Patents

Literature

335results about How to "Easy to suture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

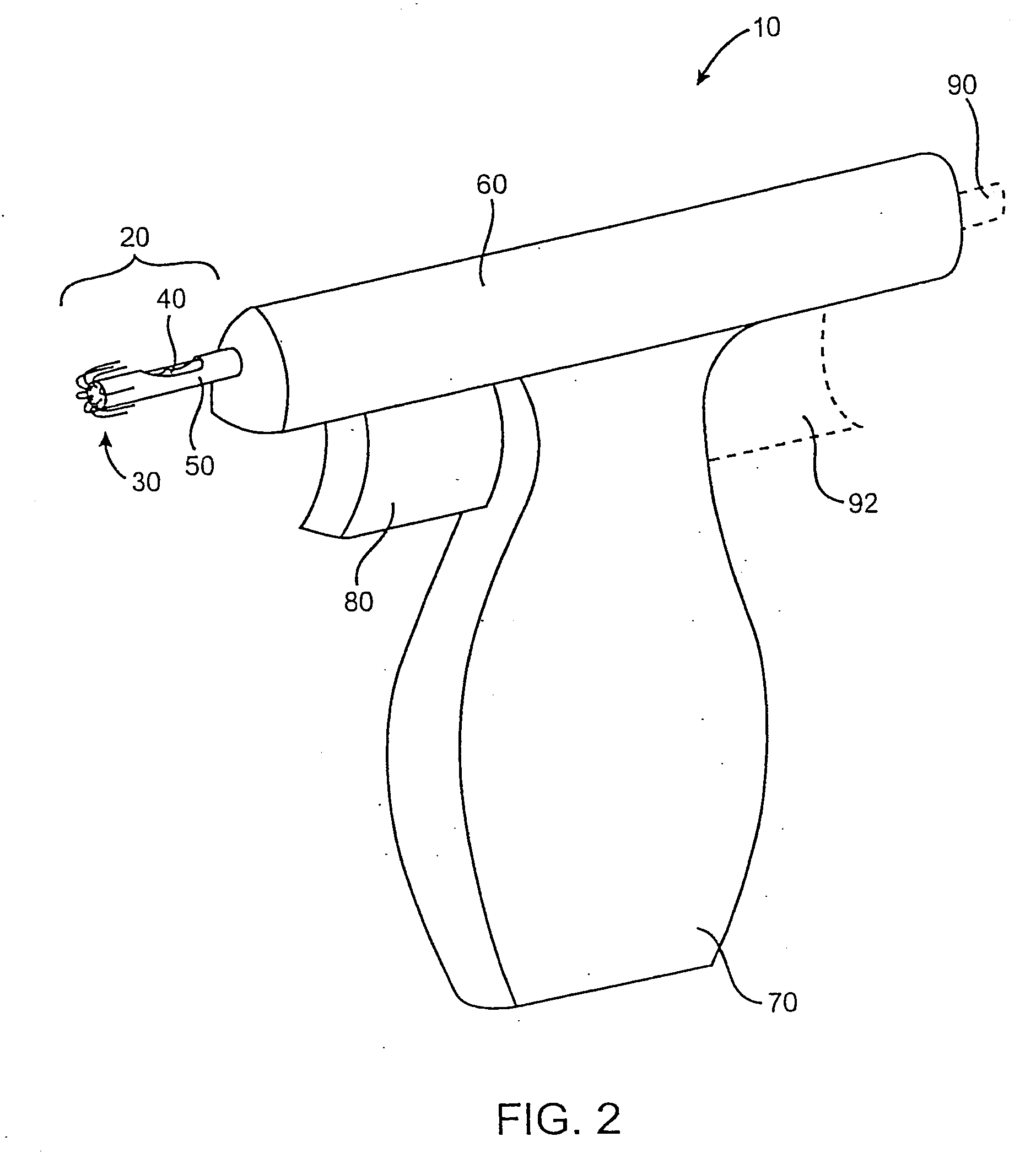

Device and method for performing end-to-side anastomosis

InactiveUS7048747B2Simplify deliveryReduce amount of timeSuture equipmentsSurgical needlesEnd to side anastomosisBiomedical engineering

