Patents

Literature

60results about How to "Guaranteed stitching quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid image splicing method based on wide-angle lenses

InactiveCN103971352ASplicing speed is fastHigh speedImage enhancementImage analysisCoordinate mappingImage sequence

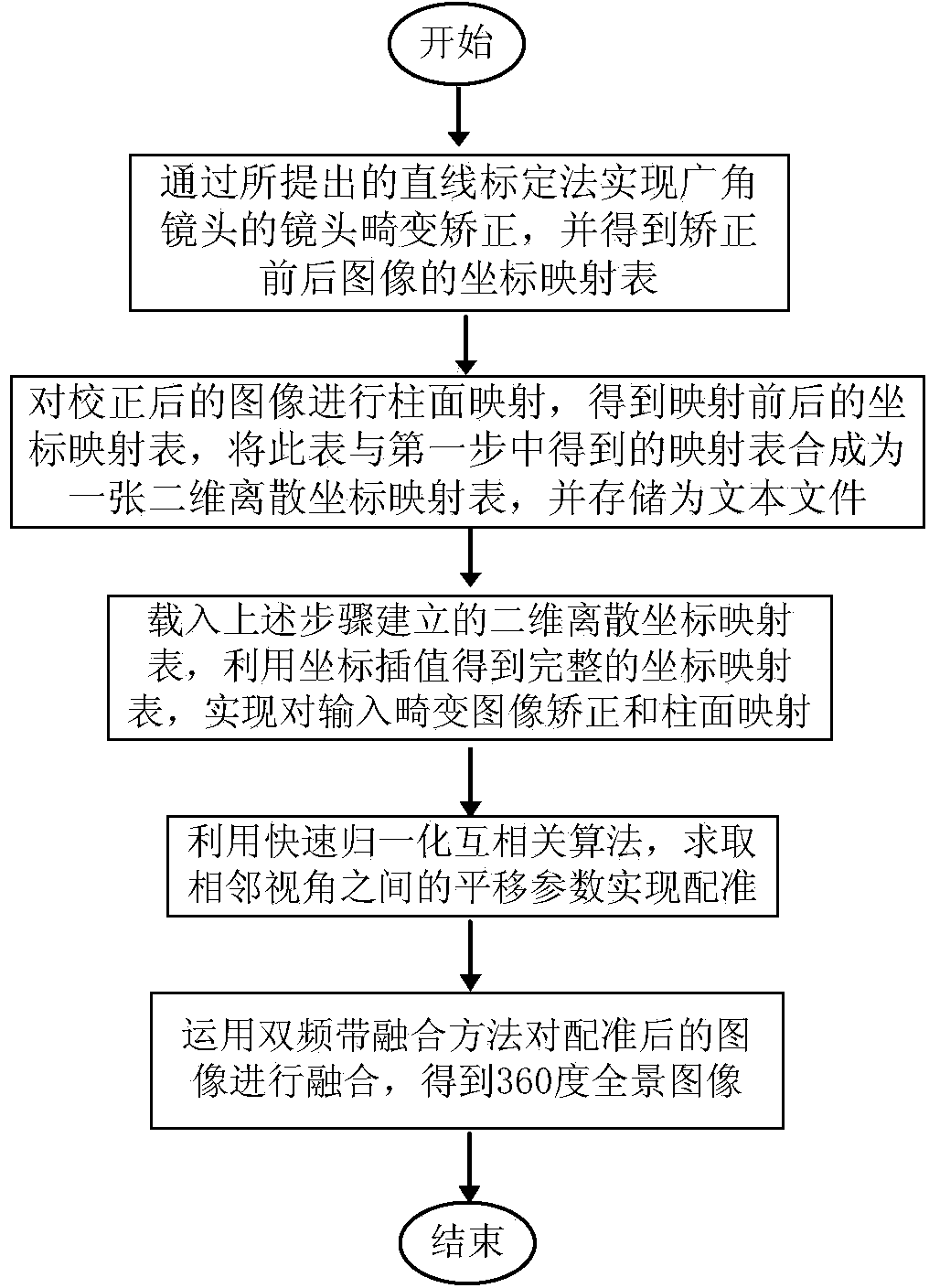

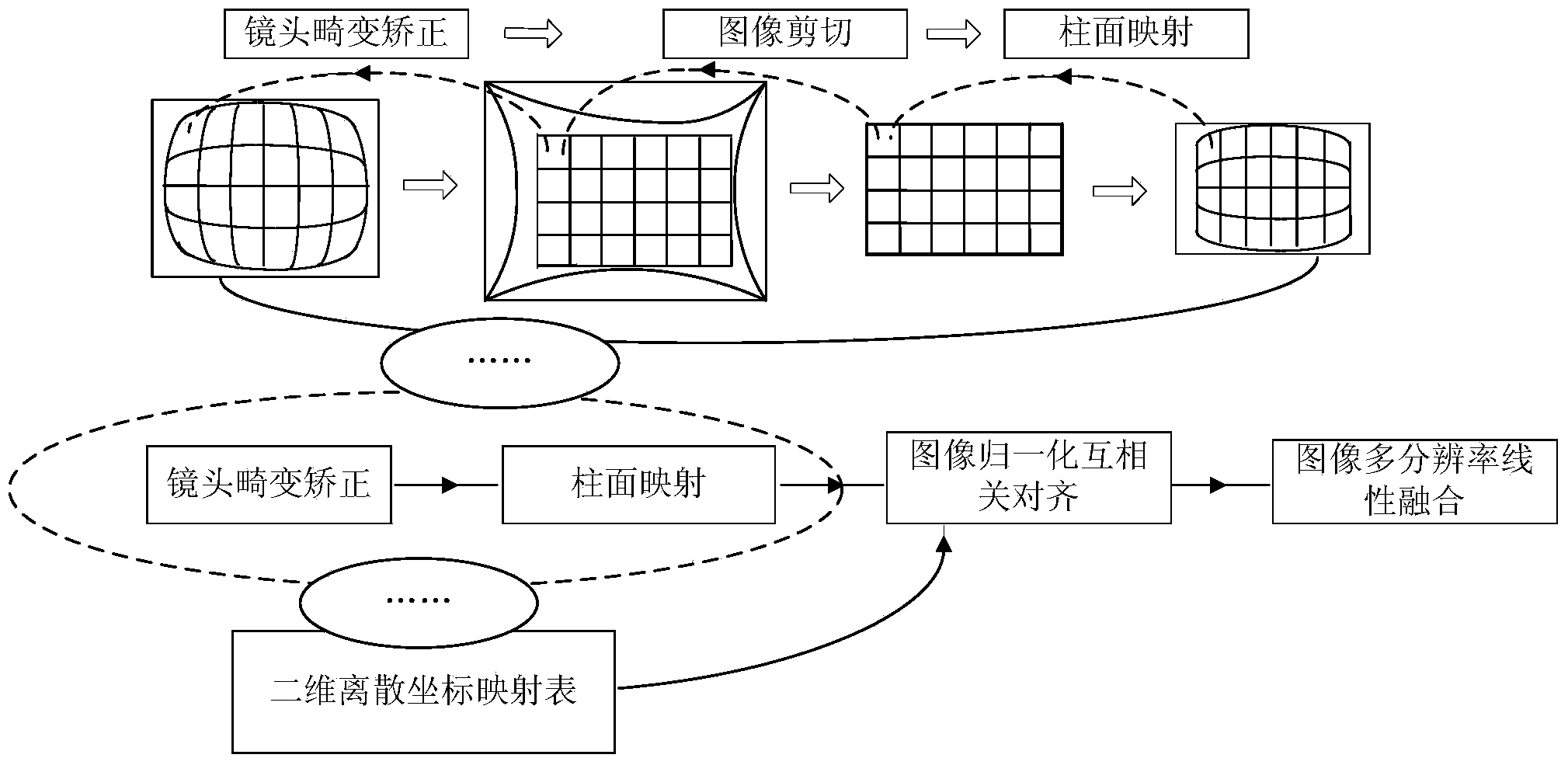

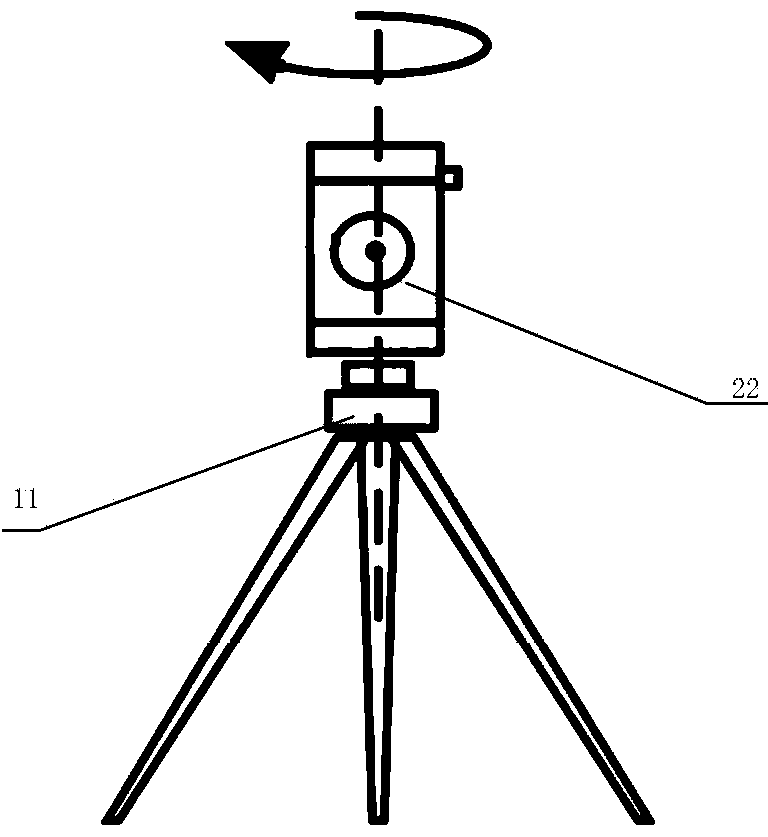

The invention discloses a rapid image splicing method based on wide-angle lenses. The method includes the steps that firstly, distortion correction is conducted on images acquired through the wide-angle lenses; secondly, cylindrical surface mapping is conducted on the images on which distortion correction is conducted, and a two-dimensional discrete coordinate mapping table is generated for each wide-angle lens; thirdly, the two-dimensional discrete coordinate mapping table of each wide-angle lens is loaded, and distortion correction and cylindrical surface mapping are sequentially conducted on the distortion images acquired through the wide-angle lenses according to the tables; fourthly, translation parameters between adjacent visual angle images on which cylindrical surface mapping is conducted are acquired, and the adjacent visual angle images are registered; fifthly, the registered adjacent visual angle images are fused, wherein Laplacian pyramids are established for registered adjacent visual angle image sequences respectively, linear fusion is conducted on a high-frequency pyramid image overlaying region and a low-frequency pyramid image overlaying region, and then a fused image of the adjacent visual angle images is obtained. The method has the advantages of being high in splicing speed and real-time performance.

Owner:SOUTH CHINA UNIV OF TECH

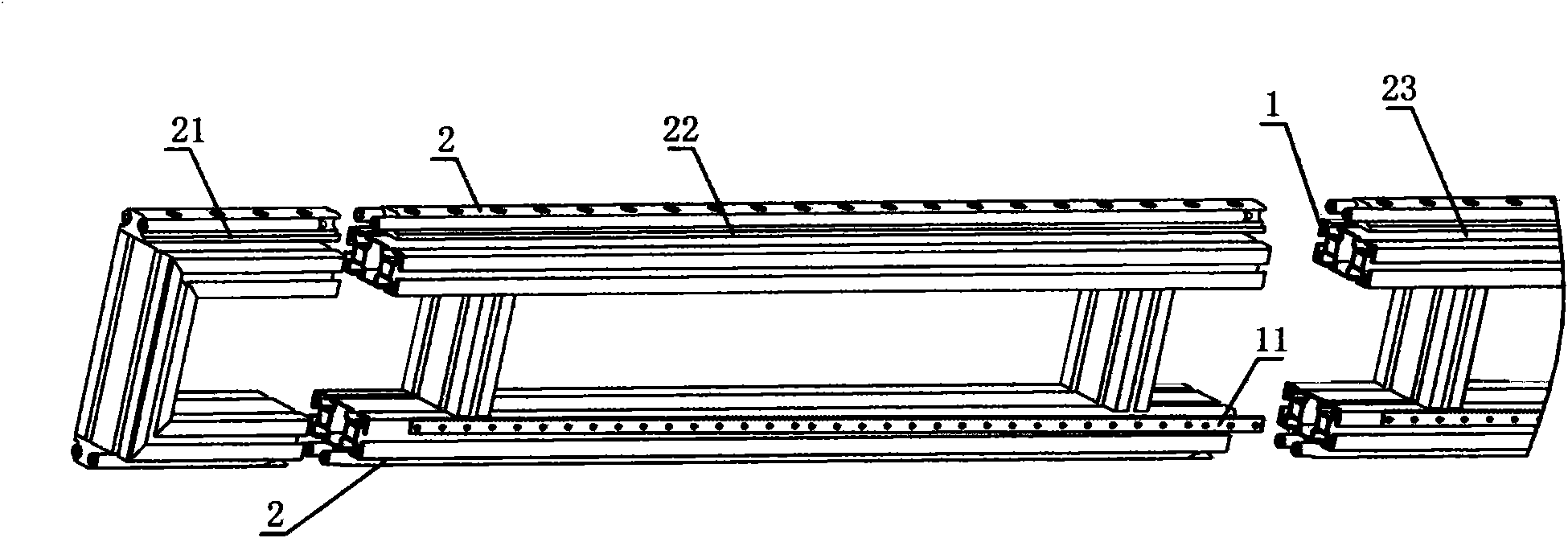

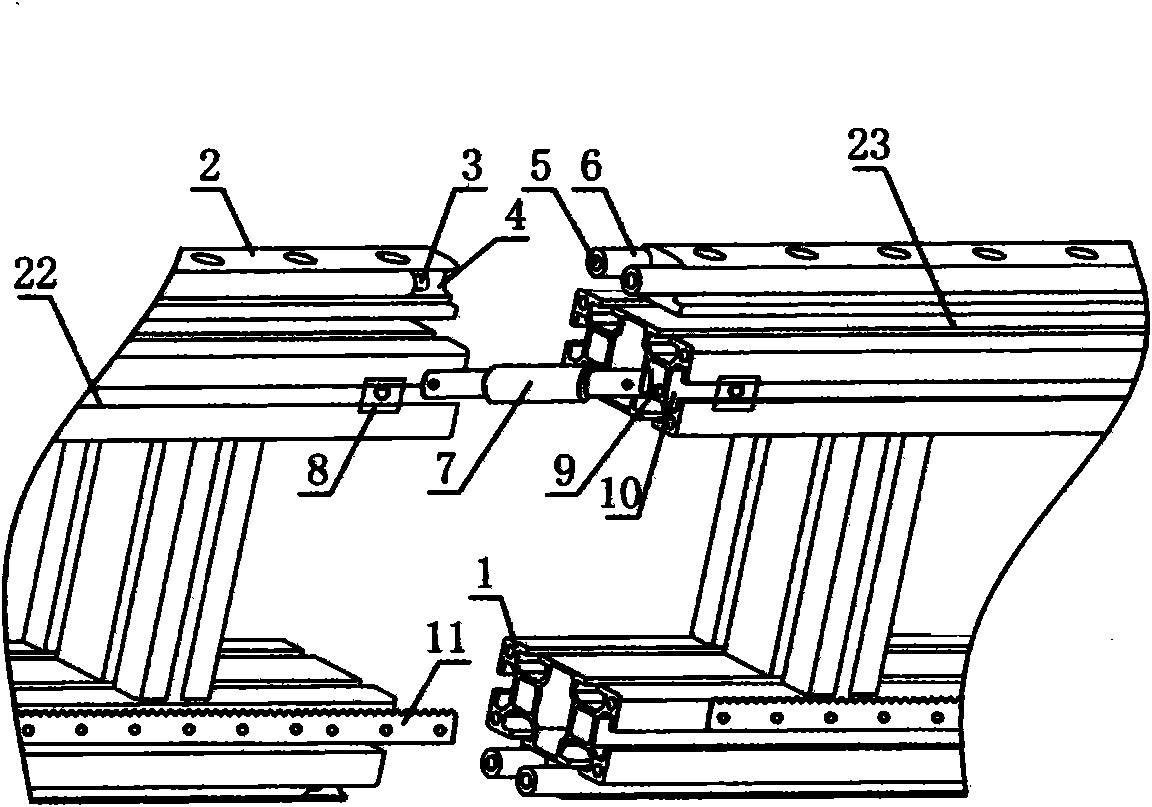

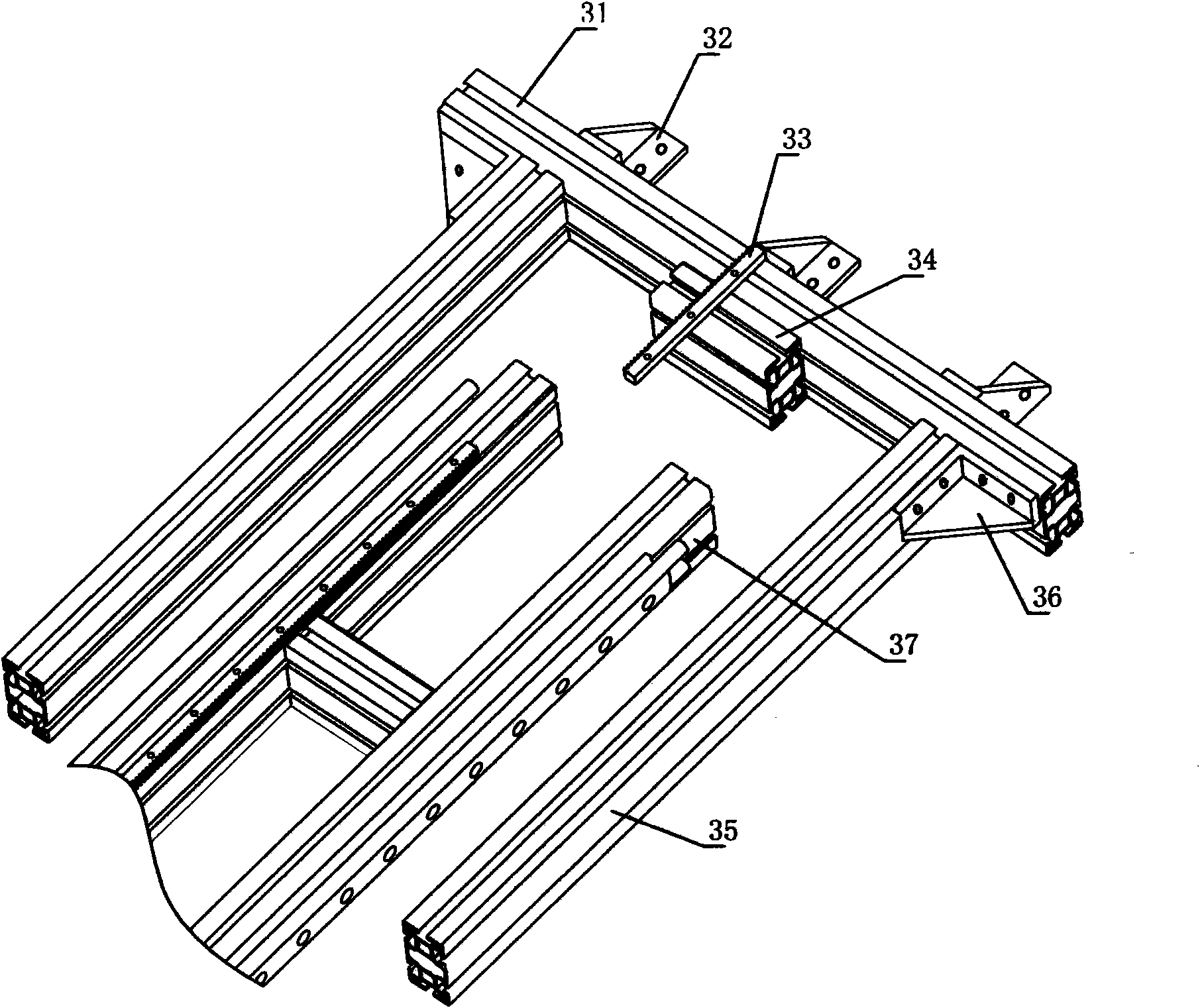

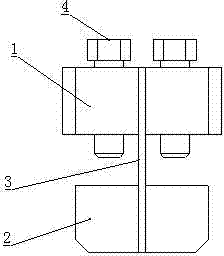

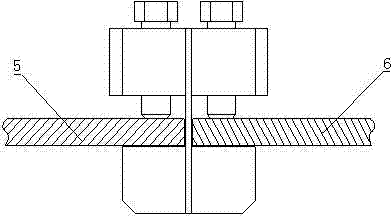

Portable spliced guide rail, butt joint method and work fixture

InactiveCN102152162AReduce weightEasy to assemble and disassembleLinear bearingsAssembly machinesButt jointEngineering

The invention discloses a portable spliced guide rail, a butt joint method and a work fixture. The spliced guide rail is divided into a base section part, an extension section and a tail section which are mutually in butt joint along a cross section direction, wherein butt joint faces are connected in a mutual intersection manner, so that the defects of poor butt-joint stability, low connection strength and difficult in precision guarantee on the same horizontal plane are avoided. On the butt joint faces of a guide rail body, two pairs of positioning pins and positioning holes are adopted, sothat the positioning is accurate and the positional connection is reliable; guide posts and guide faces are mutually matched so that the splicing accuracy is enhanced; and auxiliary dowel shafts are used for fixed connection so that the structural stability and the integrity of the spliced guide rail are ensured, and the specially designed work fixture ensures that the butt joint process of the guide rail is more accurate and easier to operate. The entire spliced guide rail has a simple structure, is convenient for butt joint, and can be dismounted and assembled without professional personnel, and the extended guide rail is beneficial to enlargement of an applicable range for product processing and is suitable for popularization and application in various industries and fields.

