Patents

Literature

155results about How to "Overcoming deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

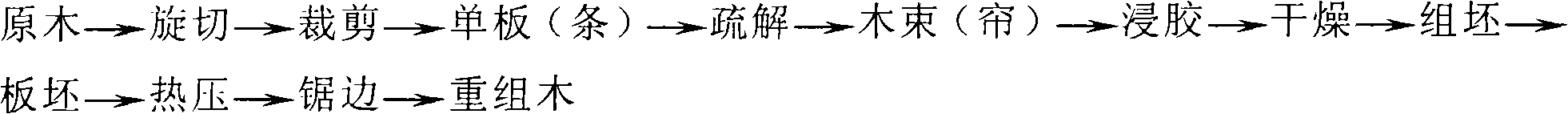

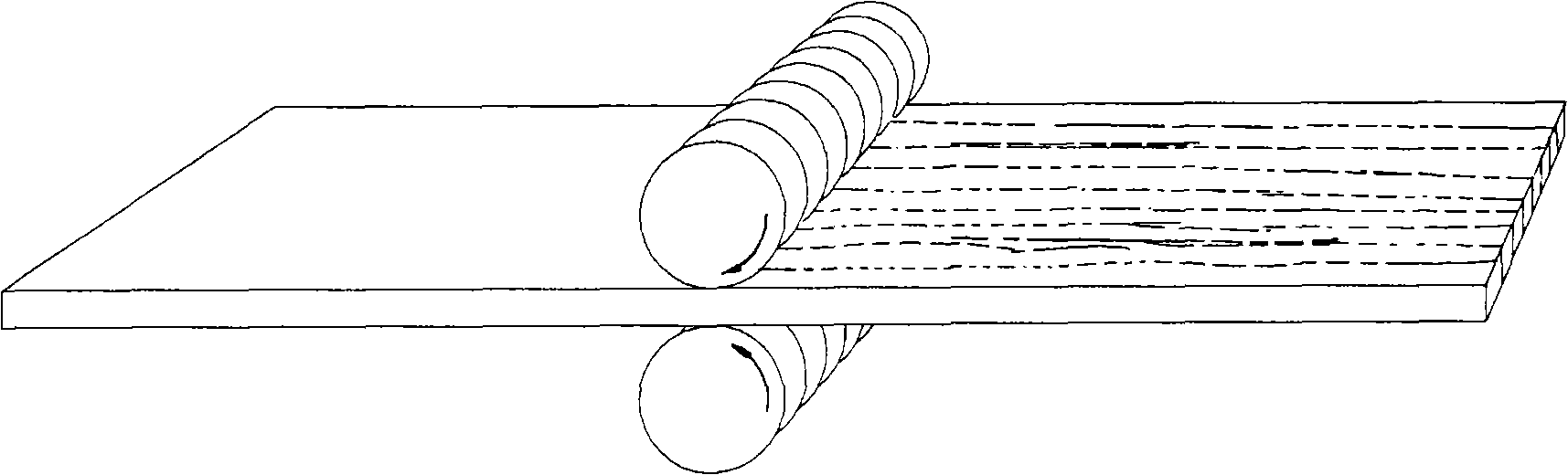

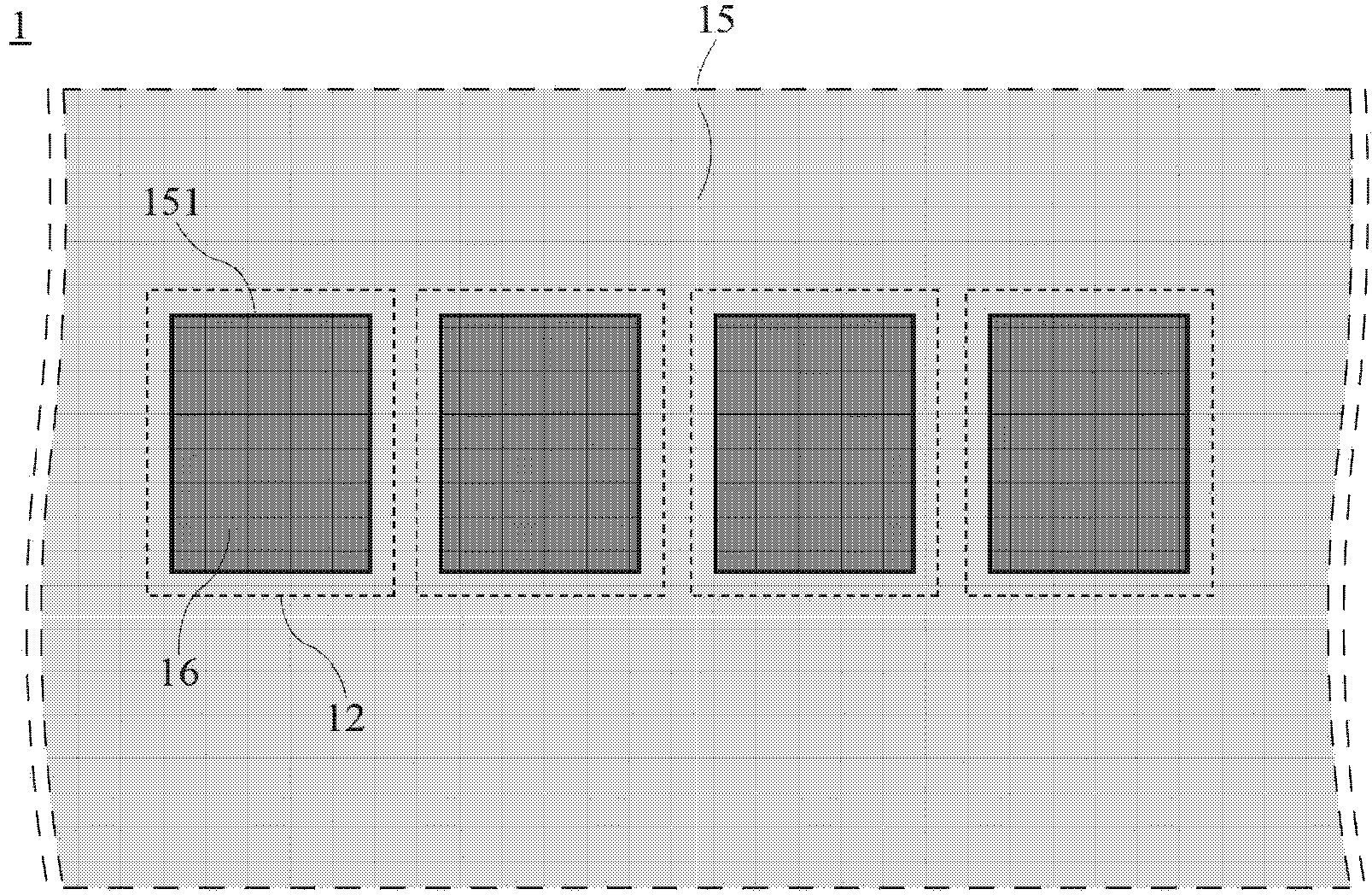

Recombination wood and manufacturing method thereof

ActiveCN101357470AEfficient use ofIncrease productivityAldehyde/ketone condensation polymer adhesivesFlat articlesPulp and paper industryMechanical property

The invention provides a method for manufacturing reconstituted wood. Rotary cut is carried out on the raw wood for preparing a veneer or a veneer strip, defibering is carried out on the veneer, the forming points and / or wood bunch shades or wood bunches of striation crack are formed along the natural texture of wood on the veneer, then dipping, drying and hot pressing for molding the reconstituted wood are carried out. Compared with the prior art, the method of the invention solves the problem that wood bunch is irregular; the rate of utilizing wood and production efficiency of wood bunch are improved; defibering process is simplified and energy consumption for defibering is lowered. The process facilitates the cracks on the wood bunch shades and wood bunches to be very even and facilitates the dipping of wood bunch shades or wood bunches to be very even in the following dipping process; the product problems such as warp, deformation, jump fibre, and the like, are overcome, which are aroused by uneven defibering in making wood bunches from raw wood directly in the prior art, and the boards that the surface is very smooth, the mechanical performances such as stiffness and intensity, and the like, are higher than the raw material itself are made, therefore the fast-growing forest wood with worse performances and wider source can be made into the products of reconstituted wood which can compare beauty with noble hardwood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

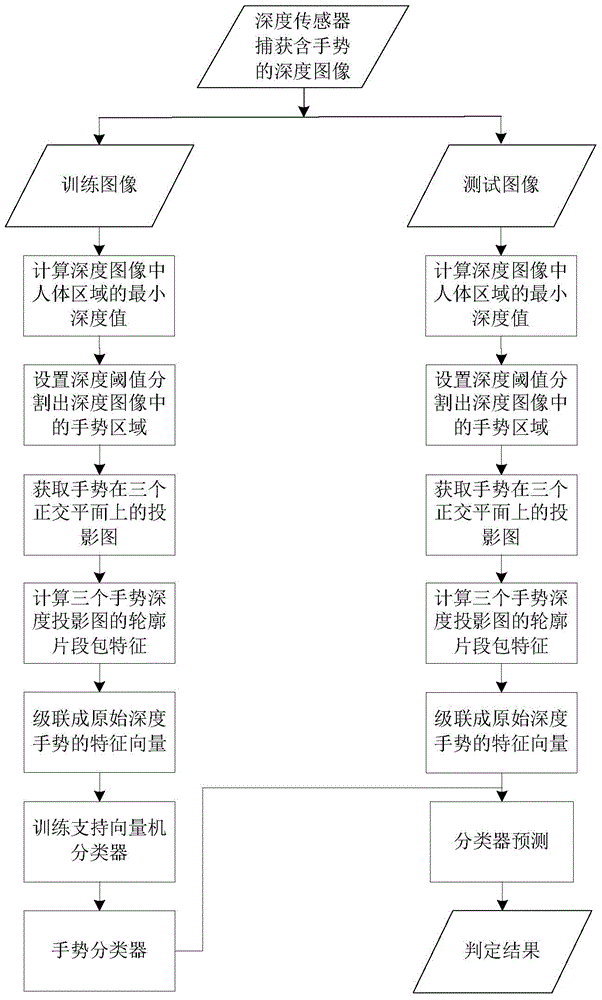

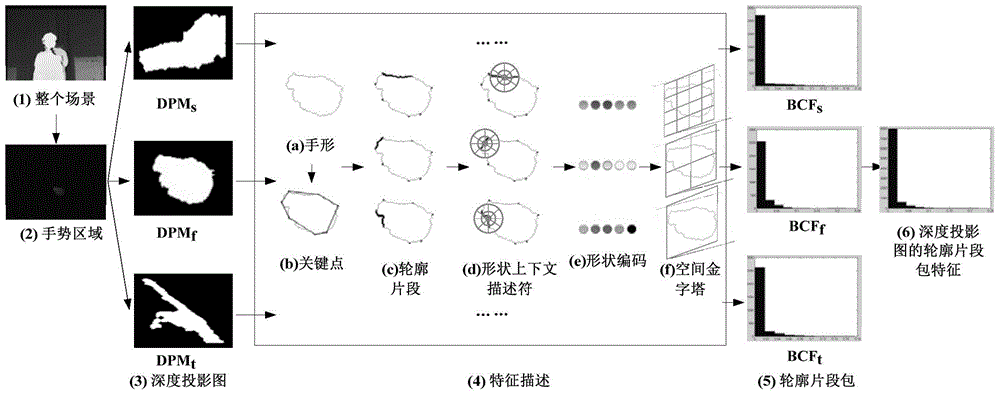

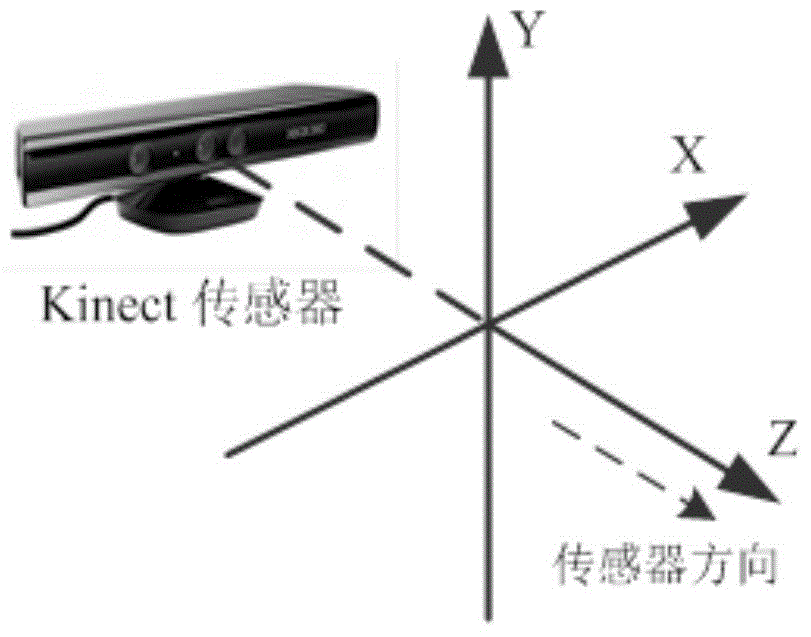

Gesture recognition method based on depth image and gesture recognition system based on depth images

ActiveCN104636725AComprehensive gestureImprove performanceInput/output for user-computer interactionCharacter and pattern recognitionFeature vectorData set

The invention discloses a gesture recognition method based on depth images. The method comprises the following steps: acquiring depth images in a training data set and a test date set by virtue of a depth sensor; calculating the minimal depth values of human body regions in the images, and partitioning gestures in the depth images by use of a depth threshold in combination with a preset condition that a human hand is an object nearest to the sensor; then acquiring projection drawings of the gesture on three orthogonal planes, namely a front-view projection drawing, a side-view projection drawing and a top-view projection drawing; further extracting the outline fragment packet characteristics of the three projection drawings and cascading to form a characteristic vector of the original depth gesture; and finally classifying the gesture characteristic vectors acquired from the depth images to be recognized by virtue of a training classifier, thereby obtaining recognition results of the to-be-recognized gestures. The invention further provides a corresponding gesture recognition system. The method is simple and practical in gesture recognition, high in popularization capability and high in recognition accuracy and can be used for effectively overcoming the influence of adverse factors such as busy background, illumination, noises and self occlusion.

Owner:武汉众智数字技术有限公司

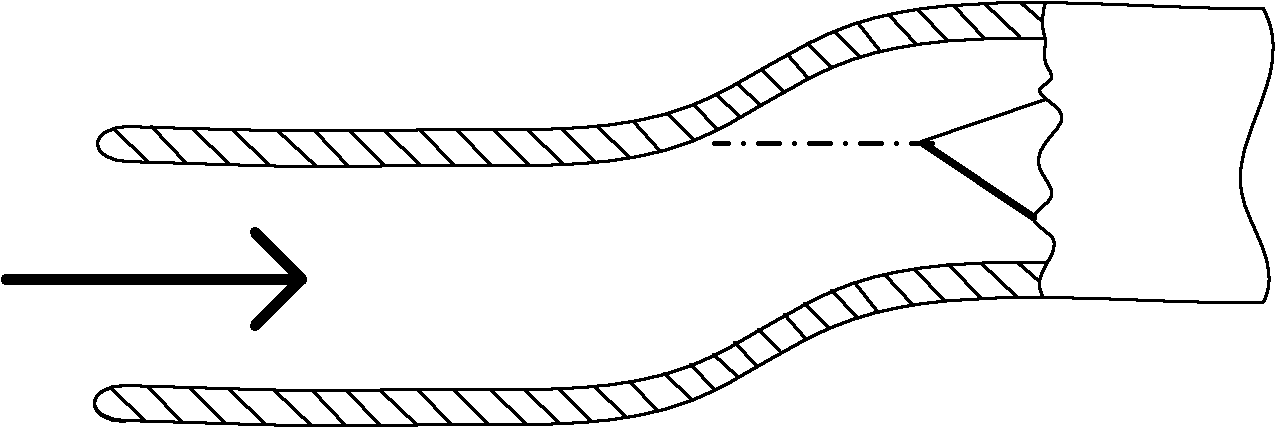

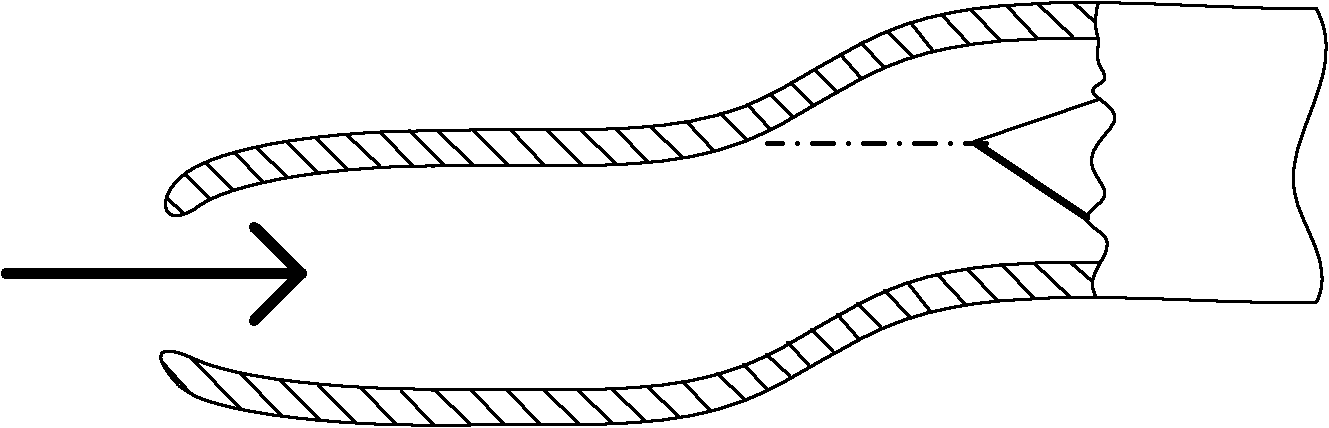

Shape memory polymer pipeline and use of shape memory polymer pipeline as aircraft engine intake

InactiveCN101922591AImprove performanceOvercoming demandsFlexible pipesTurbine/propulsion air intakesAirplaneAerodynamics

The invention relates to a shape memory polymer pipeline and use of the shape memory polymer pipeline as an aircraft engine intake, in particular to a shape memory polymer pipeline and use thereof, which solve the problem that a structure of the conventional aircraft engine intake cannot be deformed according to requirements, so air inflow cannot be regulated and the shape of the air intake cannot be changed to cause that the through capacity of the aircraft engine intake is discordant with the requirement of an engine to influence the aerodynamics performance of an air engine. The shape memory polymer pipeline is made of a shape memory composition material, and the shape memory composition material consists of 5 to 98 volume parts of shape memory polymer materials, 2 to 95 volume parts of reinforcement phase materials and 0 to 100 volume parts of resistance heating materials; and the shape memory polymer pipeline serving as the aircraft engine intake overcomes the defect that the structure of the conventional air intake cannot be deformed according to the requirements, and regulates the air inflow and changes the shape of the air intake, so that the through capacity of the air intake is in accordance with the requirement of the engine to improve the aerodynamics performance of aircrafts.

Owner:HARBIN INST OF TECH

Wood-wool, fibre board and method for making same

InactiveCN101298153ALow costOvercoming deformationWood working apparatusDomestic articlesSolid woodEngineering

The invention discloses wood-wool, a wood-wool plate and a preparation method thereof. The wood-wool plate comprises wood-wools formed by untwining in the fibre direction; furthermore, the wood-wools are arranged along the fibre direction. Compared with the existing general wood-wool plate, the wood-wool plate prepared by the method of the invention uses generally abandoned single-plate edge angle waste material as raw material and greatly reduces the cost of the wood-wool plate; the usage performance of the prepared wood-wool plate complies with the requirement of the positioning structure wood-wool plate standard (LY / T1580-2000); the wood-wool plate prepared in the fibre direction is equivalent to the solid wood plate on sensing and performance and overcomes the defects of the solid wood plate such as deformation and weather resistant.

Owner:BEIJING FORESTRY UNIVERSITY

Method for preparing WC-Co cemented carbide through microwave sintering

The invention provides a method for preparing WC-Co cemented carbide through microwave sintering. The method comprises the steps of WC powder and Co powder batching and mixing, compacting and sintering, wherein in the step of sintering, compacts, SiC chips, carbon black and alumina powder are put in an alumina fiber insulating bag sleeve and then the alumina fiber insulating bag sleeve is put in a microwave high temperature furnace, the products in the furnace are heated to 500-600 DEG C at a heating speed of 5-10 DEG C / min and the heat is preserved and then the products are heated to 1400-1500 DEG C at a heating speed of 30-80 DEG C / min and the heat is preserved, thus obtaining the WC-Co cemented carbide. The method has the advantages of simple process, convenience in operation, short sintering period and low energy consumption, can replace the existing WC-Co cemented carbide processes, is used for producing the WC-Co cemented carbide by adopting the intermittent or continuous microwave sintering mode and is suitable for industrial application. The prepared WC-Co cemented carbide has excellent performances.

