Patents

Literature

32results about How to "Improve physical performance indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

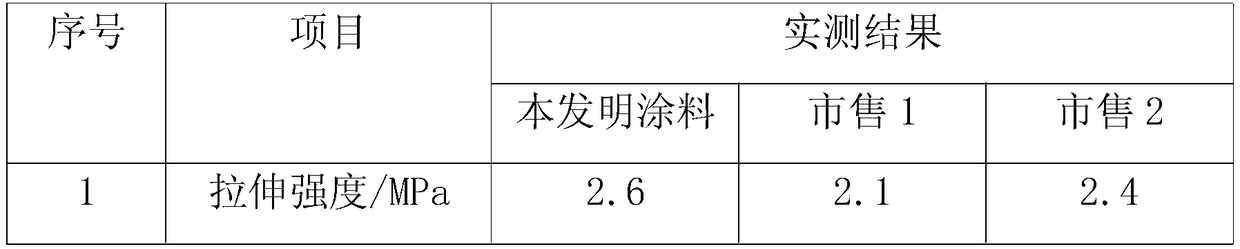

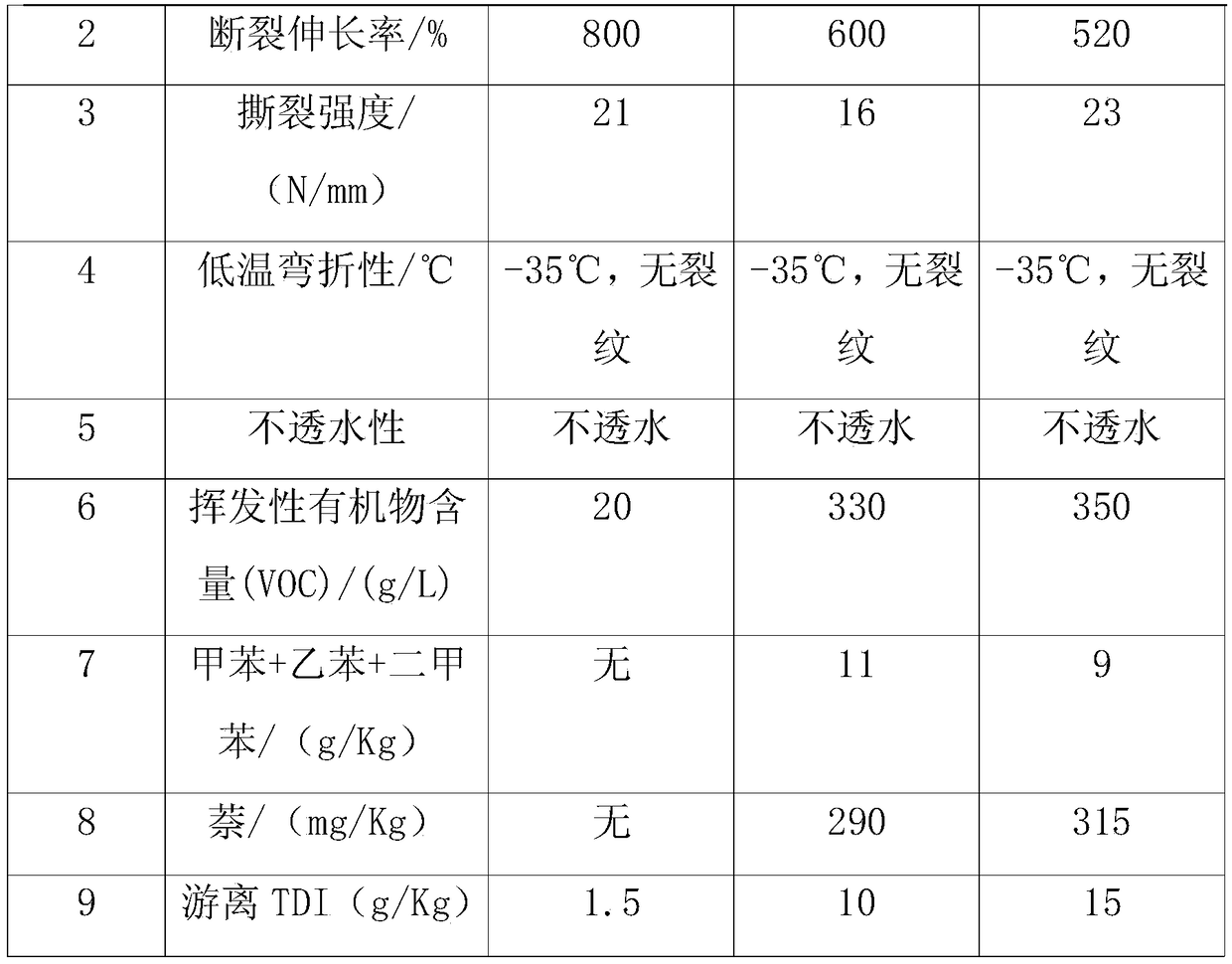

Colourful environmental-friendly synthesized polymer waterproof paint

InactiveCN102108234AWith comprehensive performanceImprove physical performance indicatorsPolyurea/polyurethane coatingsMulticolor effect coatingsUltravioletSynthetic Polymeric Macromolecules

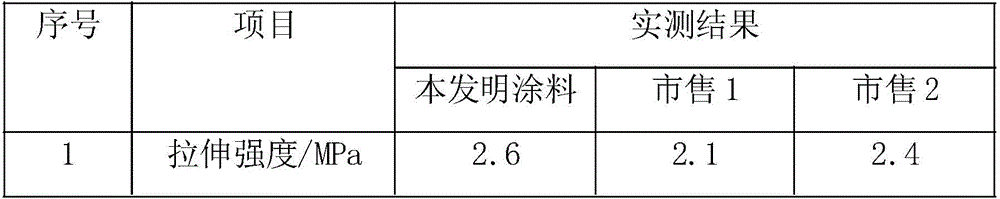

The invention relates to a colourful environmental-friendly synthesized polymer waterproof paint which comprises the following components in parts by weight: 3-7 parts of petroleum resin, 5-15 parts of styrene-ethylene-butylene-styrene (SEBS), 5-15 parts of styrene-butylene-styrene (SBS), 5-10 parts of thermoplastic polyurethane elastomer, 4-8 parts of terpene resin, 4-8 parts of poly-alpha-methyl styrene, 2-5 parts of tung oil, 10-15 parts of mica powder, 0.2-0.5 part of antiager D, 0.2-0.5 part of antioxidant 264, 0.2-0.5 part of defoaming agent, 0.3-0.5 part of ultraviolet absorber, 35-45 parts of 120 # solvent, 5-15 parts of butyl acetate and 1-3 parts of color paste. The paint has the characteristics of unique waterproof property, acid-base resistance, ultraviolet irradiation resistance, heat insulation, anti-aging property, high adhesion strength, water repellent, good leakage-resisting effect, heat resistance, frost resistance and good elongation; and the paint also has the advantages of wide application range, moderate price, environmental friendliness, durability and the like, and is convenient to use, thereby meeting the demand of people in a real life.

