Metal conductive film, manufacturing method, touch panel and electronic product

A technology of metal conduction and manufacturing method, which is applied in the direction of cable/conductor manufacturing, conductive pattern formation, conductive layer on insulating carrier, etc. It can solve the problems of unfavorable large-size conductive film production and the inability of the machine to be directly integrally formed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

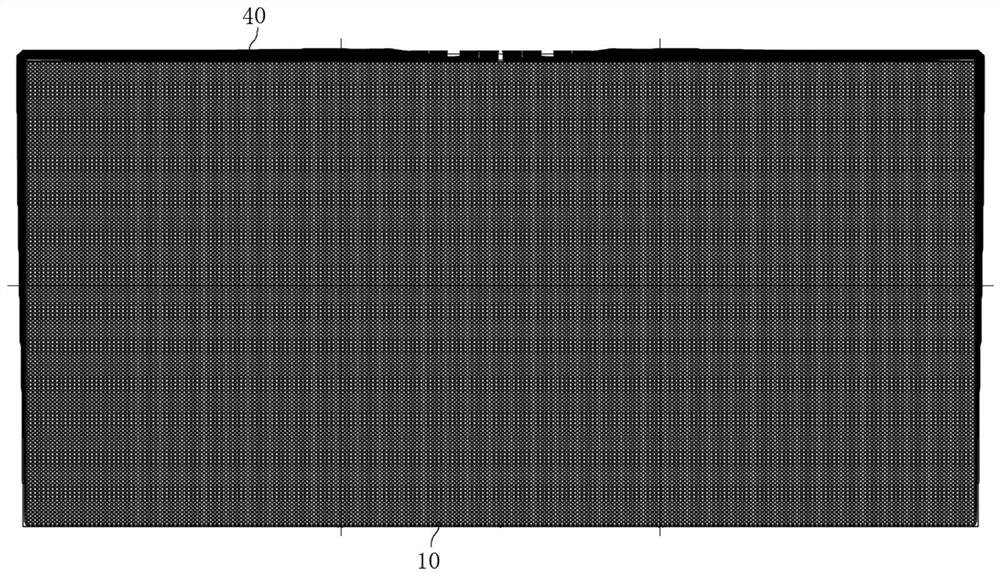

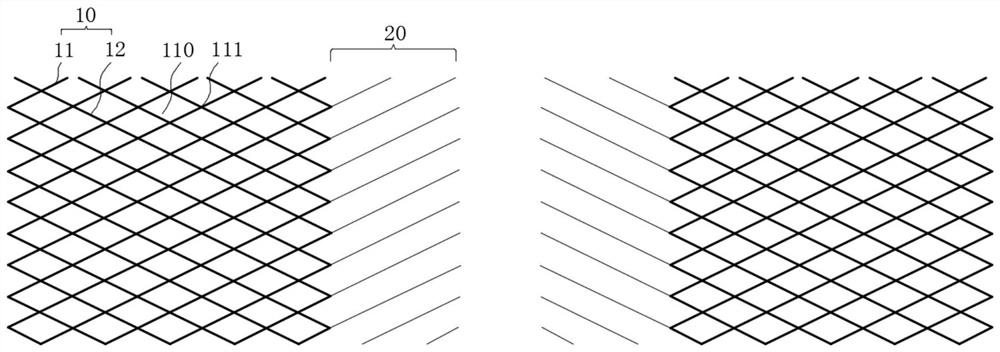

[0042] refer to Figure 1-6 , a metal grid conductive film, comprising at least two traces in the same form and located in the same plane, and the splices are superimposed to form a continuous metal grid layer 10, wherein the base of the metal grid layer is formed along the original The split part 20 for splicing is extended by trace extension, and the split part is superimposed and arranged to form a patchwork 30 for realizing continuous conduction between the metal grid layers to be spliced. When splicing, multiple metal grid layers can be spliced along the same plane. Specifically, the split parts of the metal grid layers to be spliced are stacked together to form a continuous conductive seam, so as to ensure that the grid A continuous conduction whole is formed between the grid layer and the grid layer, so as to solve the problem that the existing equipment cannot integrally form a large-sized metal conductive film.

[0043] As a preferred technical solution of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com