Owner:CENT SOUTH UNIV

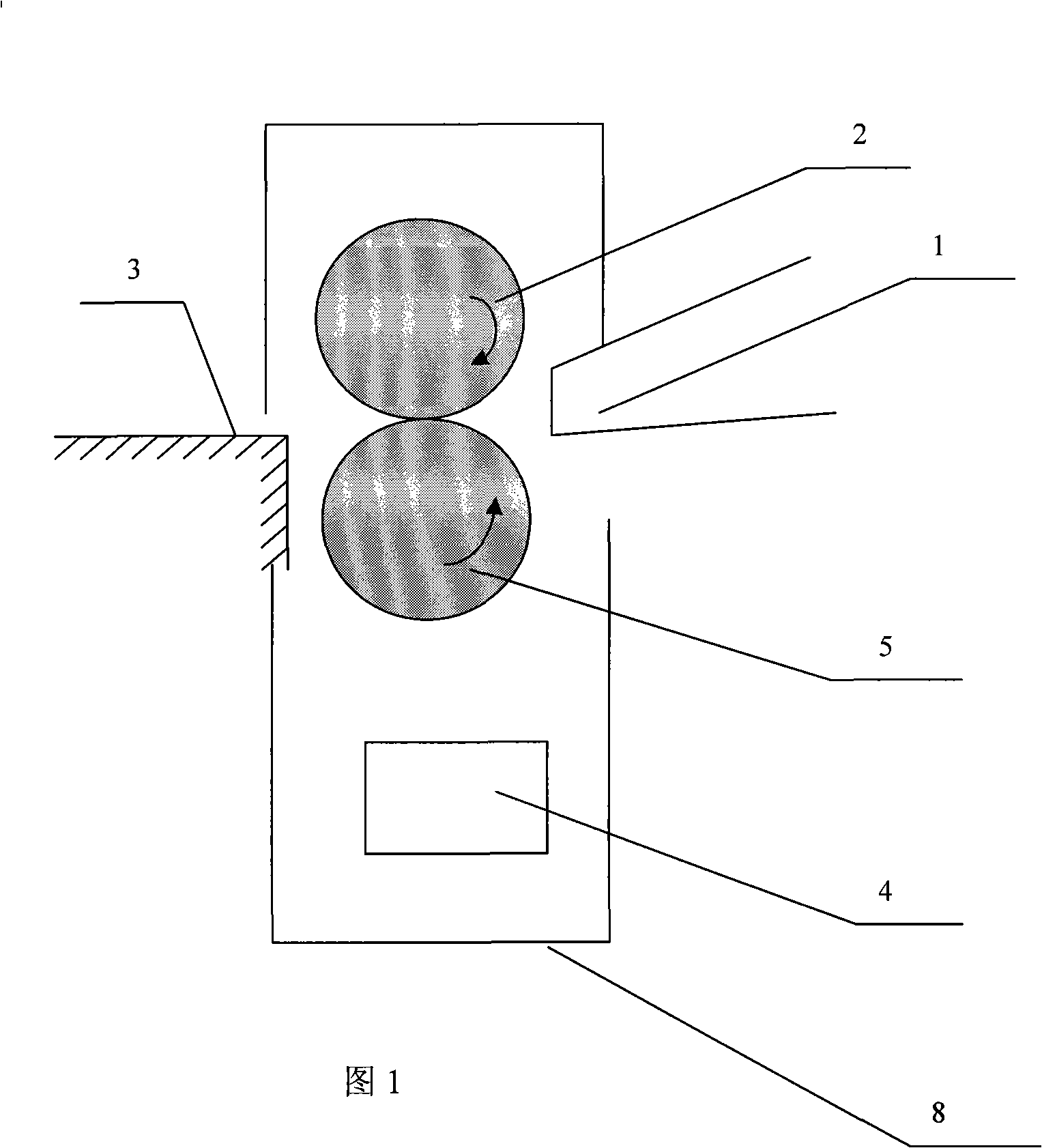

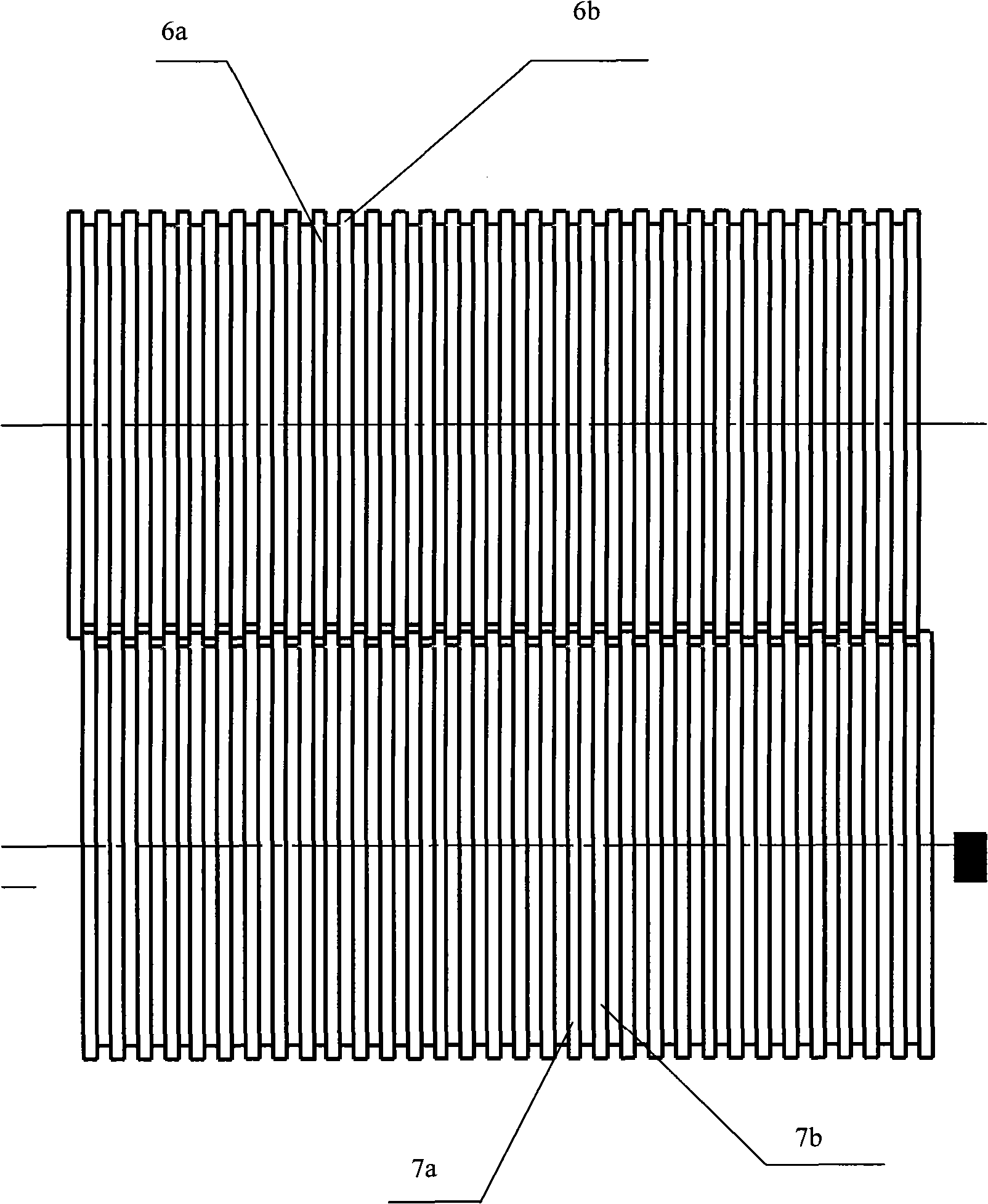

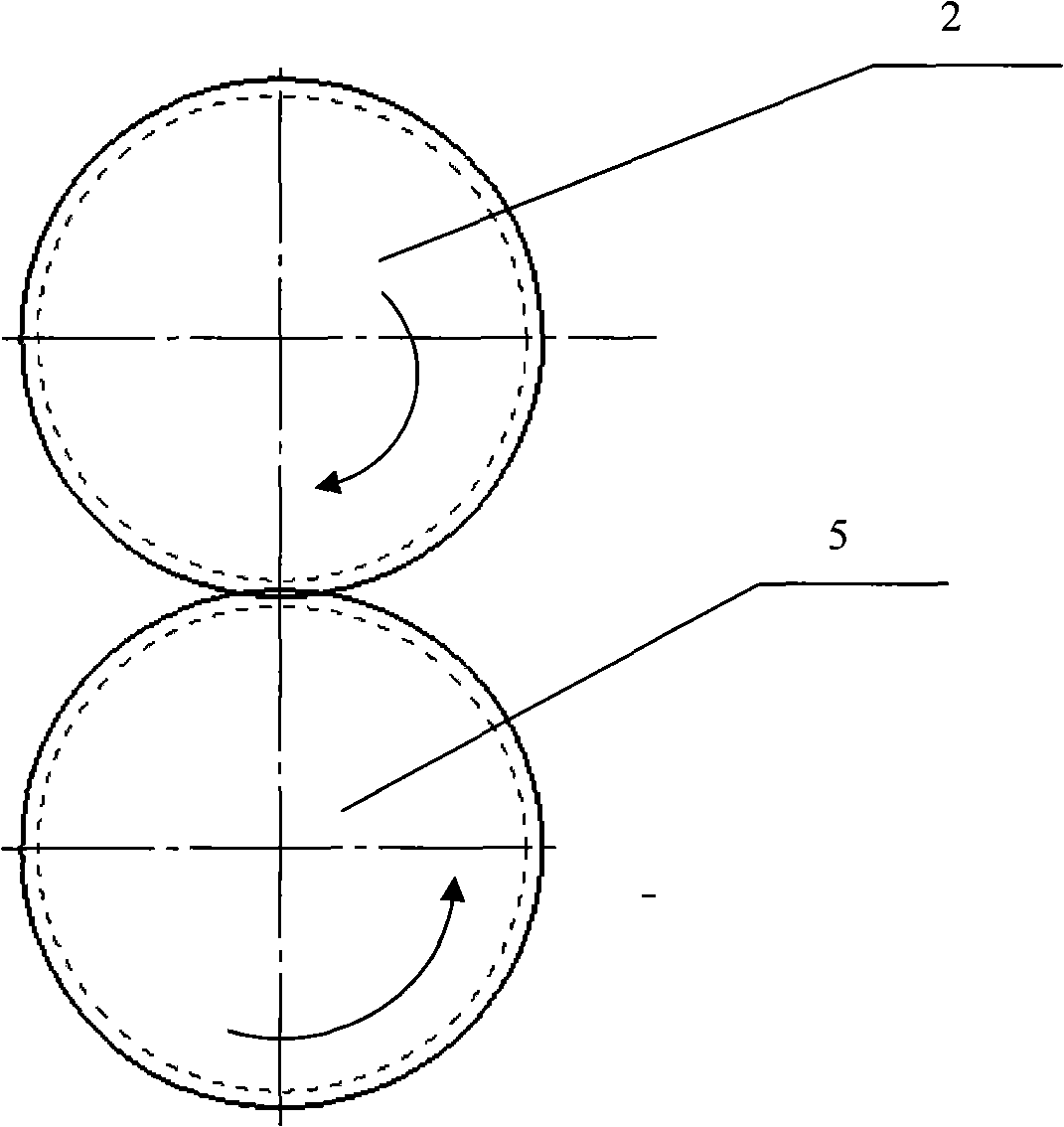

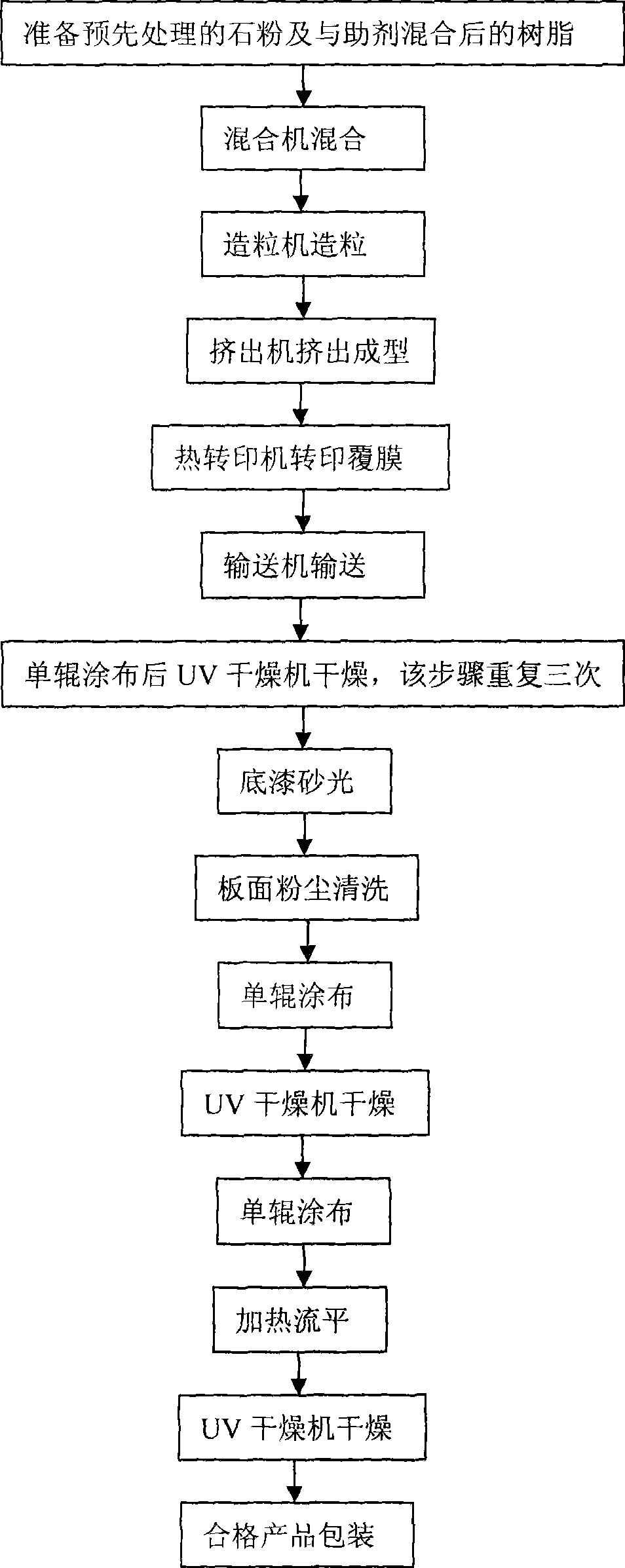

High strength waterproof stone-wood floor and technique for producing the same

InactiveCN101481232AOvercome fear of waterOvercoming deformationSolid waste managementPolyvinyl chlorideHigh intensity

The invention discloses a high-strength waterproof stone-wood floorboard which is prepared from the following raw materials by weight parts: 45 to 65 weight parts of stone powder, 20 to 30 weight parts of PVC resin, 2 to 5 weight parts of UV resistant agent, 1 to 2 weight parts of stearic acid, 2 to 5 weight parts of coupling agent, 3 to 5 weight parts of CPE, 3 to 5 weight parts of dibutyl ester and 2 to 4 weight parts of antioxidizer. The invention also discloses a production technology for the high-strength waterproof stone-wood floorboard. The high-strength waterproof stone-wood floorboard also has the advantages of low cost, heat insulation, environmental protection, waste reutilization and the like.

Owner:SHENZHEN KELAX COMPOUND MATERIAL

Fully-automatic brick packing and unloading method for sintered bricks

InactiveCN103407794AOvercoming deformationOvercoming problems such as lack of bricksStacking articlesDe-stacking articlesBrickConveyor belt

The invention discloses a fully-automatic brick packing and unloading method for sintered bricks. The method comprises the following steps that firstly, the sintered bricks piled in a sintering kiln are transferred from a kiln cart to a conveyor belt I by an unloading clamp according to layers and moved into a transportation clamp, the transportation clamp is used for clamping a certain amount of sintered bricks each time to form a horizontal piling layer, the horizontal piling layer is transported onto a conveyor belt II and conveyed into a horizontal packing machine along the conveyor belt II so as to carry out packing in a horizontal direction, secondly, a piling clamp is used for transferring the horizontal piling layer onto a pallet on a conveyor belt III, the piling of horizontal piling layers in a height on the pallet is completed, thirdly, the packing of sintered brick piles in a longitudinal height is carried out in a horizontal packing machine, after the completion of packing, the sintered brick piles are unloaded from the pallet through a brick holding machine, and the brick packing and unloading of the sintered bricks is finished. According to the method, the problem of moving sintered bricks due to a blanking piling gap is solved, actions of brick unloading, sequencing, packing, piling, unloading, transporting on the pallet and the like are carried out in a separating way, and continuous automation of brick unloading as well as high-efficient production is realized.