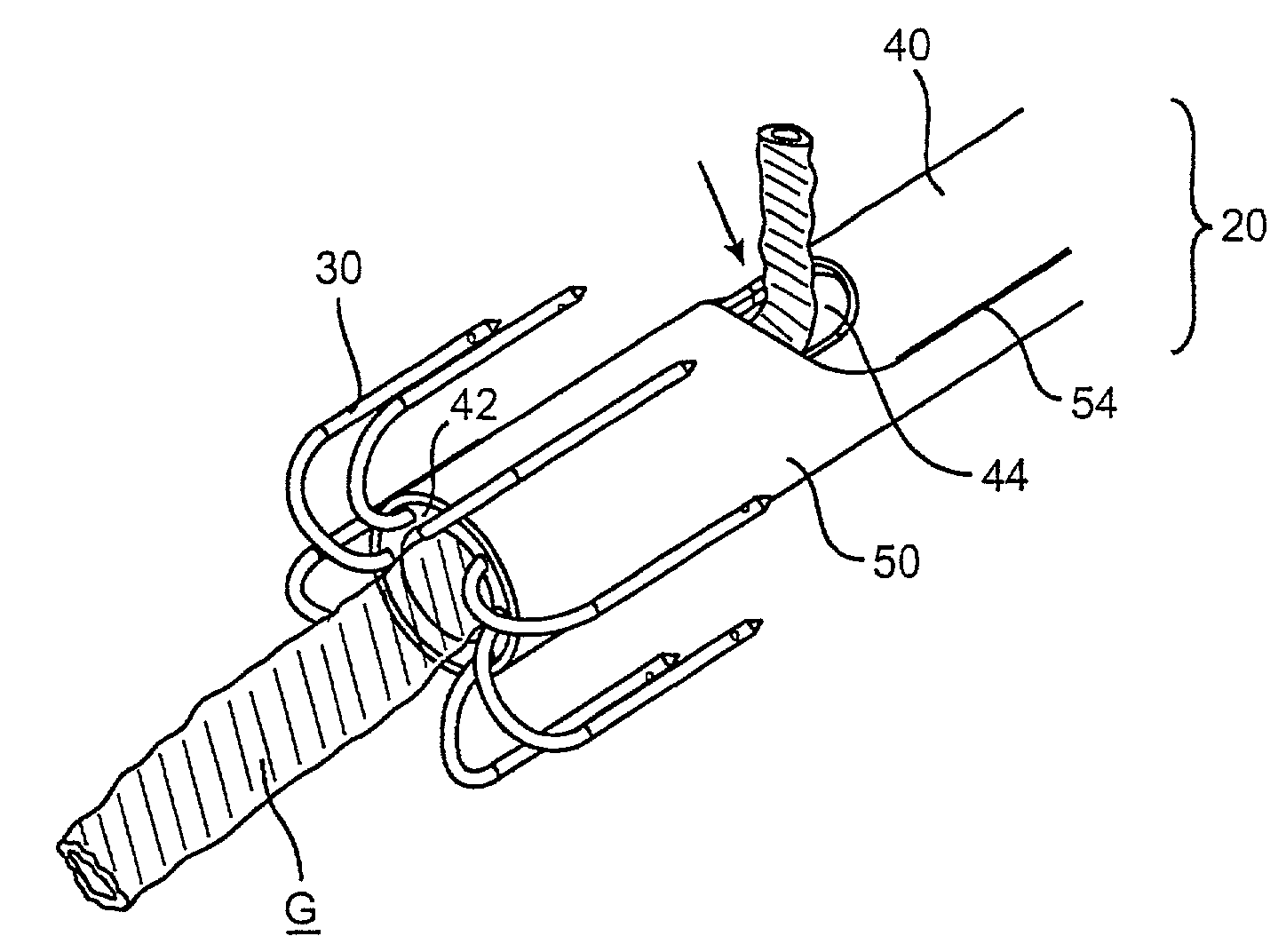

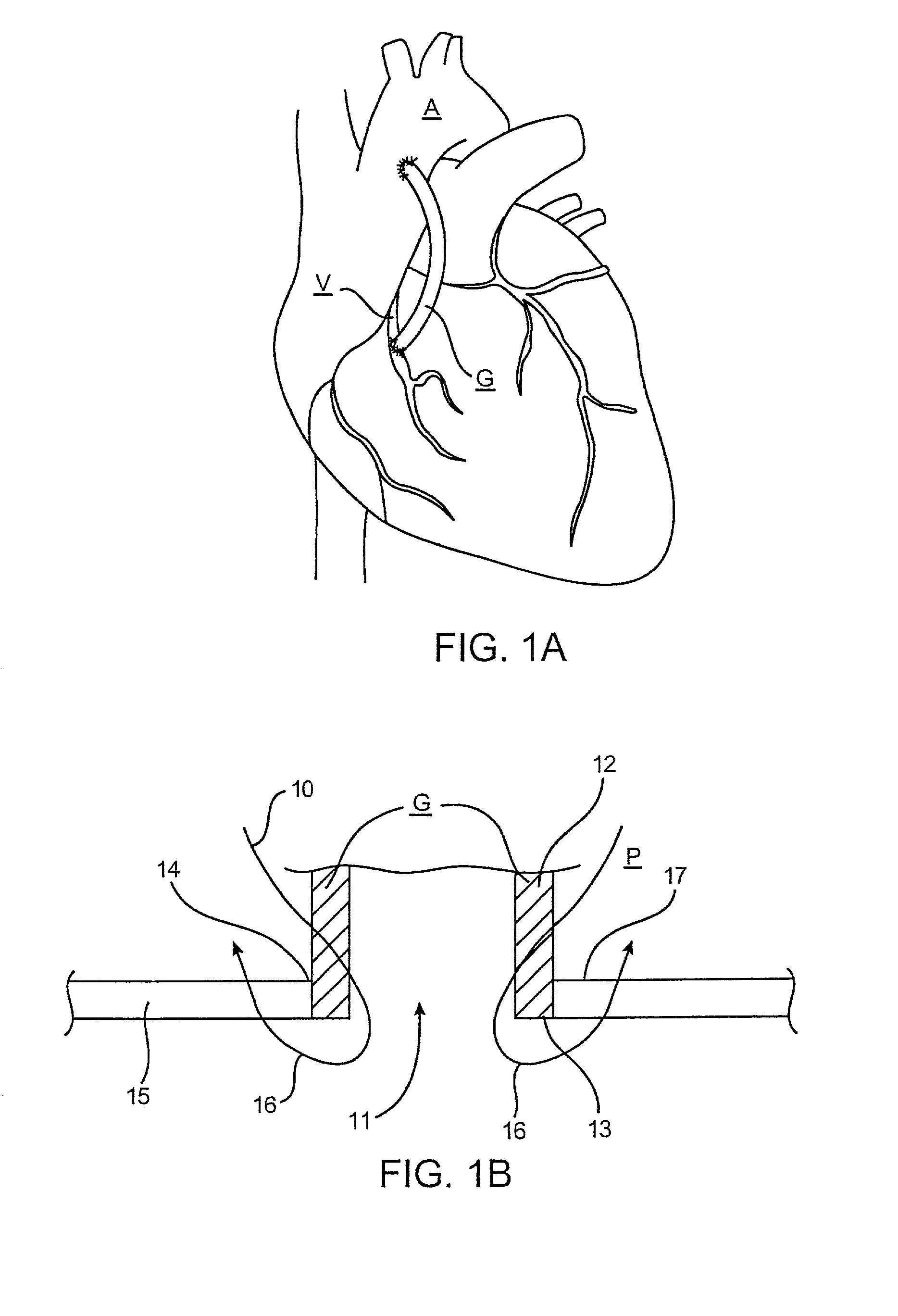

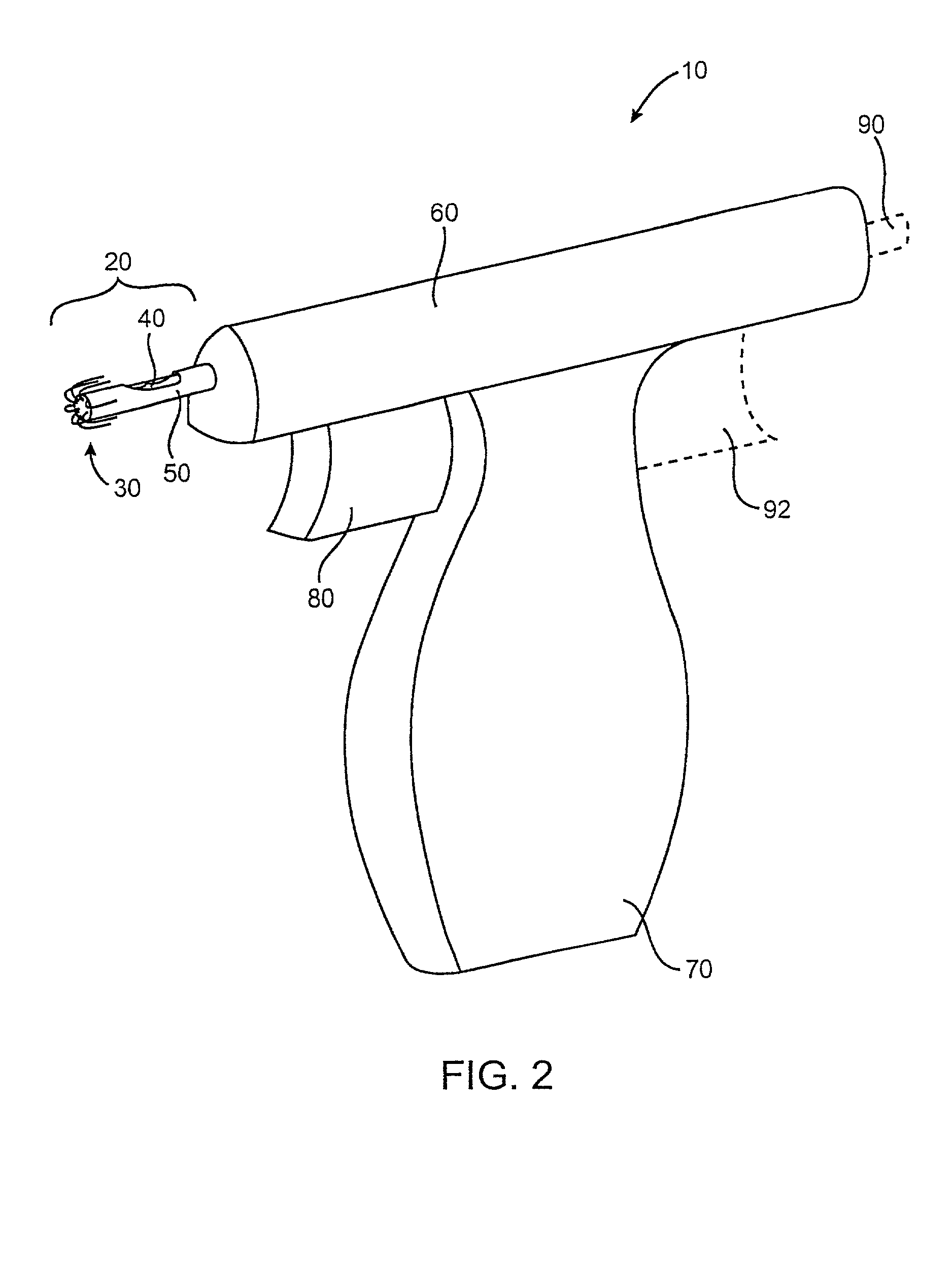

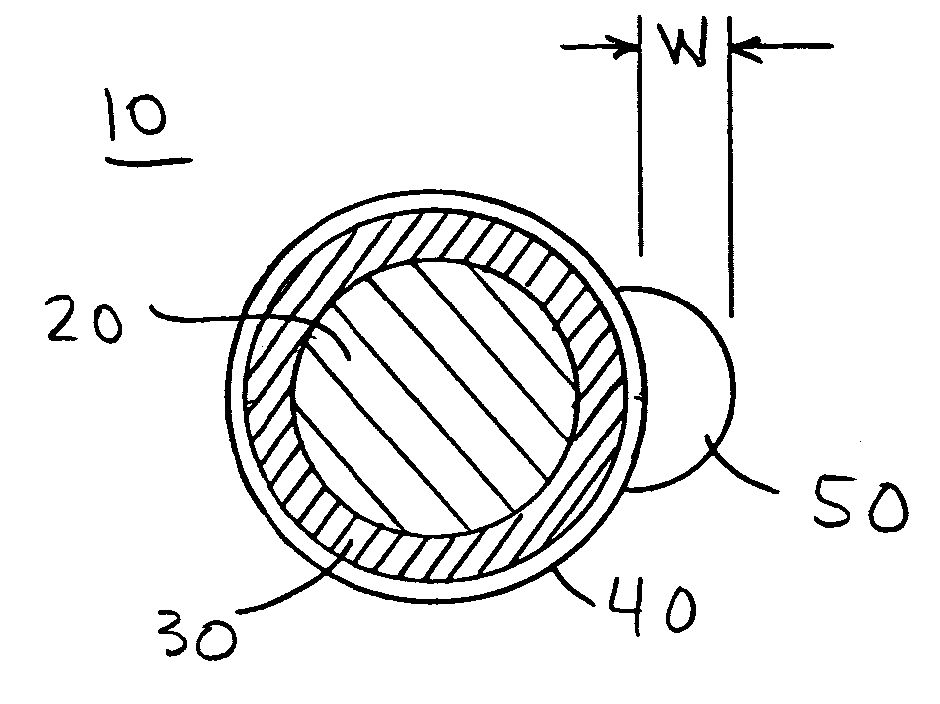

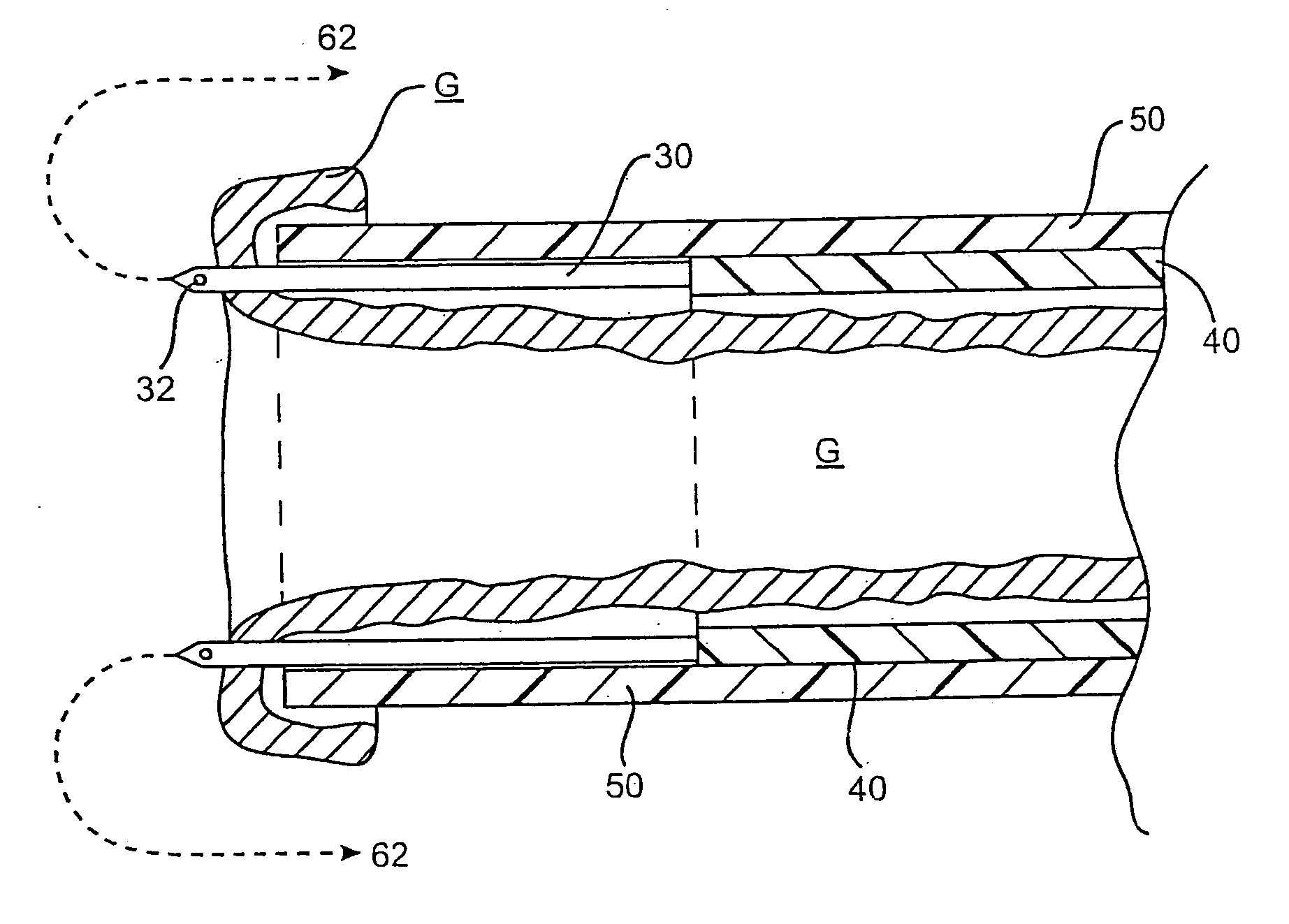

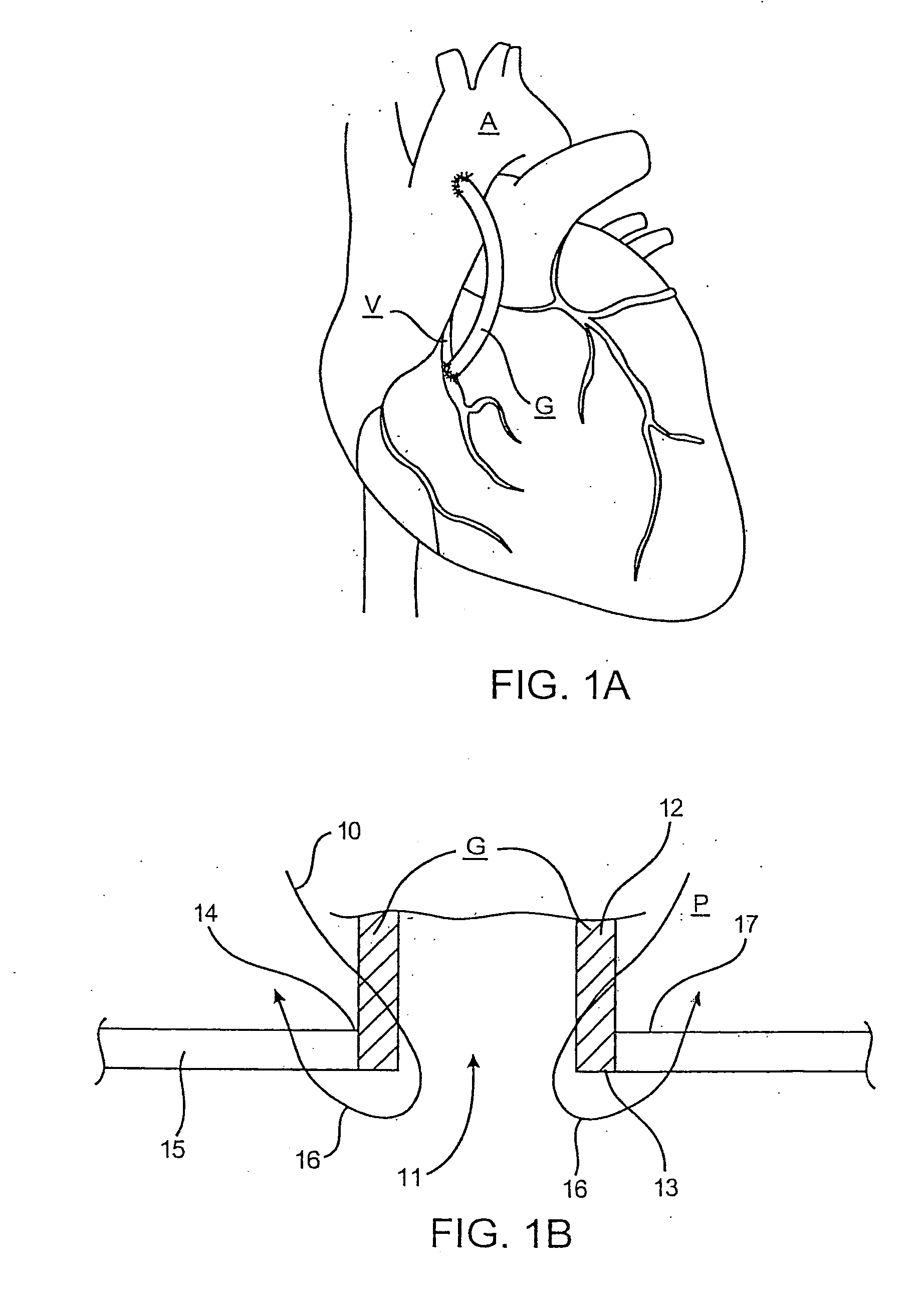

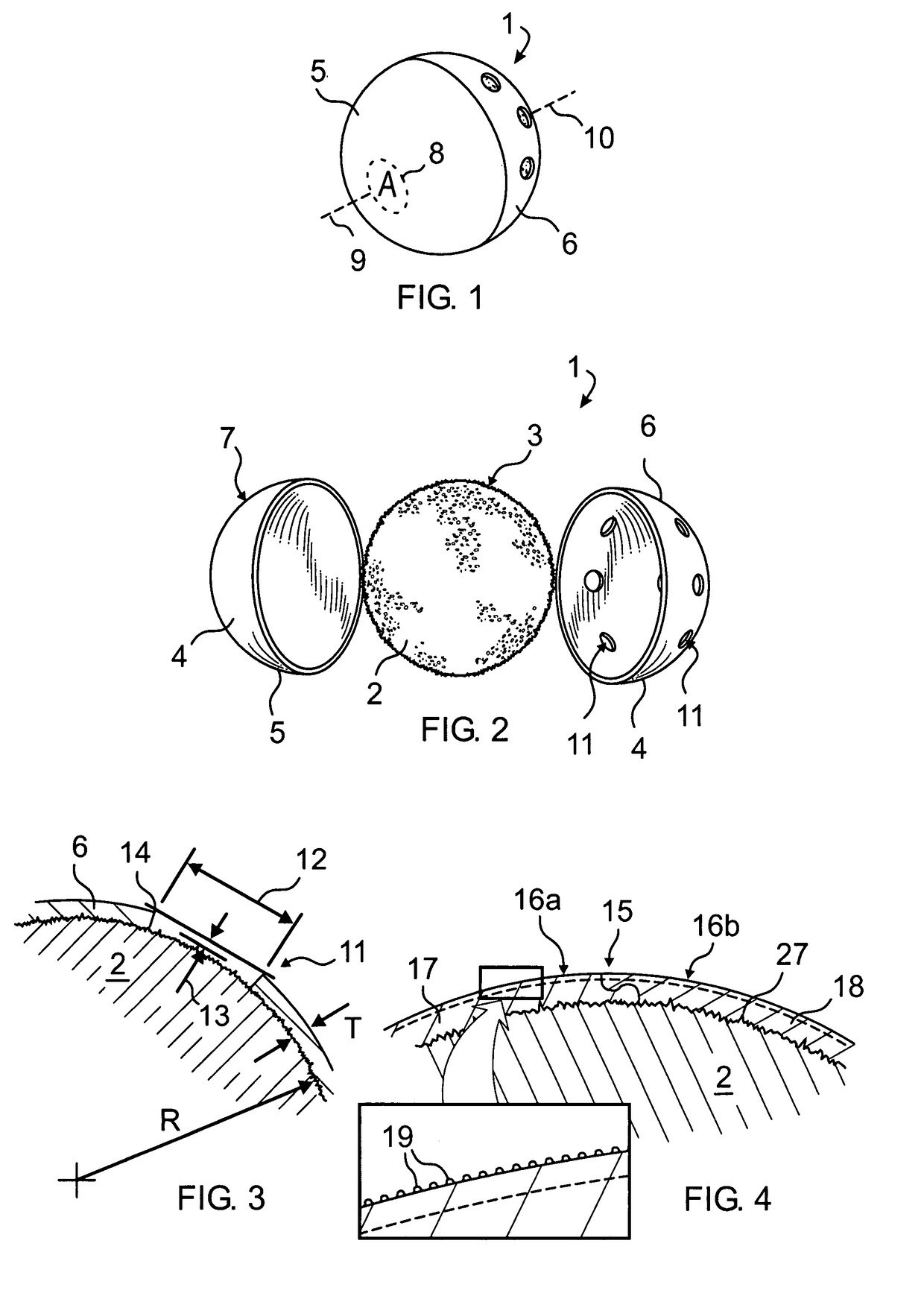

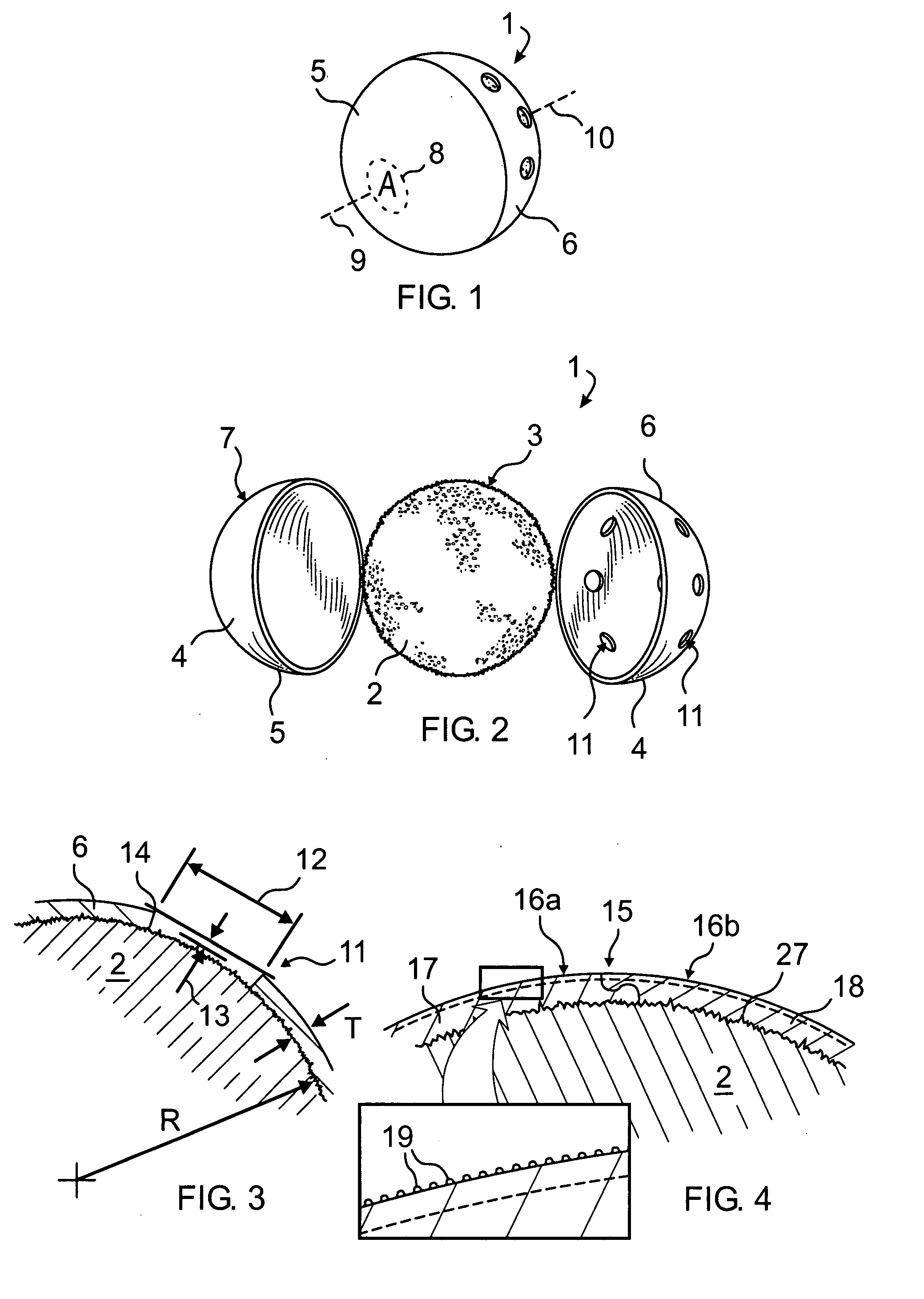

Devices, methods, and kits are provided for suturing an end of a first body duct to a hole in the side of a second body duct. The present devices and methods are used to simplify the suturing procedure and thus reduce operating time. In one embodiment, the present device includes a structure for holding the end of the first body duct and positioning the end adjacent to the hole in the side of the second body duct. The structure of the device is typically a shaft having a surface adapted to receive the first body duct. A plurality of needles are arranged on the structure to be advanced along a plurality of paths. Each needle path first passes radially into and forwardly out of the end of the first body duct and into the hole of the second body duct. The path then everts so that the needles and associated sutures will pass outwardly through tissue peripheral to the hole when the end of the first body duct is on the structure adjacent to the hole in the second body duct. The needles preferably travel along such paths when they are advanced forward. In one embodiment, the device uses a J-shaped tube for guiding one of the needles along the desired path. In another embodiment, shape-memory needles having an arcuate profile are used to create the desired path.

Owner:ABBOTT LAB INC

Heart valve annuloplasty prosthesis sewing cuffs and methods of making same

An annuloplasty prosthesis for a heart valve has a sewing cuff added to the conventional structure. The sewing cuff is preferably an extension of the fabric cover that is provided around the core of the prosthesis. The sewing cuff preferably extends radially outwardly from cross sections of the remainder of the prosthesis. Methods of making such a sewing cuff are also disclosed.

