Low hydroxyl content white carbon black and preparation method thereof

A white carbon black and hydroxyl technology is applied in the field of low hydroxyl content white carbon black and its preparation. properties, improved processability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

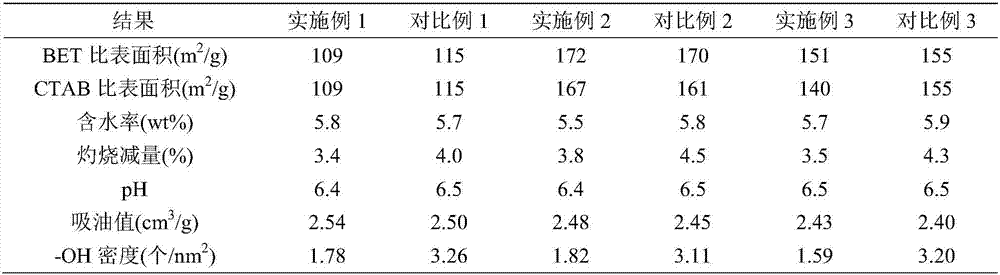

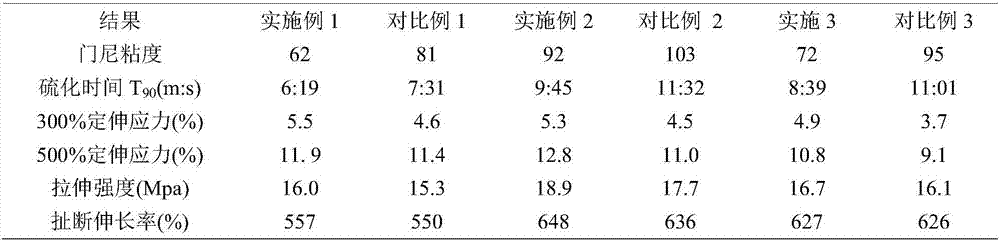

Examples

Embodiment 1

[0088] (1) Add water to the reactor, and feed steam to control the temperature of the water at 97°C, and then continue to add the concentration (in the form of Na 2 (O represents) be the water glass solution of 2.60N and the vitriol oil, prepare the reaction bottom liquid that pH is 9.0, temperature remains constant during the preparation reaction bottom liquid, wherein the water glass total amount that uses in the precipitation reaction includes bottom liquid preparation the amount consumed in

[0089] (2) maintain the temperature of 97 DEG C to continue to be stable, add the water glass solution used in the concentrated sulfuric acid and the precipitation reaction dropwise to the reaction bottom liquid at the same time within 130min, so that the water glass and the concentrated sulfuric acid are precipitated and reacted, during the whole reaction stage Always keep the reaction temperature stable and the pH of the reaction system at 9.0;

[0090](3) After dropping the concen...

Embodiment 2

[0104] (1) Add water to the reaction kettle, and feed steam, control the temperature of the water to maintain at 81°C, and then continue to add the concentration (in the form of Na 2 (O represents) be the water glass solution of 2.60N and the vitriol oil, prepare the reaction bottom liquid that pH is 9.0, temperature remains constant during the preparation reaction bottom liquid, wherein the water glass total amount that uses in the precipitation reaction includes bottom liquid preparation the amount consumed in

[0105] (2) maintain the temperature of 81 DEG C to continue to be stable, add the water glass solution used for the concentrated sulfuric acid and the precipitation reaction dropwise to the reaction bottom liquid at the same time within 130min, so that the water glass and the concentrated sulfuric acid are precipitated and reacted, during the whole reaction stage Always keep the reaction temperature stable and the pH of the reaction system at 9.0;

[0106] (3) After...

Embodiment 3

[0120] (1) Add water to the reactor, and feed steam, control the temperature of the water to maintain at 75°C, and then continue to add the concentration (in the form of Na 2 (O represents) be 2.60N water glass solution and the vitriol oil, prepare the reaction bottom liquid that pH is 8.0, temperature remains constant during the preparation reaction bottom liquid, wherein the water glass total amount that uses in the precipitation reaction includes bottom liquid preparation the amount consumed in

[0121] (2) Keep the temperature of 75° C. continuously stable, add the water glass solution used for the water glass and the concentrated sulfuric acid dropwise in the reaction bottom liquid at the same time within 130min, so that the water glass and the concentrated sulfuric acid are precipitated, and during the whole reaction stage Always keep the reaction temperature stable and the pH of the reaction system at 8.0;

[0122] (3) After dropping the concentrated sulfuric acid and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com