Owner:何仕杰

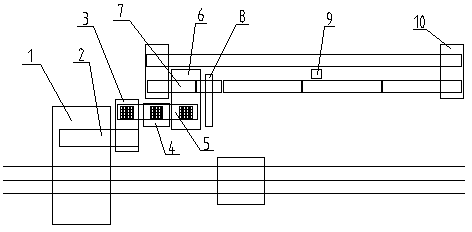

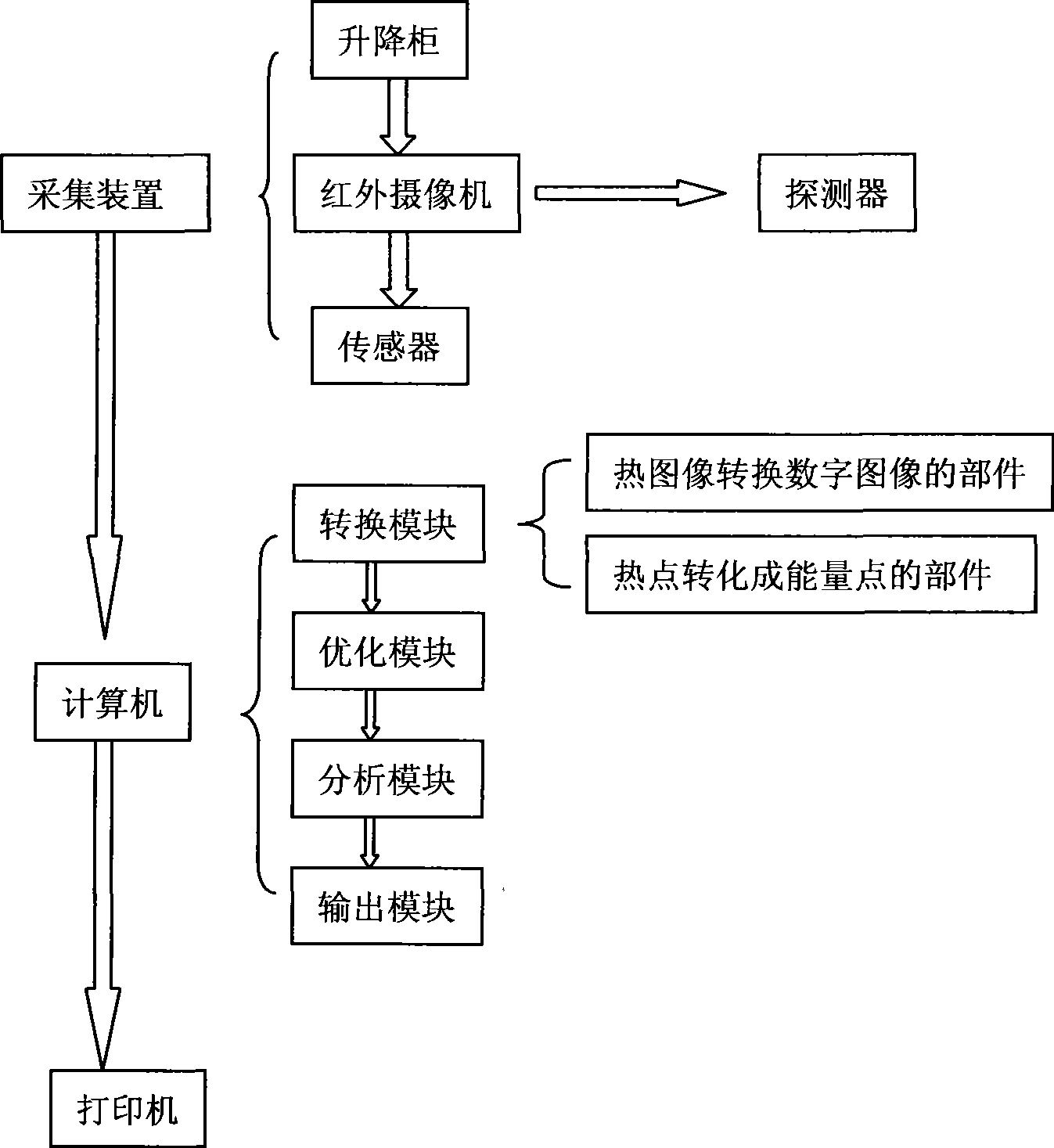

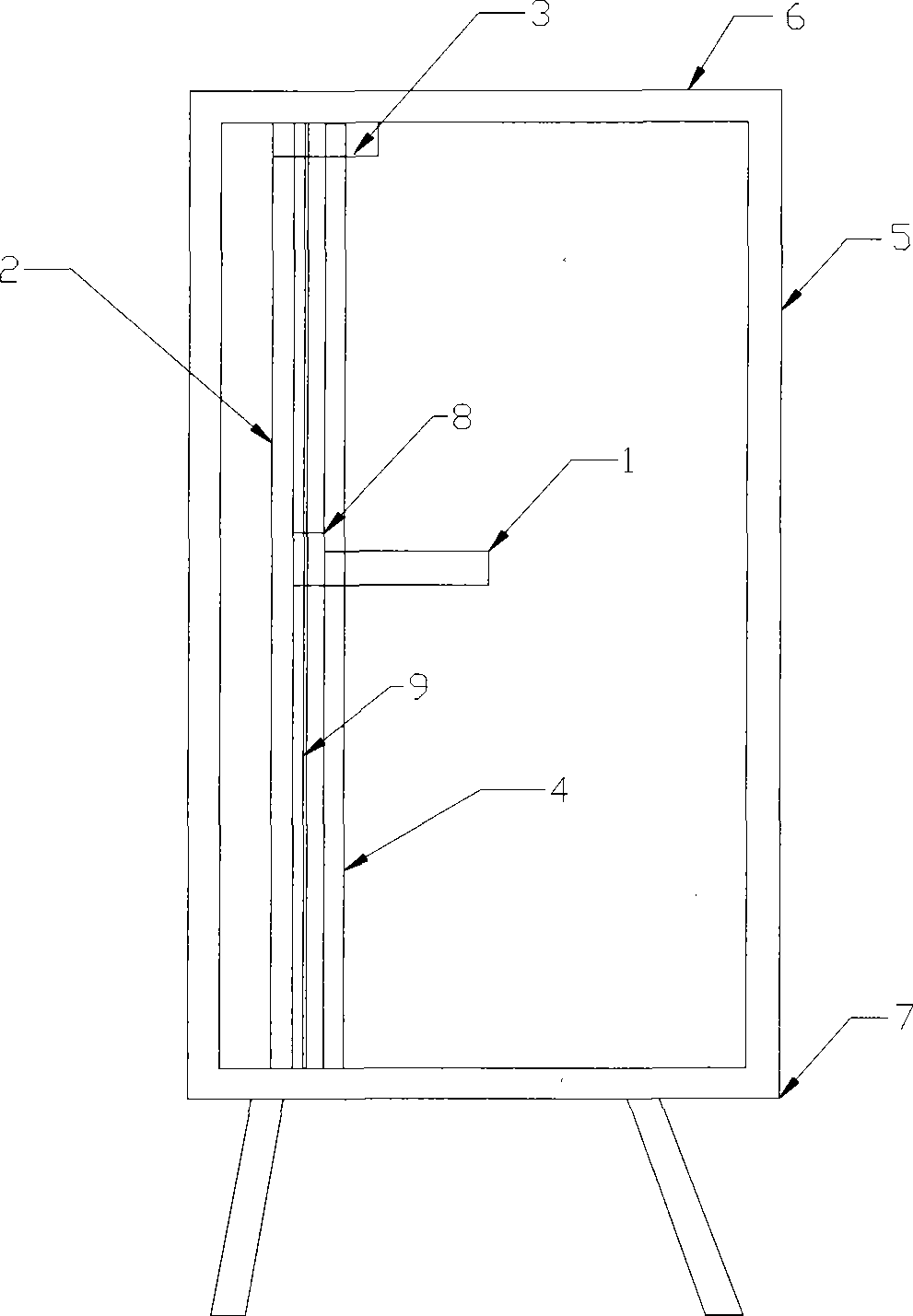

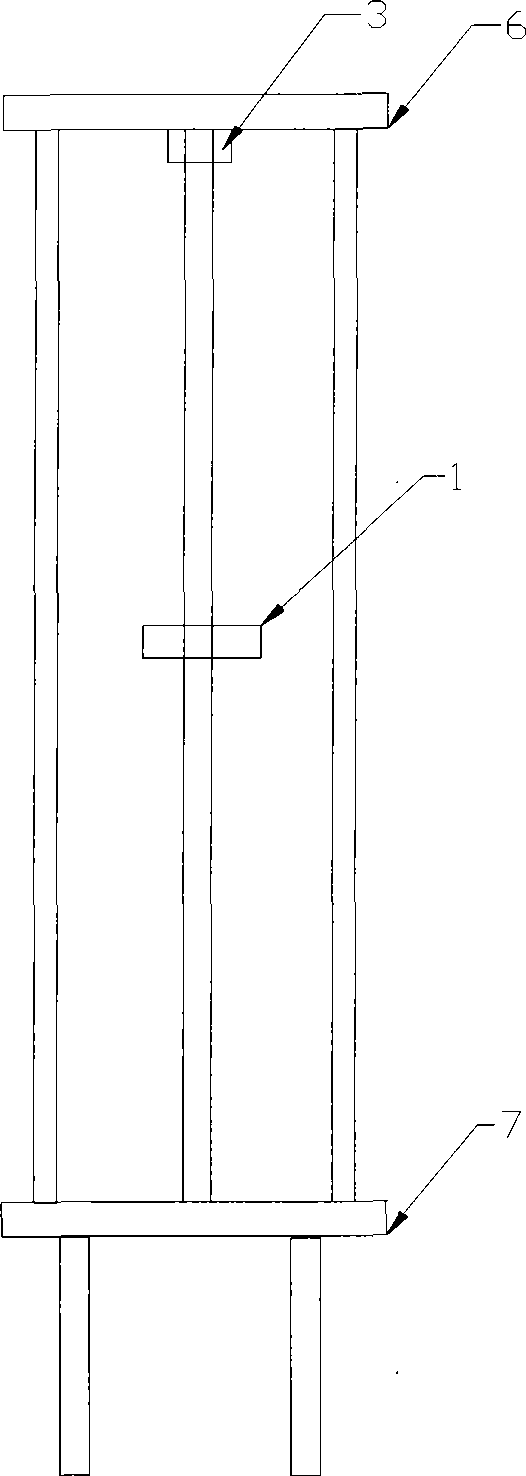

Thermal pattern assay apparatus

InactiveCN101390748AIntuitive and convenient analysis and diagnosisImprove firmnessDiagnostic recording/measuringSensorsAutomatic processingImagery technique

The invention relates to a device to analyze an infrared thermal picture of a person under test. Currently, infrared thermal pictures can not be treated automatically after being inputted into a computer; the pictures that are provided can not fully reflect or predict the functional changes of the organs of the person under test; and the creativity of certain imaging technology leads to external or internal trauma to the patient. The device makes use of the picture of the person under test, inputs the picture into the computer, converts the picture into digital temperature picture, analyzes the converted digital temperature picture through an analyzing program, and compares the analysis result with the data bank of the computer to get the health state of the person under test. The method can detect diseases at early stage before the appearance of the symptoms, provides a plurality of set of data and information through thermal picture scanning, and gives a full estimation to the health state of the person under test. A converted three-dimensional hotspot picture or energy picture is direct and convenient to analyze and diagnose. The device changes the motion mode of an infrared video camera, and adopting the motion mode of directly moving up and down, the device avoids the occasion of false contour of the picture during the scanning process.

Owner:北京东信康达数字科技有限公司

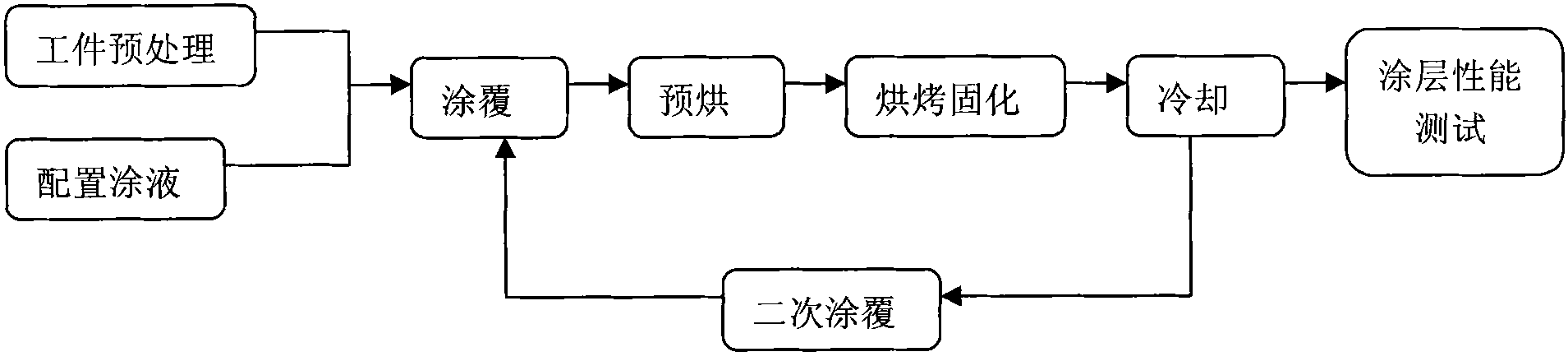

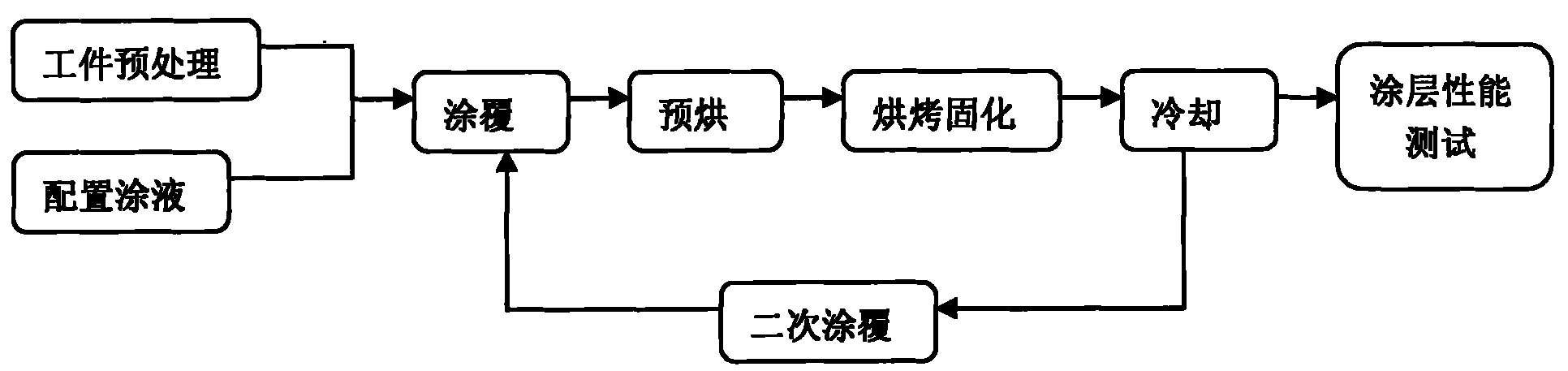

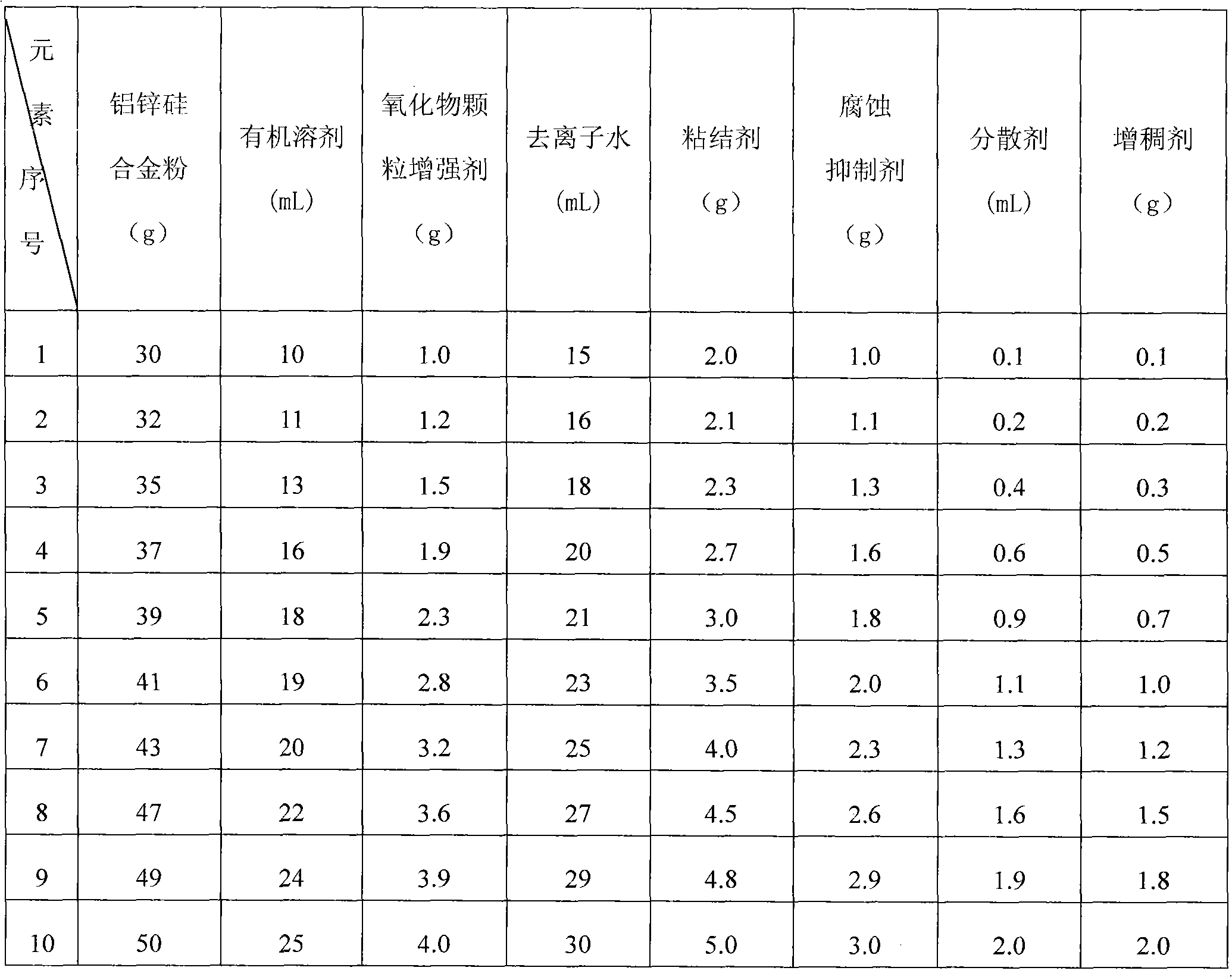

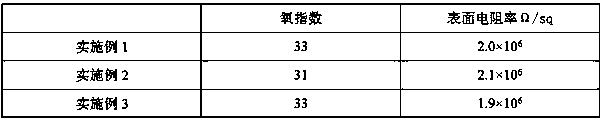

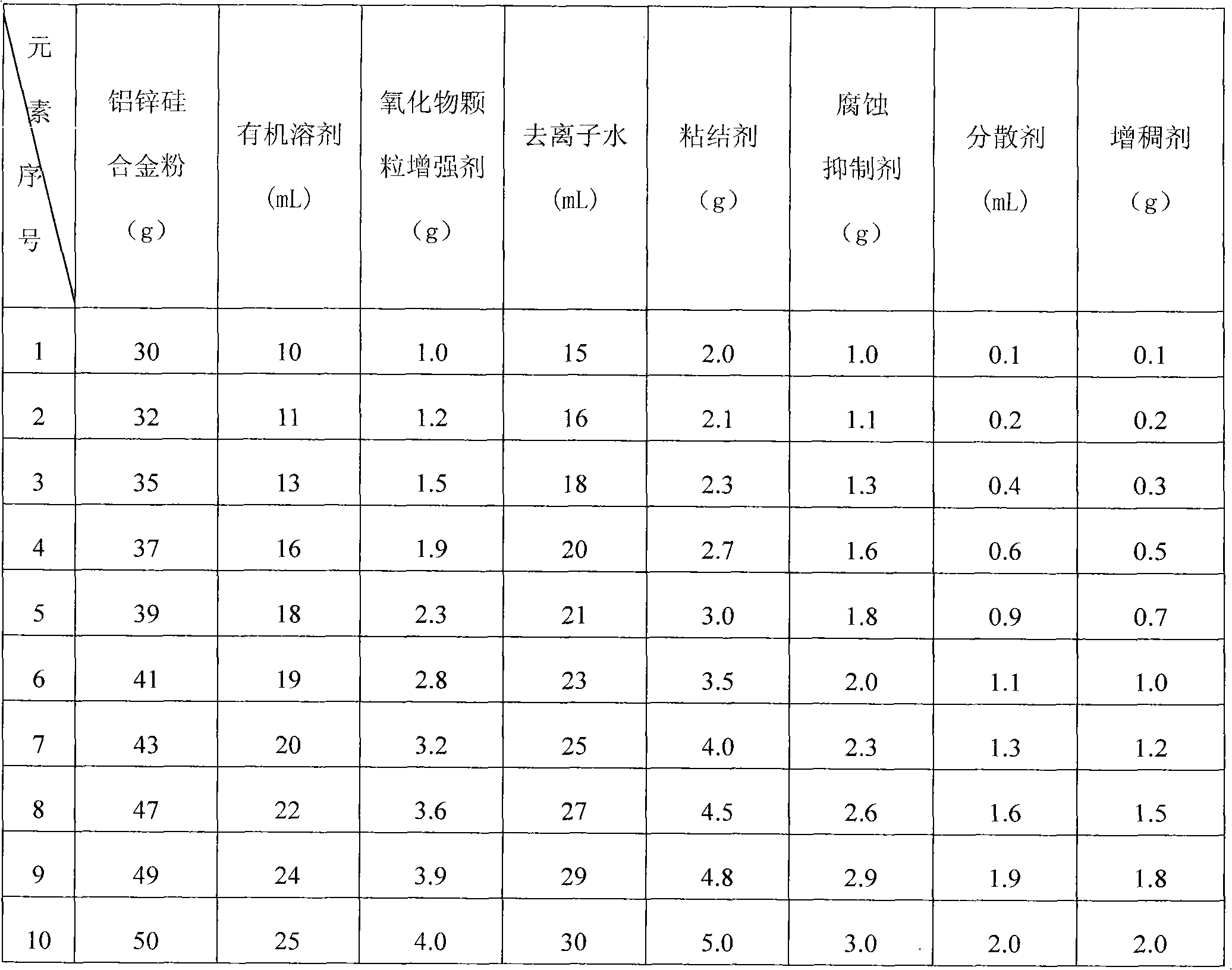

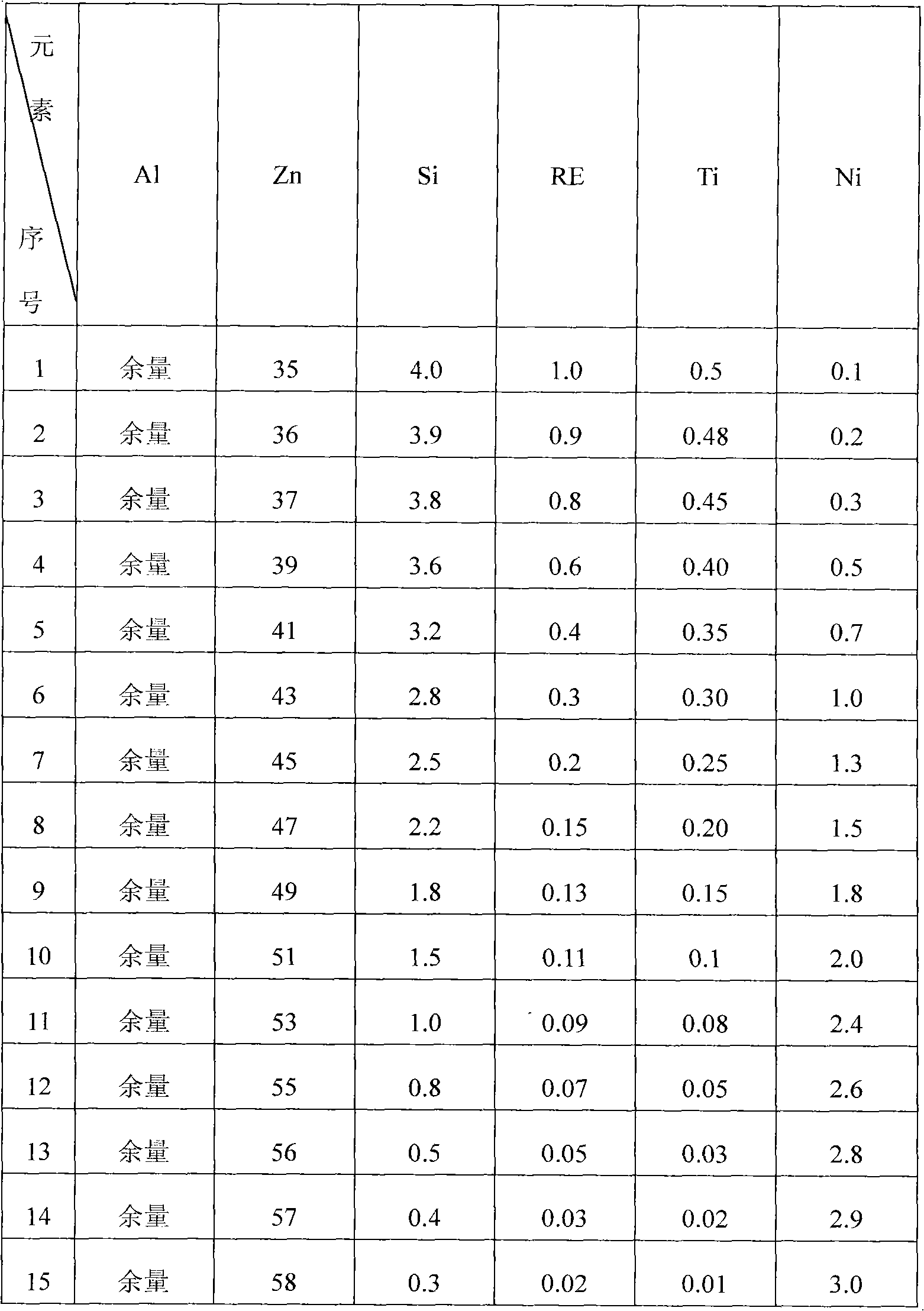

Coating-processing process for marine-climate resisting engineering-part surface coating

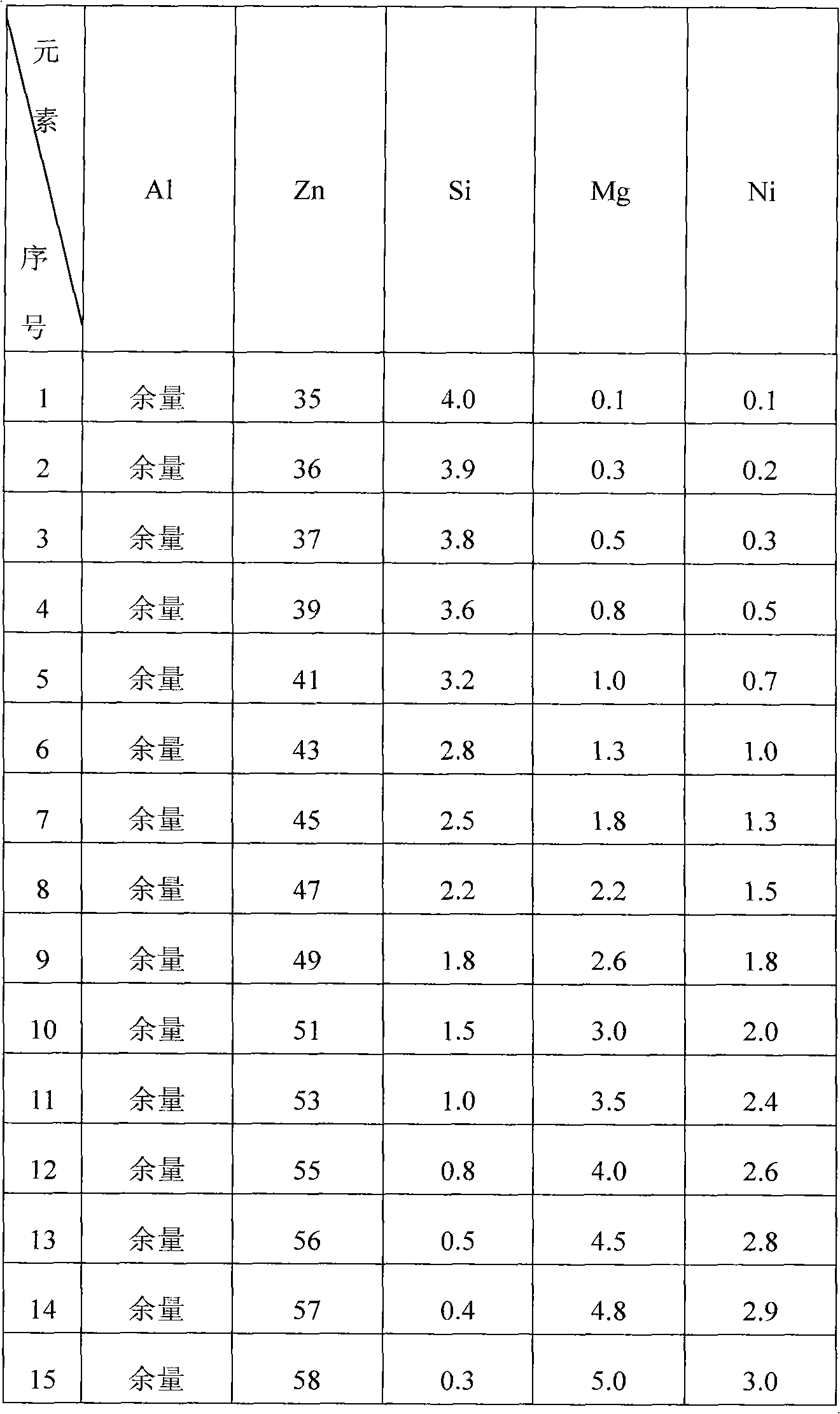

ActiveCN102463212AReduce preparation energy consumptionSexual stabilityPretreated surfacesSpecial surfacesOrganic solventSilicon alloy

The invention relates to a coating-processing process for marine-climate resisting engineering-part surface coatings, which comprises the followings steps of: preprocessing a workpiece; configuring a coating solution, wherein the coating solution comprises aluminum-zinc-silicon alloy powder, an organic solvent, a nano-oxide particle enhancer, deionized water, a binder, a corrosion inhibitor, a dispersant and a thickener; coating; preliminarily drying; roasting and curing; cooling; and coating for the second time after cooling the roasted workpiece to the room temperature.

