Novel plastic gear

A plastic gear, a new type of technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, components with teeth, etc., can solve problems such as affecting transmission stability and service life, gear without heat dissipation structure, gear wear and other problems , to overcome the problem of deformation, stable transmission performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

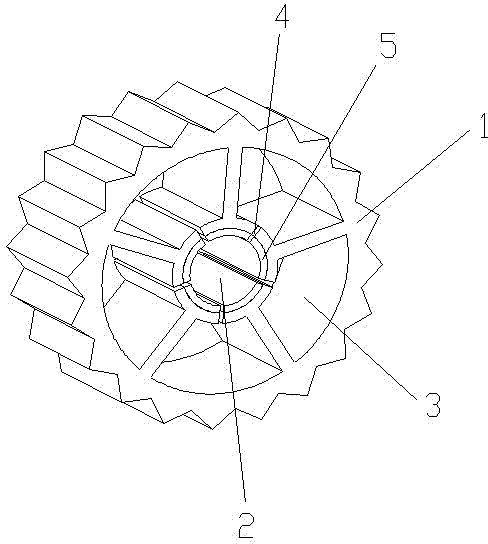

[0014] as attached figure 1 A novel plastic gear of the present invention shown includes a gear body 1; a shaft hole 2 is opened in the center of the gear body 1; a fan-shaped through groove 3 is opened around the shaft hole 2 on the gear body 1; A heat dissipation groove 4 is opened on the shaft hole 2; a wear-resistant layer 5 is arranged in the shaft hole 2; the heat dissipation groove 4 is opened in the center of the lower surface of the fan-shaped through groove 3; the number of the fan-shaped through groove 3 is at least three.

[0015] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0016] The novel plastic gear of the present invention is equipped with fan-shaped through grooves and cooling grooves, which can dissipate the heat generated by the friction between the gear and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com