cylinders and the grasping mechanisms are sequentially connected at the bottom ends of the fixing columns from top to bottom in the vertical direction correspondingly; rotating shafts on the rotating air cylinders can drive the multistage air cylinders to rotate in the length directions of the rotating shafts; and the multistage air cylinders can drive the grasping mechanisms to rise and fall in the vertical direction. According to the manipulator, the problems that in the prior art, when a manipulator is used, a grasping mechanism on the manipulator cannot rotate, or steering is not flexible, an air cylinder used for lifting the grasping mechanism bears the limited weight, and a piston rod on the air cylinder is prone to deforming are solved.

Owner:ANHUI YUEERWEI PLASTIC MACHINE CO LTD

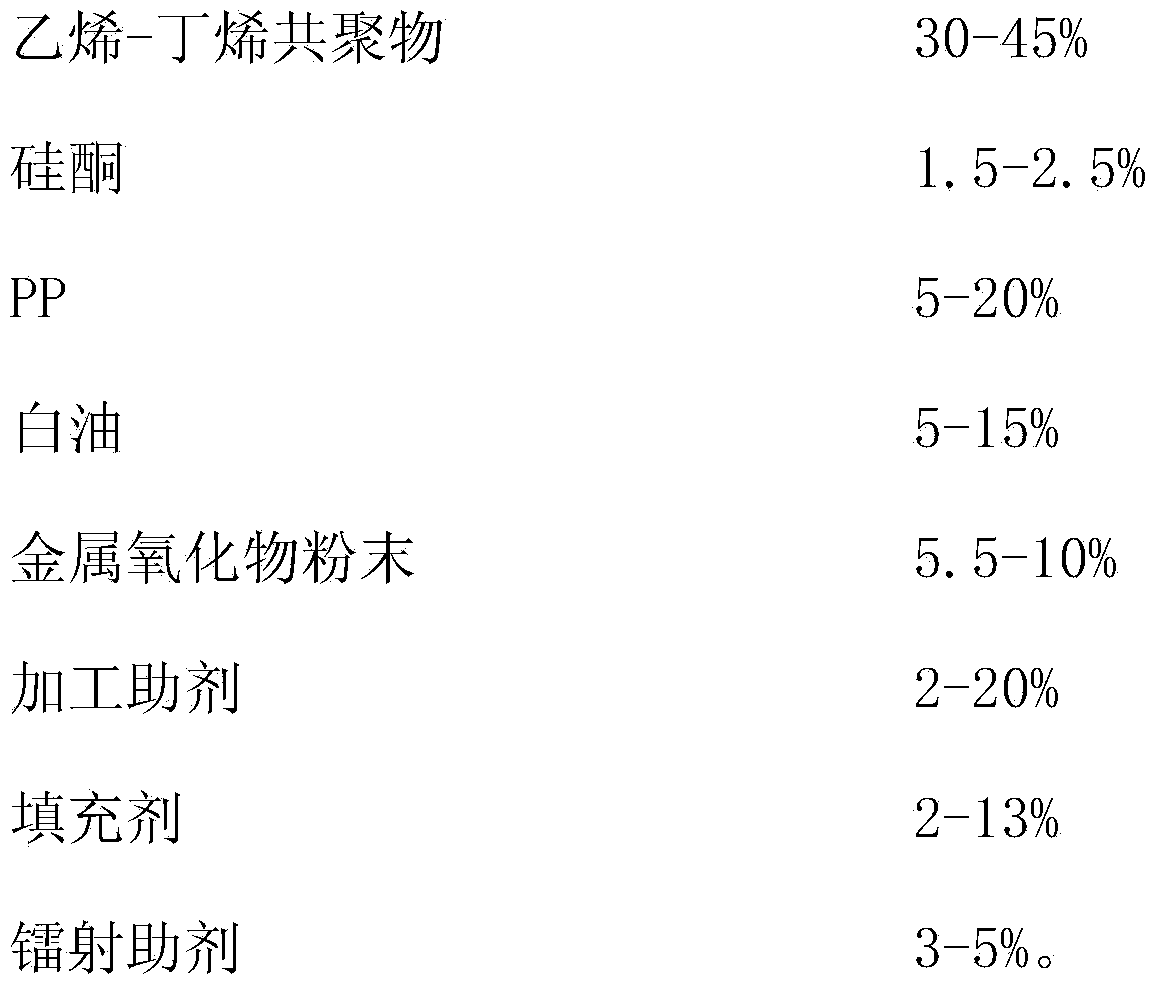