Owner:JIANGSU LINLONG NEW MATERIALS

Manufacturing method of ultra thin-walled light metal alloy housing or frame

The invention discloses a manufacturing method of an ultra thin-walled light metal alloy housing or frame. The method includes firstly, designing a composite casting simulation model comprising no less than two housing monomers or frame monomers with computer simulation software, and manufacturing a mould according to the composite casting simulation model, wherein segmentation processing allowance is reserved among the monomers; secondly, preparing light metal alloy semi-solid stuff, injecting the stuff into the mould of a casting machine, and casting a composite cast with a method of a semi-solid forming; and thirdly, manufacturing an ultra thin-walled light metal alloy housing or frame finished product through the processes of machining segmentation, finish machining and the like. According to the manufacturing method of the ultra thin-walled light metal alloy housing or frame, the manufacturing yield and the production efficiency of the ultra thin-walled light metal alloy housing or frame can be improved, the manufactured ultra thin-walled light metal alloy housing or frame has the advantages of light weight, low density, good heat dissipation, good hardness and impact resistance and the like, and the needs of 3C (Computer, Communication and Consumer Electronic) products can be perfectly met.

Owner:福建顶誉铸造有限公司

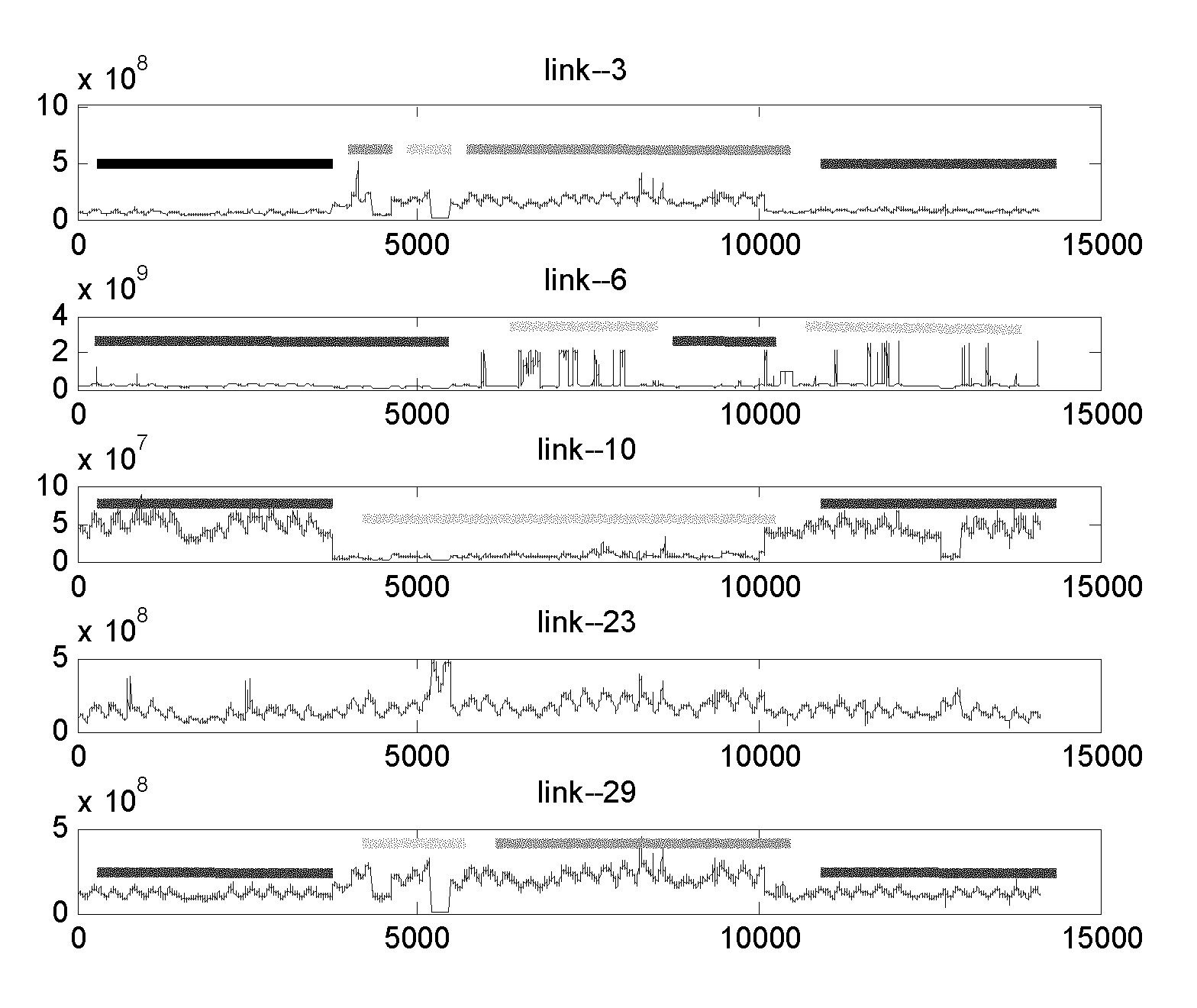

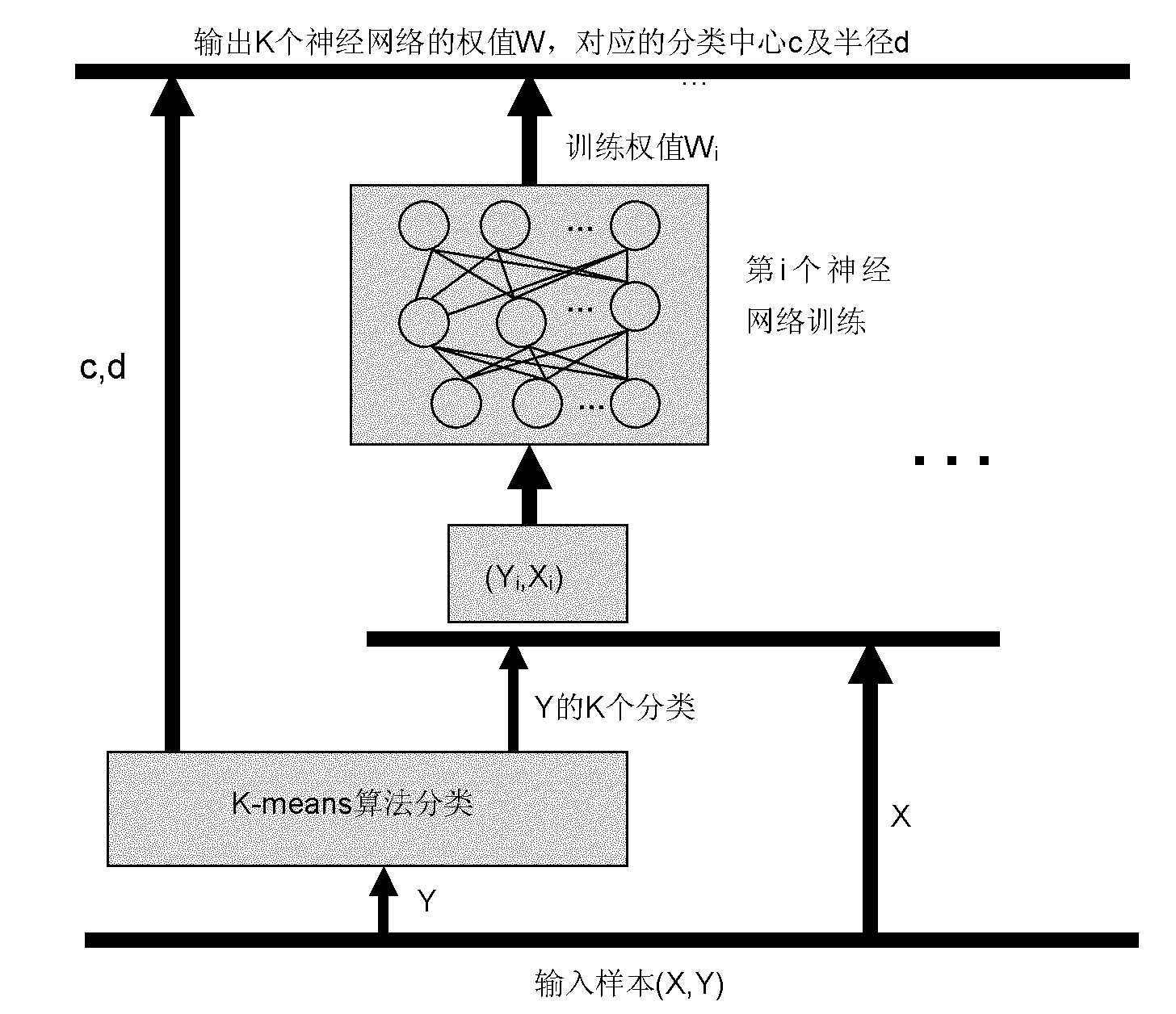

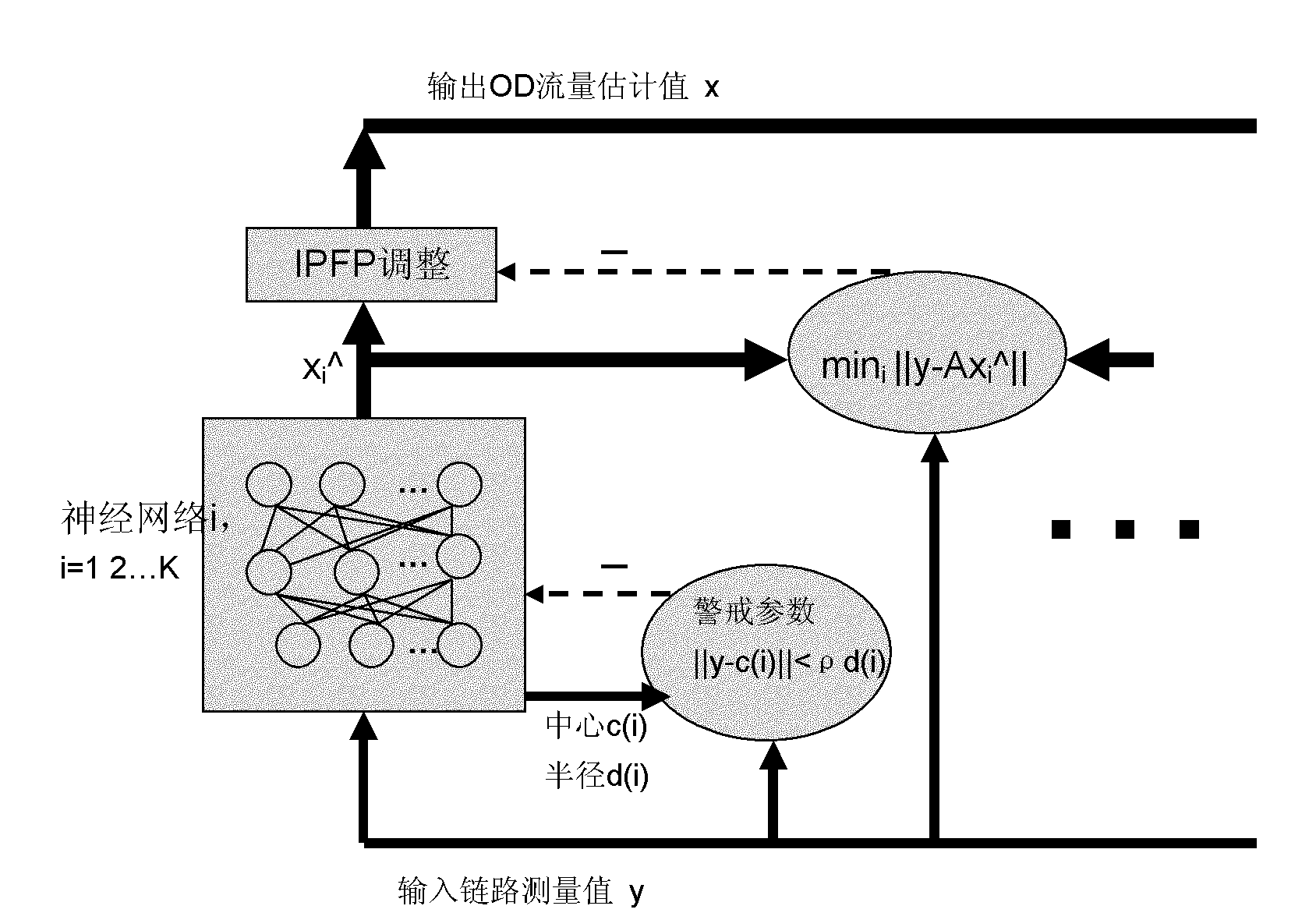

Multi-neural network-based traffic matrix estimation method

ActiveCN102136087AReduce mistakesOvercoming deformationData switching networksNeural learning methodsTraffic capacityNerve network

The invention provides a multi-neural network-based traffic matrix estimation method, which can improve the accuracy of the conventional network traffic matrix estimation. According to the method, the problem of memory fading or deformation of the traditional neural network used in traffic matrix estimation can be effectively overcome by respectively training sampled traffics before classifying. The errors of the multi-neural network-based estimation is remarkably less than that of estimation based on the traditional neural network.

Owner:HUNAN UNIV

Wood-base composite thickening plates and manufacture method thereof

ActiveCN102744752AOvercoming deformationHigh dimensional stability and corrosion resistancePressure impregnationDomestic articlesContinuous productionHigh polymer

The invention relates to wood-base composite thickening plates and a manufacture method thereof. The wood-base composite thickening plates are composed of three organic high polymer materials of fast-growing wood accounting for 65-70% of the total weight of the plates, 18-20% of phenolic resin and 12-15% of bentonite. The thickness of the plates ranges from 40mm to 200mm, and the size of the breadth of the plates can be set according to requirements. The manufacture method achieves replacement of a method of drying a veneer and dipping glue with a method of finishing vacuum dehydration and glue dipping by one step, manual paving is replaced with mechanical paving to overcome unevenness of blank paving, a method of preheating to increase blank temperature to quicken heat conducting during plate lamination is used, limiting bottleneck of producing thickened plates is broken through, and continuous production of the thickened plates is achieved. The high-quality wood-base composite material for improving the conditions that natural wood resource is shortened for wooden product machining industries is provided, a production method for saving energy and reducing cost is provided for application of fast-growing wood, and the wood-base composite thickening plates are favorable for protecting natural forest resource and environment simultaneously.

Owner:ERDOS CITY HUALIN SALIX TECH CO LTD

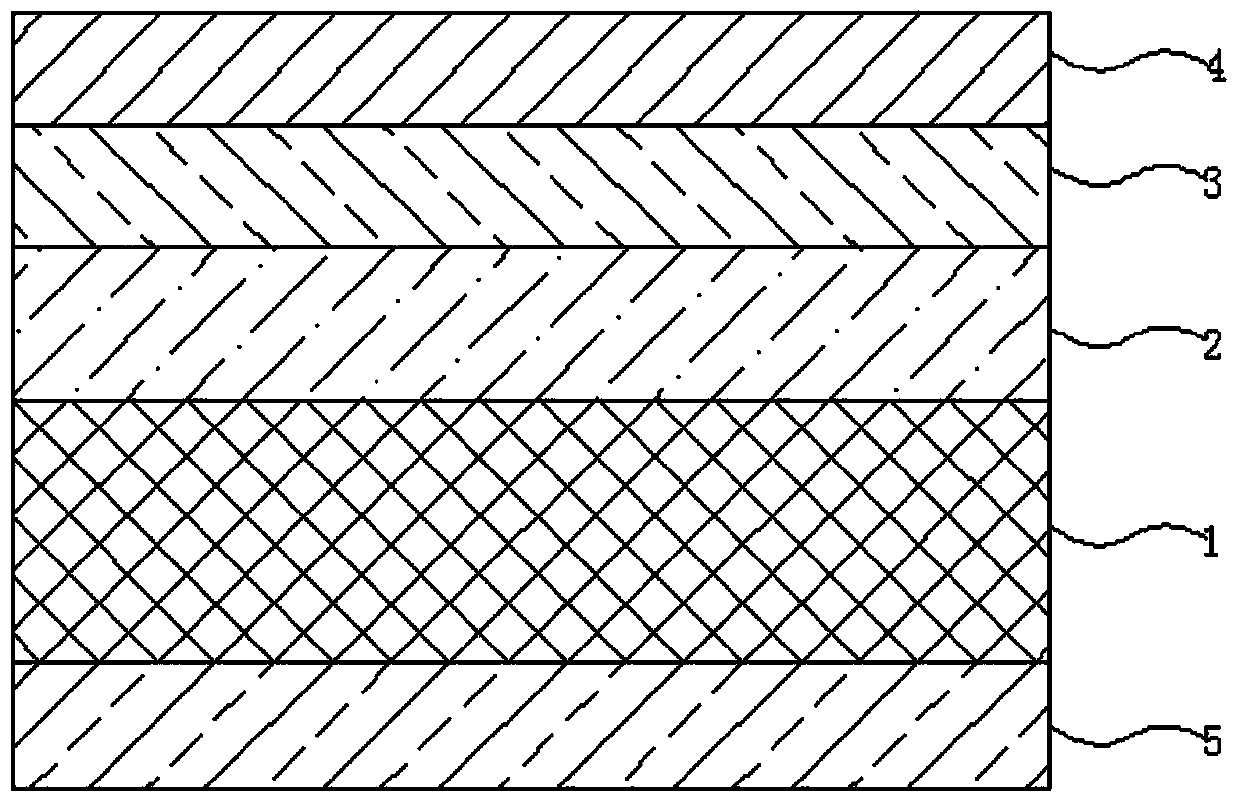

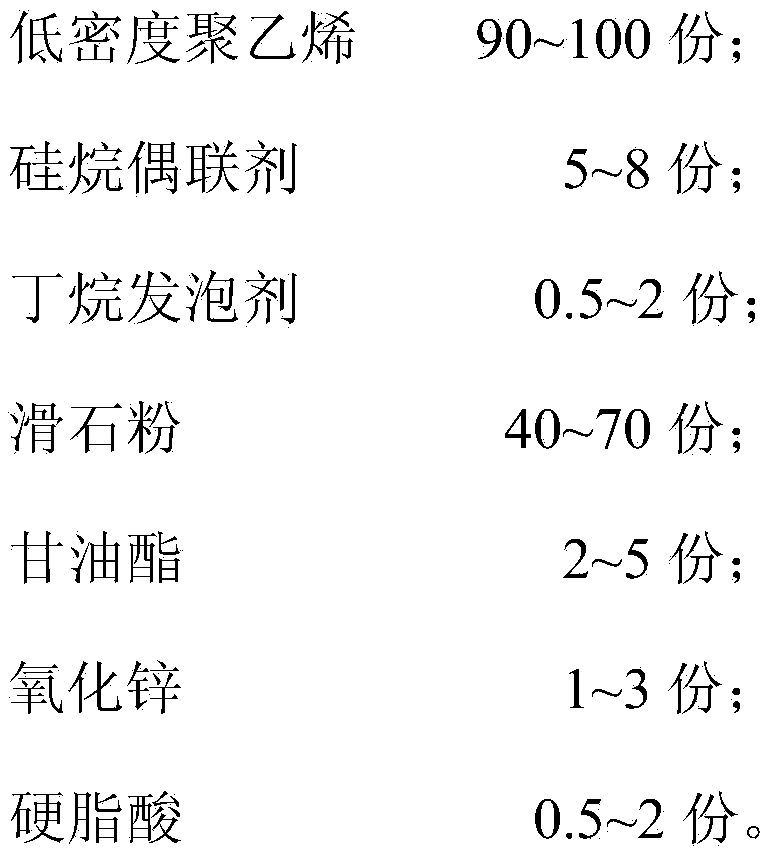

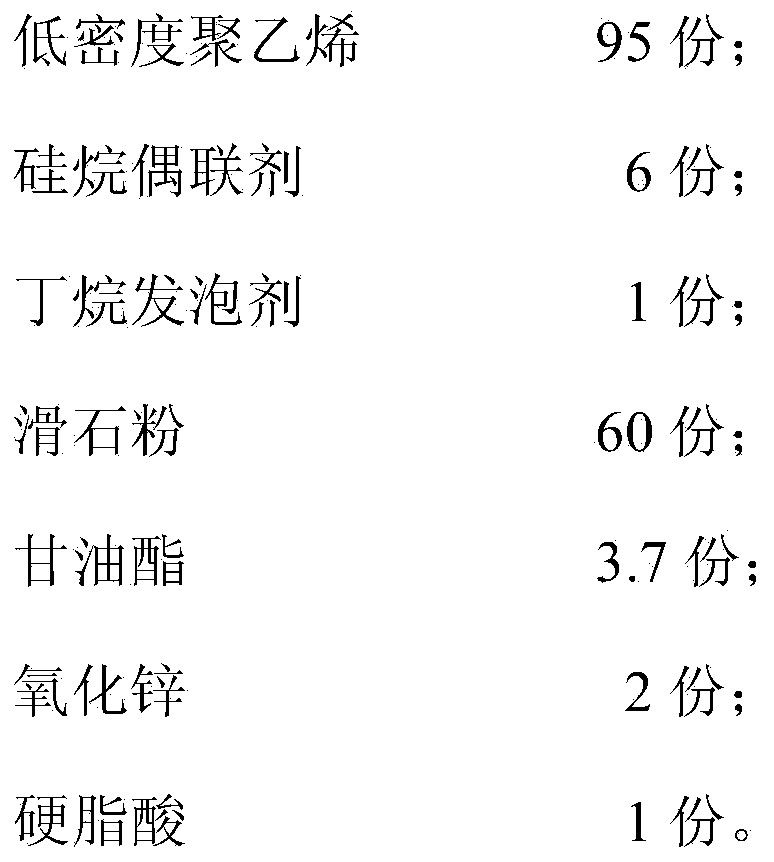

EPE material for crawling pad, preparation method of EPE material and crawling pad

InactiveCN104403173AFine and uniform cellsFlexibleSynthetic resin layered productsLow-density polyethyleneFoaming agent

The invention discloses an EPE material for a crawling pad, a preparation method of the EPE material and the crawling pad. The EPE material comprises the following components in parts by mass: 90-100 parts of low density polyethylene, 5-8 parts of a silane coupling agent, 0.5-2 parts of a butane foaming agent, 40-70 parts of talcum powder, 2-5 parts of glyceride, 1-3 parts of zinc oxide and 0.5-2 parts of stearic acid. The crawling pad prepared from the EPE material is favorable in water resistance, is flexible, light and elastic, can absorb and disperse external impact force through bending to achieve a buffer effect, overcomes the defects of deformation and poor rebound resilience, and meanwhile, has a thermal insulating effect and is easy to clean.