Owner:北京灿烂阳光科技发展有限公司

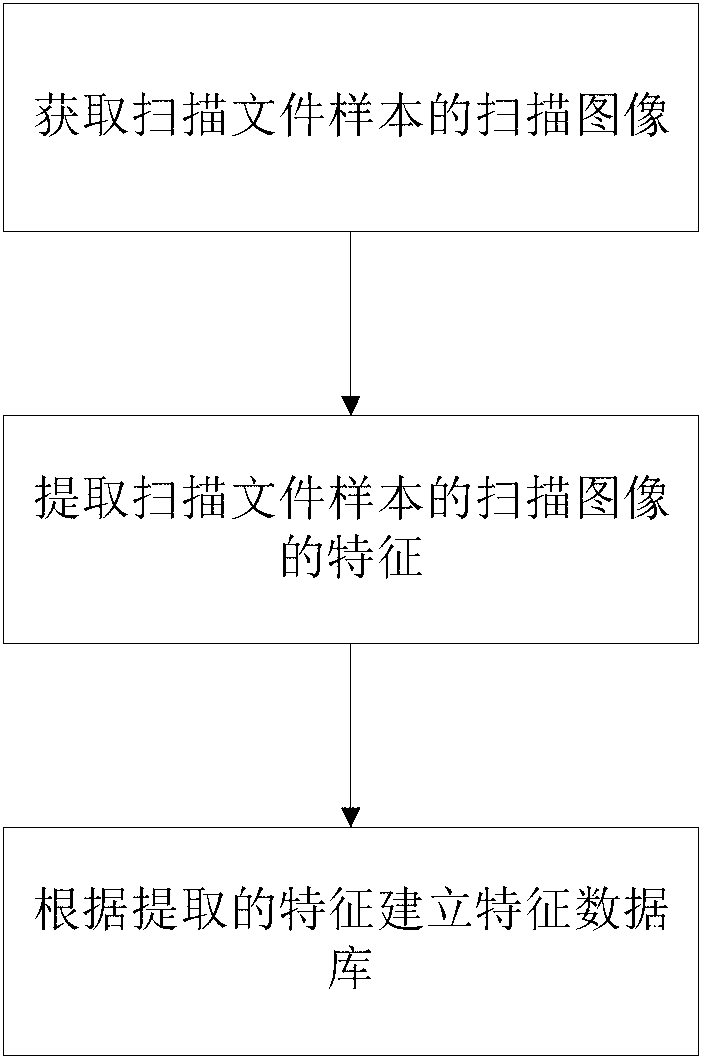

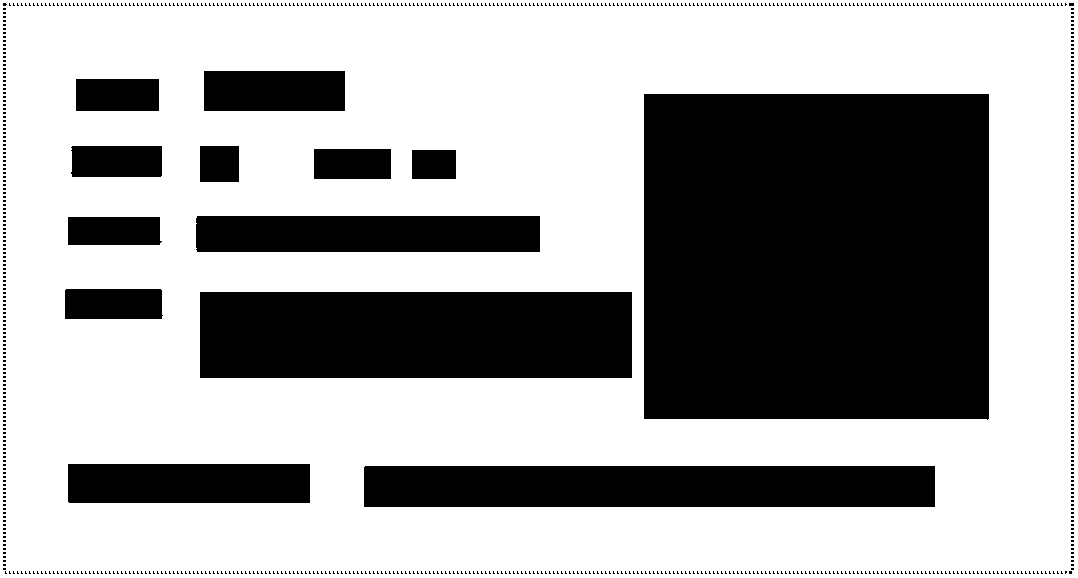

Image mosaic method and system for two-sided scanning

ActiveCN102708557ARealize automatic splicingConvenient duplex scanning operationImage enhancementImage analysisFeature extractionFeature data

The invention discloses an image mosaic method and a system for two-sided scanning. A feature database of scan files is built before the image mosaic method is applied. The image mosaic method includes obtaining scan images of scan files, wherein the scan images comprise front images and back images of the scan files; performing slant correction on the scan images; performing position segmentation and feature extraction on the scan images; performing direction judgment and direction correction on the scan images according to comparison of features of the extracted scan images with the feature data; and mosaicing the front images with the back images in the scan images. According to the image mosaic method and the system, two-sided scan operation of users is greatly facilitated, mosaic quality of the two-sided scan images is guaranteed, and the image mosaic method and the system can be widely applied to the image scan field.

Owner:GUANGZHOU ZONERICH COMP EQUIP

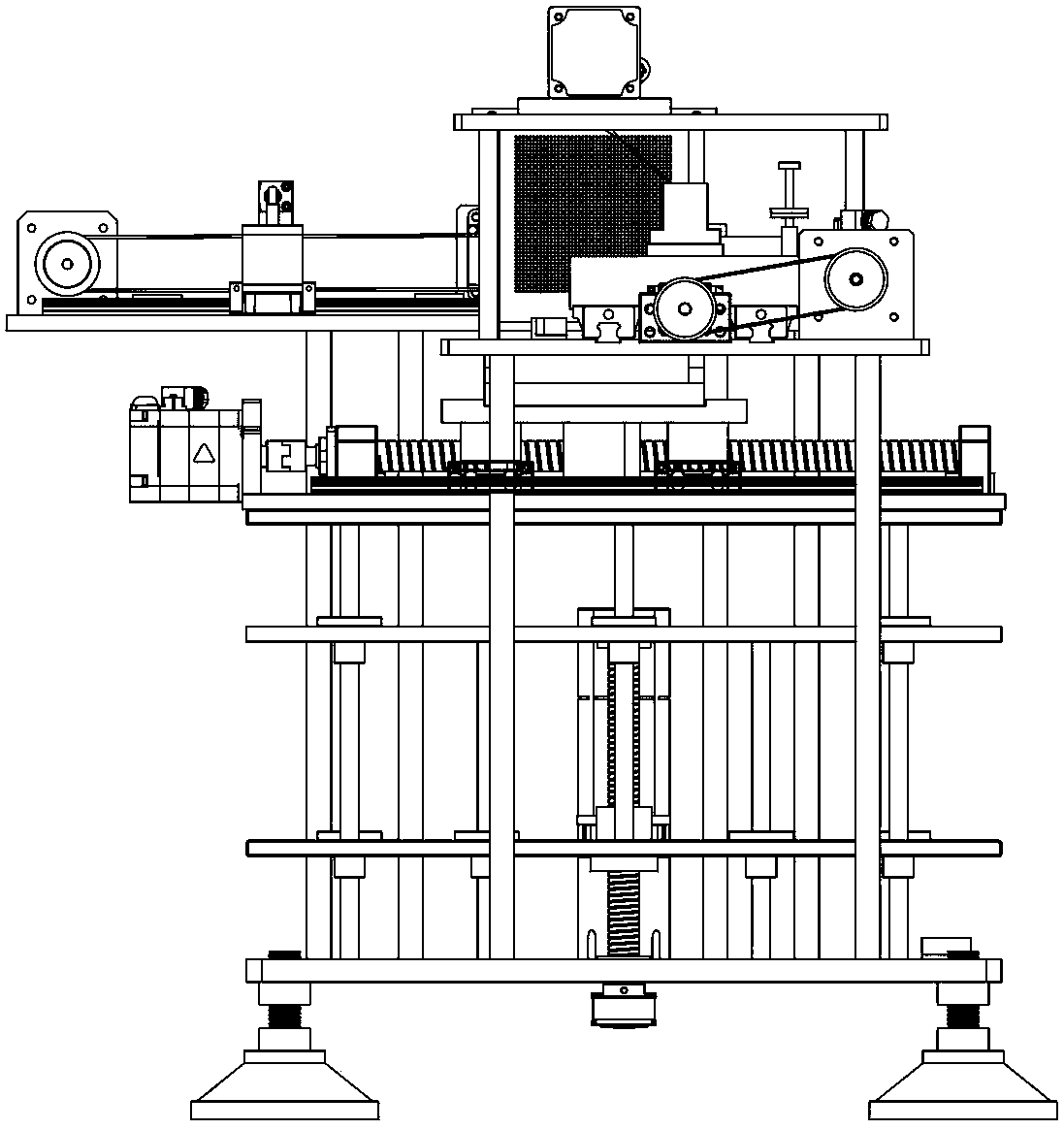

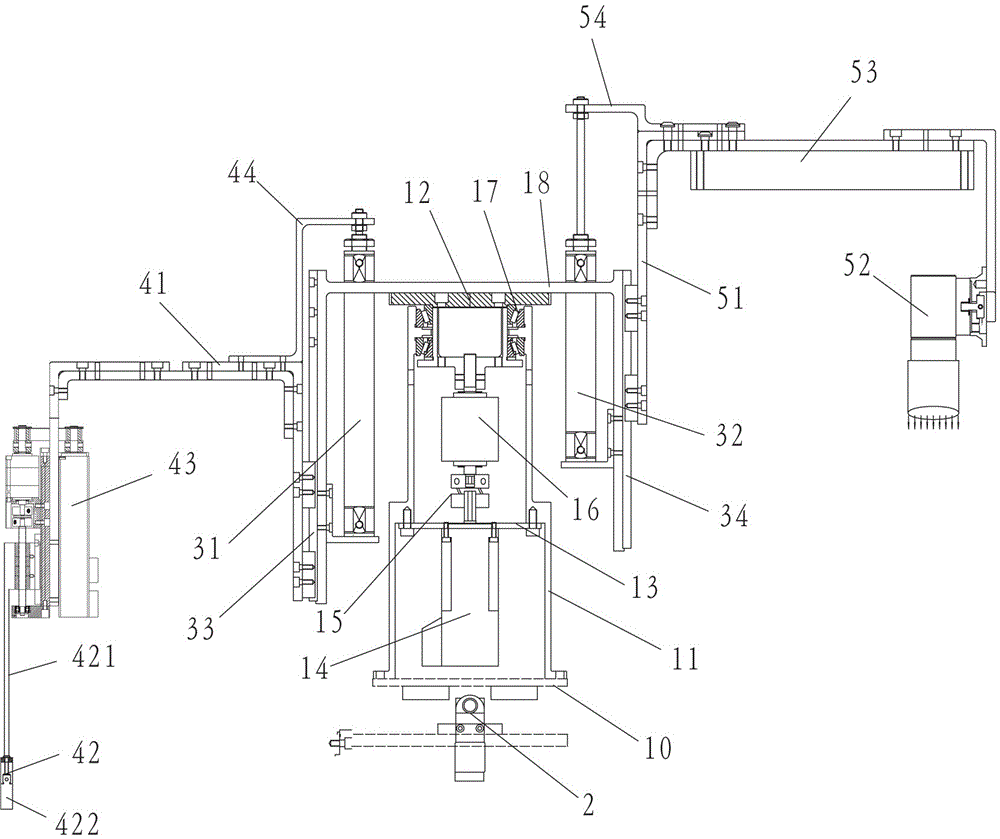

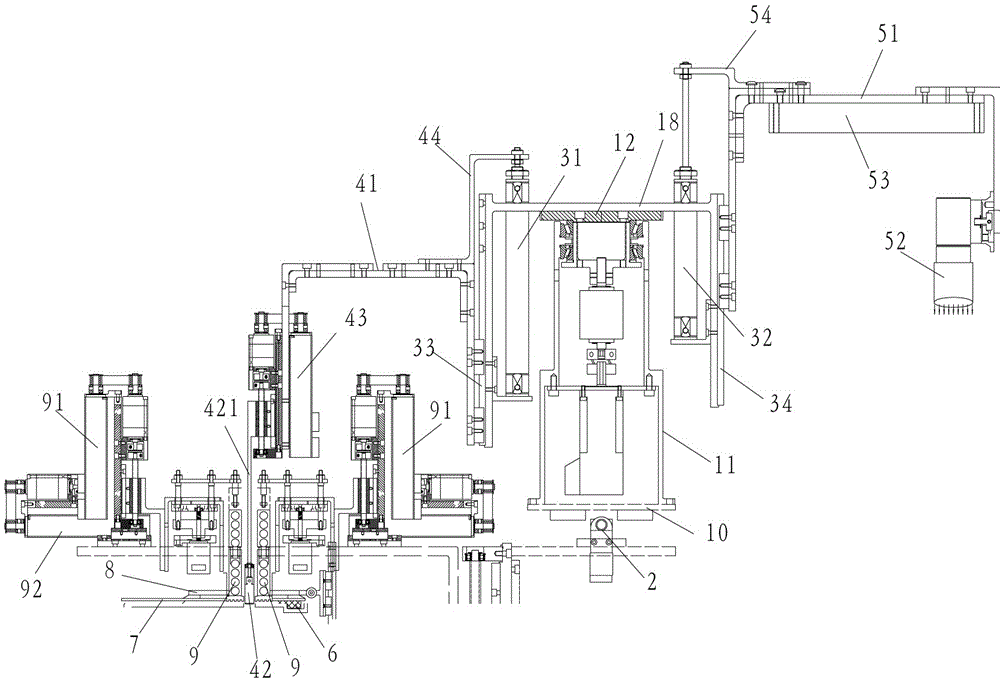

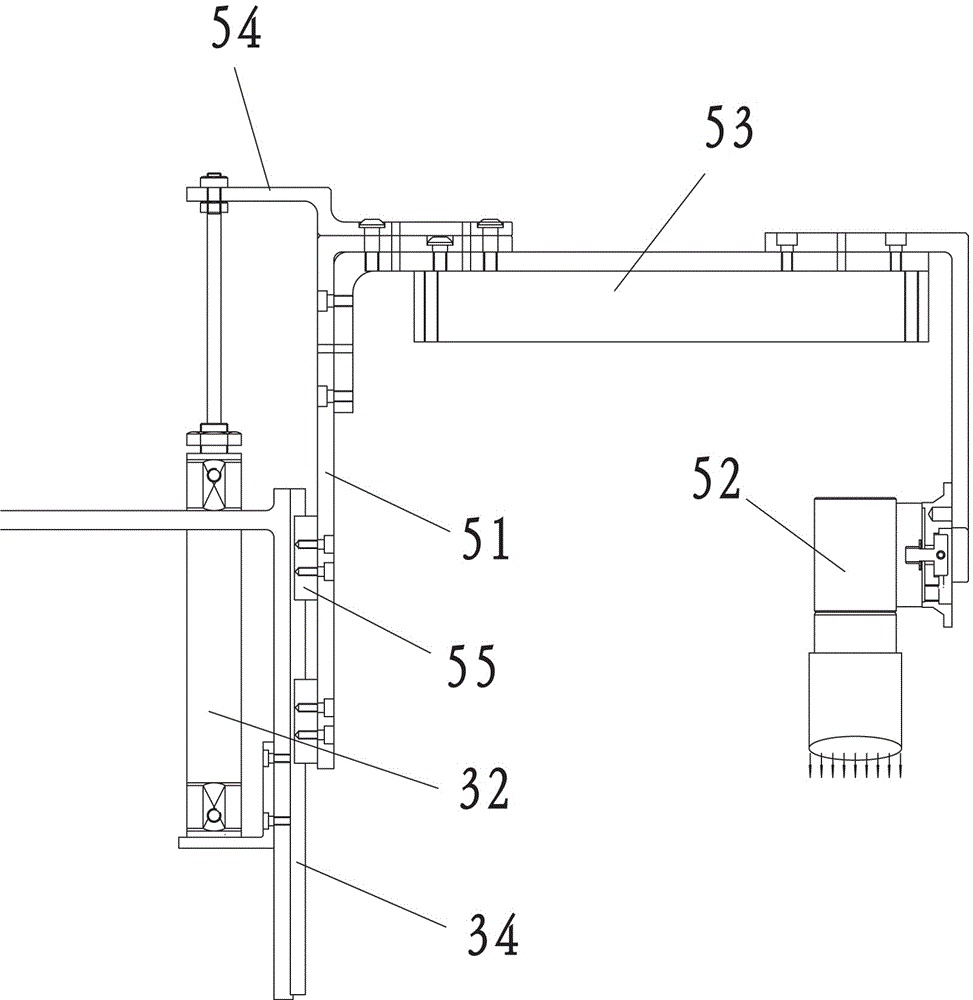

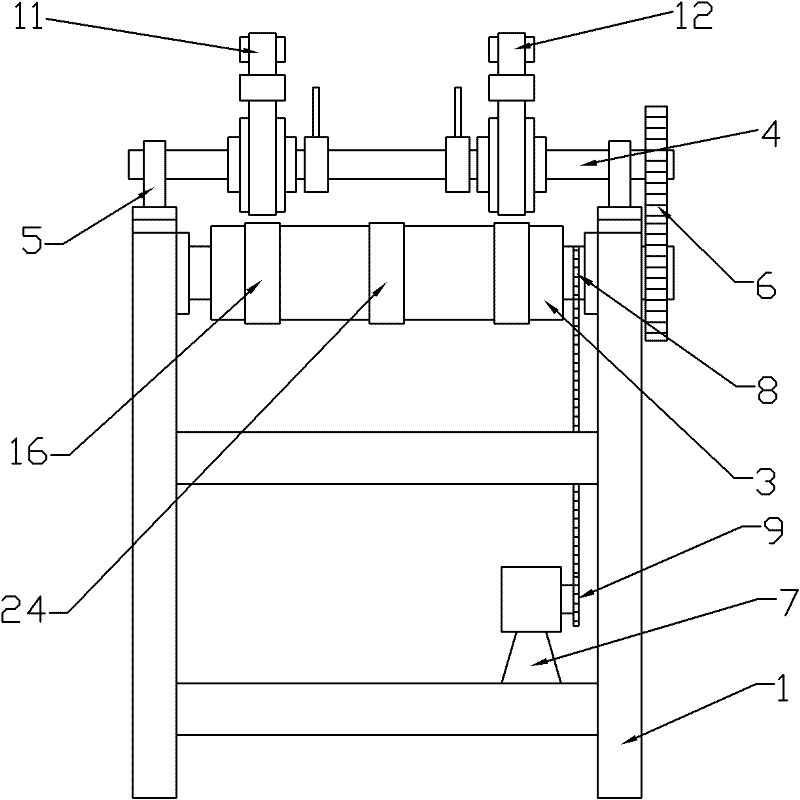

Device for replacing steel needle with Z-direction steel needle three-dimensional fabrics and buckling fibers

The invention discloses a device for replacing a steel needle with Z-direction steel needle three-dimensional fabrics and buckling fibers. The device comprises a movable workbench, a steel needle replacing mechanism, a wire feeding mechanism, a locking mechanism, a tension control mechanism and a control system, wherein the movable workbench is driven by a servo motor, is composed of a Z-directionmovable platform and a Y-direction movable platform, and is provided with a three-dimensional fabric clamping device; the steel needle replacing mechanism drives a special clamp X to move in an X-direction through the servo motor, so that needle clamping is completed; the wire feeding mechanism drives a wire feeding needle to move in the X-direction through the servo motor, so that yarns are fedinto the three-dimensional fabrics; the locking mechanism drives a crankshaft rocking bar mechanism through a step motor to realize swinging a hook needle back and forth to complete locking; and the tension control mechanism rotates back and forth through the step motor to drive a yarn storage to move back and forth, so that yarn storage and tension control are completed. The device is compact instructure, is novel and reasonable in design, realizes automation of replacing the steel needle with Z-direction steel needle three-dimensional fabrics and buckling fibers, improves production efficiency and product consistency, is high in practicability, is good in using effect, and is convenient to popularize.