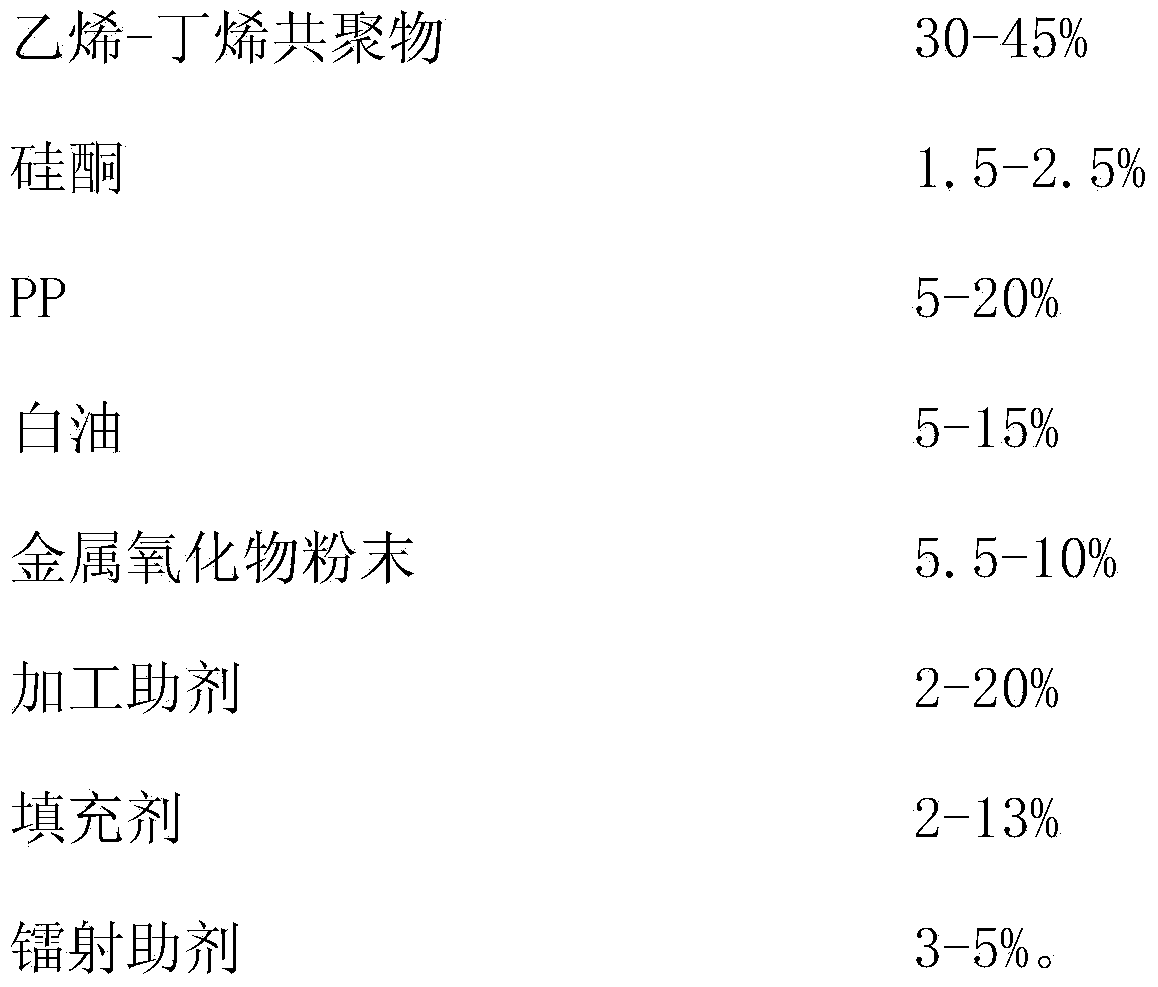

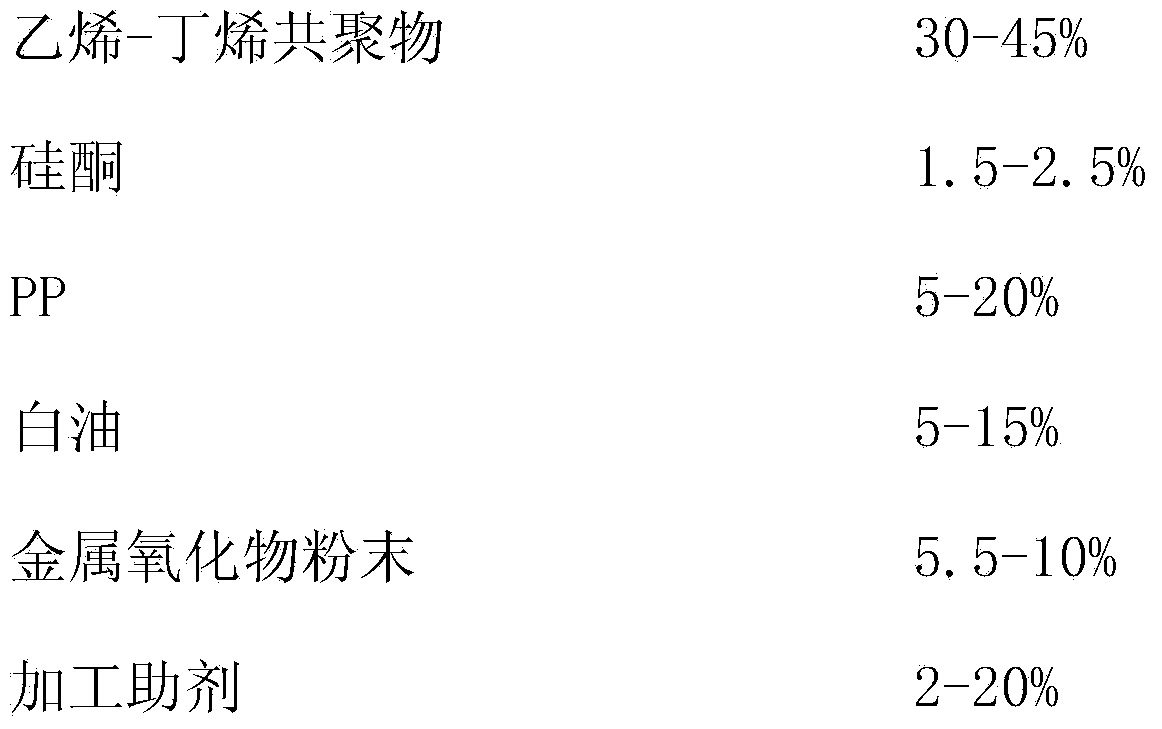

Laser engraving material for plastic products and preparation method thereof

ActiveCN104004311AOvercome deformationOvercome shortcomings such as unclear edgesButeneProcedure Agents

The invention discloses a laser engraving material for plastic products, and the laser engraving material is prepared by the following components in percent by mass: 30-45% of ethylene-butene copolymer (SEBS), 1.5-2.5% of silicone, 5.20% of PP (Propene Polymer), 5-15% of white oil, 5.5-10% of metal oxide powder, 2-20% of processing aid, 2-13% of filler and 3-5% of laser additive. The invention also discloses a preparation method of the laser engraving material for plastic products, and the method comprises the steps of burdening, stirring, extrusion, cooling, granulation