Owner:ST JUDE MEDICAL LLC

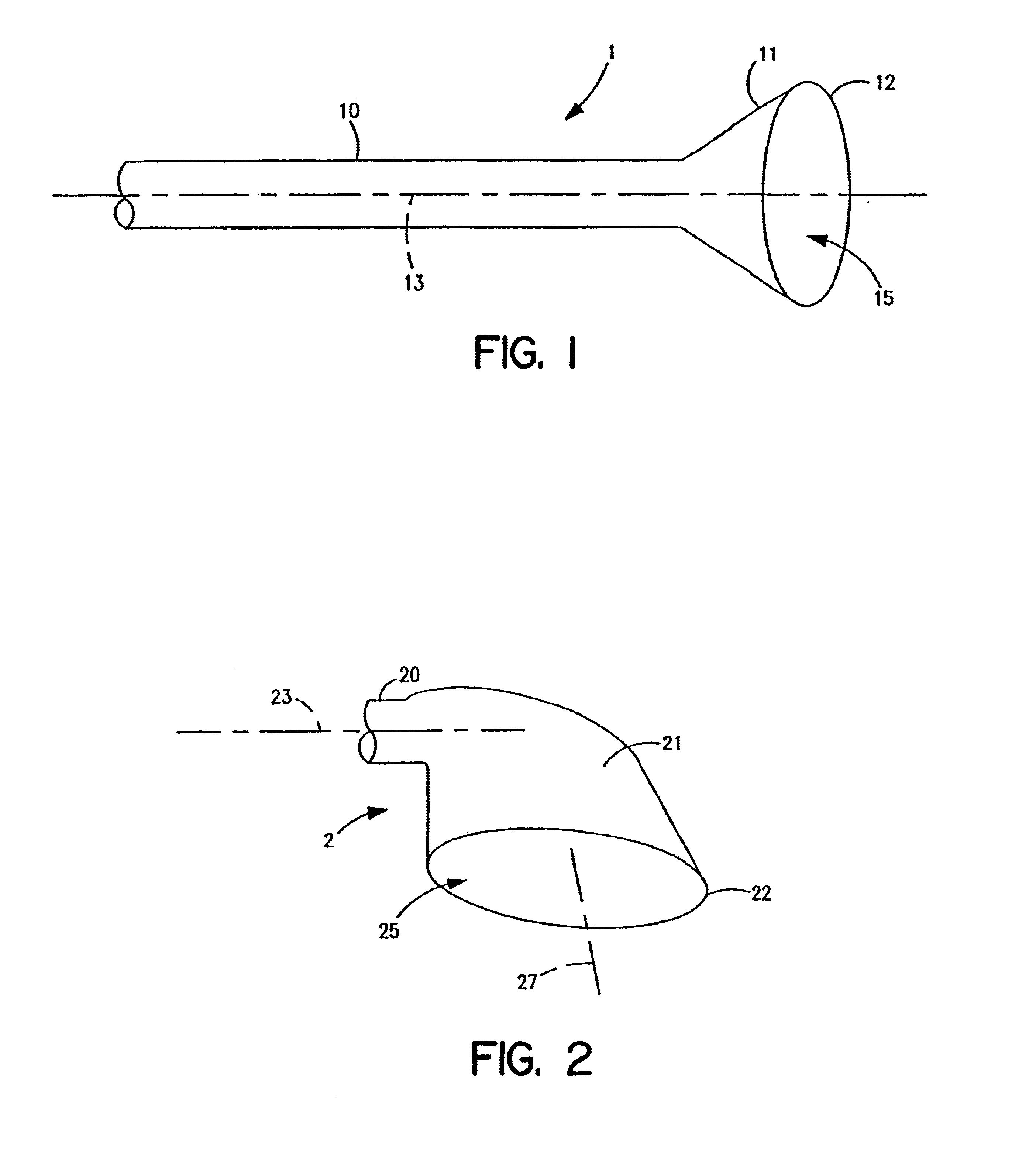

Device and method for performing end-to-side anastomosis

InactiveUS20060167477A1Simplifies suture deliveryAmount of timeSuture equipmentsSurgical needlesEnd to side anastomosisCatheter

Devices, methods, and kits are provided for suturing an end of a first body duct to a hole in the side of a second body duct. The present devices and methods are used to simplify the suturing procedure and thus reduce operating time. In one embodiment, the present device includes a structure for holding the end of the first body duct and positioning the end adjacent to the hole in the side of the second body duct. The structure of the device is typically a shaft having a surface adapted to receive the first body duct. A plurality of needles are arranged on the structure to be advanced along a plurality of paths. Each needle path first passes radially into and forwardly out of the end of the first body duct and into the hole of the second body duct. The path then everts so that the needles and associated sutures will pass outwardly through tissue peripheral to the hole when the end of the first body duct is on the structure adjacent to the hole in the second body duct. The needles preferably travel along such paths when they are advanced forward. In one embodiment, the device uses a J-shaped tube for guiding one of the needles along the desired path. In another embodiment, shape-memory needles having an arcuate profile are used to create the desired path.