Owner:TIANJIN POLYTECHNIC UNIV

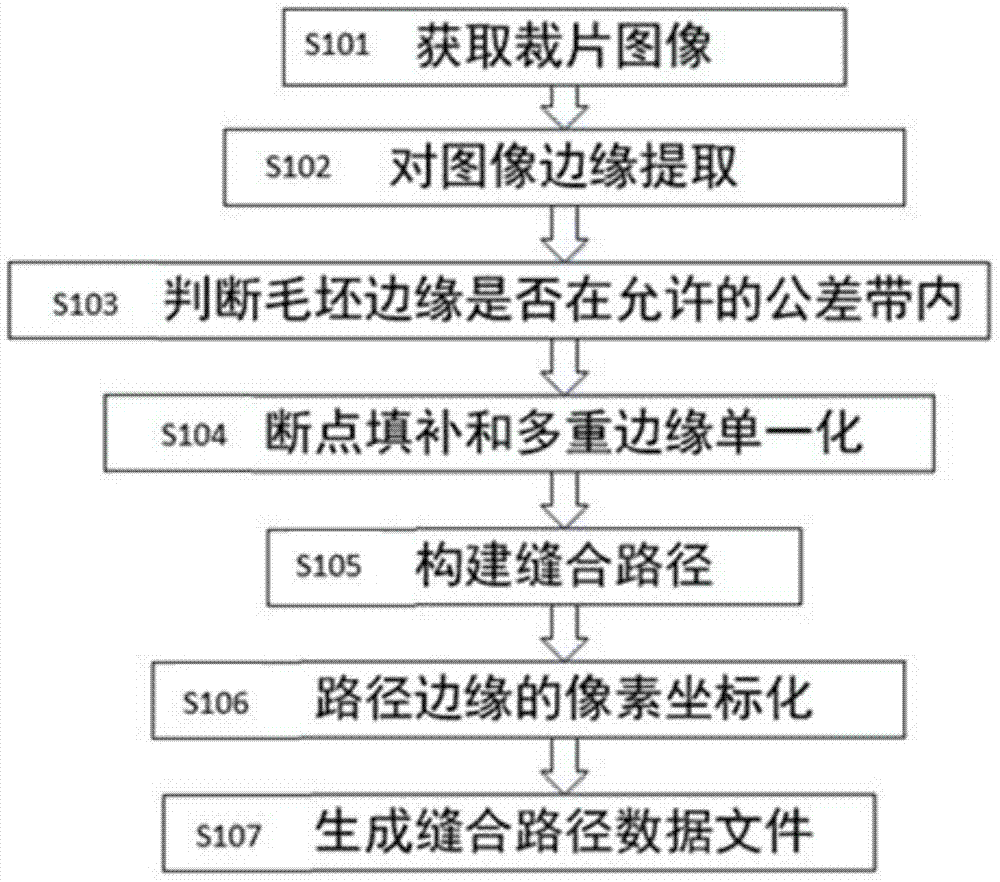

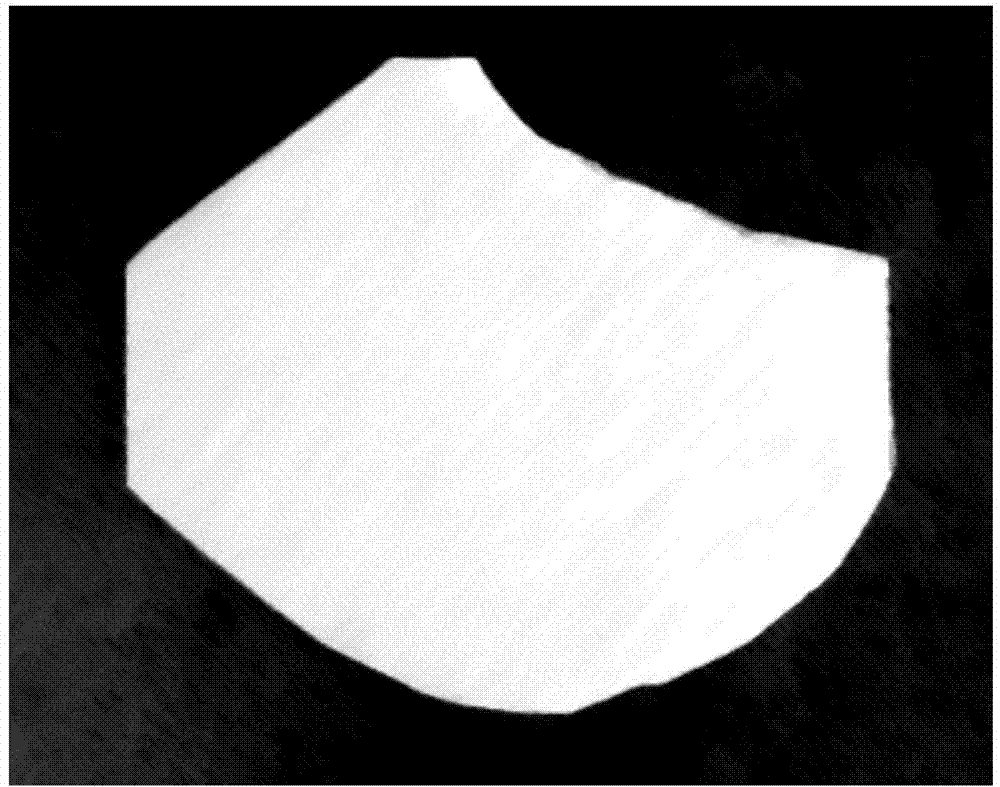

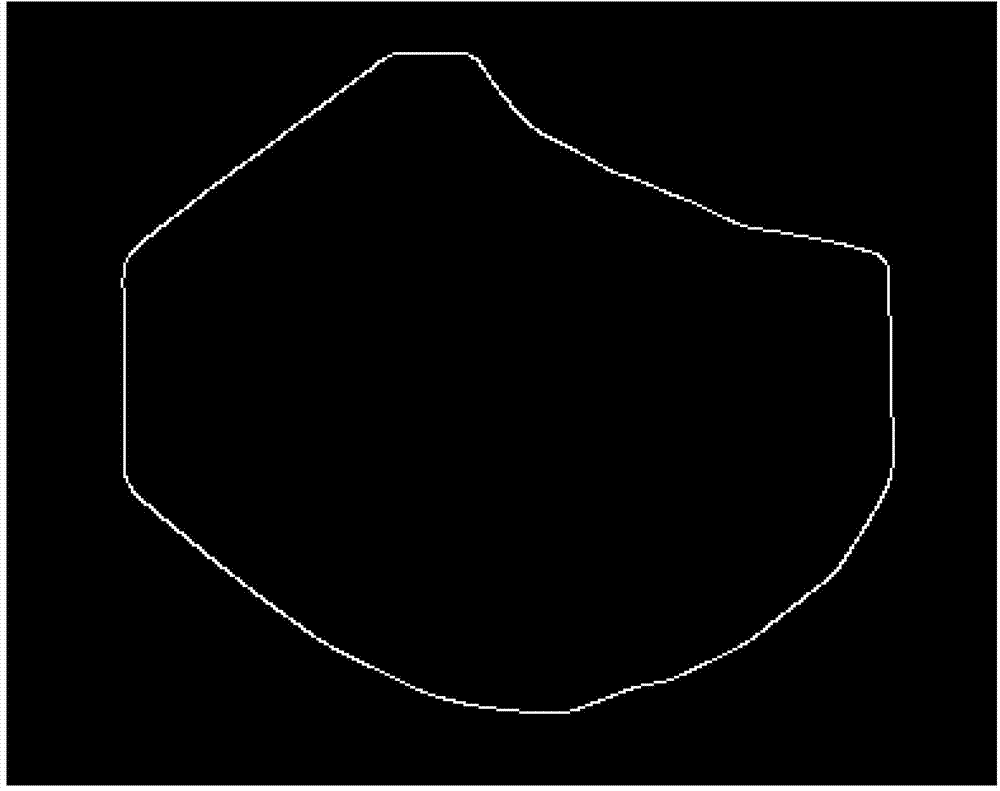

Method for obtaining sewing path of cut pieces

ActiveCN104711784AReduce processIncrease productivityProgramme-controlled sewing machinesEdge extractionEngineering

The invention discloses a method for obtaining a sewing path of cut pieces and belongs to the field of control of industrial sewing machines. The method comprises the following steps: taking photos for the cut pieces so as to obtain cut-piece images; carrying out edge extraction on the obtained cut-piece images, thereby obtaining edges of the cut pieces; judging the obtained edges so as to obtain sewable cut pieces with the edges positioned in an ideal range; carrying out breakpoint filling treatment and multi-edge simplification treatment on the edges of the sewable cut pieces obtained by the step S103 so as to obtain single and continuous edges; carrying out retraction or expansion on the edges obtained by the step S104 so as to construct the sewing path; carrying out coordinatization on pixel points of the sewing path obtained by the step S105 so as to obtain a coordinate graph of the pixel points of the sewing path; and generating the sewing path according to the coordinate graph obtained by the step S106. The method disclosed by the invention has the advantages that the sewing path can be efficiently generated, so that the plate manufacturing procedure is replaced and the quality and efficiency of sewn products in industrial production are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Installation method of overlength mast with large inclination angle of space structure

ActiveCN103850515AControl precisionGuaranteed stitching qualityTowersBuilding material handlingSpatial structureAnchor point

The invention relates to an installation method of an overlength mast with a large inclination angle of a space structure, which belongs to the technical field of architectural engineering construction. The installation method comprises the following steps: mast shaping and manufacturing in subsections, field splicing, anchor point and base arranging, integral hoisting, cable rope arranging, mast inclination implementing, process monitoring, cable rope checking, fastening, and installing the overlength mast with the large inclination angle with the length being more than 40m and the inclination angle being 65 degrees on the space structure. According to the method, floor subsection splicing and integral hoisting in situ are adopted, and a cable rope is released slowly through a chain block to control the angle of the mast, so that the mast in the space structure is inclined slowly so as to be positioned accurately; the requirement of the installation accuracy of a space structure system is met; the problems of how to control the dimensional accuracy of the mast, and large deviation of the spatial position, angle and relative position of mast installation in the space structure are solved; and meanwhile, the stability and the safety of a structure stress system are ensured, the installation quality of the mast is improved, and the risk of installation construction of the overlength mast with the large inclination angle is reduced.

Owner:杭州建工集团有限责任公司

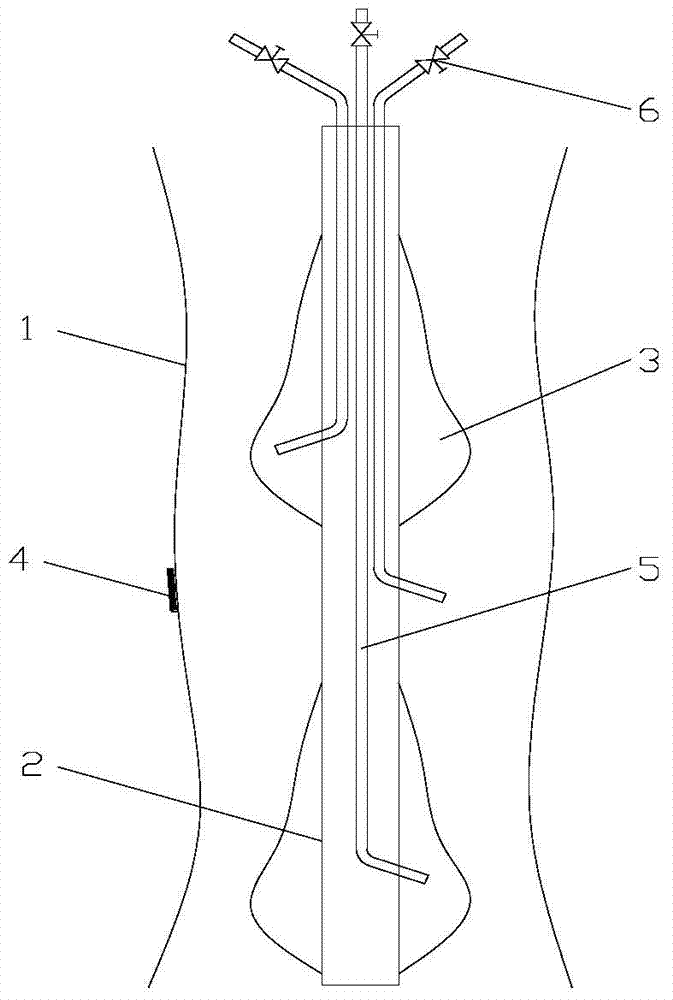

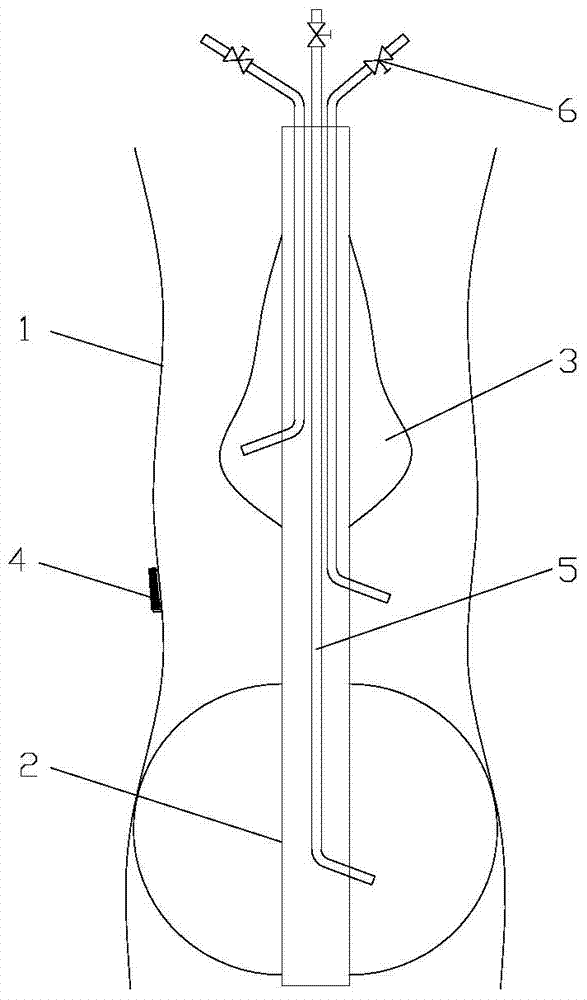

Leakage detecting device for digestive tract anastomotic stoma and leakage detecting method thereof

InactiveCN104720757AAlleviate pain and sufferingReduce economic pressureDiagnostic recording/measuringSensorsStomaOesophageal tube

The invention discloses a leakage detecting device for a digestive tract anastomotic stoma and a leakage detecting method thereof, and belongs to the technical field of treatment gullets. The leakage detecting device comprises a leakage detecting header tube and two air bag sets which are arranged on the leakage detecting header tube in dispersing and sleeving modes. Three independent leakage detecting branch tubes are arranged in the leakage detecting header tube, and the leakage detecting branch tubes are communicated with an air source. Two leakage detecting branch tubes are communicated with the two air bag sets respectively, and the other leakage detecting branch tube is communicated with a cavity located between the two air bag sets. The leakage detecting method includes the steps of equipment leakage detecting, air inflation, leakage detecting, suturing anew if air holes exist and suturing again. According to the leakage detecting device for the digestive tract anastomotic stoma and the leakage detecting method thereof, the two air bag sets with the independent leakage detecting branch tubes are arranged, independent air inflation can be conducted on the air bag sets, and thus the anastomotic stoma section of a gullet can form an airtight cavity; then air inflation is conducted on the airtight cavity through the other leakage detecting branch tube, the anastomotic stoma can be distended completely, real-time accurate leakage detecting is facilitated, hence, the suture quality is guaranteed, the treatment cycle is greatly shortened, and illness suffering and economic pressures of patients can be better reduced.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Continuous high-frequency welding machine and welding method

InactiveCN100460188CGuaranteed complete fusion bondingMake up for the problem of uneven local gapsEngineeringCopper

The present invention is developed on the basis of available continuous HF fusion welding machine and fusion welding method and has improved long non-ferrous metal electrode plate. Structurally, the present invention has flexible material inside the longitudinally open-mouthed section, conducting copper sheet on the flexible material and insulating layer on the conducting copper sheet; as well as wheel protecting belt below the movable HF electrode plate heat jointing and settling assembly. The present invention has the advantages of the complete fusion and adhering of the jointed material, no adhesion between the HF electrode plate heat jointing and settling assembly and the jointed material and high welding quality.

Owner:杭州中凌广告器材有限公司

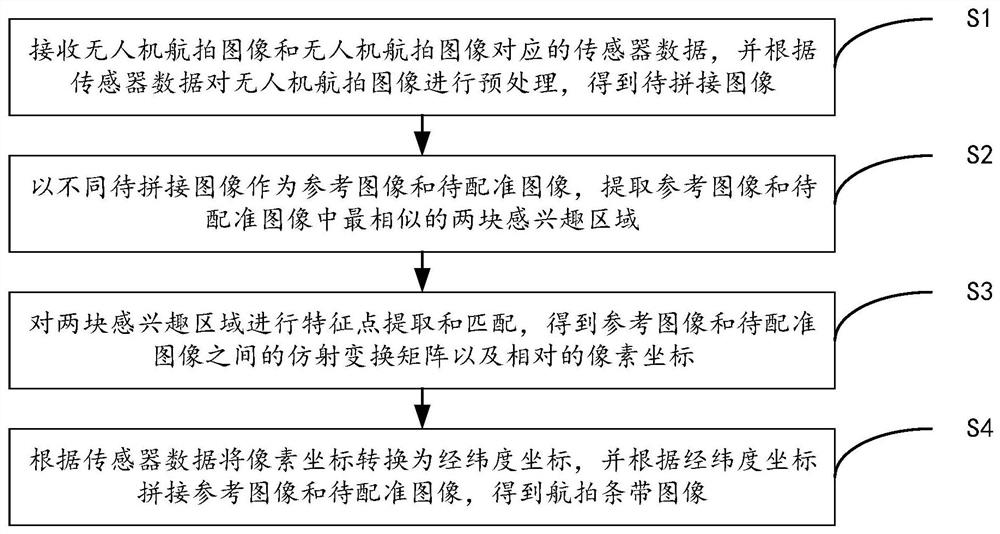

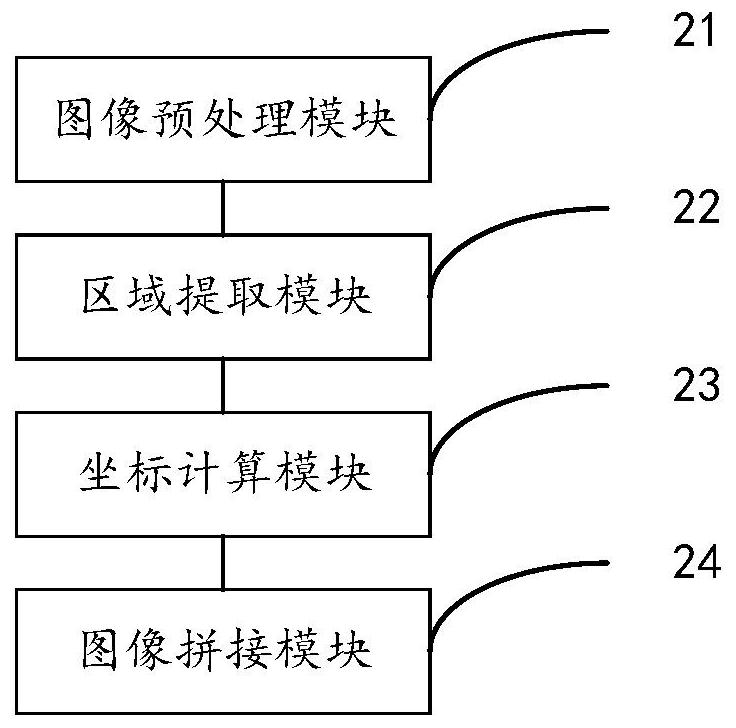

Splicing generation method and device for ultra-large aerial strip images

PendingCN112163995AQuick stitchingBreak outImage enhancementImage analysisImage extractionImage resolution

The invention discloses a splicing generation method and device for ultra-large aerial strip images. The method comprises the following steps: receiving aerial images of an unmanned aerial vehicle andsensor data corresponding to the aerial image of the unmanned aerial vehicle, and preprocessing the aerial images of the unmanned aerial vehicle according to the sensor data to obtain to-be-spliced images; taking different to-be-spliced images as a reference image and a to-be-registered image, and extracting two most similar areas of interest in the reference image and the to-be-registered image;performing feature point extraction and matching on the two areas of interest to obtain an affine transformation matrix between the reference image and the to-be-registered image and opposite pixel coordinates; and converting the pixel coordinates into latitude and longitude coordinates according to the sensor data, and splicing the reference image and the to-be-registered image according to thelatitude and longitude coordinates to obtain an aerial strip image. The aerial images of the unmanned aerial vehicle can be quickly spliced to generate the aerial strip images with super-high resolution.

Owner:SUN YAT SEN UNIV

Skin anastomat convenient to use at multiple angles

ActiveCN112603417AEasy to use from multiple anglesConvenient lighting workDiagnosticsMedical devicesBiomedical engineeringGeneral surgery

The invention discloses a skin anastomat convenient to use at multiple angles, which comprises a skin anastomat body, a first hydraulic cylinder, a medicine spraying assembly, a second manipulator, an adjusting assembly, an illuminating lamp and a control box, and is characterized in that the skin anastomat body is provided with a first slide way, the first slide way is slidably connected with a first sliding block, meanwhile, a first electric telescopic rod is fixed to the first sliding block, a threaded fixing piece is fixed to one end of the first electric telescopic rod, the medicine spraying assembly is used for sterilizing and cleaning a wound, a first fixing plate is fixed to the second manipulator, and the adjusting assembly is used for closing up the wound. According to the skin anastomat convenient to use at multiple angles, an operation wound can be directly folded, the angle of a folding plate can be adjusted according to needs, disinfection and cleaning can be carried out before suture and during operation suture, the spray head and the disinfection gauze can rotate at multiple angles, and light supplementing treatment can be carried out when light is insufficient.