Owner:白铁林

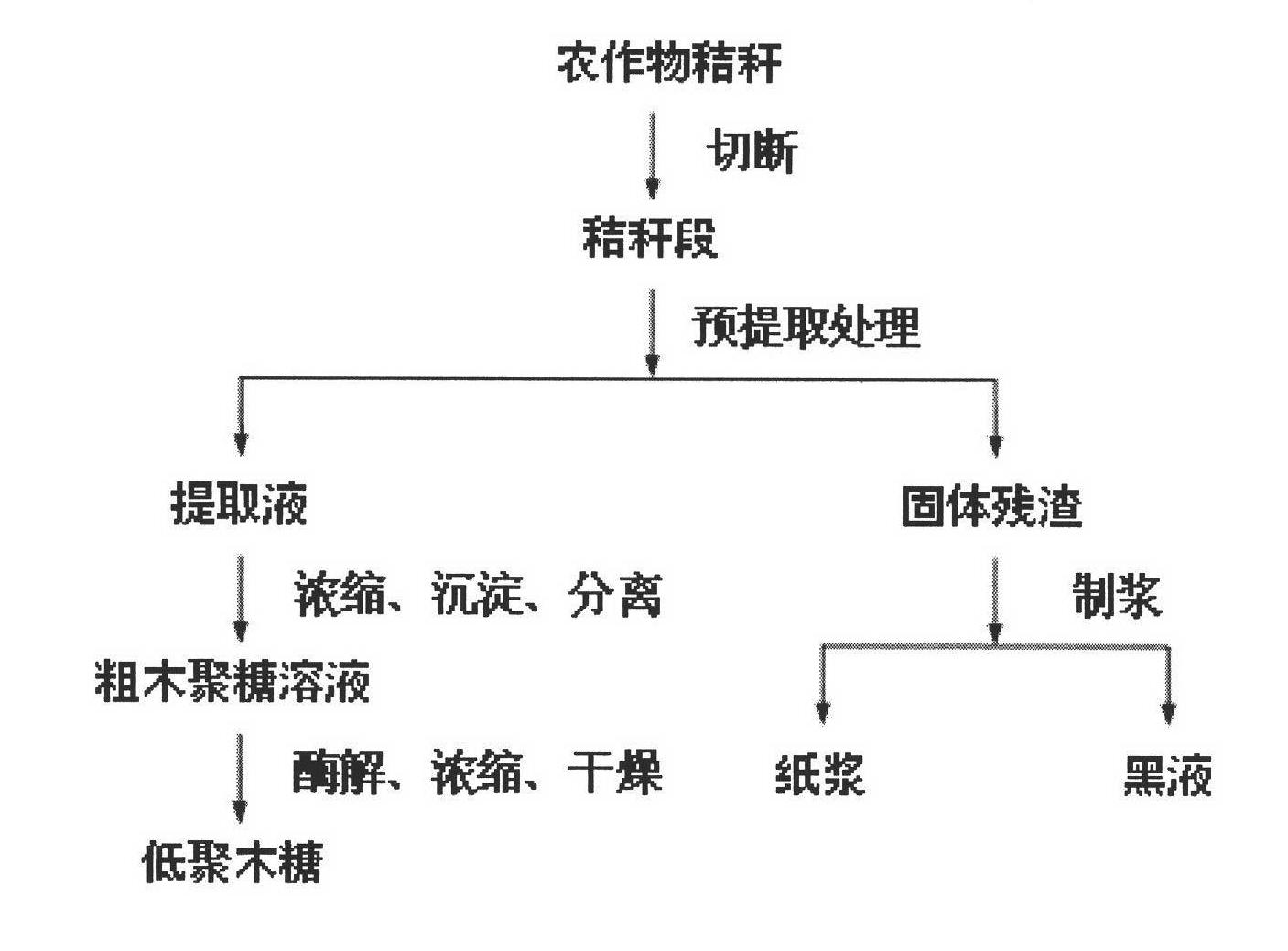

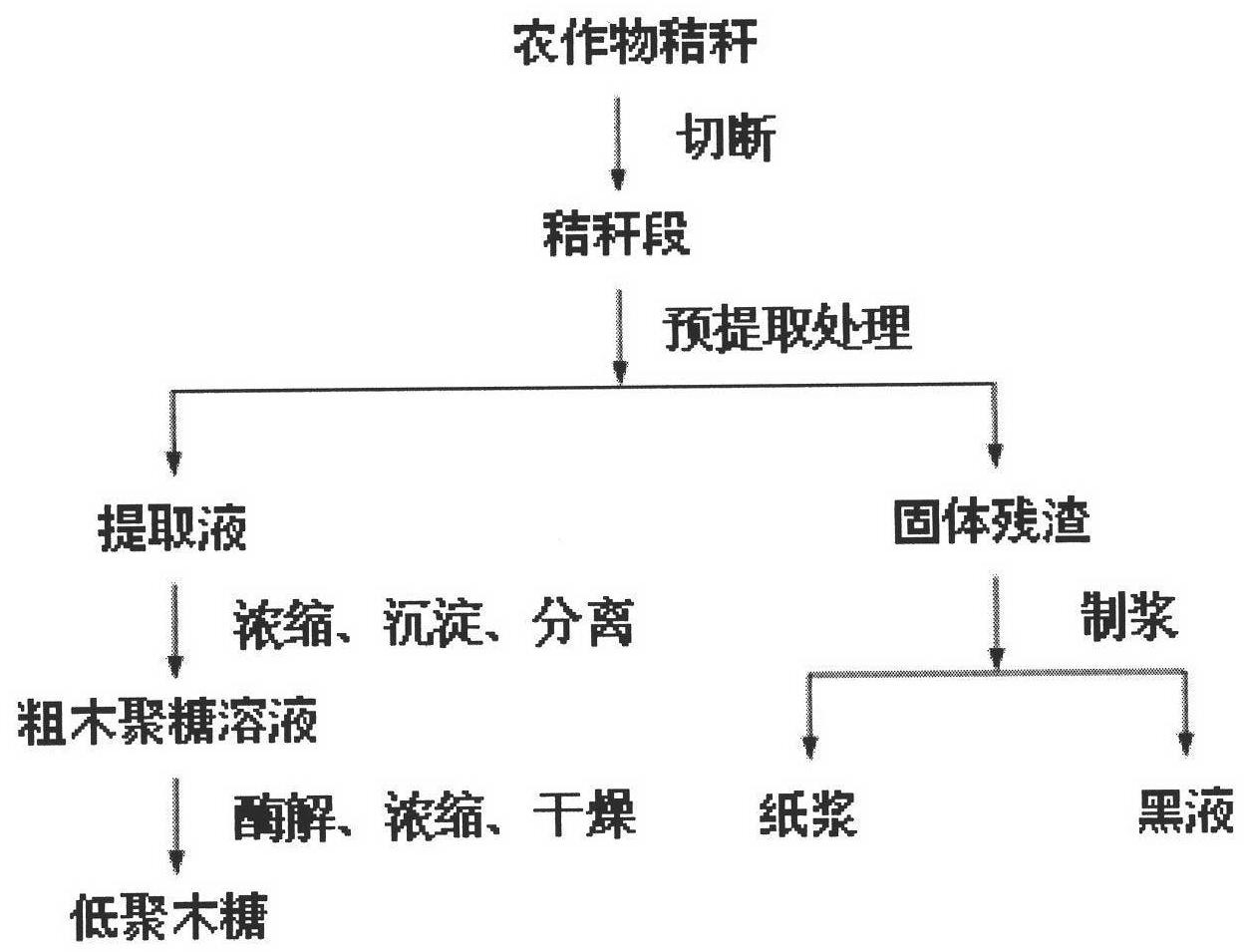

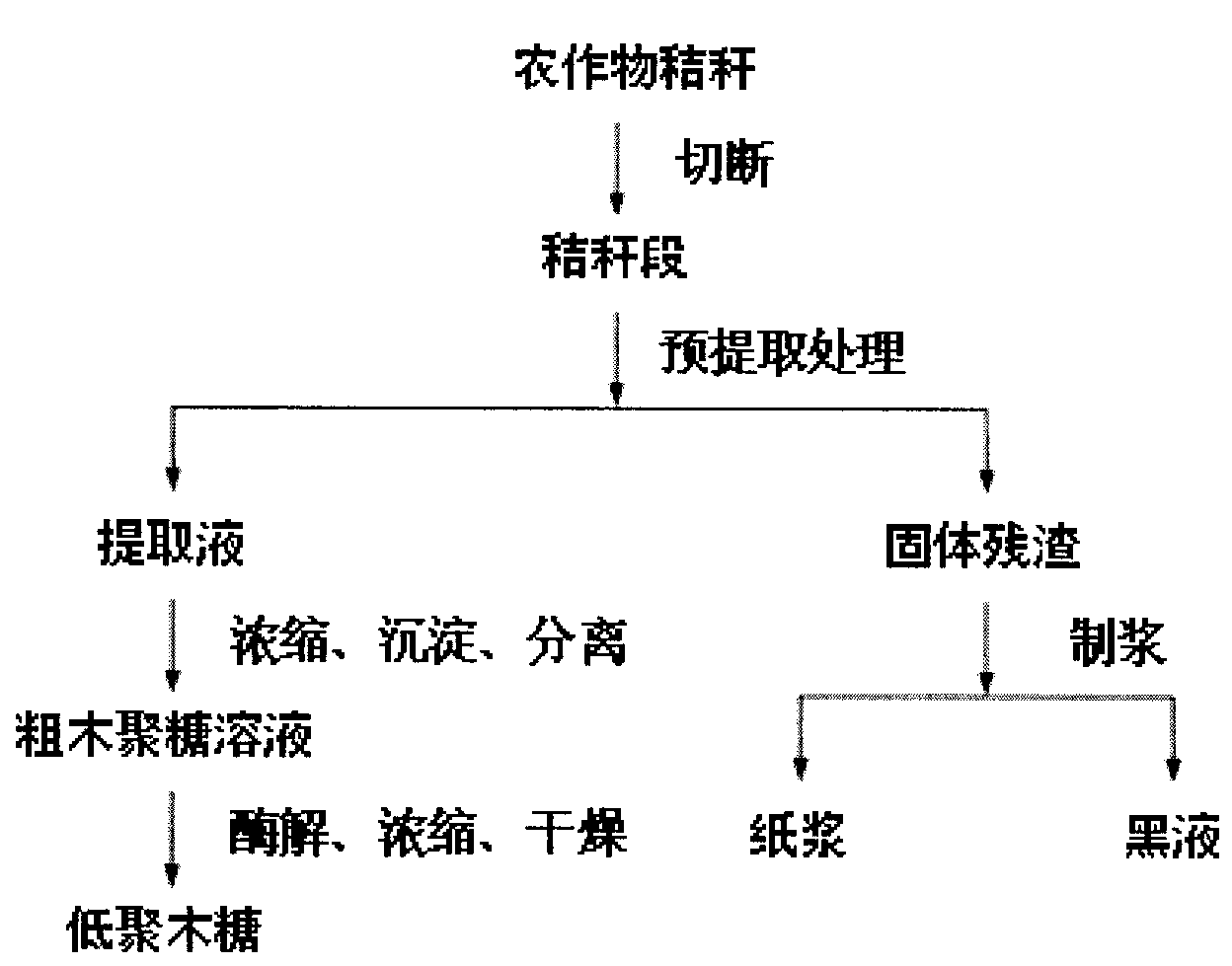

A kind of method for preparing xylo-oligosaccharide and paper pulp

ActiveCN102277761AImprove fiber qualityImprove physical performance indicatorsPretreatment with alkaline reacting compoundsPulping with inorganic basesFiberOligosaccharide

The invention discloses a method for preparing oligosaccharide and paper pulp, belonging to the technical fields of pulping and the comprehensive utilization of pulping. The method comprises the steps of: using crop straws as raw materials, pre-treating the raw materials to obtain a pre-extracting solution, concentrating the pre-extracting solution by a membrane separation method, then obtaining a crude xylan solution via precipitation and centrifugal separation, and then preparing oligosaccharide via enzymolysis, vacuum concentration and frozen-drying. The pre-treated solid residues are stewed via an alkaline process so as to prepare unbleached paper pulps of which the indexes such as fiber length, whiteness, fracture length, tear resistance, folding strength and the like are all improved. The generated black liquid has the characters of low viscosity and high heat productivity. The method for preparing oligosaccharide and paper pulp integrates the comprehensive utilization method with the biomass transformation method on the premise of optimizing the traditional alkaline chemical pulping technique to prepare products with high additional values, namely oligosaccharide, thereby increasing the quality of the paper pulp and the extraction, vaporization and combustion performances of the black liquid.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

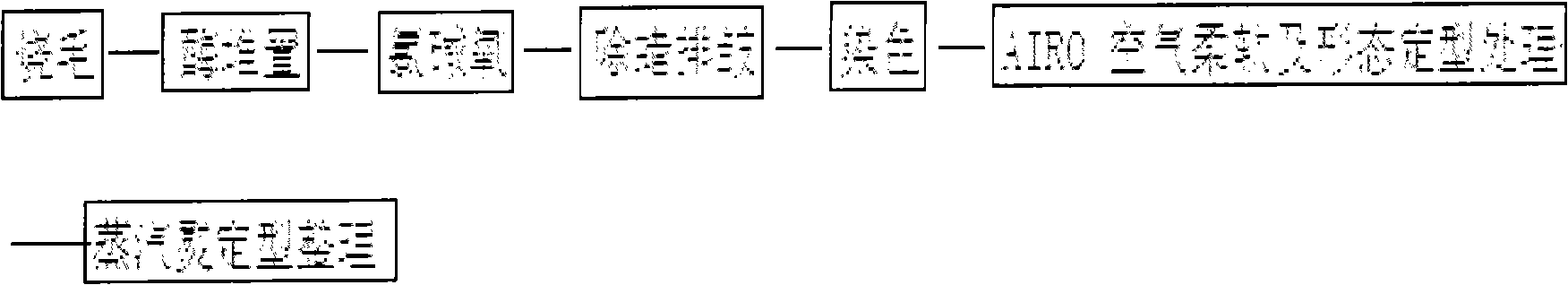

Dyeing and finishing process of pure-flax Huashu textile fabric

ActiveCN102021840AWith shape memory functionMaintain the shape of micro-creasesBiochemical fibre treatmentBleaching apparatusWaxWater resources

The invention relates to a dyeing and finishing process of a pure-flax Huashu textile fabric, comprising the following steps of: singeing fabrics, stacking enzymes, oxidizing chlor-alkali, removing wax and crimples, dyeing, softening by AIRO air, shaping and ironing and finishing by steam. The pure-flax Huashu textile fabric not only maintains the original excellent characteristics of pure-flax fabrics, but also has good drapability, skin intimacy, low strength loss and high dye fastness, has the functions of shaping details and remembering small folds, eliminates itchy feeling and expands the use field of fabrics. The invention has reasonable process design, is environment-friendly and greatly reduces the use of energy and water resources.

Owner:安徽中天新材料科技股份有限公司

Novel thermoplastic elastomer composite self-adhesion sport field paving coiled material and manufacture process thereof

The invention relates to a novel thermoplastic elastomer composite self-adhesion sport field paving coiled material. The coiled material comprises a main body layer made of thermoplastic elastomer, wherein a creep deformation self-adhesion layer is arranged on the bottom surface of the main body layer, and the thermoplastic elastomer is prepared by blending and modifying ethylene propylene diene monomer rubber and polyolefin resin. The manufacture process comprises the steps of: blending the ethylene propylene diene monomer rubber, the polyolefin resin and naphthenic oil in proportion, and carrying out twin-screw extrusion, so as to obtain the thermoplastic elastomer; adding an assistant agent and the naphthenic oil, heating and carrying out high-speed stirring and blending, carrying out compound extrusion by utilizing a pin extruder, then carrying out knurling, overlap edge profiling, microwave foaming, vulcanizing and double-roll gluing, and carrying out crimping to prepare the novel thermoplastic elastomer composite self-adhesion paving coiled material after cooling. According to the novel thermoplastic elastomer composite self-adhesion sport field paving coiled material, the shortage of the prior art can be improved, the performance index of the product is improved, and the manufacture process is simple; the controllable thickness is 4-13mm, and the novel thermoplastic elastomer composite self-adhesion sport field paving coiled material is mainly applied to the fields of athletic tracks in sport fields, basketball courts, tennis courts, badminton courts and the like.