Owner:ARCIA ROVIL P +2

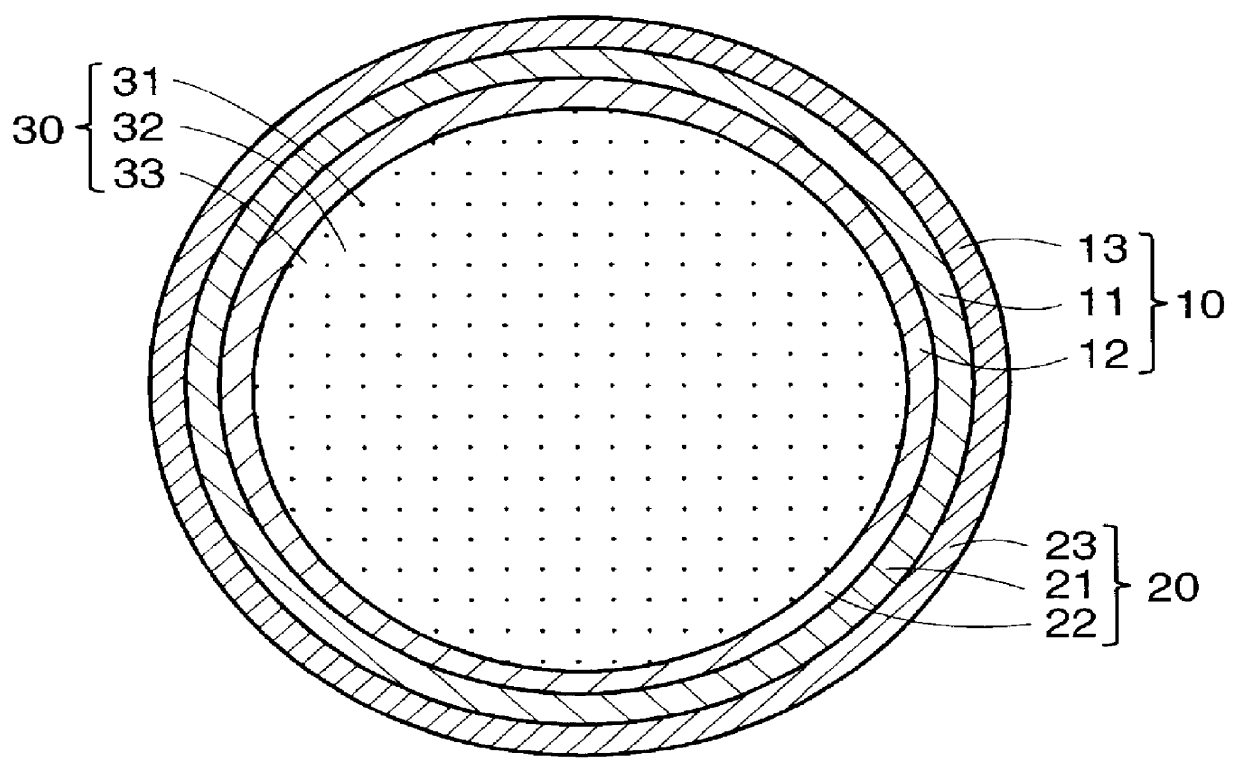

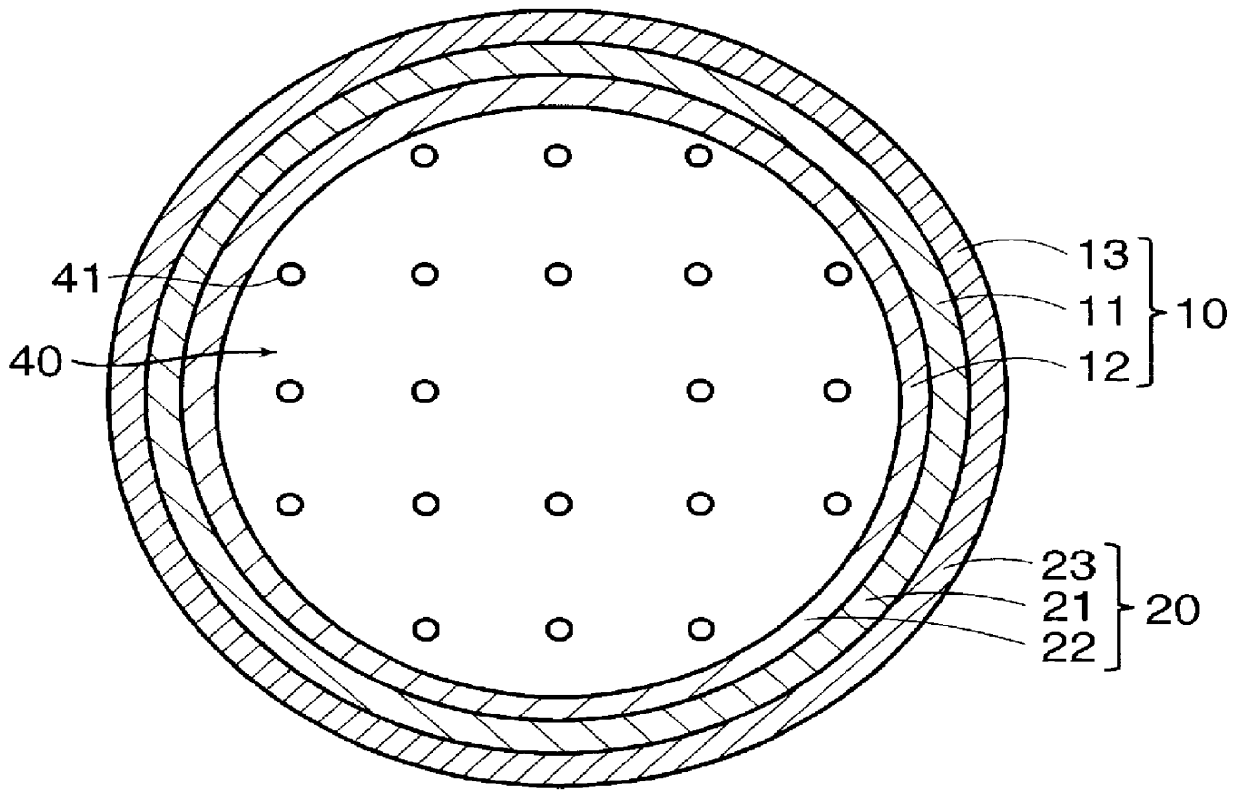

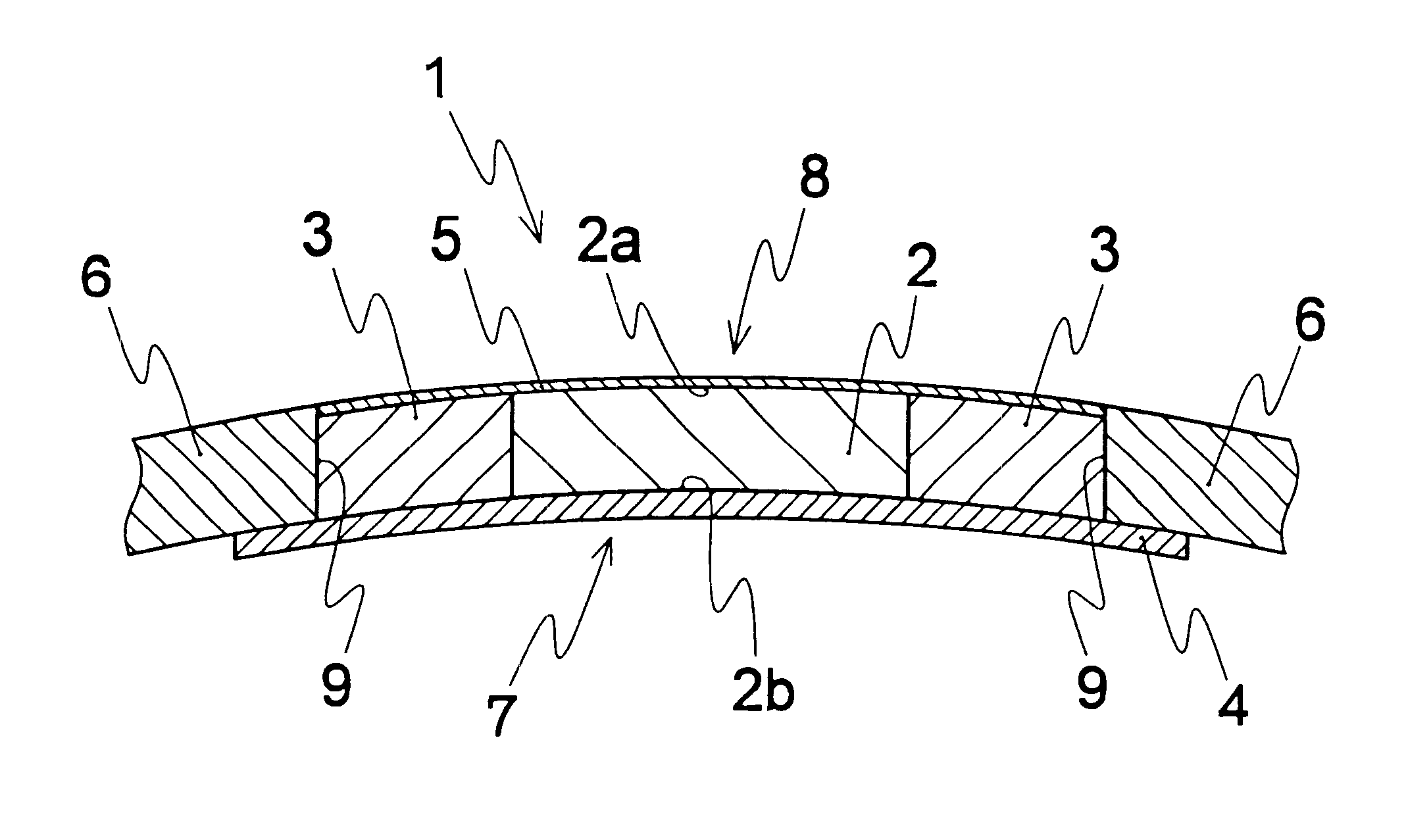

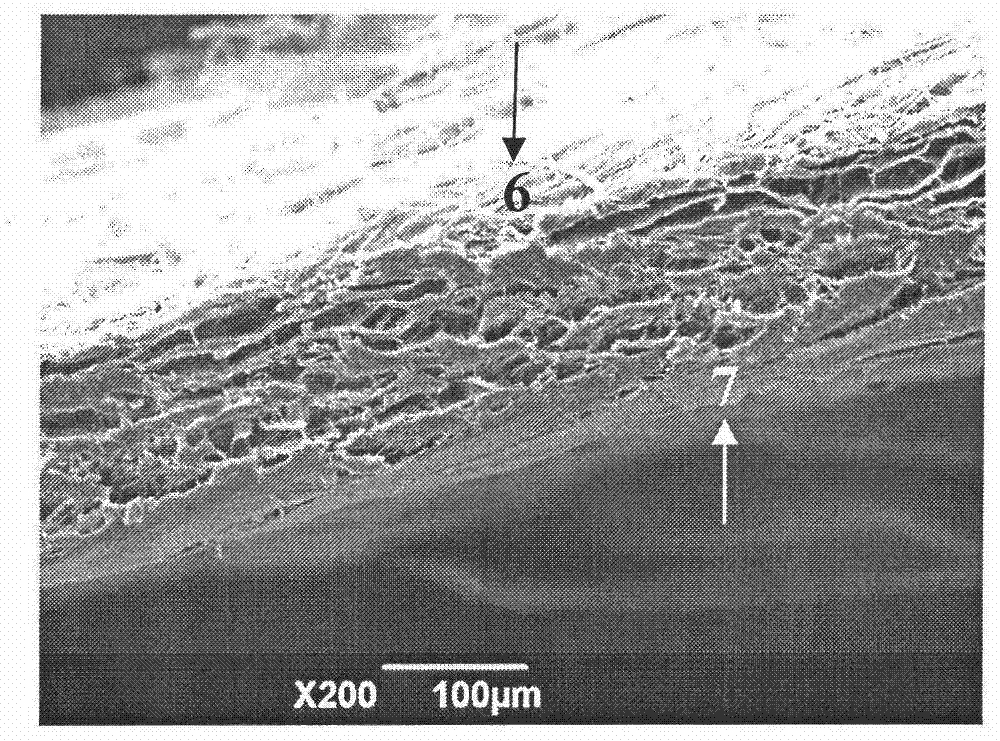

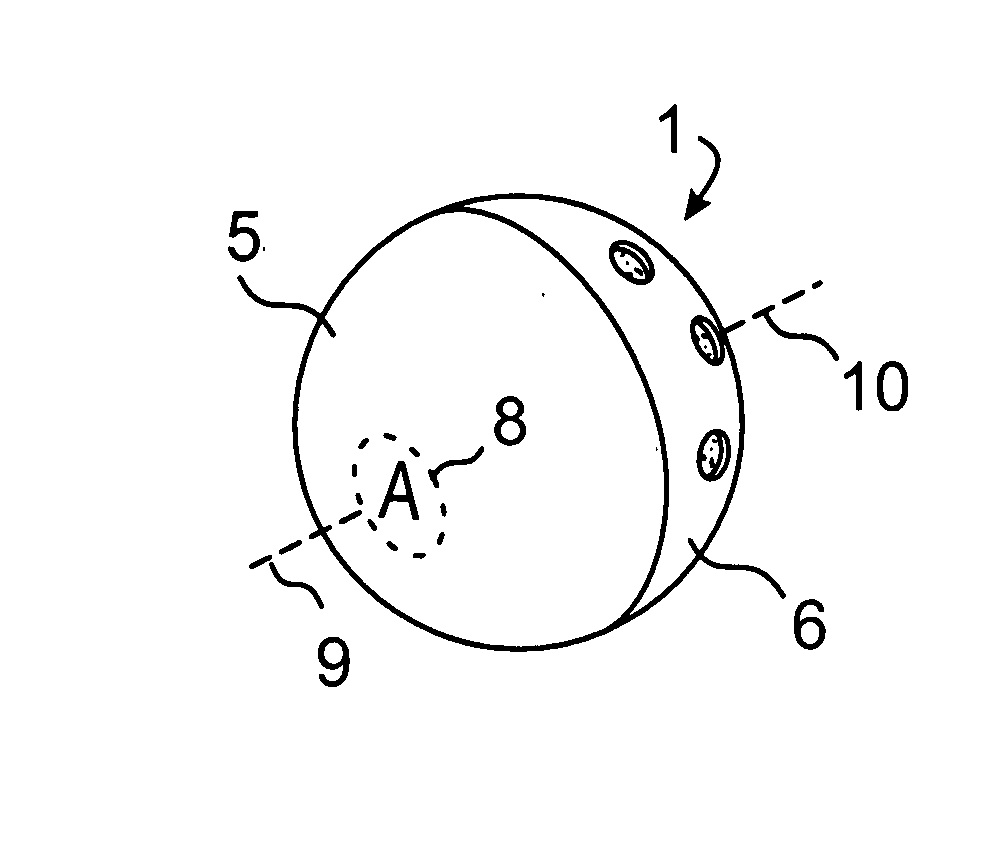

Artificial neural canal

InactiveUS6090117AStay in shapePrevent intrusionTubular organ implantsTissue regenerationMedicineBlood capillary