Owner:SUZHOU JIUDING

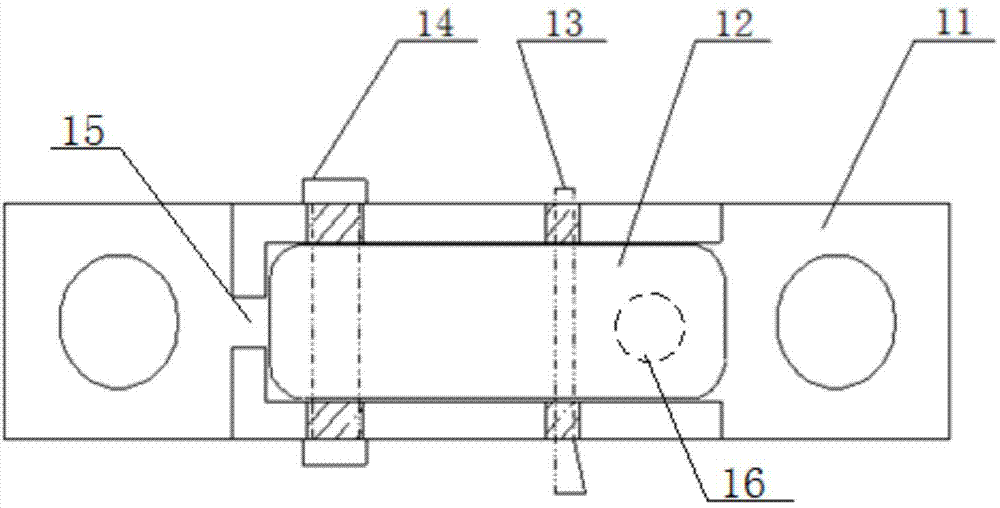

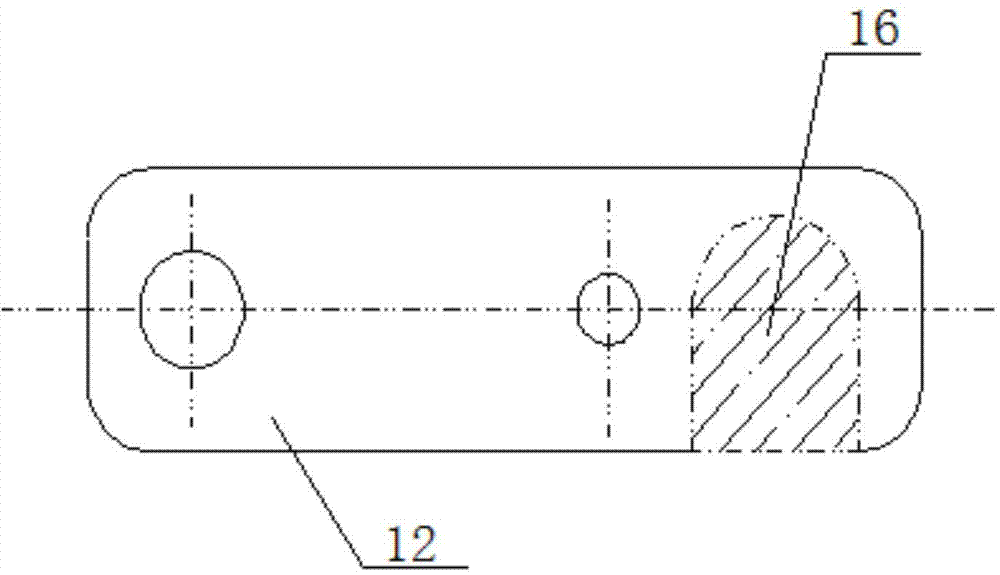

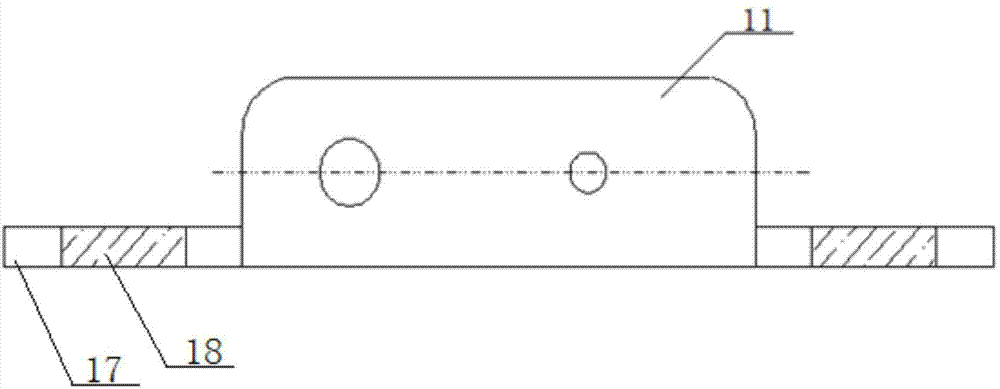

Connecting piece for auxiliary frame and installation method thereof

ActiveCN104712220ANot easy to cause damageShorten the installation cycleFrame fasteningGlass fiberAlloy

The invention discloses a connecting piece for an auxiliary frame and an installation method of the connecting piece for the auxiliary frame. An inner shaft is arranged in a shell, a fixing pin and a positioning pin are arranged in the direction perpendicular to the principle axis of the inner shaft, the positioning pin is arranged at one end of the inner shaft, and the fixing pin is arranged in the middle of the inner shaft. A limiting device is arranged in the shell and is located at the end fixed to the positioning pin through the inner shaft. A cavity is formed in the portion, opposite to the shell, of the surface of the inner shaft, and a spring is arranged in the cavity. According to the connecting piece for the auxiliary frame and the installation method of the connecting piece for the auxiliary frame, the connecting piece serving as a universal connecting piece can be applied to aluminum alloy doors / windows or plastic steel doors / windows or aluminum wood doors / windows or glass fiber reinforced plastic doors / windows, and standard installation is achieved; meanwhile, the connecting piece is arranged between an outer frame and the auxiliary frame, the displacement and deformation performance is effectively improved, connection of the auxiliary frame and the outer frame is not affected, the problem that doors / windows deform due to deformation of a building is solved, and the service life is greatly prolonged; meanwhile, the connecting piece is convenient to dismantle, and installation efficiency is improved.

Owner:常州玖洲联横建材有限公司

Method for preparing W-Cu alloy in microwave infiltration way

The invention relates to a method for preparing W-Cu alloy in a microwave infiltration way, which comprises the following steps: 1. dispensing W powder and reduced Cu powder according to the weight percentage of W-3Cu, then ball-milling and mixing; 2. fetching the mixed powder and electrolytic copper powder according to design components, and respectively pressing the mixed powder under the pressure of 150-510MPa to form a cylindrical W framework and an infiltrated Cu pressed billet; 3. putting the pressed cylindrical W framework, the infiltrated Cu pressed billet and SiC slices into an alumina fiber heat-preserving sheath and then putting the sheath into an oven chamber of a microwave high-temperature oven, and vacuumizing the oven chamber to the vacuum degree within 100Pa by a vacuum pump; 4. injecting mixed protection gases of N2 and H2 into the oven chamber of the microwave oven, regulating the output power of the microwave high-temperature oven, heating to about 1350 DEG C at a temperature-rise speed of about 30 DEG C / min, preserving the heat, powering the microwave oven off and cooling to obtain the ideal alloy. The invention has simple process, convenient operation, short sintering period, low energy consumption and excellent performance of the obtained W-Cu alloy and can substitute for the prior process for preparing the W-Cu alloy in an infiltration way.

Owner:CENT SOUTH UNIV

Magnesium-nickel-containing coating for marine climate-resistant preservative treatment

ActiveCN102010624AEnvironmentally friendlySexual stabilityAnti-corrosive paintsOrganic solventAdhesive

The invention relates to a coating for marine climate-resistant engineering part preservative treatment, which comprises 30.0 to 50.0g of aluminum-zinc-silicone alloy powder, 10.0 to 25.0mL of organic solvent, 1.0 to 4.0g of nano-oxide particle reinforcing agent, 15.0 to 30.0mL of deionized water, 2.0 to 5.0g of adhesive, 1.0 to 3.0g of corrosion inhibitor, 0.1 to 2.0mL of a dispersing agent and 0.1 to 2.0g of thickening agent, wherein the aluminum-zinc-silicone alloy powder consists of aluminum, zinc, silicone, magnesium and nickel.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

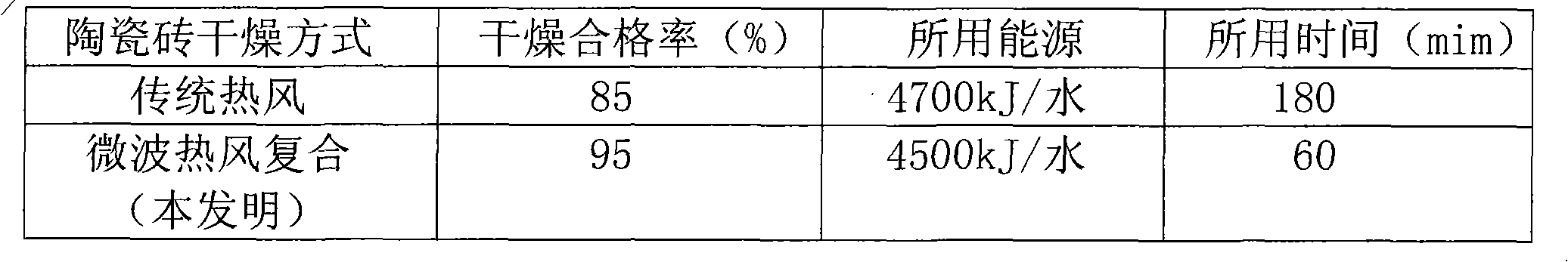

Method for producing large-size thin ceramic bricks by microwave and hot air composite drying

The invention relates to a method for producing large-size thin ceramic bricks by microwave and hot air composite drying, and belongs to the technical field of ceramic brick body dehydration production process. The method has the main technical characteristic that: the ceramic brick body is dried by using microwave and hot air respectively. The method comprises the following steps of: putting theceramic brick body with moisture content of 16 to 18 percent into a microwave drying room to perform drying treatment; and allowing the ceramic brick body to enter a hot air drying room to perform microwave forming drying and hot air dying. The method has the advantages of high drying speed, uniform heating and drying, high forming quality of products, high thermal efficiency, balanced thermal stress, time conservation, and capability of making the ceramic brick body uniformly changed during dehydrating and drying by microwave dehydrating and drying at first, and the method also has the advantage of reducing the dehydrating cost of the ceramic brick body by dehydrating and drying the ceramic brick body with the hot air.

Owner:中国国检测试控股集团陕西有限公司

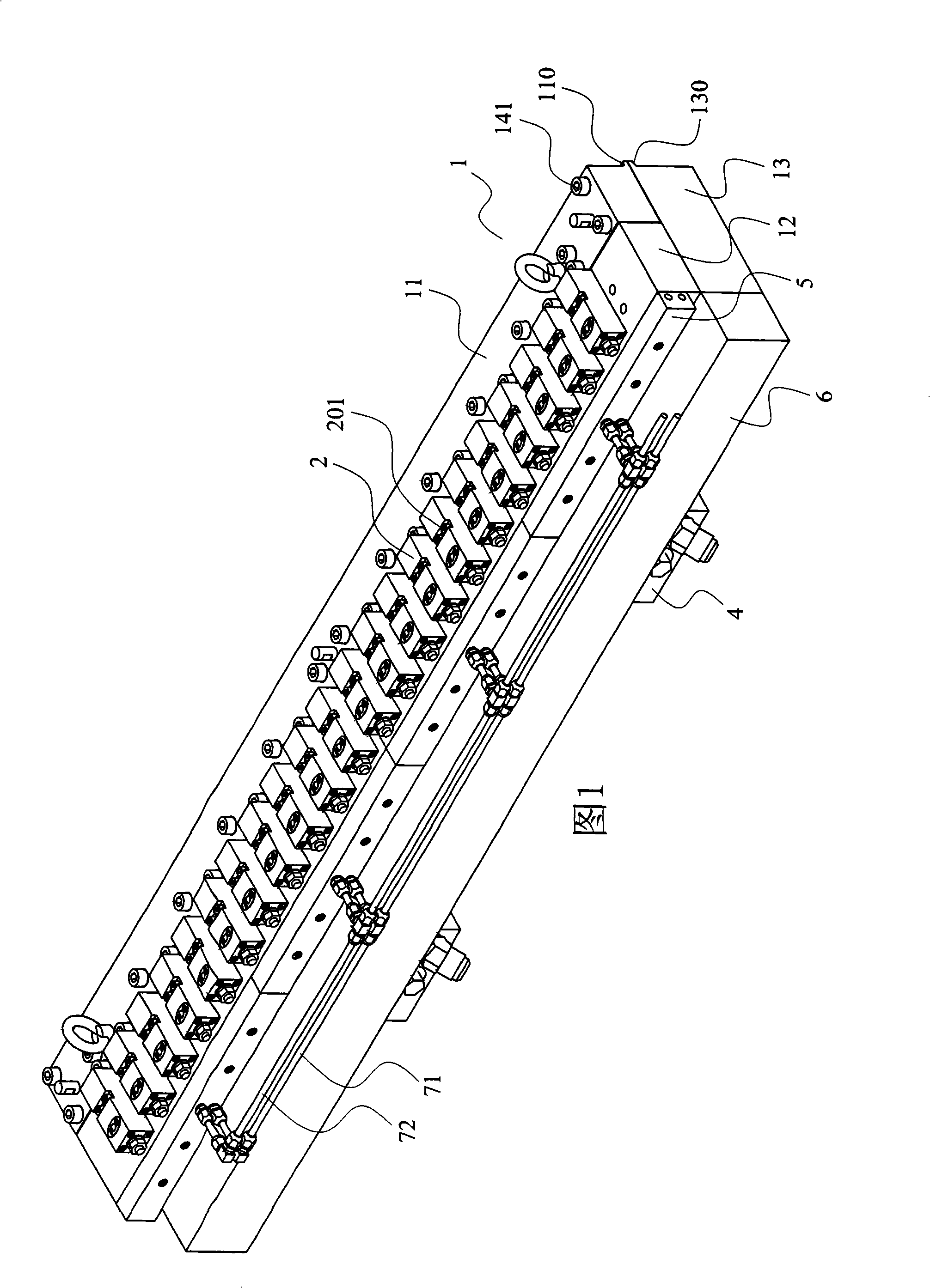

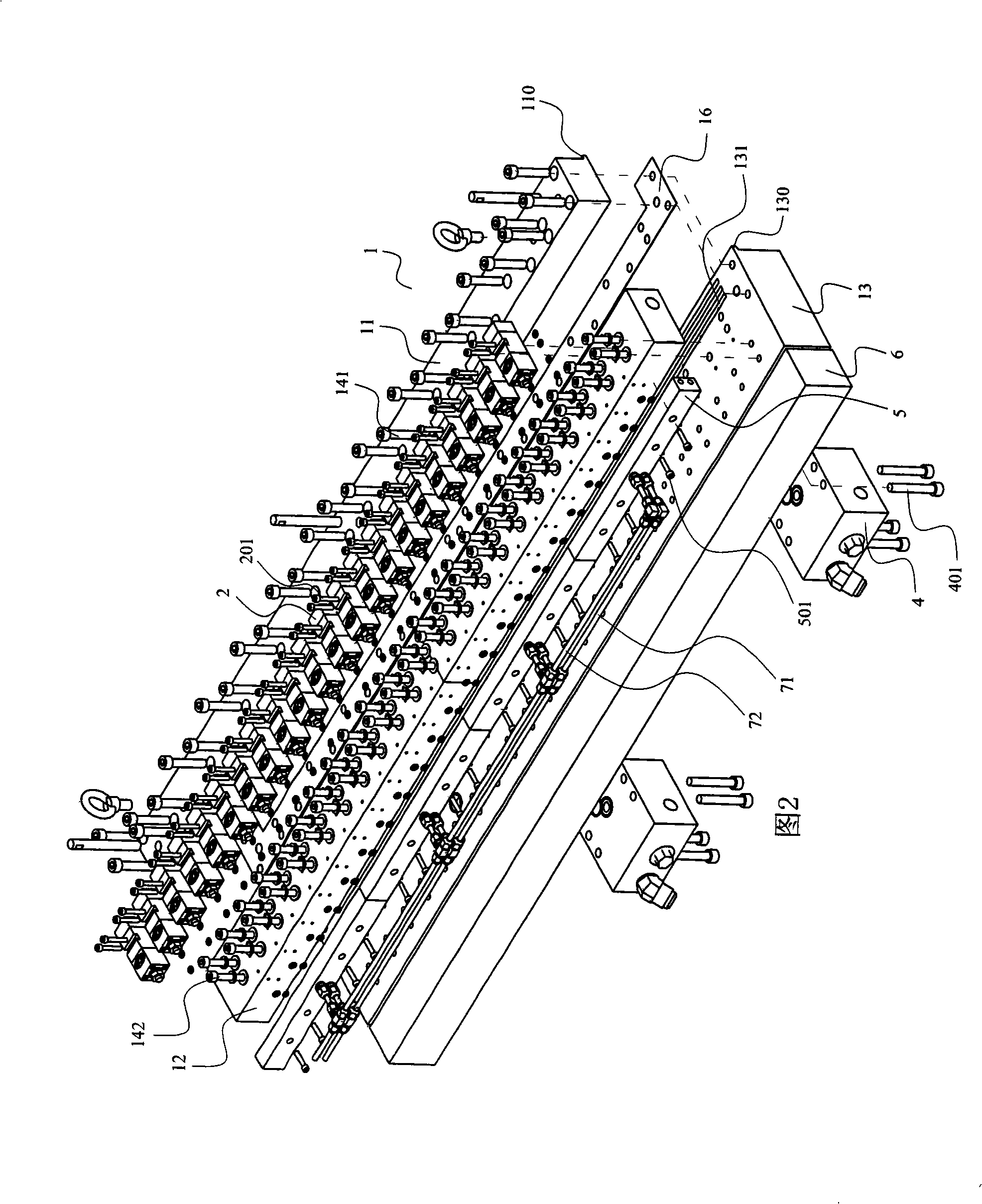

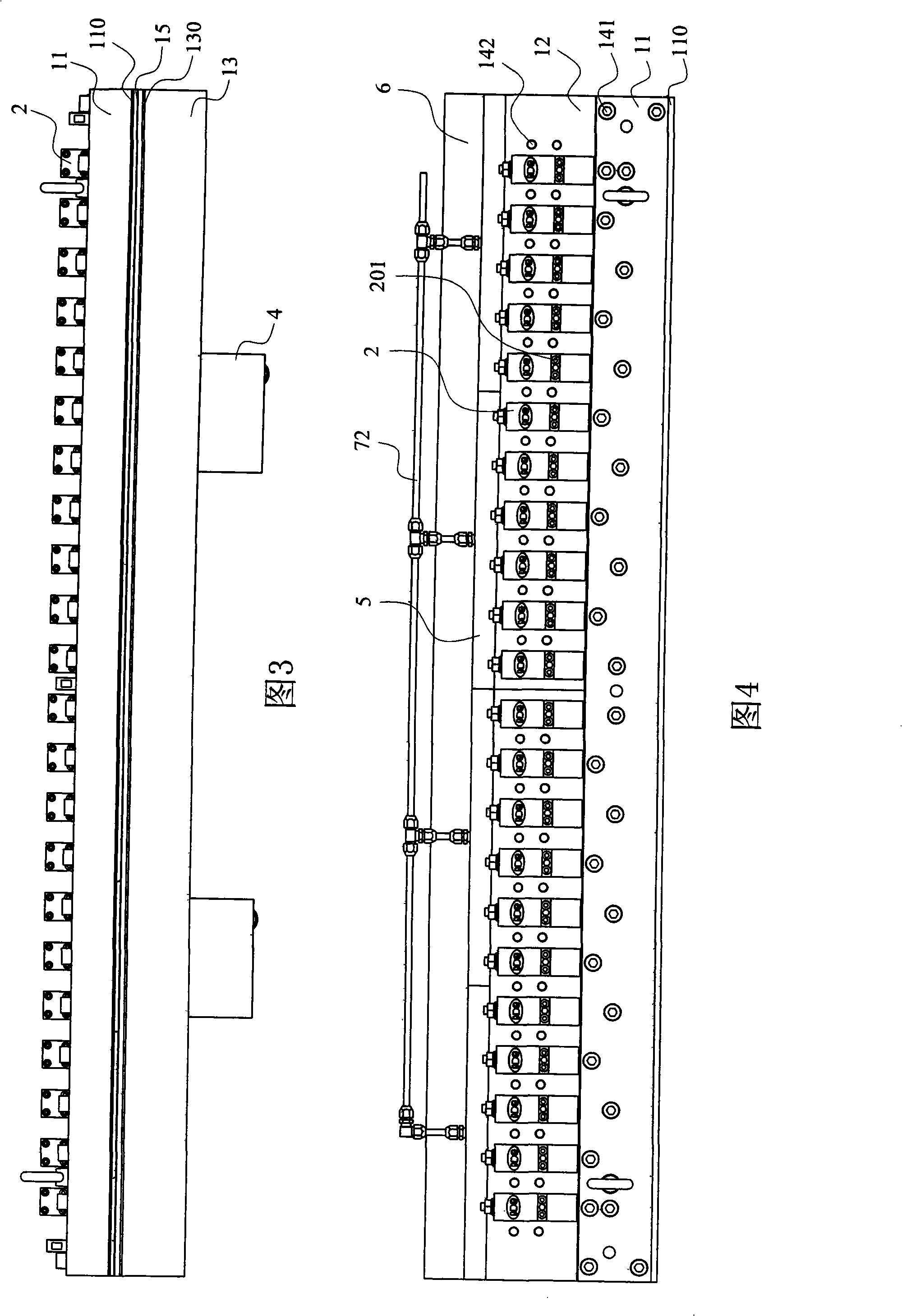

Narrow slit type coating mold and method for producing the same

InactiveCN101347774AConstant and uniform fluidityEvenly distributedLiquid surface applicatorsCoatingsEngineeringCoating

The invention provides a slot-typed coating die and a manufacturing method thereof. The die comprises a module, a plurality of distributors and a plurality of heating devices which are arranged along the length direction of the module at intervals; each distributor is provided with a liquid inlet and a liquid outlet which are communicated with each other by a liquid passage, as well as a valve component which can open / close the liquid passage in an operable way; the module is provided with a slot which extends along the length direction and opens to the front end of the module; a plurality of uniform-flow troughs are formed in the slot; at least a liquid inlet pipeline, a liquid accumulation chamber which extends along the length direction and is communicated with the liquid inlet pipeline, as well as a plurality of first liquid manifolds and a plurality of second liquid manifolds which are corresponding to a plurality of distributors are formed in the module; each first liquid manifold is communicated with the liquid accumulation chamber and the liquid inlet of the corresponding distributor; each second liquid manifold is communicated with the uniform-flow trough in the slot and the liquid outlet of the corresponding distributor. The manufacturing method of the invention comprises that the end surface of the opening of the slot is ground under the simulation working state so as to lead the planeness to achieve the required precision.