Owner:CHANGZHOU ANKANG MEDICAL EQUIP

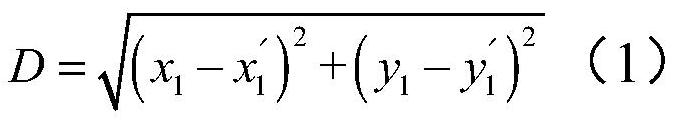

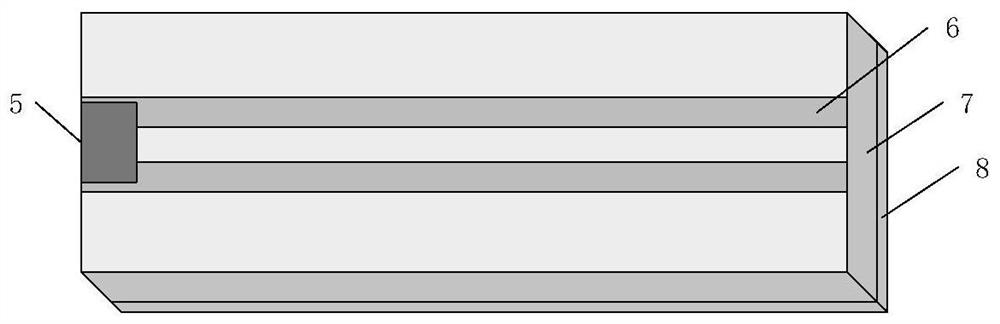

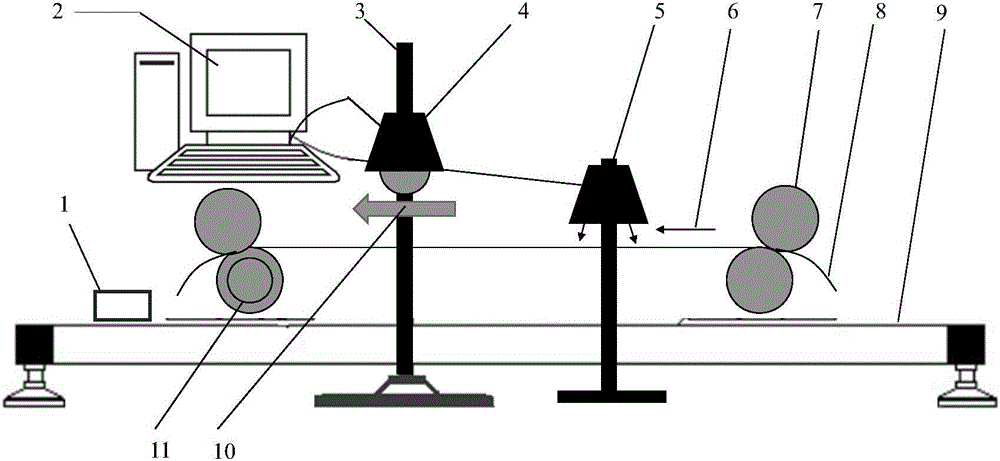

Rapid splicing method and system for workpiece images with sparse feature points

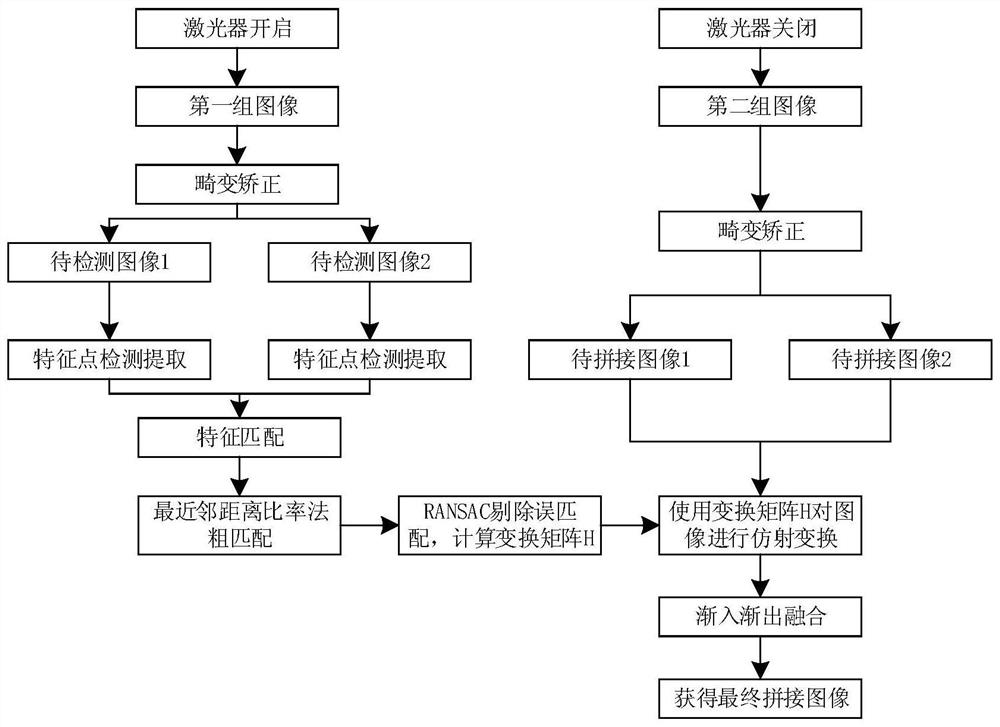

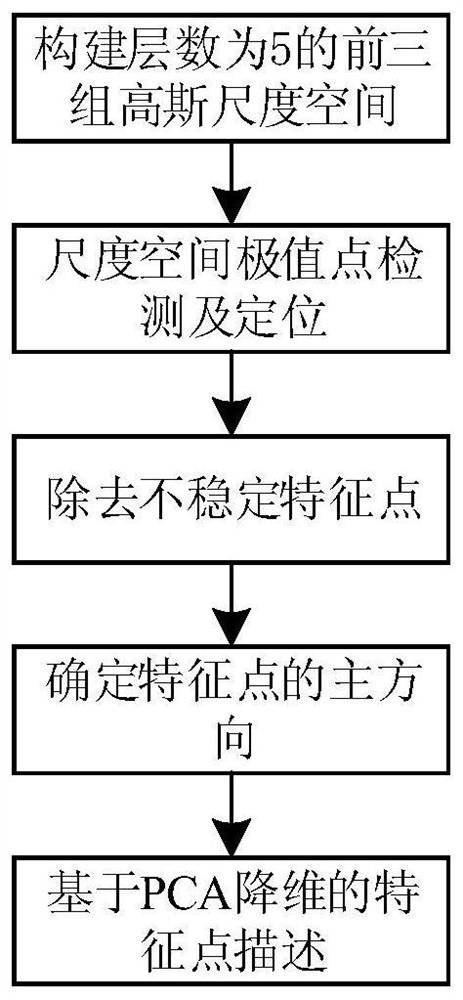

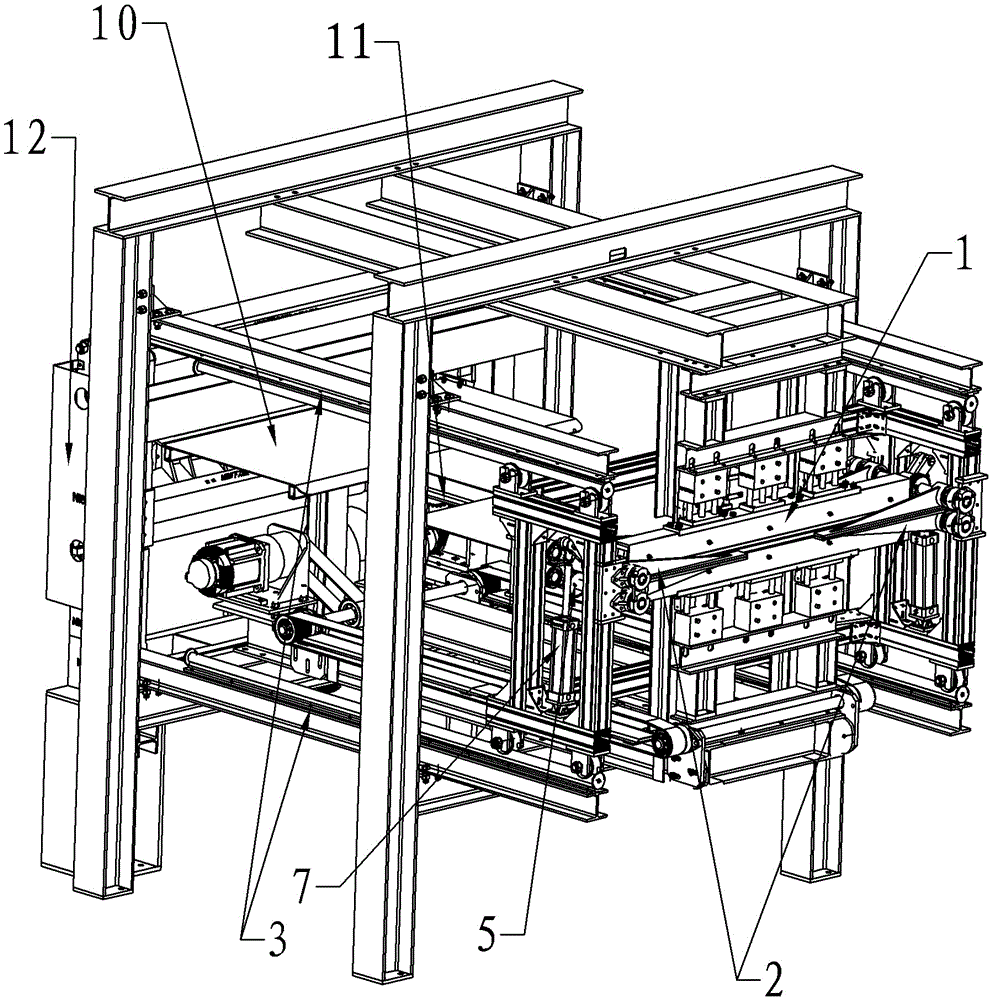

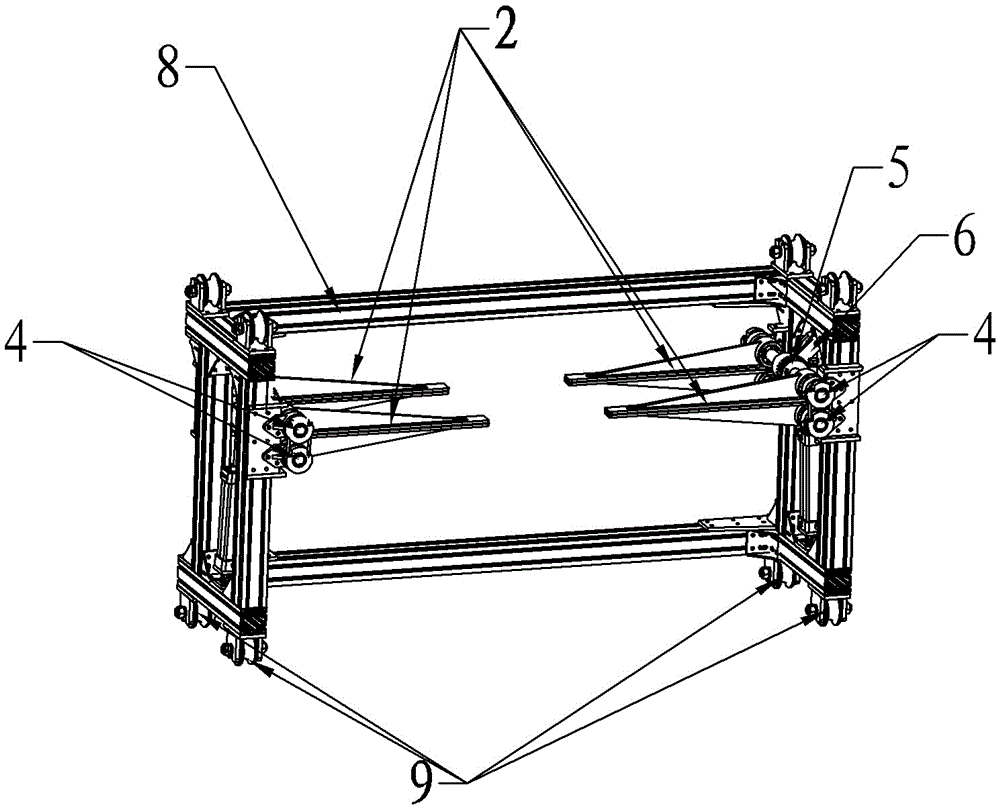

ActiveCN111915485AMaintain stabilityTargetedGeometric image transformationManufacturing computing systemsGraphicsImaging processing

The invention relates to the technical field of image stitching. According to the rapid splicing method and system for the workpiece images with the sparse feature points, a laser is used for projecting graphic signs in view overlapping areas of cameras, stable sign points with obvious features are provided, the size of the overlapping areas between the cameras is reduced while the image splicingprecision is improved, and the image processing speed is increased. According to the technical scheme, therapid splicing system for the workpiece images with the sparse feature points includes a plurality of strip-shaped light sources which are arranged on the two sides of a workpiece respectively so as to provide illumination conditions for an image capturing system, a plurality of industrial cameras which are used for detecting the workpiece, a plurality of lasers installed between the industrial cameras, a controller for controlling the strip-shaped light source and the laser device, and anindustrial personal computer which is electrically connected with the industrial personal computer so as to correct a shot image; The rapid splicing method for the workpiece images with the sparse feature points. The method comprises the steps of S1, image acquisition, S2, image preprocessing, S3, feature point detection matching and S4, image splicing fusion.

