Special two-component water-based paint for buses and coating process of two-component water-based paint

A two-component, water-based paint technology, which is applied in the direction of surface coating liquid devices, coatings, anti-corrosion coatings, etc., can solve the problem that water-based paint technology is immature, cannot adapt to the construction environment, and two-component water-based paint cannot satisfy customers In order to achieve the effect of shortening the flash-drying time, improving the film-forming efficiency and shortening the flash-drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

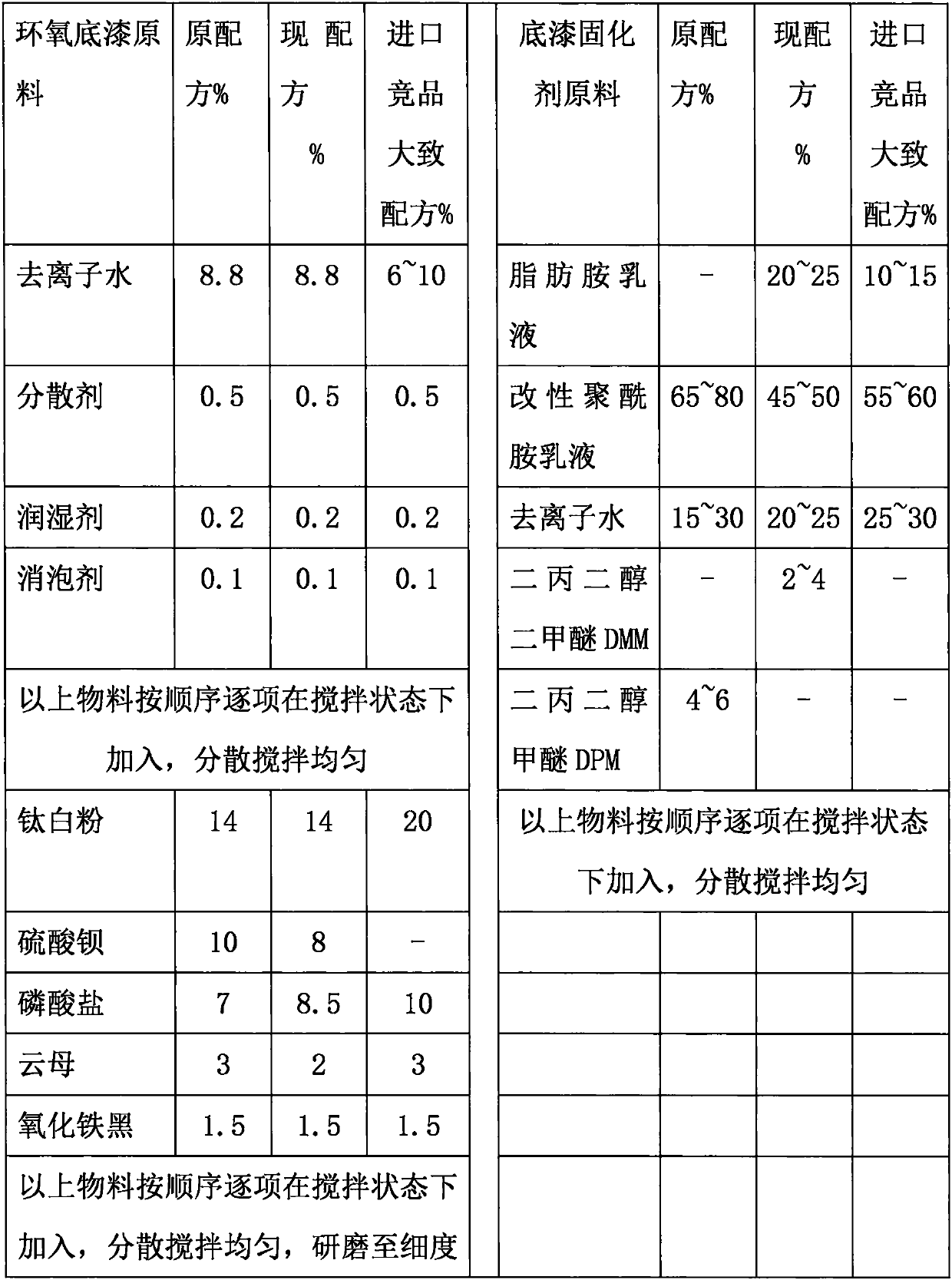

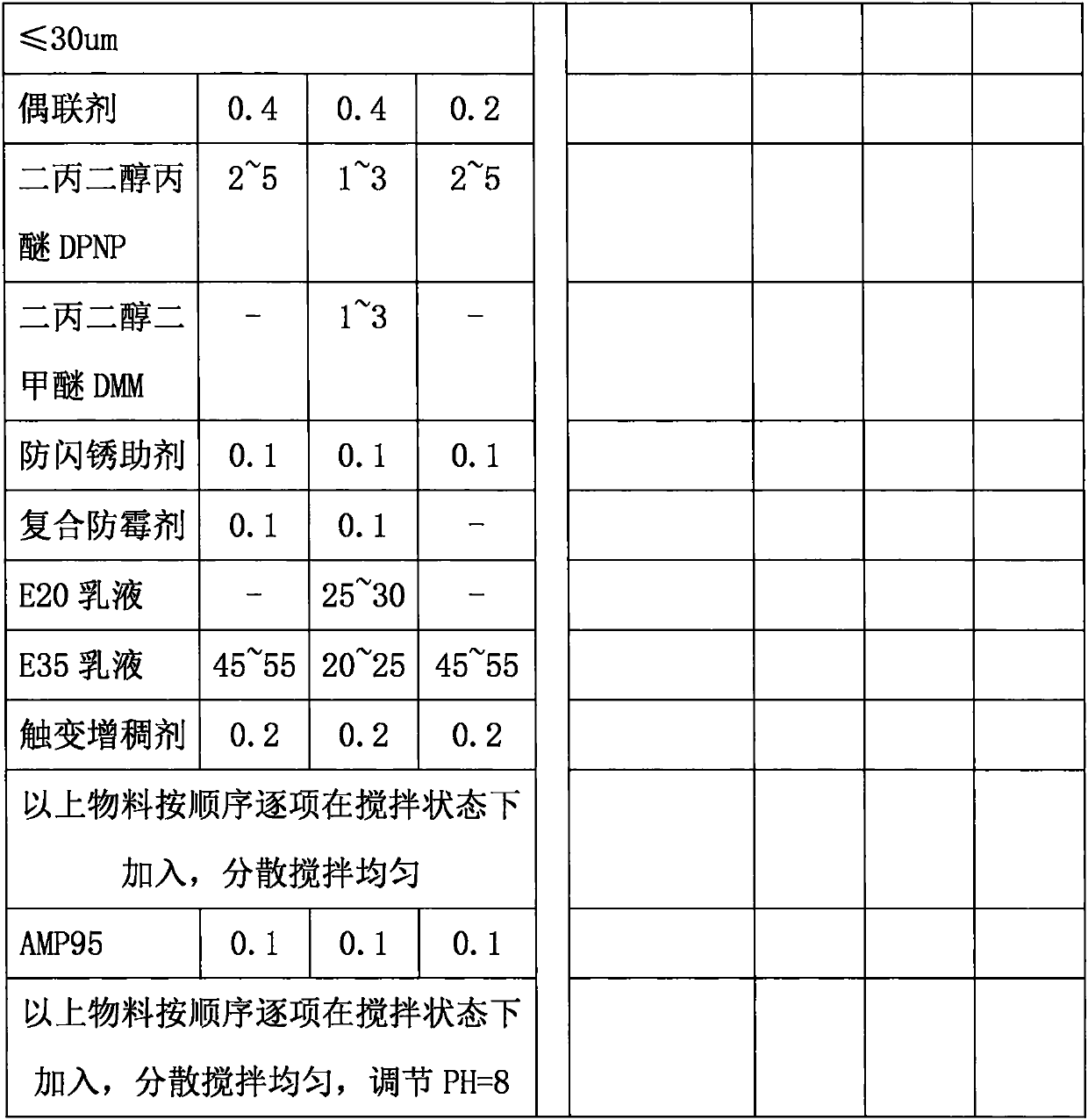

[0037] 1. Two-component water-based epoxy primer

[0038] A. This product is matched with E20 and E35 epoxy equivalent emulsions to increase the solid content of the original construction, reduce the viscosity of the original paint, and reduce the water consumption for dilution, which not only ensures sufficient chemical resistance, salt spray performance, but also balances Improved adhesion, drying speed, flexibility;

[0039] B. In order to meet the on-site curing speed requirements, the curing agent adopts a compound structure of aliphatic amine and modified polyamide. On the basis of improving the curing speed, the original salt spray, chemical resistance, water resistance and adhesion are maintained , flexibility and other characteristics;

[0040] C. The cross-linking density is designed at 70-75%, keeping the excess of epoxy groups, controlling the PVC at 28-32%, and the concentration of phosphate anti-rust pigments at 20-25%. While ensuring the necessary salt spray pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com