and the like. According to the laser engraving material for plastic products, the problem that the common plastic materials cannot undergo laser engraving and are easy to be fired and fused is overcome, the display of special colors during the laser is realized so that the engraved images and texts directly display colors without coloring process after the engraving, and the process is reasonable; and the laser engraving material for plastic products is particularly suitable for the high-end products such as earphone wires and the like.

Owner:DONGGUAN YINGTONG WIRE +1

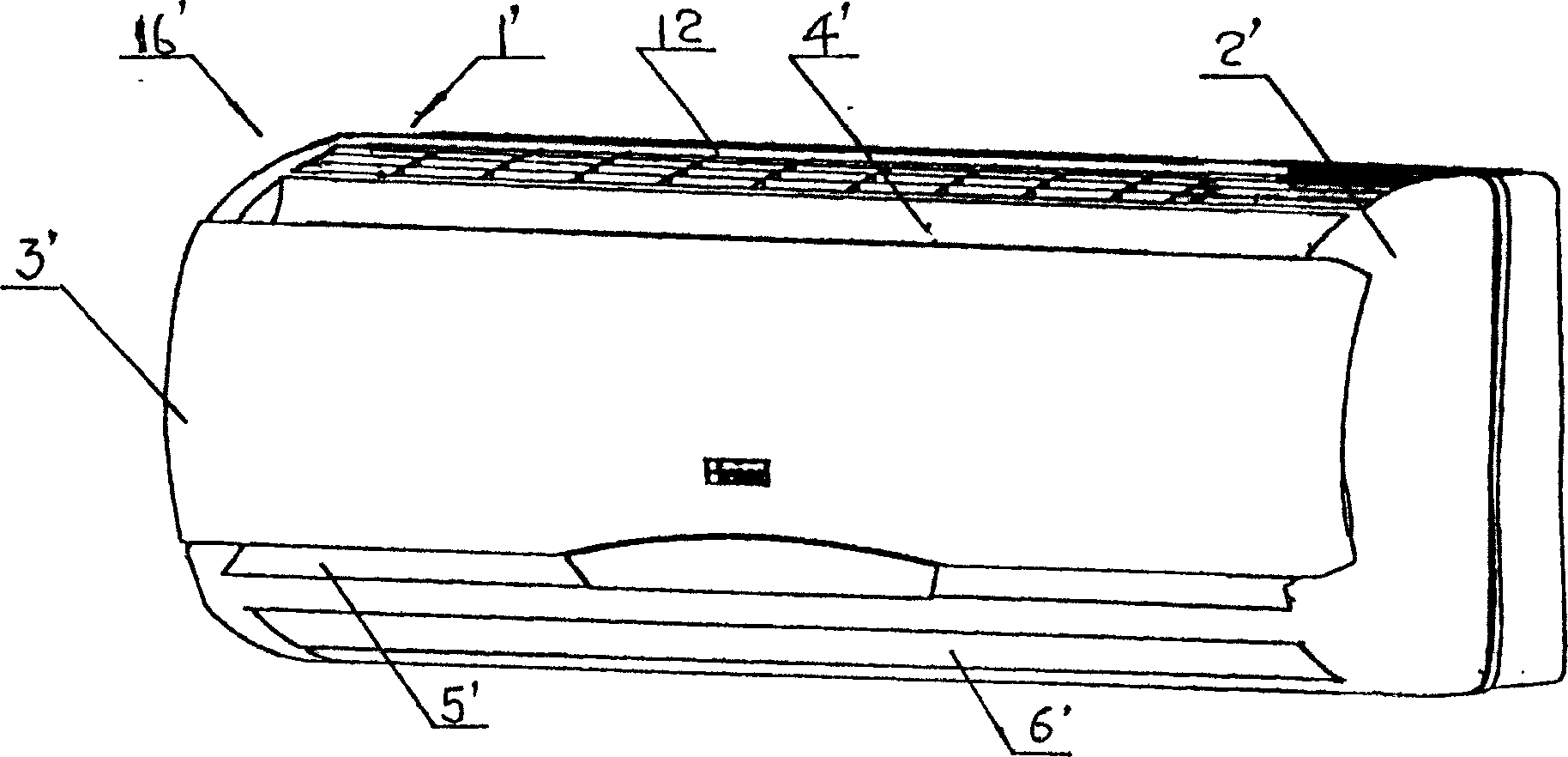

Front plate decorative board structure of indoor unit of air conditioner

ActiveCN1854619ABeautiful appearanceOvercome deformationHeating and ventilation casings/coversEngineeringSurface plate

