Narrow slit type coating mold and method for producing the same

A slit type, coating technology, applied in the direction of surface coating liquid devices, coatings, etc., can solve the problems of difficult to precisely control and adjust the supply and transportation, difficult to evenly distribute, and the limitation of the length and size of the mold, to achieve constant and uniform fluidity, improve coating uniformity, and overcome the effect of front-end face deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

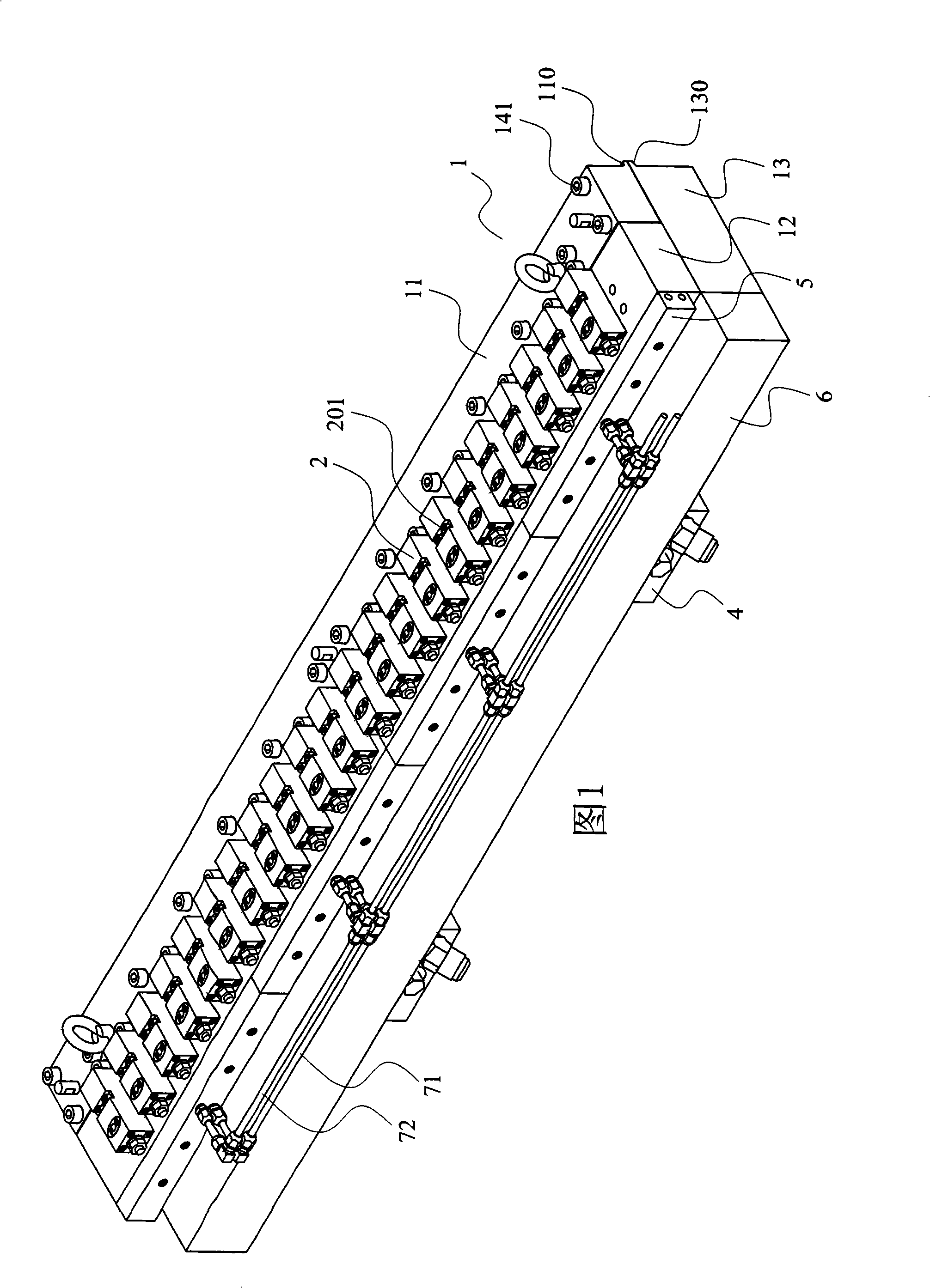

