Wood sleeve line coating machine

A wire wrap and wood sleeve technology, which is applied to wood processing appliances, the joining of wooden veneers, and other plywood/plywood appliances, etc., can solve the problems of inconvenient processing and cumbersome equipment use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail:

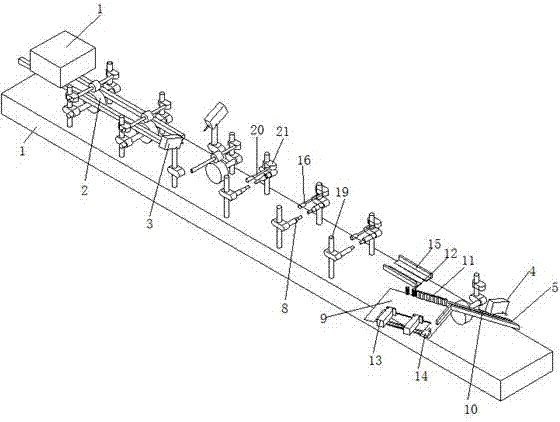

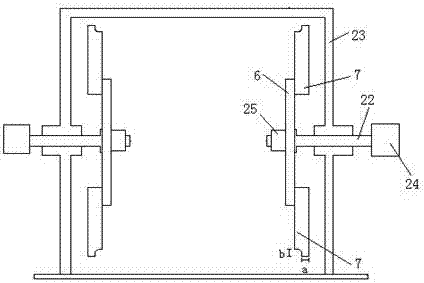

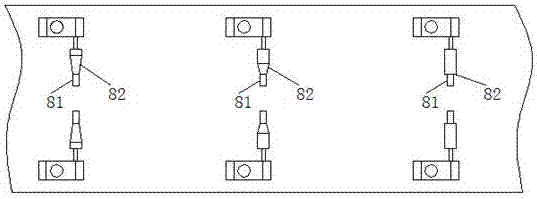

[0028] Such as Figure 1~5 As shown, a wooden wire covering machine includes a frame 1 and a conveying track. The conveying track is composed of a plurality of transmission wheels 2 arranged on the frame 1, and grooves are sequentially arranged along the moving direction of the conveying track. Mechanism, gluing mechanism Ⅰ3, skin folding mechanism, gluing mechanism Ⅱ4 and the side plate conveying mechanism arranged on the side of the conveying track. Firstly, the lower end of the bottom plate covered with the outer skin is provided with two symmetrical hemming grooves on the outer skin through the outer skin groove cutting mechanism. Complete the hemming process to cover the side of the bottom plate with the outer skin. After the outer skin on one side is folded, it is higher than the upper surface of the bottom plate. The inner side of the outer skin is coated with glue by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com