Preparation method of fluorine-containing low refractive index yb3+ doped quartz glass

A quartz glass, low refractive index technology, applied in the field of rare earth doped quartz glass, to achieve the effect of high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

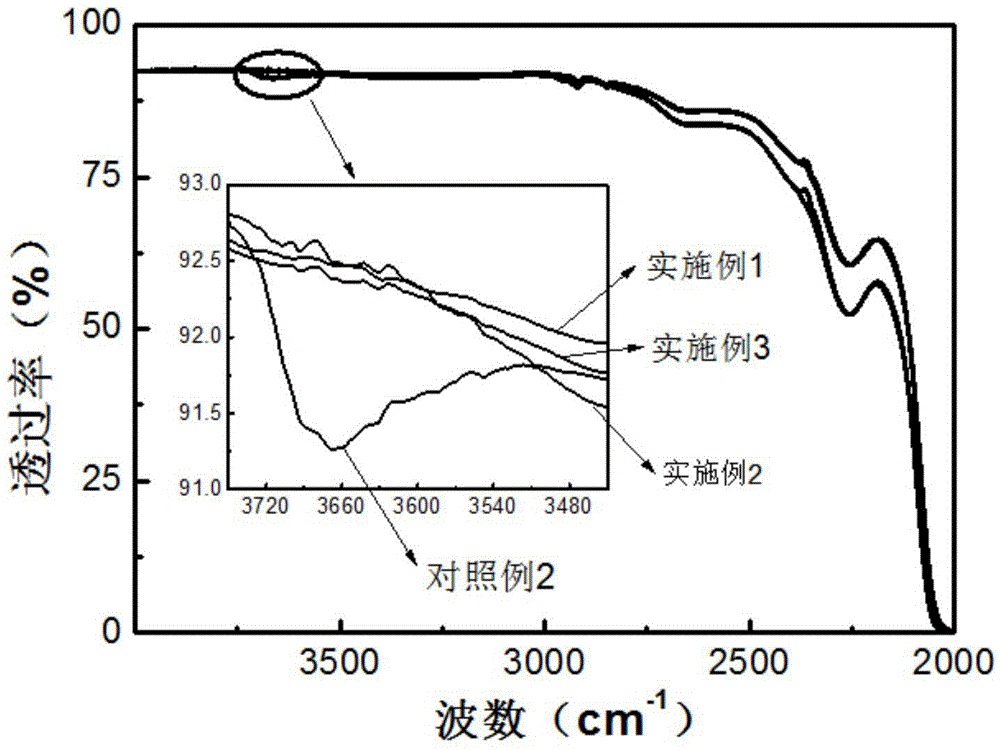

Embodiment 1

[0039] The basic composition of the glass is 0.2Yb 2 o 3 -1.5Al 2 o 3 -98.3 SiO 2 (mol%), F was introduced with F / Si=5wt% when preparing the sol. Under room temperature and magnetic stirring, according to Si(OCH 3 ) 4 :CH 3 OH:H 2 The molar ratio of O=1:4:2, using ammonia water as a catalyst, prepares a transparent sol liquid. Then according to the designed glass formula, add AlCl 3 ·6H 2 O and YbCl 3 ·6H 2 O and NH 4 F, Stir at room temperature for 1 hour to form a doped sol, and let it stand in a closed container until it gels; place the gel in a tube furnace at 600°C in an oxygen atmosphere for 12 hours to remove residual carbon and hydroxyl groups, Obtain silicon oxide powder; use ball milling equipment to ball mill the silicon oxide powder, and use a 150-mesh polytetrafluoro sieve to screen the powder with a particle size below 100 microns; place the sieved powder in a vacuum of 10 -3 Melt at 1650°C for 8 hours in a Pa high temperature furnace. The refracti...