Owner:QUANZHOU NDC SPRAY COATING SYST FABTING

Anti-static/flame-retardant XPE environment-friendly foam material for vehicle and preparation method of XPE environment-friendly foam material

The invention provides an XPE environment-friendly foam material for an anti-static / flame-retardant vehicle and a preparation method of the XPE environment-friendly foam material. The XPE environment-friendly foam material is mainly prepared from, by weight, 60-80 parts of PE resin, 4-8 parts of anti-static agent, 20-30 parts of self-made composite flame retardant, 5-20 parts of foaming agent, 2-5 parts of cross-linking agent and 3-5 parts of blowing promoter. The material is prepared through extrusion of an XPE master slice in a single-screw extruder, calendaring, continuous normal-pressure foaming in a foaming furnace, cooling and shaping, and trimming and coiling. Anti-static and flame-retardant performance is integrated in the XPE foam material, the formulation is simple and scientific, the material has the anti-static performance and the flame-retardant performance, chemical and physical performance is stable, electrostatic induction and inflammability are completely eliminated, and the foam material is safe, free of toxins and smells and environmentally friendly, and saves energy.

Owner:FUJIAN SANSHENG IND

Rare earth-titanium-nickel-containing sea climate resisting paint used for anti-corrosive treatment

ActiveCN102010625AEnvironmentally friendlySexual stabilityAnti-corrosive paintsRheniumOrganic solvent

The invention relates to a sea climate resisting paint used for performing anti-corrosive treatment on engineering parts. The paint comprises the following components: 30.0 to 50.0 grams of aluminum-zinc-silicon alloy powder, 10.0 to 25.0 milliliters of organic solvent, 1.0 to 4.0 grams of nanometer-scale oxide particle reinforcing agent, 15.0 to 30.0 milliliters of deionized water, 2.0 to 5.0 grams of binder, 1.0 to 3.0 grams of corrosion inhibitor, 0.1 to 2.0 milliliters of dispersant and 0.1 to 2.0 grams of thickener, wherein the aluminum-zinc-silicon alloy powder consists of aluminum (Al), zinc (Zn), silicon (Si), rhenium (RE), titanium (Ti) and nickel (Ni).

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

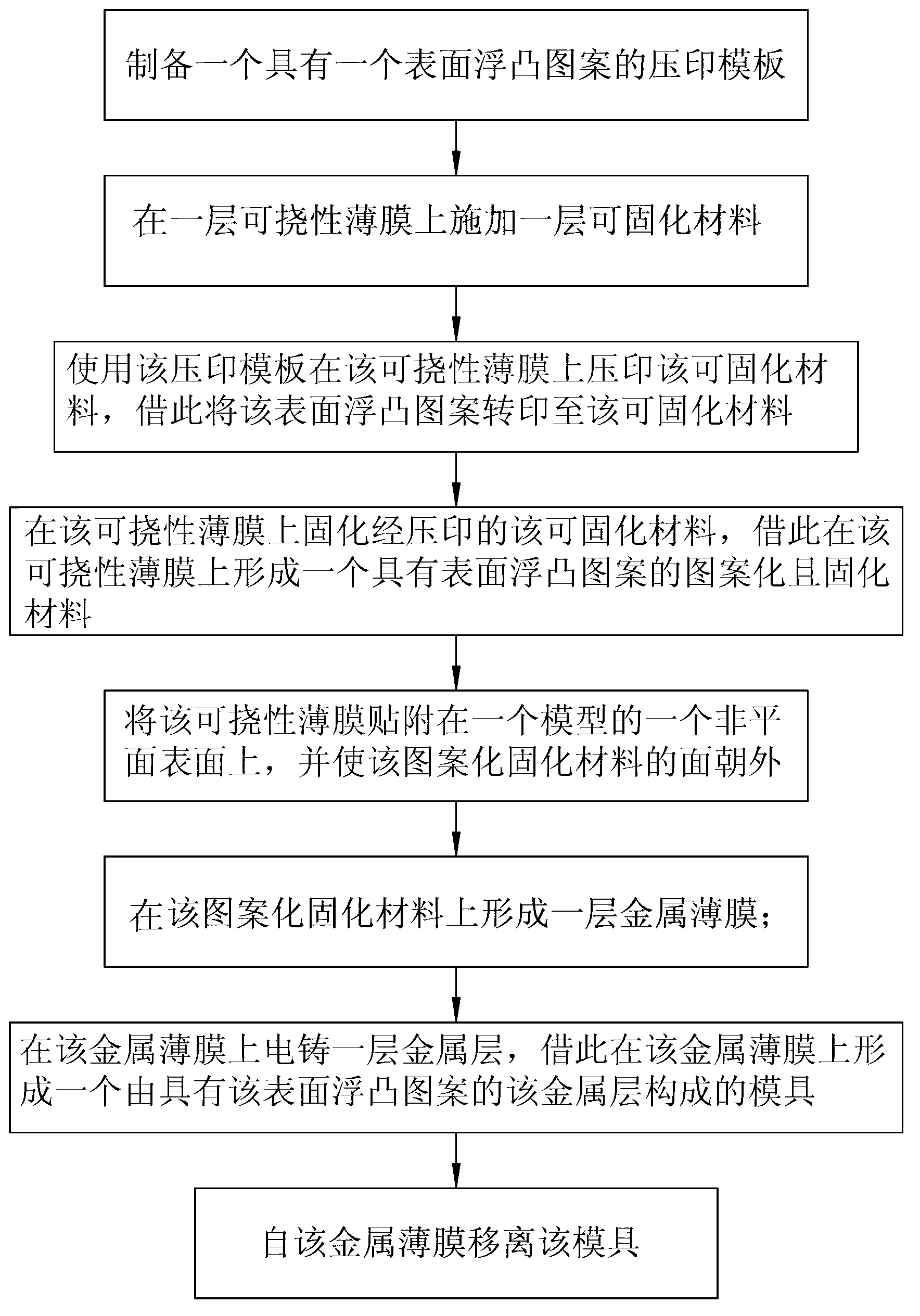

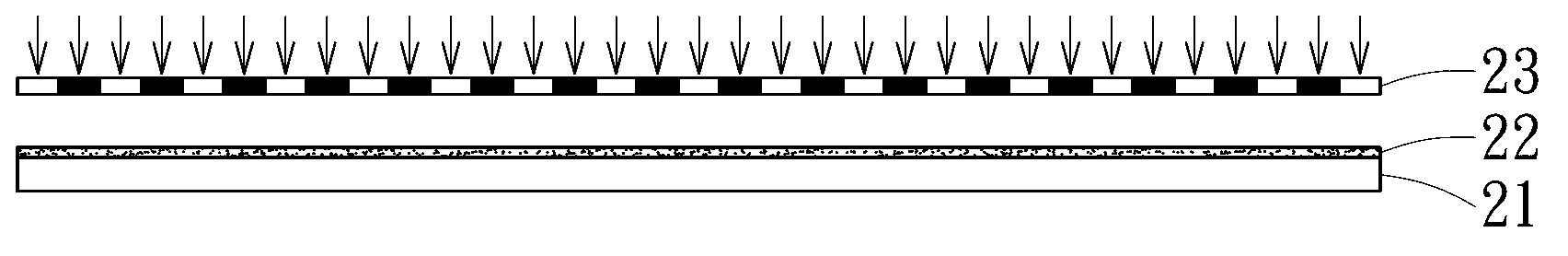

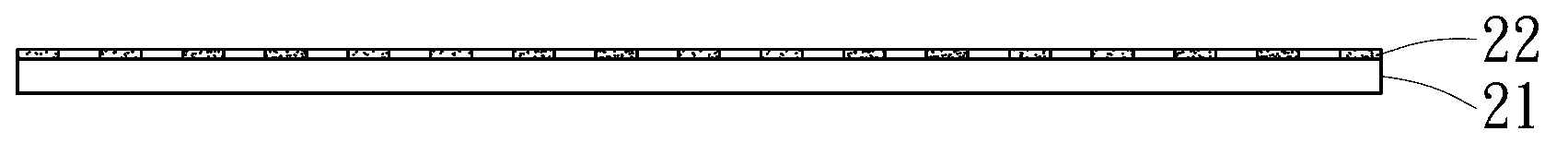

Molding tool with a three dimensional surface relief pattern and method of making the same

Owner:TAIWAN GREEN POINT ENTERPRISE

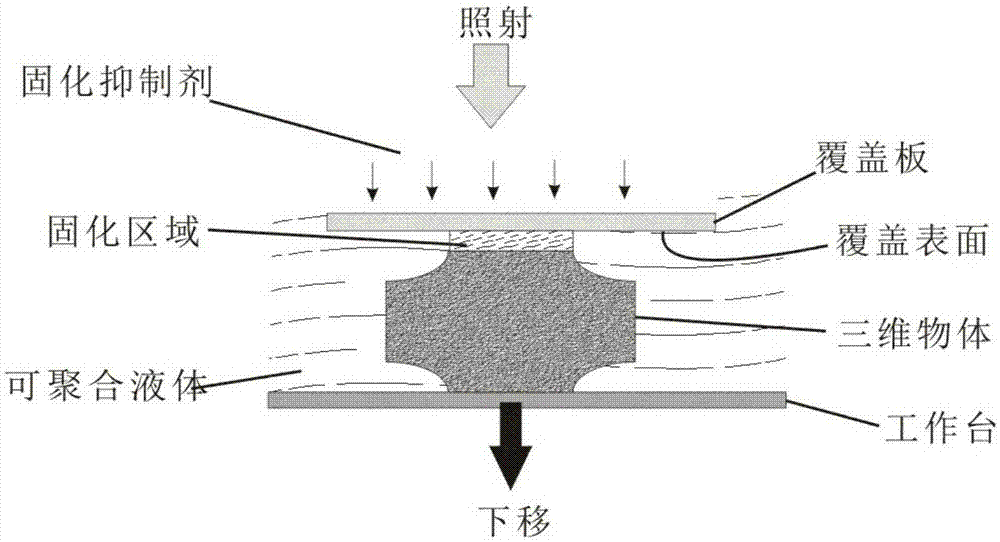

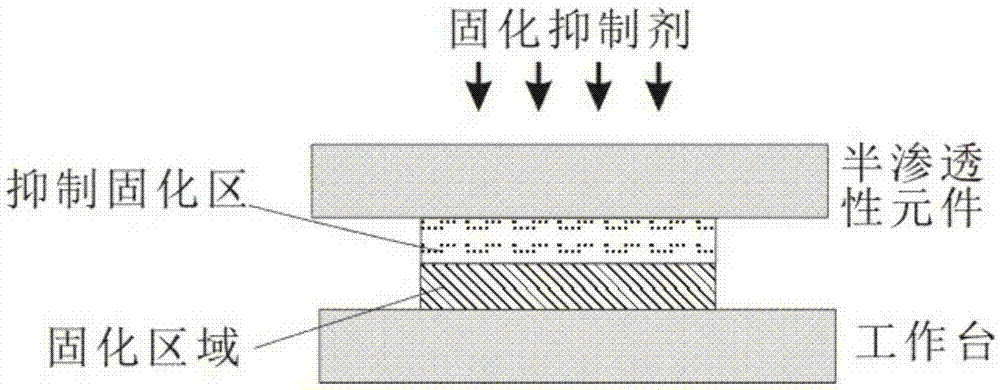

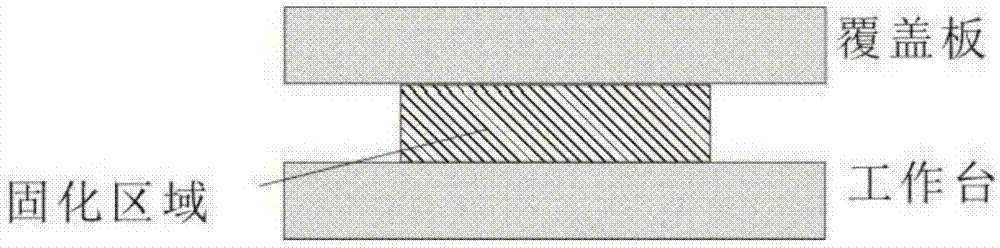

3D printing equipment and method

ActiveCN106976230AEasy or damage-free disengagementOvercoming Cured Surface Distortion ProblemsAdditive manufacturing apparatus3D object support structuresManufacturing technologyEngineering

The invention relates to 3D printing equipment. The 3D printing equipment comprises an irradiation source, a workbench and a liquid tank. The workbench is used for bearing an established 3D body. The liquid tank is used for containing polymerizable liquid of the established 3D body. The 3D printing equipment further comprises a covering plate. The covering plate is located in the liquid tank or at the top of the liquid tank. The irradiation source irradiates from the upper side of the covering plate, and the covering plate is an element transparent to the irradiation source. The lower surface of the covering plate is provided with a covering surface, and the covering surface is kept to make contact with the polymerizable liquid in the printing process. The invention further provides a 3D printing method. According to the technical scheme, new irradiation curing can be performed without scraping flat, and the defects that the liquid level fluctuates, the machine is complex, the speed is low and continuous printing cannot be achieved in a traditional 'from-top-to-bottom' 3D manufacturing technology are overcome.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