A front-panel decorative board of the room unit of air conditioners is made up of at least two layers. One layer is the cover plate made up of plastic units PVC and the other layer is a protection face-plate made of organic glass fixed on the outside surface of the cover plate.

Owner:HAIER GRP CORP +1

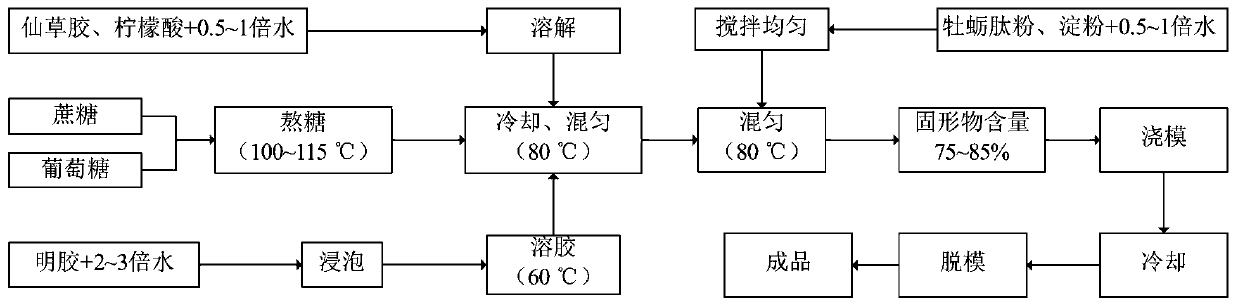

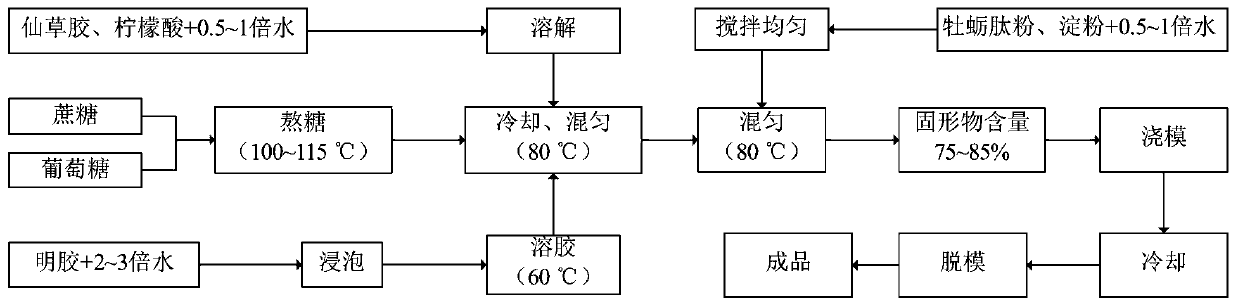

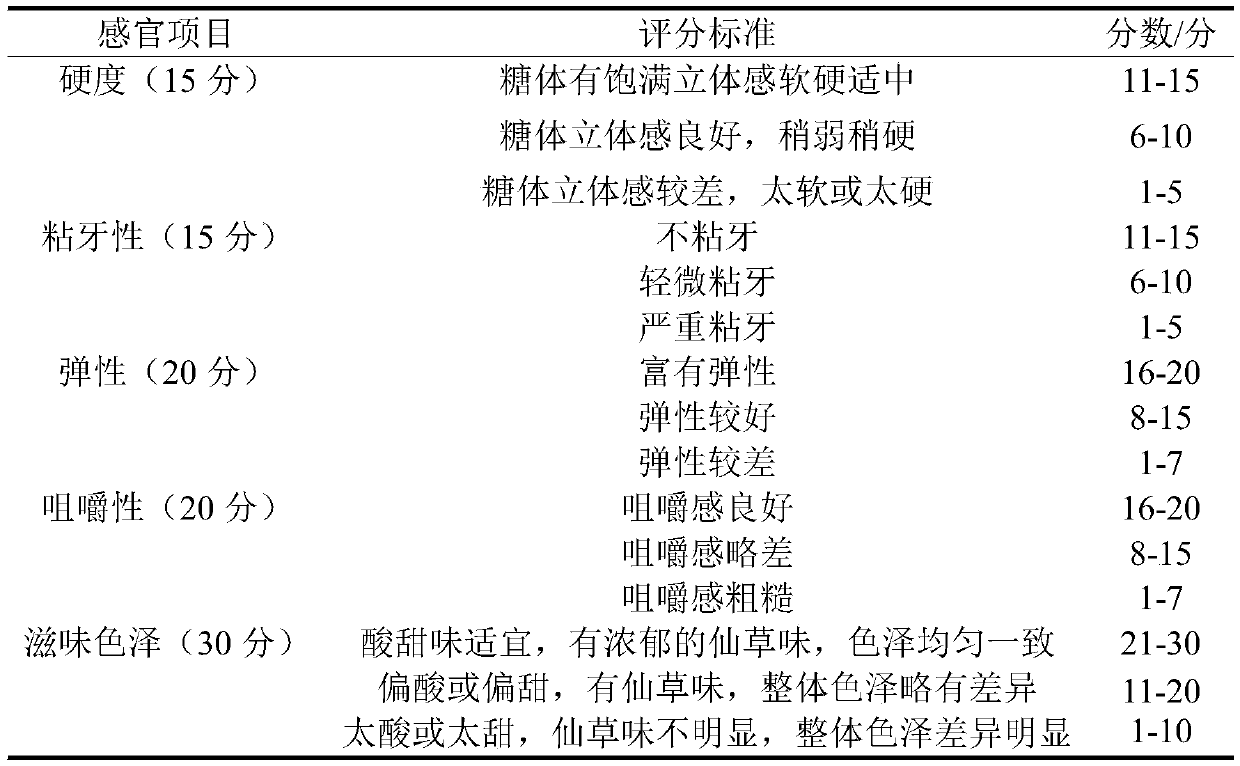

Mesona chinensis extract soft candy containing oyster peptides and preparation method thereof

InactiveCN110012958AHigh deformation resistanceImprove nutrition and health benefitsConfectionerySweetmeatsNutrientPeptide

The present invention provides a mesona chinensis extract soft candy containing oyster peptides and a preparation method thereof. The soft candy is prepared from a mesona chinensis extract and oysterpeptide powder. The soft candy is prepared from the following raw material components in mass percentages: 0.2%-4% of a mesona chinensis extract, 0.05%-0.2% of oyster peptide powder, 5-13% of gelatin,1-4% of starch, 35-55% of sugar and 0.2-2% of citric acid. Aiming at texture, anti-deformation rate, mouthfeel, taste, color, luster and nutrition of the mesona chinensis extract soft candy, the useratios of the mesona chinensis extract, oyster peptide powder, sugar, starch and citric acid are comprehensively optimized. The prepared mesona chinensis extract soft candy is rich in nutrients, is smooth on surface, brownish yellow, non-sticky to teeth, elastic, high in deformation resistance, sweet, sour and tasty and has a flavor characteristic of mesona chinensis.