Owner:高捷体育股份有限公司

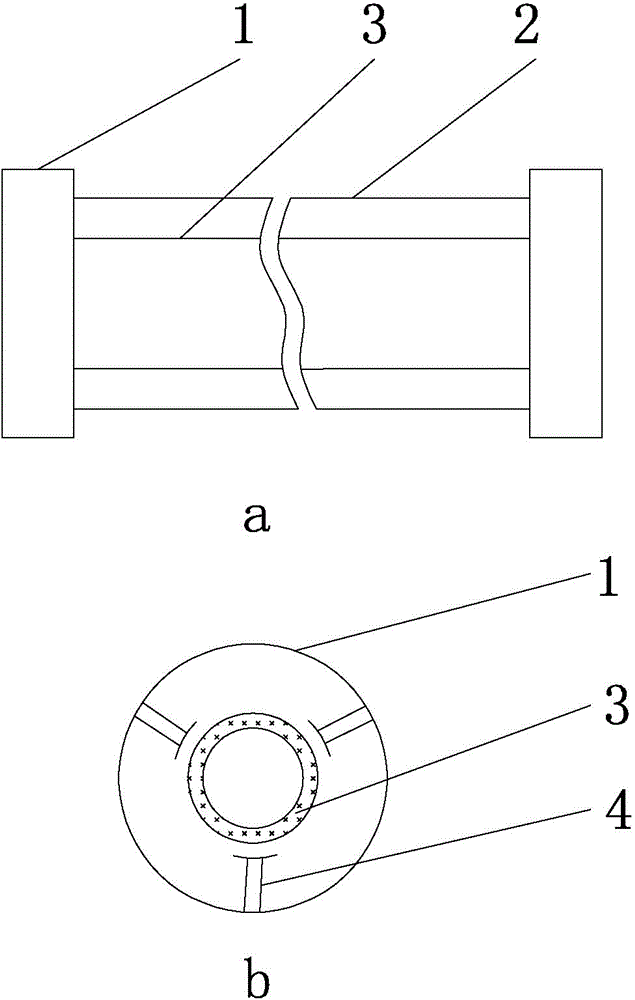

Polymer composite heat resisting waterproof sheet and preparation method thereof

ActiveCN101186133AImprove physical performance indicatorsMeet the needs of the projectOther chemical processesSynthetic resin layered productsMaleic anhydridePolypropylene

The invention belongs to waterproof material technical field in water conservancy and civil building engineering, and in particular discloses a macromolecule composite heat-resistance waterproof sheet used for production of waterproof coil and the preparation method. The technical proposal is that the invention consists of a middle layer consisting of polypropylene, HDPE and maleic anhydride grafting agent and surface layers consisting of linear polyethylene and HDPE bonded at two side surfaces of the middle layer; the macromolecule composite heat-resistance waterproof sheet is extruded and compounded by the middle layer and the surface layers at two sides of the middle layer; the physical performances of the formed waterproof sheet are greatly improved; by detection, the longitudinal and transverse tensile strength is more than 300N / 50mm, namely, more than 500%; the perforation resistance reaches more than 80KN / m when the thickness is more than 0.5mm and reaches 30KN / m when the thickness is less than 0.5mm, thus meeting the engineering requirement.

Owner:衡水中裕铁信防水技术有限公司

Transparent solvent-free single-component waterproof paint and preparation method thereof

ActiveCN105969154AExtended service lifeImprove waterproof performancePolyurea/polyurethane coatingsSolvent freeSolvent

The invention provides a transparent solvent-free single-component waterproof paint and a preparation method thereof. The transparent solvent-free single-component waterproof paint comprises the following raw materials in parts by weight: 30-45 parts of combined polyether polyol, 10-20 parts of isocyanate, 0.01-0.02 parts of a polymerization inhibitor, 10-20 parts of a plasticizer, 0.1-0.2 parts of a wetting dispersant, 0.04-0.08 parts of a catalyst, and 0.1-0.3 parts of a carbon dioxide inhibitor. According to the invention, the environmental protection raw materials substitute toxic solvents, a reaction-type antifoaming agent is employed for preparing the high-solid content environment-friendly type transparent solvent-free single-component waterproof paint, and the waterproof paint has the advantages of excellent coating performance, low cost, safety, environmental protection, and non pollution.

Owner:河北朴智伟业防水材料有限公司

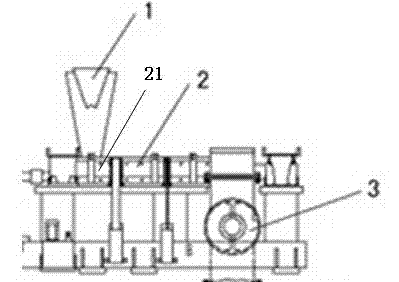

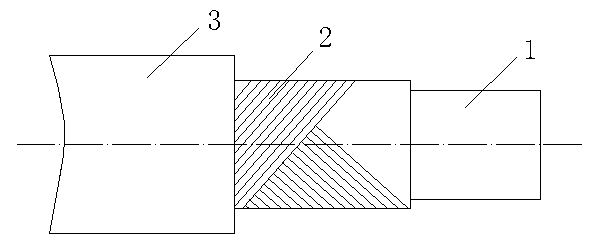

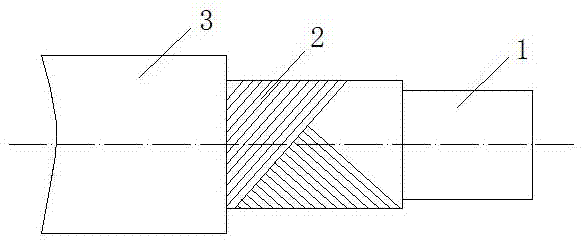

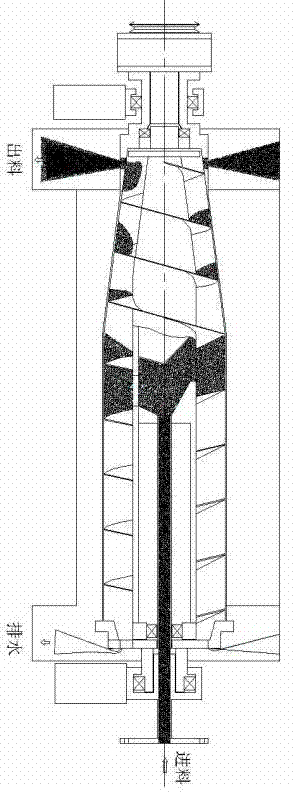

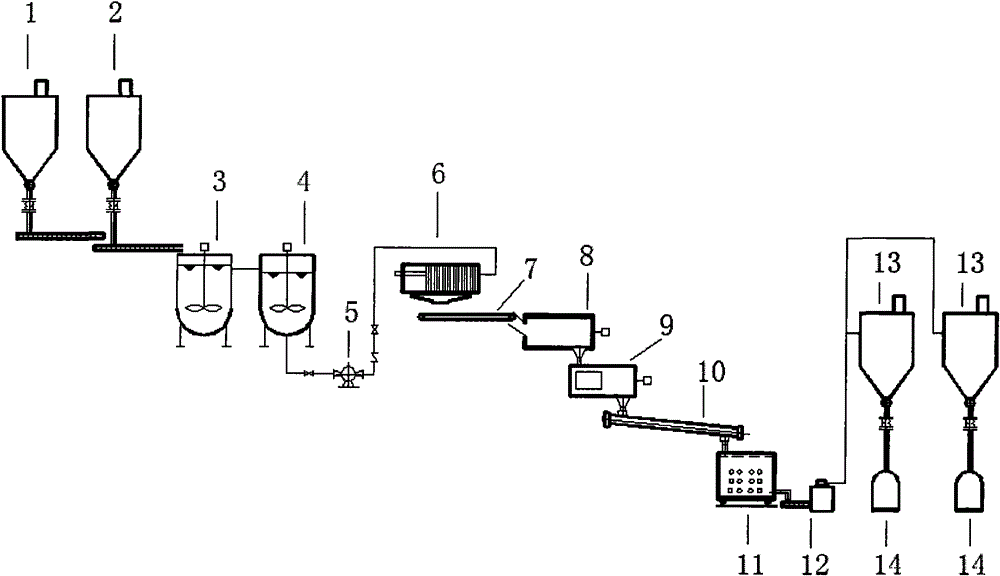

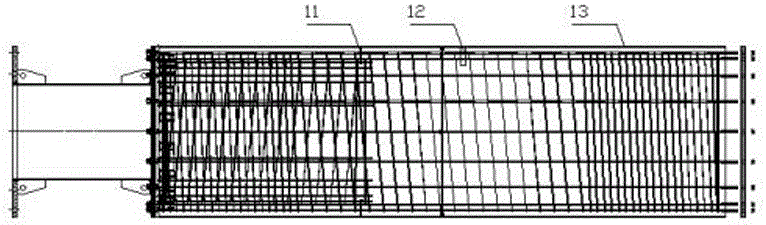

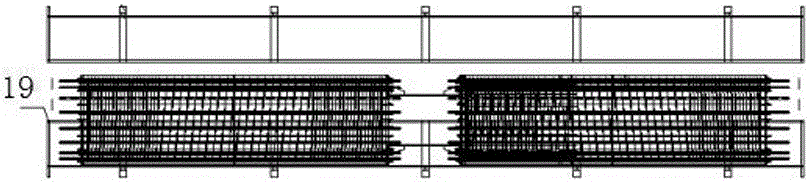

Defibrator system and defibrination method thereof

InactiveCN103088684AIncrease profitIncrease production capacityFibrous raw materialsPulp beating/refining methodsControl systemWood fibre

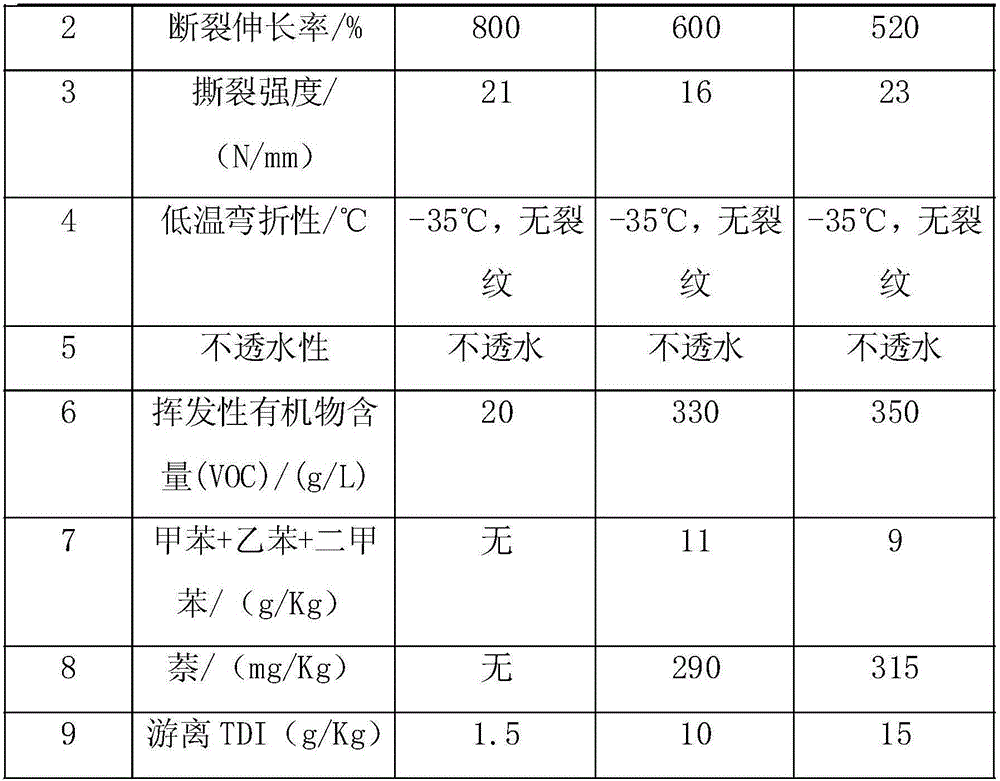

The invention provides a defibrator system and a defibrination method of the defibrator system, wherein the defibrator system comprises a feed hopper and a defibrator. The feed hopper is longitudinally arranged on the front end of a twin-screw extruder, a back-jet resisting device, a vertical drop hopper, a horizontal preheat tank with screw conveying, a belted screw feeder and the defibrator are sequentially arranged on the rear end of the twin-screw extruder, and steam balance control systems are arranged on inlet and outlet of the horizontal preheat tank. The defibrination method of the defibrator system comprises the following steps: feeding wood chips of a certain specification into the longitudinally arranged feed hopper; conducting primary dissociation and conquassation on the wood chips through dynamic extrusion of the twin-screw extruder; feeding the conquassated wood chips into the vertical drop hopper; conducting precooking on the conquassated wood chips dropping into the horizontal preheat tank by self-weight at temperature from 110 to 130 degrees centigrade in the horizontal preheat tank; feeding the precooked conquassated wood chips into the defibrator by the belted screw feeder through the screw conveying of the horizontal preheat tank; and forming wood fiber with high physical property after defibration of the defibrator. The defibrator system and the defibrination method of the defibrator system are high in using raw materials and capable of improving capacity by at least 50 percents.

