Patents

Literature

71results about How to "Overcome elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula of pure binary super low interface tension composite oil-displacement agent of surfactant and pdymer for triple oil production

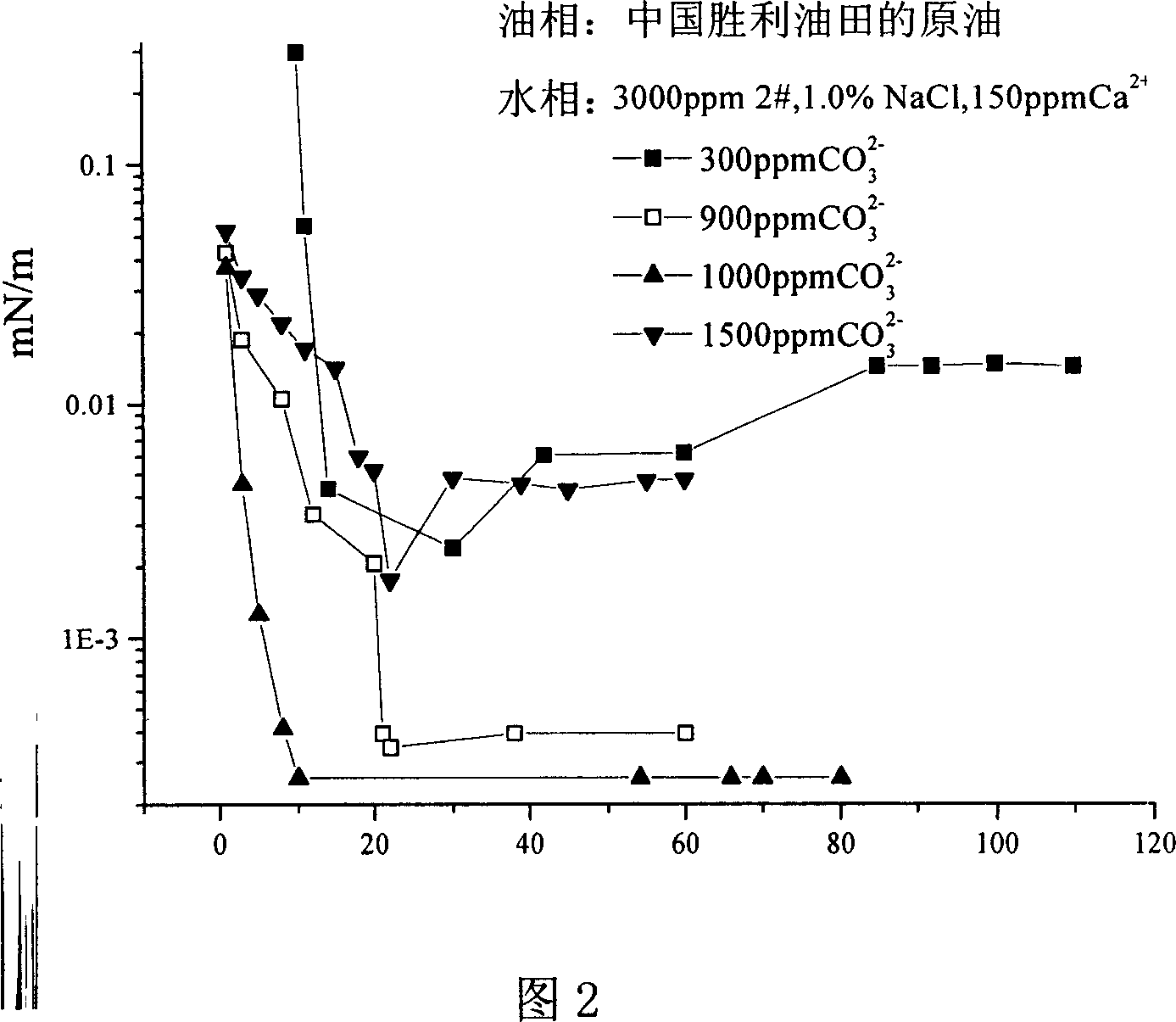

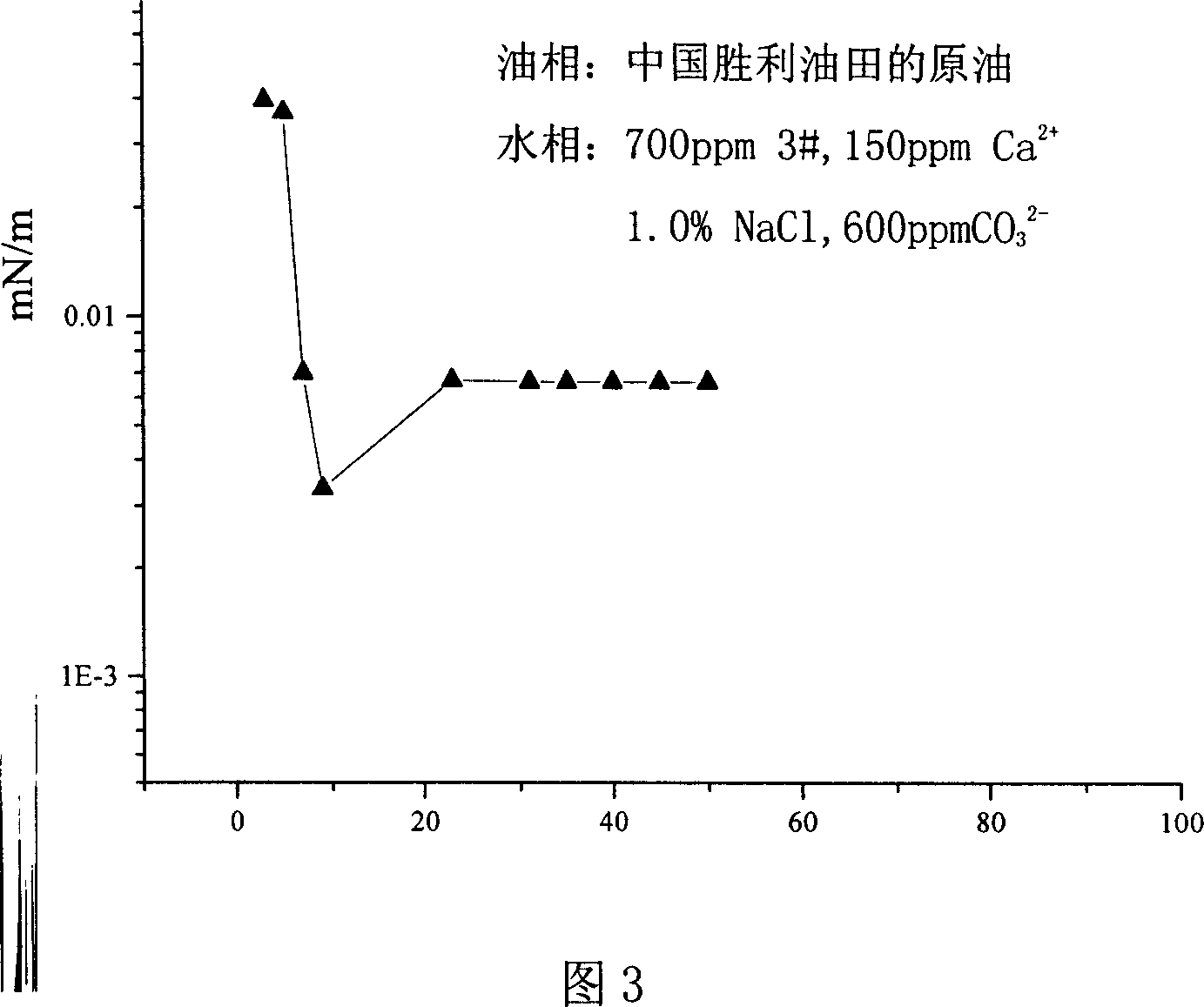

The composite oil-displacement agent consists of polymer 0-0.3 wt.%, surfactant 0.05-0.6 wt% and water 99.1-99.95 wt%, and is produced in kettle reactor with coagulated petroleum fraction from raw oil. It has surfactant concentration not higher than available systems, high interface tension reducing effect and stable performance. The ternary composite oil-displacement agent has no alkali and saltwhile reaching superlow interface tension and thus no alkali scale formed, no loss in polymer viscosity and viscolerasticity. In the compounding of the composite oil-displacement agent, common sewagemay be used and this produces certain environment protection effect.

Owner:PETROCHINA CO LTD

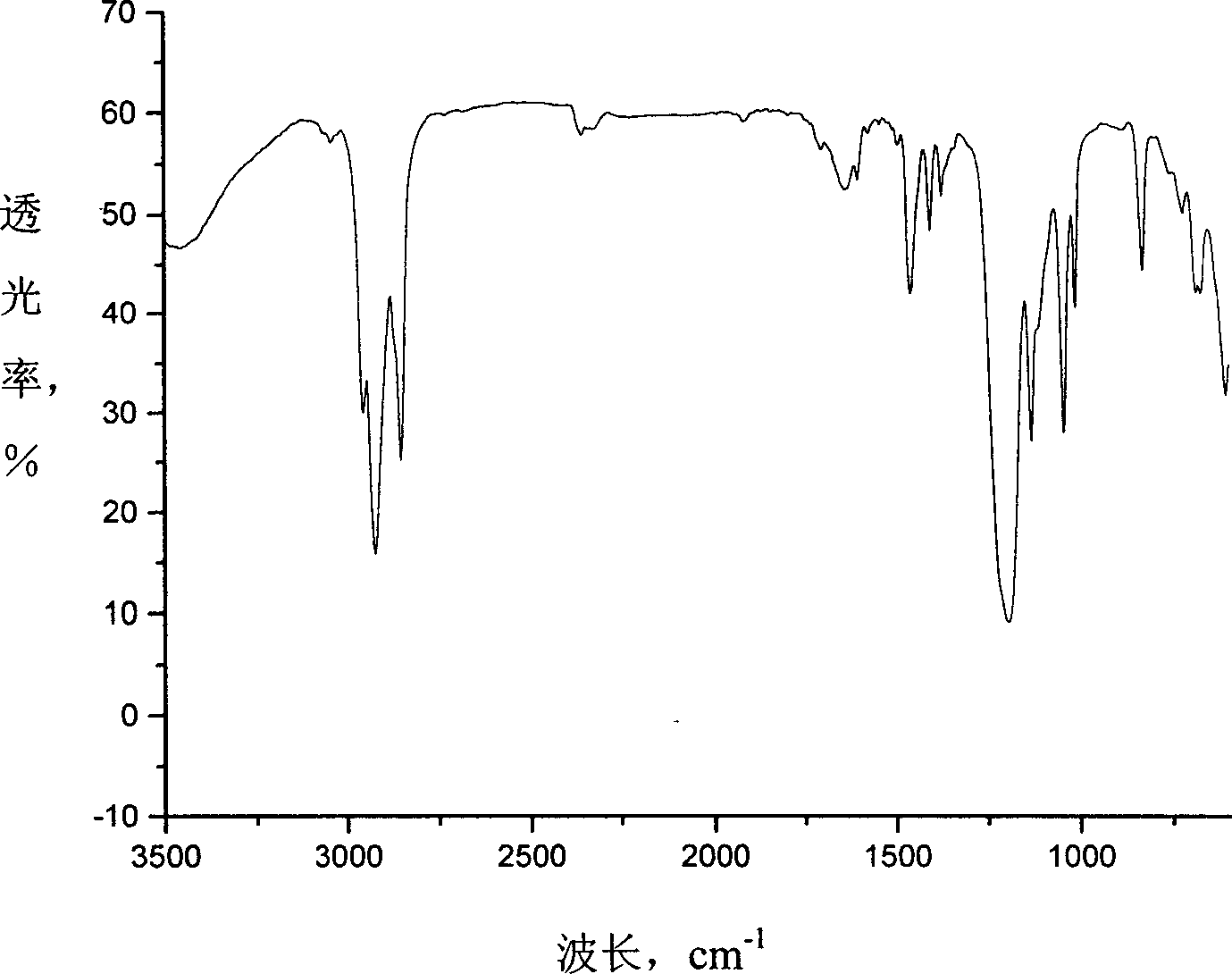

Oil-displacing agent for enhancing crude oil recovery efficiency in tertiary recovery

InactiveCN101665685AOvercome elasticityOvercome structureDrilling compositionSalt resistanceActive agent

The invention relates to an oil-displacing agent for enhancing crude oil recovery efficiency in tertiary recovery and a preparation method thereof, belonging to the technical field of intensified oilproduction in oil fields. The surface active agent used in the invention comprises following components in percentage by weight: 0.01-0.3 percent of water soluble high molecular polymer, 0-20 percentof non-ionic surface active agent, 5-65 percent of anion active agent, 0-5 percent of ampholytic active agent, 0.01-1.5 percent of additive and the balance of water. The oil-displacing agent and the polymer are based on a novel intensified oil displacing system which has complementary structure and good compatibility and is obtained by various associations and the interaction among molecules. Thesystem has the performances of high temperature resistance, salt resistance, higher viscosity, ultralow interfacial tension, and the like, is in accordance with the environmental requirement and can obviously enhance the oil recovery efficiency of oil fields after being used for oil-displacing.

