Laser engraving material for plastic products and preparation method thereof

A laser engraving and product technology, applied in the field of earphone products, can solve the problem of inability to carry out laser laser engraving, and achieve the effect of saving process, convenient processing and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

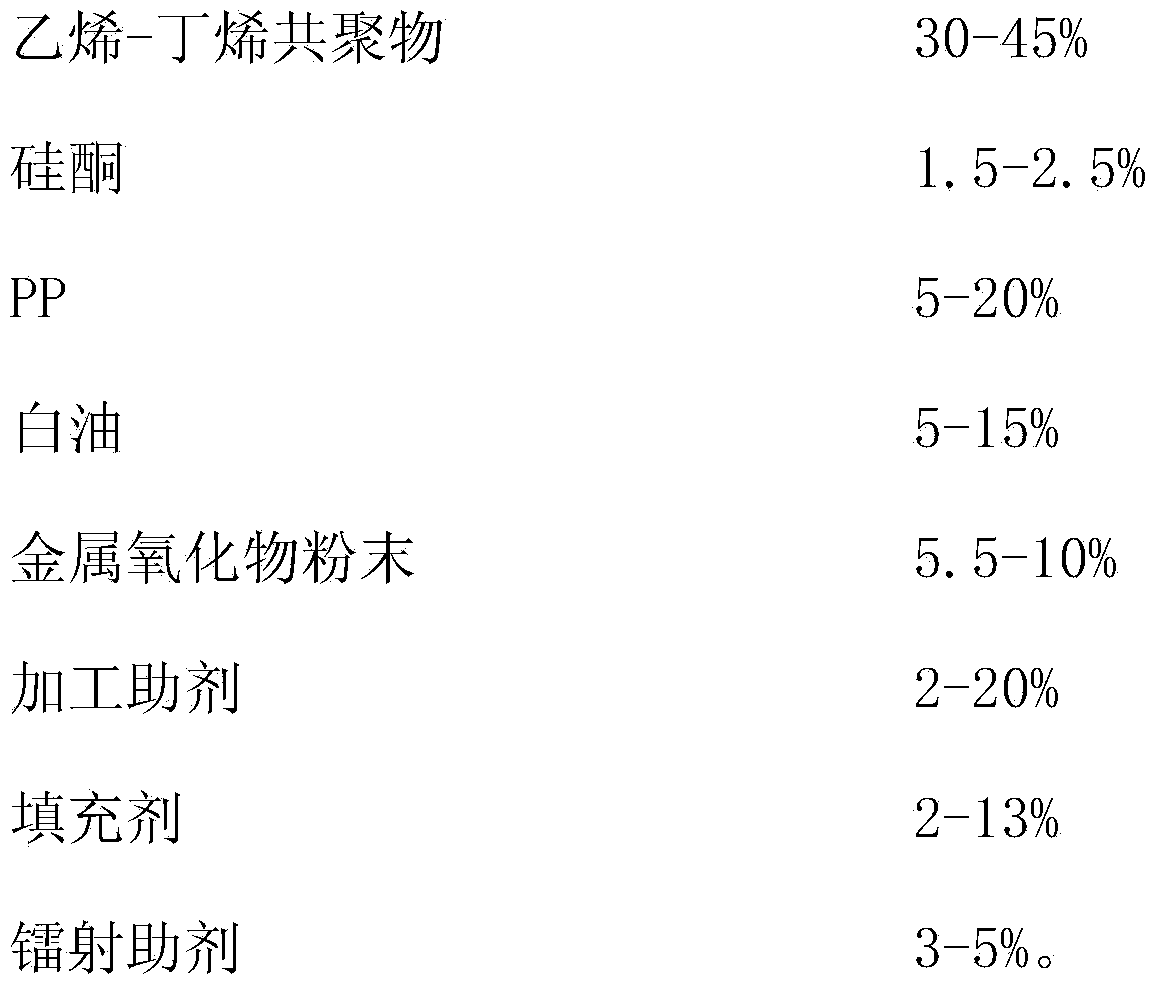

[0029] Embodiment 1: The laser engraving material for plastic products provided by the present invention is processed by the raw materials of the following mass percentages:

[0030]

[0031] Wherein, the metal oxides are white magnesium oxide (MgO), calcium oxide (CaO), aluminum oxide (Al2O3), black copper oxide (CuO), manganese dioxide (MnO2), ferric oxide (Fe3O4 ), red iron oxide (Fe2O3), mercury oxide (HgO), cuprous oxide (Cu2O) any one or more; the metal oxide powder is nano-scale, and its particle size is 5-10 Nano.

