Multipath conveyor installation

一种输送机、设备的技术,应用在输送机、输送机物件、运输和包装等方向,能够解决不适于接收不同规格的瓶等问题,达到紧密性提高、克服形变和干扰问题、缩减构造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

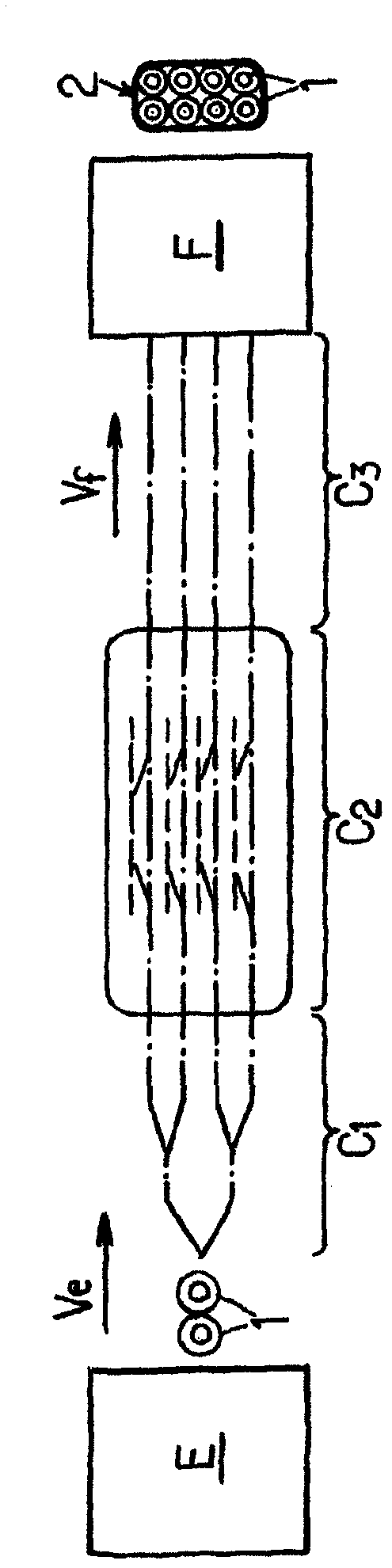

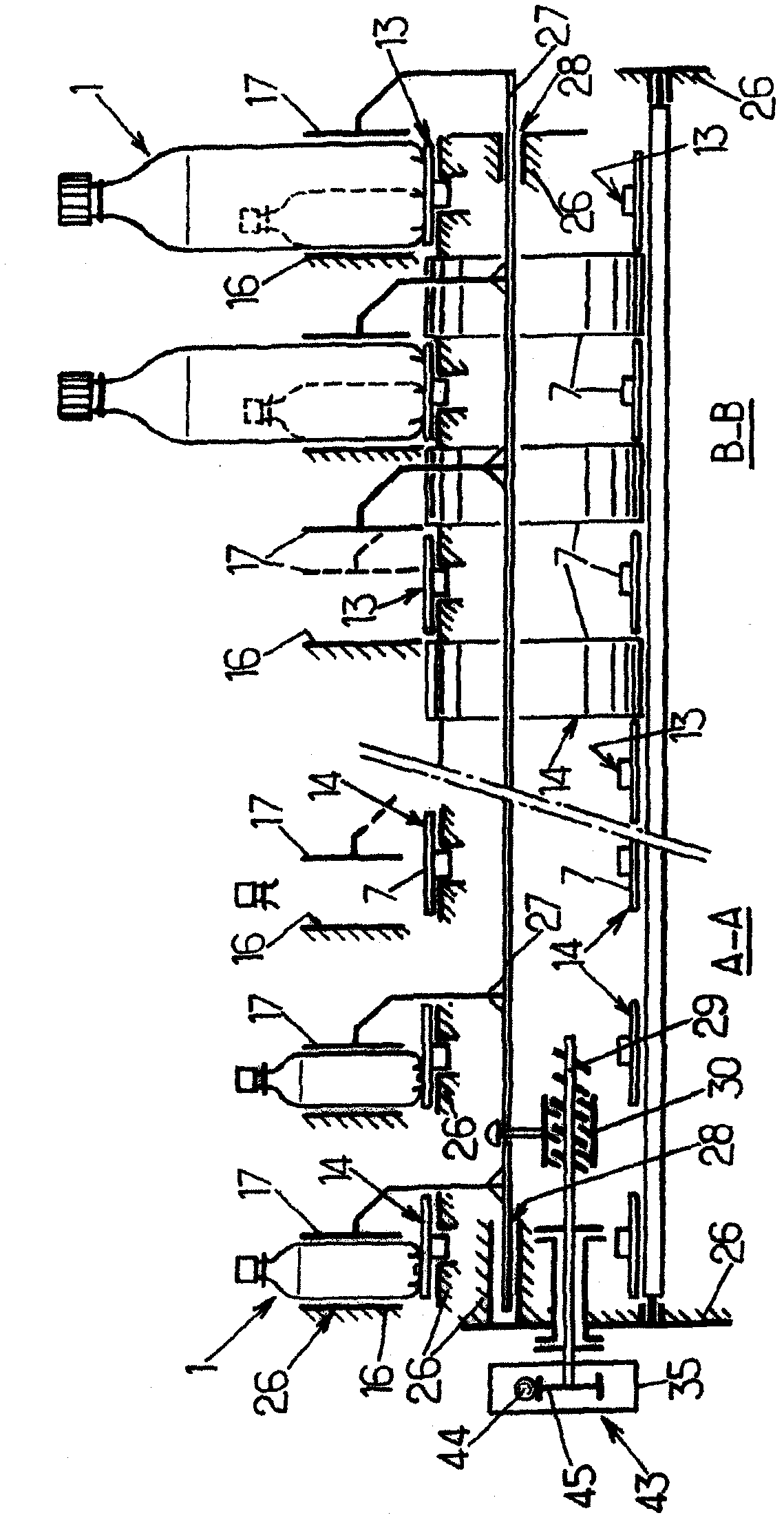

[0041] figure 1 Schematically shows an assembly line for preparing multi-pack bottles of type 1 items. This line includes, a labeling machine at the entrance E , and the pallet packer at the end F , and the conveyor equipment located between the two.

[0042] This conveyor equipment consists of a number of dedicated conveyor systems capable of controlling the variation in speed that needs to be applied to the