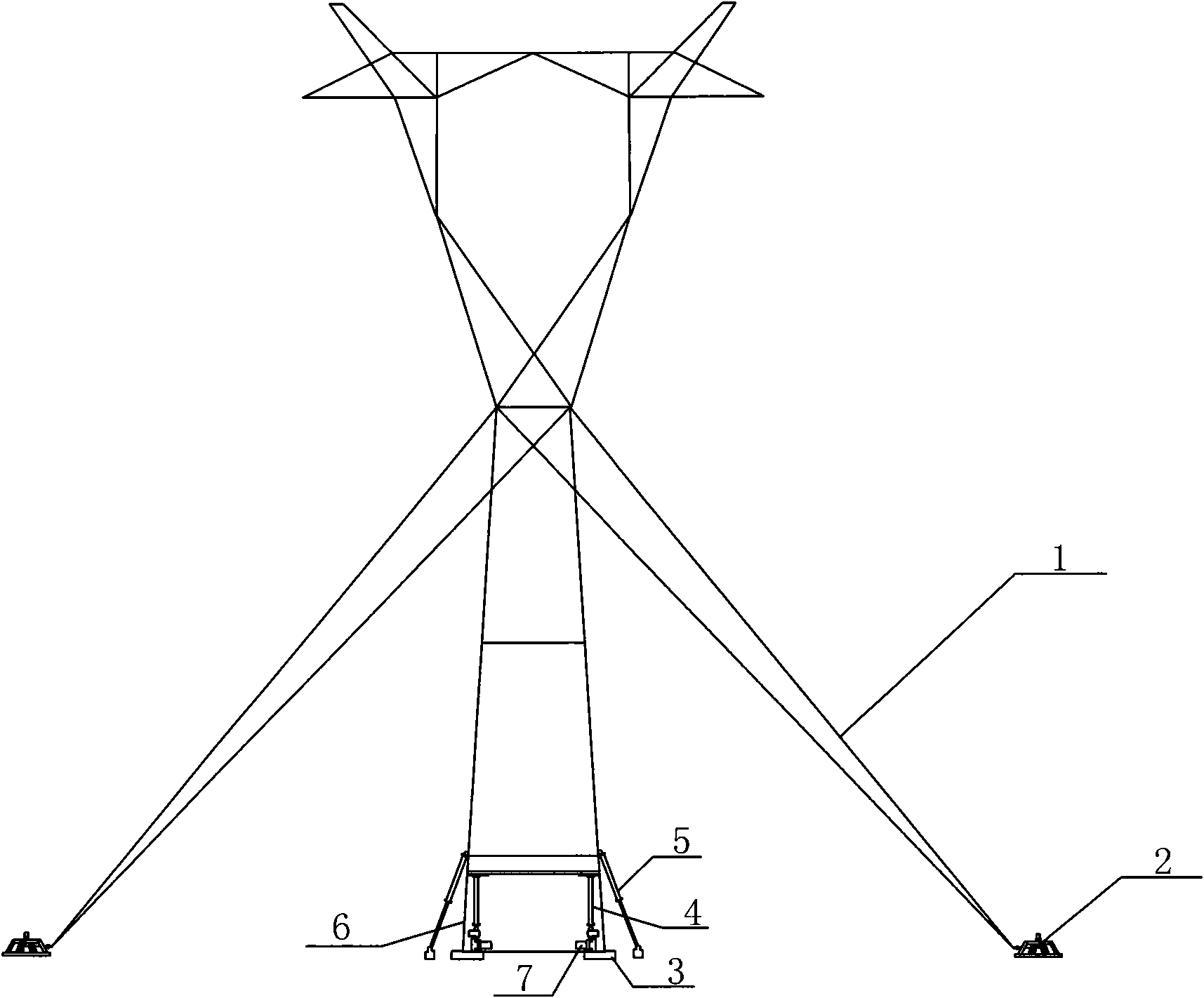

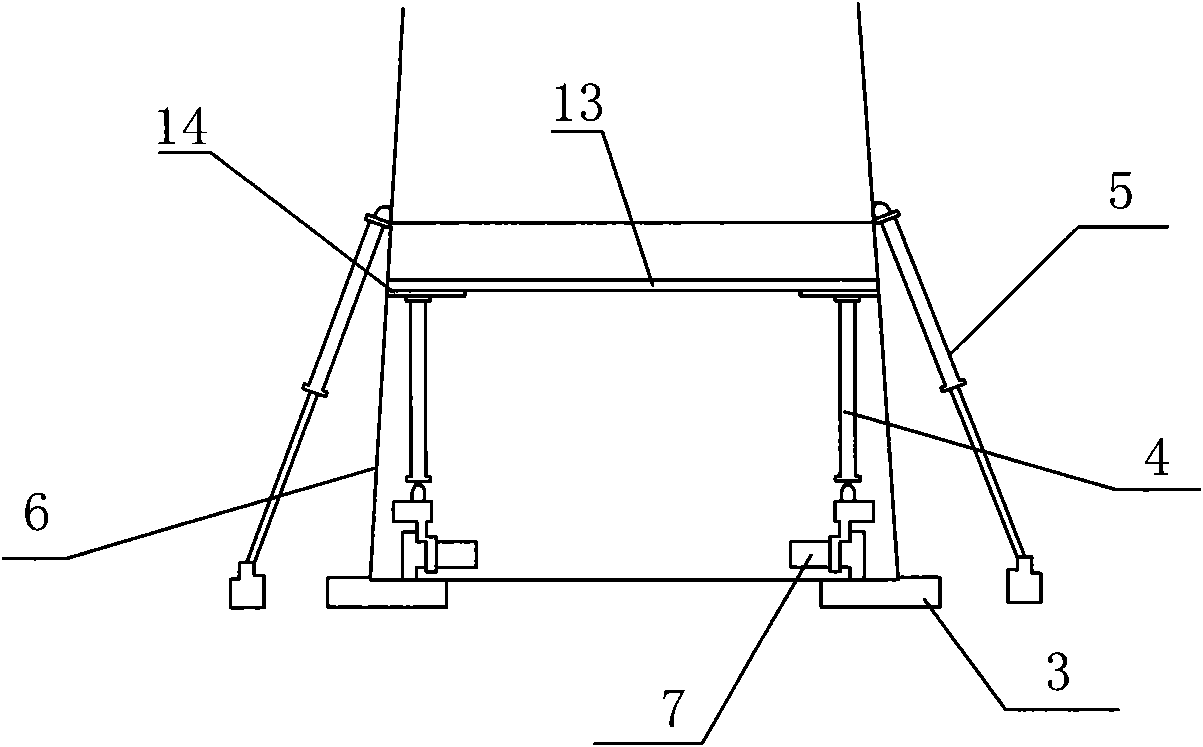

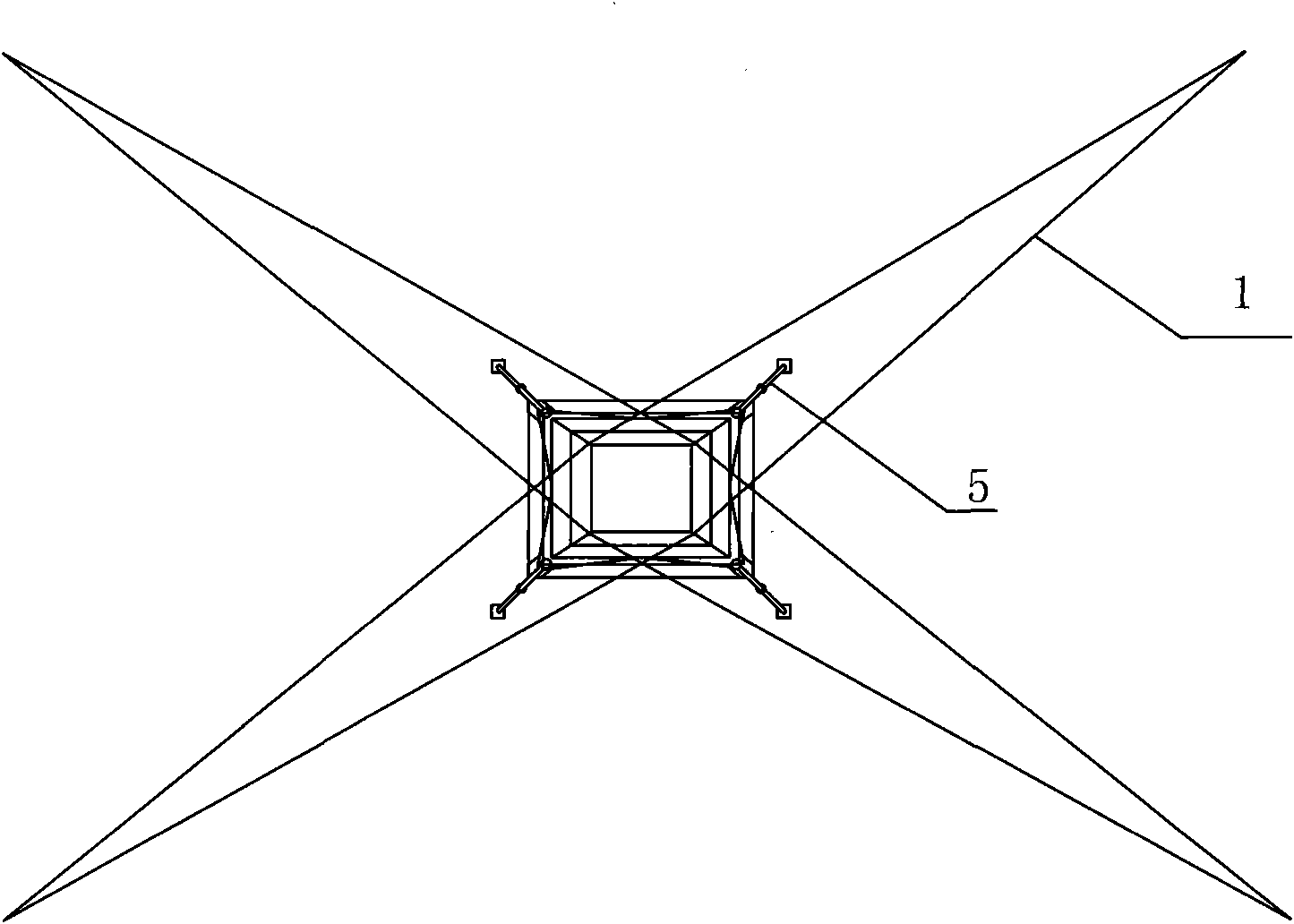

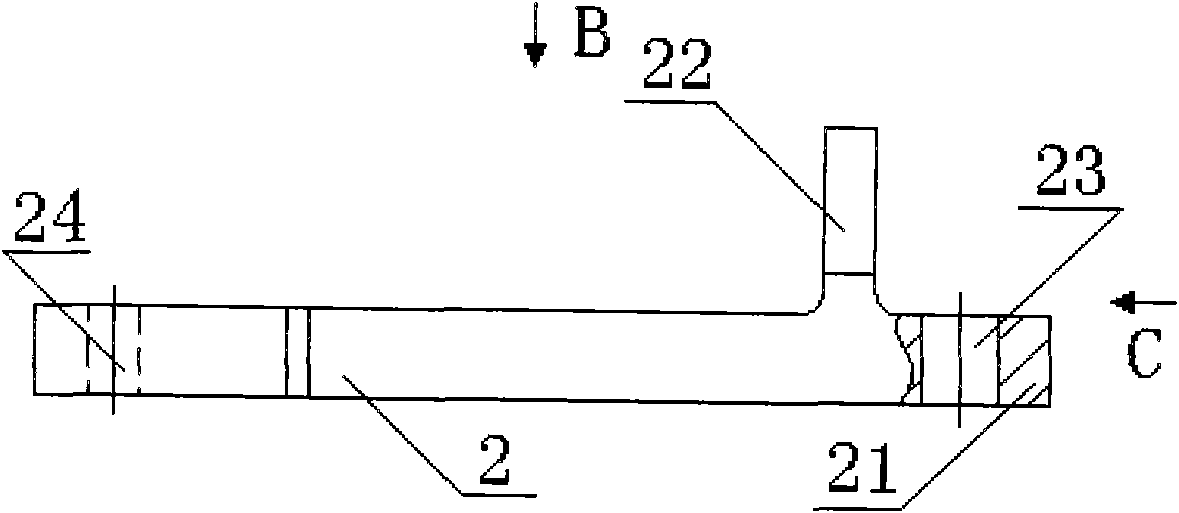

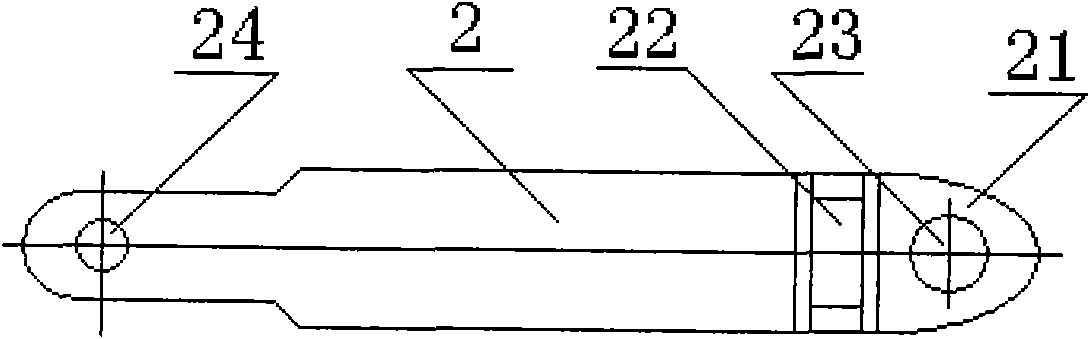

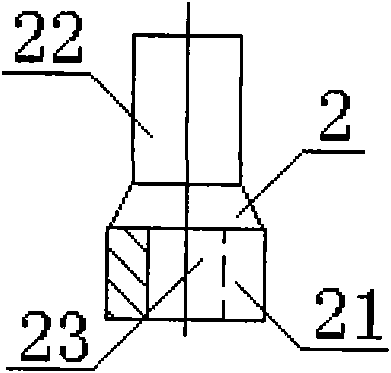

Device arranged on original foundation of high voltage transmission tower and capable of hoisting height of tower and preventing mining-induced deformation

The invention discloses a device which is arranged on the original foundation of a high voltage transmission tower and capable of hoisting the height of the tower and preventing mining-induced deformation. The device comprises a metal foundation sheath sleeved on the original foundation of a high voltage transmission tower, a reversible translation support arranged on the foundation sheath, and a vertical lifting support arranged on the reversible translation support, wherein the upper end of the vertical lifting support is connected with the tower leg of the high voltage transmission tower, and the vertical lifting support is composed of a hydraulic lifting support and a fine-tuning lifting device. The device of the invention is arranged on the original foundation of a high voltage transmission tower, and has the functions of hoisting the height of the tower and preventing mining-induced deformation, thereby solving the problem that the earth surface subsidence caused by coal mining has an effect on the high voltage transmission tower, and ensuring the safety of the tower, and realizing the stoping of resources under the high voltage transmission tower.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

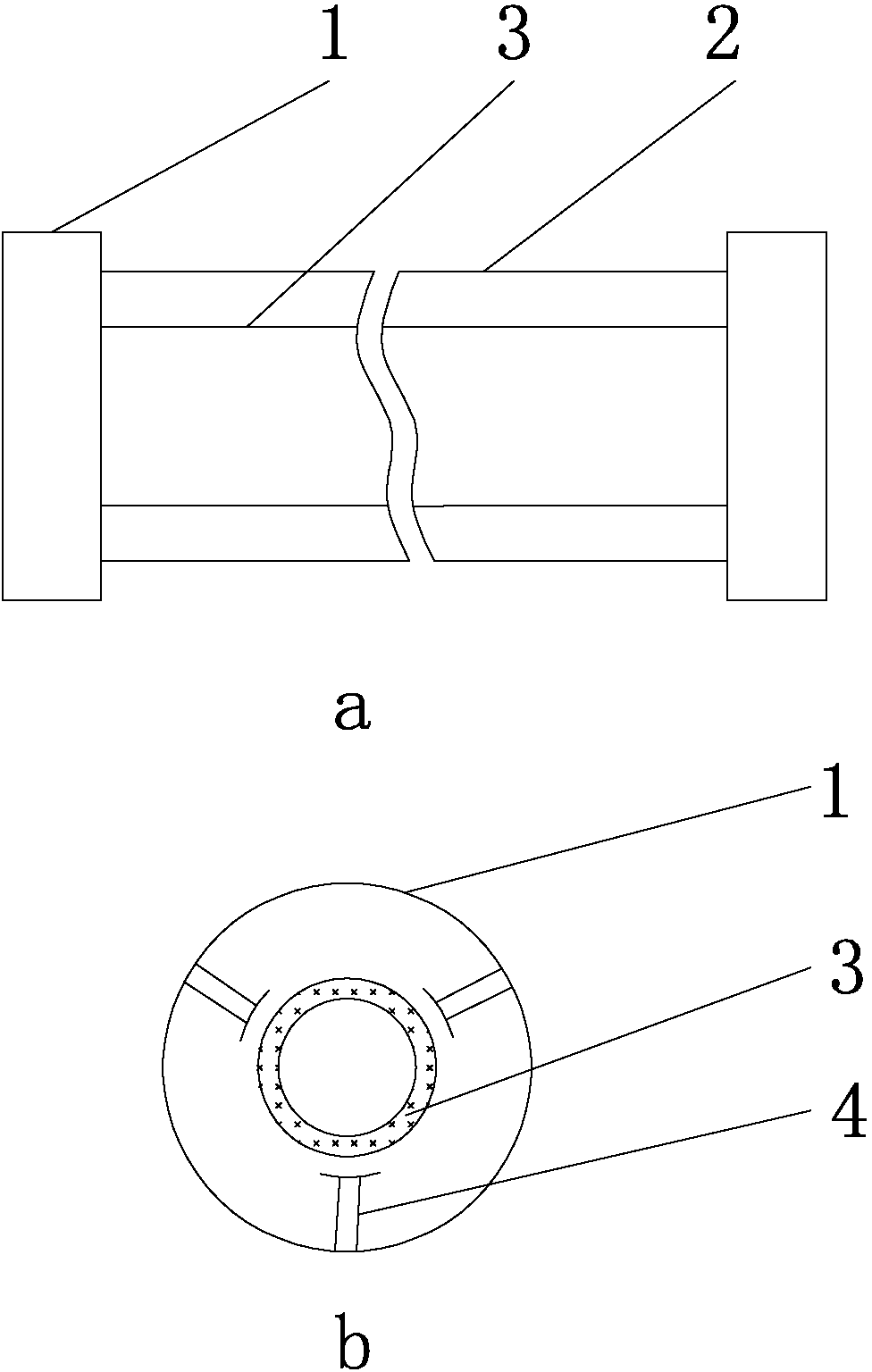

Anti-drop socket-clevis eye

InactiveCN101908747AOvercoming easy wear (breakage) damageOvercoming deformationOverhead installationEngineeringInverted t

The invention discloses an anti-drop socket-clevis eye which belongs to connection devices of high-voltage line hardware and mainly overcomes the defect that a ball head of a ball head hanging ring is easy to eject from the socket-clevis eye as a spring bolt structure is not reasonable in the traditional socket-clevis eye. The anti-drop socket-clevis eye comprises a socket-clevis eye which is provided with a jack and an inverted T-slot, wherein the jack is communicated with one end of the inverted T-slot. The anti-drop socket-clevis eye is characterized by also comprising an anti-drop baffle plate and fastening bolts, wherein the anti-drop baffle plate comprises a bottom plate and a vertical plate connected with the upper side of the bottom plate, the fastening bolts are used for connecting the socket-clevis eye with the anti-drop baffle plate, a bolt bottom plate through hole is arranged at one end of the bottom plate, a lug boss which is provided with a bolt hanging plate through hole is arranged at the notch end of the inverted T-slot of the socket-clevis eye, the other end of the bottom plate and the vertical plate are respectively positioned in the jack of the socket-clevis eye and at the notch end of the inverted T-slot, and the fastening bolts are positioned in the bolt bottom plate through hole and the bolt hanging plate through hole. The invention has the advantages of simple structure, convenient disassembly, assembly and overhauling and good anti-drop effect.

Owner:WUHAN HAIXIANG ELECTRIC POWER CIRCUITRY SHOCKPROOF GOLDTOOL

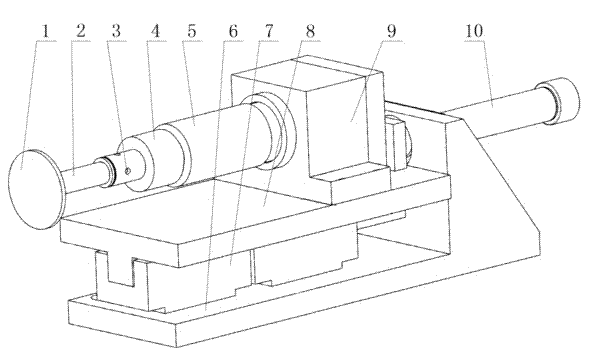

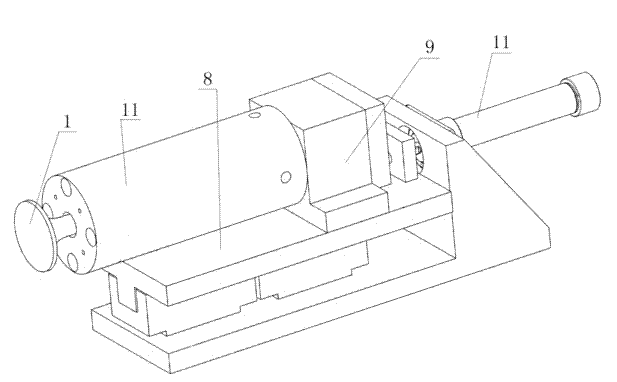

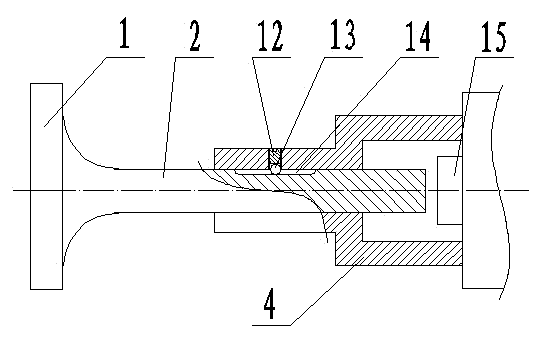

Manganese stripping high-frequency rapping apparatus of electrolytic manganese negative plate

The invention discloses a manganese stripping high-frequency rapping apparatus of an electrolytic manganese negative plate. The apparatus comprises a high-frequency pneumatic hammer, a rapping head, a connection sleeve, a bracket and a moving mechanism, wherein the high-frequency pneumatic hammer comprises a hammer head; the rapping head comprises a moving rod; the connection sleeve is arranged on the high-frequency pneumatic hammer; the hammer head of the high-frequency pneumatic hammer is arranged in the connection sleeve; the moving rod of the rapping head is mounted in the connection sleeve and can do axial reciprocating motion in the connection rod; one end of the moving rod of the rapping head is positioned near the hammer head of the high-frequency pneumatic hammer; the high-frequency pneumatic hammer is arranged on the moving mechanism through a support; and the moving mechanism is arranged on the bracket. The manganese stripping high-frequency rapping apparatus of the electrolytic manganese negative plate can thoroughly separate manganese attached to the surface of a negative stainless steel sheet from the stainless steel sheet, and can avoid the deformation and surface damage of the stainless steel sheet.

Owner:YANCHENG ELECTRONICS EQUIP FACTORY +1

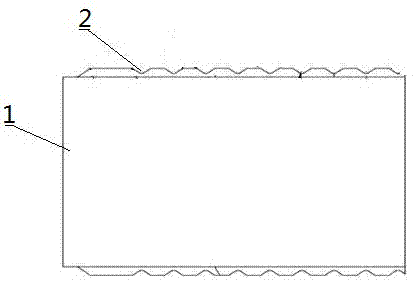

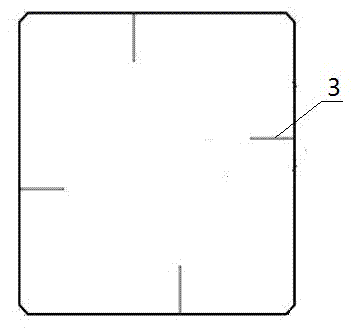

Wave-shaped setter plate

InactiveCN102767965ASolve the cracking problem caused by poor deglueOvercoming deformationCharge supportsWave shapeSetter

The invention discloses a wave-shaped setter plate which comprises a main flat plate (1), the upper surface and the lower surface of the main flat plate (1) are provided with wave-shaped grooves (2), and four sides of any surface of the main flat plate (1) are respectively provided with a linear groove (3). Because the wave-shaped setter plate is additionally provided with the wave-shaped grooves in the surfaces and the linear grooves in the circumference on the basis of a common setter plate, when a product is sintered, the contact area of the bottom of a magnetic core and the setter plate is reduced, the problem of cracking caused by unsmooth glue discharge in the sintering process of the magnetic core is solved, and the wave-shaped setter plate overcomes the defects of magnetic core deformation and crystallization caused by uneven operation.

Owner:天通(六安)新材料有限公司

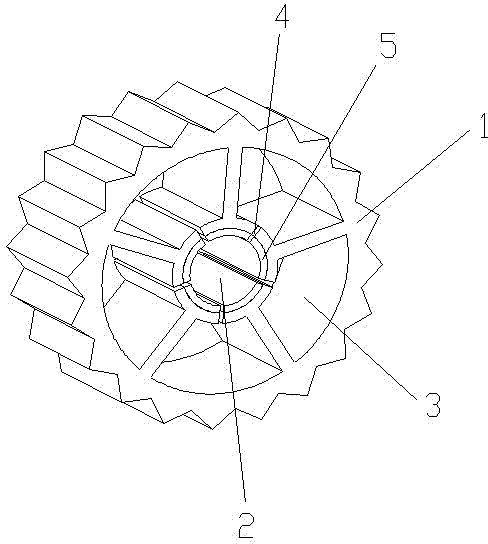

Novel plastic gear

InactiveCN102954175AOvercoming deformationImprove wear resistanceGear lubrication/coolingPortable liftingEngineeringMechanical engineering

The invention discloses a novel plastic gear which comprises a gear body. A shaft hole is arranged in the center of the gear body, at least three fan-shaped straight slots are arranged on the gear body and encircle the shaft hole, radiating grooves are arranged on the shaft hole, an abrasion-resistant layer is arranged in the shaft hole, and the radiating grooves are arranged in centers of lower surfaces of the fan-shaped straight slots. The novel plastic gear is provided with the fan-shaped straight slots and the radiating grooves, accordingly, heat generated when the gear moves and rubs with a shaft can be dissipated timely, and problems of aggregation of abrasion of the gear and deformation caused by high heat are solved. Besides, the novel plastic gear is high in abrasion resistance, stable in transmission performance and long in service life.