[0032] The laser auxiliary agent is Merck 825 laser laser engraving powder.

[0033] The filler is calcium carbonate; the processing aid is pentaerythritol ester.

[0034] A preparation method of the above-mentioned laser engraving material for plastic products, which specifically includes the following steps:

[0035] (1) Weigh raw materials according to the set ratio:

[0036]

[0037] (2) Add accurately weighed ethylene-butene copolymer (SEBS),...

Embodiment 2

[0044] The laser engraving material for plastic products provided in this embodiment and the preparation method thereof are basically the same as in Embodiment 1, except that:

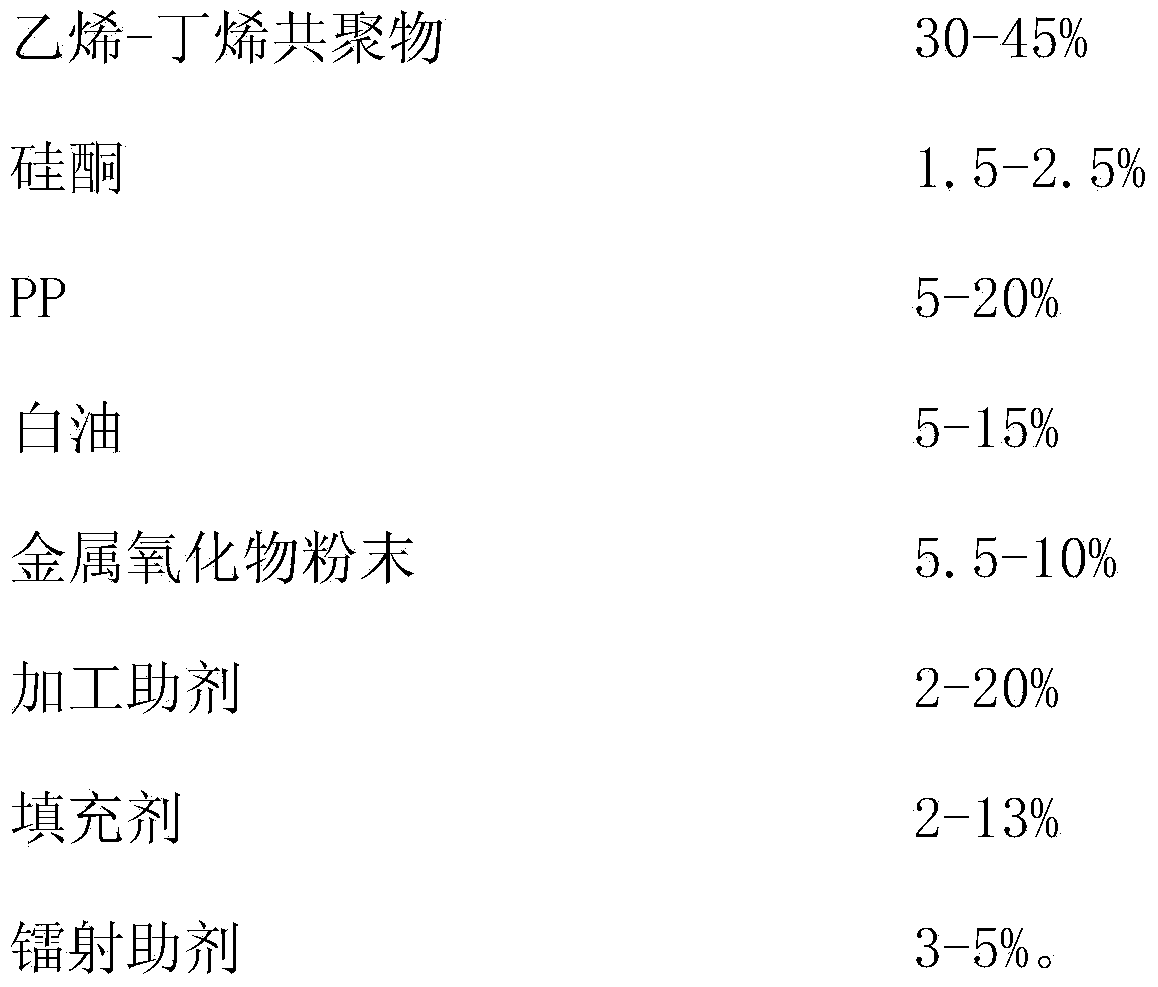

[0045] A laser engraving material for plastic products, which is made of raw materials with the following mass percentages:

[0046]

[0047] The metal oxides are nano-scale white magnesium oxide (MgO) and red iron oxide (Fe2O3).