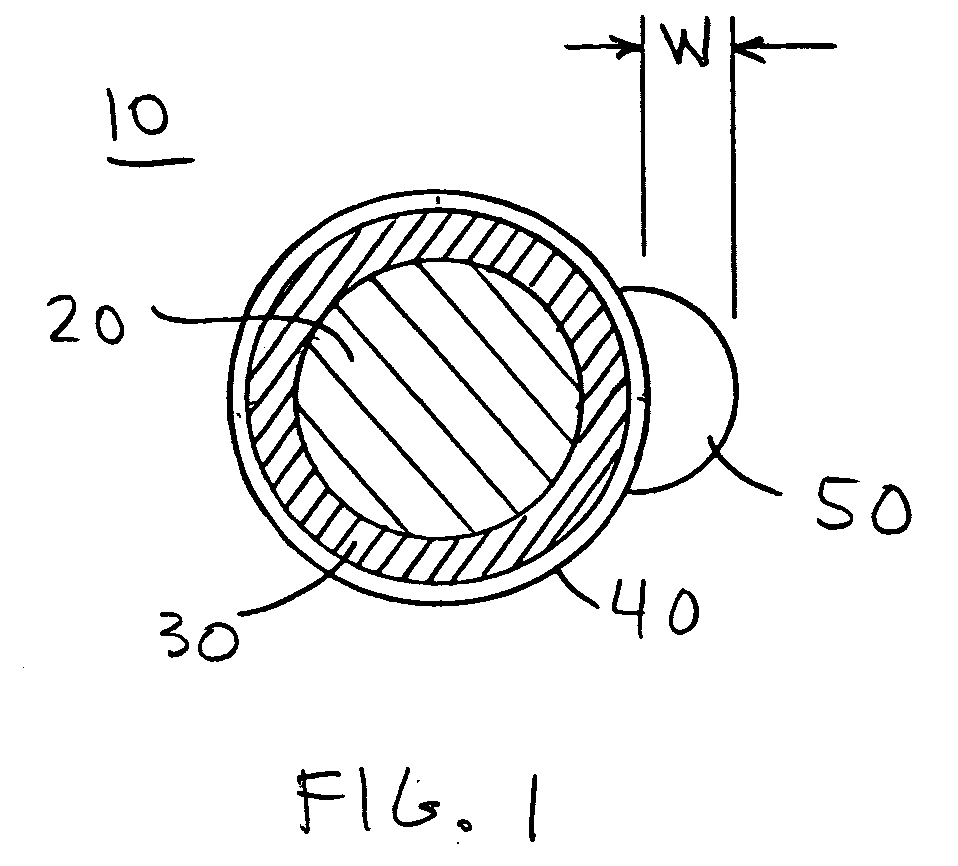

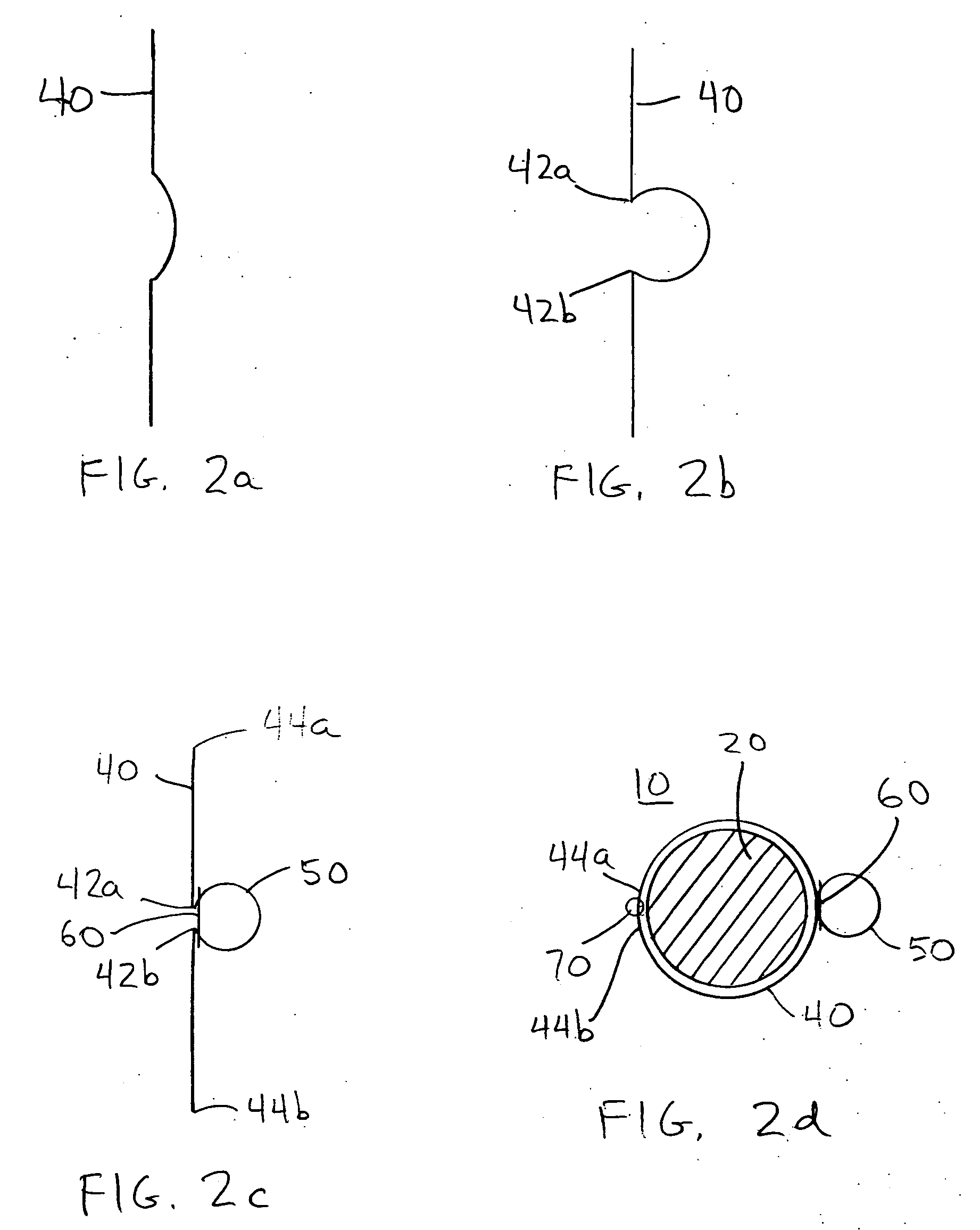

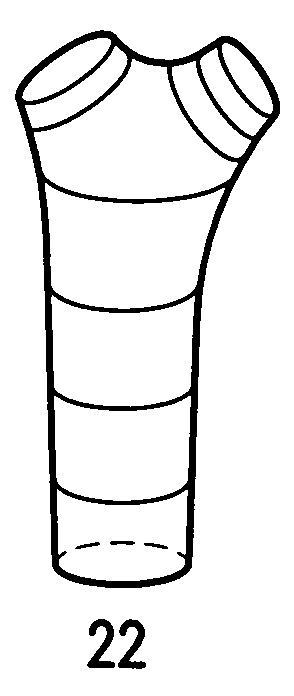

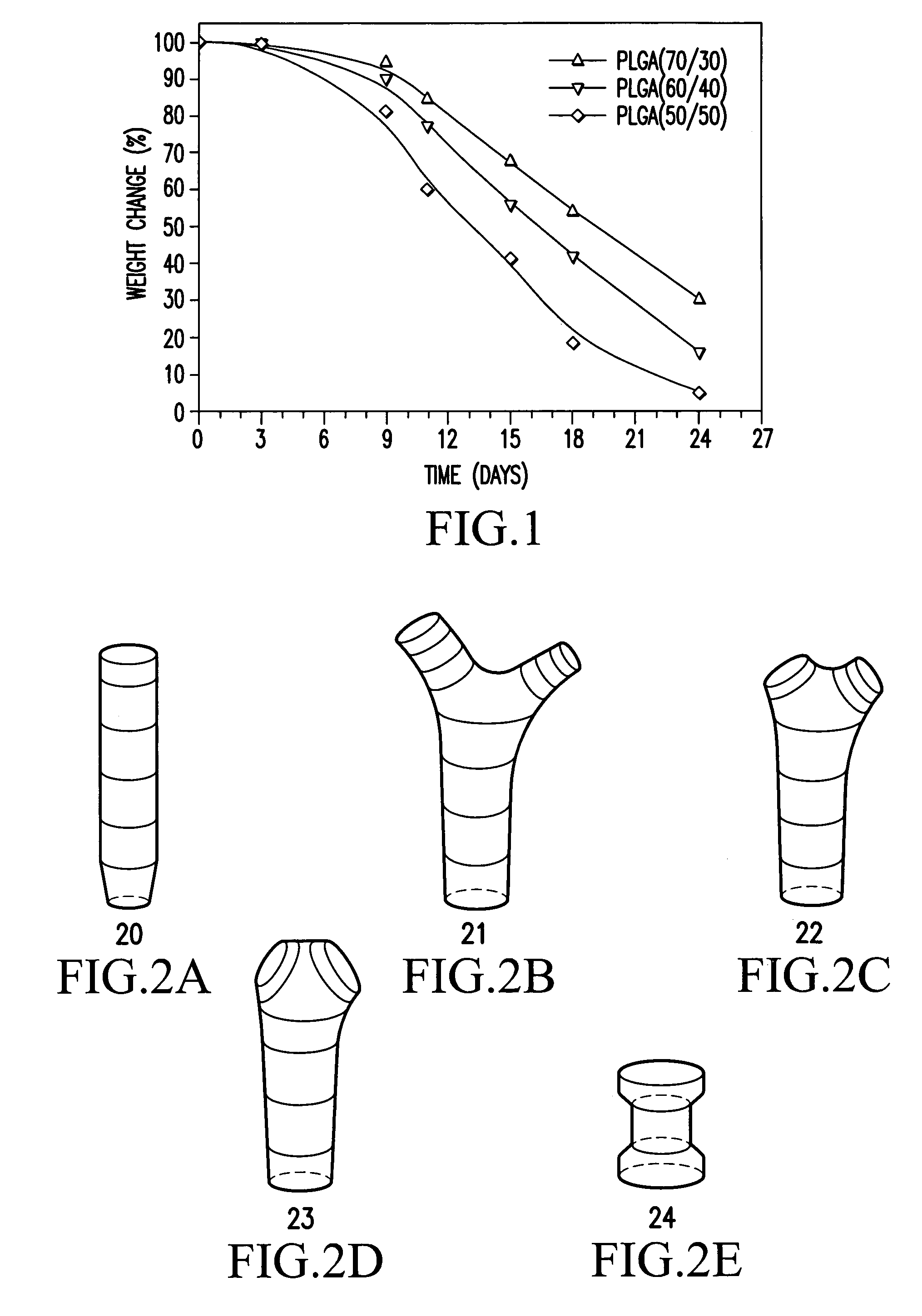

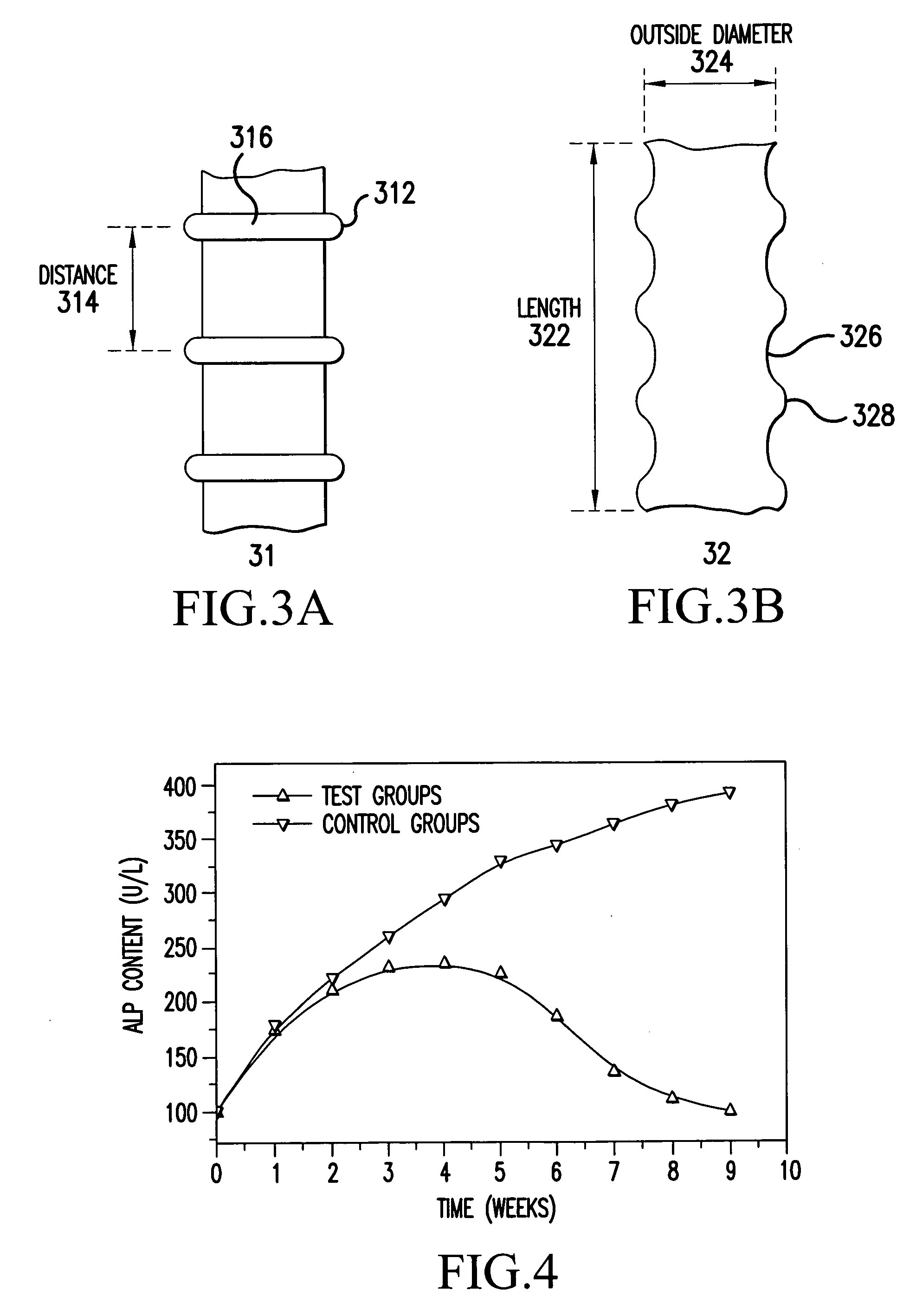

PCT No. PCT / JP97 / 04203 Sec. 371 Date May 20, 1999 Sec. 102(e) Date May 20, 1999 PCT Filed Nov. 19, 1997 PCT Pub. No. WO98 / 22155 PCT Pub. Date May 28, 1998The present invention offers an artificial tube for nerve which can remain in the body until the nerve regenerates while does not remain as a foreign body in the body following nerve regeneration, and which induces axons regenerated from severed nerve stumps, can promote infiltration of blood capillaries from the body and regeneration of nerve tissue. The present invention comprises a tube 10 or 20 having coating layers 12, 13 or 22, 23 composed of gelatin or collagen on the inner and outer surfaces of a tube 11 or 21 composed of a material being biodegradable and absorbable in vivo, and a collagen body 30 or 40 having cavities 32, 33 or 41 which pass through said tube so as to be substantially parallel to the axis of said tube; wherein, said cavities are filled with a matrix gel.

