Elastomer composite mud absorption rubber tube and manufacturing technique thereof

A production process and elastomer technology, applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems of shortened service life, increased production cost, poor bonding strength of ply layers, etc., and achieves excellent wear resistance and improved wear resistance. Adhesive strength, effect of shortening vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

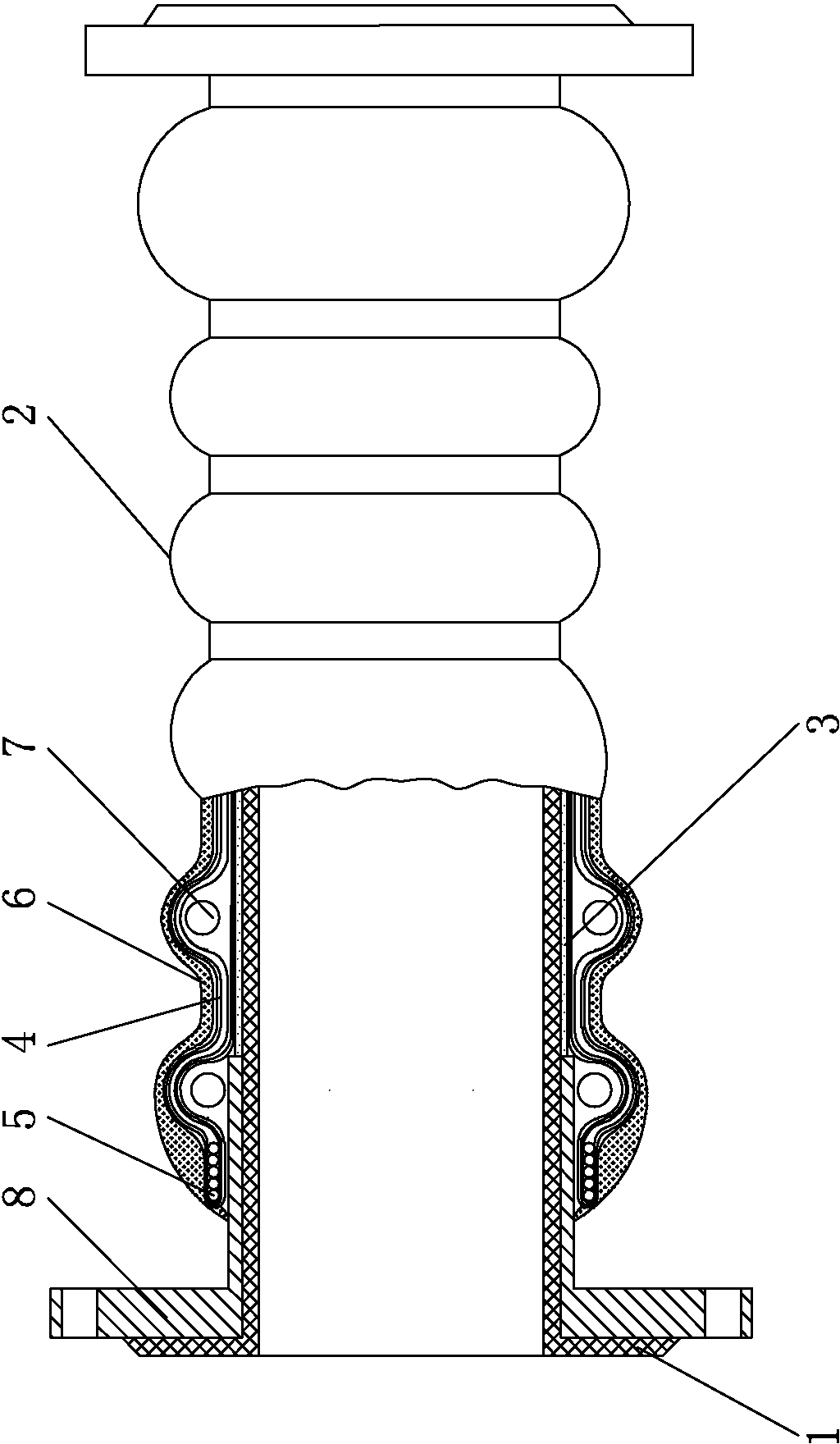

[0028] Such as figure 1 As shown, an intermediate layer 3 is arranged on the inner surface of the cord layer 4 of the mud suction hose 2, the intermediate layer is a canvas layer, and a composite layer 1 is arranged on the inner surface of the intermediate layer 3. The composite layer 1 is a polyurethane material, and the inner diameter after the composite is the same as The inner diameters of the existing mud suction hoses are the same. Cord layer 4, tight steel wire 5, rubber hose outer layer 6, steel ring 7, flange steel short sleeve 8 are the same as the prior art, and its production process is as follows:

[0029] (1) Tube embryo production: According to the thickness of the composite elastic body, design and determine the outer diameter of the forming mold for making the mud suction hose; fix one end of the flange steel short sleeve on the mud suction hose forming mold and position it according to the design requirements, and place it on the flange The inner side of the...