Owner:TIANJIN NORMAL UNIVERSITY

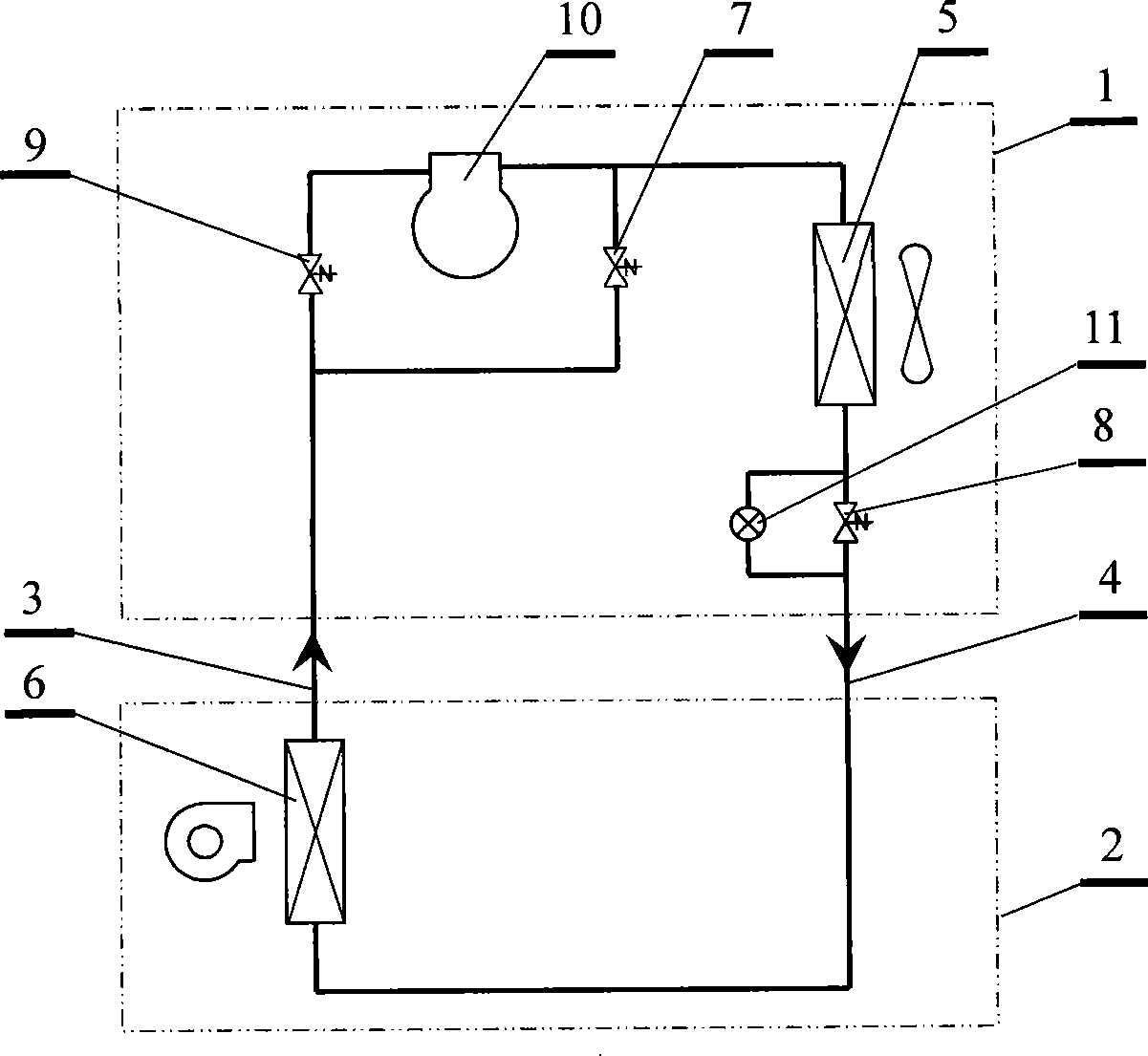

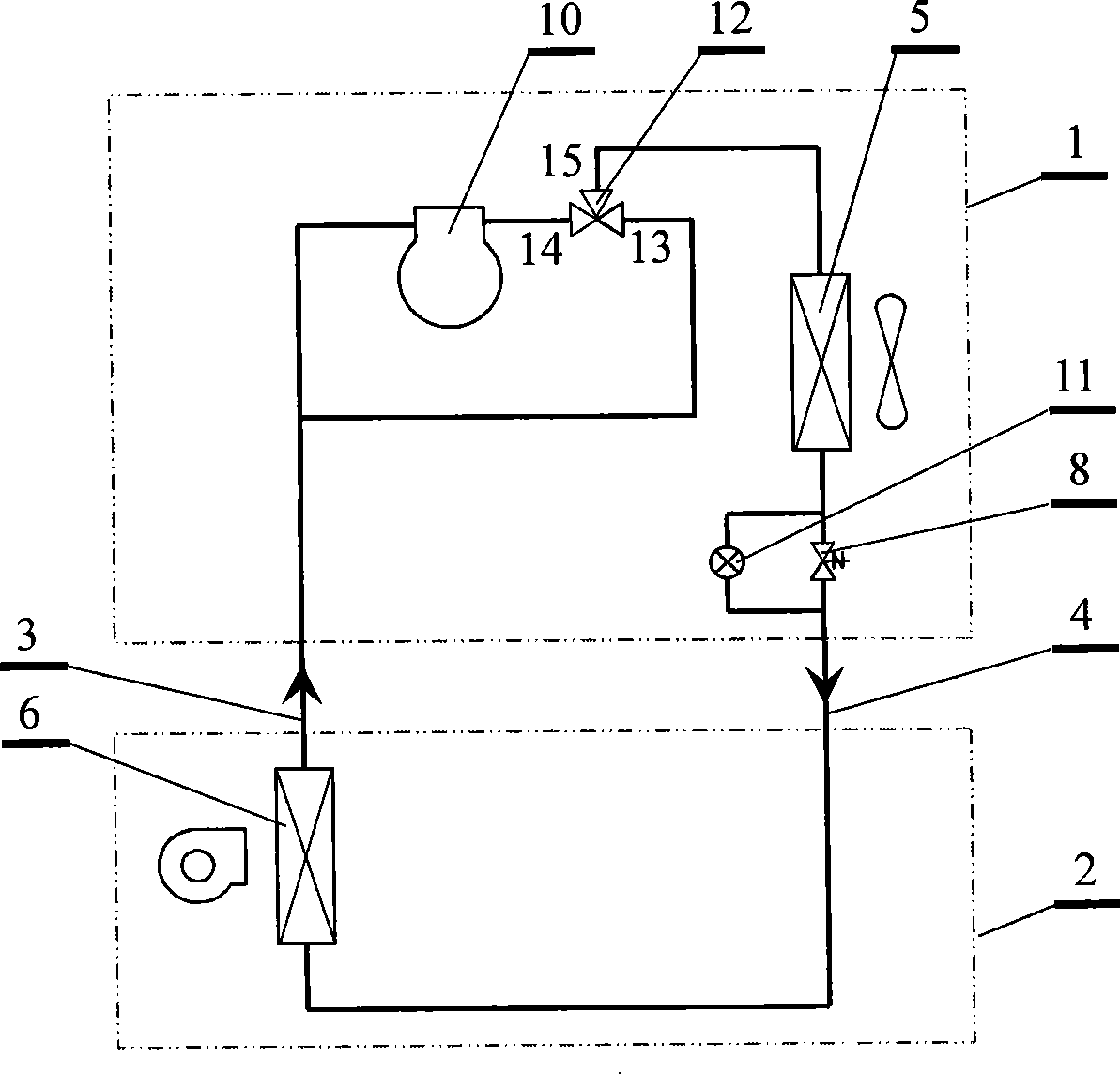

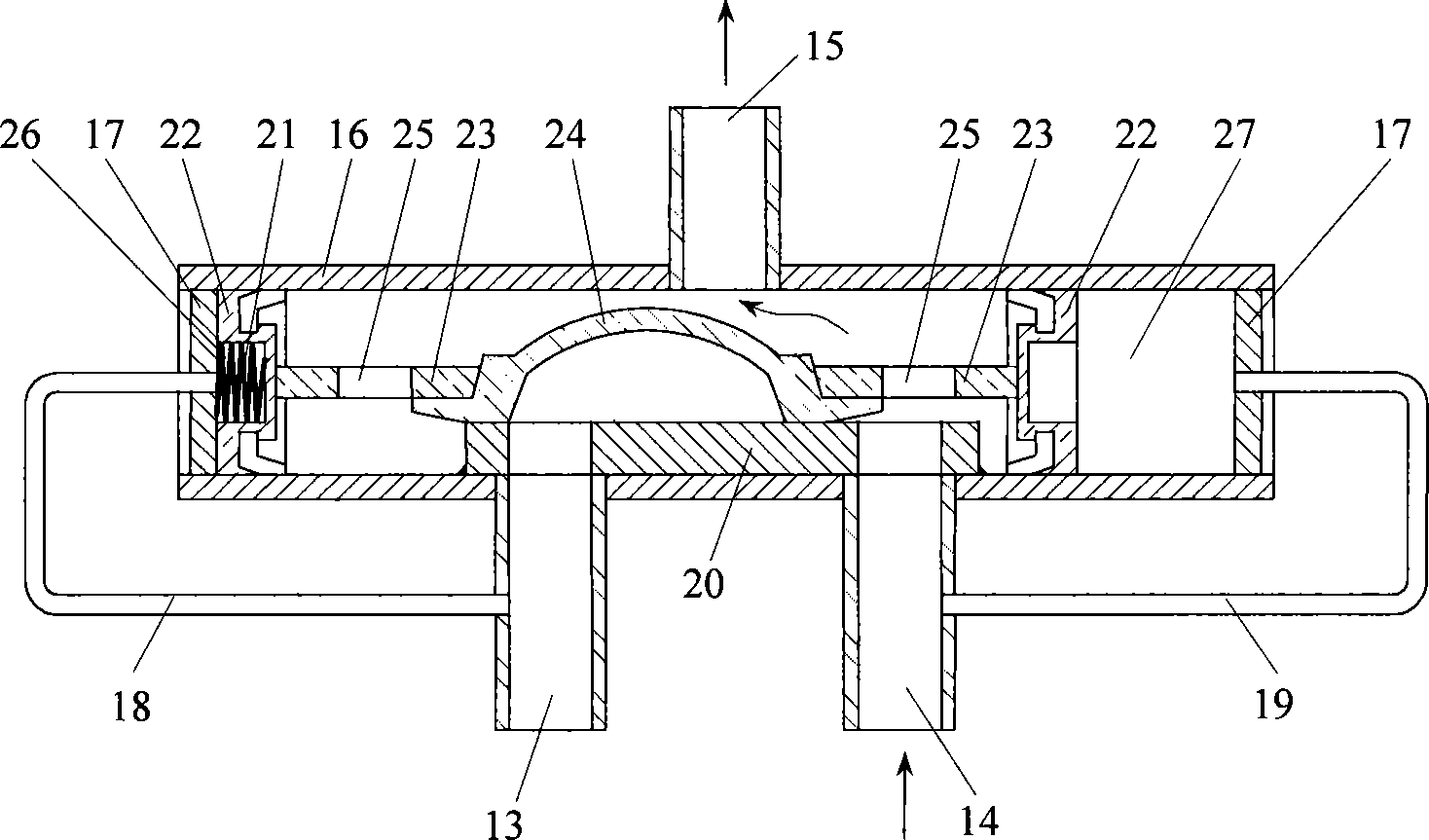

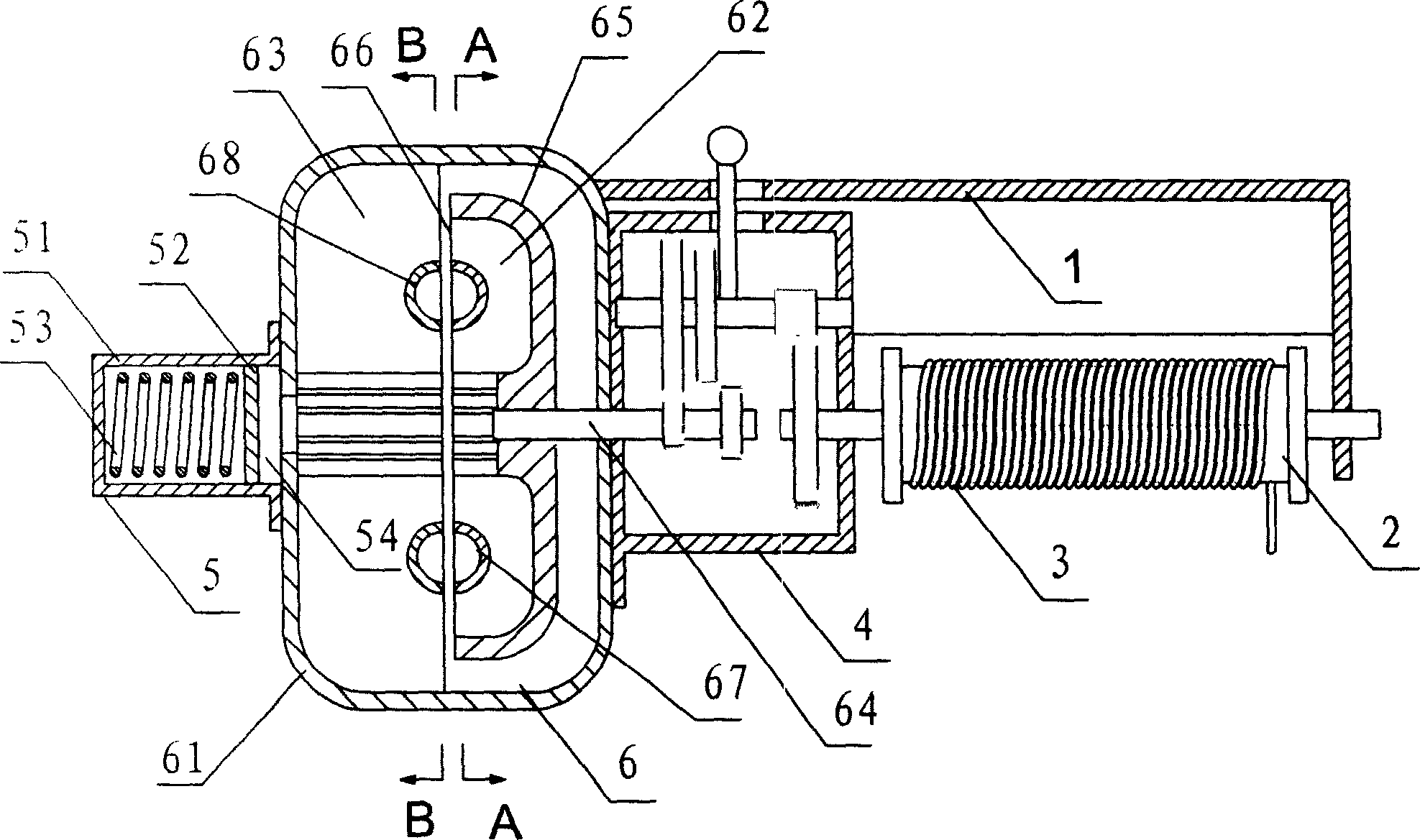

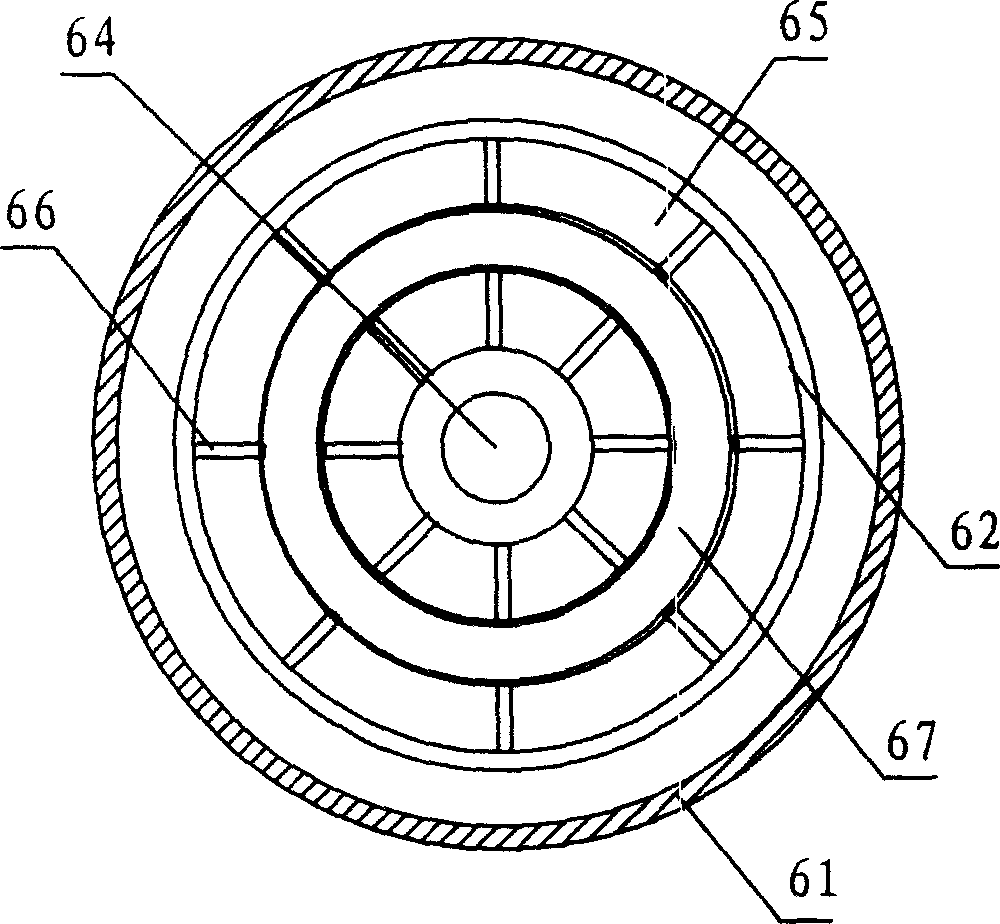

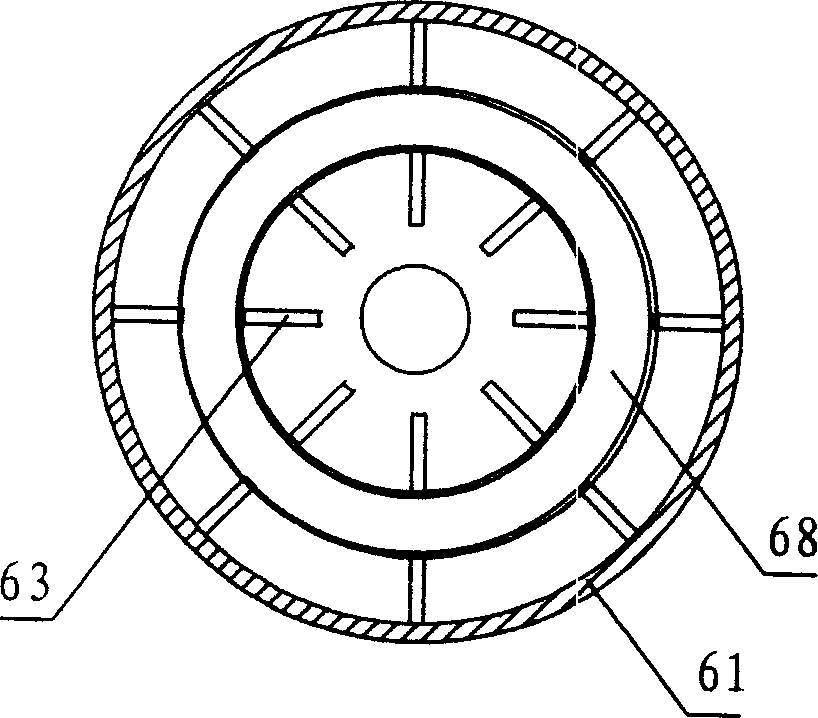

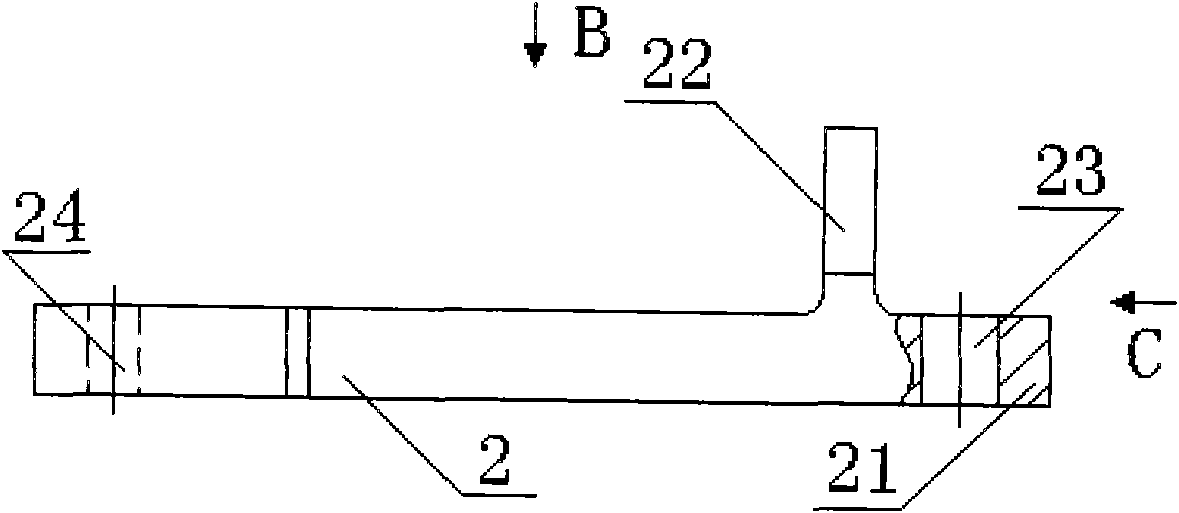

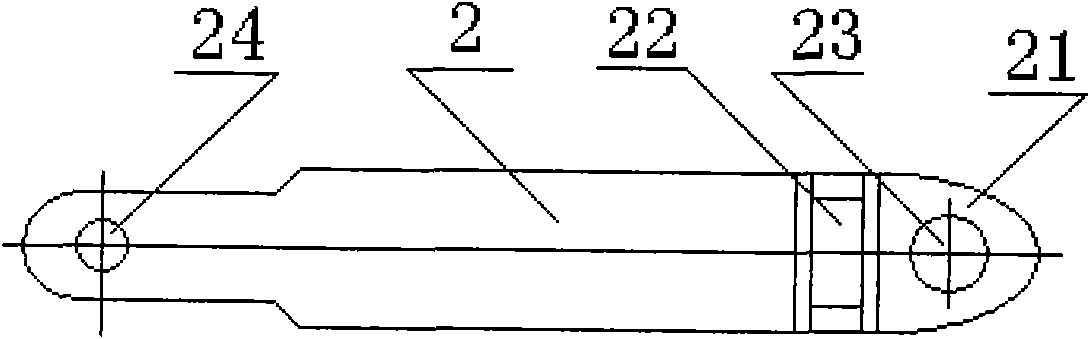

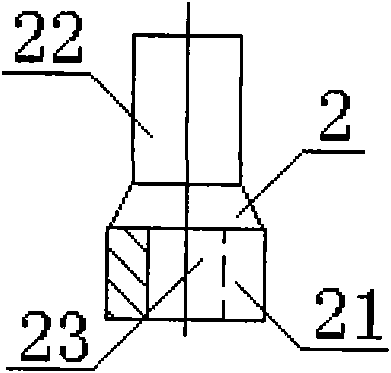

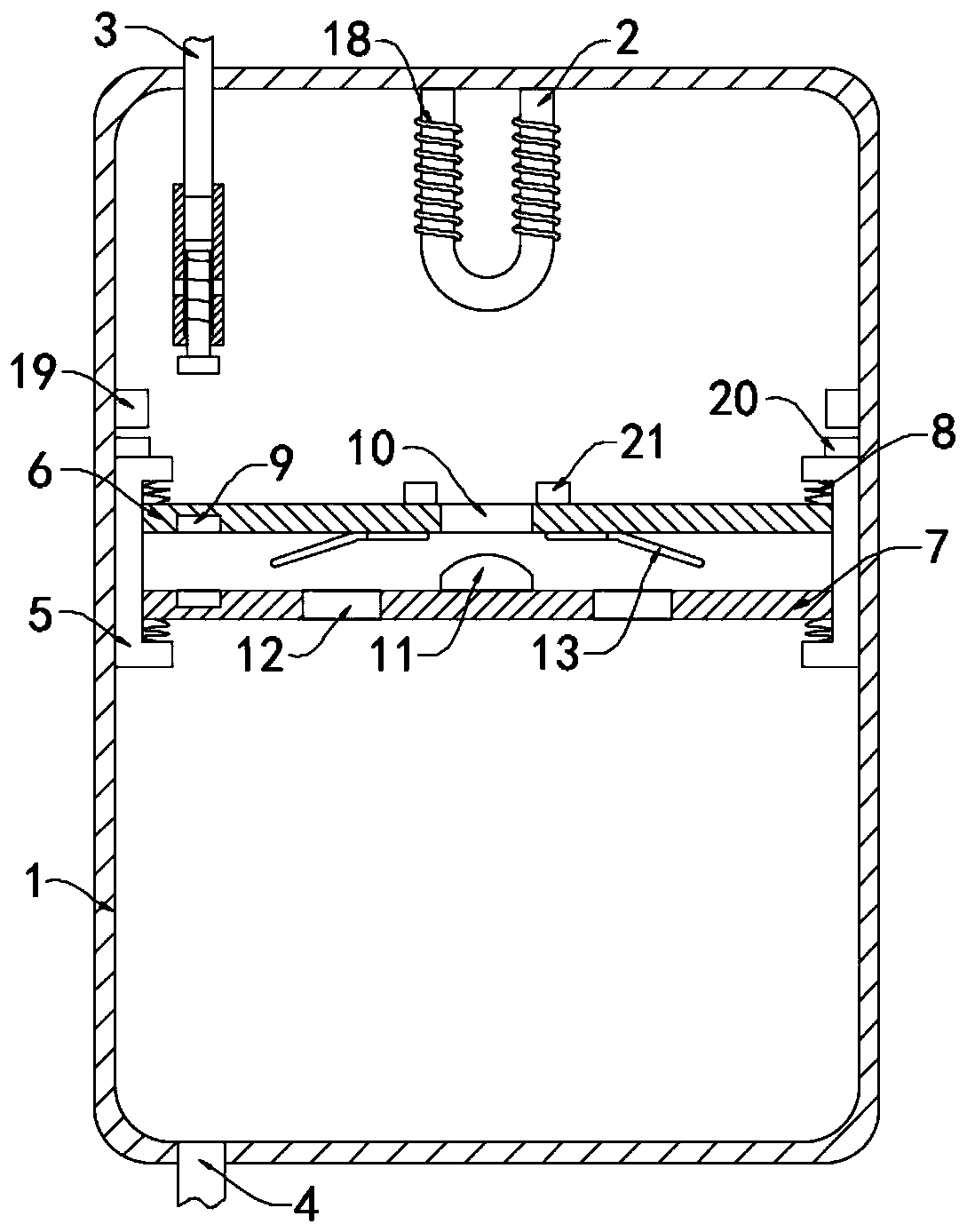

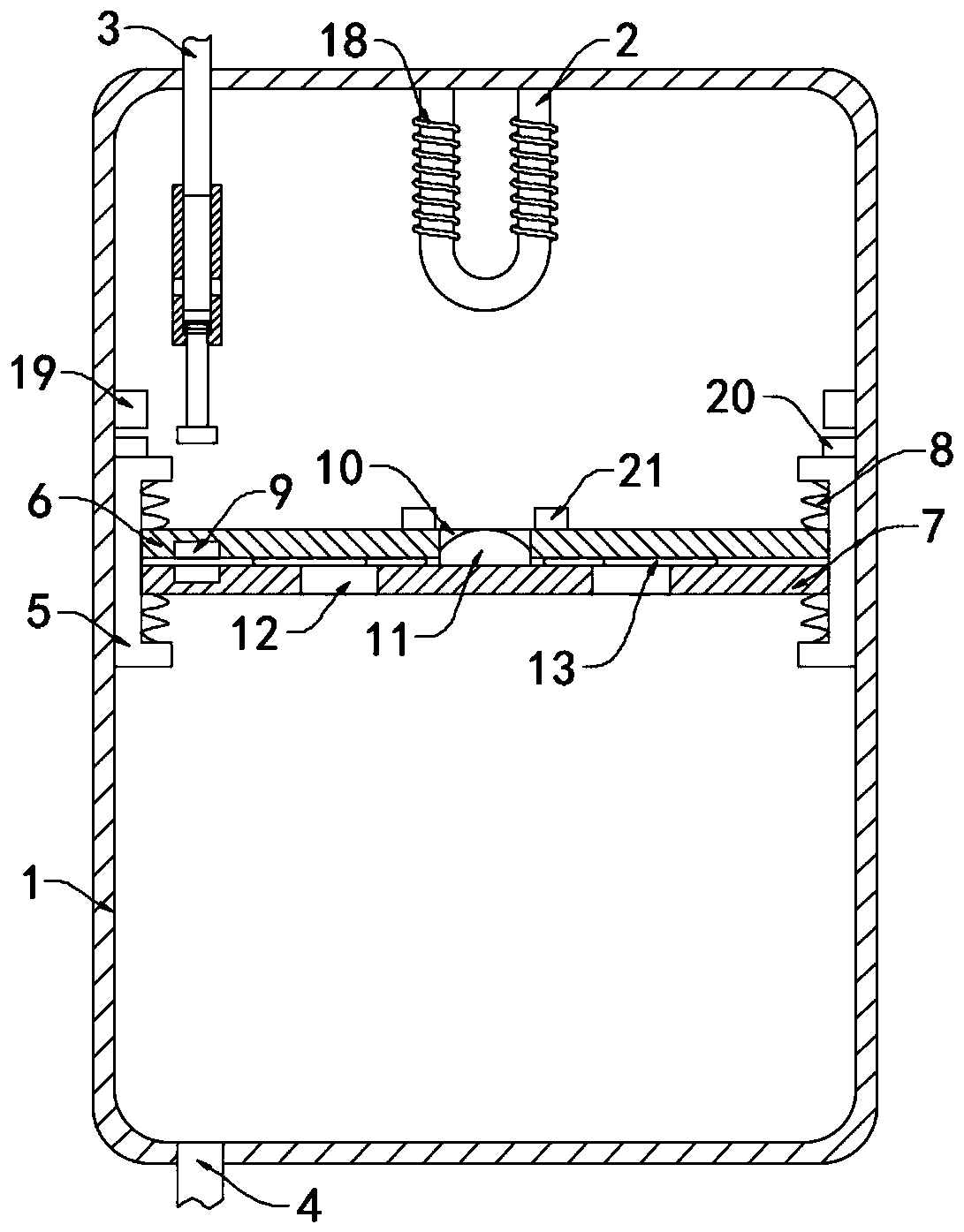

Self-operated three-way valve used for coolant circulating type machine room special machine

InactiveCN101245864AImprove reliabilityOvercome frictionOperating means/releasing devices for valvesMultiple way valvesSpring forceEngineering

The invention provides a self-operated three-way valve used for a special machine in a refrigerant circulation parallel machine room. The three-way valve comprises a valve body, a low pressure air inlet pipe, a high pressure air inlet pipe and an exhaust pipe. The valve body is internally provided with a piston component, a valve seat and a sliding valve. The internal chamber of the valve body is divided into a low pressure chamber and a high pressure chamber by a piston which can axially move. A low pressure capillary is connected between the low pressure chamber and the low pressure air inlet pipe. A low pressure capillary is connected between the high pressure chamber and the high pressure air inlet pipe. The low pressure chamber and / or the high pressure chamber are / is internally provided with a spring. By the pressure difference of the suction and exhaust when a spring force and a compressor are stated, the piston component which is arranged in the valve body drives the sliding valve to be closely attached to the surface of the valve seat to slide, thus achieving the communication between the high pressure air inlet pipe and the exhaust pipe and the communication between the low pressure air inlet pipe and the exhaust pipe. The three-way valve needs no outside power, can achieve the free switching of refrigerant refrigeration circulation and the natural circulation just according to the running state of the compressor, thus sufficiently displaying the energy-saving advantage of the special machine in the refrigerant circulation parallel machine room and improving the operation reliability.