Owner:ZHEJIANG SCI-TECH UNIV

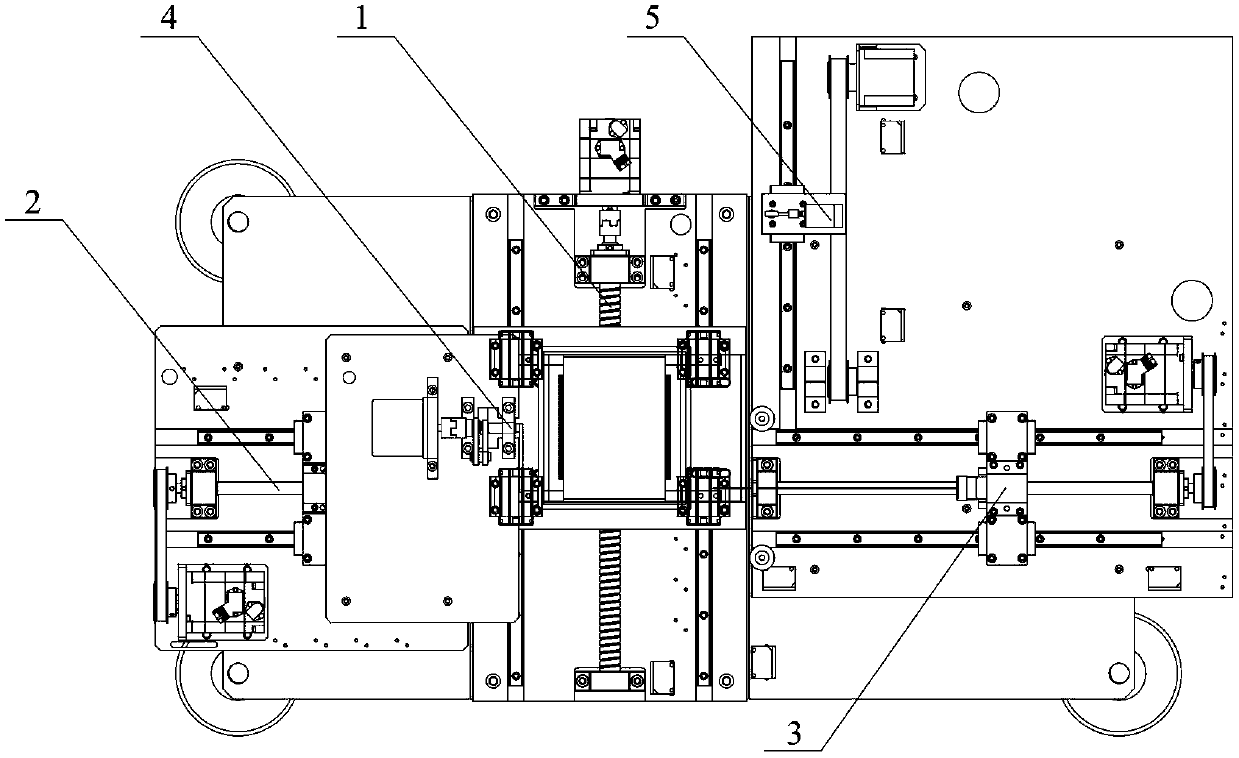

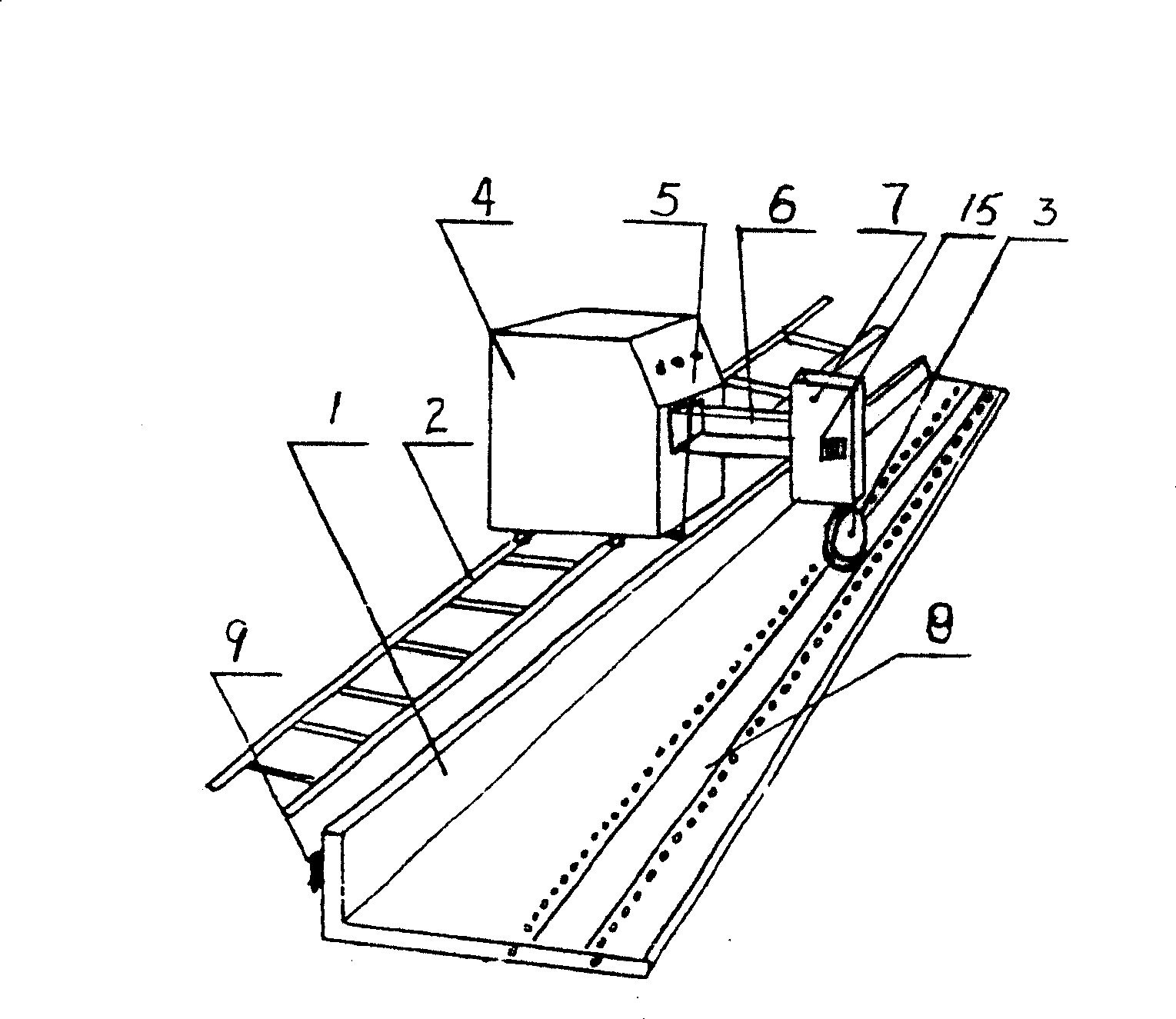

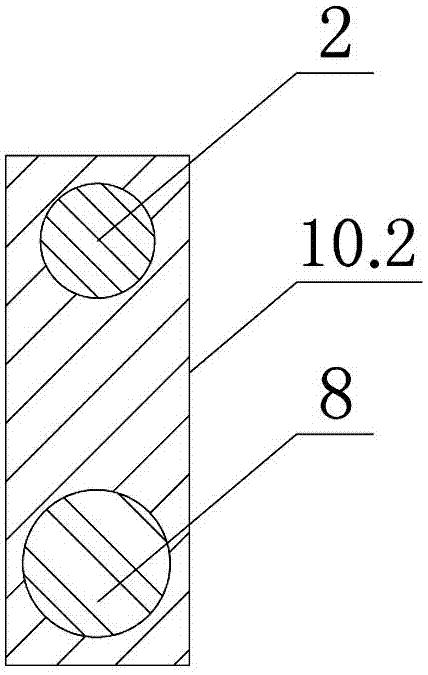

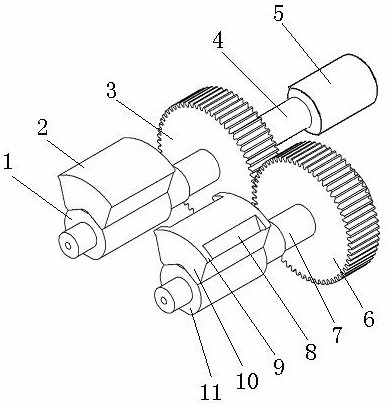

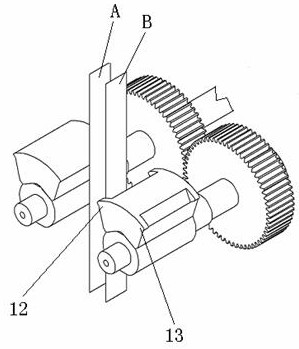

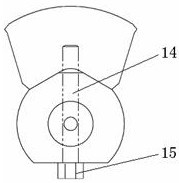

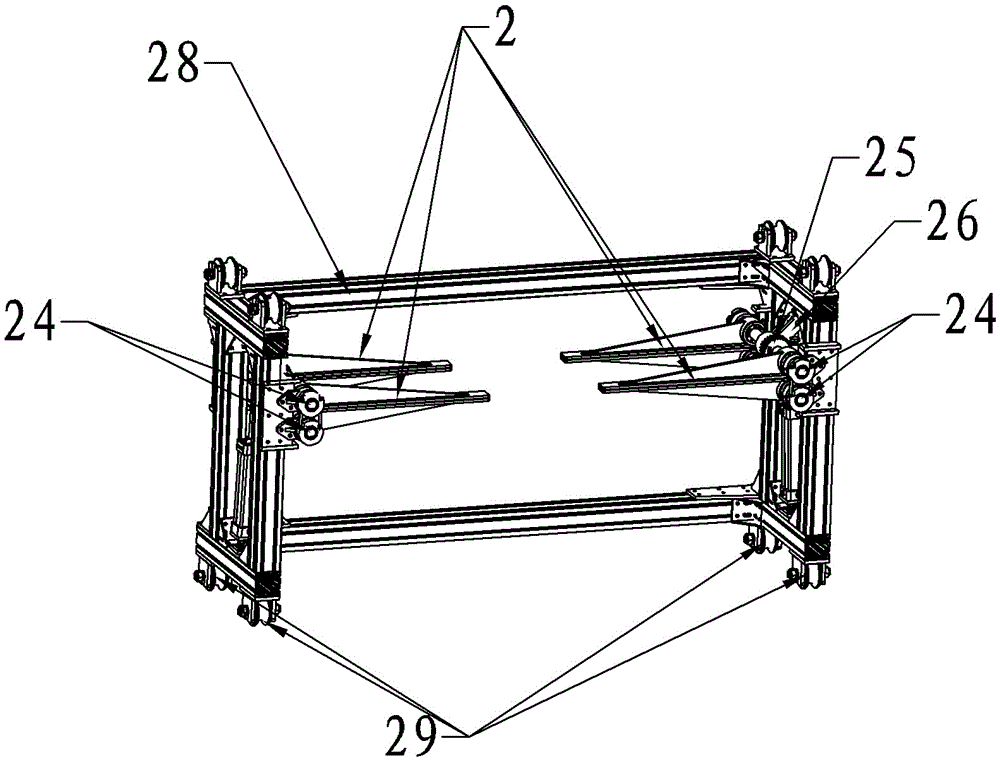

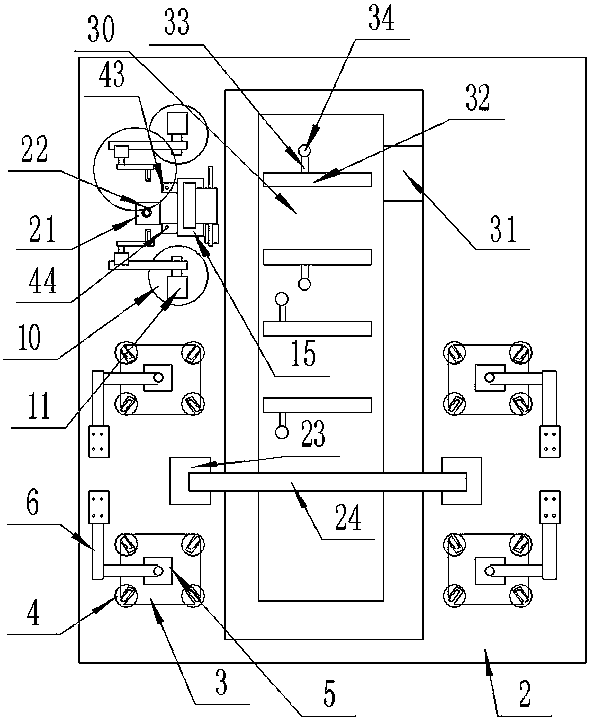

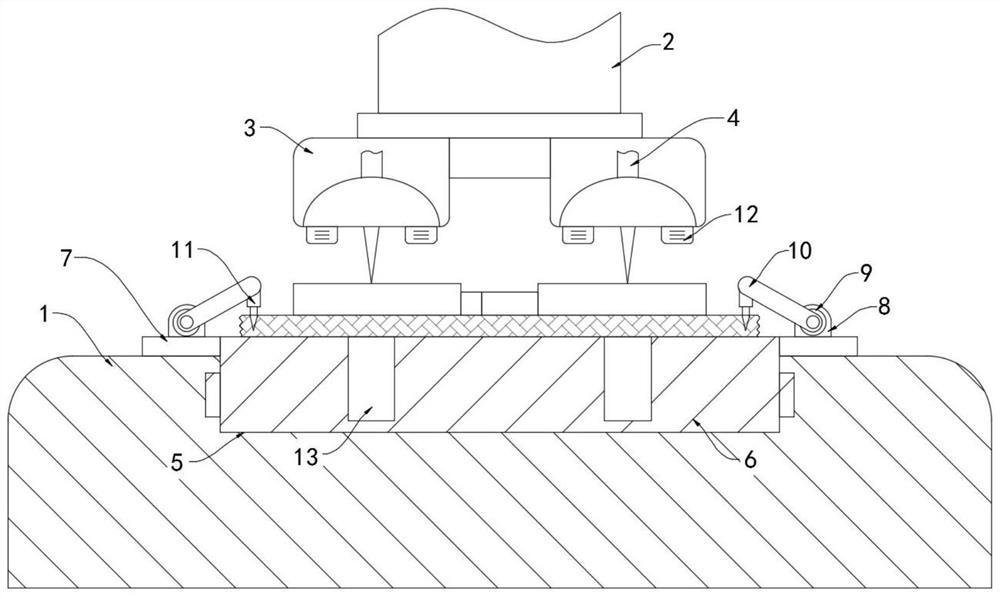

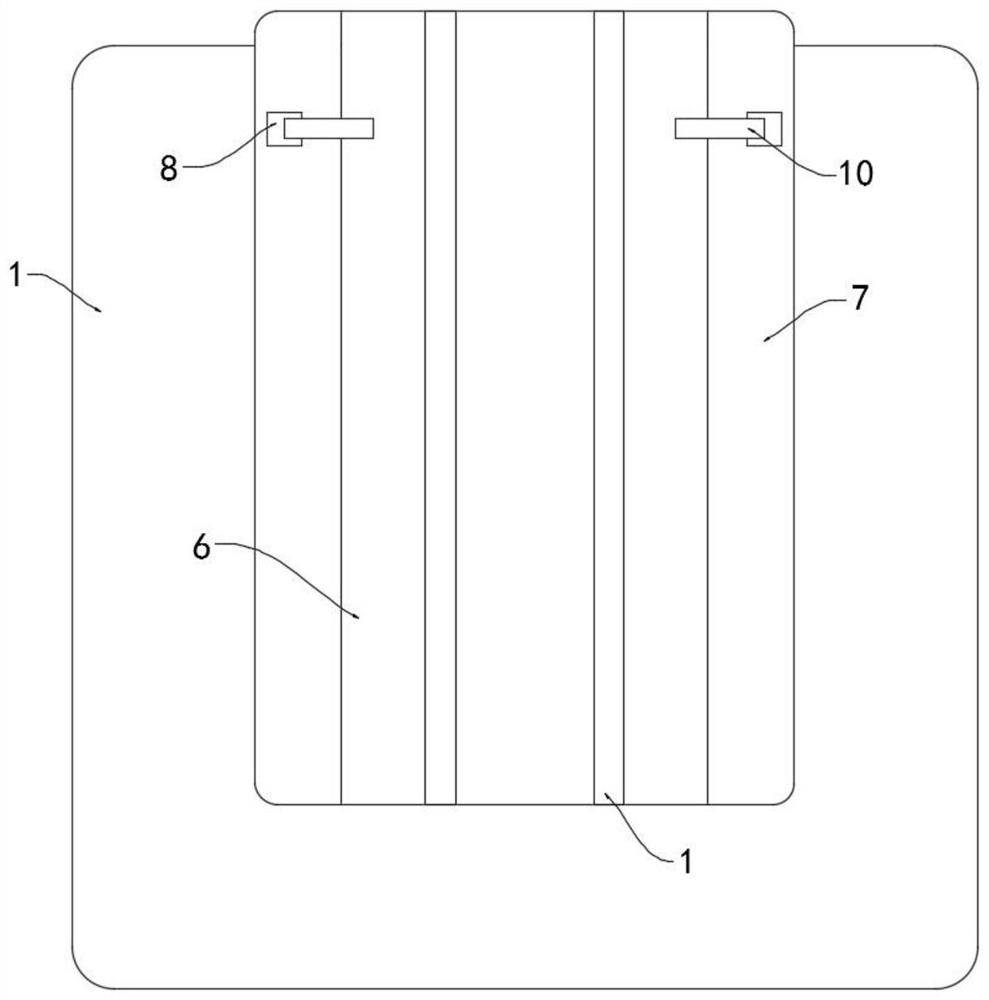

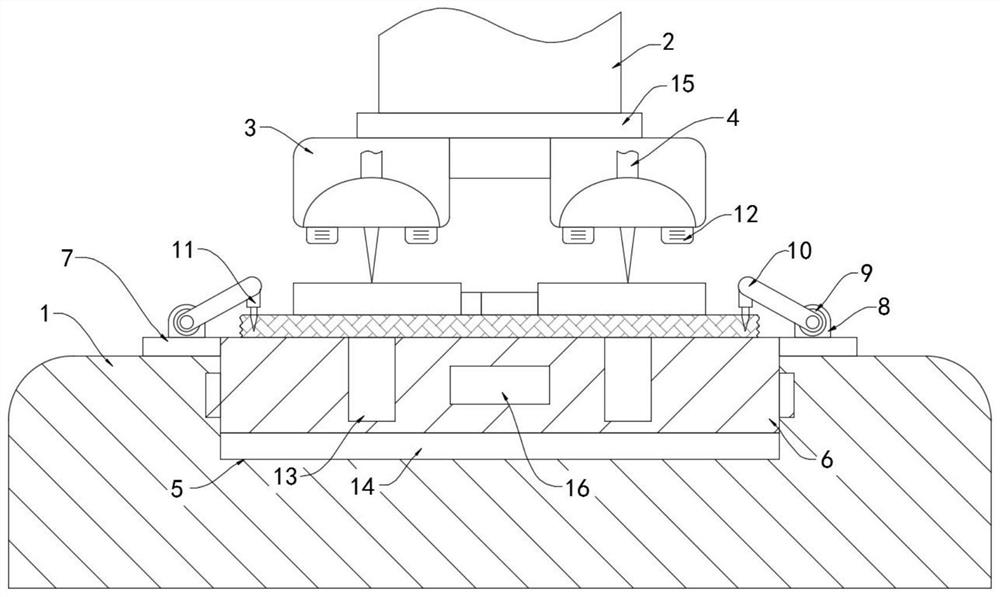

Panel unlimited lengthening mechanism

InactiveCN105599070AGuaranteed stitching qualityReduce stressWood veneer joiningEngineeringUltimate tensile strength

The invention discloses a panel unlimited lengthening mechanism. The panel unlimited lengthening mechanism comprises a pressure splicing mechanism and a panel conveying mechanism. The pressure splicing mechanism is composed of a pressure brake and a drive mechanism of the pressure brake, and the drive mechanism drives the pressure brake to exert pressure onto joints of panels for splicing. The panel conveying mechanism is composed of a panel clamp capable of being opened and closed and an opening-and-closing drive mechanism. The panel conveying mechanism is installed on a sliding rail and is driven by a horizontal movement mechanism to horizontally move to the position between the pressure brake and a discharge port for the panels. The edges of the adjacent panels are glued together under the pressure of the pressure brake through the pressure splicing mechanism, and flatness of junctions and connecting strength are guaranteed; after pressure splicing, the panel clamp is horizontally moved to the joints and clamps the joints to horizontally move, it is guaranteed that the stress of the joints is small in the panel conveying process, and disengaging or dislocating of the joints is prevented.

Owner:HESHAN JIDING MACHINERY CO LTD

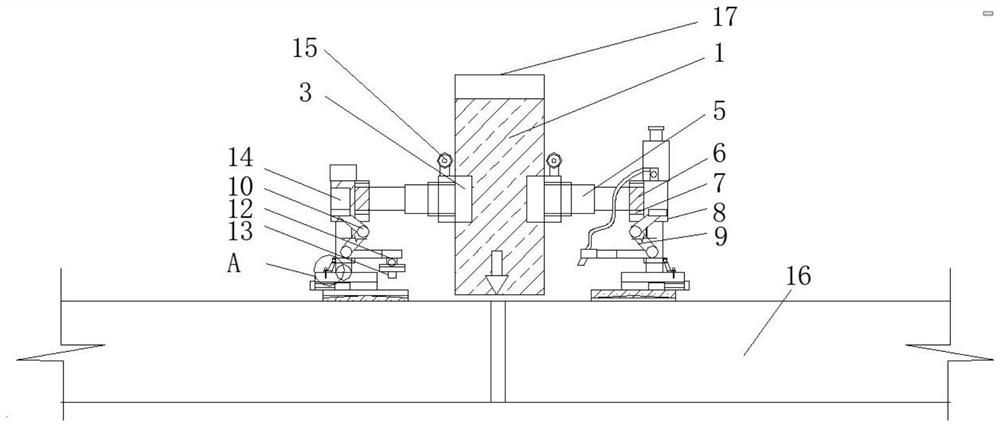

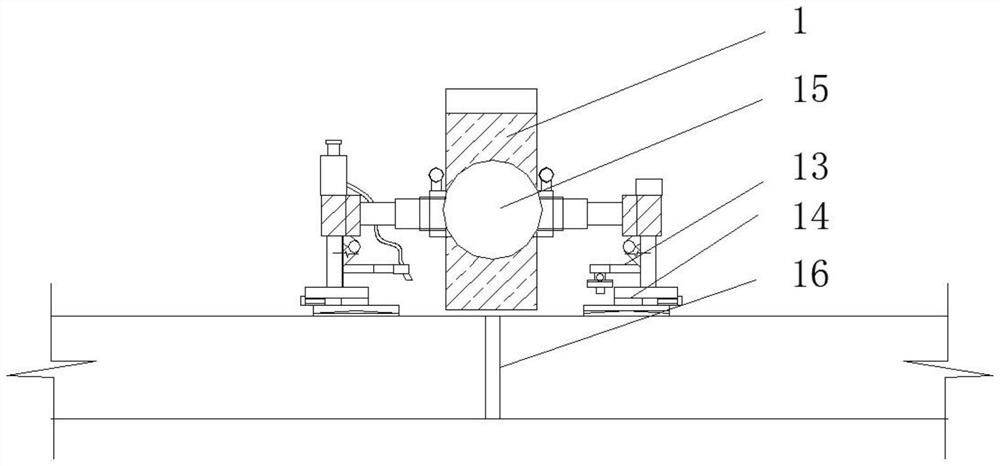

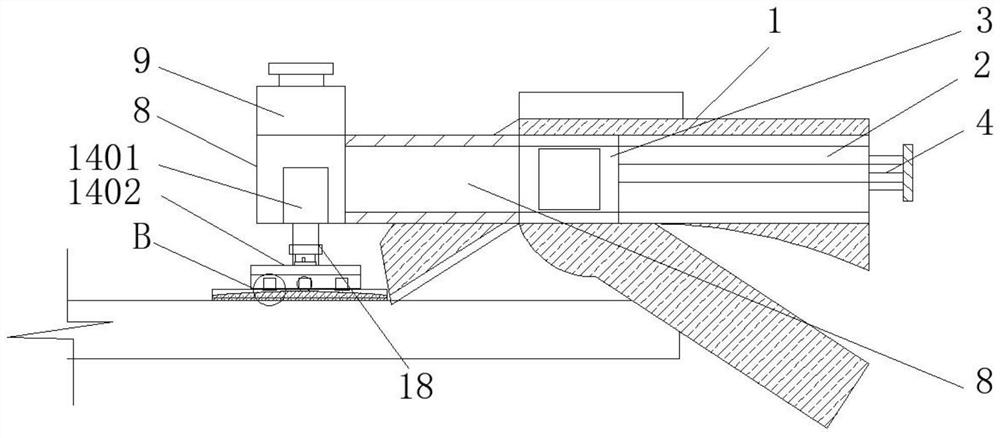

Seamless type ship body splicing tool

InactiveCN102922198AGuaranteed stitching qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineering

Owner:南通长青沙船舶工程有限公司

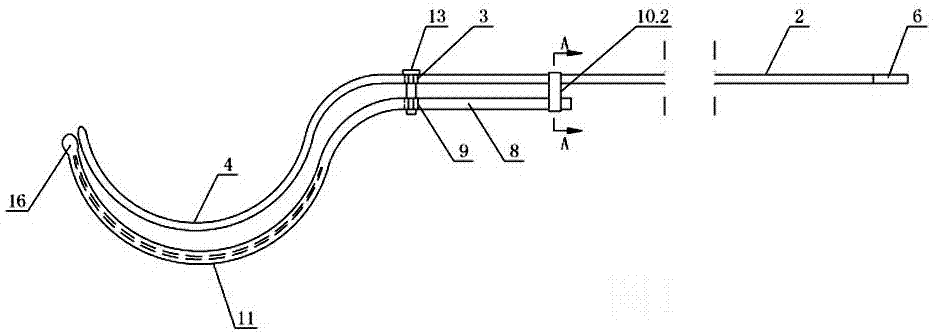

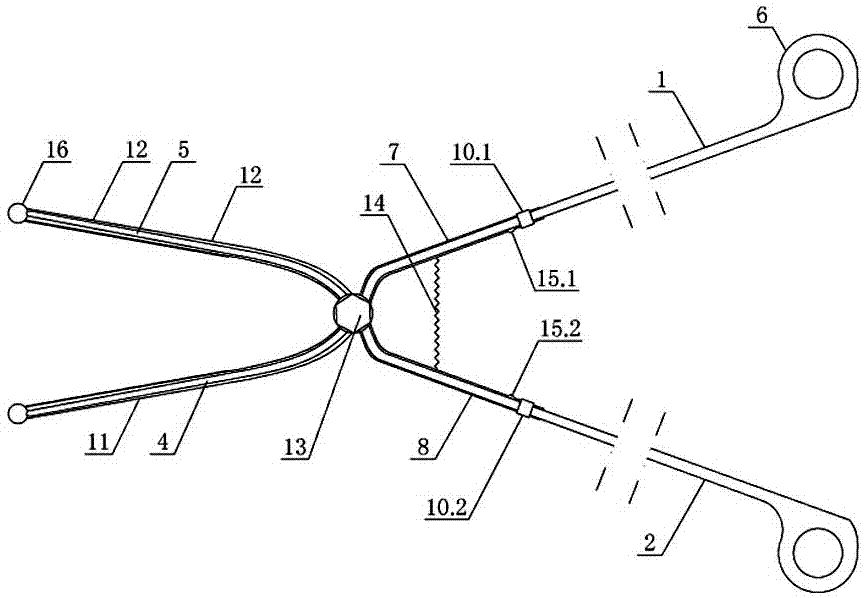

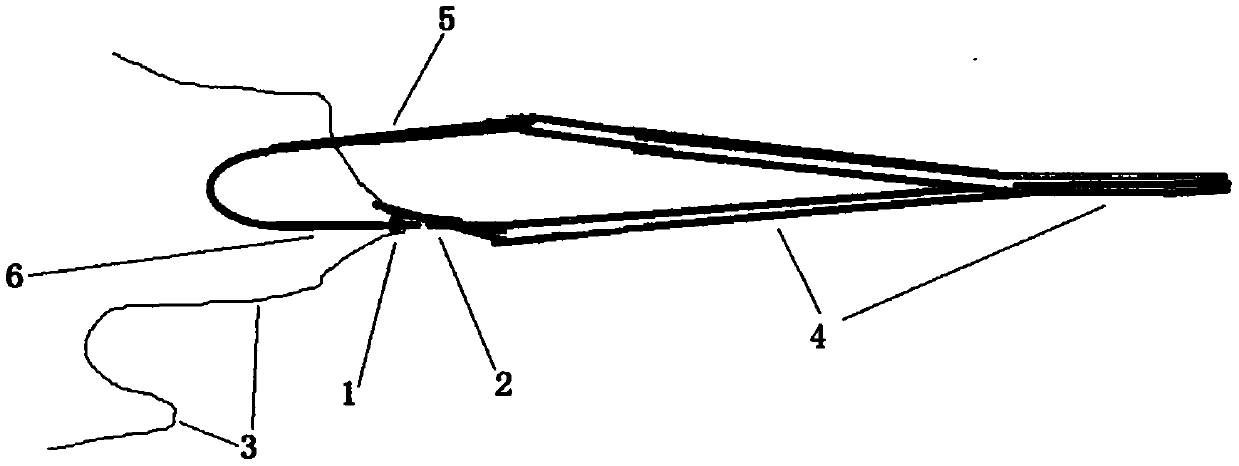

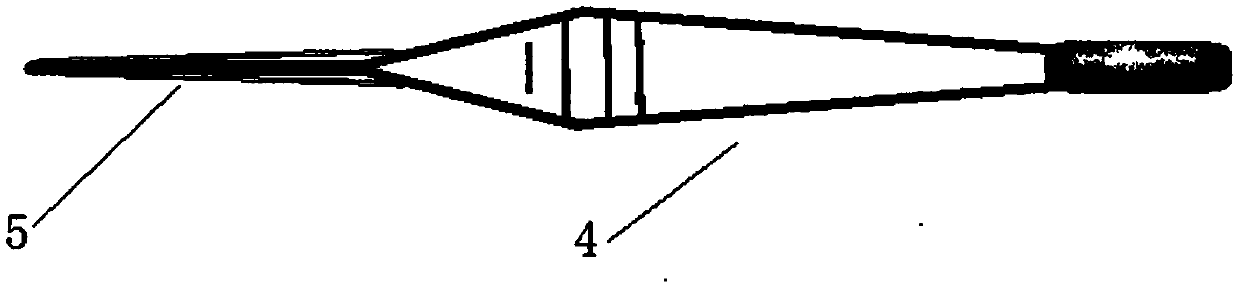

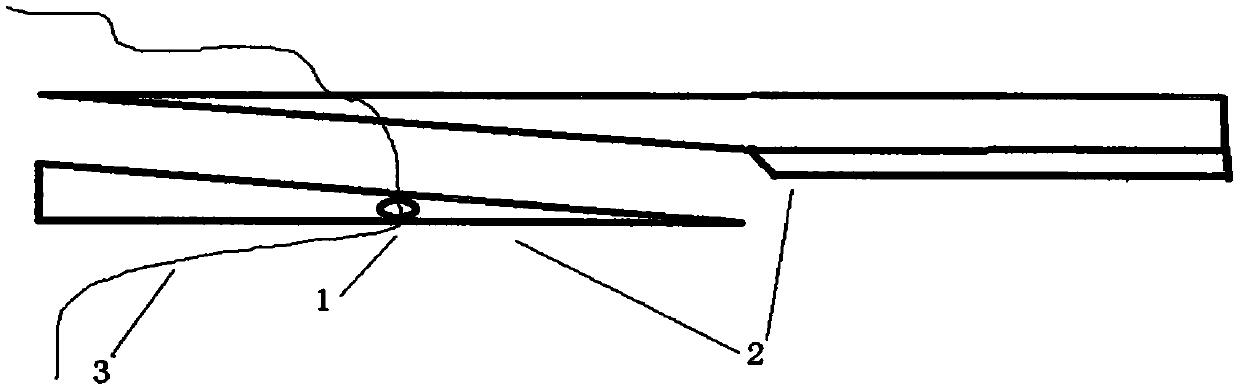

Tube side wall scissors and forceps set

ActiveCN107307894APrevent pruningGuaranteed distanceSurgical scissorsSurgical forcepsForcepsEngineering

The invention discloses a tube side wall scissors and forceps set comprising tissue scissors and clamping forceps. The tissue scissors comprise a first tool arm and a second tool arm which are hinged into a whole through a first hinge shaft, and a first blade and a second blade are arranged at the front ends of the first tool arm and the second tool arm respectively. The clamping forceps comprise a first forceps arm and a second forceps arm hinged into a whole through a second hinge shaft, and the first hinge shaft and the second hinge shaft are arranged in an up-down corresponding manner and connected into a whole in a screwed manner through an adjusting bolt. A locating sleeve is arranged on each of the first and second tool arms in a penetrating manner. The first forceps arm and the second forceps arm are connected with the first tool arm and the second tool arm respectively through the locating sleeves. A locking structure is arranged between the first forceps arm and the second forceps arm. A first forceps tip and a second forceps tip bending in the same direction are arranged at the front ends of the first forceps arm and the second forceps arm respectively. The tube side wall scissors and forceps set have clamping effect and shearing effect at the same time, the tissue scissors and the clamping forceps are arranged in a vertically spaced manner, and the distance between the tube residual ends is assured; the tissue scissors and the clamping forceps are removable, so that gravity to tubes during suturing is alleviated, overturn of tube sutured openings is avoided, and suturing quality is assured.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Guiding rolling device

PendingCN111807123ASlow down rotation speed fluctuationsSend out smoothlyWebs handlingImpactEngineering

The invention provides a guiding rolling device. The guiding rolling device comprises two rollers which rotate relatively and rolling dies which are arranged on the two rollers correspondingly. The guiding rolling device is characterized in that a buffering end with a protruding portion on at least one side and a concave portion in the middle is disposed in an axial direction on a die surface of an extrusion starting end of at least one rolling die. Vibration and impact force which occur at the moment when the two rolling dies just start to make rigid contact can be tolerated by the protrudingportions of the extrusion starting ends, meanwhile a new strip and an old strip are accommodated through the middle concave portions, the influence, on the strips, of vibration or impact force causedwhen the rigid contact occurs is eliminated fundamentally, and thus the new strip and the old strip can be smoothly rolled and connected to form one strip. Besides, vibration and impact force which occur at the moment when the two rolling dies are separated can be released through protruding portions of extrusion finishing ends, rotation speed fluctuation caused by the two rolling dies is reduced, thus the strip which is formed by rolling and connecting is delivered out stably, and the splicing quality of the new strip and the old strip is ensured.