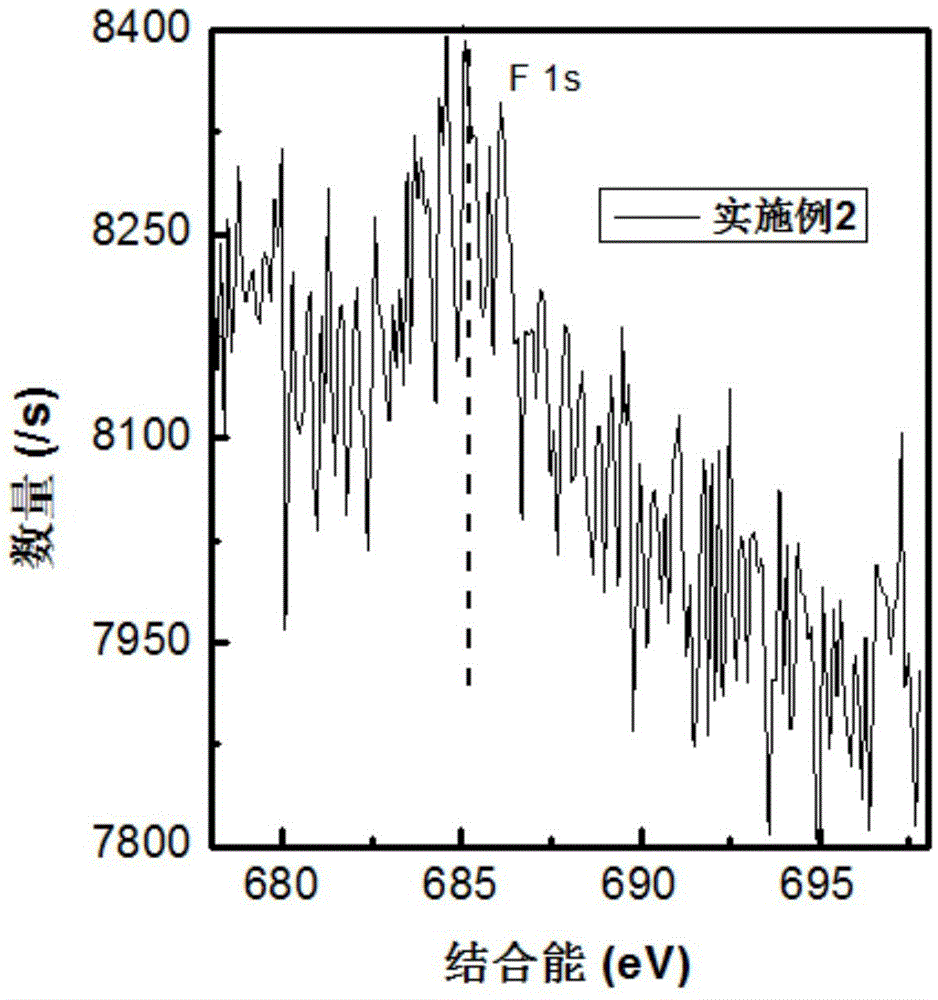

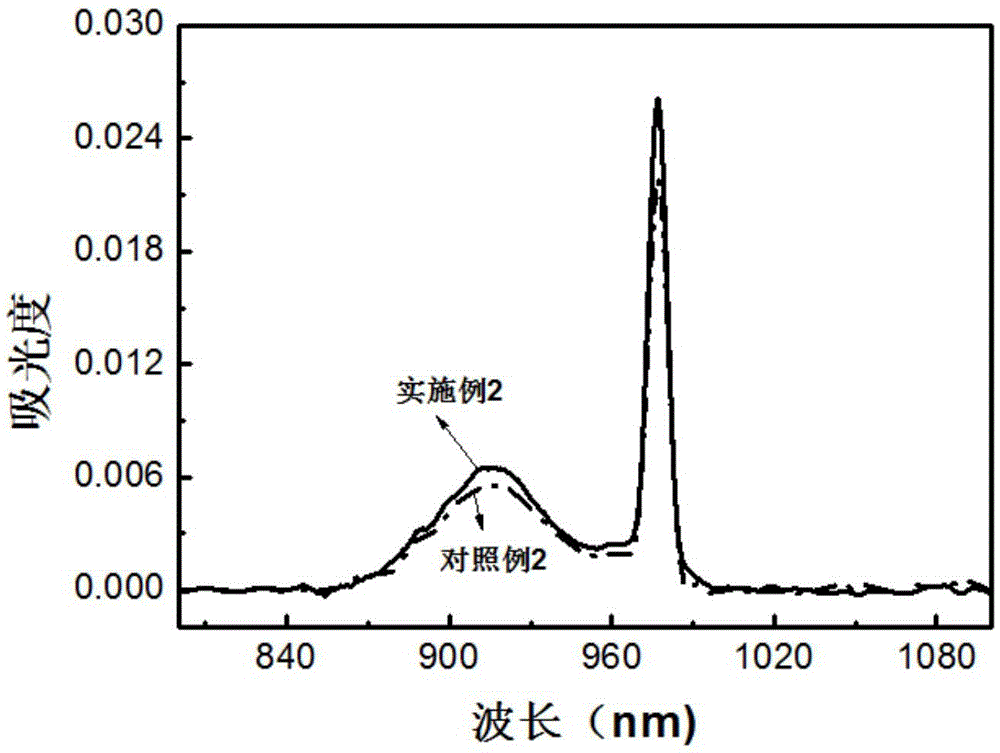

Embodiment 2

[0041] The basic composition of the glass is 0.1Yb 2 o 3 -1Al 2 o 3 -98.9SiO2 2 (mol%), F was introduced with F / Si=5wt% when preparing the sol. Under room temperature and magnetic stirring, according to Si(OC 2 h 5 ) 4 :C 2 h 5 OH:H 2 The molar ratio of O=1:4:2, using hydrochloric acid as a catalyst, prepares a transparent sol liquid. Then according to the designed glass formula, add AlCl 3 ·6H 2 O and YbCl 3 ·6H 2 O and (NH 4 ) 2 SiF 6 , stirred at room temperature for 10 hours to form a doped sol, which was left to stand in a closed container until gelation; the gel was placed in a tube furnace and kept at 1000°C for 8 hours to remove residual carbon and hydroxyl groups, and obtained Silica powder; use ball milling equipment to carry out ball milling to the described silica powder, and use a 150-mesh polytetrafluoro sieve to screen out the powder with a particle size below 100 microns; place the sieved powder in a vacuum of 10 -3 Melt at 1750°C for 3 hours ...

Embodiment 3

[0043] The basic composition of the glass is 0.1Yb 2 o 3 -1Al 2 o 3 -98.9SiO2 2 (mol%), F was introduced with F / Si=10wt% when preparing the sol. Under room temperature and magnetic stirring, according to Si(OC 2 h 5 ) 4 :C 2 h 5 OH:H 2 The molar ratio of O=1:20:10, using hydrochloric acid as a catalyst, prepares a transparent sol liquid. Then according to the designed glass formula, add AlCl 3 ·6H 2 O and YbCl 3 ·6H 2 O and NH 4 F, Stir at room temperature for 2 hours to form a doped sol, and let it stand in a closed container until it gels; place the gel in a tube furnace under an oxygen atmosphere and 1000°C for 8 hours to remove residual carbon and hydroxyl groups, Obtain silicon oxide powder; use ball milling equipment to ball mill the silicon oxide powder, and use a 150-mesh polytetrafluoro sieve to screen the powder with a particle size below 100 microns; place the sieved powder in a vacuum of 10 -3 Melt at 1750°C for 3 hours in a Pa high temperature furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com