Owner:BEIBU GULF UNIV

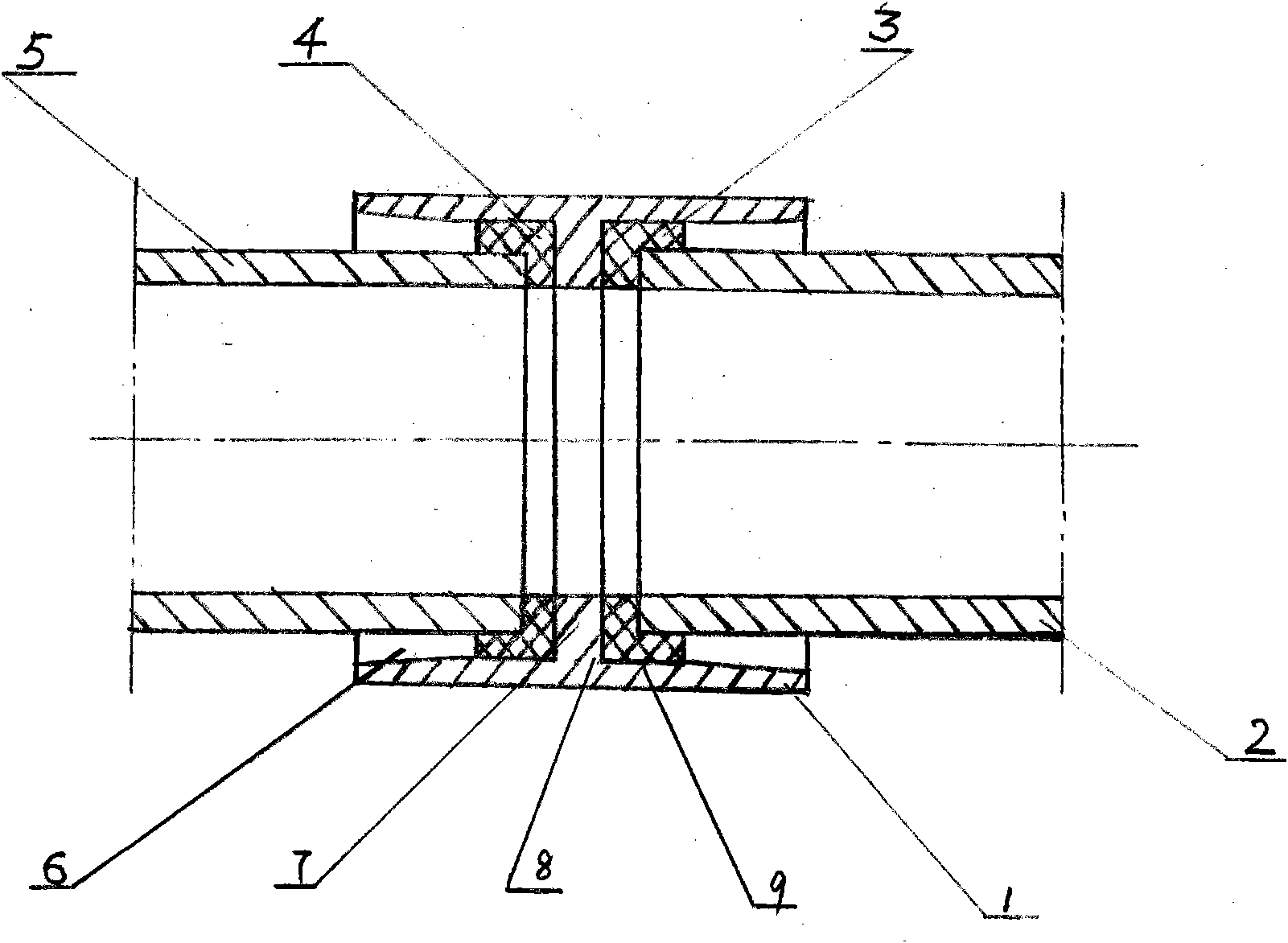

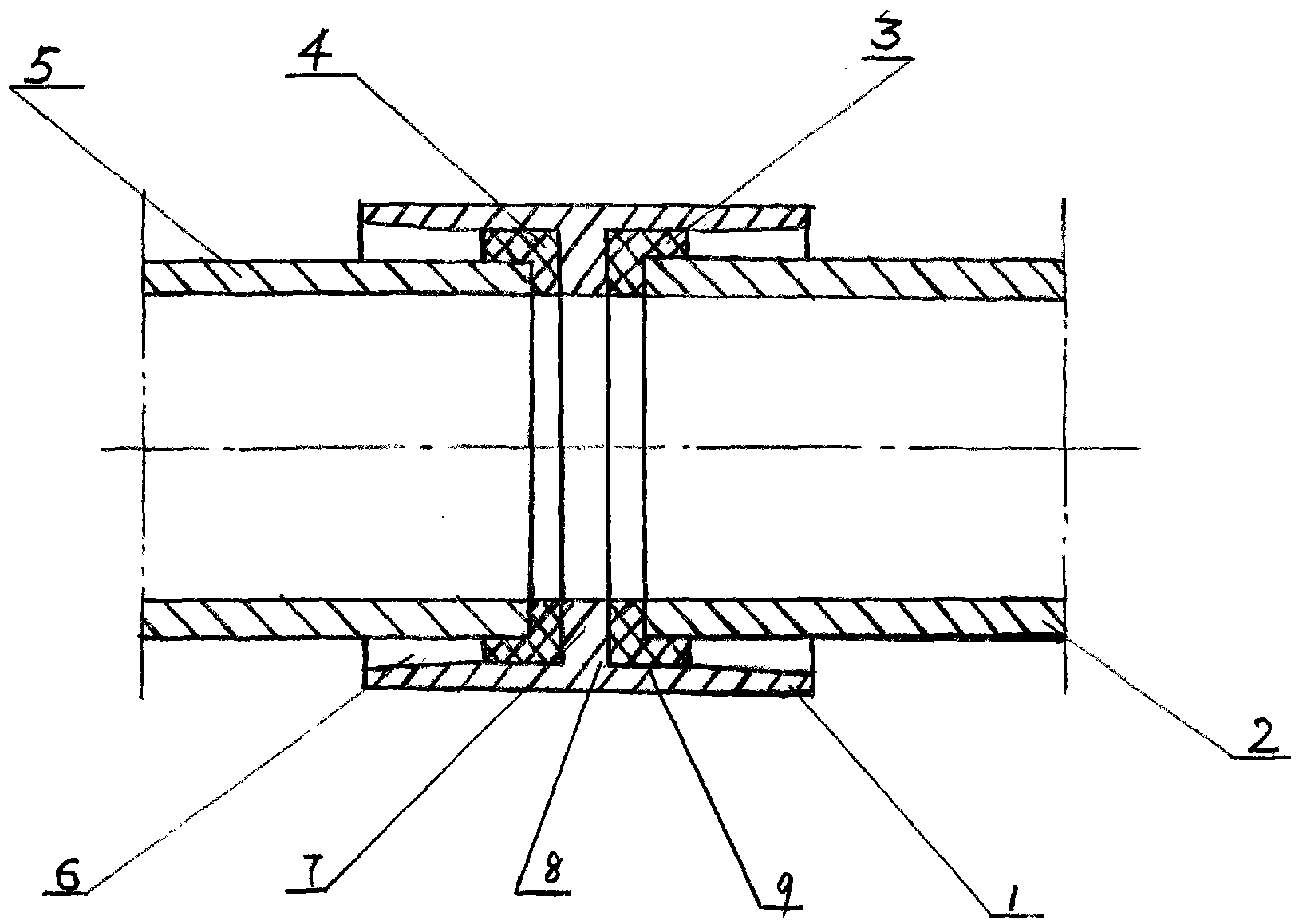

Butting pipe sleeve of plastic socket pipes and connection of plastic socket pipes

