UV resin printing projection and illumination device and algorithm

A technology for irradiation devices and resins, applied in printing devices, printing, dyeing methods, etc., can solve problems such as pollution, difficulty in adapting to processing speed, processing output, high water and energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

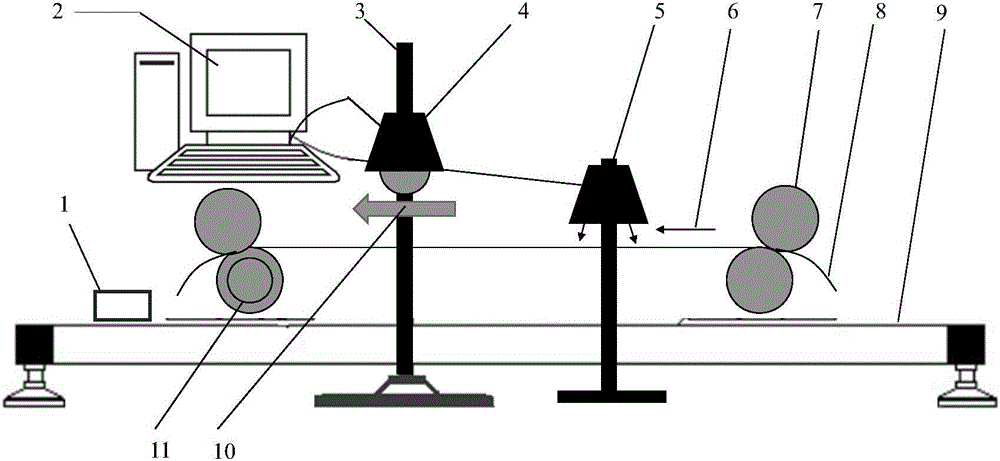

[0022] A UV resin printing projection irradiation device and an algorithm are provided, the device includes a set of units for projecting and producing monochrome printed fabrics; the device includes one or more sets of PC (2), controller (1), cylinder (7), Projector (4), sprinkler head (5), adjustable support (3), fabric (8), frame (9); rotary encoder (11) fixed on the drum reads the position of fabric movement and controls The speed of the pattern movement of the projector; the action of the sprinkler head is controlled by the controller, the UV algorithm refers to the image transition method of the projector, and the same picture or a designed continuous image is cyclically played on the projector, The entire image is connected end to end to form a complete pattern, the moving speed of the fabric is 5 meters per minute, and the irradiation time is guaranteed to be 10 seconds.

[0023] Circulation method: the size of the design pattern is exactly the full screen of the proje...

Embodiment 2

[0025] A UV resin printing projection irradiation device and an algorithm are provided, the device includes a set of units for projecting and producing monochrome printed fabrics; the device includes one or more sets of PC (2), controller (1), cylinder (7), Projector (4), sprinkler head (5), adjustable support (3), fabric (8), frame (9); rotary encoder (11) fixed on the drum reads the position of fabric movement and controls The speed of the pattern movement of the projector; the action of the sprinkler head is controlled by the controller, the UV algorithm refers to the image transition method of the projector, and the same picture or a designed continuous image is cyclically played on the projector, The entire image is connected end to end to form a complete pattern, the moving speed of the fabric is 5 meters per minute, and the irradiation time is guaranteed to be 10 seconds.

[0026] Splicing method: When the size of a pattern is smaller than the projected area, multiple i...

Embodiment 3

[0028] A UV resin printing projection irradiation device and an algorithm are provided, the device includes a set of units for projecting and producing monochrome printed fabrics; the device includes one or more sets of PC (2), controller (1), cylinder (7), Projector (4), sprinkler head (5), adjustable support (3), fabric (8), frame (9); rotary encoder (11) fixed on the drum reads the position of fabric movement and controls The speed of the pattern movement of the projector; the action of the sprinkler head is controlled by the controller, the UV algorithm refers to the image transition method of the projector, and the same picture or a designed continuous image is cyclically played on the projector, The entire image is connected end to end to form a complete pattern, the moving speed of the fabric is 5 meters per minute, and the irradiation time is guaranteed to be 10 seconds.

[0029] Judging method: When the size of a pattern is larger than the projected area, the images a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com