Owner:和雄科技(北京)有限公司

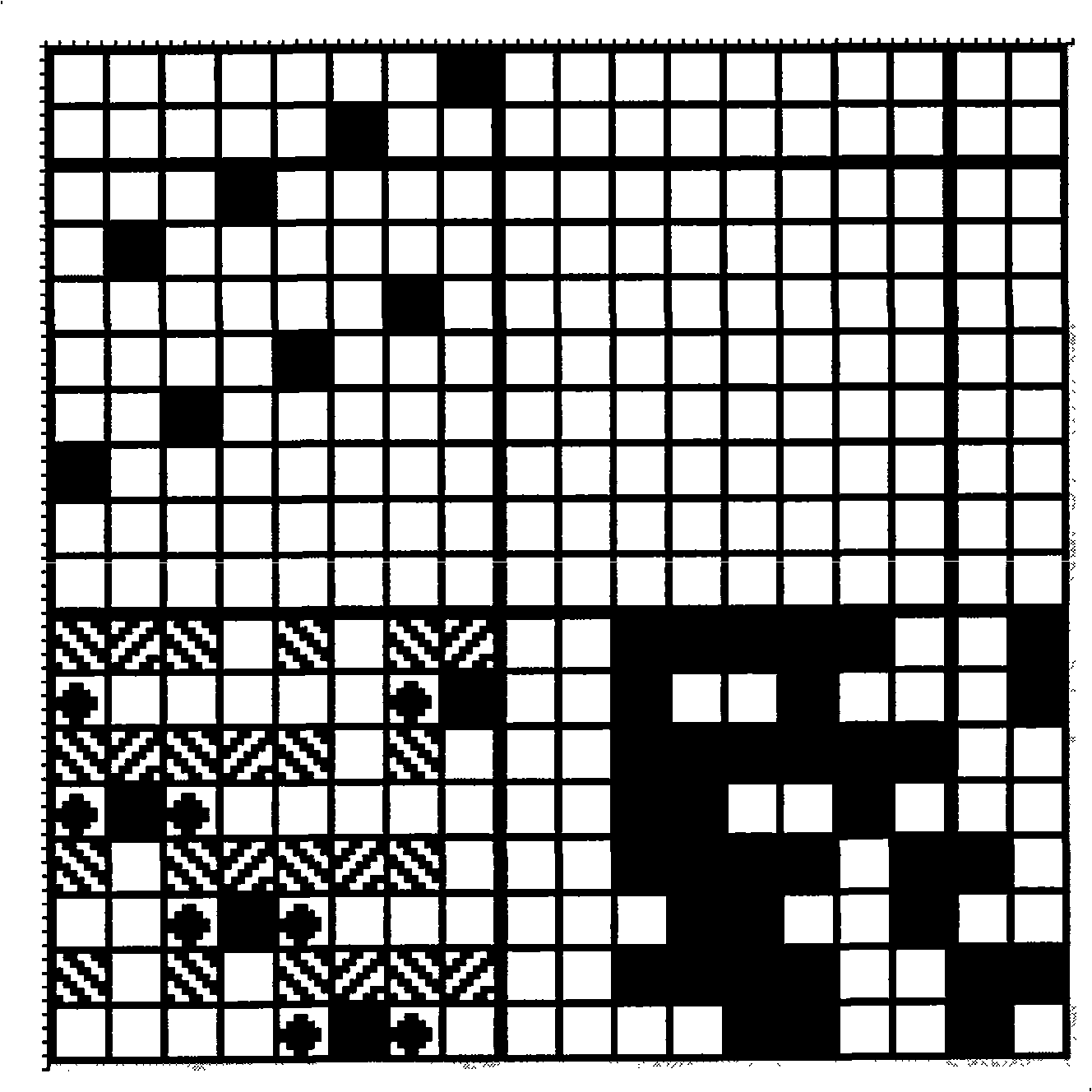

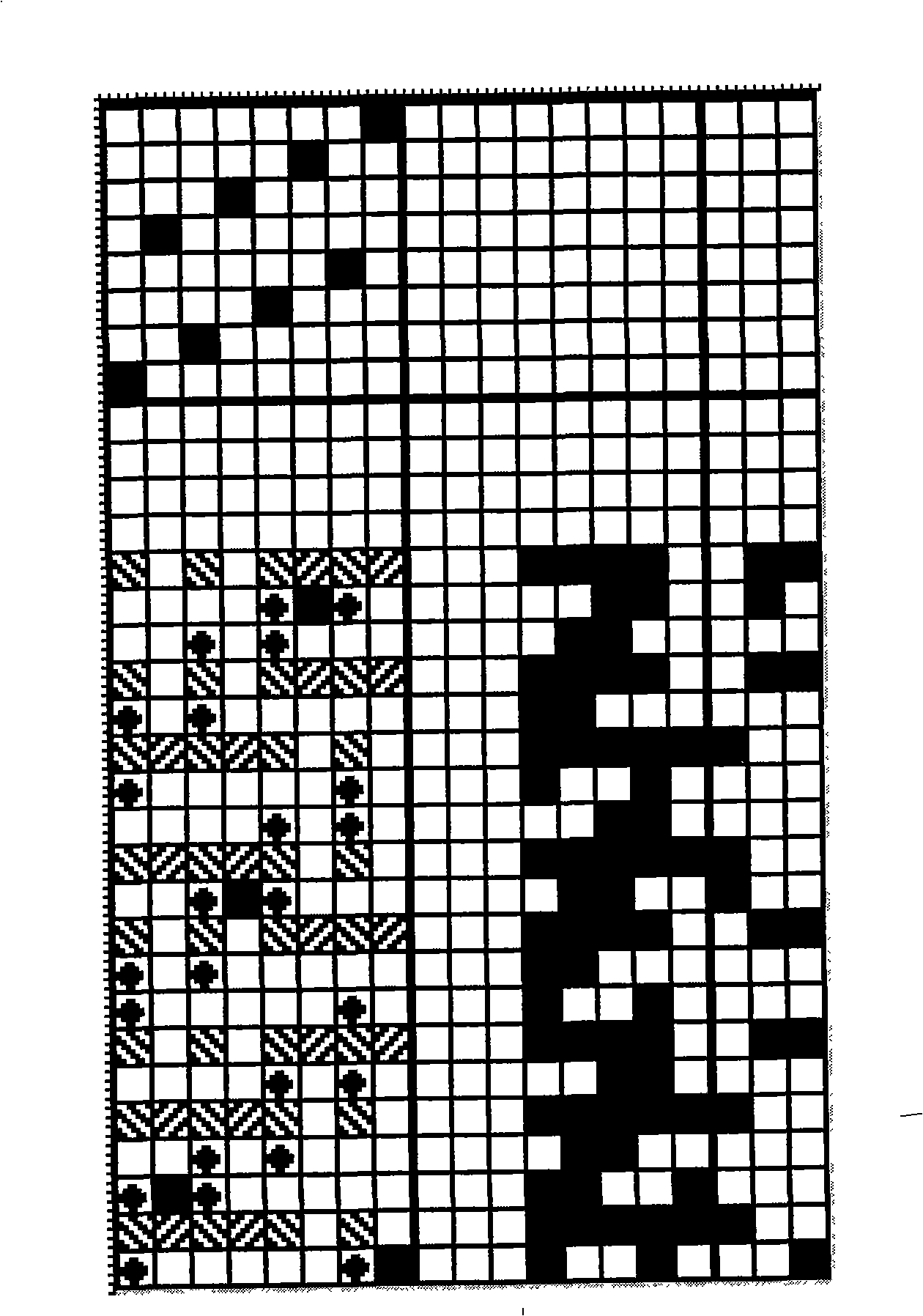

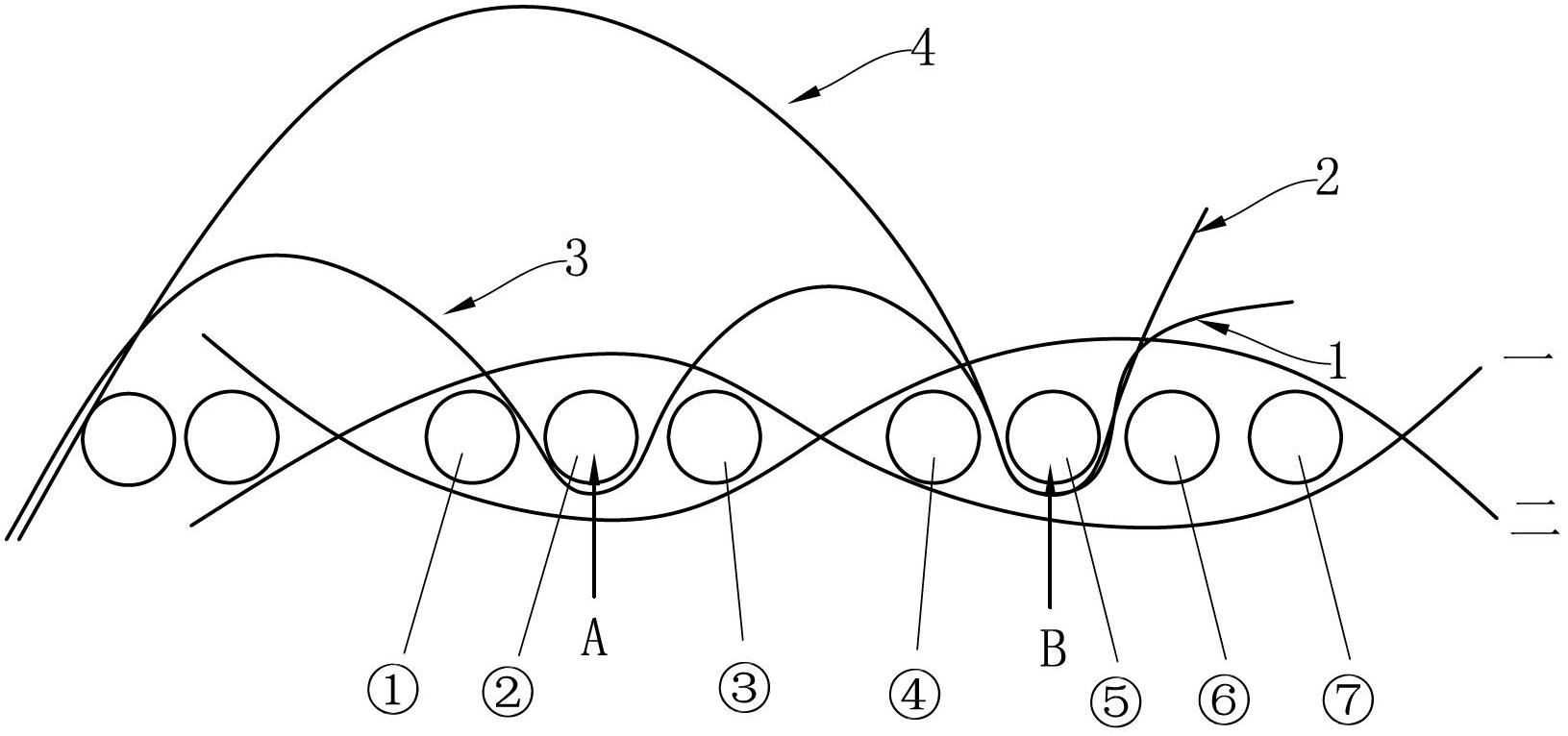

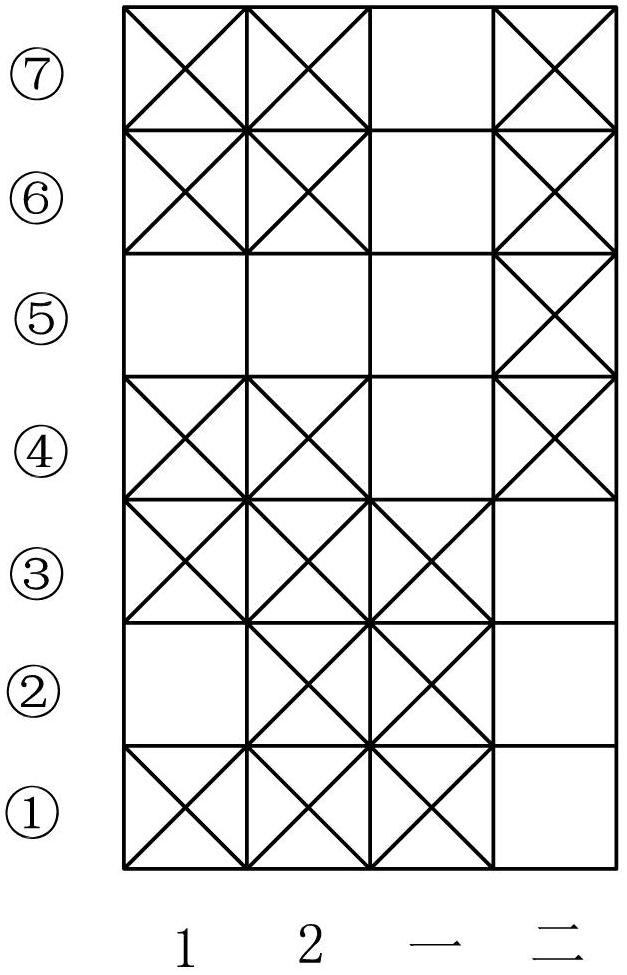

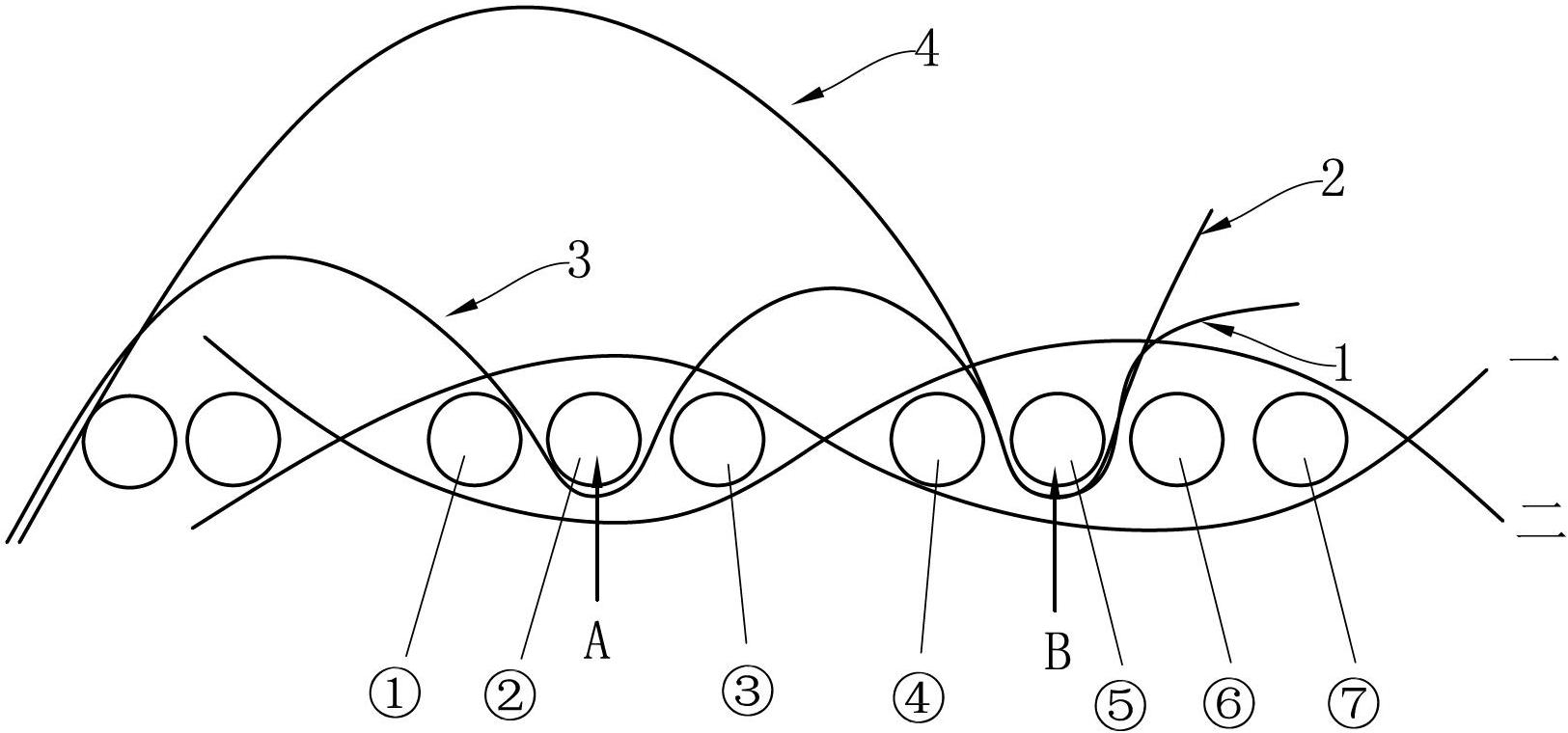

Ramie / terylene double fabric for textile wall cloth and curtain cloth and preparing method thereof

The invention relates to a ramee / terylene double woven fabric used for wall cloth and window blind fabrics, which comprises a surface layer and an inner layer, wherein, the surface layer is weaved by ramee yarns and the inner layer is weaved by terylene yarns, or the surface layer is weaved by terylene yarns and the inner layer is weaved by ramee yarns, and the surface layer and the inner layer are bond into a whole by binding joints which are not exposed on the right side and the reverse side of the fabric. The preparation method of the ramee / terylene double woven fabric adopts the ramee yarns and the terylene yarns as raw materials, and comprises a preparation procedure and a weaving procedure, and the fabric is prepared by adopting a shuttleless loom or loom with shuttles according to selected structure. When weaving by adopting the shuttleless loom, the preparation procedures of the warp comprise the steps of twist setting, winding, warping, warp sizing and warp gaiting, and the preparation procedures of the weft comprise the steps of twist setting and winding; and when weaving by adopting the loom with shuttles, the preparation procedures of the warp comprise the steps of twist setting, winding, warping, warp sizing and warp gaiting, and the preparation procedures of the weft comprise the steps of twist setting, winding and weft winding.

Owner:北京青山绿水苎麻制品有限公司 +1

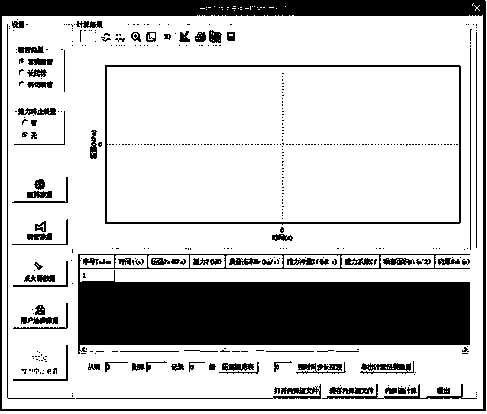

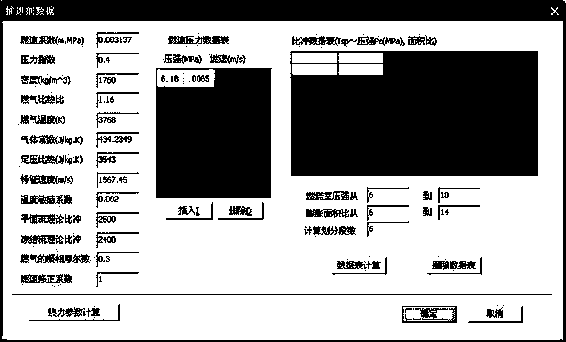

One-dimensional interior ballistic modeling and performance prediction software system of solid engine

InactiveCN107832565AHigh precisionImprove modeling speedGeometric CADDesign optimisation/simulationInternal ballisticsSoftware system

The present invention relates to a one-dimensional interior ballistic modeling and performance prediction software system of a solid engine. The system comprises a nozzle type selection module, a charge data import module, a nozzle data input module, an igniter data input module, a user selected data input module and a calculated result display module. The nozzle type selection module is used forselecting the set nozzle type; the charge data import module is used for importing the charge data; the nozzle data input module is used for parameter input of the nozzle; the igniter data input module is used for parameter input of the ignition gas mass flow rate; the user selected data input module is used for parameter input of the working end pressure, the design temperature, and the like; andthe calculated result display module is used for displaying a calculated result. According to the system provided by the present invention, defects of the inaccuracy of the conventional zero-dimensional interior ballistic calculation method, the incomplete consideration of the factors affecting the interior ballistics, and the like are overcome, the simulation precision and the modeling speed ofthe internal ballistic performance of the engine are improved, the design and calculation efficiency of the solid engine is improved, and the product development cycle is shortened.

Owner:内蒙动力机械研究所

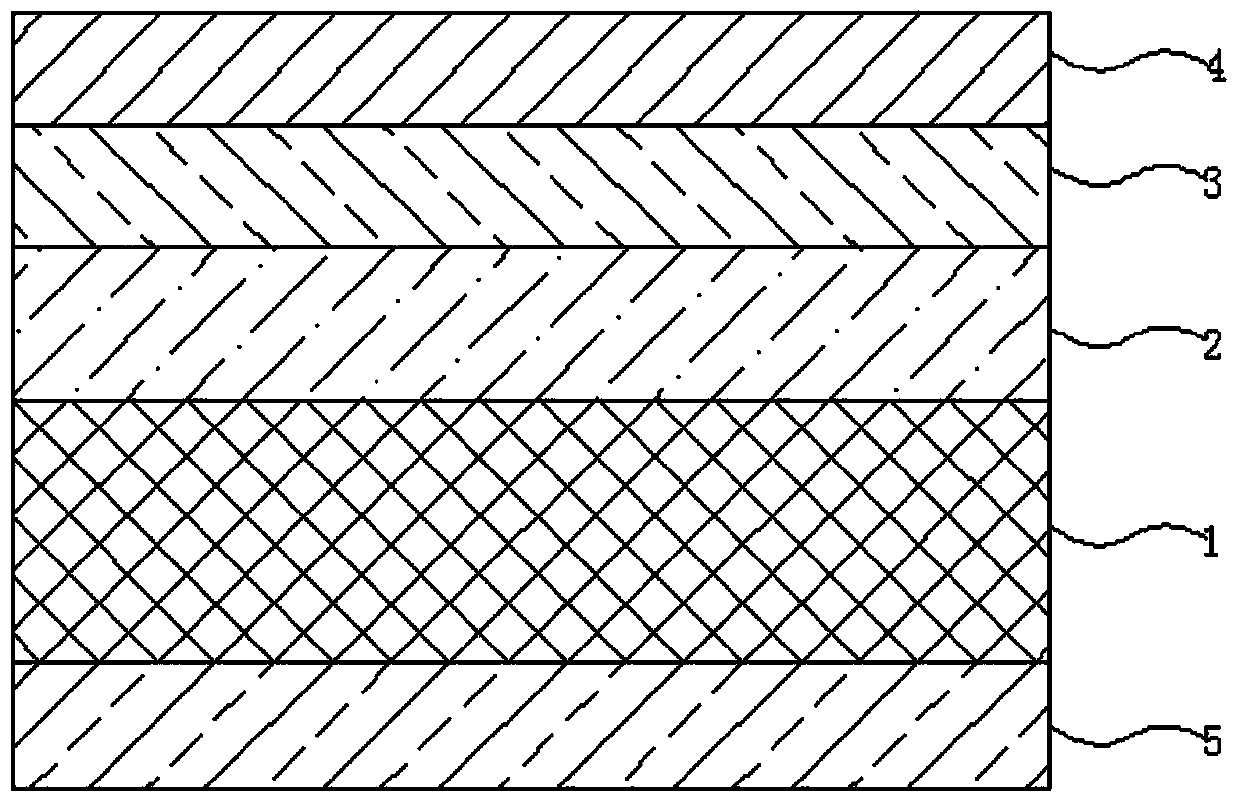

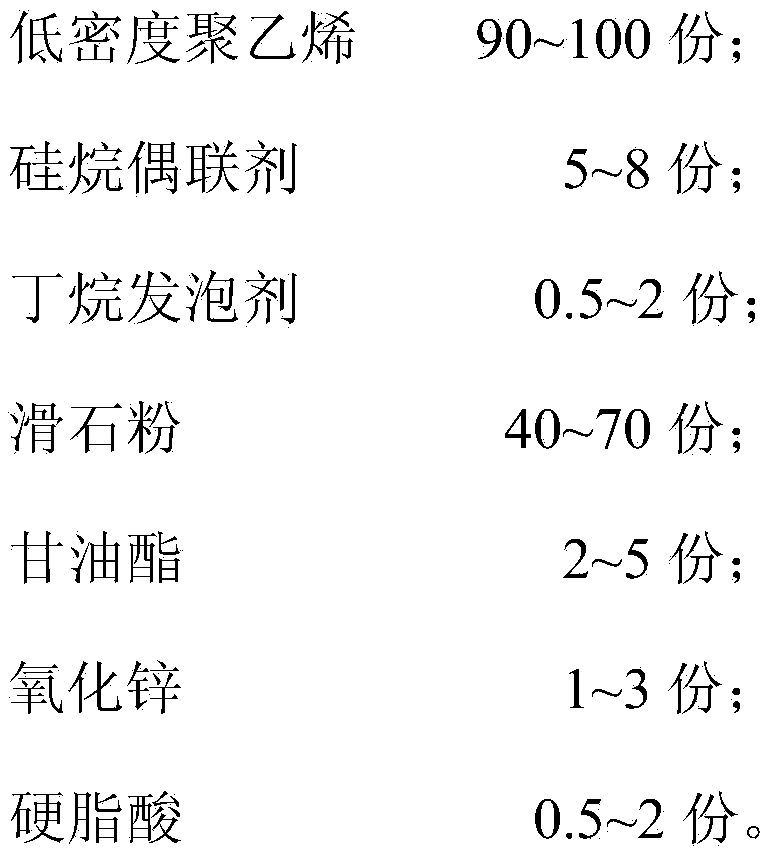

EPE material for crawling pad, preparation method of EPE material and crawling pad

InactiveCN104403173AFine and uniform cellsFlexibleSynthetic resin layered productsLow-density polyethyleneFoaming agent

The invention discloses an EPE material for a crawling pad, a preparation method of the EPE material and the crawling pad. The EPE material comprises the following components in parts by mass: 90-100 parts of low density polyethylene, 5-8 parts of a silane coupling agent, 0.5-2 parts of a butane foaming agent, 40-70 parts of talcum powder, 2-5 parts of glyceride, 1-3 parts of zinc oxide and 0.5-2 parts of stearic acid. The crawling pad prepared from the EPE material is favorable in water resistance, is flexible, light and elastic, can absorb and disperse external impact force through bending to achieve a buffer effect, overcomes the defects of deformation and poor rebound resilience, and meanwhile, has a thermal insulating effect and is easy to clean.

Owner:SUZHOU JIUDING

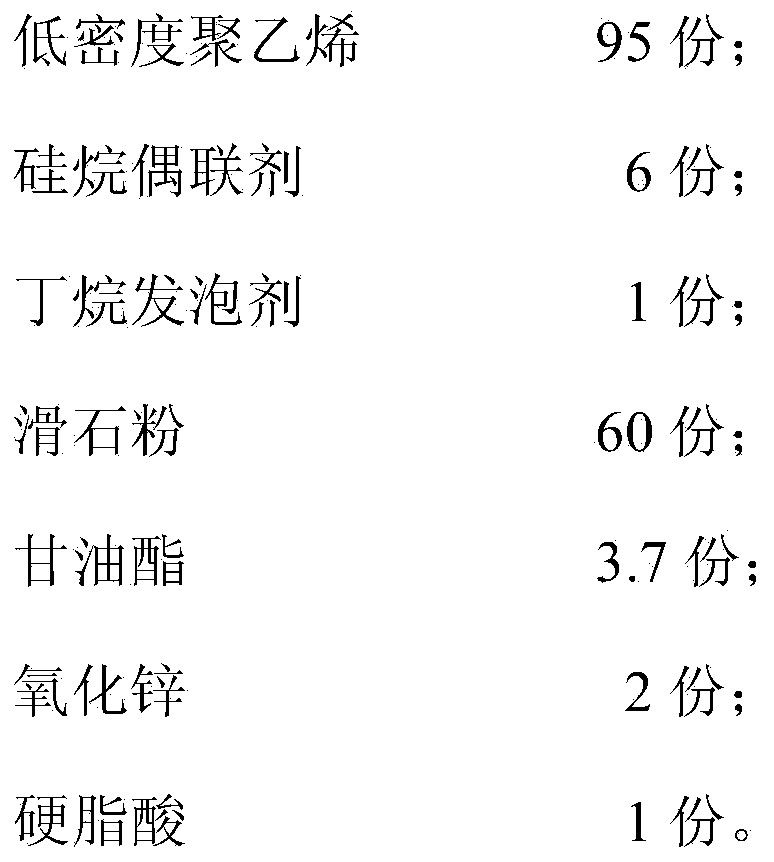

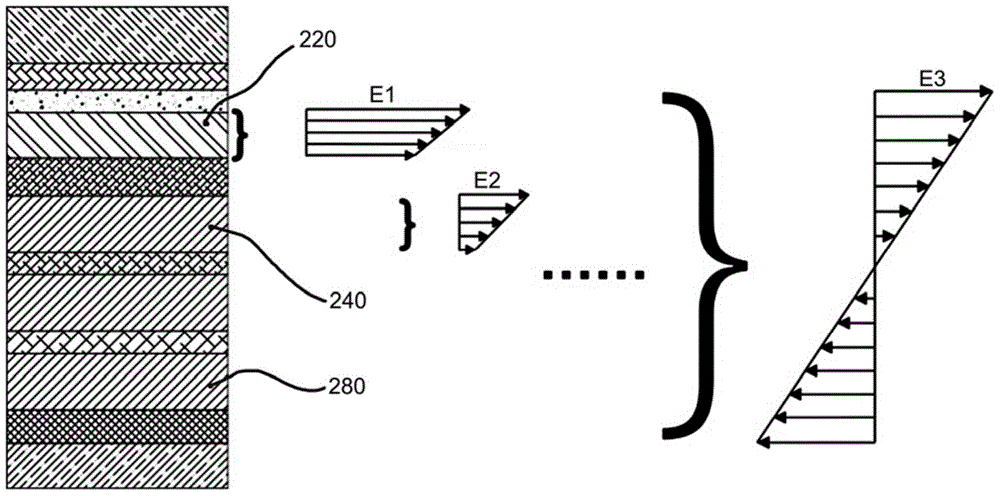

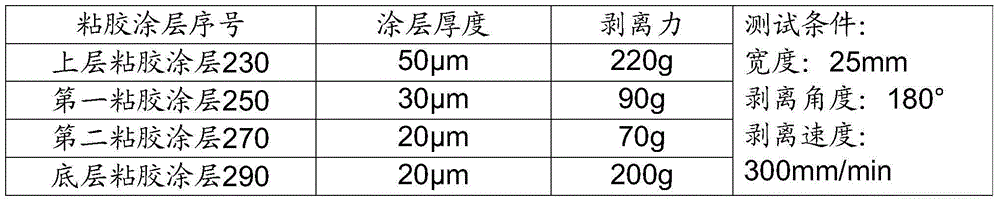

A multi-layer elastic composite film having functions of bending shape maintenance and impact resistance and a preparing method thereof

ActiveCN104608445AOvercoming bending elasticityOvercome elasticitySynthetic resin layered productsLaminationComposite filmAdhesive

The invention discloses a multi-layer elastic composite film having functions of bending shape maintenance and impact resistance and a preparing method thereof. The composite film has a function of cambered surface covering shape maintenance, a function of elastic vibration absorption and a function of resisting violent impact. The composite film comprises a film protecting layer, a using layer and a stripping layer from top to bottom. The film protecting layer is disposed on the using layer. The stripping layer is disposed under the using layer. The using layer comprises a UV coating, an uppermost transparent film, an upper adhesive coating, a first soft transparent film, a first adhesive coating, a second soft transparent film, a second adhesive coating, and a lowest soft transparent film from top to bottom. The composite film can be firmly adhered to a screen, is not liable to rebound, and has good cambered surface fitting and shape maintenance capability, thus achieving cambered surface edge covering.