InactiveCN102384328AOvercome deformationOvercome cracking defectsPipe connection arrangementsEngineeringUltimate tensile strength

The invention discloses a butting pipe sleeve of plastic socket pipes and a connection of the plastic socket pipes. The butting pipe sleeve comprises a structure in which sealing washers and the plastic socket pipes are arranged and is characterized in that a circular ring conjoined with a butting pipe sleeve outer wall is arranged in the middle of an inner cavity of the circular butting pipe sleeve outer wall; and holes at the two ends of the butting pipe sleeve are respectively horn mouths. In the connection of the plastic socket pipes, the ends of the two plastic socket pipes are respectively sleeved into the basin-shaped sealing washers; and when the plastic socket pipes sleeved into the sealing washers pass through the horn mouths, the sealing washers are compressed by the horn mouths and enter a straight pipe section of the butting pipe sleeve, so that the bottom surfaces of the sealing washers are respectively pressed against with the two side surfaces of the circular ring. When the two plastic socket pipes are connected with each other, the defects that the connecting strength of an electric hot-melting belt is not uniform, and the pipes are easy to deform and crack are overcome. The plastic socket pipes are suitable for construction in the various environments, are particularly suitable for operation in the water environment, are convenient to connect, have lower cost and reduce the labor intensity of operators.

Owner:SHANGHAI JIUTONG PLASTIC PROD

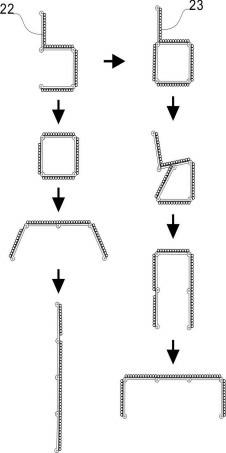

Multifunctional folding bamboo furniture

InactiveCN102113784AOvercome deformationOvercoming the problem of easy looseningScreensFoldable tablesEngineeringFolded structure

The invention discloses multifunctional folding bamboo furniture, which is characterized by being a rigid structure that adopts an easily-processed rigid material as a folding structure supporting framework and taking raw bamboos as panel materials. The folding bamboo furniture is simple in technology and compact in appearance, can be produced in batches and in an industrialization way, can be folded and deformed as well as be arranged and combined to be used as a thing to sit on, a bedding, a table, a screen and frame type furniture, and can be straightened or folded to stack so as to save containing space.

Owner:罗轶

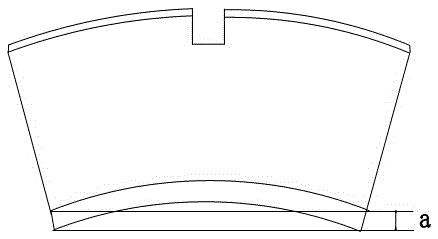

Combustion chamber of paver

The invention provides a combustion chamber of a paver, which comprises a screed box having a bottom screed, a combustion chamber, a linear heater having a linear heating pipe and a heat-insulating plate which is arranged in the combustion chamber and positioned between the linear heating pipe and the bottom screed. The combustion chamber is capable of solving the problem that the quality of road paving is lowered due to the deformation of the bottom screed caused by the local overheat of the bottom screed.

Owner:ZOOMLION HEAVY IND CO LTD

Clamping device capable of being used for conveniently clamping tire mold slide block

InactiveCN105598725APrecise positioningClamping is firmPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention provides a clamping device capable of being used for conveniently clamping a tire mold slide block. The clamping device comprises a support block capable of being used for carrying the tire mold slide block, wherein the top surface of the support block is an inclined surface; when the tire mold slide block is put on the inclined surface of the support block, the top surface of the tire mold slide block is a horizontal surface; the front side of the support block is provided with a positioning block; the tire mold slide block is abutted against the positioning block; the back side of the support block is provided with a tail clamping unit; the tire mold slide block can be clamped in the forward and backward direction when the tail clamping unit is moved; stop blocks capable of doing reciprocating moving in the left and right directions are arranged at the left and right opposite sides of the support block; the stop blocks arranged on the two opposite sides are connected through a lead screw; when the lead screw rotates, the stop blocks simultaneously approach to the center of the tire mold slide block in the left and right directions or simultaneously and outwards move, so that the slide block center is kept unchanged; the automatic centering is realized. The clamping device can realize the multi-directional positioning, and can be changed according to the tire mold slide blocks in different dimensions, and the universality is realized.