Owner:JIEYA TECH KUNSHAN CO LTD

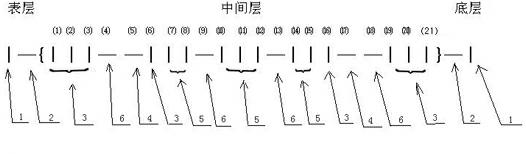

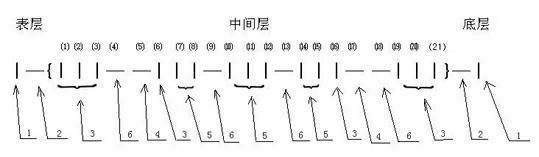

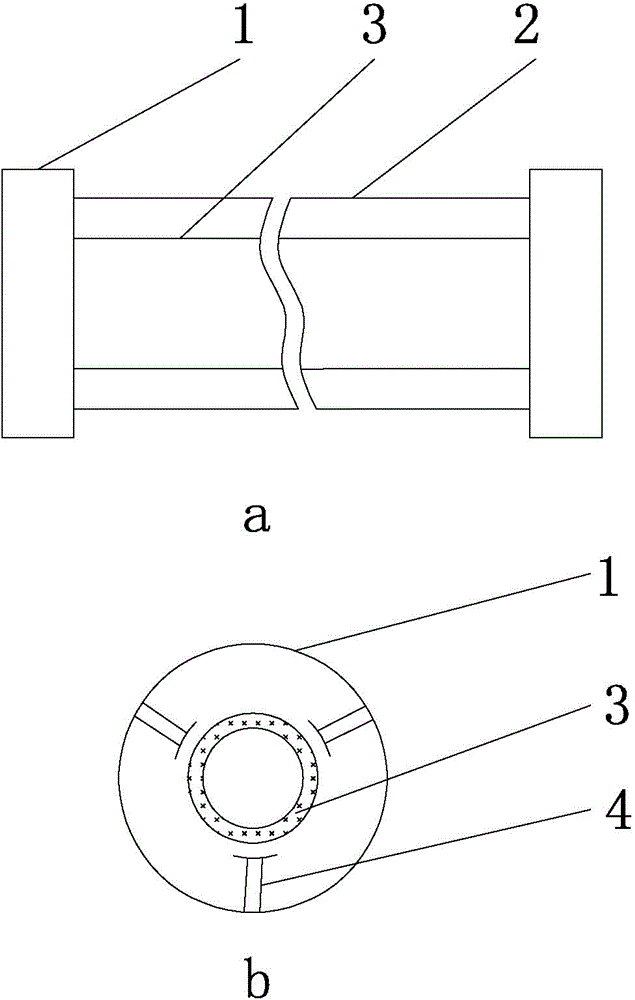

Bamboo-wood composited container floor and production method thereof

InactiveCN102581887AHigh strengthImprove flatnessWood veneer joiningWood layered productsWood veneerSurface layer

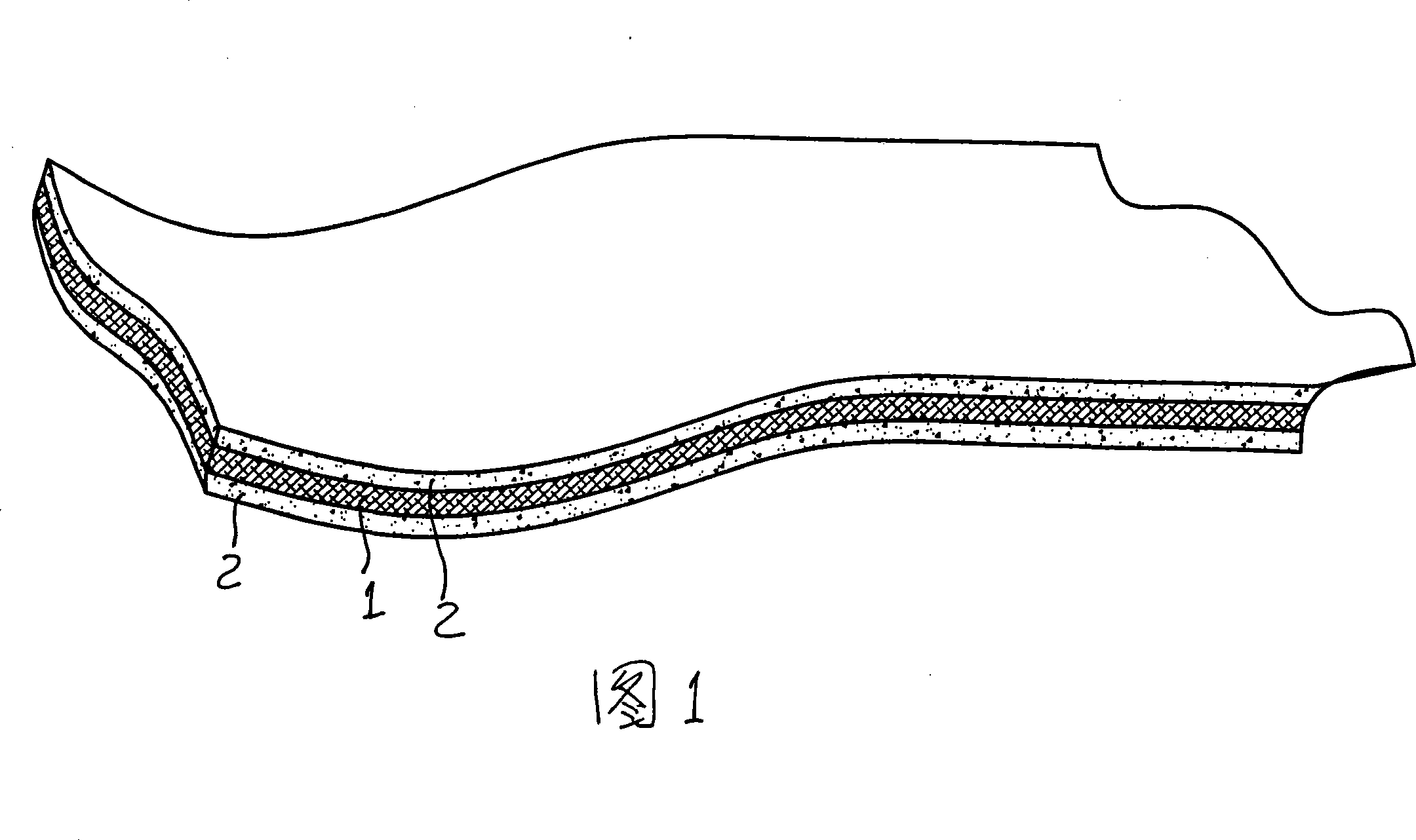

The invention relates to a bamboo-wood composited container floor and a production method thereof. The bamboo-wood composited container floor can meet service requirements, satisfies environment-friendly bamboo-and-wood composite boards, and comprises a surface layer, a bottom layer and a middle layer, wherein each of the surface layer and the bottom layer is a facing layer composed of longitudinal bond paper 1 and a transverse reconstructed veneer 2 or transverse nonwoven 2, and the middle layer is in a symmetrical structure composited with 21 layers of bamboo screens and wood veneers. Each facing layer of the container floor is composed of the bond paper and the transverse reconstructed veneer, or the bond paper and the transverse nonwoven, so that the problem cracking of surface coated films on three continuous longitudinal veneer layers is solved, and the strength of the bamboo-wood composited container floor is improved.