Owner:NALI OPTICAL MATERIAL DONGGUAN

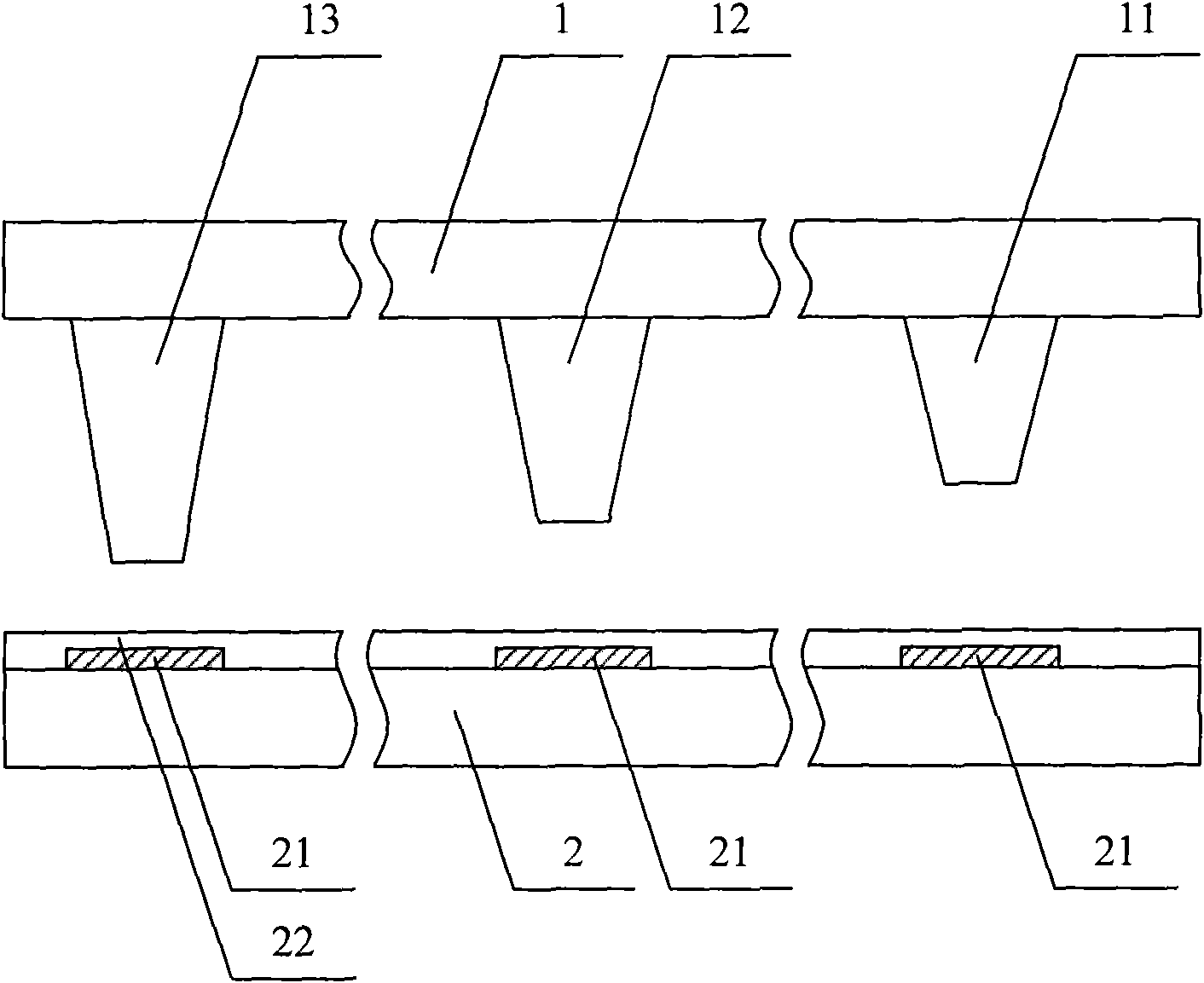

Liquid crystal display panel

InactiveCN101846854AQuality improvementImprove stabilityNon-linear opticsLiquid-crystal displayColor film

The invention relates to a liquid display panel which comprises an array substrate and a color film substrate, wherein the color film substrate comprises a main columnar septum, a vice columnar septum, wherein the main columnar septum provides first elastic force under a set gap, the vice columnar septum provides second elastic force under a gap less than the set gap, and a non-gravitational ripple region of the color film substrate is also provided with a hyper columnar septum which provides third elastic force under the set gap, wherein the third elastic force is larger than the first elastic force. Since the non-gravitational ripple region is provided with the hyper columnar septum, the elastic force provided by the septum of the non-gravitational ripple region is improved, the liquid crystal display panel of the invention effectively ensures the gap of the non-gravitational ripple region, and thereby prevents liquid crystal of the non-gravitational ripple region from entering a gravitational ripple region.

Owner:BOE TECH GRP CO LTD +1

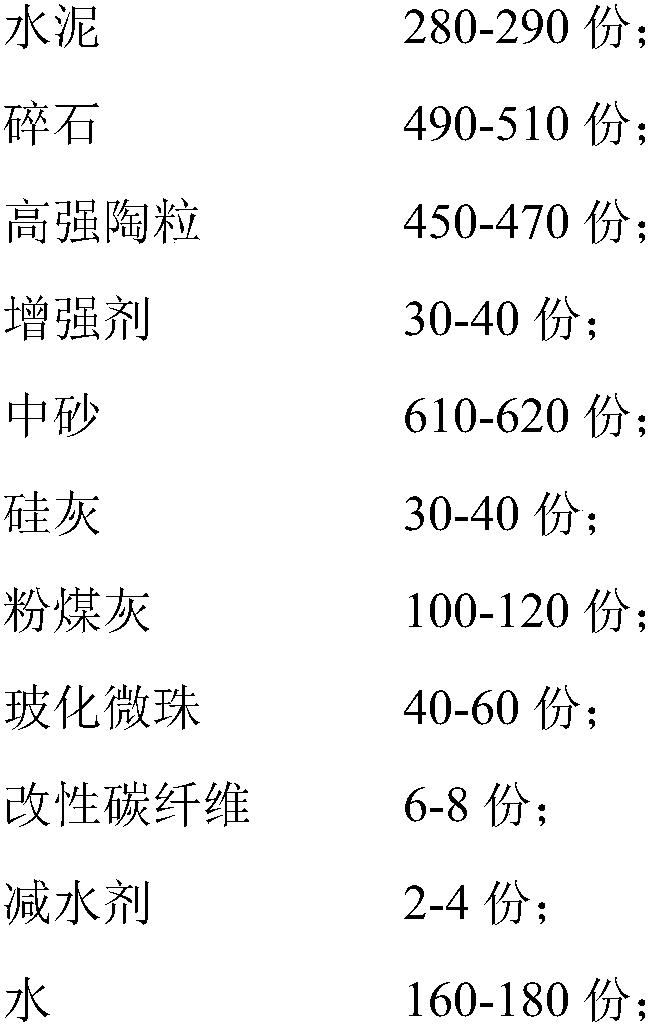

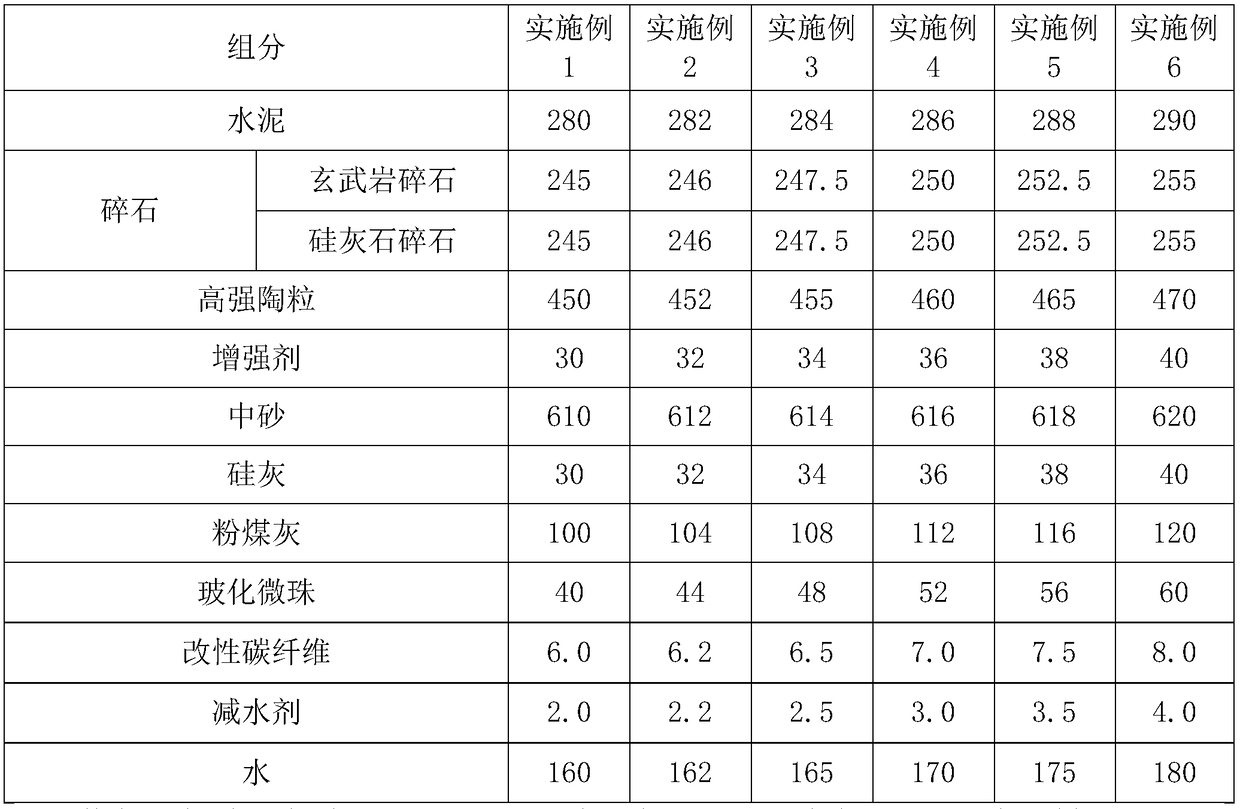

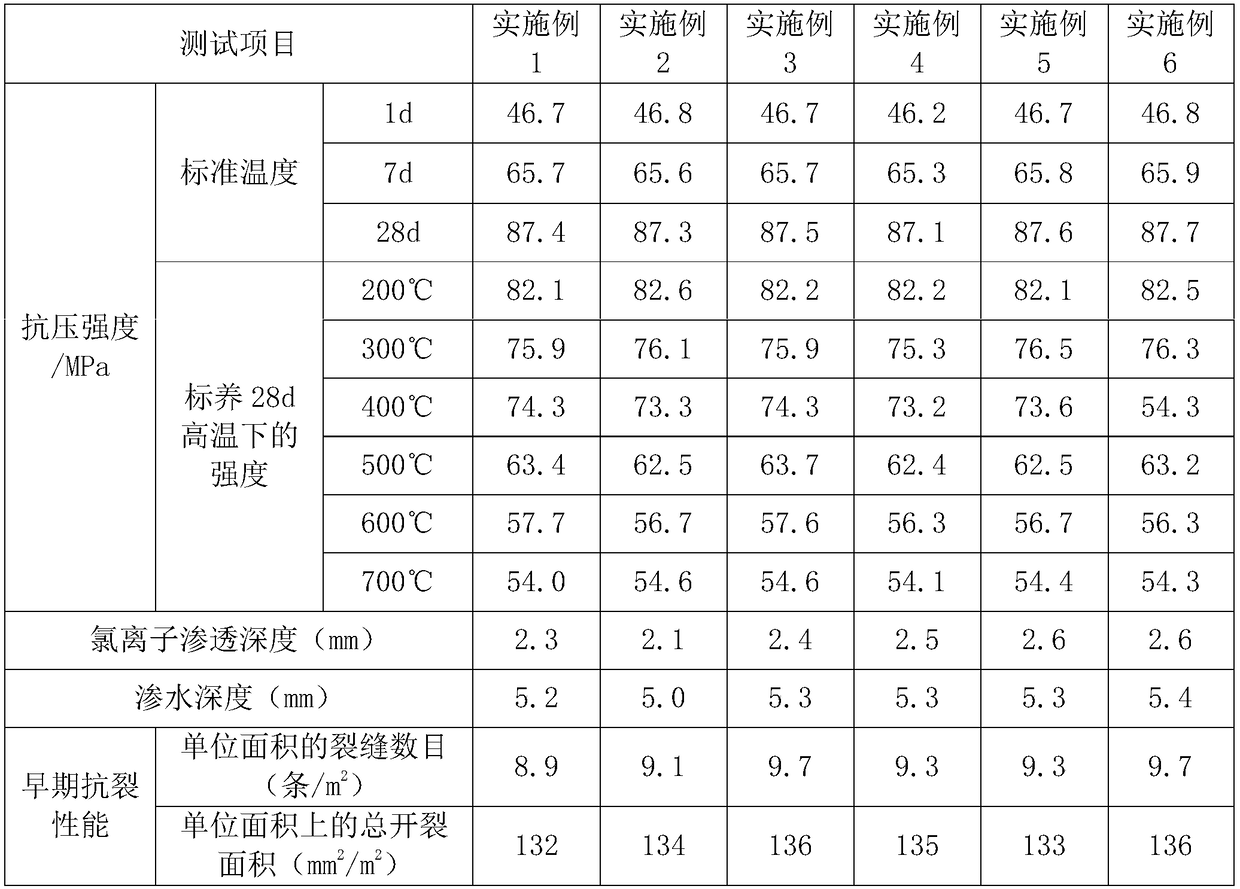

High-strength and heat-resistant concrete

The invention discloses high-strength and heat-resistant concrete and belongs to the technical field of concrete. The technical scheme is characterized in that the high-strength and heat-resistant concrete is prepared from components in parts by weight as follows: cement, crushed stone, high-strength ceramsite, a reinforcing agent, medium sand, silica fume, fly ash, vitrified microbeads, modifiedcarbon fibers, a water reducing agent and water, wherein the cement is P.O.42.5 ordinary Portland cement; the crushed stone comprises crushed basalt and crushed wollastonite. Heat resistance, impervious performance and compressive strength of the concrete are improved by the high-strength ceramsite; heat resistance and compressive strength of the concrete are improved by the reinforcing agent; aging resistance, heat resistance and cracking resistance of the concrete are improved by the vitrified microbeads; strength and flexibility of the concrete are improved by the modified carbon fibers; early strength, impervious performance and chemical corrosion resistance of the concrete are improved by the silica fume, and accordingly, strength and heat resistance of the concrete are improved.

Owner:北京建工新型建材有限责任公司

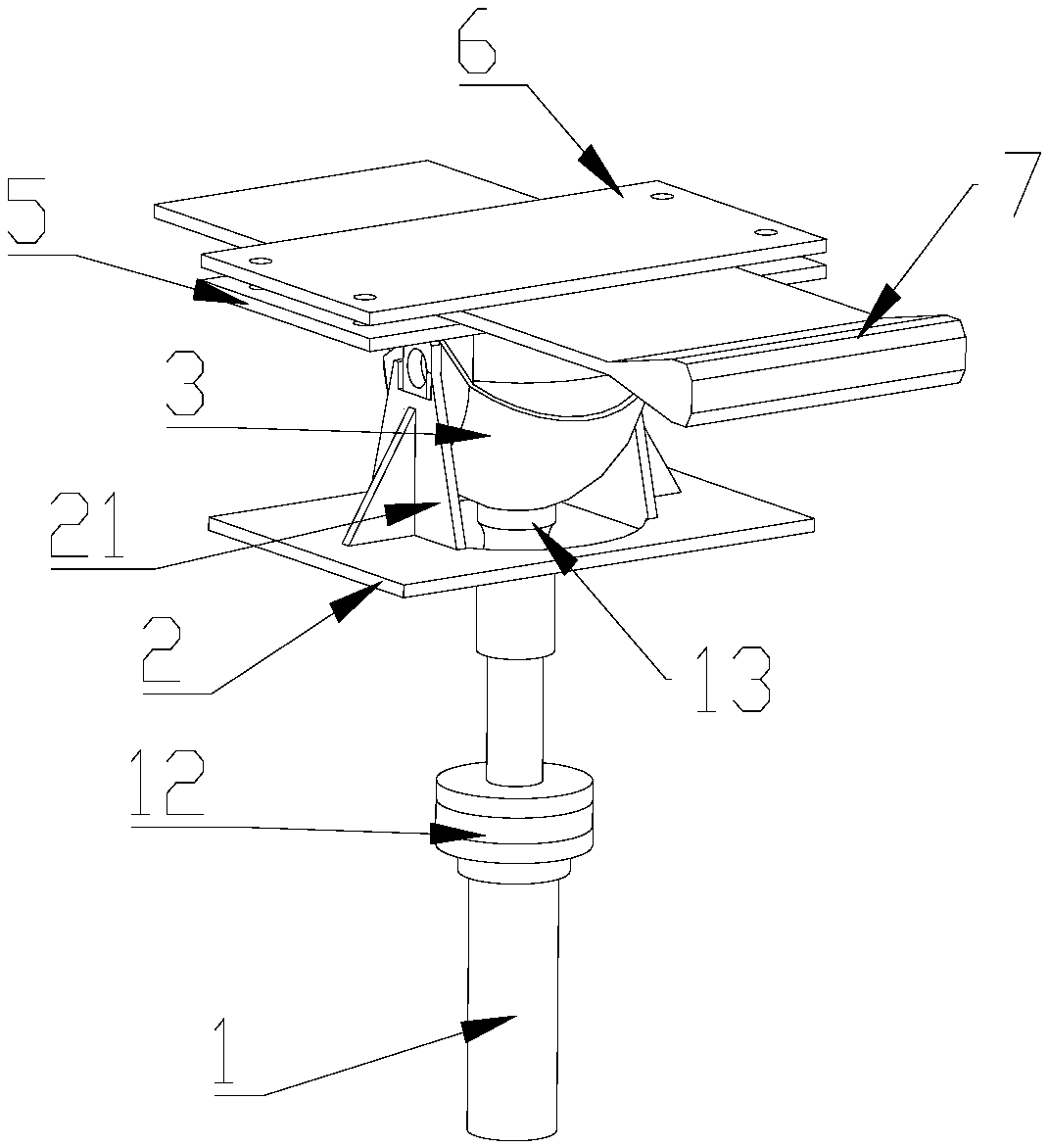

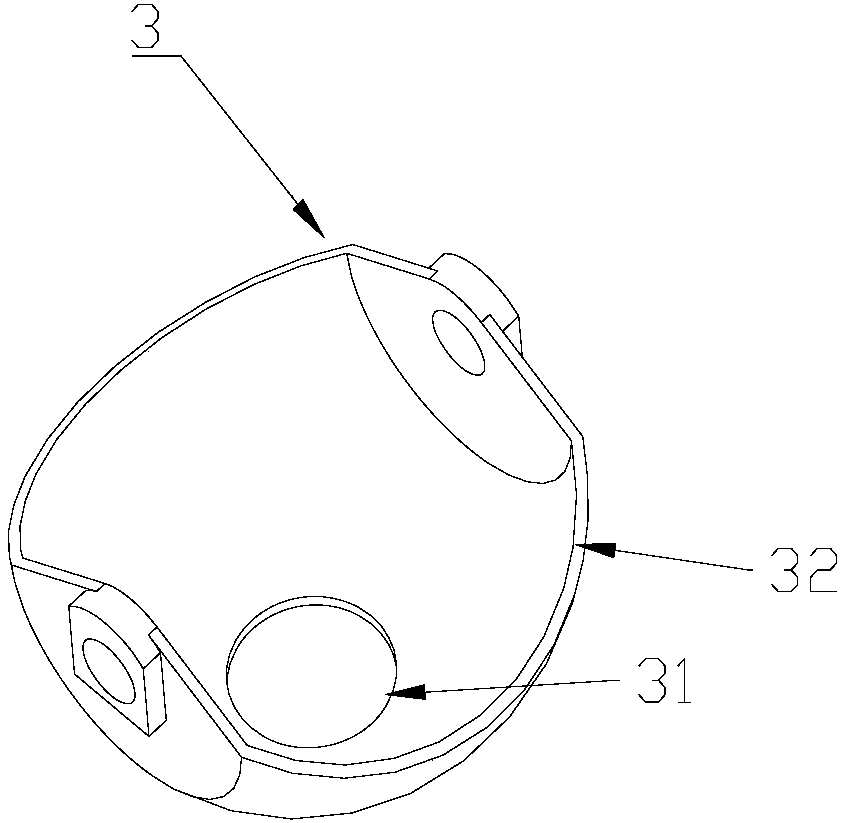

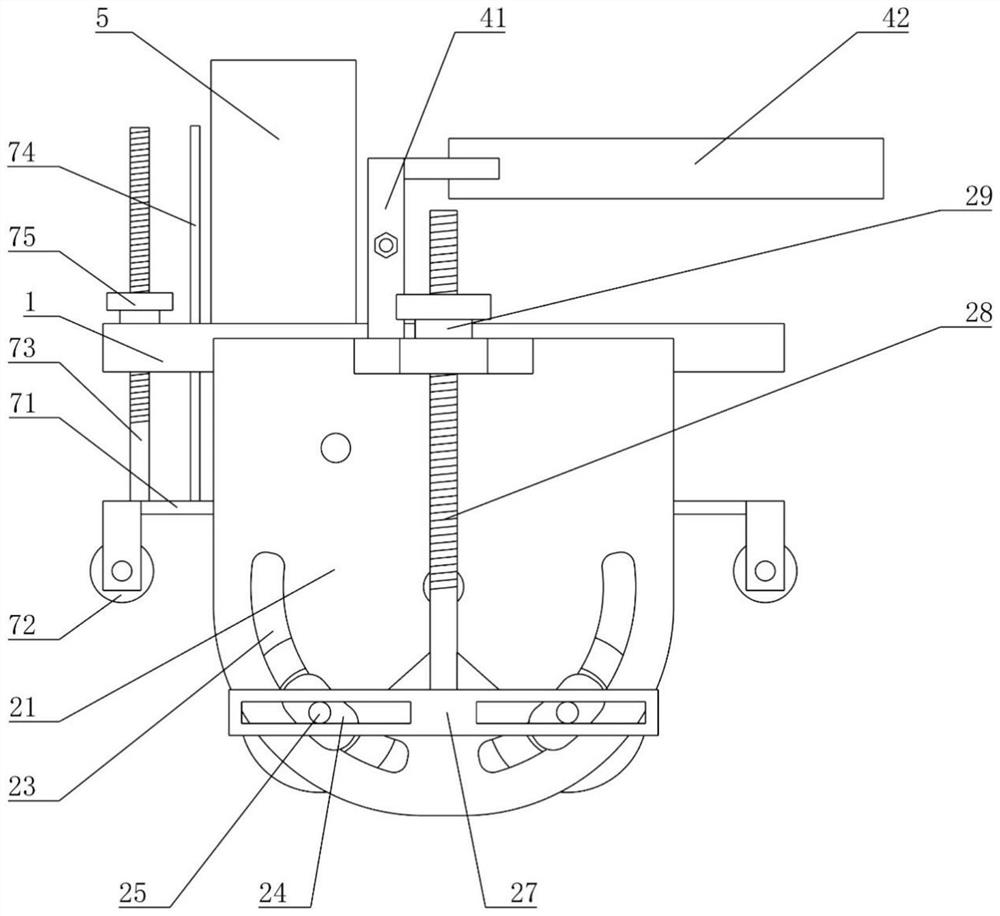

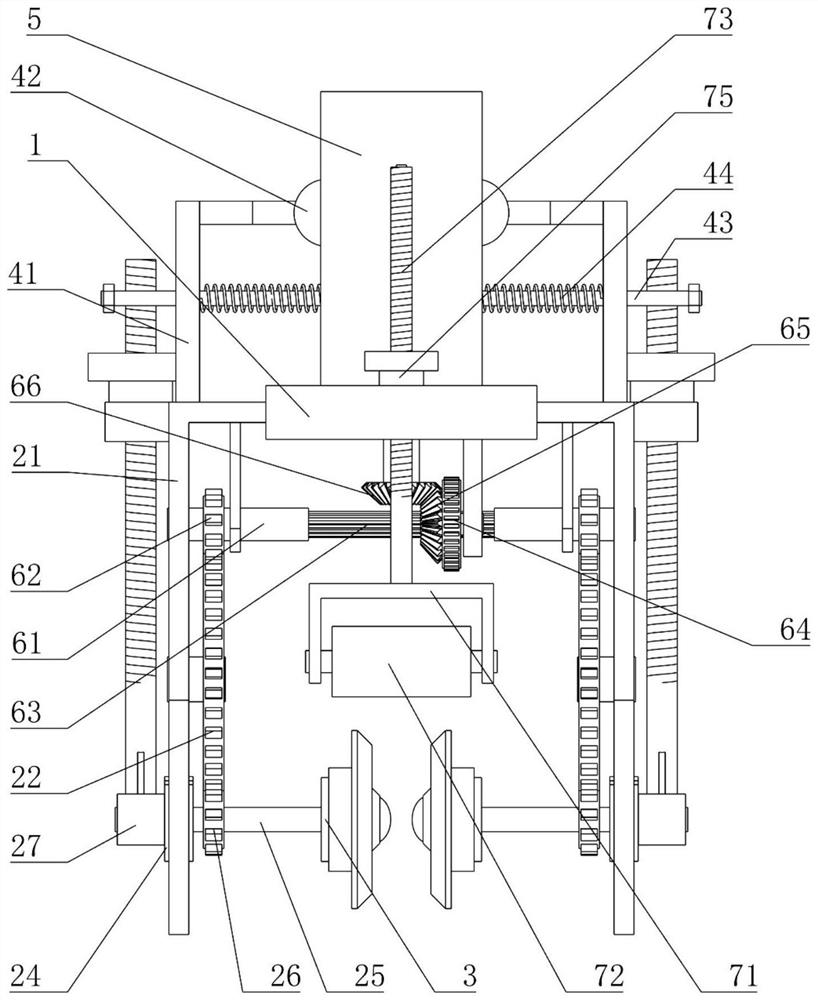

Swing type ultrasonic shot peening strengthening equipment

ActiveCN107630127AImprove strengthening efficiencyRealize multi-angle shot peeningEngineeringUltrasonic vibration

The invention discloses swing type ultrasonic shot peening strengthening equipment. The shot peening strengthening equipment comprises an ultrasonic vibrating device, a shot peening chamber and a blade clamping device, wherein the shot peening chamber comprises an outer chamber and an inner chamber for accommodating shots; the inner chamber is rotatably connected with the outer chamber; the ultrasonic vibrating device is fixedly connected with the outer chamber; and the inner chamber is fixedly connected with the blade clamping device. The shot peening device comprises the outer chamber and the inner chamber positioned in the outer chamber, the inner chamber can swing in the outer chamber to form a swing type shot peening chamber, the shortcoming of low shot peening efficiency is overcome,the problem that the angle of incoming of the shots is not adjustable is solved, the ultrasonic shot peening strengthening efficiency of a damping table can be improved effectively, multi-angle shotpeening strengthening on the damping table of blades of a fan is realized, and the real-time ultrasonic shot peening strengthening effect is enhanced.