Owner:TAPIC INT

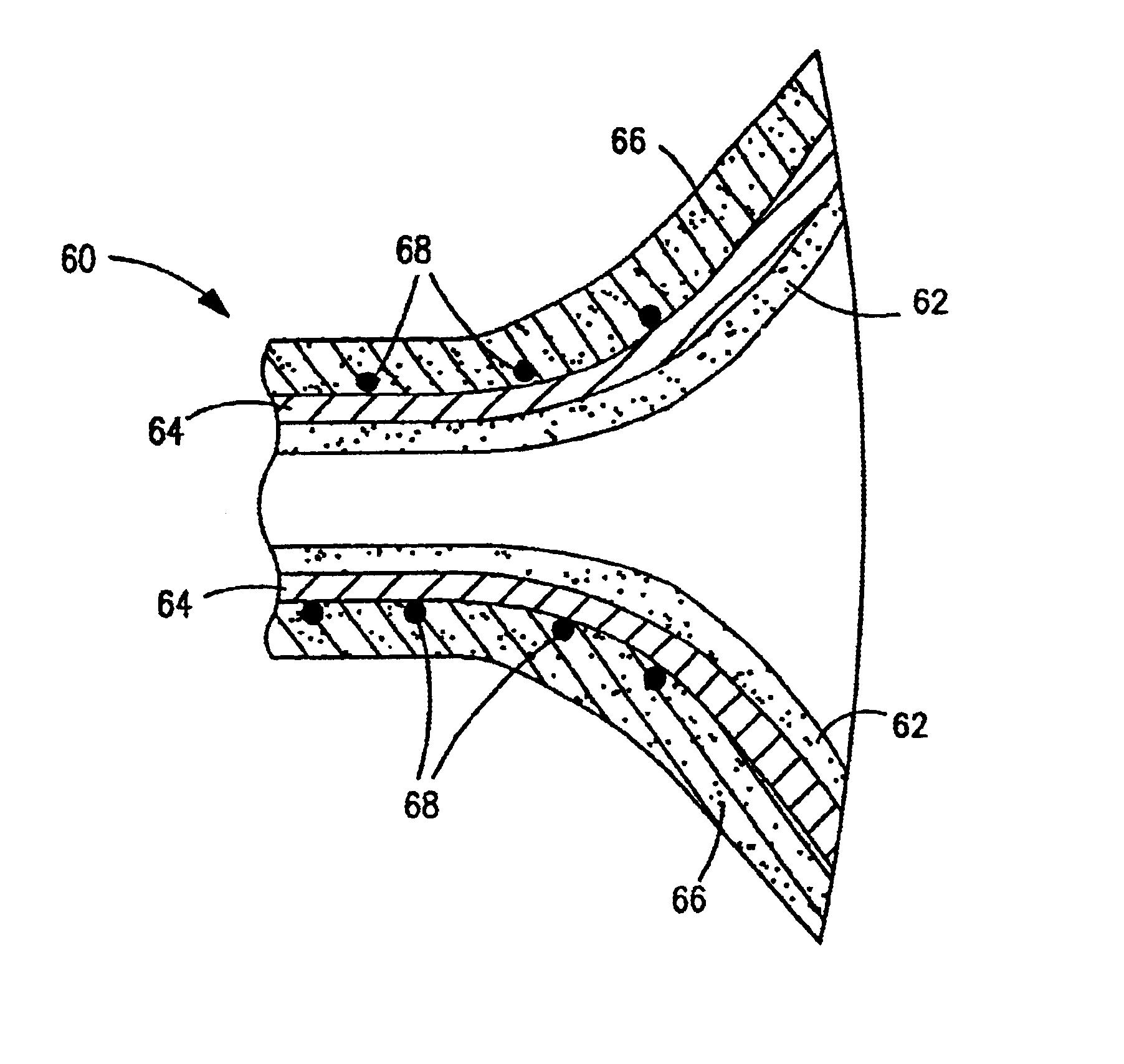

Flared coronary artery bypass grafts

InactiveUS6821295B1Increase resistanceHigh strengthLigamentsMusclesBypass graftsCoronary Artery Bypasses

A bypass graft includes a tubular portion having an internal tubular diameter and a first end and a second end. The tubular portion has a central axis. A flared portion has an adjoining end, wherein the adjoining end of the flared portion is integrally formed on and is substantially concentric with the second end of the tubular portion, and a flared end, wherein the flared end has a flared end internal diameter, such that the internal flared end diameter is greater than the internal tubular diameter. The flared portion includes a circumferential skirt for surgical attachment of the graft to a patient's blood vessel. A method for manufacturing a bypass graft, includes the steps of providing a mandrel having a tubular portion and a flared end with a flared end central axis; forming a layer of polyurethane over the mandrel; drying the layer of polyurethane on the mandrel; forming a skirt edge around the flared end of the mandrel to form an opening at a predetermined angle to the flared end central axis; forming a second edge around the tubular portion of the mandrel, and removing the graft from the mandrel.

Owner:THORATEC CORPORTION

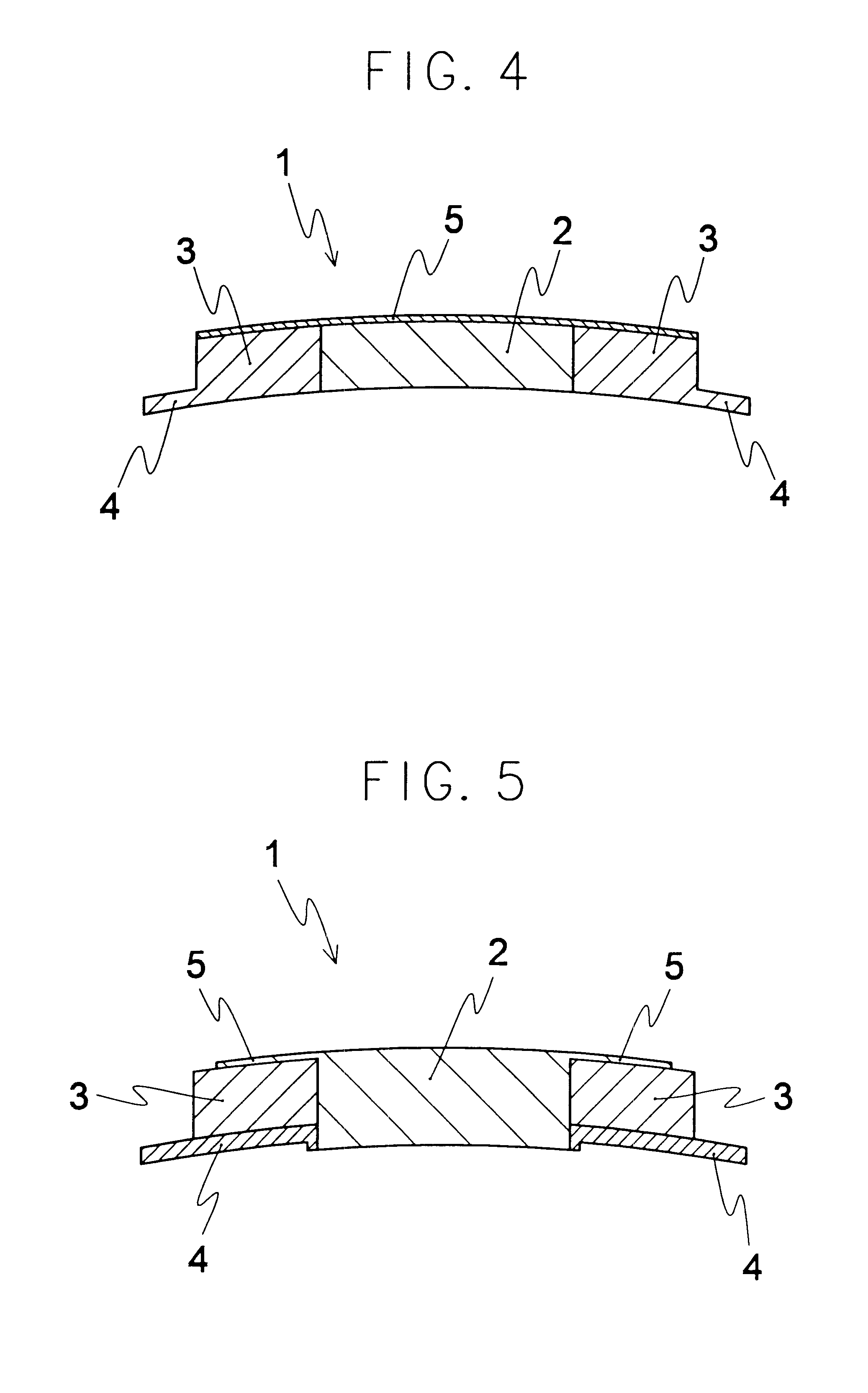

Artificial cornea

An artificial cornea comprising an optical element made of an optically transparent material, having a front surface and a posterior surface, and a skirt provided so as to support with surrounding at least a part of the optical element, characterized in that the skirt is provided with a flange on its side facing the interior of eyes during implantation of the artificial cornea and the flange radially protrudes outward from the skirt. The artificial cornea can be well compatible with ocular tissue, prevent leakage of intraocular aqueous humor and intraocular invasion of bacteria, reduce stimulation on palpebral conjunctiva and further, inhibit progression of the down growth, and which has no possibility of reduction in transparency of the optical element due to the down growth as well as detachment and extrusion from the implanted state.