Owner:MAOYOU WOOD

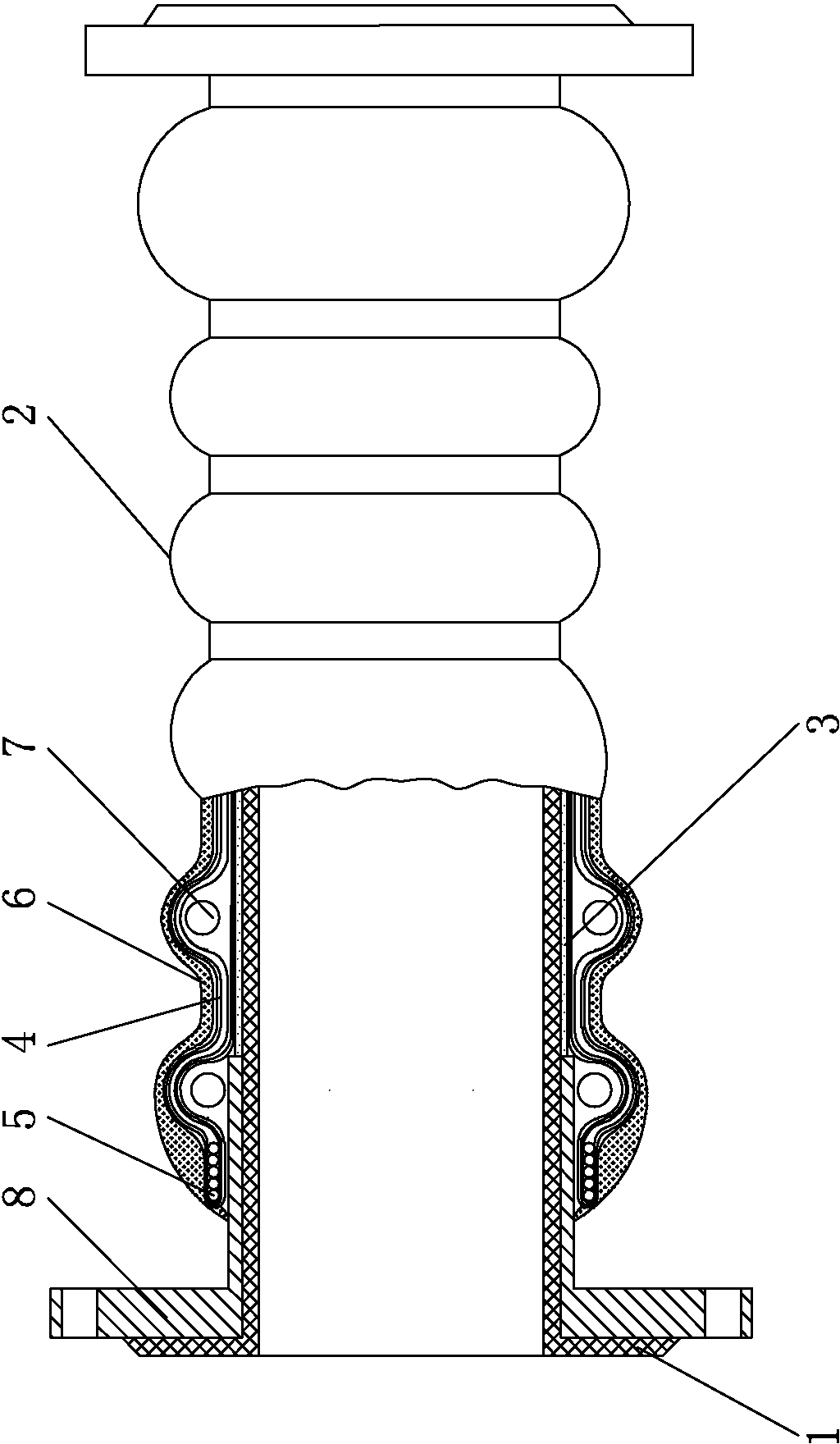

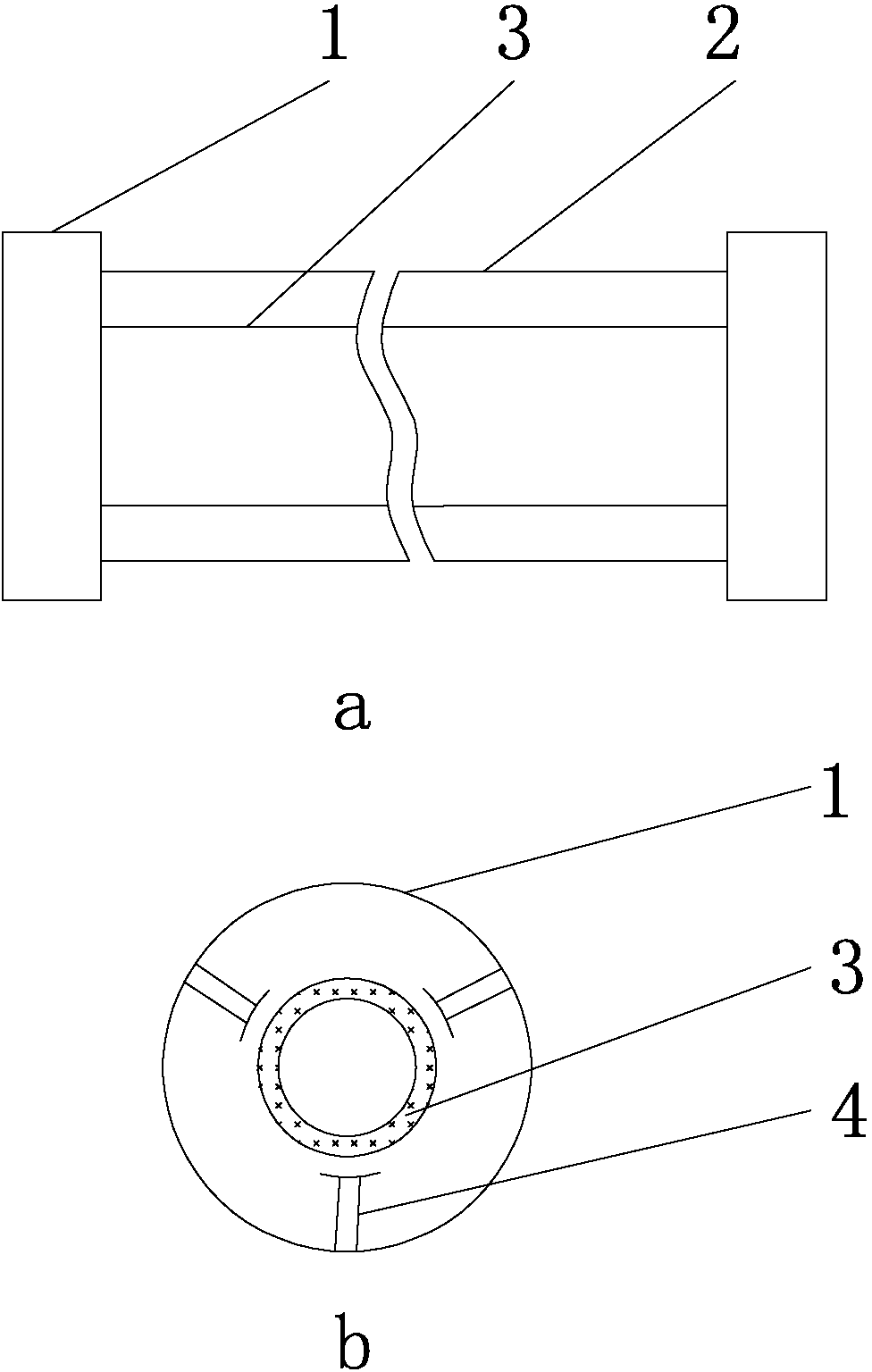

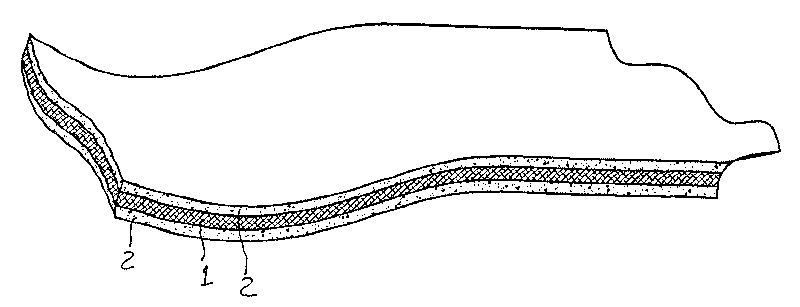

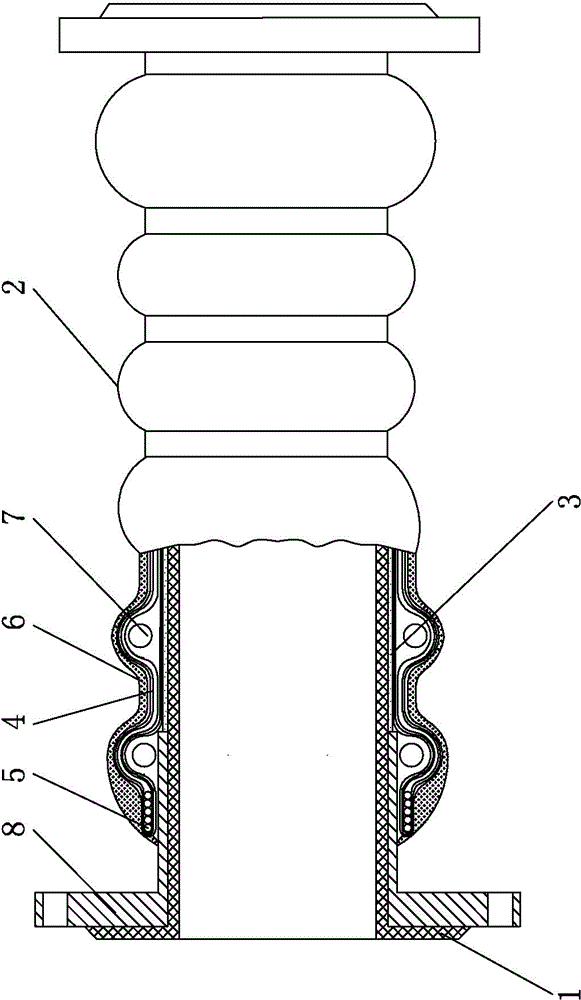

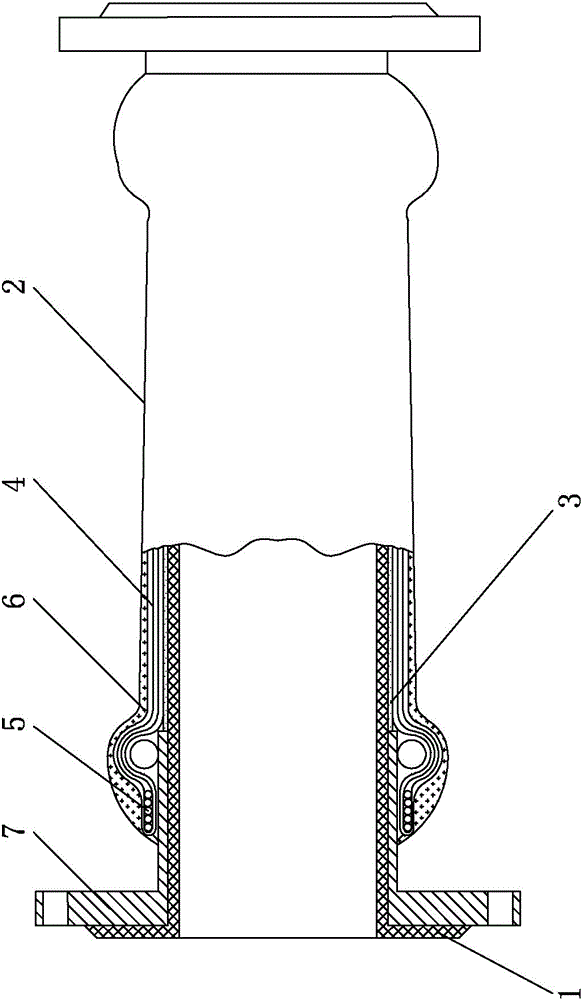

Elastomer composite mud absorption rubber tube and manufacturing technique thereof

ActiveCN103267179AShorten vulcanization timeImprove bond strengthFlexible pipesCoatingsDeformation ProblemPolyurea

The invention provides an elastomer composite mud absorption rubber tube and the manufacturing technique thereof. The elastomer composite mud absorption rubber tube mainly comprises a mud absorption rubber tube body, cord fabric, a tightening steel wire, a rubber tube outer layer, a steel ring and a flange steel short sleeve, wherein a middle layer is arranged on the inner surface of the cord fabric, the middle layer is made of canvas, a composite layer is arranged on the inner surface of the middle layer, and the composite layer is made of polyurethane materials or polyurea materials. After a rubber tube blank is manufactured, the cast-molding technique or the centrifugal molding technique or the spray-molding technique is adopted to manufacture the elastomer composite mud absorption rubber tube. According to the elastomer composite mud absorption rubber tube and the manufacturing method thereof, due to the elimination of inner glue existing in a current mud absorption rubber tube, the vulcanizing time of the tube blank is shortened; the middle canvas layer single-face rubber lining technique improves the bonding strength between an elastomer and the cord fabric; due to the fact that specialized supports are designed and used in the centrifugal technique and in the spraying technique, the deformation problem of the tube body in a manufacturing process is solved, and the uniformity of the thickness of the composite layer is guaranteed.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

Quinary P type hard alloy

The invention relates to a quinary P type hard alloy which comprises the components with the weight percentage: 16% of hard phase titanium carbide, 8% of tantalous carbide, 6% of niobium carbide, 10% of cobalt, 0.006% of lanthanum and the rest of hard phase tungsten carbide. The product of the invention has high flexure strength, good impact strength and red hardness; the hard alloy can be used for rough machining large scale alloy forgeable piece without forging a knife when in use, so as to appropriately improve the processing efficiency; furthermore, the knife has long service life.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