Owner:蔡晋

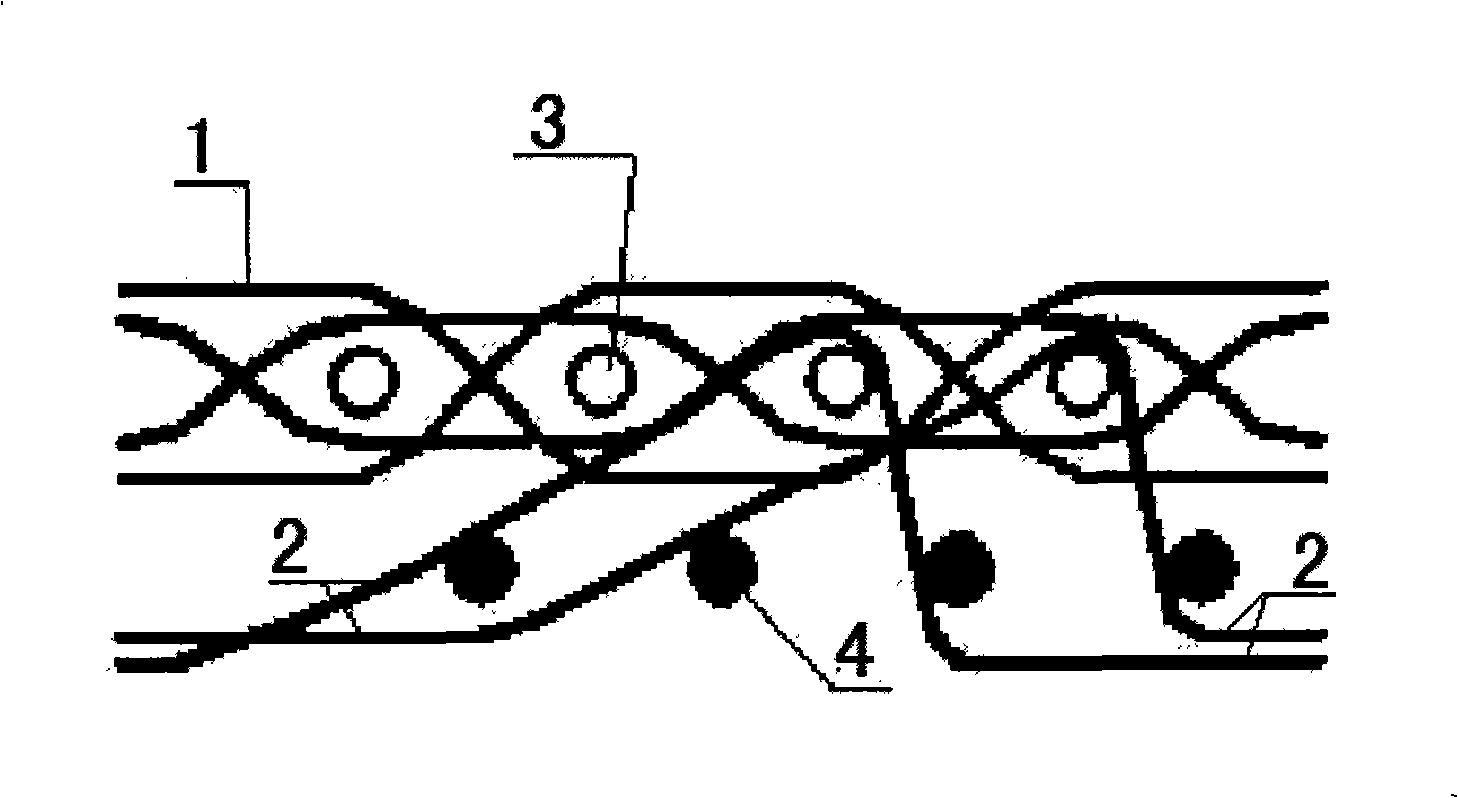

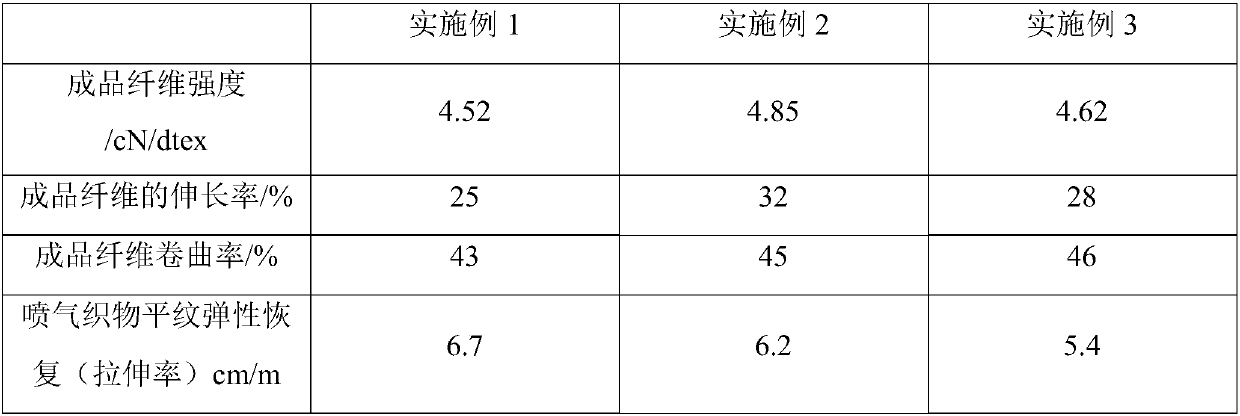

Pure cotton heavy bath mat weaving process

ActiveCN102691156AOvercome deformationOvercome elasticityBiochemical fibre treatmentBleaching apparatusYarnPulp and paper industry

The invention relates to a pure cotton heavy bath mat weaving process. Firstly fine staple cotton is spun into72.9tex of single yarns with the twist degree of 30-60 twists / 10cm, and then the single yarns are combined into four strands to make weak twist cone yarns with the twist degree of 15-25 twists / 10cm; then the weak twist cone yarns are warped and starched, and are woven into greige cloth by a variable-program beating-up loom with a specific fuzzing beating-up tissue; and the greige cloth is bleached through boiling, whitened, neutralized, softened, dried and sewed into a bath mat. According to the pure cotton heavy bath mat weaving process provided by the invention, pure cotton material is reasonably and effectively utilized in the field of bath mats, the defect that the bath mat made of the pure cotton material is deformed easily and has poor elasticity and poor durability, which can not be changed by technicists for a long time, are overcome, and the manufactured bath mat has the advantages of softness, comfort, good water absorbability, difficult generation of static electricity and the like of the pure cotton material, and can become a development trend of the bath mat weaving technology.

Owner:SUNVIM GROUP

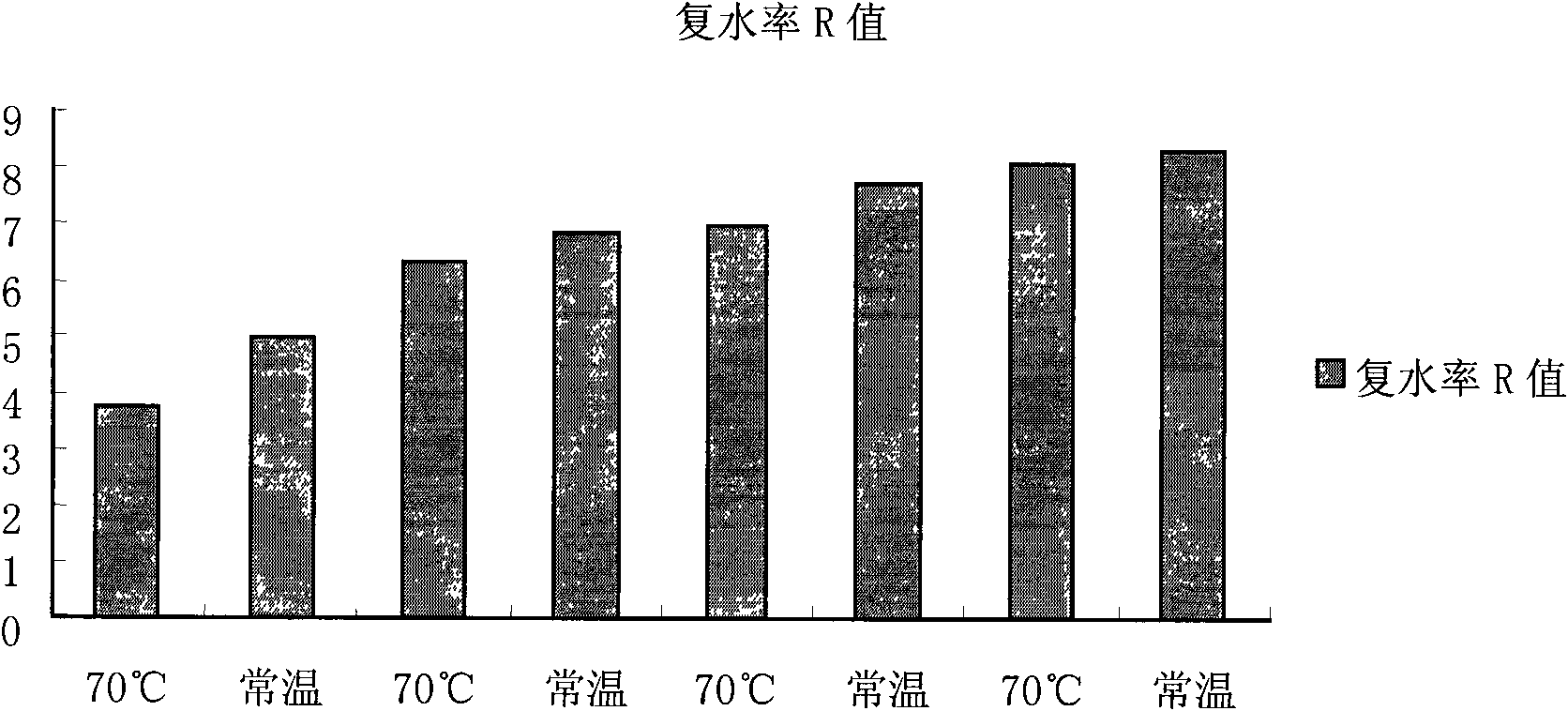

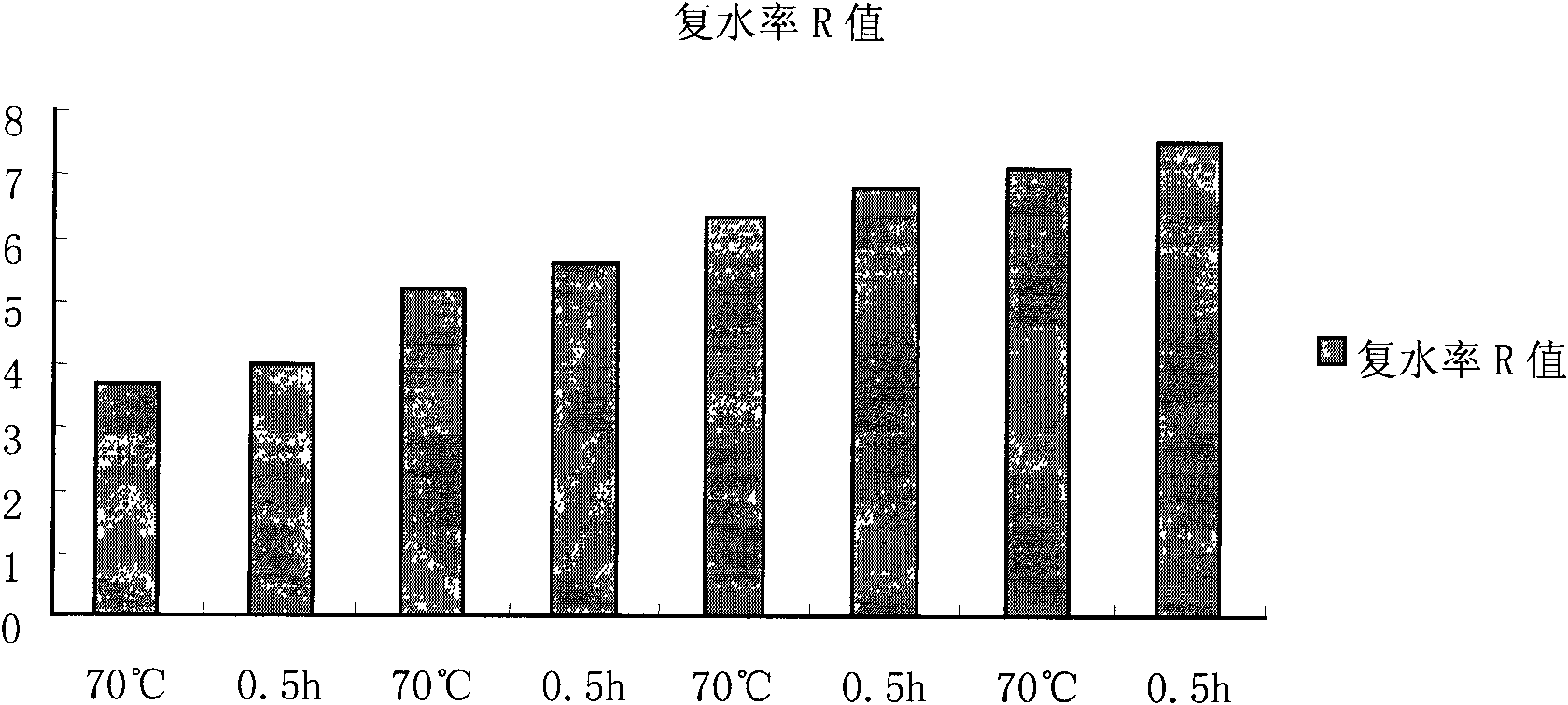

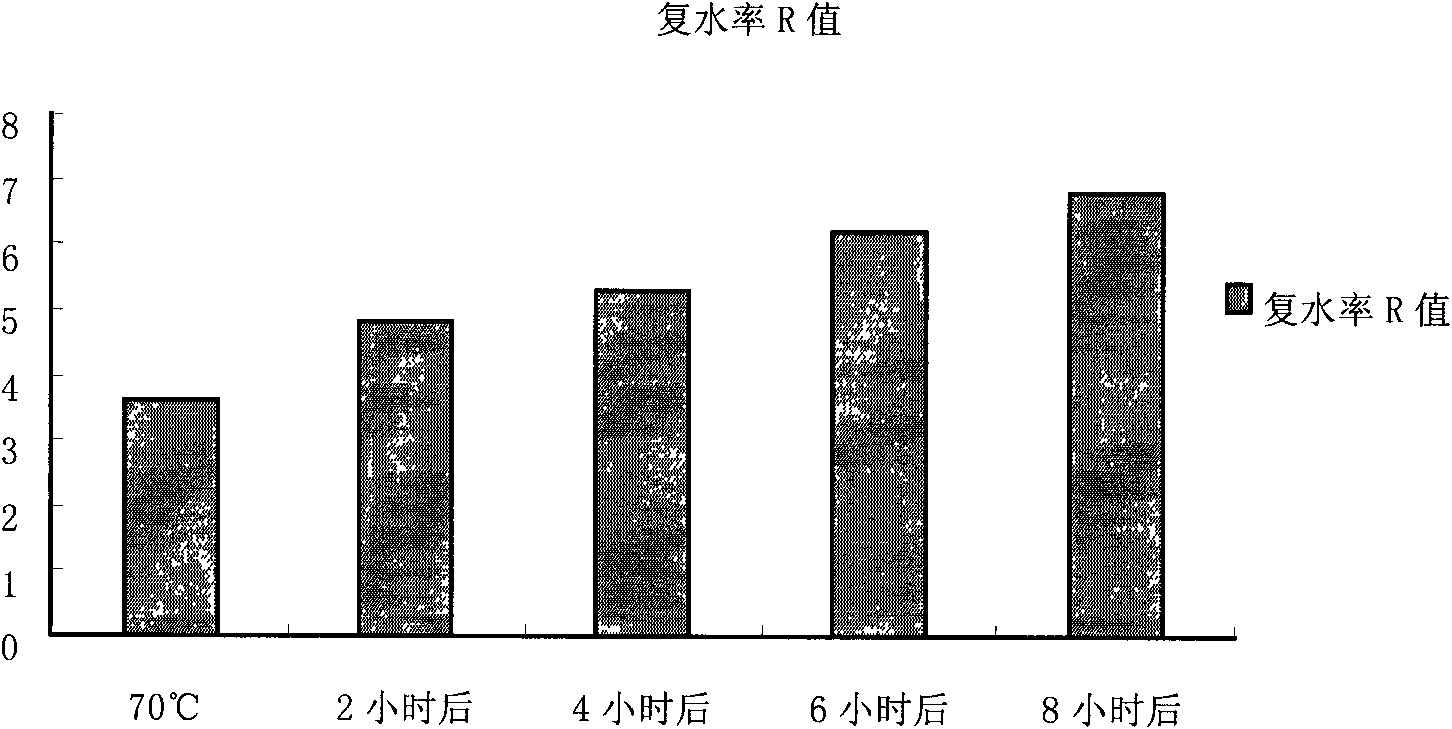

Processing method for rapidly rehydrating dried osmunds

The invention relates to a processing method for rapidly rehydrating dried osmunds, which is characterized by comprising a step of circularly immersing the dried osmunds in a heat soak solution and a normal temperature soak solution, wherein the dried osmunds are immersed for 1 h respectively in the heat soak solution and the cold soak solution each time, the temperature of the heat soak solution is 50-90 DEG C, preferably 70 DEG C, both weight ratios of the dried osmunds to the heat soak solution and the normal temperature soak solution are 1: (20-40), preferably 1: 30, and the total immersing time is 6-10h, preferably 8h. The rehydrating method adopted by the invention is short in immersing time, the rehydrated product has good quality, and the purpose of rapidly rehydrating is achieved so as to be beneficial for post-processing of the dried osmunds; meanwhile, the method optimizes rehydrating parameters and mode, thereby effectively enhancing the rehydrating effect and being beneficial for helping a producer shorten production duration better, save production cost and control quality and commercial performance of the product.

Owner:ZHEJIANG WANLI UNIV

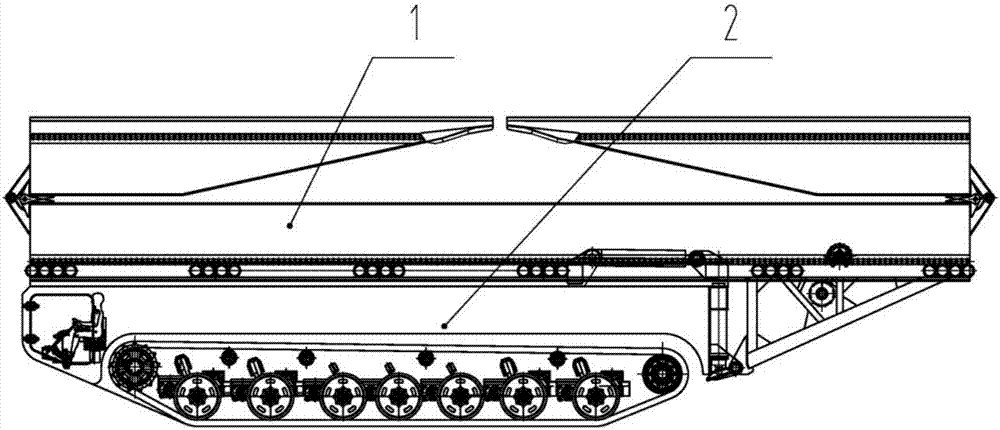

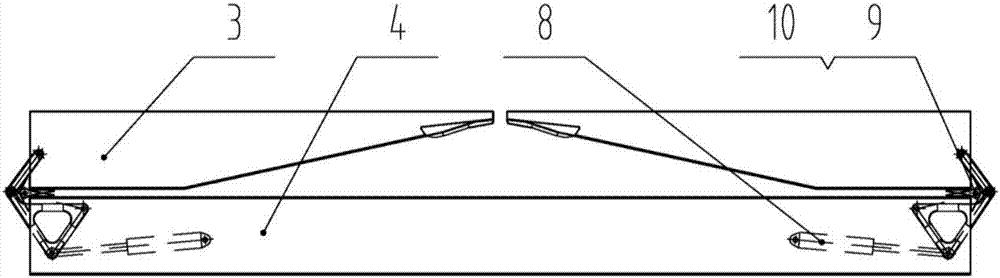

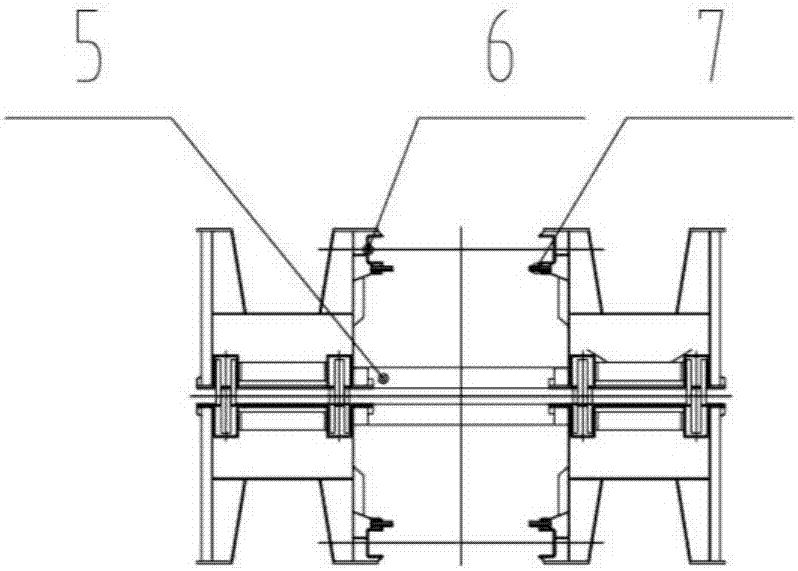

Amphibious mechanized bridge

InactiveCN107489091AAchieving amphibious operationsOvercoming small and medium gulliesBridge erection/assemblyPontoon bridge

Owner:CHINA HARZONE IND CORP

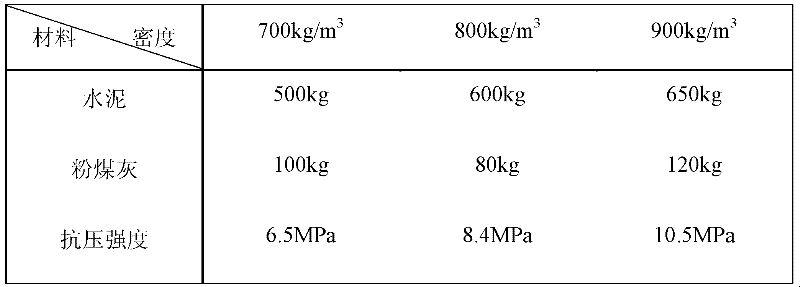

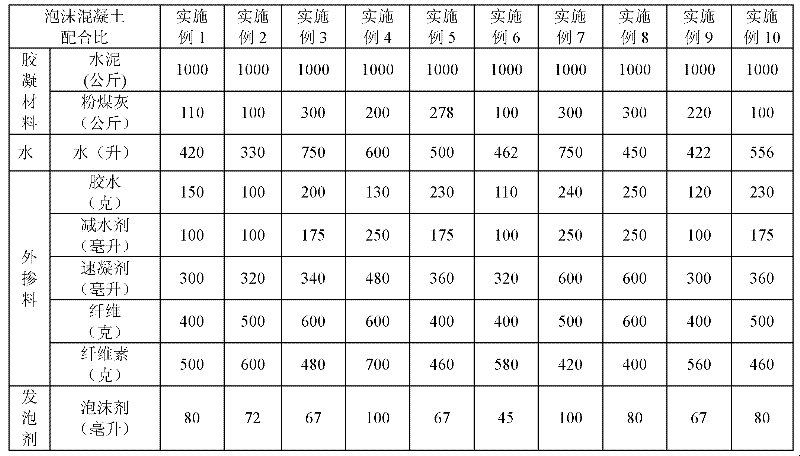

Foam concrete for wet-spraying support of coal mine and preparation method thereof

The invention relates to foam concrete for wet-spraying support of a coal mine and a preparation method. The foam concrete comprises a cementing material, water, an admixture and a foaming agent, wherein the cementing material is prepared from cement and fly ash, and the admixture comprises glue, a water reducing agent, an accelerating agent, fiber and cellulose. The invention can produce the foam concrete which not only has light weight and the functions of fire resistance, crack resistance, dynamic pressure resistance and the like, but also has great viscosity, and is particularly suitable for concrete spraying support operation of the coal mines and underground works. The formula can overcome the shortcomings of high rebound degree, large dust, incapability of ensuring spraying strength and the like during construction of a dry spraying method; and the problems of too fast solidification, pipe blockage and the like of an existing wet spraying method are also solved.

Owner:SHANDONG UNIV +2

Preparation of removing formaldehyde with phytoncide and wormwood extract and preparation method

InactiveCN108246065AEliminate pollutionOvercome CorrosivityDispersed particle separationSodium acetateZinc ricinoleate

The invention discloses a preparation of removing formaldehyde with phytoncide and a wormwood extract. The preparation comprises 2-4 parts of phytoncide, 25-26 parts of wormwood extract, sodium acetate, alanine and deionized water. A preparation method comprises the steps of: (1) heating the deionized water to 35-37 DEG C, putting in zinc diricinoleate for dispersion for 10min, (2) mixing phytoncide and the wormwood extract, continuously stirring to complete dissolution, and (3) continuing to add sodium acetate, and 2-3 parts of alanine for stirring for 1-2h. The preparation overcomes the disadvantages of chemical corrosion, short formaldehyde removal action time and high possibility of reappearance of formaldehyde of the traditional formaldehyde remover and the traditional odor removal agent. After dilution by 500-1000 times, the preparation can effectively and persistently reduce a formaldehyde content indoors and quickly remove a peculiar smell by an atomization or spraying method,and therefore, effectively eliminates the urgent problem of formaldehyde pollution caused by interior decoration.