Owner:KUNMING DINGCHENGQIXIN TECH CO LTD

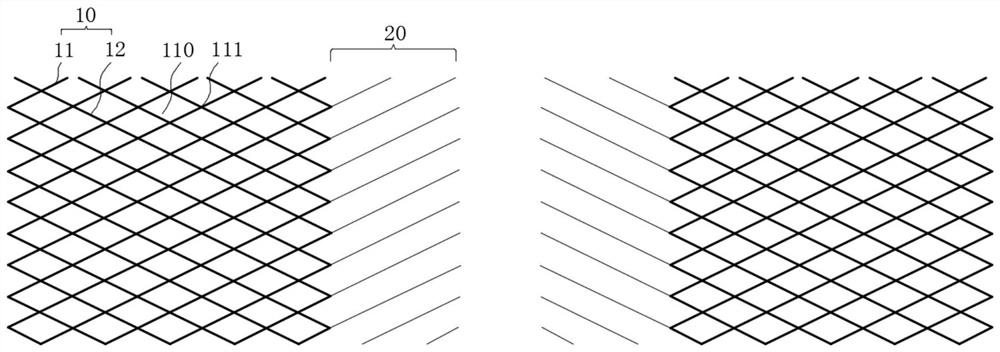

Metal conductive film, manufacturing method, touch panel and electronic product

PendingCN113194623ANo visible chromatic aberrationPlay the role of continuous conductionConductive layers on insulating-supportsConductive pattern formationEngineeringTouch panel

The invention provides a metal grid conductive film which comprises at least two metal grid layers which are consistent in wiring form and located in the same plane, the splicing positions of the metal grid layers are arranged in an overlapped mode to form a continuous trend, and a splitting part used for splicing is formed on the base portion of each metal grid layer along the extension of the original wiring. The splitting part is arranged in an overlapped mode to form an abutted seam used for achieving continuous conduction between the metal grid layers to be spliced, and the abutted seam comprises an irregular area which is formed by the splitting part and the base portion in an overlapped mode and is different from an original metal grid layer pattern. The invention further discloses a manufacturing method of the metal grid conductive film, a touch panel and an electronic product. When the large-size metal conductive film is prepared, a plurality of metal grid layers can be used for splicing, and particularly, the split parts of the metal grid layers to be spliced are overlapped together to form a continuously-conducted splicing seam, so that a continuously-conducted whole is formed between the grid layers, and the splicing quality is ensured.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

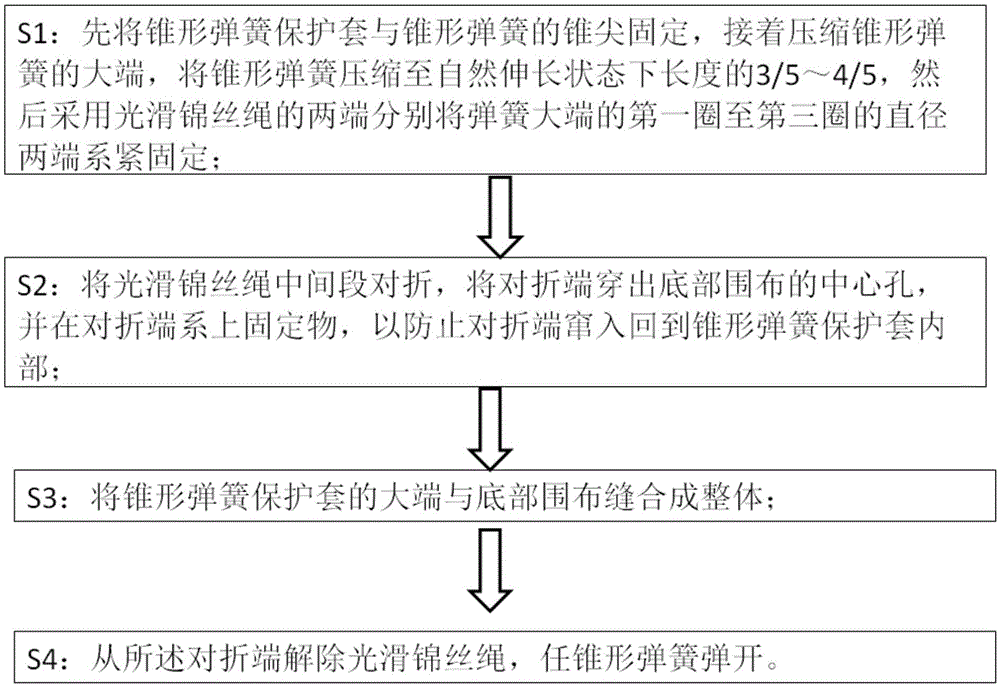

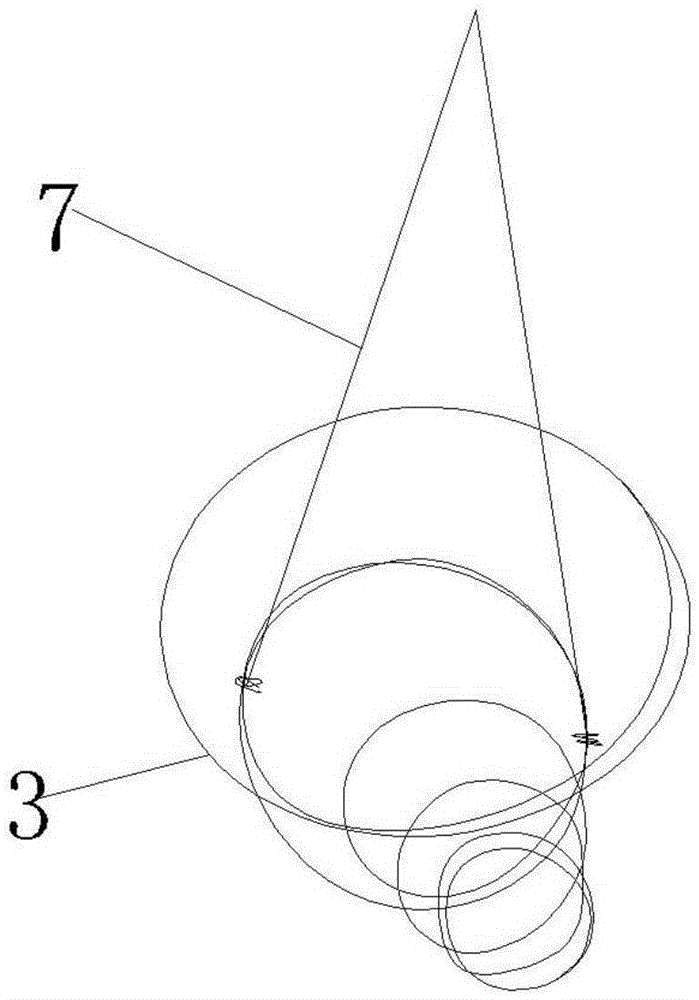

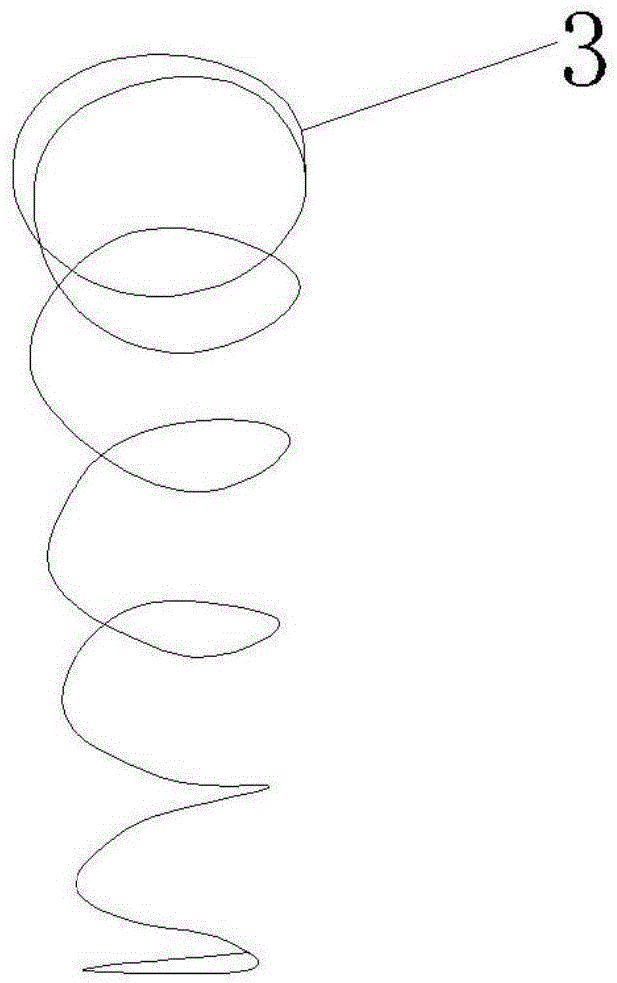

Sewing method for drogue parachute opening spring

The invention discloses a sewing method for a drogue parachute opening spring, which relates to the field of parachutes. The method comprises the following steps of S1, first fixing a conical spring protective sleeve together with a conical tip of a conical spring; next, compressing a big end of the conical spring; compressing the conical spring to 3 / 5-4 / 5 of the length of the conical spring in a natural extending state; and then respectively tying and fixing two ends of diameters of the first circle to the third cycle of the big end of the spring by using two ends of a smooth nylon yarn rope; S2, folding the middle section of the smooth nylon yarn rope, exerting the folded end to penetrate through a central hole of a bottom enclosing cloth, and tying a fixture at the folded end so as to prevent the folded end from jumping into the conical spring protective sleeve; S3, integrally sewing the big end of the conical spring protective sleeve and the bottom enclosing cloth; and S4, untying the smooth nylon yarn rope from the folded end so that the conical spring is flipped. The sewing method for the drogue parachute opening spring, disclosed by the invention, is advantaged in that the difficulty in sewing the spring protective sleeve and the bottom enclosing cloth can be reduced, the sewing quality can be effectively ensured and the method can be conveniently and effectively operated by workers.