Owner:QINGDAO AGRI UNIV

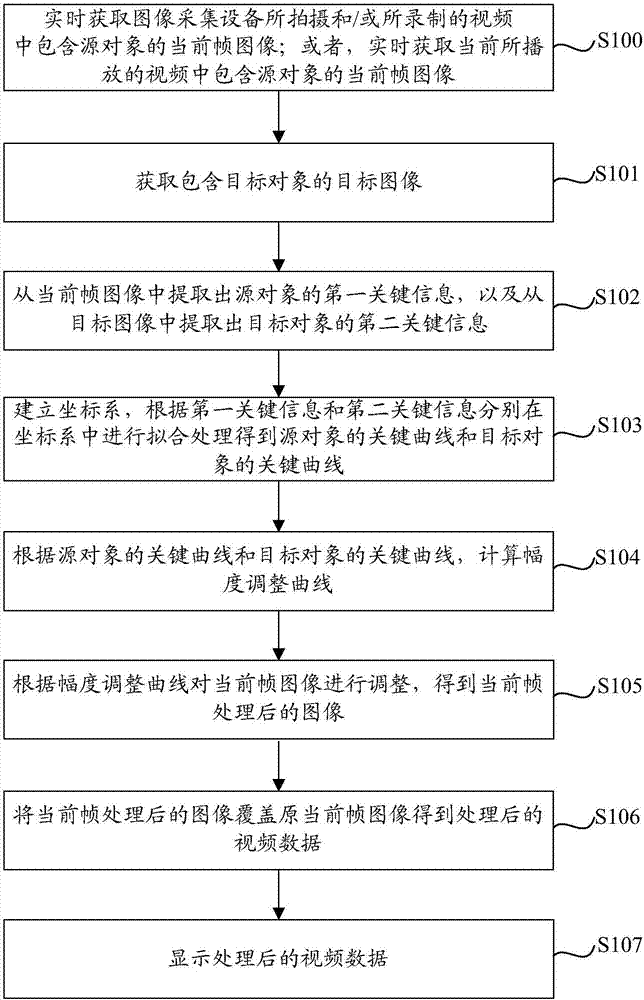

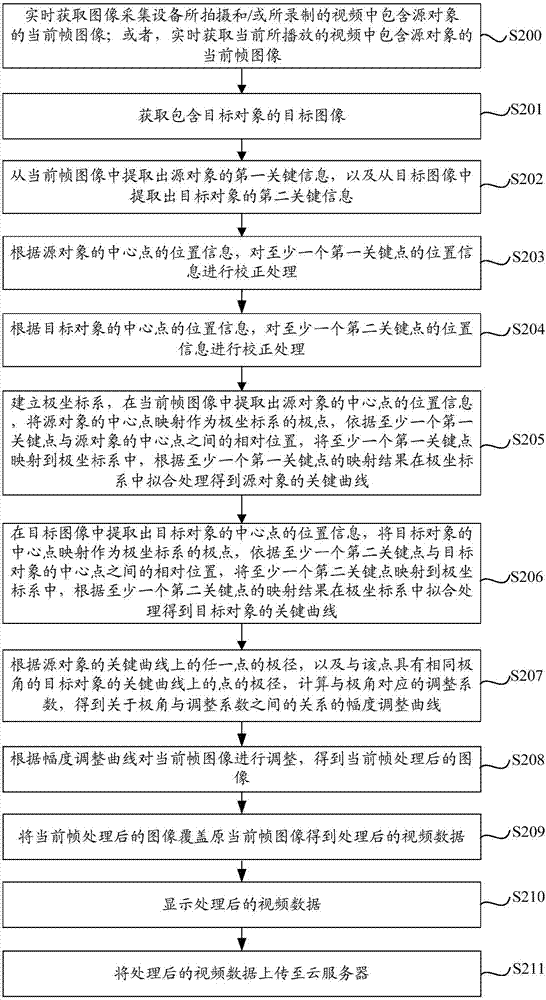

Real-time processing method and device of video object transformation and calculation device

ActiveCN107492068AFine effectBeautify display effectImage enhancementTelevision system detailsDisplay processingTime processing

The invention discloses a real-time processing method and device of video object transformation and a calculation device. The method comprises steps of acquiring the current frame image including a source object from a video; acquiring a target image including a target object; extracting first key information of the source object from the current frame image, and extracting second key information of the target object from the target image; establishing a coordinate system, and carrying out fitting in the coordinate system according to the first key information and the second key information so as to obtain a key curve of the source object and a key curve of the target object; calculating an amplitude adjusting curve according to the key curve of the source object and the key curve of the target object; adjusting the current frame image according to the amplitude adjusting curve so as to obtain an object after the current frame processing; covering the current frame image by use of the image after the current frame processing so as to obtain processed video data; and displaying the processed video data. According to the invention, the image after the current frame processing after the transformation is quite natural; the object transformation processing effects are quite precise; and the video displaying effects are quite good.

Owner:BEIJING QIHOO TECH CO LTD

Connecting device of drain pipe

InactiveCN101539227AOvercoming uneven connection strengthOvercome deformationSleeve/socket jointsCast ironElectric heating

The invention discloses a connecting device of a drain pipe, which comprises structures of wrapped drain pipes and sealing rings. Two ends of a straight connecting pipe are provided with annular grooves which can be embedded in the sealing ring; the cross-sectional shape of each annular groove can be a structure of square, trapezoid and semicircle; the connecting pipe can be a wrapped pipe, a straight wall pipe or a cast-iron pipe; and two ends of the connecting pipe are provided with 2 to 8 annular grooves which can be embedded in rubber sealing rings. The technology has the advantages of overcoming the defects of easy deformation and cracking of the pipe caused by uneven bonding strength of an electric-heating fusion band, is suitable for construction in various environments, particularly suitable for operations in water environment, has convenient connection and lower relative cost, and reduces the labor intensity of the operations.

Owner:SHANGHAI JIUTONG PLASTIC PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com