Owner:于思海

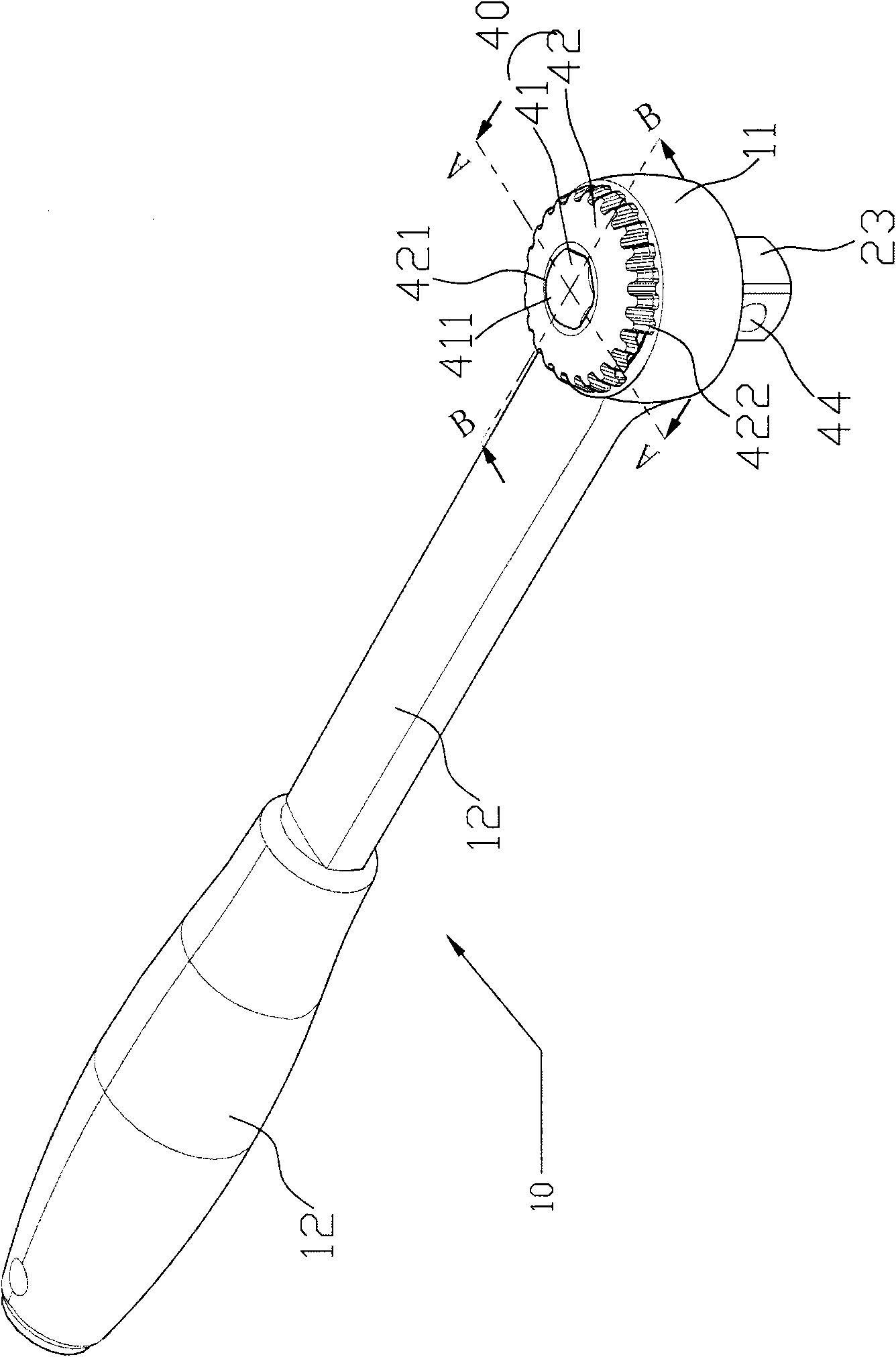

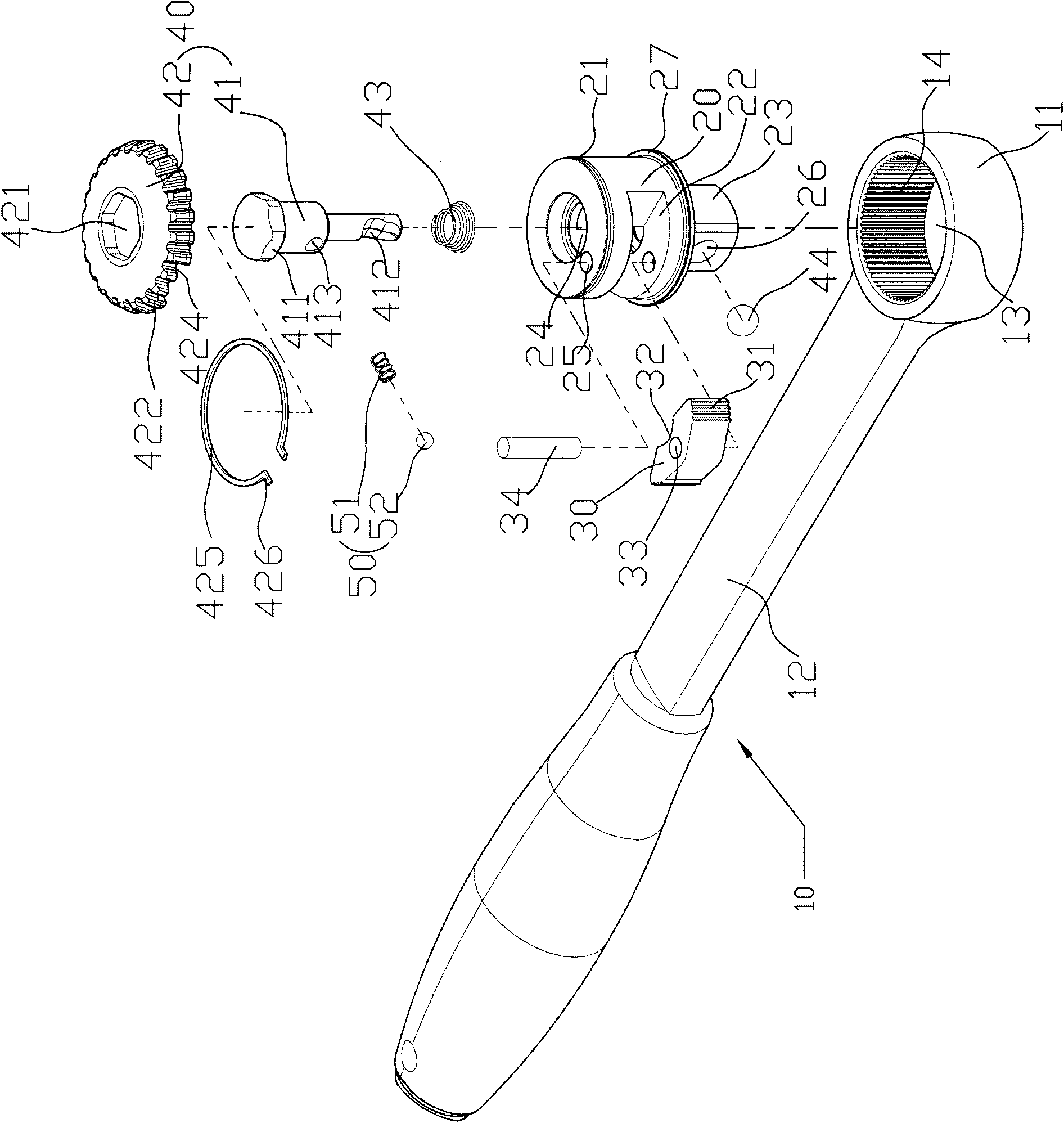

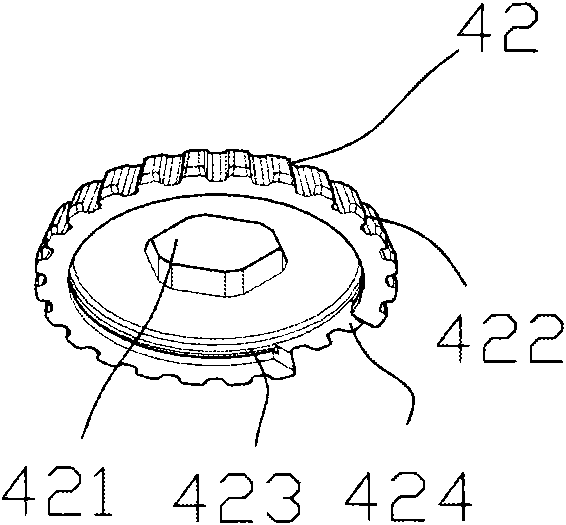

Ratchet spanner

The invention discloses a ratchet spanner, comprising a body, a driving piece, at least one clamping piece, a reversing device and a push device, wherein the reversing device comprises a control piece and a toggling piece; the control piece can be rotatably arranged in an axle hole of the driving piece, one end of the control piece is provided with a clamping part, the push device is arranged in the clamping part and is elastically butted against the positioning part of the clamping piece; the toggling piece is pivoted on one end of the driving piece and is provided with a clamping hole in which the clamping part of the control piece can be held, and the toggling piece can be interlocked with the control piece to rotate. The ratchet spanner of the invention adopts the design of separating the control piece from the toggling piece, so that when being accidentally touched, the toggling piece can not be interlocked with the control piece to move down, and a sleeve barrel combined with the combination part of the driving piece can not be accidentally separated, thereby ensuring the ratchet spanner to be considerably safe and reliable; and the ratchet spanner has the advantages of easy and fast processing, reduced production cost and better structural strength.

Owner:胡厚飞

Anti-drop socket-clevis eye

InactiveCN101908747AOvercoming easy wear (breakage) damageOvercoming deformationOverhead installationEngineeringInverted t

The invention discloses an anti-drop socket-clevis eye which belongs to connection devices of high-voltage line hardware and mainly overcomes the defect that a ball head of a ball head hanging ring is easy to eject from the socket-clevis eye as a spring bolt structure is not reasonable in the traditional socket-clevis eye. The anti-drop socket-clevis eye comprises a socket-clevis eye which is provided with a jack and an inverted T-slot, wherein the jack is communicated with one end of the inverted T-slot. The anti-drop socket-clevis eye is characterized by also comprising an anti-drop baffle plate and fastening bolts, wherein the anti-drop baffle plate comprises a bottom plate and a vertical plate connected with the upper side of the bottom plate, the fastening bolts are used for connecting the socket-clevis eye with the anti-drop baffle plate, a bolt bottom plate through hole is arranged at one end of the bottom plate, a lug boss which is provided with a bolt hanging plate through hole is arranged at the notch end of the inverted T-slot of the socket-clevis eye, the other end of the bottom plate and the vertical plate are respectively positioned in the jack of the socket-clevis eye and at the notch end of the inverted T-slot, and the fastening bolts are positioned in the bolt bottom plate through hole and the bolt hanging plate through hole. The invention has the advantages of simple structure, convenient disassembly, assembly and overhauling and good anti-drop effect.

Owner:WUHAN HAIXIANG ELECTRIC POWER CIRCUITRY SHOCKPROOF GOLDTOOL

Narrow distillate alpha-olefin derived alkylbenzene sulfonate and its synthesis method and uses

InactiveCN1800159ASimple ingredientsImprove product qualitySulfonic acids salts preparationDrilling compositionCarbon numberSynthesis methods

The invention relates to an alkyl benzene sulfonate surface catalyst of the narrow cut alpha-olefin derivatize and its synthesis method and the applied in teritary oil extraction. 1) Choosing perfume raw material (such as benzene, toluene, ethylbenzene, xylene, propyl benzene, cumene or their any mixing substance) to react with the alpha-alkene with the average carbon number 14-24(each raw material is the narrow cut whose carbon chain distribute is less than 3 carbon atoms) to prepare for the narrow carbon chain distributed alkyl perfume compound; 2) Preparing for the narrow carbon chain distributed alkyl benzene sulfonate by sulfonation and inactivating the alkyl perfume compound from the step 1). The alkyl benzene sulfonate with different chain long is single used or matched with the base to form oil displacement surface catalyst product.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

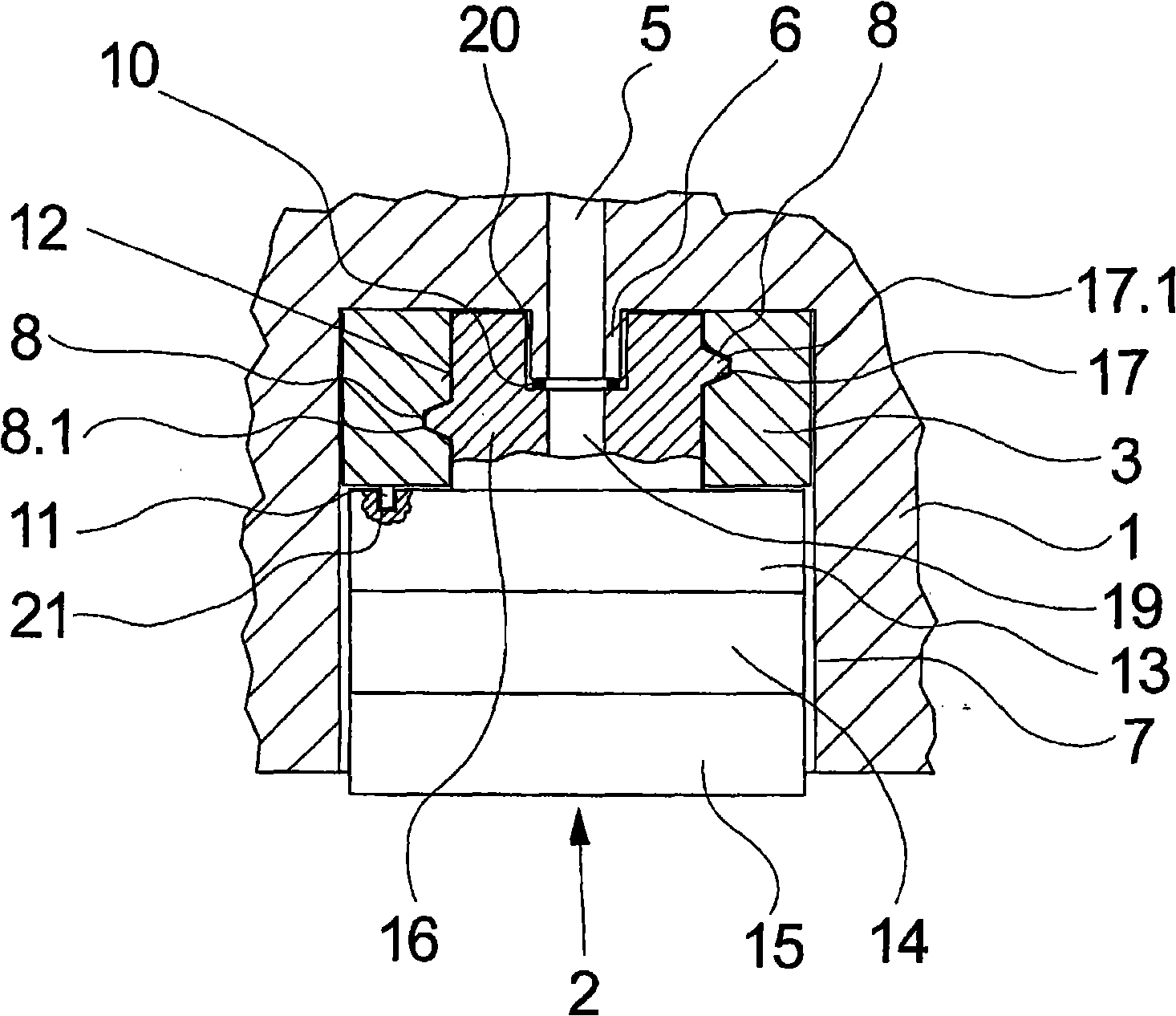

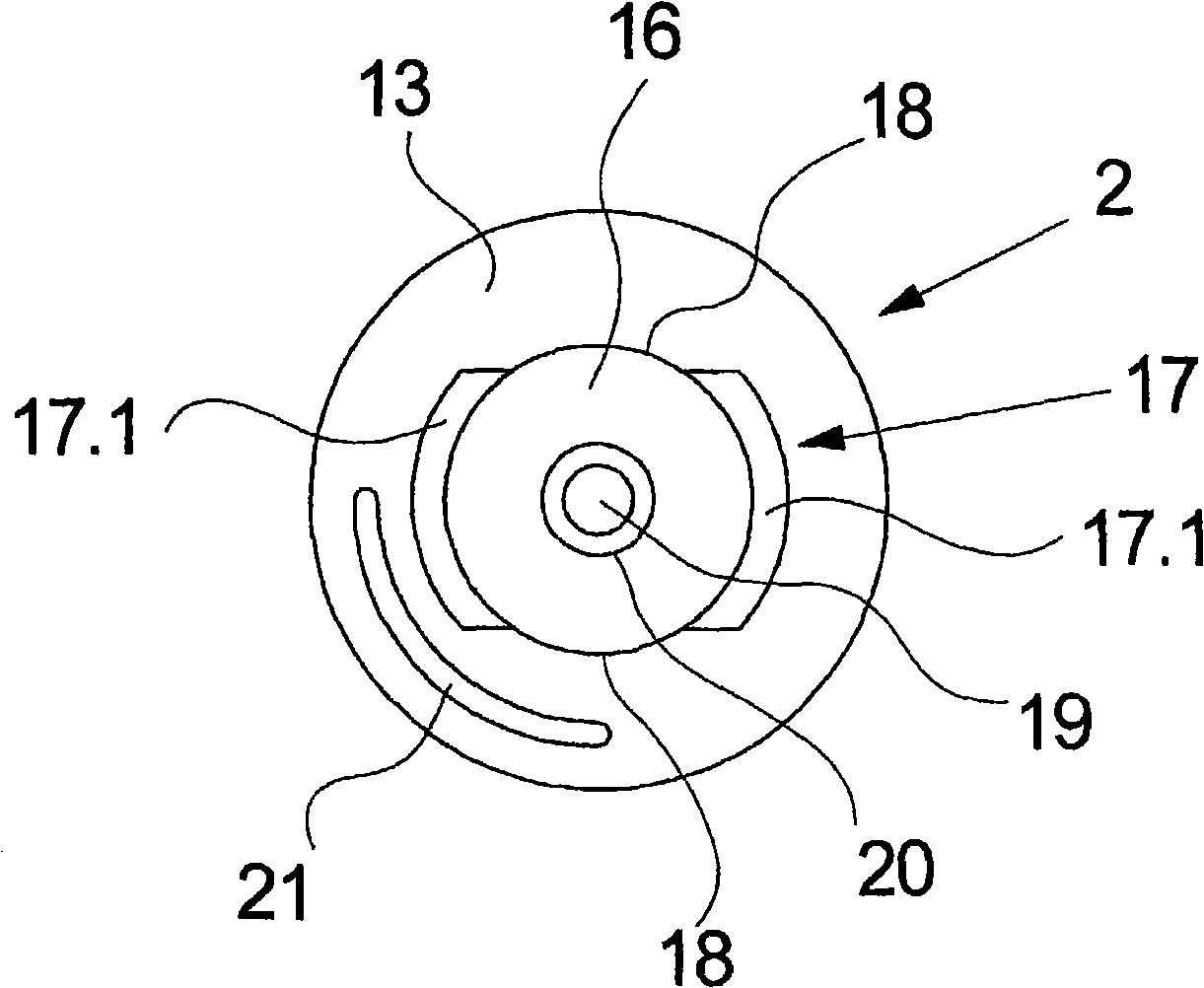

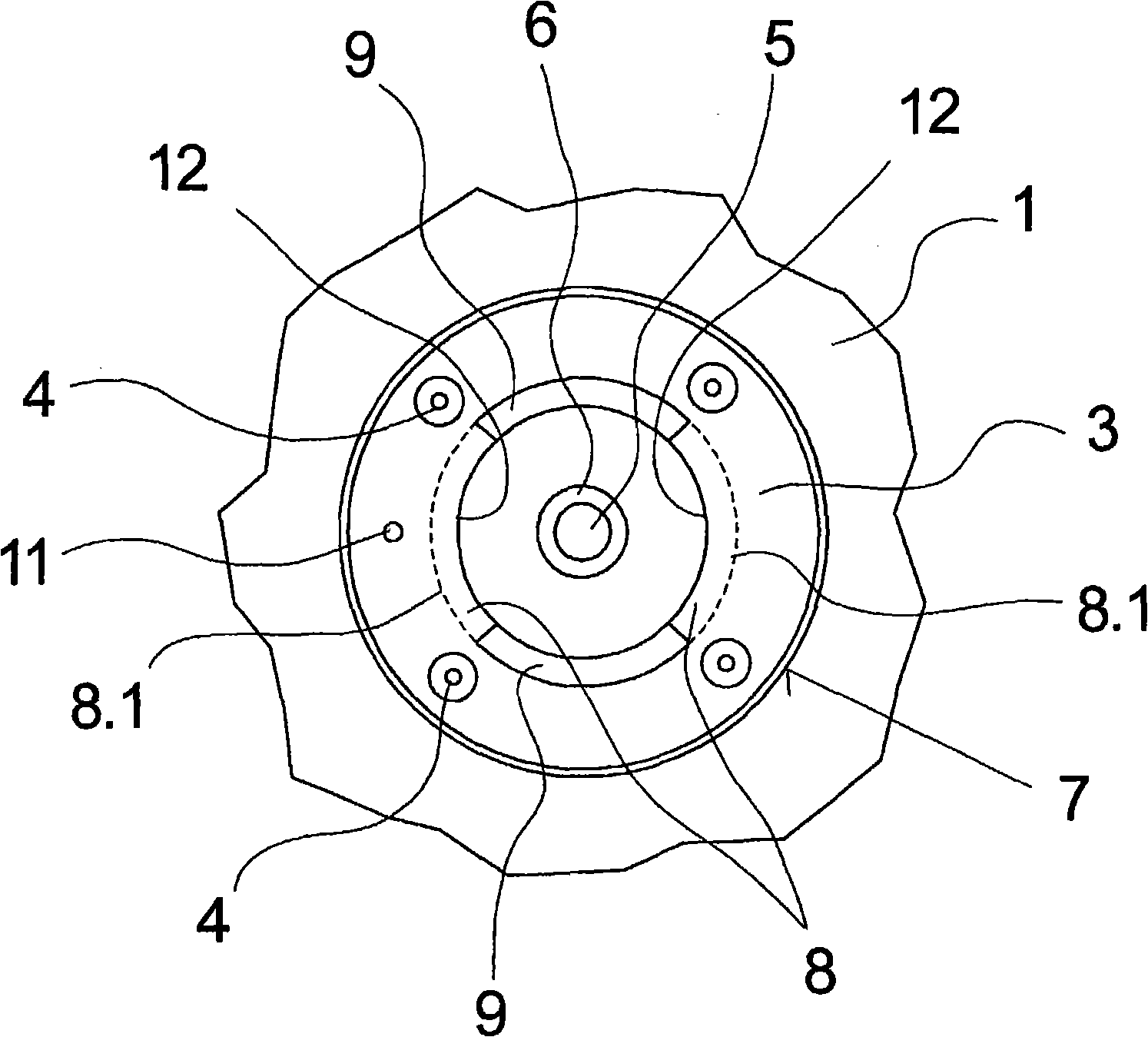

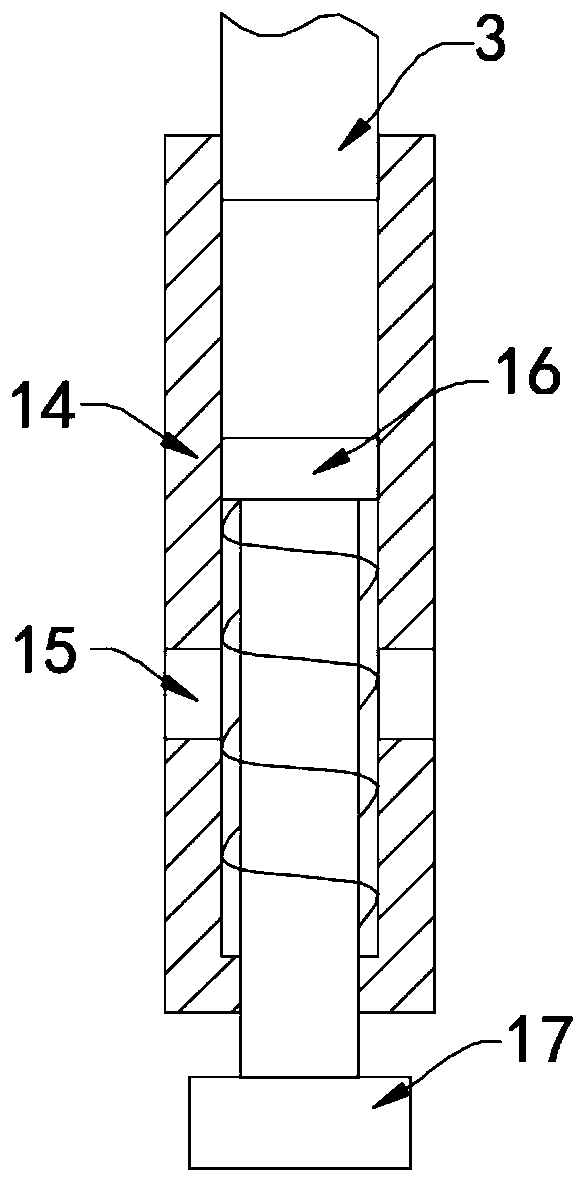

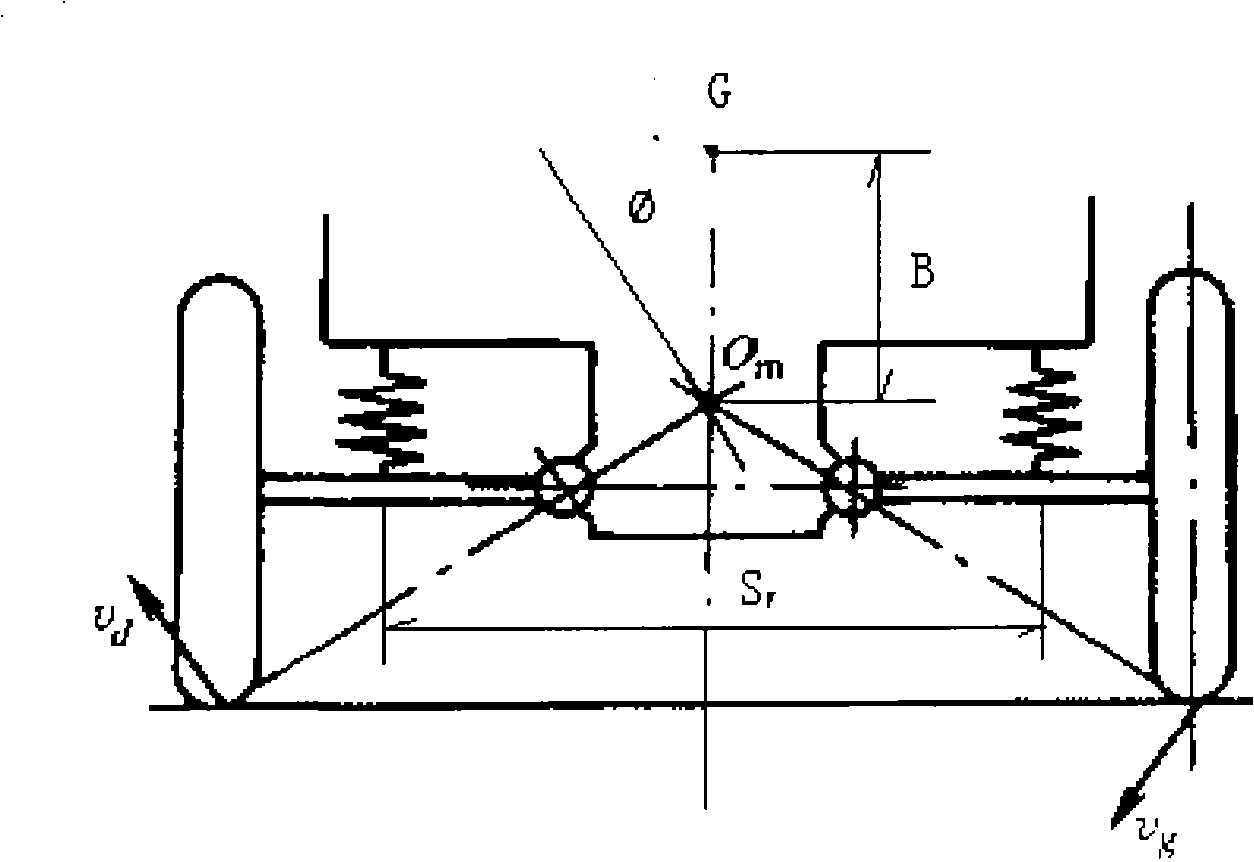

Spinning device

InactiveCN101275297APrecise trackAchieving plate-like structural formsSpinnerette packsEngineeringScrew thread

The invention relates to a spinning device for melting and spinning a plurality of single filament, having a nozzle holder and a detachable spinning nozzle assembly held on a melt joint of the nozzle holder with a melt inlet. The nozzle holder has a holding part for accepting the spinning nozzle assembly with thread screw at the lower side for fixing function. The spinning nozzle assembly has a corresponding holding part with corresponding thread screw for cooperation with the holding part. For fixing and high sealing between the spinning nozzle assembly and the nozzle holder with partly rotation, according to the invention, the corresponding thread screw forms from external thread screw of a thread section with one full circle only on the corresponding holding part. The thread section is a plurality of thread gaps on circumference direction. The thread screw forms from inner thread of a thread groove with one full circle only on the holding part. The thread groove stops by a plurality of thread cuts in circumference. The thread gap of the external thread has an arc size more than that of the thread cut of the inner thread each. The quantity of the thread gap is identical with that of the thread cut.