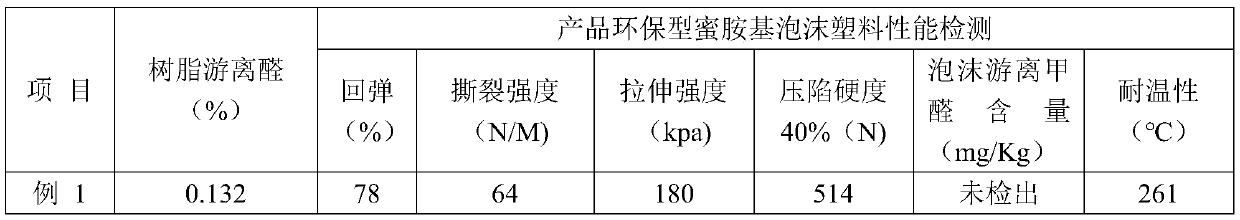

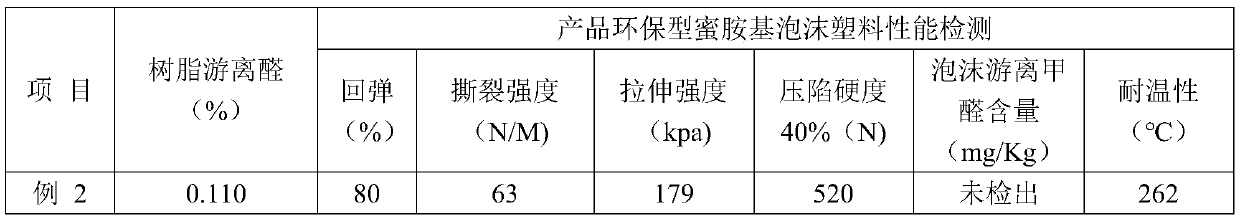

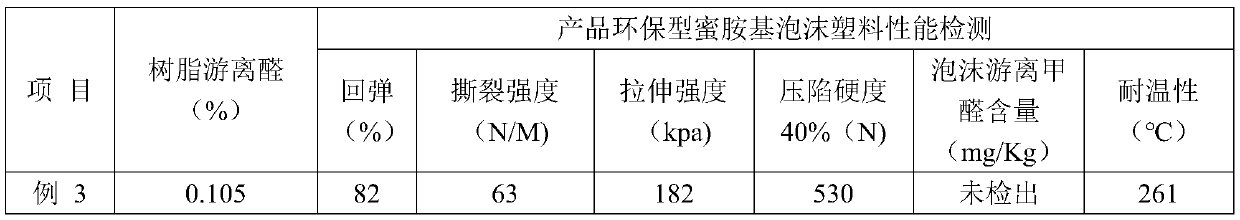

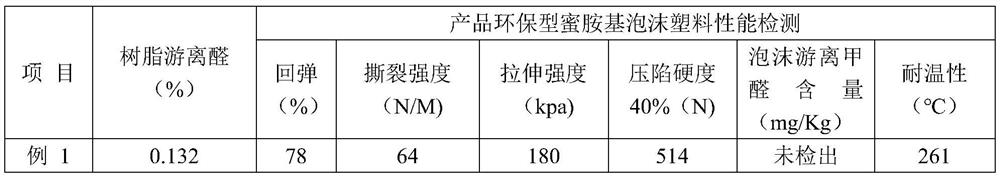

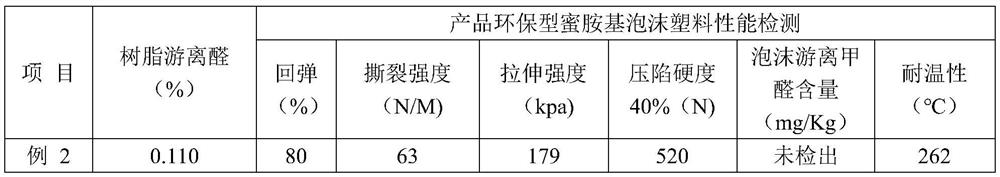

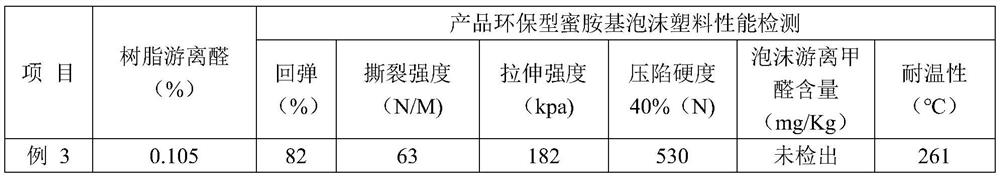

Preparation method of environment-friendly type melamine-based foamed plastic

The invention discloses a preparation method of environment-friendly type melamine-based foamed plastic, comprising the following steps: firstly adding melamine, paraformaldehyde and water into a reactor, adding a modified monomer, adjusting pH value of the solution, and then reacting by steam heating; adding a formaldehyde-removal functional monomer after the reaction and continuously stirring and reacting to obtain expandable low-formaldehyde melamine-based resin; successively adding an emulsifier, a compound curing agent and a foaming agent into an auxiliary agent reaction vessel and uniformly mixing to obtain a mixed auxiliary agent; cooling the resin, respectively metering and carrying out high-speed emulsification on the resin and the mixed auxiliary agent in a twin-screw extruder, carrying out microwave foaming after the emulsification to obtain melamine-based foam M1; and finally drying the melamine-based foam M1 successively by superheated steam and microwave drying treatmentso as to obtain the environmentally-friendly type melamine-based foamed plastic product. According to the invention, industrial production of the melamine-based foamed plastic product with zero formaldehyde release is realized, and the key indexes for industrialization of the melamine-based foamed plastic and the environmental safe process bottleneck are solved.

Owner:PUYANG GREEN FOAM CO LTD

Method for preparing enhanced belt for nano SiO2/PET enhanced RTP

ActiveCN103264511AQuality improvementImprove physical performance indicatorsNano sio2Companion animal

The invention discloses a method for preparing an enhanced belt for nano SiO2 / PET enhanced RTP, wherein the method is characterized in that: the method uses filament bundle prepared by a nano SiO2 PET composite material as a start material, and orderly comprises the following steps of drawing-off, cabling and impregnating. The method has advantages of reasonable technology, good quality of finished product and low production cost, satisfies technology requirement for enhancing a RTP pipe, and provides powerful technology support for widely popularizing and utilizing the RTP pipe in the fields of petroleum exploitation and transport, sea exploitation, city common waterpipe and facilities for a field army.