[0048] The laser auxiliary agent is Merck 825 laser laser engraving powder.

[0049] Described filler is calcium carbonate; Described processing aid is pentaerythritol ester.

[0050] A kind of preparation method of laser engraving material for above-mentioned plastic products, its specific steps are as follows:

[0051] (1) Weigh raw materials according to the set ratio:

[0052]

[0053] (2) Add accurately weighed ethylene-butene copolymer (SEBS), silicone, PP, white oil, metal oxide powder, processing aids, fillers, and laser additives into the reaction kettle at...

Embodiment 3

[0058] The laser engraving material for plastic products provided in this embodiment and its preparation method provided in this embodiment are basically the same as those in Embodiments 1 and 2, except that:

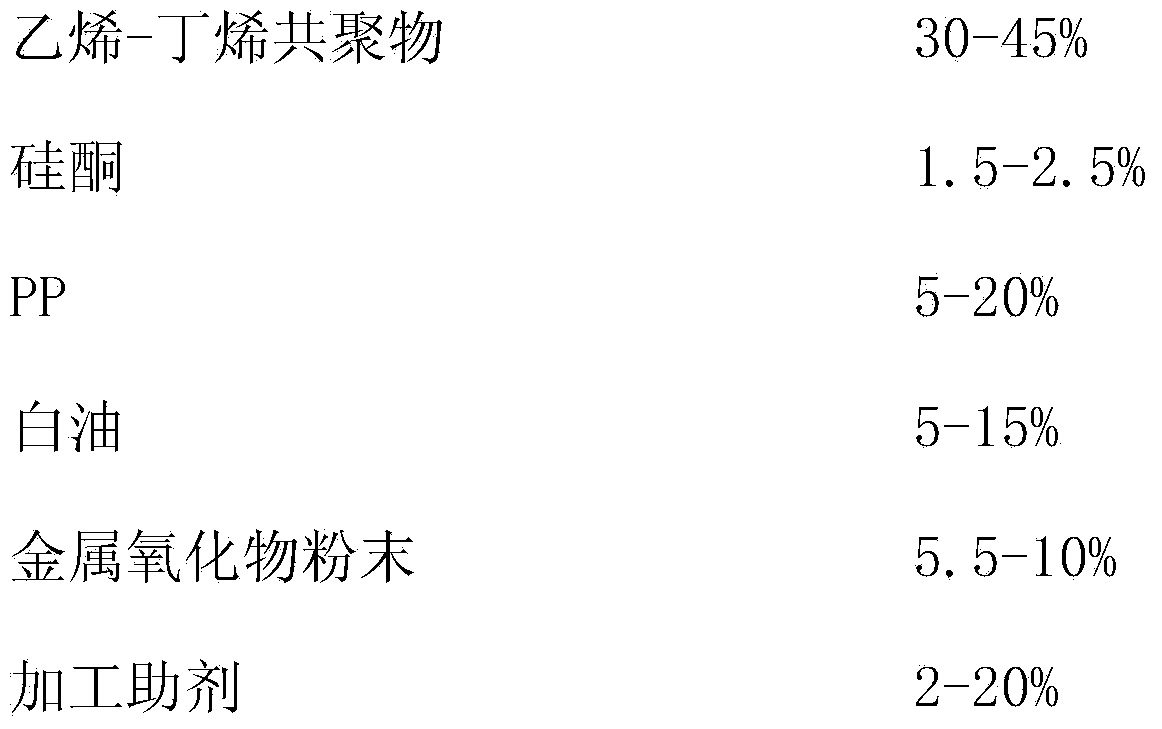

[0059] A laser engraving material for plastic products, which is made of raw materials with the following mass percentages:

[0060]

[0061] The metal oxide powder is nano-scale white calcium oxide (CaO), black copper oxide (CuO);

[0062] A preparation method of a laser engraving material for plastic products, the difference is that: the low-speed stirring temperature is 50°C; the mixing extrusion temperature is 150°C; and the cooling water temperature is 8°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com