Owner:OERLIKON TEXTILE GMBH & CO KG

TiC-particle-reinforced titanium-aluminum-molybdenum alloy material by in-situ synthesis and preparation method thereof

The invention discloses a TiC-particle-reinforced titanium-aluminum-molybdenum alloy material by in-situ synthesis. The alloy material comprises, by mass, 0.2%<=Al<=2.5%, 0.5%<=C<=1.5%, 2.5%<=Mo<=3% and the balance Ti and inevitable impurities. The alloy material is prepared according to a method including: 1) compounding by weighing powdered aluminum, graphite powder, molybdenum powder and titanium powder of a corresponding quantity according to the mass percent; 2) ball-milling and mixing; 3) pressing mixture subjected to ball milling and sieving by means of bidirectional mould pressing; 4) placing a green pressing on a cathode of a vacuum container; 5) regulating the vacuum degree in a furnace; and 6) performing particle bombardment sintering for the pressing and the cathode after argon gas reaches the working gas pressure. Carbon substitutes for part of aluminum to serve as an alloying element to be introduced to alloy, and a means that high-melting-point dispersed TiC particle phases are introduced to reinforce a matrix by solid solution strengthening of C and hollow cathode rapid sintering in-situ reaction, so that the TiC-particle-reinforced titanium-aluminum-molybdenum alloy material which is high in strength and wear resistance and low in cost is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

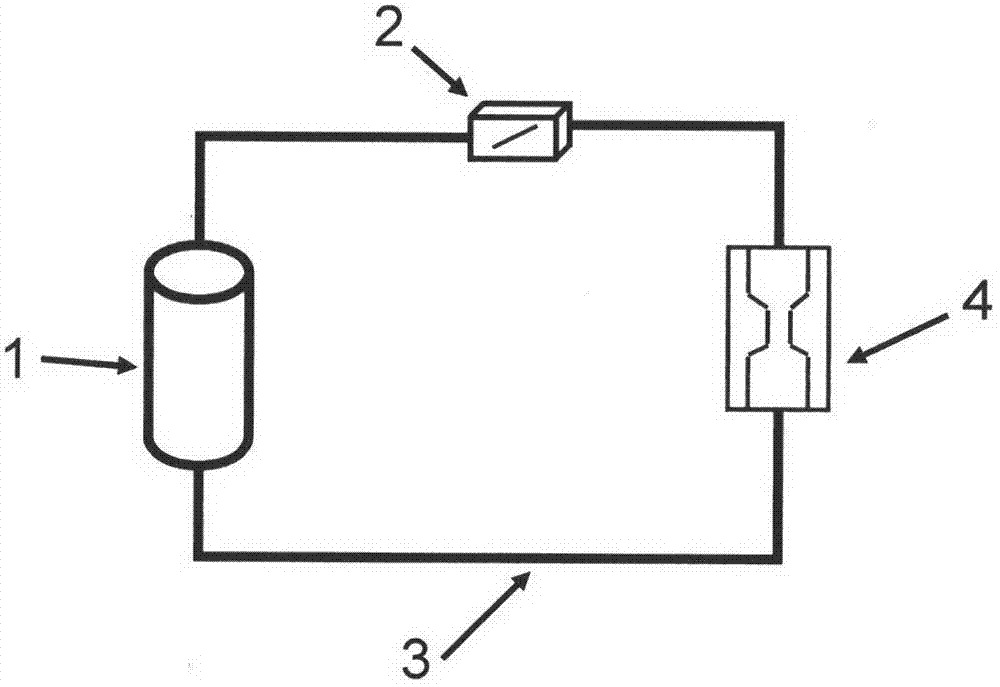

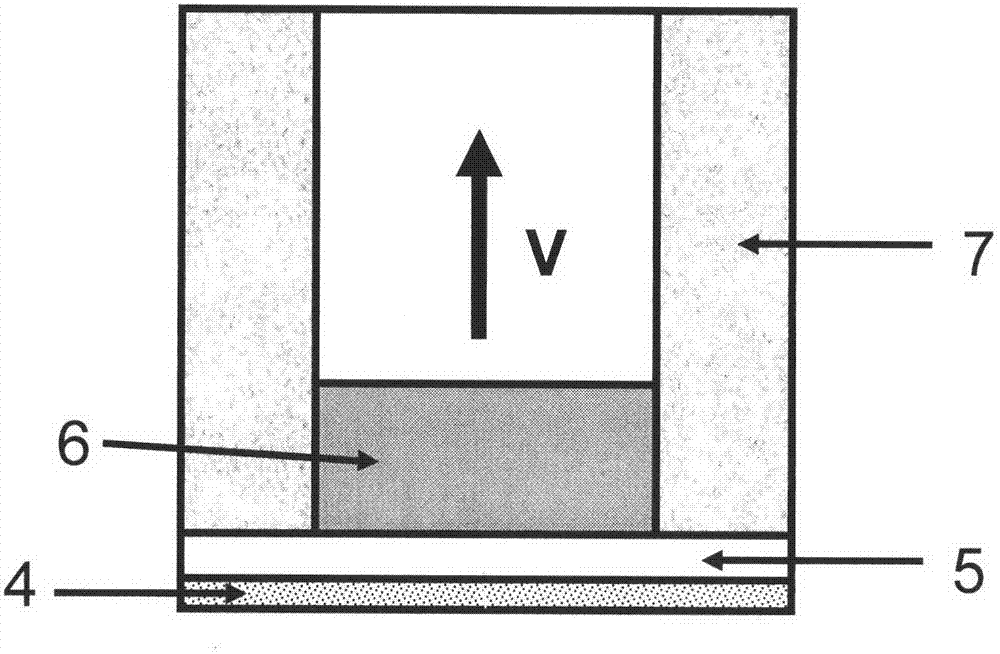

Automatic pressure-stabilizing descaling water heater

ActiveCN110986355AEfficient separationAvoid conditions that affect useWater heatersThermodynamicsEngineering

The invention belongs to the field of household appliances, and especially relates to an automatic pressure-stabilizing descaling water heater. The water heater comprises a water tank, a heating pipe,a heating pipe and a water outlet pipe. The heating pipe is arranged at the inner top surface of the water tank, the water inlet pipe and the water outlet pipe fixedly communicate with the upper endand the lower end of the water tank, two sliding blocks with U-shaped sections are arranged in the water tank, the two sliding blocks are symmetrically arranged relative to a heat receiving pipe and are in sealed sliding connection with the side wall of the water tank, an upper plate and a lower plate are arranged between the two sliding blocks, the opposite faces of the upper plate and the lowerplate are connected with the inner side walls of the sliding blocks through extension springs and are in sealed sliding connection with the side walls of the sliding blocks, permanent magnets with thesame polarity attracting each other are fixedly embedded in the opposite side walls of the upper plate and the lower plate, a plurality of upper through holes are formed in the upper plate, a plurality of stand columns matched with the upper through holes are arranged on the lower plate, and a plurality of lower through holes are formed in the lower plate. By arranging the descaling mechanism, scale on the heating pipe is scraped off along with up-down movement of an induction coil on the heating pipe, and cleanliness of the heating pipe can be effectively guaranteed.

Owner:金迪(聊城市)知识产权运营有限公司

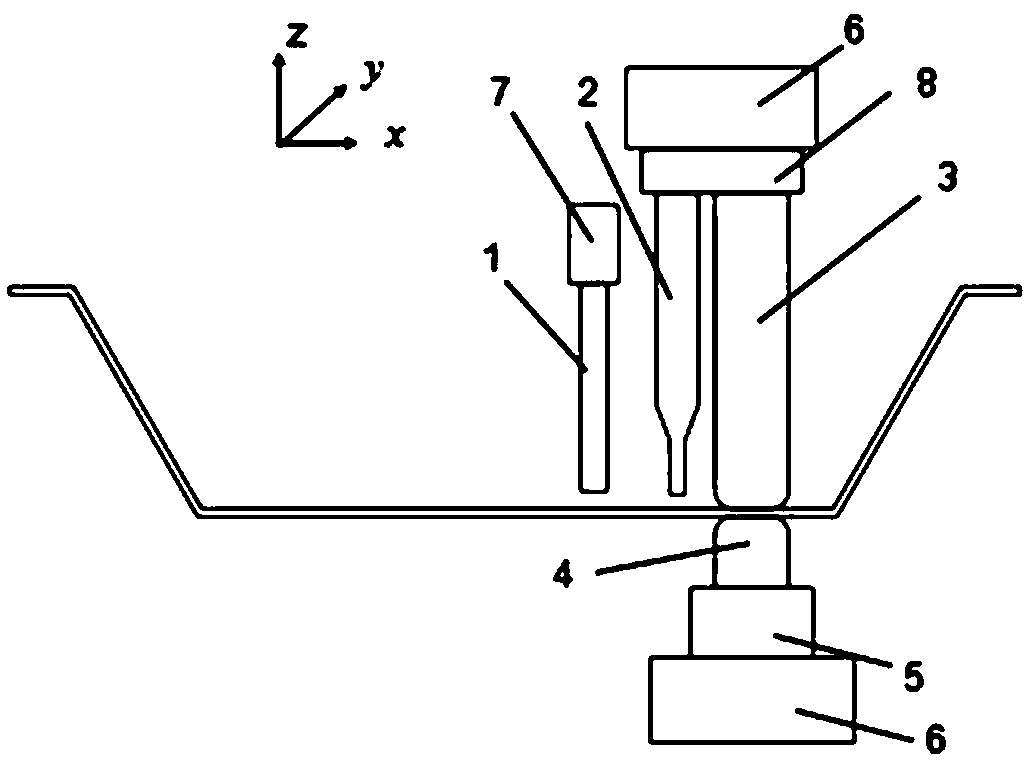

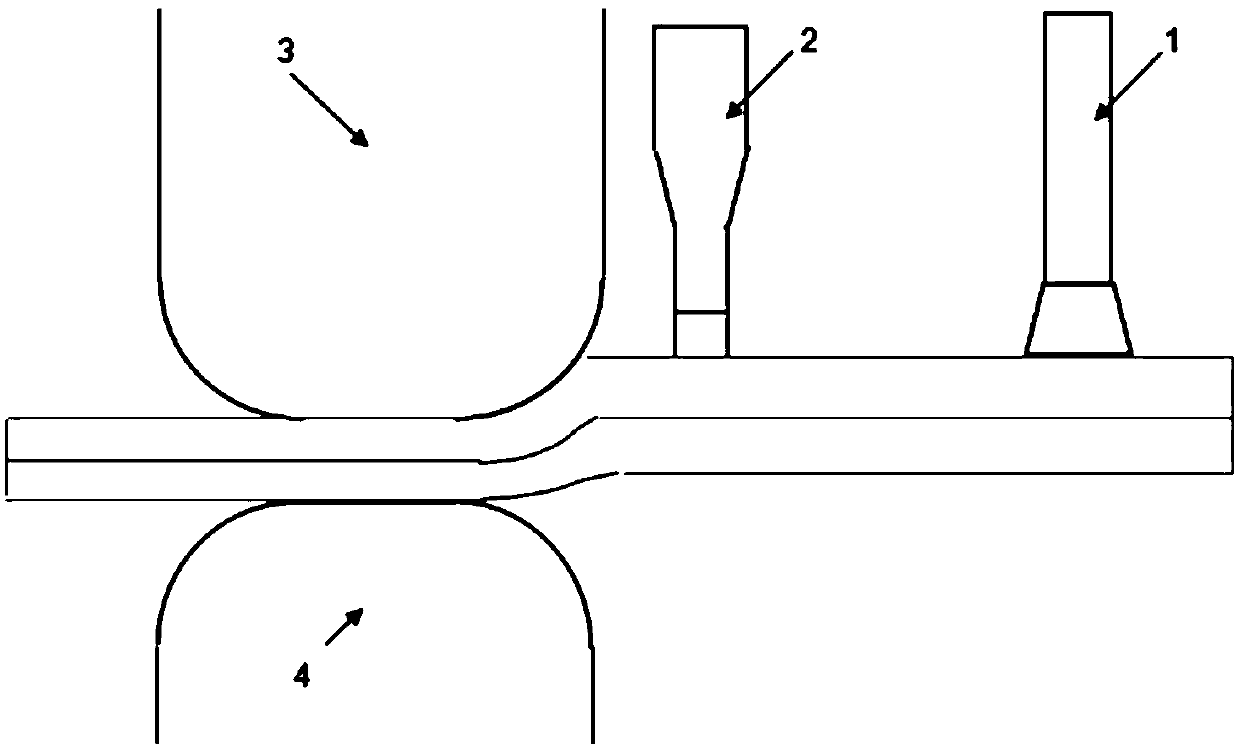

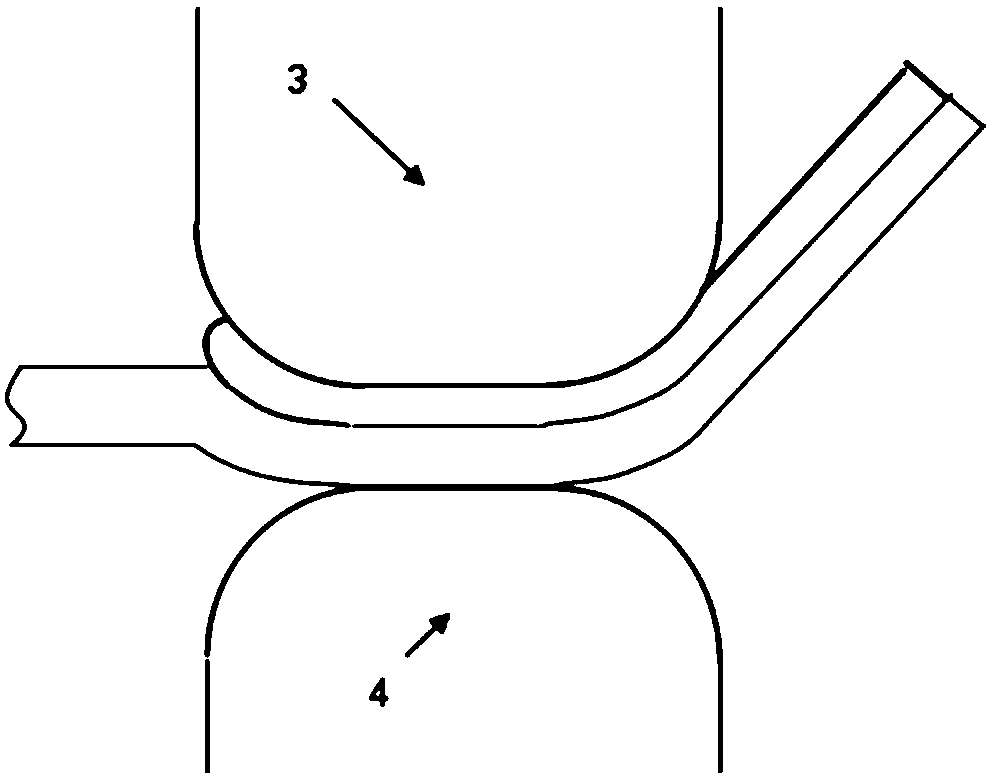

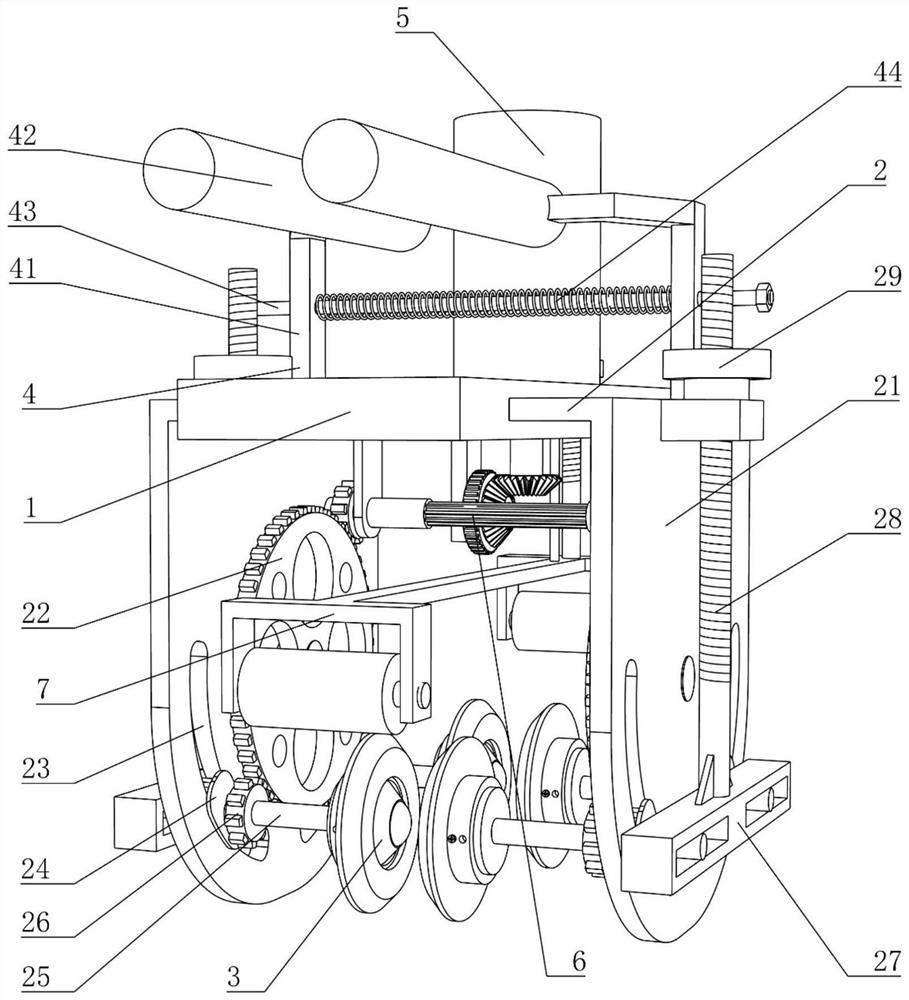

Sheet metal compound forming device and method

ActiveCN109622960AReduced processing performanceLow costAdditive manufacturing apparatusIncreasing energy efficiencyIntegrated operationsEngineering

The invention relates to a sheet metal compound forming device and method. The device comprises a driving tool head module, an auxiliary tool head, a backpressure air cylinder, powder spray heads, a first driving module and a second driving module, wherein the driving tool head module comprises a bracket, a laser device installed on the bracket, and a driving tool head installed on the bracket; the driving tool head is opposite to the auxiliary tool head, to-be-machined sheet metal is arranged between the driving tool head and the auxiliary tool head, and the two ends are fixed by fixtures; the auxiliary tool head is connected with the backpressure air cylinder; the first driving module is connected with the bracket and the backpressure air cylinder and drives the tool head and the auxiliary tool head to move synchronously; the powder spray heads are installed on the same side of the driving tool head; and the second driving module is connected with the powder spray heads. Compared with the prior art, according to the sheet metal compound forming device and method, the additive manufacturing technique and the incremental forming technique are combined, compound machining and incremental forming machining integrated operation on heterogeneous metal laminated plates is achieved, the machining procedure and cost are reduced, and the production efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

TiC particle-reinforced titanium-aluminum-molybdenum-silicon alloy material synthesized in situ and preparation method thereof

The invention discloses a TiC particle-reinforced titanium-aluminum-molybdenum-silicon alloy material synthesized in situ. The alloy material consists of the following components in percentage by mass: more than or equal to 0.2 percent and less than or equal to 2.5 percent of Al, more than or equal to 0.5 percent and less than or equal to 1.5 percent of C, more than or equal to 2.5 percent and less than or equal to 3 percent of Mo, more than or equal to 0.2 percent and less than or equal to 0.4 percent of Si and the balance of Ti and inevitable impurities. The alloy material is prepared with a method comprising the following steps of: (1) preparing materials: weighing corresponding amounts of aluminum powder, graphite powder, molybdenum powder, silicon powder and titanium powder according to the percentage by mass; (2) mixing through ball milling; (3) making a mixture sieved through ball milling in the step (2) pass through a bidirectional die pressing green compact; (4) placing a green compact onto the cathode of a vacuum container; (5) adjusting the vacuum degree in a furnace; and (6) after argon reaches the working air pressure, sintering a blank and the cathode through particle bombardment. Carbon serving as an alloying element is introduced into an alloy instead of a part of aluminum, and a measure for introducing a high-melting-point diffused TiC particle phase-strengthened substrate through solution strengthening of carbon and a rapid sintering in-situ reaction of a hollow cathode is used, so that a low-cost particle-reinforced alloy material with high strength and high wear resistance is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Deburring device for aluminum alloy formwork for building

ActiveCN113601310AAdjustable spacingSpeed up deburring workEdge grinding machinesGrinding carriagesGear wheelElectric machinery

The invention discloses a deburring device for an aluminum alloy formwork for a building, and belongs to the technical field of grinding tools. The deburring device comprises a base, two grinding assemblies symmetrically and slidably mounted on the two sides of the base, and a control assembly used for driving the two grinding assemblies to abut against the grinding position. A motor is arranged on the base, and a transmission assembly used for connecting the motor with a first gear is arranged below the base. According to the deburring device, the base, the grinding assemblies, the control assembly, the transmission assembly and the motor are arranged, the two grinding assemblies can clamp the aluminum alloy formwork through the control assembly, and the motor drives grinding heads to rotate through the transmission assembly; the two grinding heads are arranged on each grinding assembly, so that the device can conduct deburring work on the four edges of two through holes at the same time, and the working efficiency is greatly improved; and the distance between the grinding heads is adjusted by arranging a first adjusting sleeve, a first lead screw, a limiting frame and other components, and thus the device can be used for deburring work of the through holes of the aluminum alloy formworks with different hole distances.