bottles 1 in order to change their speed from leaving the labeling machine to E speed Ve into pallet packers F speed f .

[0043] Conveyor equipment includes:

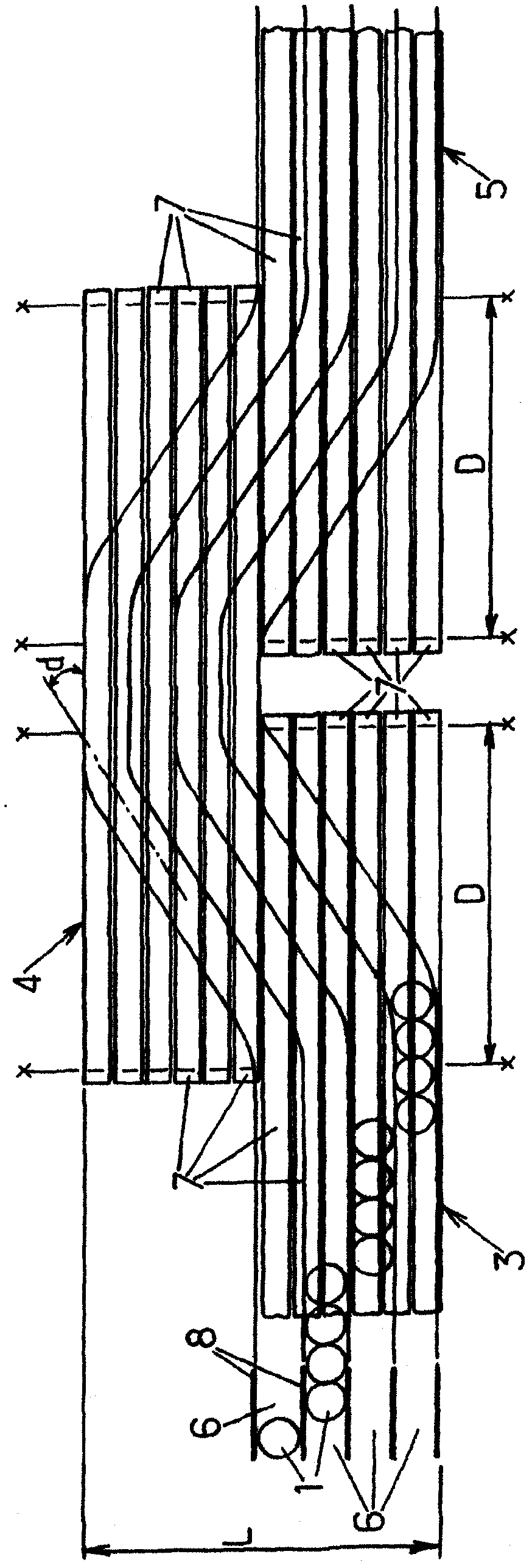

[0044] -First conveyor system C1 , the first conveyor system C1 Starting from a single route, assign bottle 1 to multiple single-column routes in the form of multiple strings;

[0045] -Second multipath conveyor system C2 , the second multipath conveyor system C2 Equivalent to the multifunctional conveyor of the present invention, the speed of bottle 1 is in the second multipath conveyor system C2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com