Owner:SUZHOU YEMING PLASTIC PRODS FACTORY

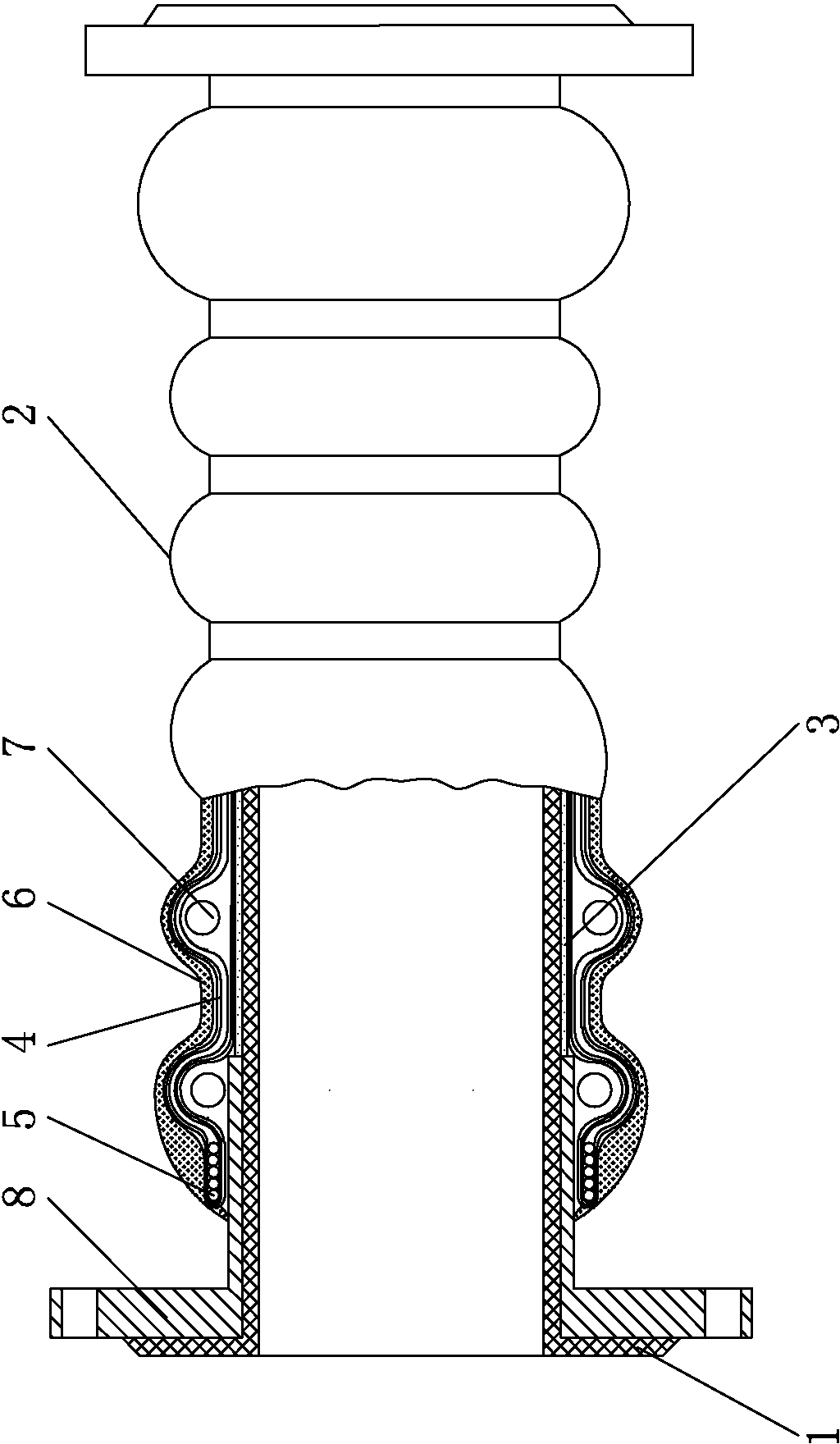

Elastomer composite mud absorption rubber tube and manufacturing technique thereof

ActiveCN103267179AShorten vulcanization timeImprove bond strengthFlexible pipesCoatingsDeformation ProblemPolyurea

The invention provides an elastomer composite mud absorption rubber tube and the manufacturing technique thereof. The elastomer composite mud absorption rubber tube mainly comprises a mud absorption rubber tube body, cord fabric, a tightening steel wire, a rubber tube outer layer, a steel ring and a flange steel short sleeve, wherein a middle layer is arranged on the inner surface of the cord fabric, the middle layer is made of canvas, a composite layer is arranged on the inner surface of the middle layer, and the composite layer is made of polyurethane materials or polyurea materials. After a rubber tube blank is manufactured, the cast-molding technique or the centrifugal molding technique or the spray-molding technique is adopted to manufacture the elastomer composite mud absorption rubber tube. According to the elastomer composite mud absorption rubber tube and the manufacturing method thereof, due to the elimination of inner glue existing in a current mud absorption rubber tube, the vulcanizing time of the tube blank is shortened; the middle canvas layer single-face rubber lining technique improves the bonding strength between an elastomer and the cord fabric; due to the fact that specialized supports are designed and used in the centrifugal technique and in the spraying technique, the deformation problem of the tube body in a manufacturing process is solved, and the uniformity of the thickness of the composite layer is guaranteed.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

Net and line cutter

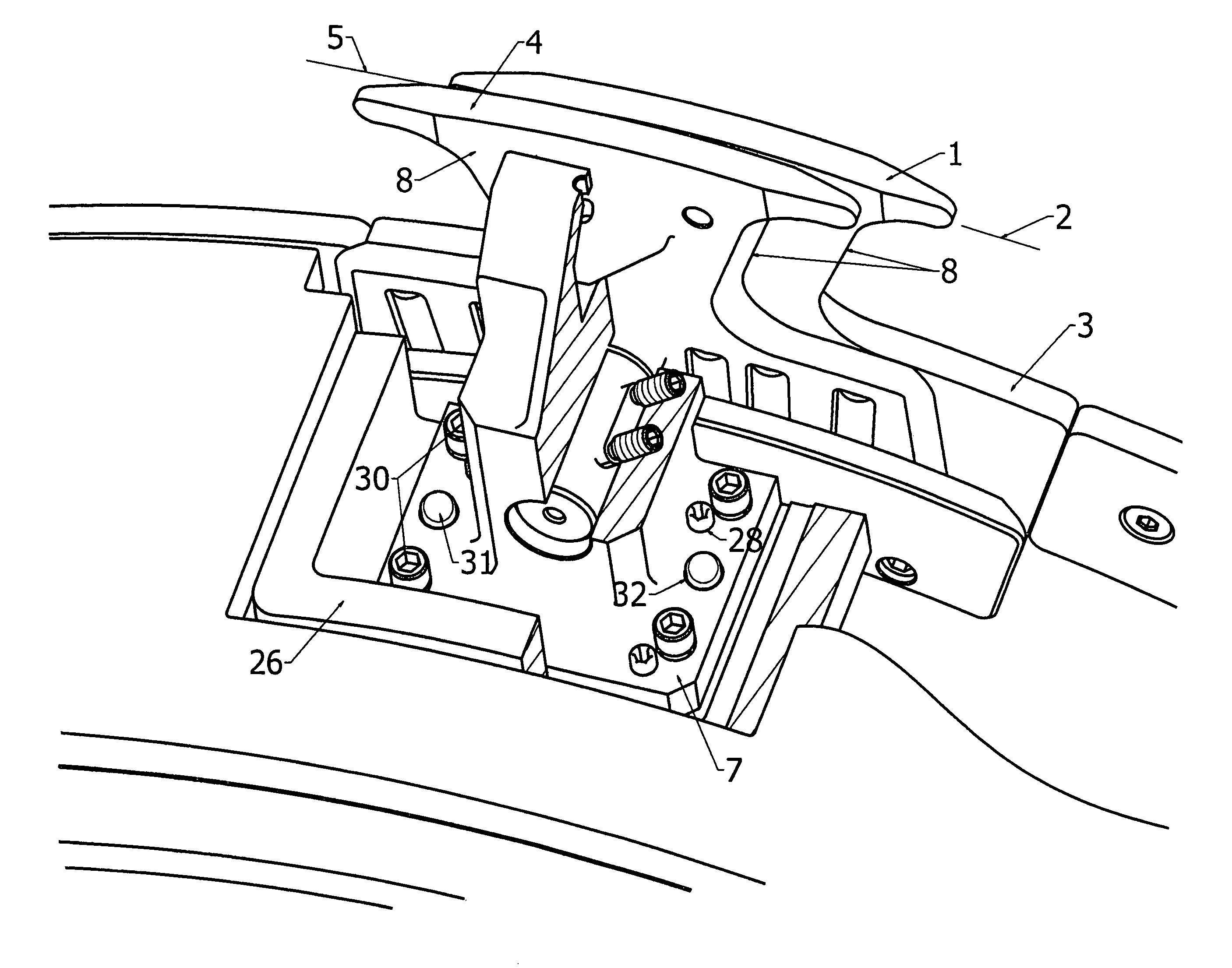

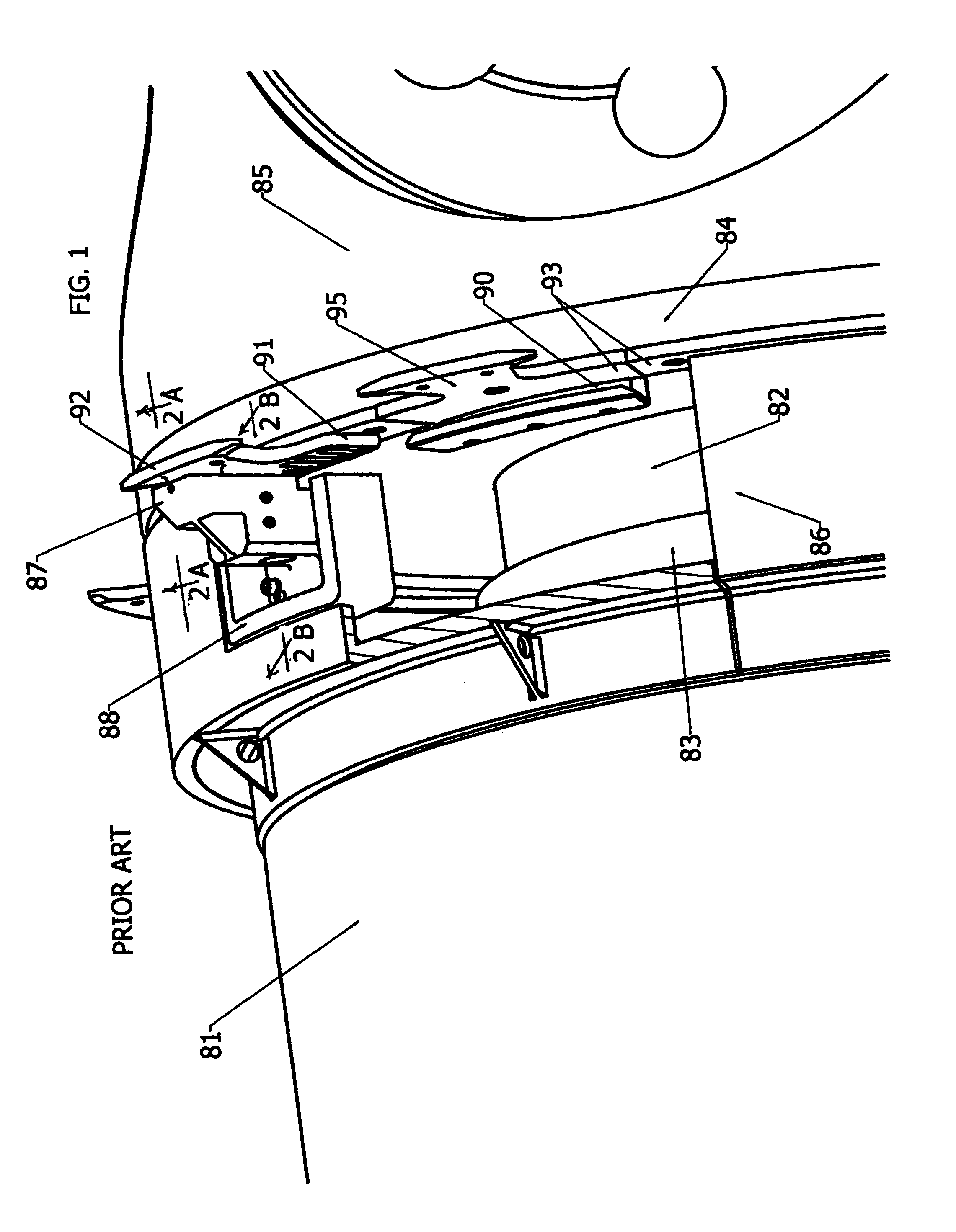

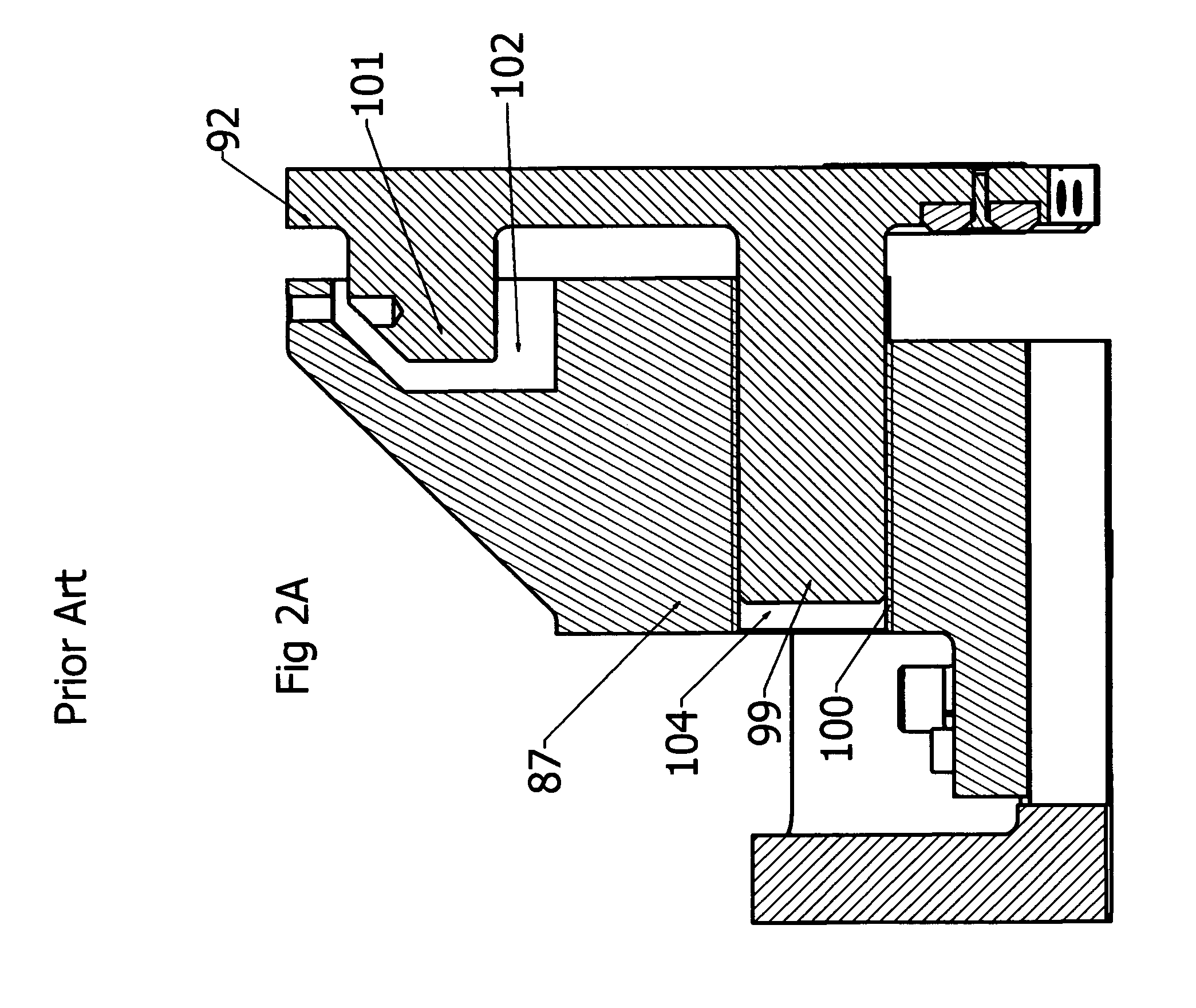

ActiveUS7581995B1Enhanced adjustment of positionEasy to adjustPropellersPump componentsPropellerForeign matter

Apparatus shears foreign matter that might entangle propellers and related structures on a moving vessel by action of a blade rotating with the propeller that cooperates with a non-rotating blade held close to the rotating blade. The mechanisms for holding the blades close and parallel include a lubricant packed passage for a supporting cylinder portion of the non-rotating blade, enclosed clamping elastic bias elements for controlled movement of the cylinder, and adjustments for holding the blade parallel.

Owner:SPURS MARINE MFG

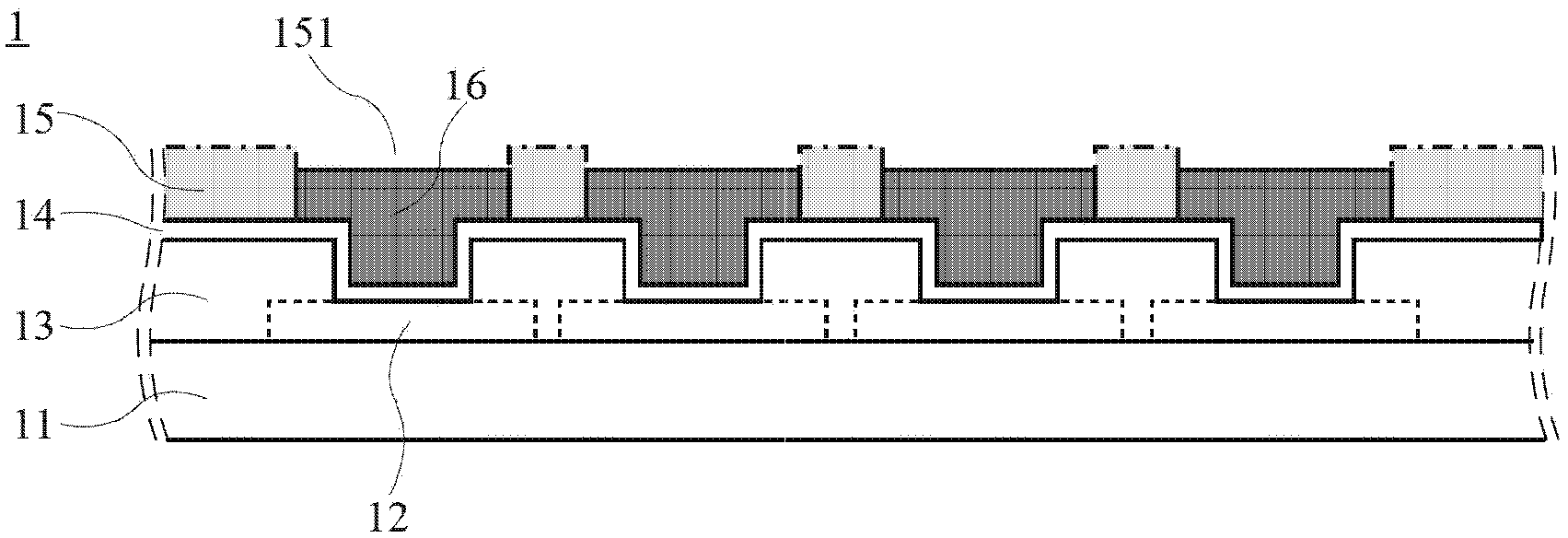

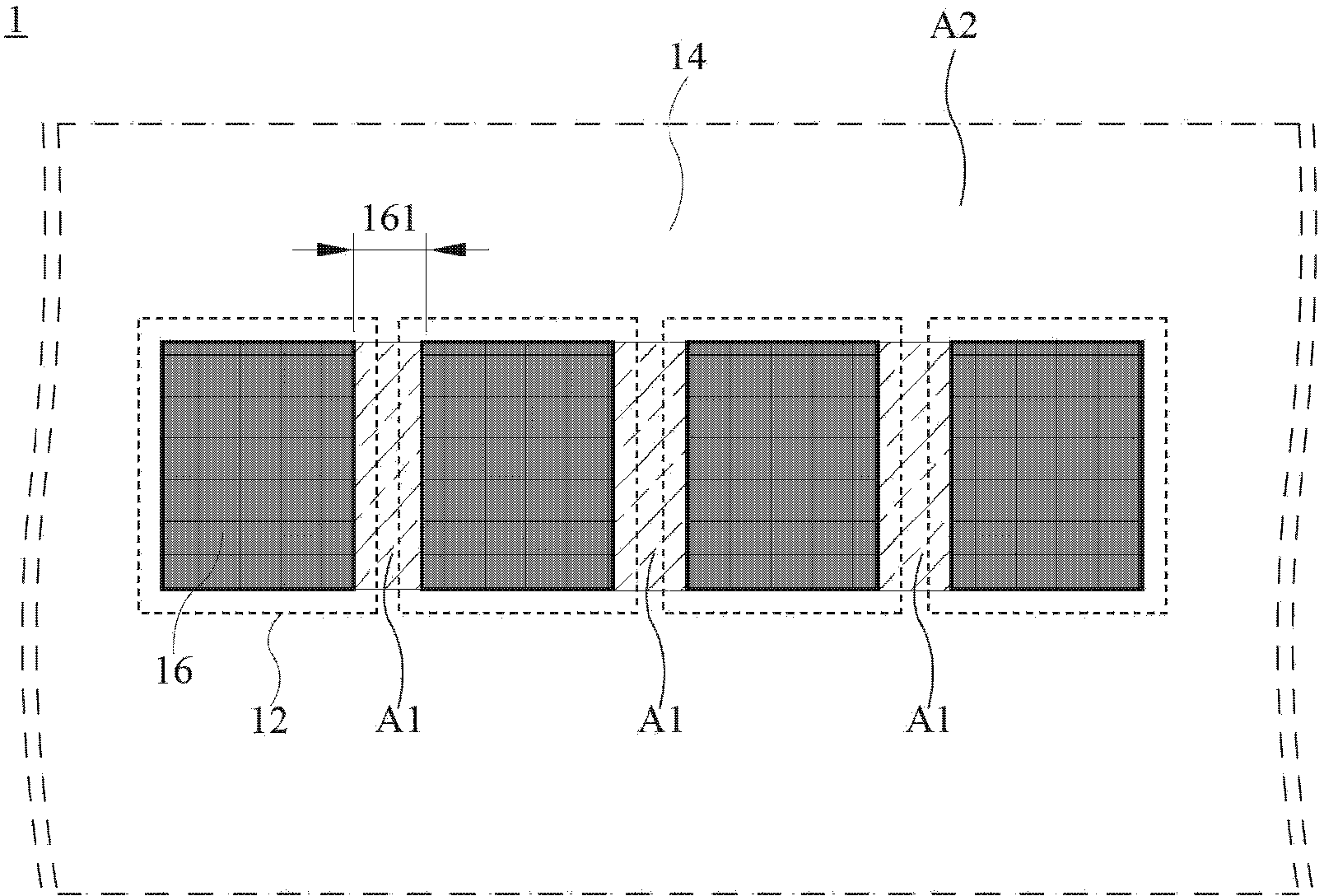

Conductive structure and method for forming the same

ActiveCN103390608ASolve the problem of uneven etchingOvercoming deformationSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor chip

A conductive structure for a semiconductor chip and a method for forming the conductive structure are provided. The semiconductor chip comprises a plurality of first pads and second pads. The pad area is defined with a first area, a second area and a third area, wherein the first area is located between the second area and the third area. Each of the first pads and the second pads are interlaced to each other on the first area. The conductive structure comprises a plurality of conductive bumps formed on each of the first pads and the second pads respectively to electrically connect with each of the first pads and the second pads. Each of the conductive bumps has a first bump-width disposed on the first area and a second bump-width disposed on one of the second and third areas in which the first bump-width is shorter than the second bump-width.

Owner:CHIPMOS TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com