Owner:河南源宏高分子新材料有限公司

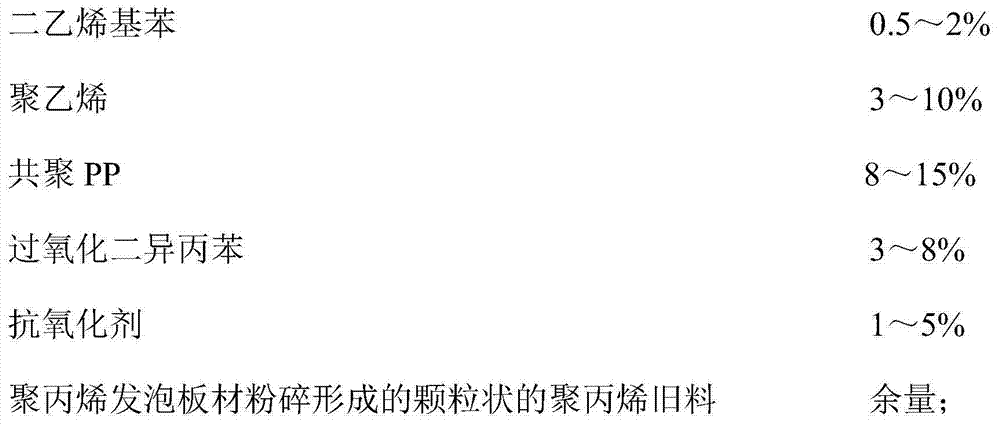

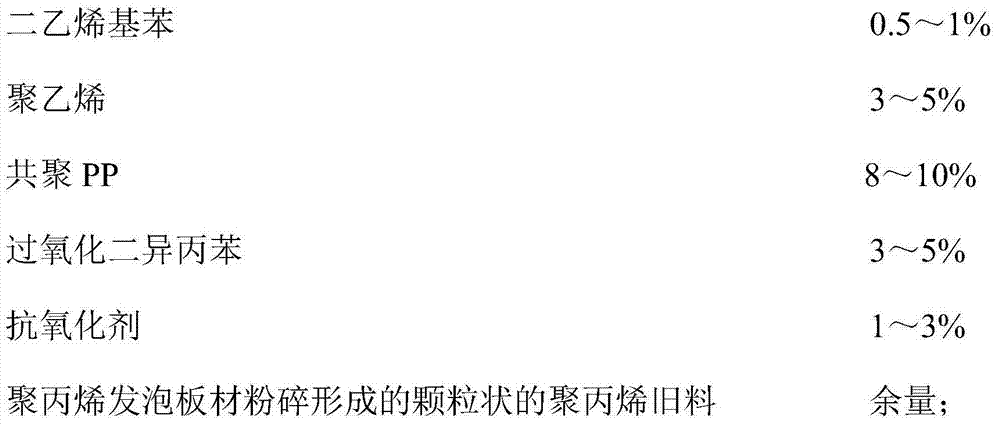

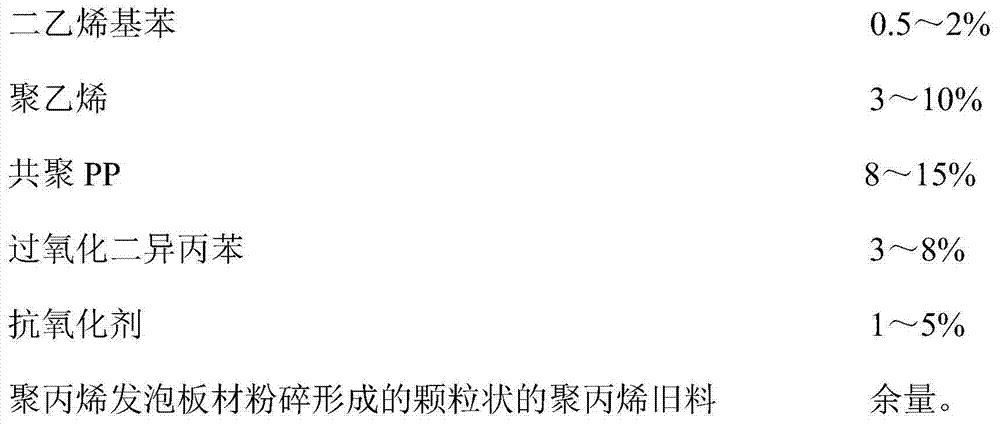

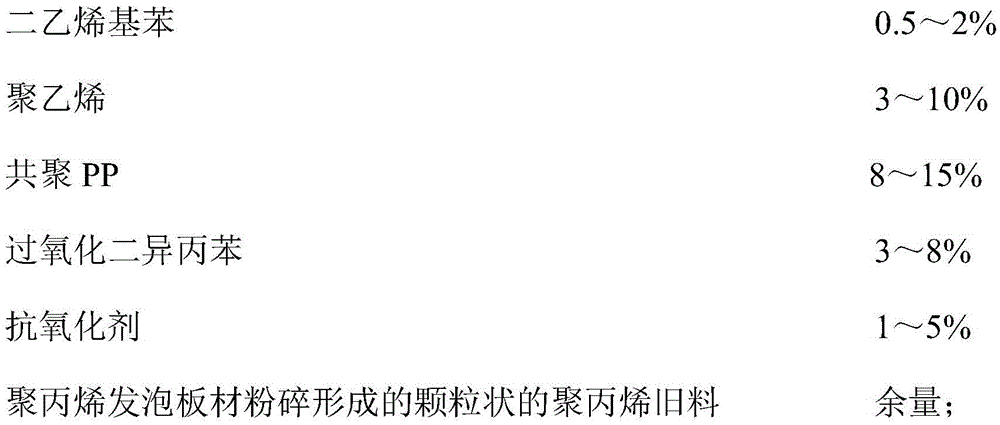

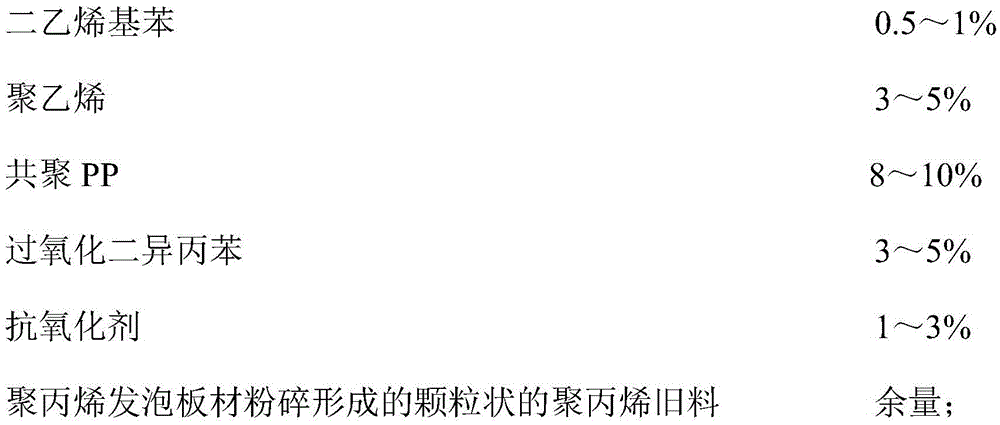

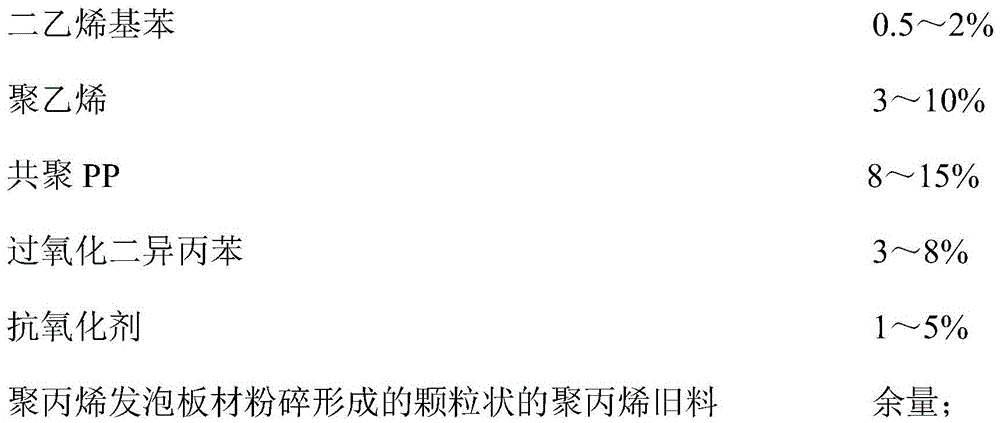

Modified foaming process for reclaimed materials of multilayered co-extruded polypropylene core layer

ActiveCN104118190ASimple processEasy to implementLaminationLamination apparatusPolypropylenePolymer chemistry

The invention discloses a modified foaming process for reclaimed materials of a multilayered co-extruded polypropylene core layer. The modified foaming process comprises the following step: extruding an upper-layer intensified sheet material through a first screw rod extruder; and extruding an intermediate foaming sheet material through a second screw rod extruder; extruding an upper-layer intensified sheet material through a third screw rod extruder; and compounding the upper-layer intensified sheet material, the intermediate foaming sheet material and a lower-layer intensified sheet material to form a composite foaming sheet material. The modified foaming process is simple and easy to carry out; the polypropylene foaming materials can be circularly utilized, the energy conservation and the environmental protection are realized, and all physical property indexes of the polypropylene foaming materials are improved.

Owner:惠州市峄董塑胶科技有限公司

Method for preparing quinary P-type hard alloy

The invention relates to a method for preparing a quinary P-type hard alloy. The quinary P-type hard alloy consists of the following components in percentage by weight: 16 percent of hard-phase titanium carbide, 8 percent of tantalum carbide, 6 percent of niobium carbide, 10 percent of cobalt, 0.006 percent of lanthanum, and the balance of hard-phase tungsten carbide. The preparation method comprises the following steps: mixing the components, wet-milling the mixture by a tilting wet mill, and discharging the mixture after wet-milling; and waxing and pelletizing the mixture through spray drying, pressing the mixture to form a shape by an automatic press, sintering the mixture in vacuum, and tempering the mixture to obtain a sintered finished product. The product prepared by the method has high bending strength, good impact strength and good red hardness; and when the product is coarsely processed into a large-size alloy forged piece, a cutter is not driven during use, the processing efficiency can be properly improved, and the service life of the cutter is long.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

Polymer composite heat resisting waterproof sheet and preparation method thereof

ActiveCN101186133BImprove physical performance indicatorsMeet the needs of the projectOther chemical processesSynthetic resin layered productsSurface layerHeat resistance

The invention belongs to waterproof material technical field in water conservancy and civil building engineering, and in particular discloses a macromolecule composite heat-resistance waterproof sheetused for production of waterproof coil and the preparation method. The technical proposal is that the invention consists of a middle layer consisting of polypropylene, HDPE and maleic anhydride grafting agent and surface layers consisting of linear polyethylene and HDPE bonded at two side surfaces of the middle layer; the macromolecule composite heat-resistance waterproof sheet is extruded and compounded by the middle layer and the surface layers at two sides of the middle layer; the physical performances of the formed waterproof sheet are greatly improved; by detection, the longitudinal andtransverse tensile strength is more than 300N / 50mm, namely, more than 500%; the perforation resistance reaches more than 80KN / m when the thickness is more than 0.5mm and reaches 30KN / m when the thickness is less than 0.5mm, thus meeting the engineering requirement.

Owner:衡水中裕铁信防水技术有限公司

Preparation method of nanometer sio2/pet enhanced RTP reinforcement band

Owner:河南源宏高分子新材料有限公司

Method for preparing oligosaccharide and paper pulp

ActiveCN102277761BImprove fiber qualityImprove physical performance indicatorsPretreatment with alkaline reacting compoundsPulping with inorganic basesFiberOligosaccharide

The invention discloses a method for preparing oligosaccharide and paper pulp, belonging to the technical fields of pulping and the comprehensive utilization of pulping. The method comprises the steps of: using crop straws as raw materials, pre-treating the raw materials to obtain a pre-extracting solution, concentrating the pre-extracting solution by a membrane separation method, then obtaining a crude xylan solution via precipitation and centrifugal separation, and then preparing oligosaccharide via enzymolysis, vacuum concentration and frozen-drying. The pre-treated solid residues are stewed via an alkaline process so as to prepare unbleached paper pulps of which the indexes such as fiber length, whiteness, fracture length, tear resistance, folding strength and the like are all improved. The generated black liquid has the characters of low viscosity and high heat productivity. The method for preparing oligosaccharide and paper pulp integrates the comprehensive utilization method with the biomass transformation method on the premise of optimizing the traditional alkaline chemical pulping technique to prepare products with high additional values, namely oligosaccharide, thereby increasing the quality of the paper pulp and the extraction, vaporization and combustion performances of the black liquid.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Elastomer composite mud absorption rubber tube and manufacturing technique thereof

ActiveCN103267179BShorten vulcanization timeHigh bonding strengthFlexible pipesCoatingsElastomer compositesEngineering

The invention provides an elastomer composite mud absorption rubber tube and the manufacturing technique thereof. The elastomer composite mud absorption rubber tube mainly comprises a mud absorption rubber tube body, cord fabric, a tightening steel wire, a rubber tube outer layer, a steel ring and a flange steel short sleeve, wherein a middle layer is arranged on the inner surface of the cord fabric, the middle layer is made of canvas, a composite layer is arranged on the inner surface of the middle layer, and the composite layer is made of polyurethane materials or polyurea materials. After a rubber tube blank is manufactured, the cast-molding technique or the centrifugal molding technique or the spray-molding technique is adopted to manufacture the elastomer composite mud absorption rubber tube. According to the elastomer composite mud absorption rubber tube and the manufacturing method thereof, due to the elimination of inner glue existing in a current mud absorption rubber tube, the vulcanizing time of the tube blank is shortened; the middle canvas layer single-face rubber lining technique improves the bonding strength between an elastomer and the cord fabric; due to the fact that specialized supports are designed and used in the centrifugal technique and in the spraying technique, the deformation problem of the tube body in a manufacturing process is solved, and the uniformity of the thickness of the composite layer is guaranteed.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

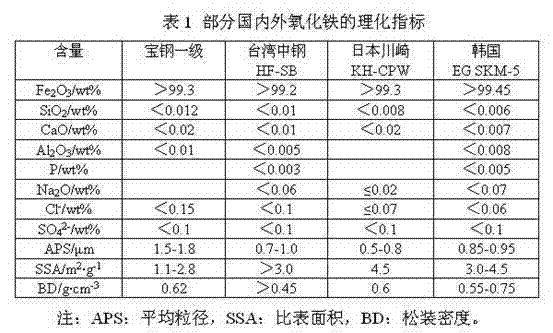

Method for purifying ferric oxide red by wet method

ActiveCN102674470BGood chemical propertiesImprove physical performance indicatorsFerric oxidesAmmonium Hydrogen CarbonateImpurity

The invention aims to provide a method for purifying ferric oxide red by a wet method. The method comprises the process route of water-washing, dehydrating and drying and is characterized in that an additive with the ammonia content of 0.05 to 35 percent is added in the water-washing process; impurities are separated by a centrifugal dehydrator during dehydration; preferably, the additive can be ammonia, ammonia water, ammonium carbonate or ammonium hydrogen carbonate with the ammonia content of 0.05 to 35 percent; and the drying method is rotary kiln drying or pulping-centrifugal spraying drying. High-quality ferric oxide powder is obtained by purifying the ferric oxide powder and can serve as a raw material of a high-end product with high magnetic conductivity.

Owner:BENXI HUANYU MAGNETIC IND

A kind of preparation method of environment-friendly melamine-based foamed plastics

The invention discloses a preparation method of an environment-friendly melamine-based foam plastic. First, add melamine, paraformaldehyde and water into the reactor, and add modified monomers to adjust the pH value of the solution, and then heat the reaction with steam; after the reaction, add aldehyde-removing functional monomers and continue to stir the reaction to obtain volatile low-formaldehyde Melamine-based resin; add emulsifier, compound curing agent and foaming agent to the auxiliary reaction kettle in sequence and mix well to obtain mixing auxiliary; cool down the temperature of the obtained resin, and then enter the twin-screw machine by metering and mixing auxiliary at the same time. High-speed emulsification, microwave foaming after emulsification, to obtain melamine-based foam M1; finally, the melamine-based foam M1 is dried by superheated steam and microwave drying in sequence, and an environmentally friendly melamine-based foam plastic product is obtained after drying. The invention realizes the industrialized production of zero-formaldehyde-releasing melamine-based foam plastic products, and solves the key indicators of the industrialization of the melamine-based foam plastic and the bottleneck of environmental protection and safety technology.