Embodiment 2

[0032] Such as figure 1 As shown, an intermediate layer 3 is arranged on the inner surface of the cord layer 4 of the mud suction hose 2, the intermediate layer is a canvas layer, and a composite layer 1 is arranged on the inner surface of the intermediate layer 3. The composite layer 1 is a polyurethane material, and the inner diameter after the composite is the same as The inner diameters of the existing mud suction hoses are the same. Cord layer 4, tight steel wire 5, rubber hose outer layer 6, steel ring 7, flange steel short sleeve 8 are the same as the prior art, and its production process is as follows:

[0033] (1) tube embryo production: same as embodiment 1;

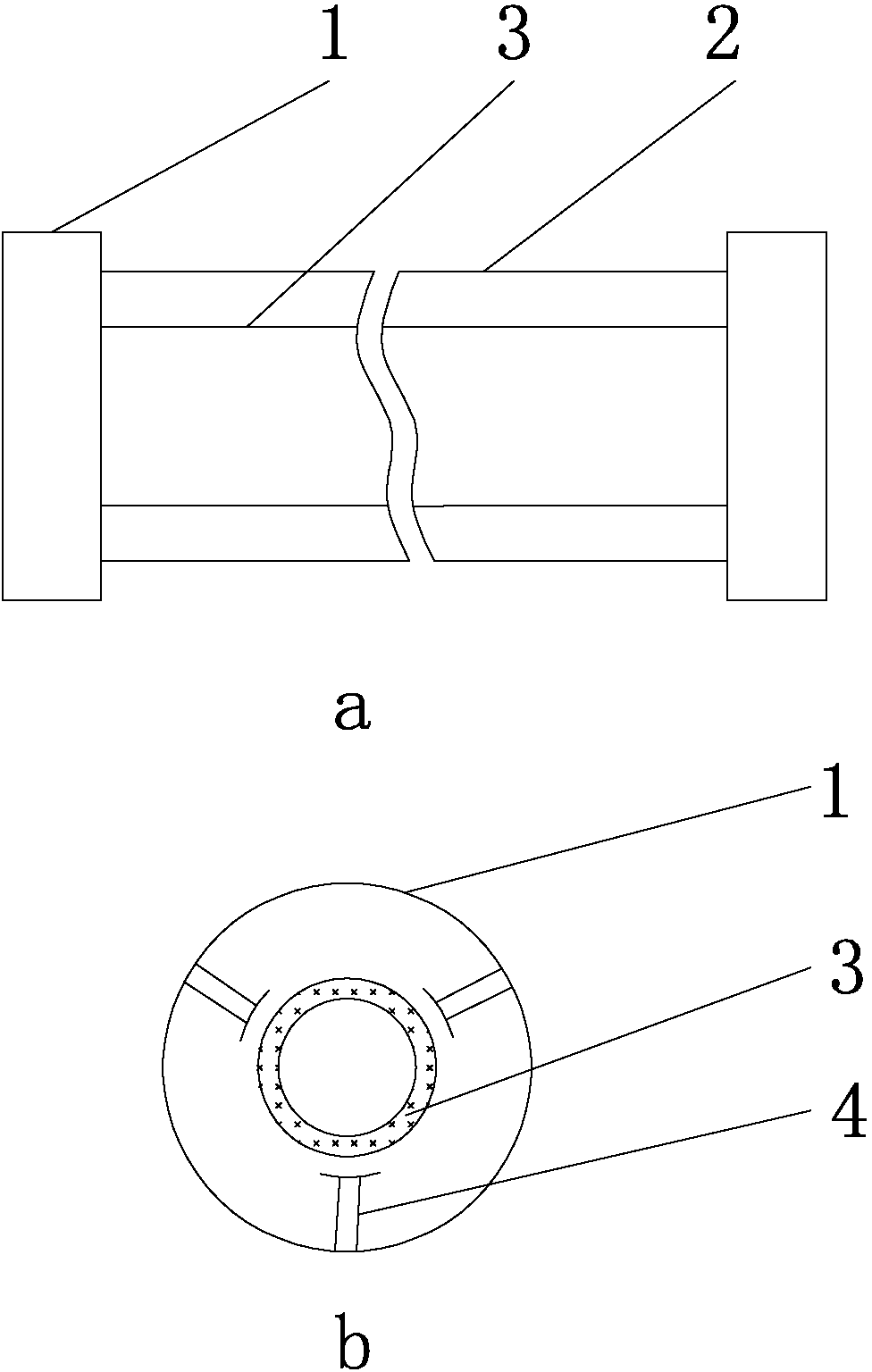

[0034] (2) Centrifugal forming: fix the finished suction hose embryo on the bracket ( figure 2 , the bracket is composed of 2 circular frames, and 3 length-adjustable fixed arms are uniformly arranged in each circular frame, and the fixed arms are connected with the circular frame by bolts, and the adjacent ...

Embodiment 3

[0036] Such as figure 1 As shown, an intermediate layer 3 is arranged on the inner surface of the cord layer 4 of the mud suction hose 2, the intermediate layer is a canvas layer, and a composite layer 1 is arranged on the inner surface of the intermediate layer 3. The composite layer 1 is a polyurethane material, and the inner diameter after the composite is the same as The inner diameters of the existing mud suction hoses are the same. Cord layer 4, tight steel wire 5, rubber hose outer layer 6, steel ring 7, flange steel short sleeve 8 are the same as the prior art, and its production process is as follows:

[0037] (1) tube embryo production: same as embodiment 1;

[0038] (2) Centrifugal forming: fix the finished suction hose embryo on the bracket ( figure 2 , the bracket is composed of 3 circular frames, and 3 fixed arms with adjustable length are evenly arranged in each circular frame, the fixed arms and the circular frame are connected by bolts, and the adjacent two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com