A production process of large-diameter sc-shaped steel-concrete piles

A production process and large-diameter technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as failure to produce satisfactory pipe piles, achieve high physical performance indicators and mechanical performance indicators, improve durability, and high Effect of flexural and shear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the accompanying drawings, the large-diameter SC-type steel-concrete pile or column production process of the present invention will be further described:

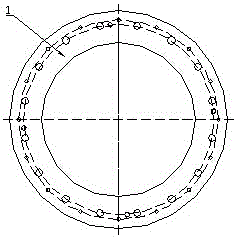

[0030] The first step, at first, according to the design drawings, make the supporting tools that need to be used: head plate 1, intermediate connector 2, pull rod 3 and steel pipe mandrel 4 with rubber tube 5, such as figure 1 , figure 2 , image 3 and Figure 4 shown.

[0031] The second step, such as Figure 5 As shown, the round steel 6 is straightened and stretched to the specified diameter length, and the material is finely cut and blanked according to the design requirements, and one end of the round steel is pierced.

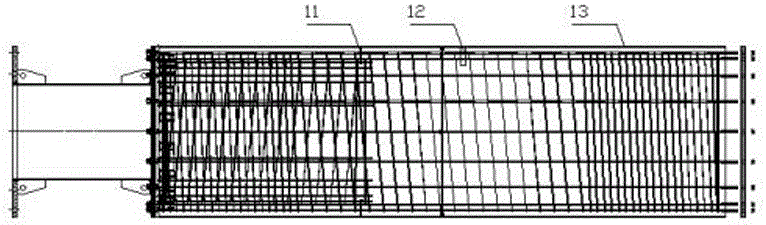

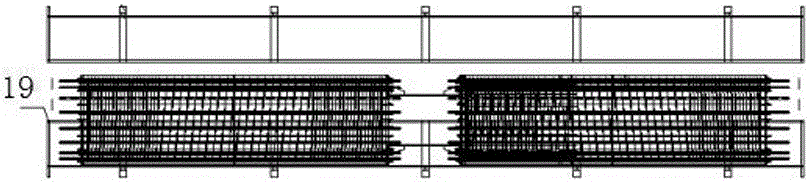

[0032] In the third step, the prepared round steel and spiral bars are rolled and welded to form the outer reinforcement cage 7 and the pile top pipe joint reinforcing cage reinforcement 8 installed inside the outer reinforcement cage, such as Figure 6 and F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com