Owner:HUBEI QINGTONGHUI AVIATION TECH CO LTD

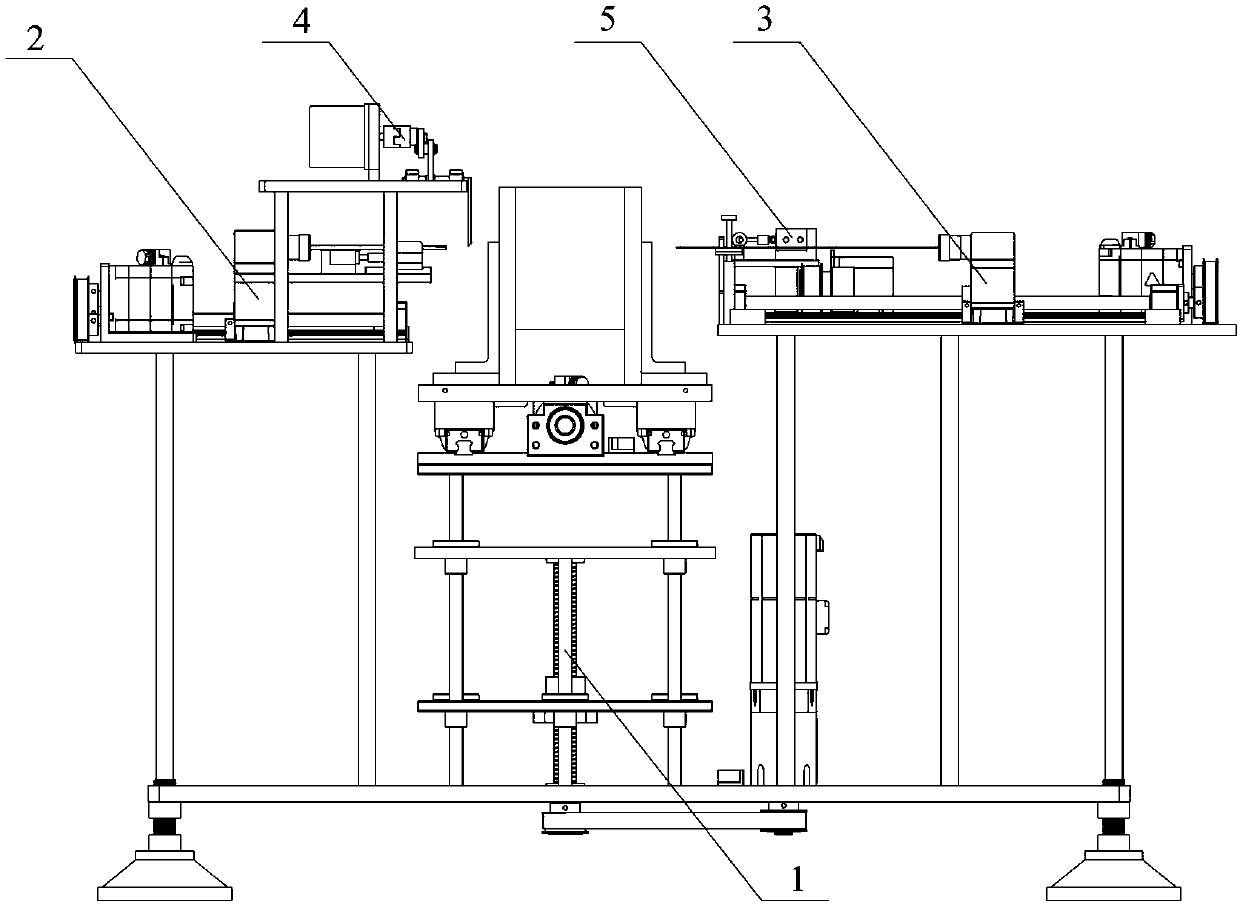

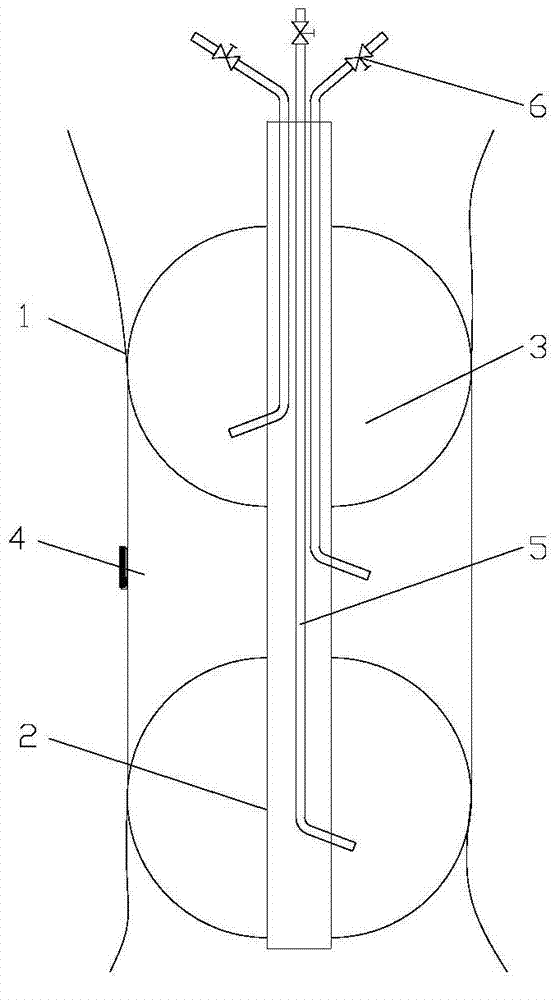

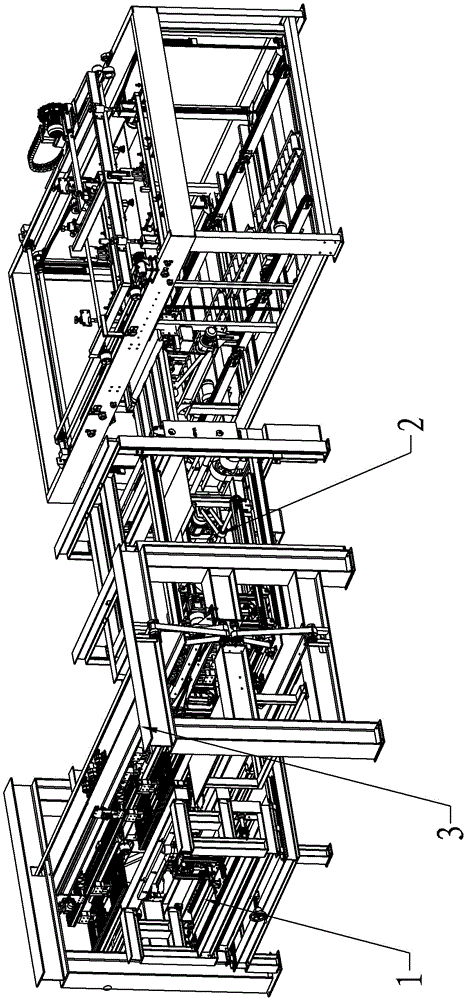

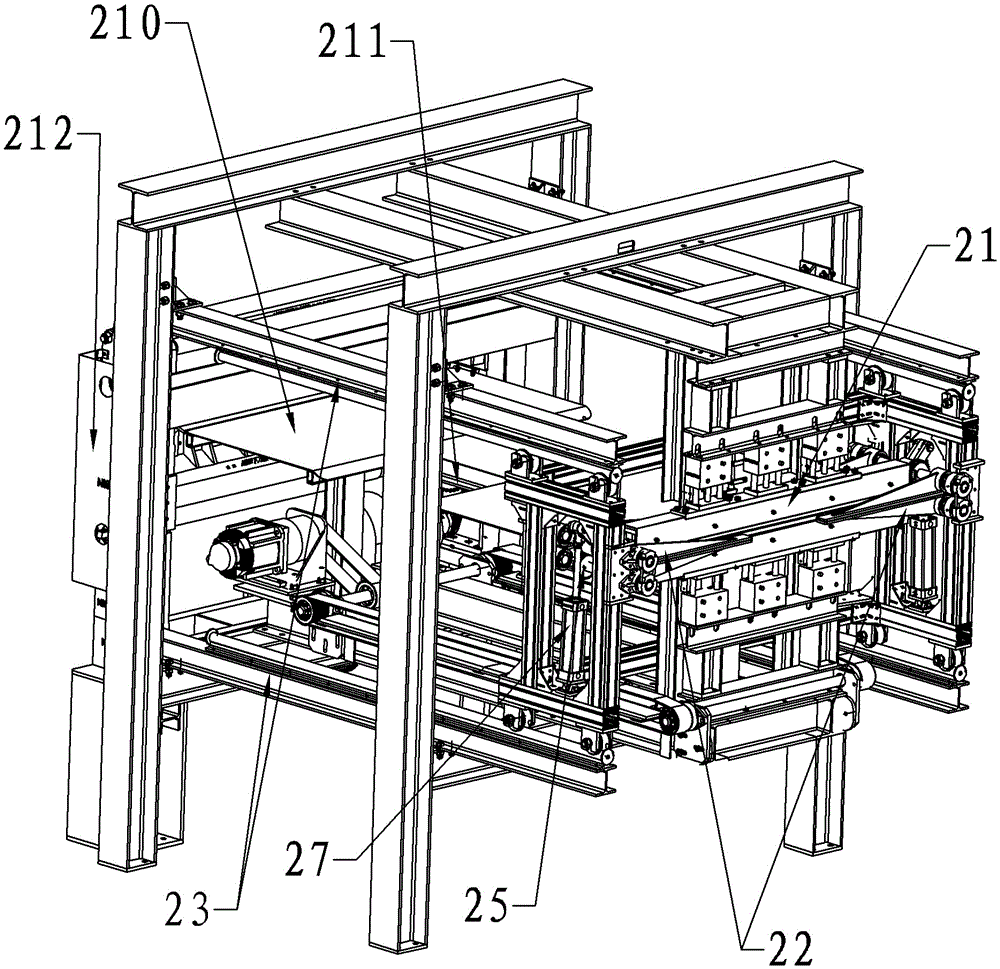

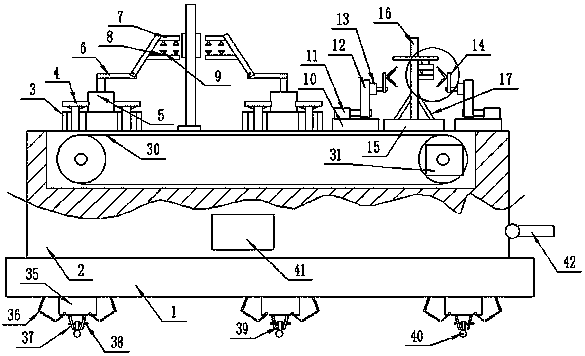

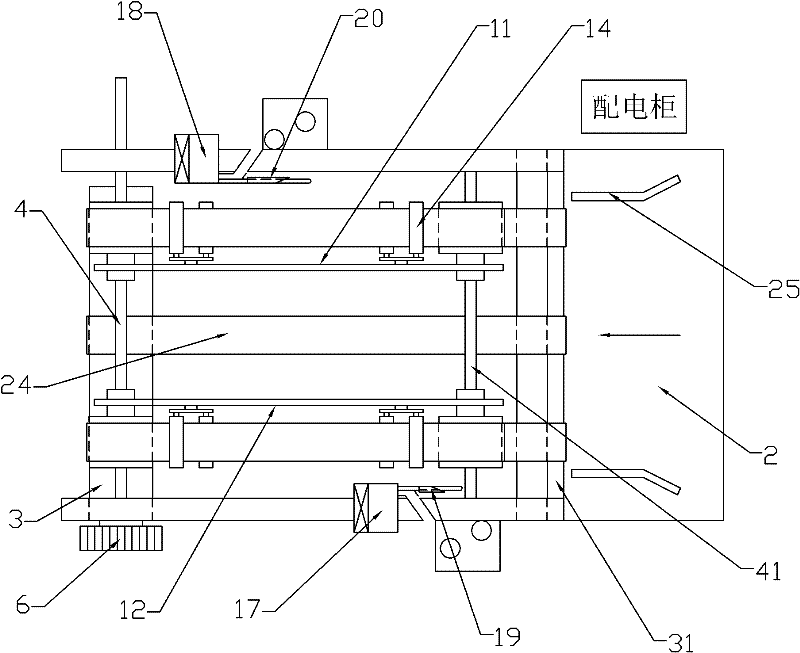

Full-automatic unlimited lengthening machine

ActiveCN105583918AGuaranteed stitching qualityReduce processing costsOther plywood/veneer working apparatusWood veneer joiningEngineeringMachining process

The invention discloses a full-automatic sheet unlimited lengthening machine, which at least comprises a sheet cutting and chamfering mechanism, a sheet unlimited lengthening mechanism and a double-station sheet conveying mechanism; the sheet cutting and chamfering mechanism has the advantages that a notch is flat and smooth, machining precision is high, a large amount of flying dust cannot be generated during a machining process, and the like; the sheet unlimited lengthening mechanism is used for completing splicing between sheets and conveyance after splicing to ensure that spliced parts of the sheets are subjected to a small force during a conveying process, therefore the spliced parts are prevented from being disengaged or staggered; the double-station sheet conveying mechanism is used for completing reclaiming and synchronous conveyance of machining stations to ensure that two machining stations are capable of synchronously obtaining sheets to be machined, so that the requirement of synchronous and continuous machining is met. According to the full-automatic sheet unlimited lengthening machine, all machining procedures from cutting to splicing of the sheets are completed in a full-automatic manner by matching the mechanisms, therefore splicing quality of the sheets is ensured while production efficiency is effectively increased.

Owner:HESHAN JIDING MACHINERY CO LTD

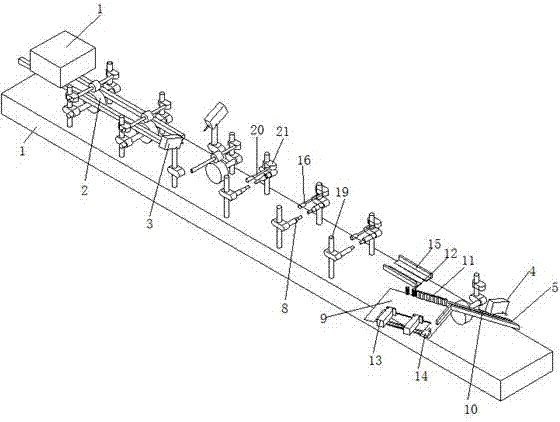

Wood sleeve line coating machine

ActiveCN107443501AGuaranteed to stickGuaranteed stitching qualityOther plywood/veneer working apparatusWood veneer joiningEngineeringMechanical engineering

The invention discloses a wood sleeve line coating machine, and belongs to the field of wood processing equipment. The wood sleeve line coating machine comprises a frame, and a conveying rail arranged on the frame and consisting of multiple transmission wheels; a skin slotting mechanism, a gluing mechanism I, a skin edge folding mechanism, a gluing mechanism II and a side plate conveying mechanism arranged on the side surface of the conveying rail are arranged in the movement direction of the conveying rail in sequence; and a side plate outlet is formed in the back end of the side plate conveying mechanism near one side of the conveying rail. The wood sleeve line coating machine finishes the coating and assembly work with high quality, and improves the working efficiency.

Owner:河北简工科技有限公司

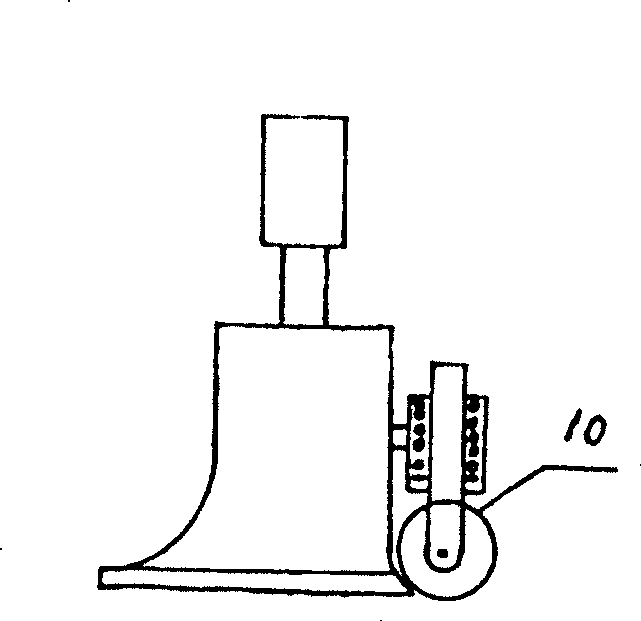

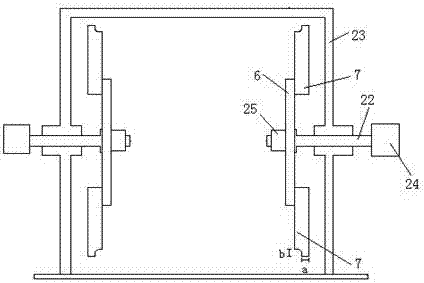

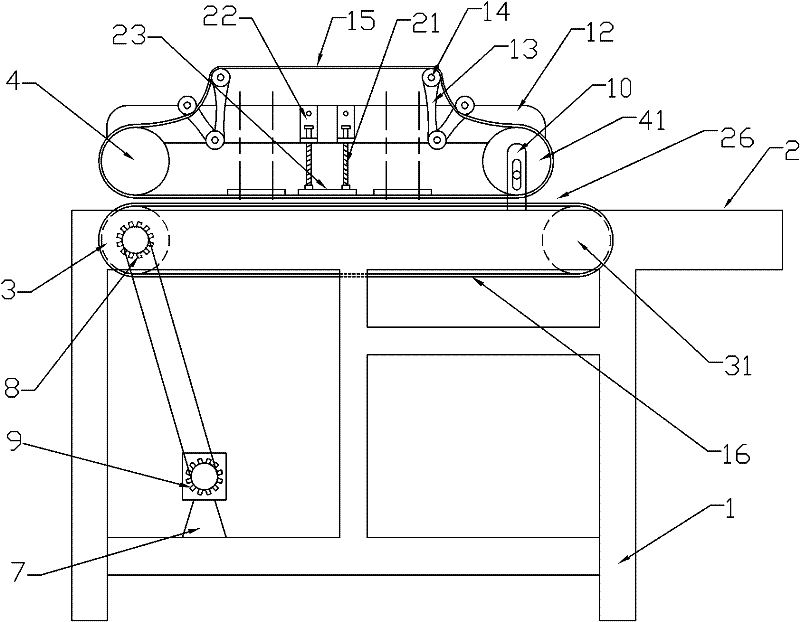

Tracking sewing equipment

InactiveCN103103697AImprove efficiencyGuaranteed stitching qualityProgramme-controlled sewing machinesEngineeringNumerical control

The invention provides tracking sewing equipment. The tracking sewing equipment comprises a sewing platform, wherein a numerical control (NC) two-shaft positioning device is arranged at the upper portion of the sewing platform and is provided with a sewing device and a tracking device, the sewing device faces the sewing platform, the sewing platform is provided with at least two positioning nails which are used for positioning a transparent hard film covered on the sewing platform, and the transparent hard film is provided with positioning holes corresponding to the positioning nails and traces clothes to be sewn arranged on the sewing platform through a tracing pen. According to the tracking sewing equipment, the tracking device is used for controlling the NC two-shaft positioning device to be matched with the sewing device to sew the clothes, compared with the traditional manual sewing method, the sewing efficiency is largely improved, and sewing quality is effectively guaranteed as sewing accuracy is improved.

Owner:WUJIANG LANRUITE TEXTILE

Butadiene styrene rubber finished product block packaging bag sealing device

PendingCN111017335AStrong pressing forceEasy crimpingWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses a butadiene styrene rubber finished product block packaging bag sealing device. The butadiene styrene rubber finished product block packaging bag sealing device solves the problems that an existing packaging bag sealing device is complex in structure relatively, and packaging bag continuous seal work cannot be conveniently achieved. The butadiene styrene rubber finished product block packaging bag sealing device comprises a machine sewing device and a conveying belt arranged below the machine sewing device and is characterized in that two pressing belts are arranged onthe upstream side of the machine sewing device, the conveying belt is located on the lower sides of the pressing belts, the upstream ends of the two pressing belts are opened towards the two sides inthe horizontal direction, and the downstream end sides are arranged next to each other side by side. The conveying belt is used for vertically conveying packaging bags contained with finished blocks,and an opening part of a packaging bag is pressed and attached by the two pressing belts, and is sewn by the machine sewing device.

Owner:浙江维泰橡胶有限公司

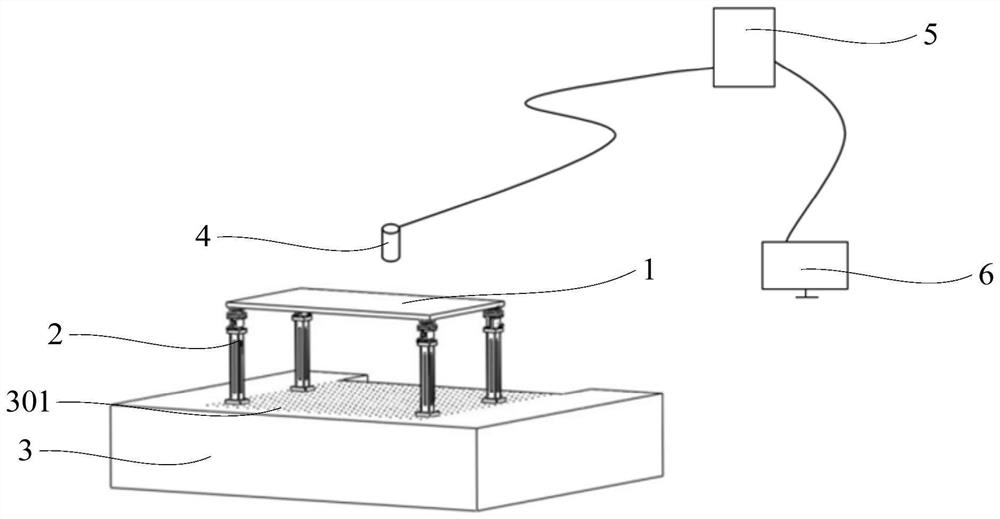

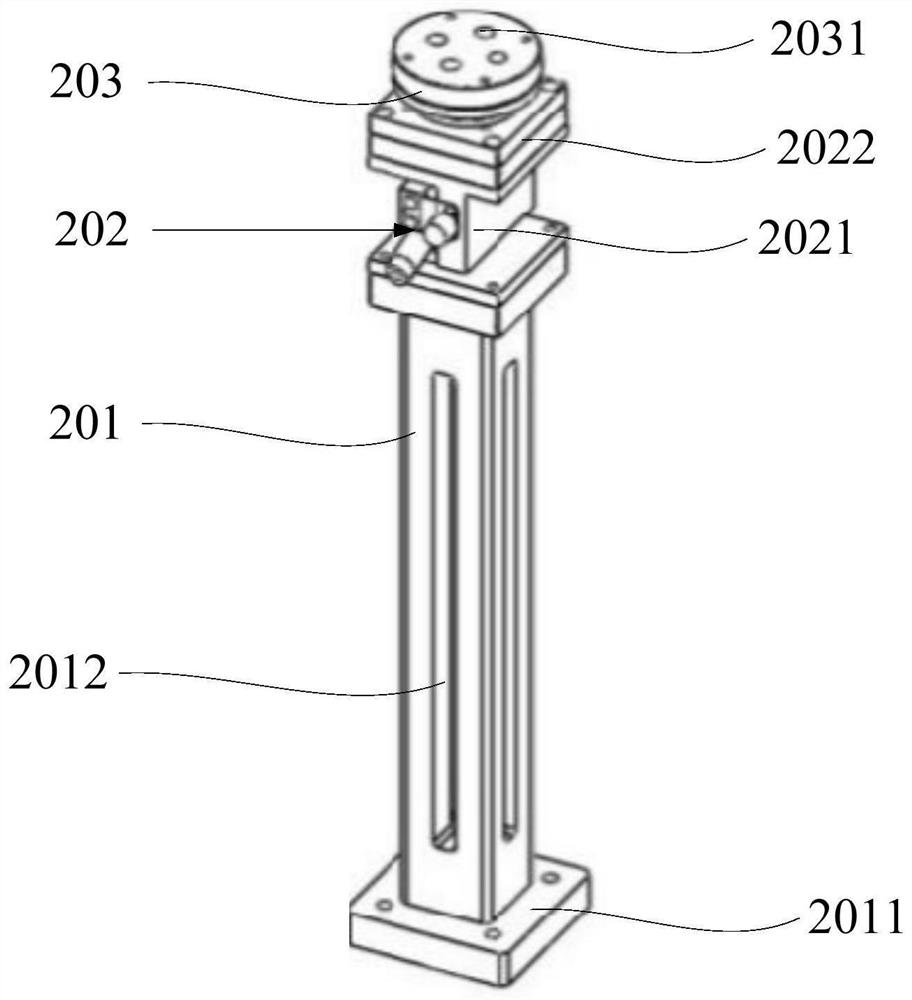

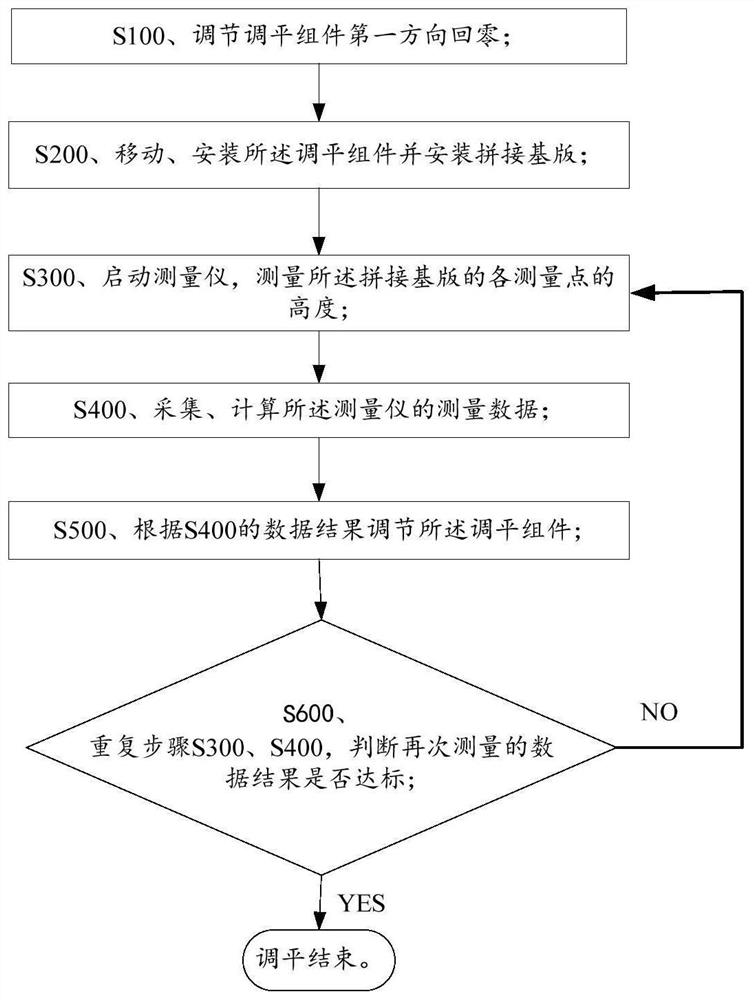

Chip splicing platform and chip splicing substrate leveling method

PendingCN112309916AGuaranteed flatnessImprove yieldSemiconductor/solid-state device manufacturingComputer hardwareEngineering

The invention relates to the technical field of semiconductors, in particular to a chip splicing platform and a chip splicing substrate leveling method. The chip splicing platform comprises: a splicing substrate, which is provided with a splicing surface and is used for supporting a chip; and a leveling assembly, which is connected with the splicing substrate, is provided with a telescopic structure, and is used for supporting the splicing substrate and adjusting the flatness of the splicing surface. According to the chip splicing platform provided by the invention, the flatness of the splicing surface of the splicing substrate can be adjusted by adjusting the leveling assembly, so the splicing surface is close to be horizontal to the greatest extent, the flatness of a spliced chip is ensured, splicing efficiency is improved, and chip yield is increased.