Owner:邳州市景鹏创业投资有限公司

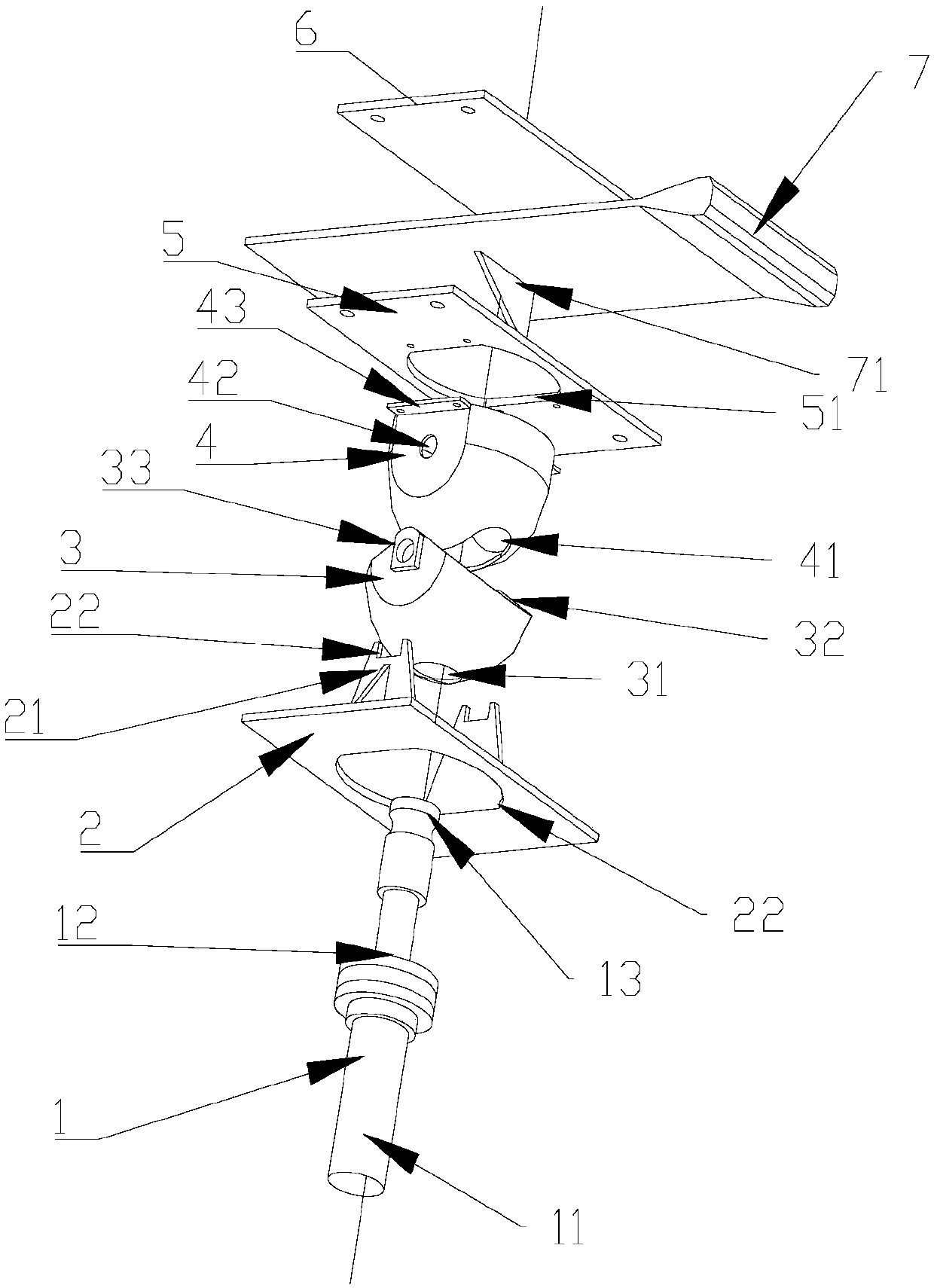

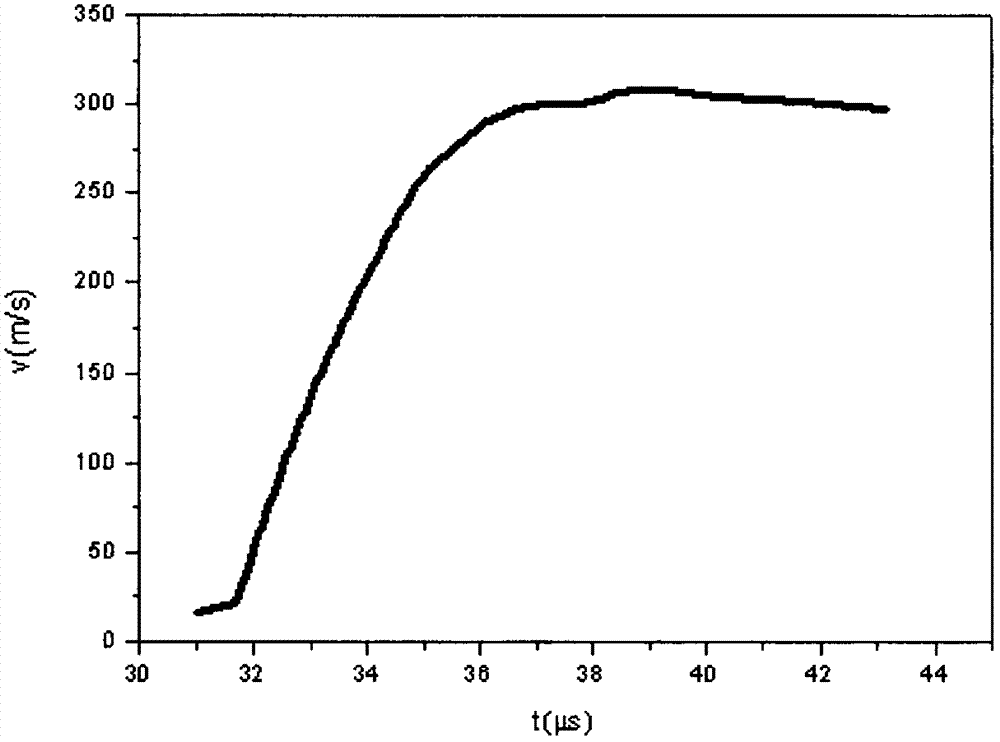

Discharge-induced explosion loading driving device

The invention discloses a discharge-induced explosion loading driving device, which comprises a gun barrel (7), an insulating flake (5) closely clinging to the bottom of the gun barrel (7) and a metal bridge foil (4) closely clinging to the lower surface of the insulating flake (5). Transmission lines (3) are connected to the two ends of the metal bridge foil (4). The device is characterized in that a high-density projectile body (6) is arranged in the gun barrel (7), and is adhered to the upper surface of the insulating flake (5). The characteristics of easiness for operation, low time drift and the like of discharge-induced explosion loading are kept, and the device also has the advantages of structural integrity of a loaded high-density projectile body, stable flight state without rotation, speed stability and controllability within a medium / low-speed range, and the like, and is applied to a miniature crash test with high requirements on time synchronization and low requirements on speed.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

In-situ synthesized TiC particle-reinforced titanium aluminium alloy material and preparation method thereof

The invention discloses an in-situ synthesized TiC particle-reinforced titanium aluminium alloy material which comprises the following components by mass: 0.2%<=Al<=2.5%, 0.5%<=C<=1.5%, and the balance of Ti and inevitable impurities; the alloy material is prepared by the following method: 1) material preparation, that is, weighing corresponding amounts of aluminium powder, graphite powder and titanium powder according to the above mass ratio; 2) ball milling mixing; 3) performing compaction of the mixture after ball milling and sieving in step 2) through bidirectional mold pressing; 4) putting the green compact on a vacuum container cathode; 5) adjusting the vacuum degree of the furnace; 6) performing particle bombardment sintering of the green compact and the cathode when the argon reaches a working air pressure. According to the invention, carbon substitutes part of aluminium and is introduced into the alloy as an alloying element; and the particle-reinforced titanium aluminium alloy material with high strength, wear resistance, and low cost is obtained by means of carbon solid solution reinforcement and matrix reinforcement by introducing high-melting point dispersed TiC particles through hollow cathode rapid sintering in-situ reaction.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Elastic embossing warp knitted blanket and preparation method thereof

The invention discloses an elastic embossing warp knitted blanket and a preparation method thereof. The blanket is prepared from 12 to 22 parts of PET polyester, 5 to 18 parts of chinlon, 35 to 65 parts of wool, 2 to 11 parts of corn fiber, 1 to 7 parts of coconut fiber, and 20 to 35 parts of dacron, wherein the fineness of the wool is 16 to 19 micrometers. According to the elastic embossing warpknitted blanket and the preparation method thereof provided by the invention, the stretched fine wool is adopted as a main component of a woolen blanket, so that the blanket has the advantages of capability of reserving light wool fabrics, fineness, softness, suitability for personal use, convenience in caring, and applicability for four seasons; the blanket overcomes the defects of poor toughnessand small elasticity of a wool blanket made of finedrawn wools.

Owner:SUQIAN SHENLONG HOME TEXTILE

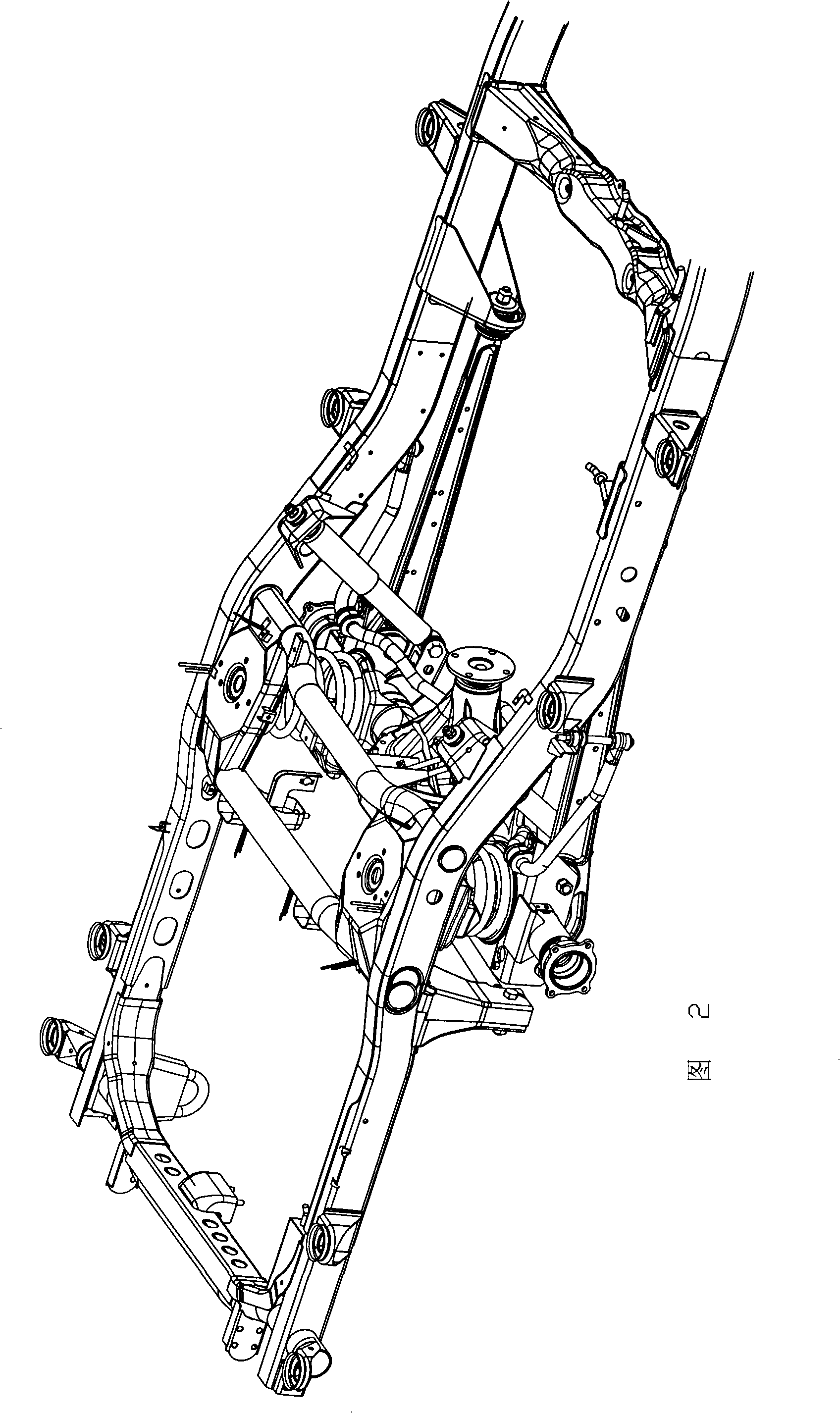

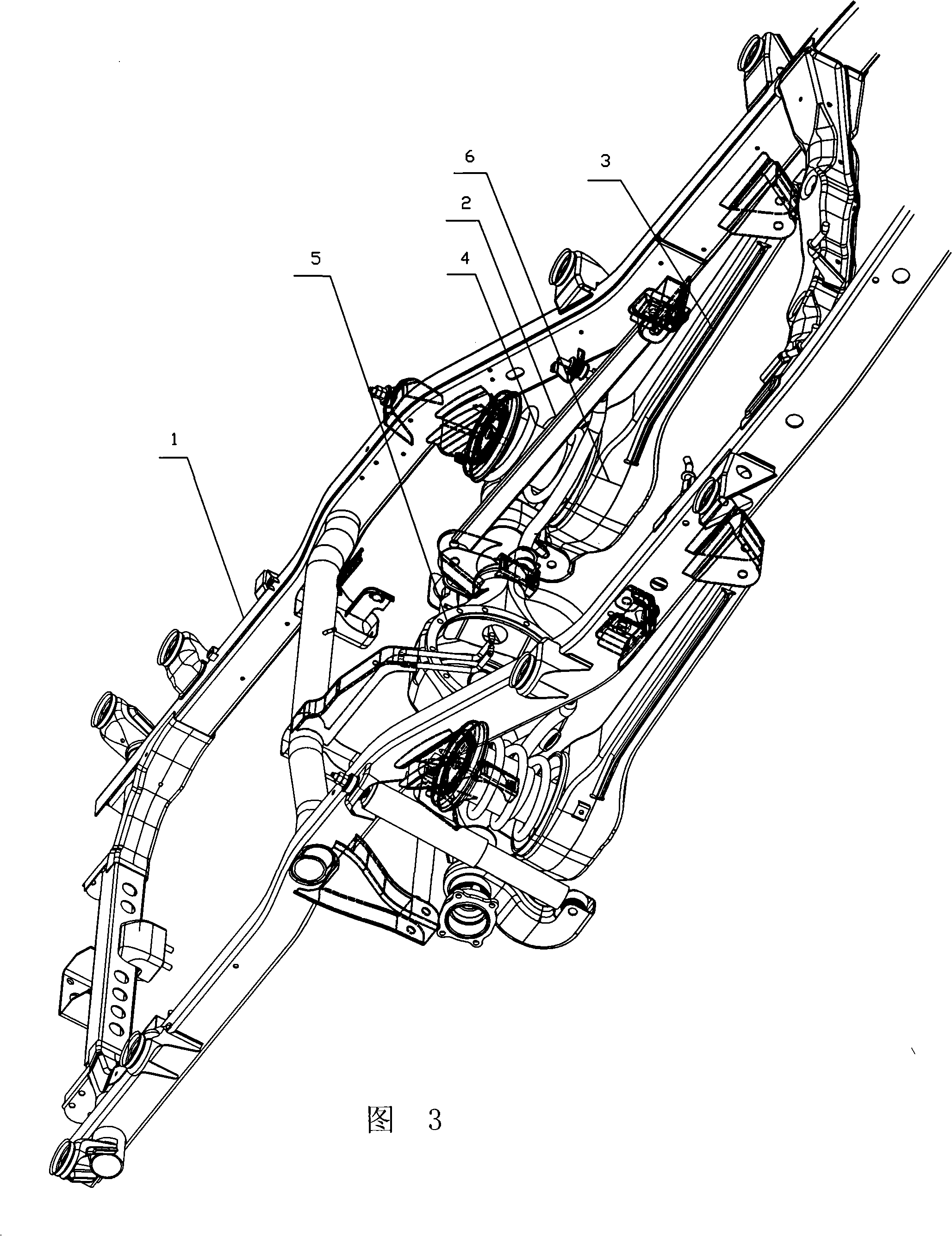

Rear suspension device of sport utility vehicle

InactiveCN101269617ALower centroid heightReduce roll angleResilient suspensionsVehicle frameEngineering

A rear suspension fork device for a motile multifunctional vehicle (SUV) is achieved by the following proposal: the upper side of the lower swing-arm of the present vehicle five-link suspension fork and the lower side of the vehicle frame longitudinal beam are respectively provided with a spring seat; the upper and the lower ends of the spring are respectively connected to the spring seat. The rear suspension fork device has simple and reasonable structure as well as easy processing, and can effectively lower the centroid height, increase the spring distance, and improve the operation stability and the drive security; the rear suspension fork device can be used by matching with various SUV vehicles so that the industrialized production can be achieved, and the rear suspension fork device can be used as the renewal product of rear suspension fork of existing SUV vehicles.

Owner:湖南长丰汽车研发股份有限公司

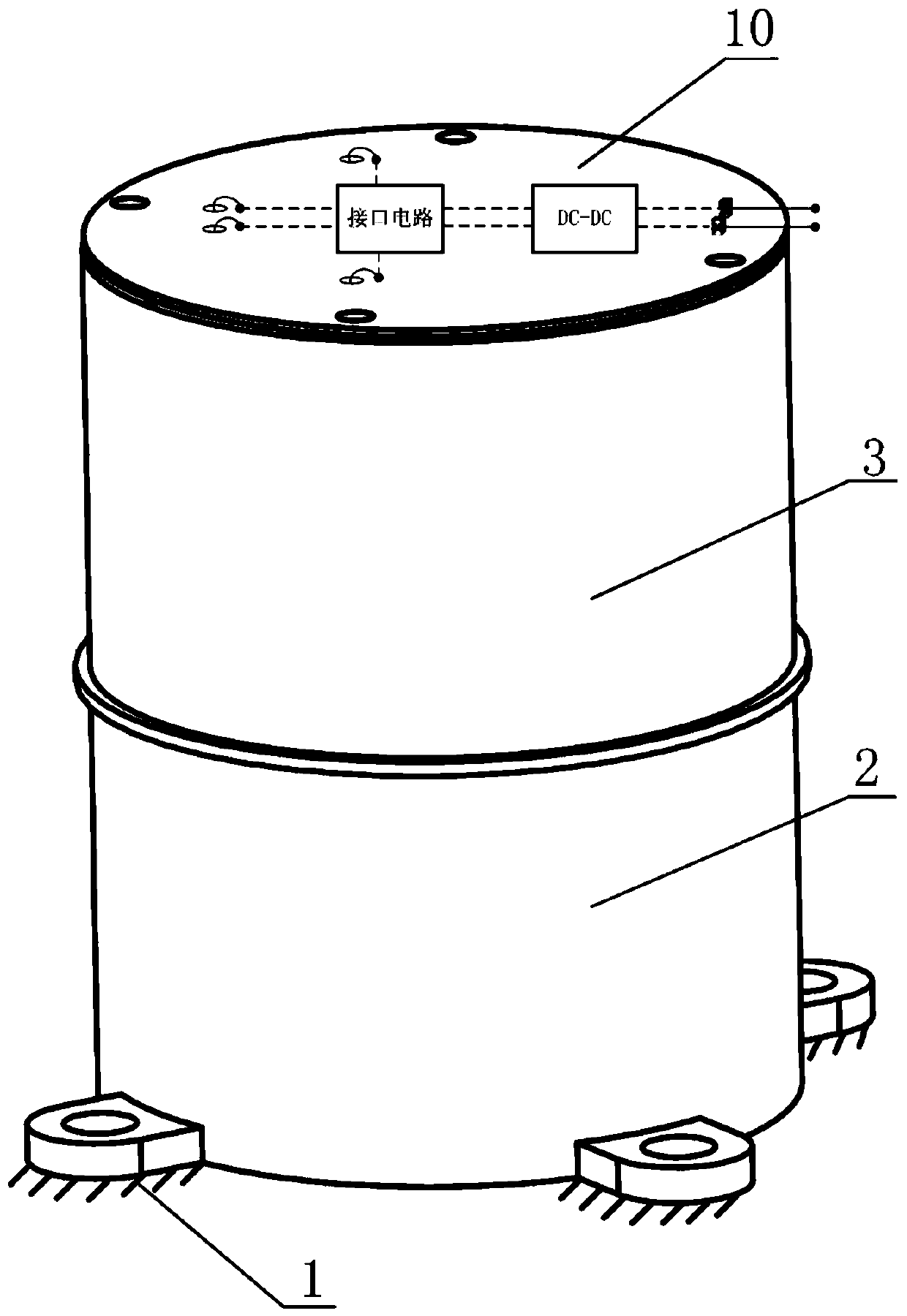

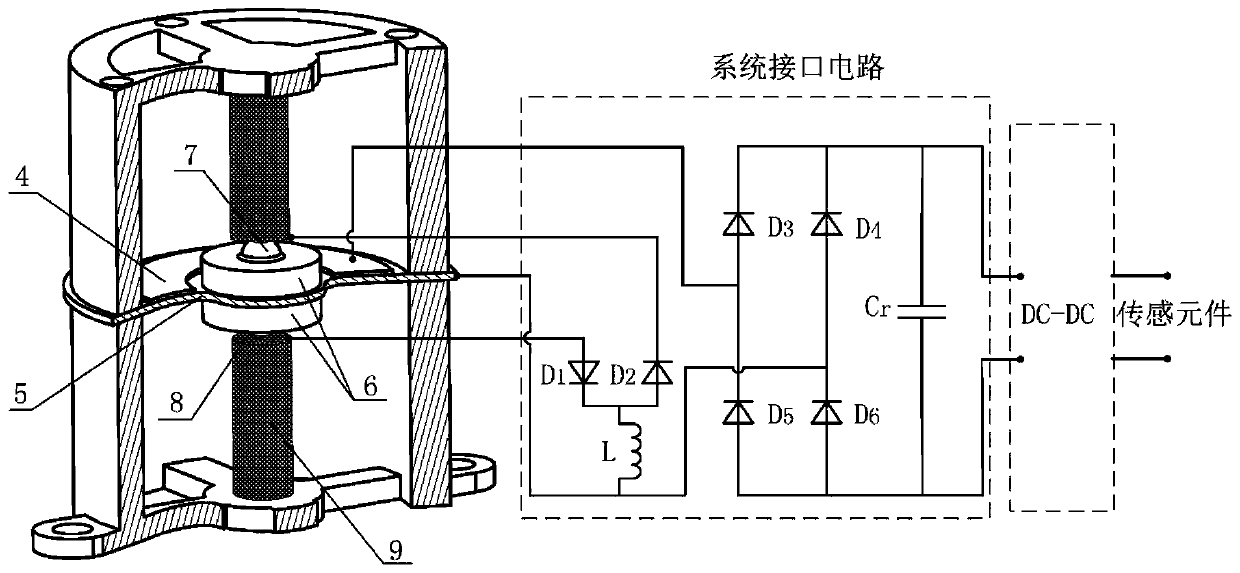

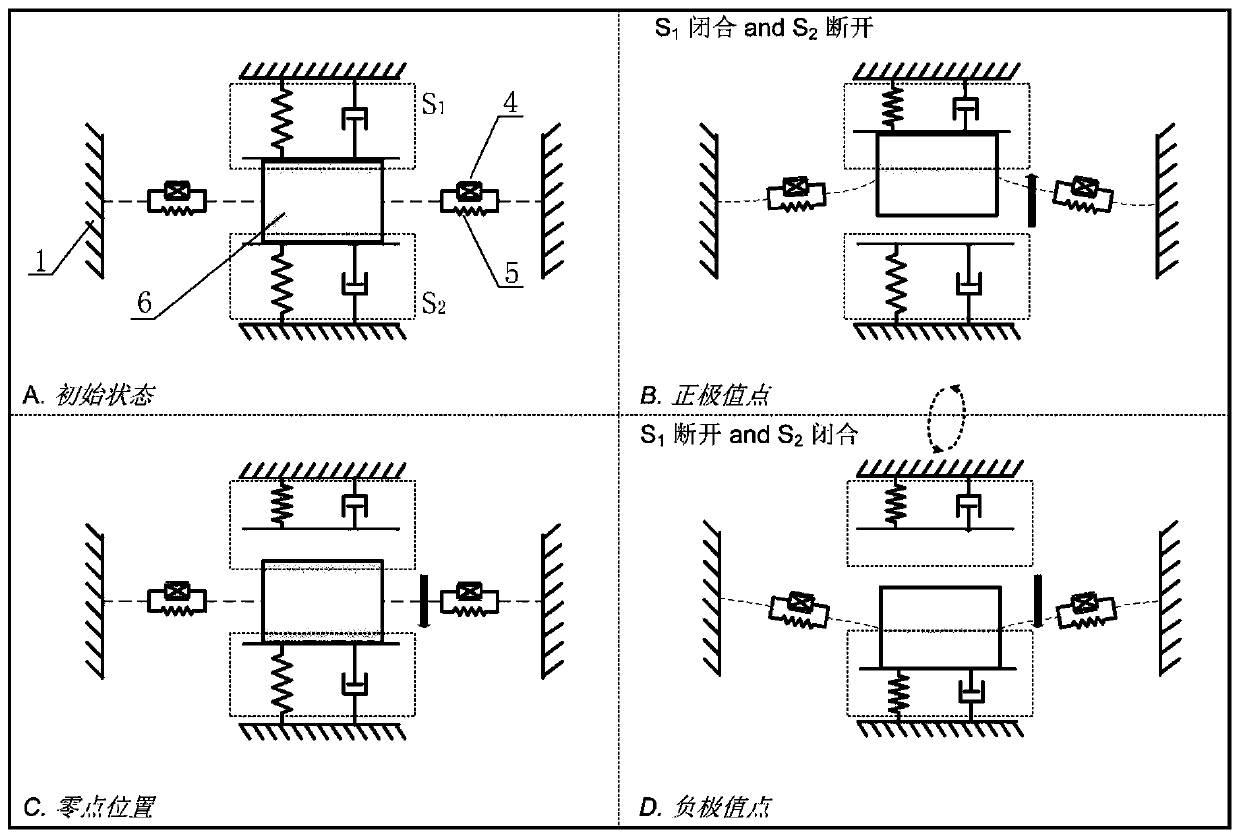

Adaptive mechanical switch synchronous recovery device integrated with viscous damping material

ActiveCN109698639ASimple structureImprove performancePiezoelectric/electrostriction/magnetostriction machinesElectric switchesViscous dampingElectricity

The invention discloses an adaptive mechanical switch synchronous recovery device integrated with a viscous damping material, which comprises an upper support seat, a lower support seat, a piezoelectric diaphragm energy collector, an adaptive detection switch mechanism and an energy storage circuit board. The piezoelectric diaphragm energy collector comprises a diaphragm, a piezoelectric element and mass blocks. The two mass blocks are arranged at the center of the diaphragm, and each mass block is provided with a spherical contact. The piezoelectric element is attached to one side of the diaphragm. The adaptive detection switch mechanism comprises two slow rebound springs, each slow rebound spring is provided with a conductive contact surface on one end thereof, and the conductive contactsurfaces are respectively adjacent to the spherical contacts. The recovery device of the invention has simple structure and reliable performance, and is convenient to process and install. The installation space is unlimited, and the collector can be closed without external interference.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com