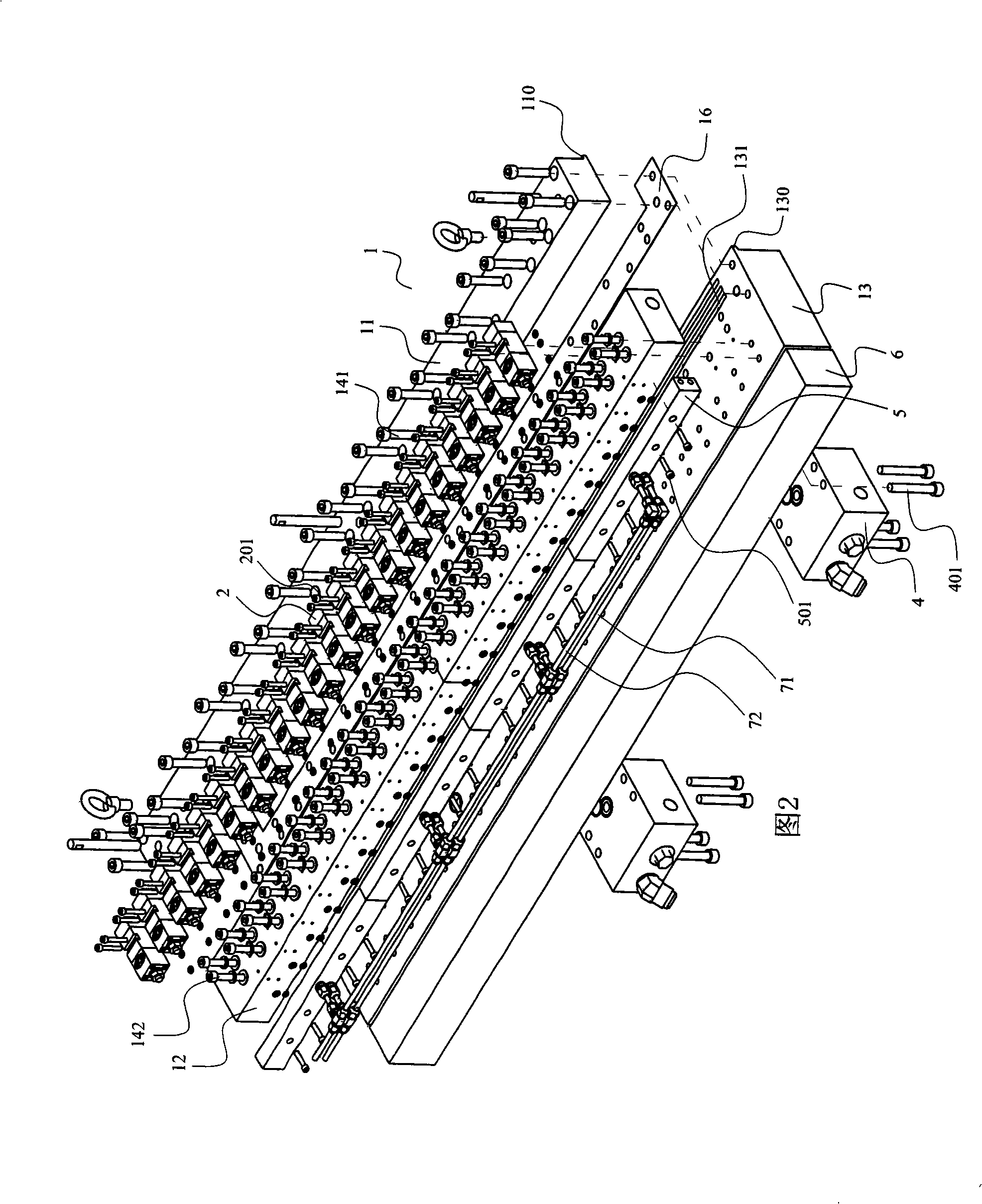

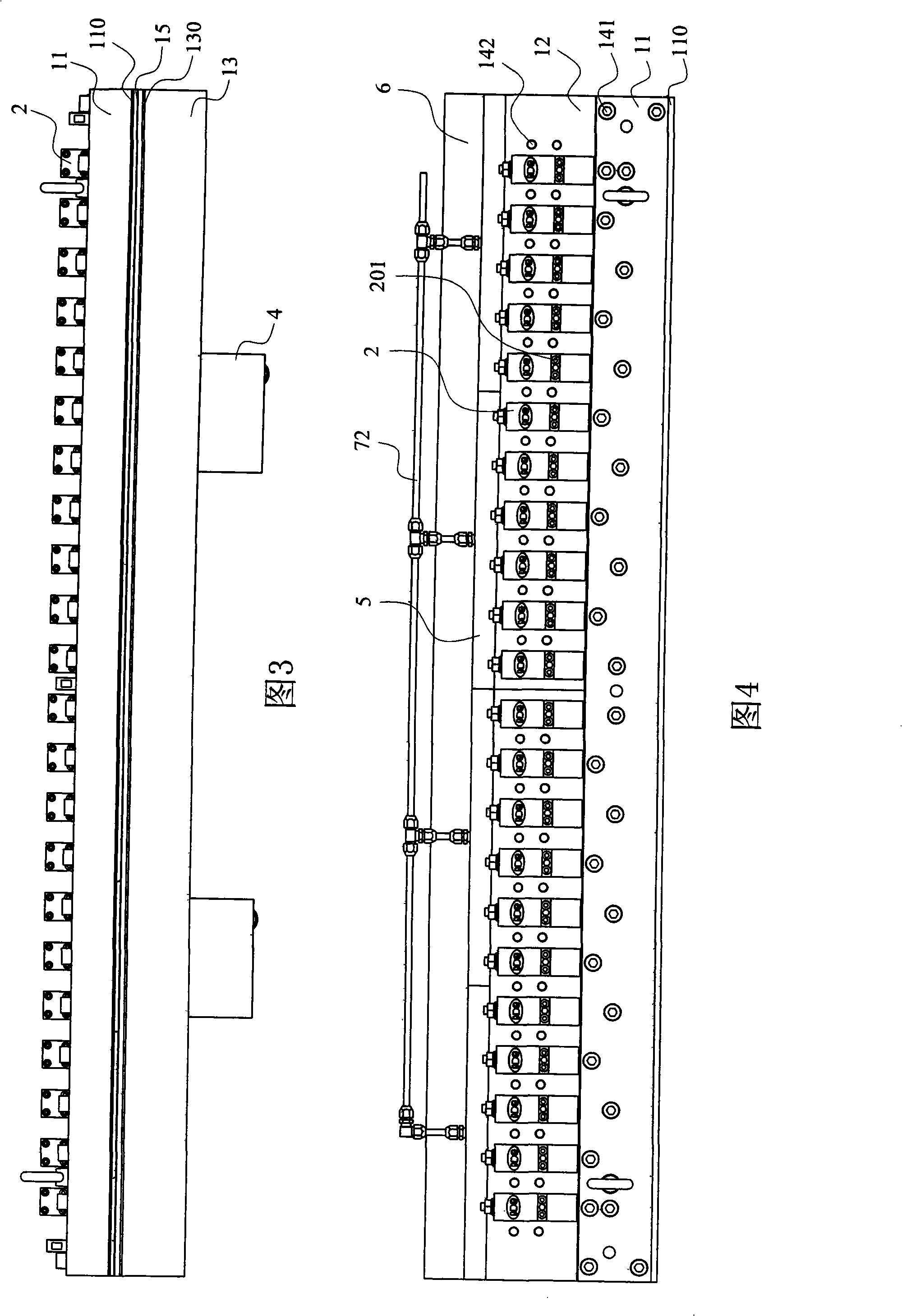

[0033] best practice

[0034] The slit coating die provided by the invention can be used to apply hot melt adhesive liquid to continuously conveyed coils or carriers. Refer to Figure 1 to Figure 8 , the mold includes a module 1, a plurality of liquid distributors 2 fixedly installed on the module 1, a plurality of heating devices 3, a plurality of liquid filtering devices 4, a gas distribution device and a junction box 6, and the gas distribution device includes a gas distribution seat 5 , and the first gas delivery pipeline 71 and the second gas delivery pipeline 72 connected to the gas distribution seat 5 . The structure and interconnection of each component are described in detail as follows:

[0035] The module 1 is assembled by the upper coating block 11, the connecting block 12 and the lower coating block 13, the upper coating block 11, the connecting block 12 are arranged front and back and are arranged up and down opposite to the lower coating block 13, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com