Owner:BEIJING SEMICON EQUIP INST THE 45TH RES INST OF CETC

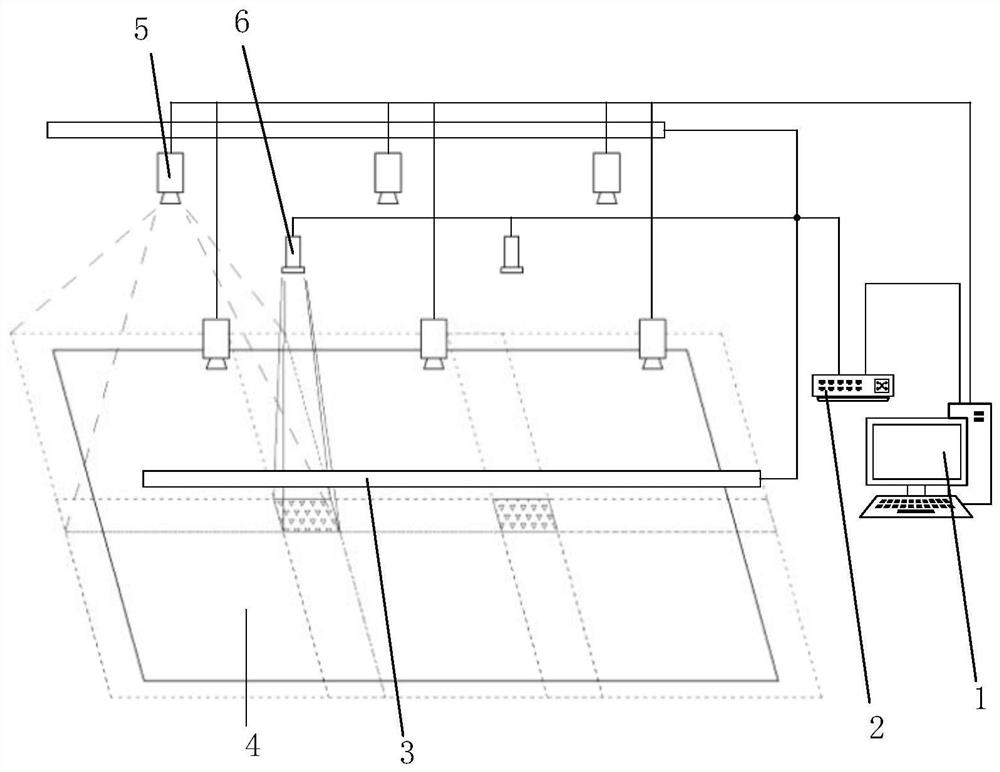

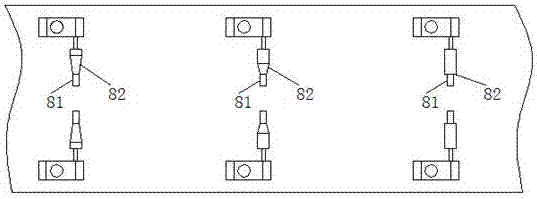

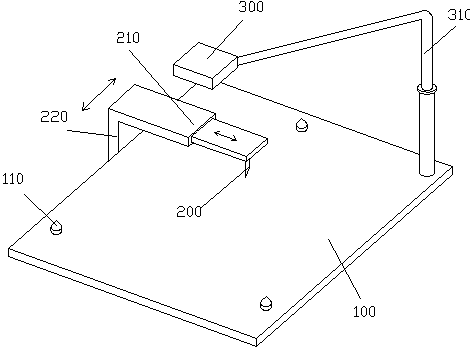

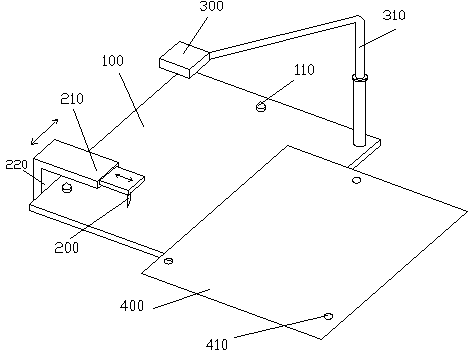

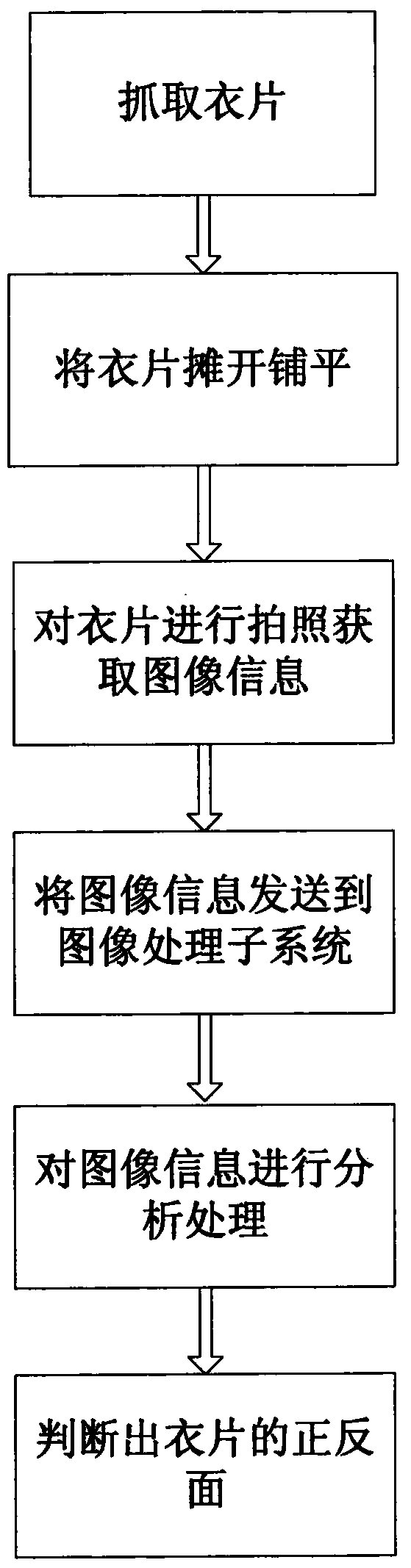

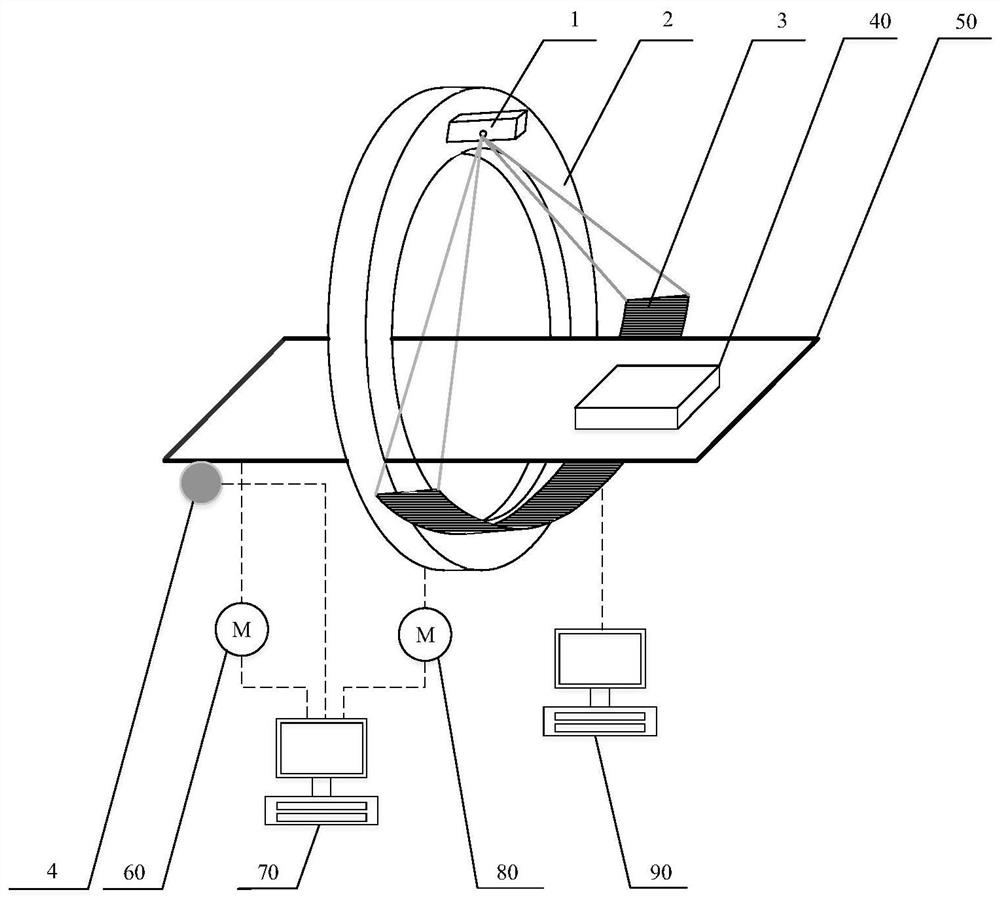

System and method for quick identifying front and back of garment piece fabric by automatic production line

InactiveCN108729011AGuaranteed stitching qualityHigh degree of automationKnittingProduction lineImaging processing

The invention relates to a system for quick identifying the front and back of a garment piece fabric by an automatic production line. The system includes a working table, a garment piece gripping device, a garment piece spreading and leveling device, a camera device and an image processing subsystem. Another technical scheme of the invention is to provide a method for quick identifying the front and back of the garment piece fabric based on the system for quick identifying the front and back of the garment piece fabric. First a garment piece is picked up to the working table through the garment piece gripping device, the garment piece on the working table is automatically spread and leveled through the garment piece spreading and leveling device, the well adjusted garment piece is photographed through the camera device, and image information is sent to the image processing subsystem for analysis and matching to determine the front and back of the garment piece fabric, which is favorable for enabling a linking machine to better perform automatic alignment, the automation degree of a linking machine system is improved, and the seaming quality of the linking machine is ensured.

Owner:DONGHUA UNIV

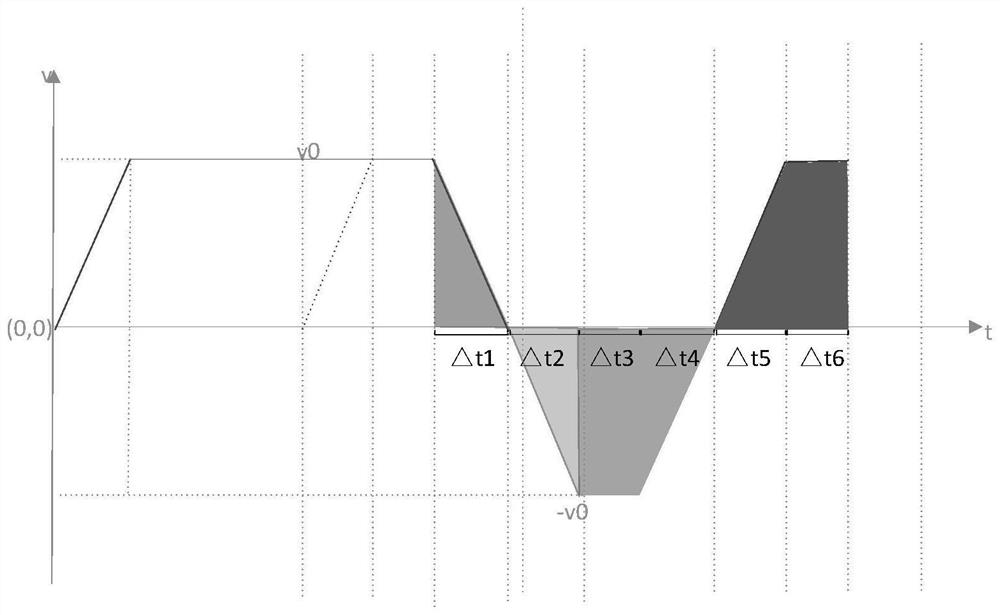

CT detection method of CT detection device, and detection device

ActiveCN112748134AGuaranteed splicing effectImprove security efficiencyMaterial analysis using wave/particle radiationNuclear radiation detectionRadiologyEngineering

The invention relates to a CT detection method of a CT detection device, and the detection device, and relates to the technical field of CT detection. The problem that once a belt is stopped, a security inspector needs to move a detected object entering a detection area out of a monitoring area to carry out security inspection again is solved. The detection method comprises the following steps: acquiring a first image and movement data of a conveyor belt, wherein the movement data comprises the movement speed and the movement time of the conveyor belt; determining that the conveyor belt stops moving according to an externally input stop instruction; detecting whether the first image is the same as a pre-stored background image or not, wherein the background image is an image corresponding to the conveyor belt when no detection object exists; when the first image is different from the background image, generating a moving instruction according to the first image, the moving data and the rewinding time; controlling the conveyor belt to move through the moving instruction; acquiring a second image of the detected object; and splicing the first image and the second image to obtain a complete image of the detected object. According to the technical scheme provided by the invention, the security check efficiency can be improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Reverse laparoscope incision stitching instrument

PendingCN111544067AEasy to operateSimple and fast operationSuture equipmentsSurgical needlesMuscle layerLaparoscopes

The invention discloses a reverse laparoscope incision stitching instrument which comprises a forceps type needle holding handle and a stitching instrument front needle end structure. The needle end is of a U-shaped structure, and suturing is conducted from the abdominal wall inner layer peritoneum to the outer side muscle layer and subcutaneous tissue. And the problem of difficulty in suturing patients with obesity and abdominal wall thickness is effectively solved. The laparoscope stitching instrument is convenient to use, comfortable to operate and easier for an operator to master due to the forceps type operating handle. Meanwhile, an abdominal wall fixing device is not needed in the stitching process, positioning is accurate, stitching is quick, stitching is performed under laparoscope monitoring, and surgical safety is improved.

Owner:苗瑞超

UV resin printing projection and illumination device and algorithm

ActiveCN106400545ARealize continuous productionGuaranteed stitching qualityFibre treatmentTypewritersTextile printerEngineering

The invention discloses a UV resin printing projection and illumination device and an algorithm, and belongs to the technical field of textile. The device comprises one set or more sets of PC, a controller, a roller, a projector, a spraying head, an adjustable bracket, a fabric and a machine frame, and can comprise a steeping press roller and a steeping press cylinder, wherein the action of the spraying head and the action of the projector are controlled by the controller; the controller communicates with the PC; and a rotary encoder fixed on the roller reads the moving position of the fabric and controls the pattern moving speed of the projector. The UV algorithm relates to a projector image transition method, wherein the projector circularly plays the same picture or a designed continuous image, and the whole image is connected end to end to form an integral pattern. The printing fabric is processed by the method, so UV printing continuous production can be realized, a large pattern can be produced and the splicing quality of the pattern is guaranteed.

Owner:JIANGNAN UNIV

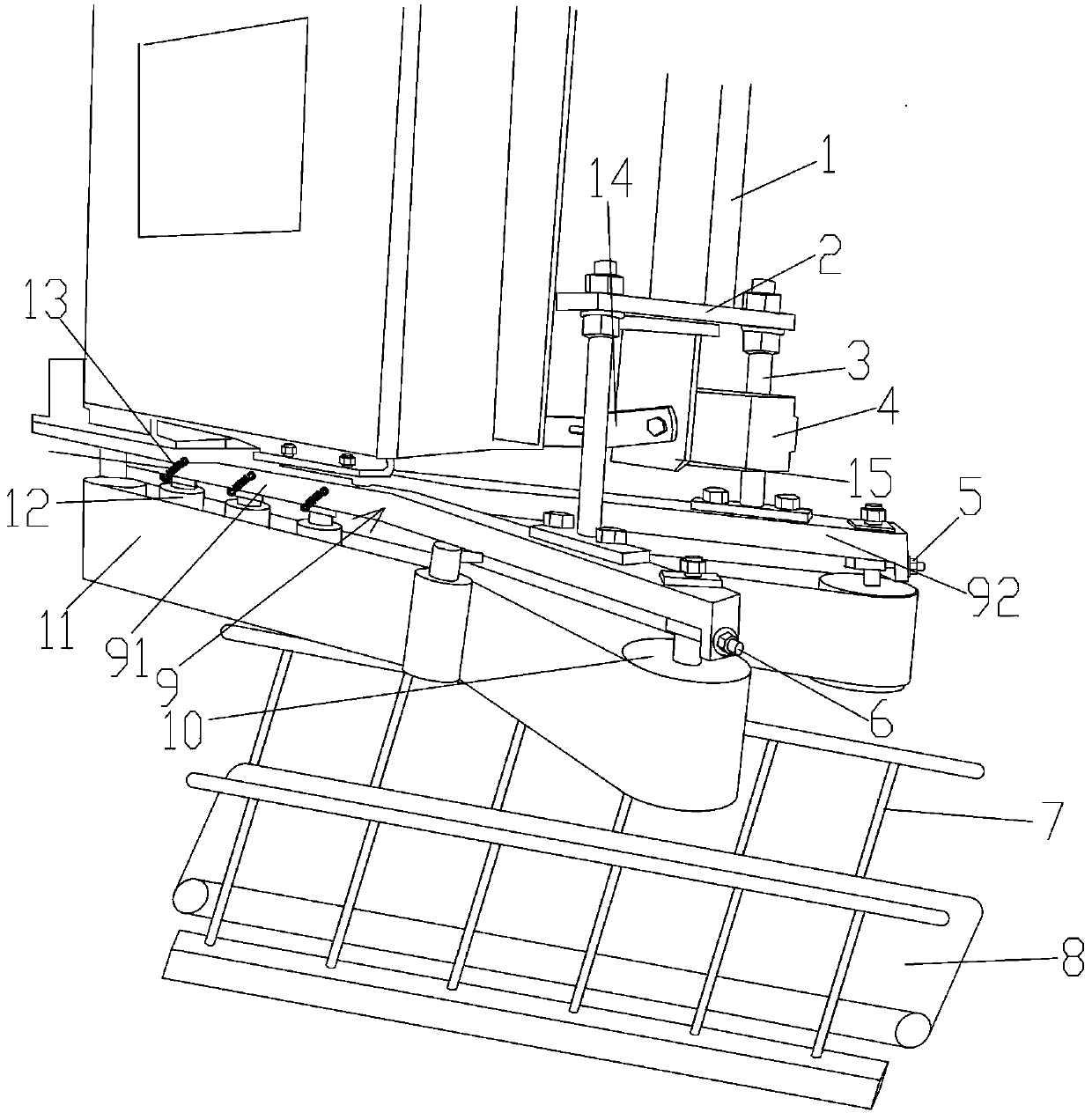

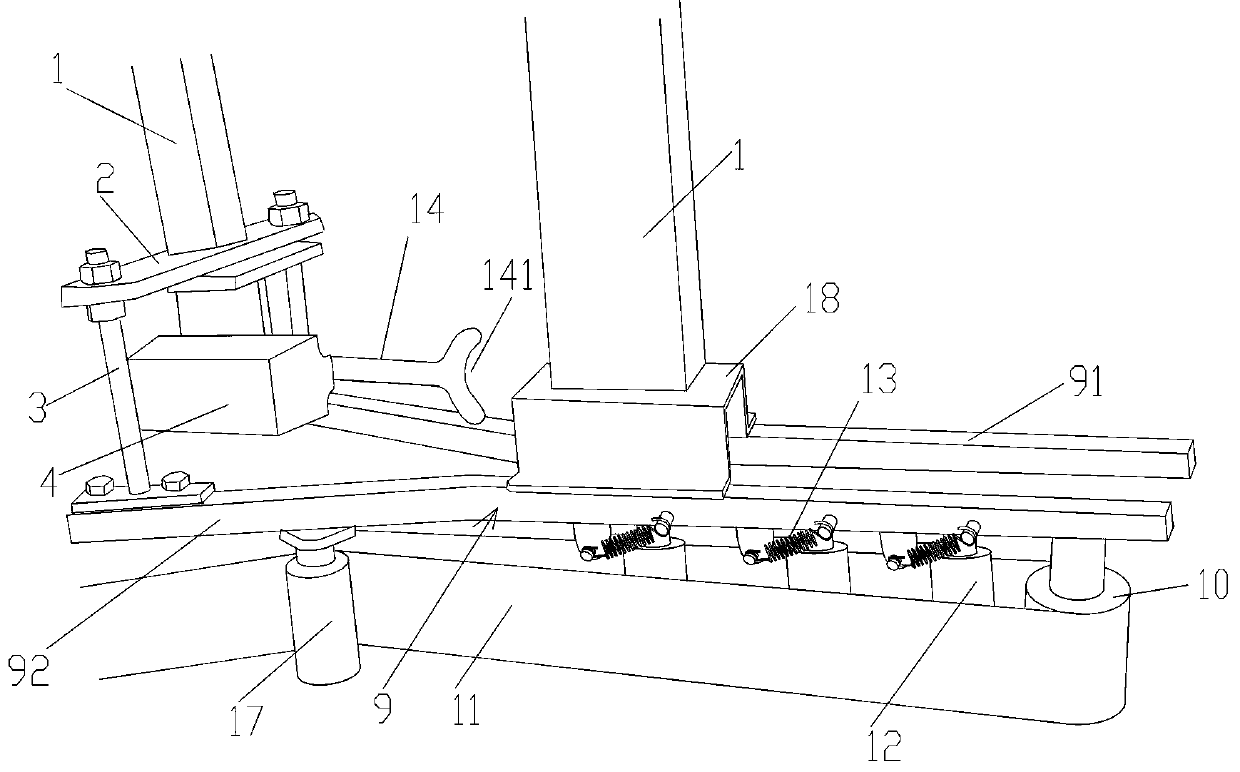

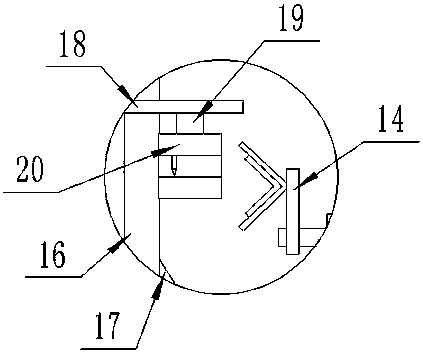

Rotary detection device for accurate looping of linking machine

The invention discloses a rotary detection device for accurate looping of a linking machine. The rotary detection device comprises a turn table, wherein a square bracket is fixed on the turn table; a pressure fork assembly is arranged at one side of the square bracket; a camera component is arranged at the other side of the square bracket; the pressure fork assembly and the camera component can move up and down relative to the square bracket; the camera component comprises a camera; the turn table is driven by a rotary motor and can drive the square bracket to rotate; the pressure fork assembly comprises a loop pressure fork; a plurality of press sheets are arranged at the bottom part of the loop pressure fork; each press sheet is in an elastic sheet structure; and the distance between the adjacent press sheets corresponds to the distance between projection points of the adjacent sewing needles on a sewing plate in the horizontal plane. The stretching condition of a fabric loop is detected through the camera component; and the size of the loop stretched by the fabric stretching device is controlled according to the actual condition, so that the linking machine can be relatively accurately sleeved by the loops; meanwhile, the loop pressure fork can ensure that the loops completely sleeve sewing needles; and the sewing quality of the linking machine is ensured.

Owner:叶军忠 +2

A packaging bag processing device for fat powder

ActiveCN107053763BEasy to operateIncrease productivityBag making operationsPaper-makingMechanical engineering

Owner:深圳友邦塑料印刷包装有限公司

One-off forming machine for sewing-up valve sack double openings

InactiveCN102161243BEasy to sutureImprove seaming efficiencyEnvelopes/bags making machineryDrive shaftEngineering

Owner:JINAN LIYU MACHINERY TECH

Fixing device for zipper machine

The invention belongs to the field of zipper installation, and particularly relates to a fixing device for a zipper machine. The fixing device comprises a horizontally-arranged placing table, a vertically-arranged lifting rod is arranged at the upper end of the placing table, two pressing heads are fixedly connected to the lower end of the lifting rod, and a needle head is arranged on each pressing head in a penetrating mode. A vertically-arranged sliding groove is formed in the upper side wall of the placing table, a bearing plate is slidably connected into the sliding groove, the upper end of the bearing plate extends out of the sliding groove, connecting strips are fixedly connected to the side walls of the two sides of the bearing plate, a fixing pile is fixedly connected to the upperside wall of each connecting strip, and the two fixing piles are symmetrically arranged at the upper end of the bearing plate. By arranging fixing needles, after a textile fabric is placed on the bearing plate, connecting rods are pulled upwards and then loosened, the connecting rods can drive the fixing needles to be nailed on the textile fabric under the elastic action of coil springs, the textile fabric can be effectively fixed, the textile fabric is prevented from inclining in the zipper sewing process, and the sewing quality is guaranteed.

Owner:杭州永智信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com