Owner:PUYANG GREEN FOAM CO LTD

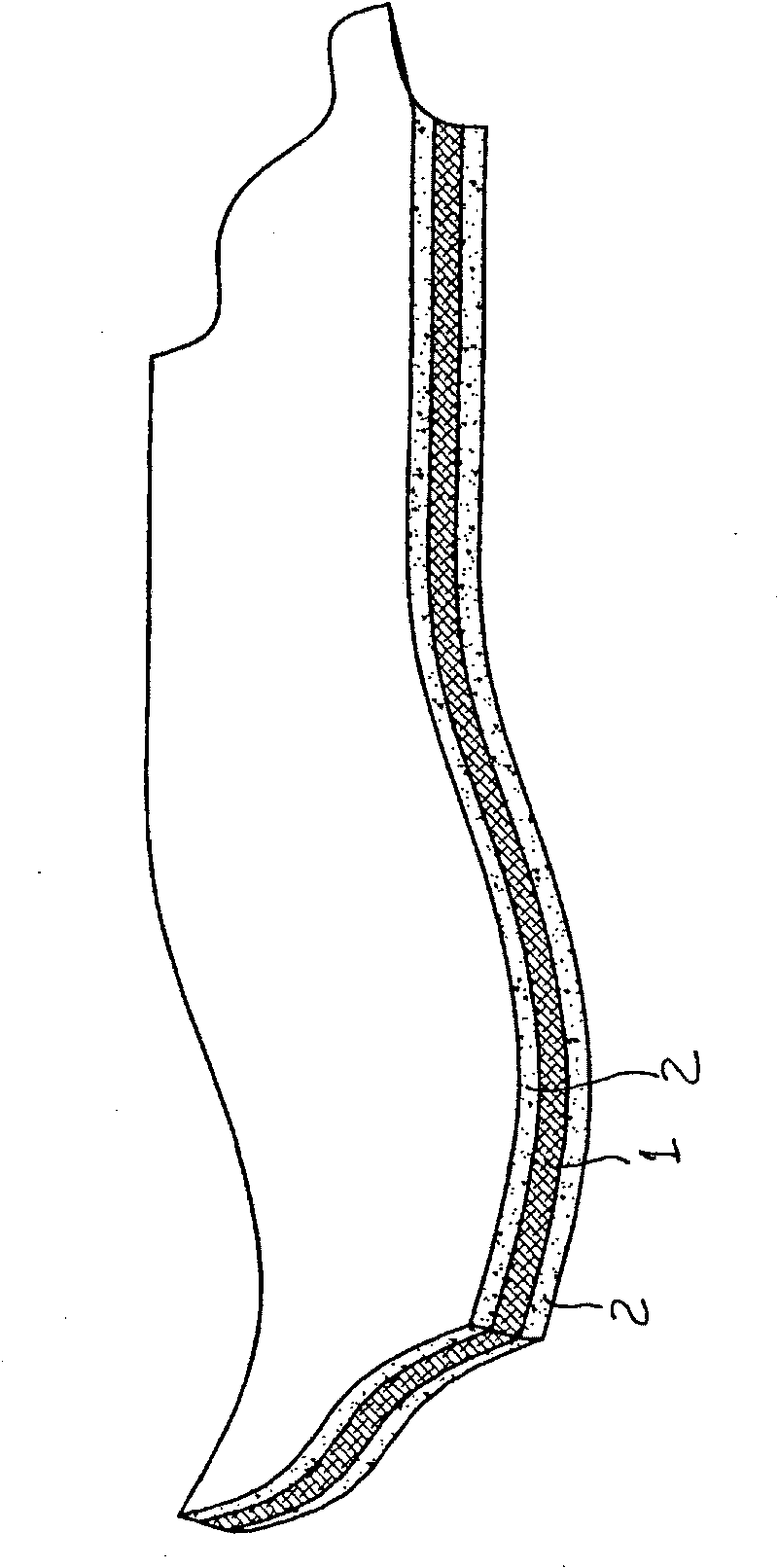

A kind of elastomer composite mud discharging rubber hose and its production process

ActiveCN103277599BShorten vulcanization timeHigh bonding strengthFlexible pipesTubular articlesVulcanizationSludge

The invention provides an elastomer composite sludge discharging rubber pipe and a production process thereof. The elastomer composite sludge discharging rubber pipe is mainly composed of a cord fabric layer, a tightening steel wire, a rubber pipe outer layer and a flange steel short sleeve, an intermediate layer which is a canvas layer is arranged on the inner surface of the cord fabric layer of the sludge discharging rubber pipe, and a composite layer is arranged on the inner surface of the intermediate layer and made of polyurethane materials or polyurea materials. After a pipe blank is prepared, the elastomer composite sludge discharging rubber pipe is made by respectively adopting a pouring forming process, a centrifugation forming process or a spraying forming process. Due to omission of inner-layer rubber of existing sludge discharging rubber pipes, vulcanization time of the pipe blank of the sludge discharging rubber pipe is shortened; a single-face rubber lining process is adopted to the intermediate canvas layer, so that bonding strength of an elastomer and the cord fabric layer is improved; and a special support is designed and used in the processes of centrifugation and spraying, so that the problem of deformation of a pipe body during manufacturing is solved and thickness uniformity of the composite layer is guaranteed.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

A kind of transparent solvent-free one-component waterproof coating and preparation method thereof

ActiveCN105969154BHigh solid contentExtended service lifePolyurea/polyurethane coatingsSolvent freeSolvent

The invention provides a transparent solvent-free single-component waterproof paint and a preparation method thereof. The transparent solvent-free single-component waterproof paint comprises the following raw materials in parts by weight: 30-45 parts of combined polyether polyol, 10-20 parts of isocyanate, 0.01-0.02 parts of a polymerization inhibitor, 10-20 parts of a plasticizer, 0.1-0.2 parts of a wetting dispersant, 0.04-0.08 parts of a catalyst, and 0.1-0.3 parts of a carbon dioxide inhibitor. According to the invention, the environmental protection raw materials substitute toxic solvents, a reaction-type antifoaming agent is employed for preparing the high-solid content environment-friendly type transparent solvent-free single-component waterproof paint, and the waterproof paint has the advantages of excellent coating performance, low cost, safety, environmental protection, and non pollution.

Owner:河北朴智伟业防水材料有限公司

A board production process using polypropylene foamed recycled materials

ActiveCN104118190BSimple processEasy to implementLaminationLamination apparatusPolypropylenePolymer chemistry

The invention discloses a modified foaming process for reclaimed materials of a multilayered co-extruded polypropylene core layer. The modified foaming process comprises the following step: extruding an upper-layer intensified sheet material through a first screw rod extruder; and extruding an intermediate foaming sheet material through a second screw rod extruder; extruding an upper-layer intensified sheet material through a third screw rod extruder; and compounding the upper-layer intensified sheet material, the intermediate foaming sheet material and a lower-layer intensified sheet material to form a composite foaming sheet material. The modified foaming process is simple and easy to carry out; the polypropylene foaming materials can be circularly utilized, the energy conservation and the environmental protection are realized, and all physical property indexes of the polypropylene foaming materials are improved.

Owner:惠州市峄董塑胶科技有限公司

Method for preparing quinary P-type hard alloy

The invention relates to a method for preparing a quinary P-type hard alloy. The quinary P-type hard alloy consists of the following components in percentage by weight: 16 percent of hard-phase titanium carbide, 8 percent of tantalum carbide, 6 percent of niobium carbide, 10 percent of cobalt, 0.006 percent of lanthanum, and the balance of hard-phase tungsten carbide. The preparation method comprises the following steps: mixing the components, wet-milling the mixture by a tilting wet mill, and discharging the mixture after wet-milling; and waxing and pelletizing the mixture through spray drying, pressing the mixture to form a shape by an automatic press, sintering the mixture in vacuum, and tempering the mixture to obtain a sintered finished product. The product prepared by the method hashigh bending strength, good impact strength and good red hardness; and when the product is coarsely processed into a large-size alloy forged piece, a cutter is not driven during use, the processing efficiency can be properly improved, and the service life of the cutter is long.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE CO LTD

Cambered-octagonal-surface resin diamond

The invention relates to a cambered-octagonal-surface resin diamond which is composed of the following raw materials in percentage by weight: 5-10% of silver solder, at most 5% of organic pigment, 55-60% of polyurethane resin, at most 1% of photoinitiator, 8-10% of calcium carbonate, at most 3% of assistant and the balance of organic diluent. The diamond surface of the resin diamond is a cambered octagonal structure, and thus, has higher refractivity, strength, hardness, light fastness, corrosion resistance and service life than the existing resin diamond. The experiment proves that when the resin diamond is irradiated by a gloss instrument from a 45-degree angle, the refractivity is greater than 98 degrees and is much greater than the value of 80 degrees in the existing resin diamond. Meanwhile, no phenomenon of damage is detected in a 1-kilo free falling body bounce impact elasticity test.

Owner:天津艾雅装饰材料有限公司

Preparation method of high-transmittance low-resistance air filtering paper

InactiveCN108755261AIncrease the areaImprove bindingPaper recyclingPaper/cardboardBursting strengthFiber

The invention discloses a preparation method of high-transmittance low-resistance air filtering paper. The preparation method comprises the following steps: step 1, preparing a reaction mixture; step2, preparing a mixing slurry; step 3, preparing a mixing fiber slurry; step 4, preparing a mixing powder; step 5, preparing a mixing paste; step 6, preliminarily preparing a paper base; step 7, coating and drying the paper base to obtain the final environmentally friendly efficient high-transmittance low-resistance air filtering paper. The prepared high-transmittance low-resistance air filtering paper is better in air permeability and lower in airflow resistance, the filtering efficiency is excellent, the filtering paper has the flowery odor of the plant and has the functions of preventing mould, sterilizing, and effectively repelling mosquitos, meanwhile, the deformation resistance, the differential pressure resistance and the bursting strength of the filtering paper are better, in addition, a large quantity of waste is used, the cost is lowered, the environment is protected, the resource is saved, and the preparation method has a higher practical value and an excellent application prospect.

Owner:安徽古耐家居有限公司

Resin diamond luminous bottom body

The invention relates to a resin diamond luminous bottom body comprising the following raw materials by weight: 8-10% of atomized aluminum, 30-40% of electrophoresis resin, less than or equal to 3% of a leveling agent and balance of a water-based diluent for diluting to 100%. The resin diamond luminous bottom body is high in brightness, so that a luminous bottom and a transparent substrate form a diffraction body and a refraction body, resin diamond and substrate common luminescence can be improved, the resin diamond luminous bottom body is glittering and translucent and good in contrast effect as background, resin diamond decorative performance and visual aesthetics can be improved, and resin diamond application scope can be expanded.

Owner:天津艾雅装饰材料有限公司

Purification method of dry-type iron oxide powder solid

ActiveCN101863515BGood chemical propertiesImprove physical performance indicatorsFerric oxidesPurification methodsFiltration

Owner:BAOSHAN IRON & STEEL CO LTD

Method for manufacturing anti-deformation high-efficiency filter paper

InactiveCN108797172AIncrease the areaImprove bindingPaper recyclingPaper coatingBursting strengthFiber

The invention discloses a method for manufacturing an anti-deformation high-efficiency filter paper. The method comprises the steps of step one, preparation of mixed slurry; step two, preparation of mixed fiber slurry; step three, preparation of mixed powder; step four, preliminary preparation of a paper base; step fifth, the preparation of a mixed paste; step six, the preparation of a reaction mixture; step seven, coating and drying of the paper base to obtain the final anti-deformation high-efficiency filter paper. The filter paper has good air permeability, low airflow resistance and excellent filtering efficiency, has the functions of having plant floral, being mildewproof and bactericidal and effectively repelling mosquitoes, and has excellent anti-deformation performance, pressure difference resistance performance and bursting strength performance, and the method uses a large amount of waste, reduces costs, protects the environment, saves resources, and has high practical value and good application prospects.

Owner:泾县汇鼎锋建筑装饰工程有限公司

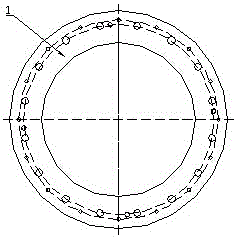

A production process of large-diameter sc-shaped steel-concrete piles

The invention relates to a production process of a large-caliber SC shape steel mixed pile or column. The production process comprises the following steps: a matched tool is manufactured, disc round steep is stretched, and an outer reinforcement cage and a reinforcing cage rib are manufactured; the outer reinforcement cage is welded with a pull rod, and the reinforcing cage rib is put in the outer reinforcement cage after coating an upper end plate; a middle joiner is connected with a keel, the assembled outer reinforcement cage coats a steel pipe, a head plate is assembled with a steel cylinder, and a steel pipe core rod is coated with a rubber pipe to be inserted in the structural part; a pile top section structure, a pile bottom section structure and a standard section structure are manufactured in sequence and are assembled, the assembled structural part is lifted into a steel mold, the mold is closed, the centrifugation is performed after the pumping of concrete, and the normal-temperature maintenance is performed; when the strength of the concrete reaches 10% of a design value, the steel pipe is pulled out; and when the strength of the concrete reaches 60% of the design value, the mold is disassembled, and the product is formed through assembling. The production process can manufacture an ultralong prestress concrete pipe pile with large diameter.

Owner:国鼎(南通)管桩有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com