Scraper for sink rolls in zinc pots

A sinking roller and scraper technology, which is applied in coating, metal material coating process, hot-dip coating process, etc., can solve the problem of zinc slag discharge that cannot be scraped off, avoid repeated bonding, and improve the effect of scraping slag Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

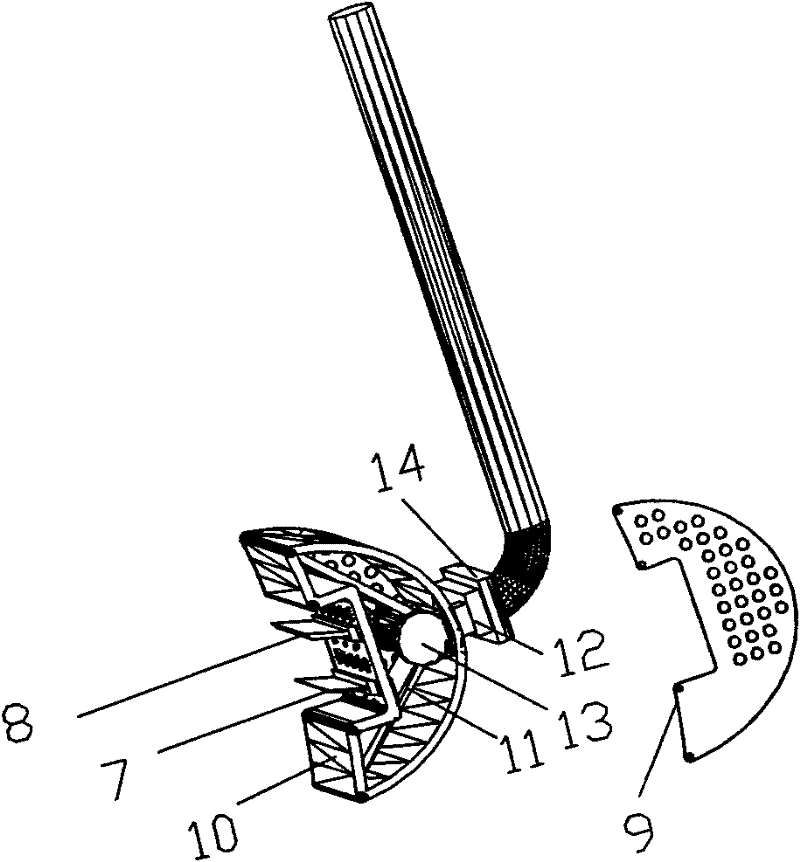

[0013] refer to image 3 and combine Figure 4 As shown, the scraper 15 of the zinc pot sinking roller includes a "bow" shaped cavity structure 10, an upper piece and its base 8, a lower blade and its base 7, a "V"-shaped fixed bracket 11, a filter residue plate 9, and an installation base 12, coupling shaft 13, knife arm 14. The cutter body adopts a "bow"-shaped cavity structure 10, and the arc of the "bow"-shaped structure 10 matches the curvature of the surface of the sunken roll of the zinc pot to be cleaned. The base is connected by a sleeve shaft, and the upper and lower double scraper blades are set on the "bow" cavity structure. Two filter residue plates 9 are arranged on both sides of the structure. The zinc pot submerged roller scraper installs the upper blade and its base 8, the lower blade and its base 7 on the concave surface of the "bow"-shaped cavity structure 10 through the fixing nut, and the stainless steel gasket can be added during the installation test....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com