Owner:MENICON CO LTD

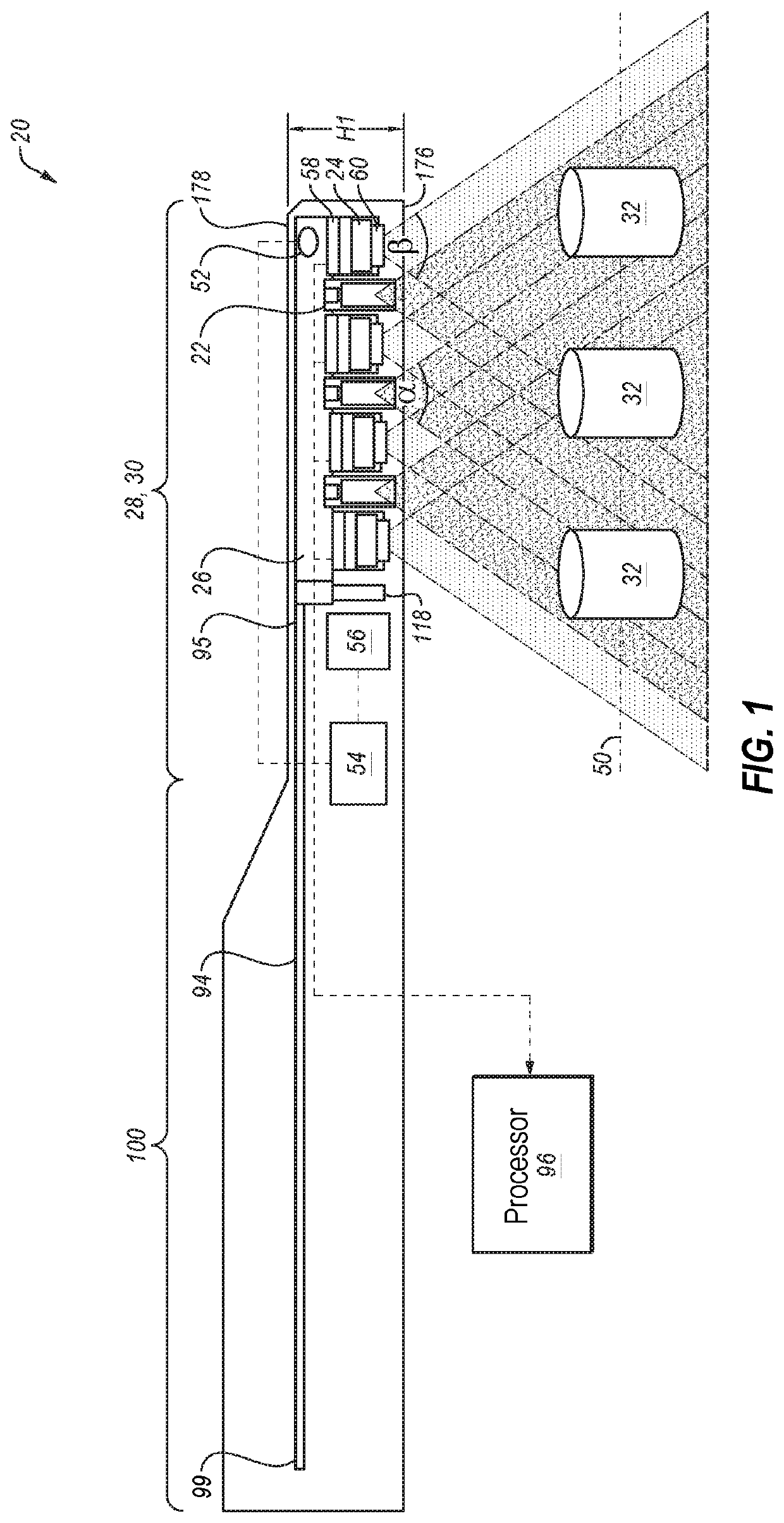

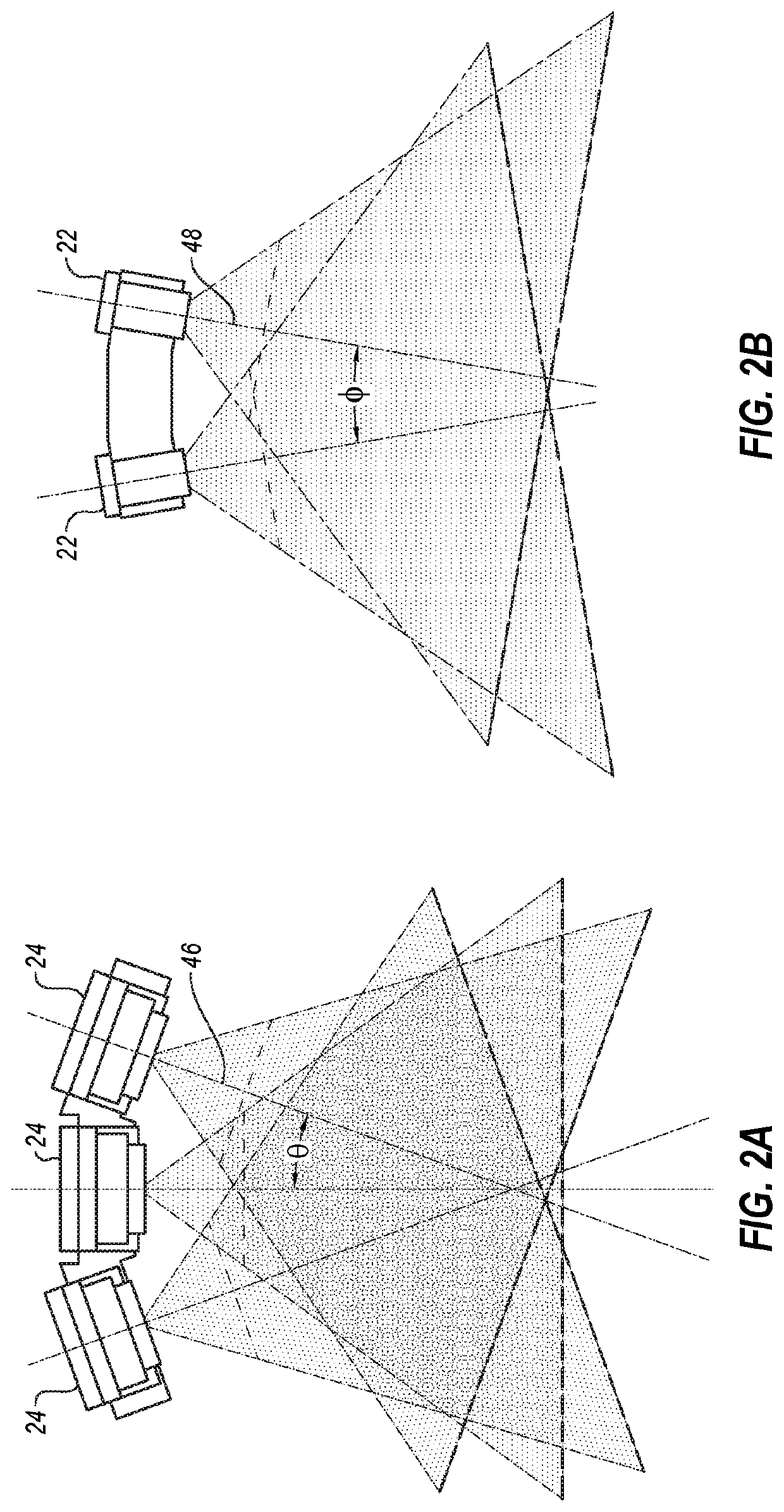

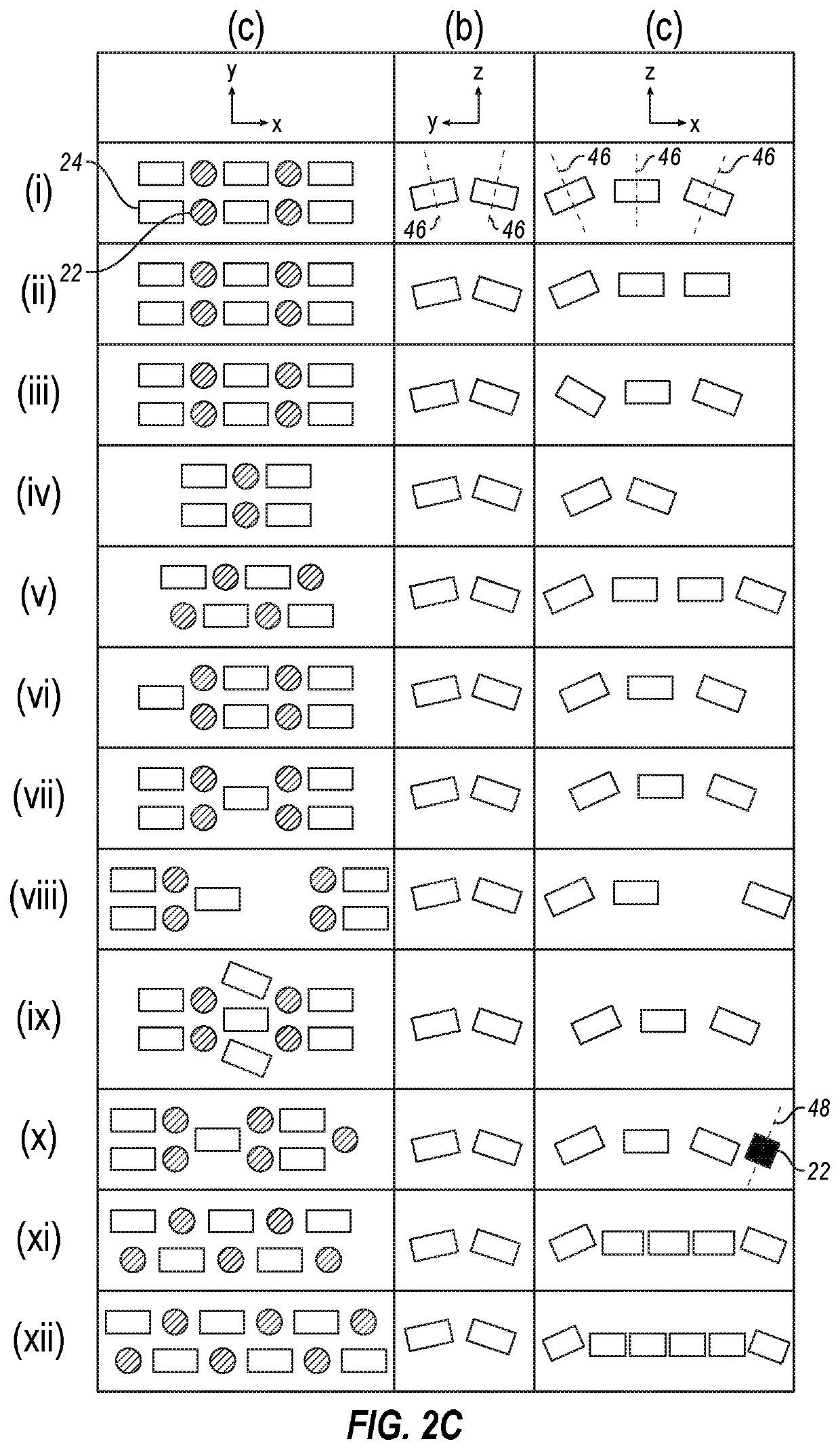

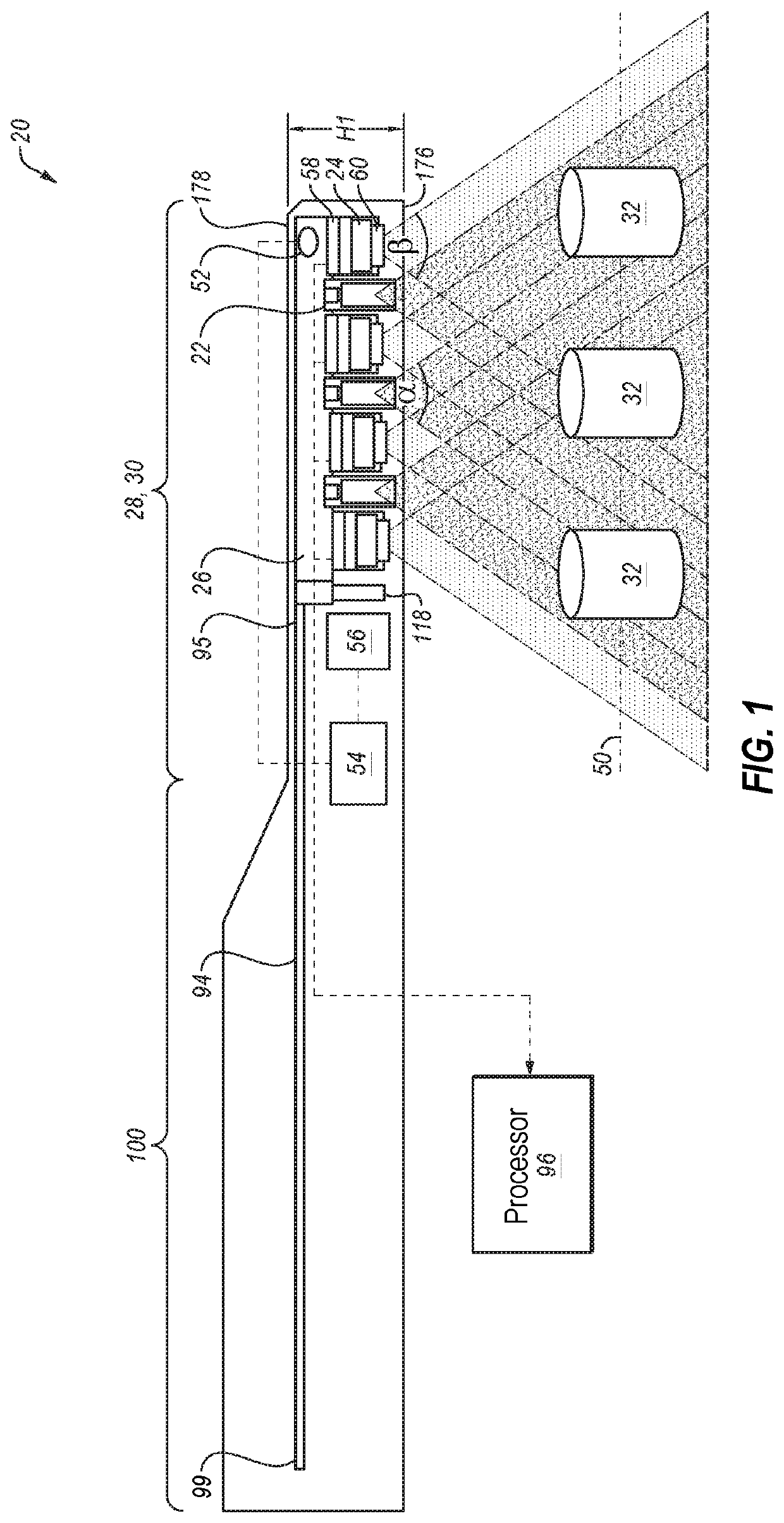

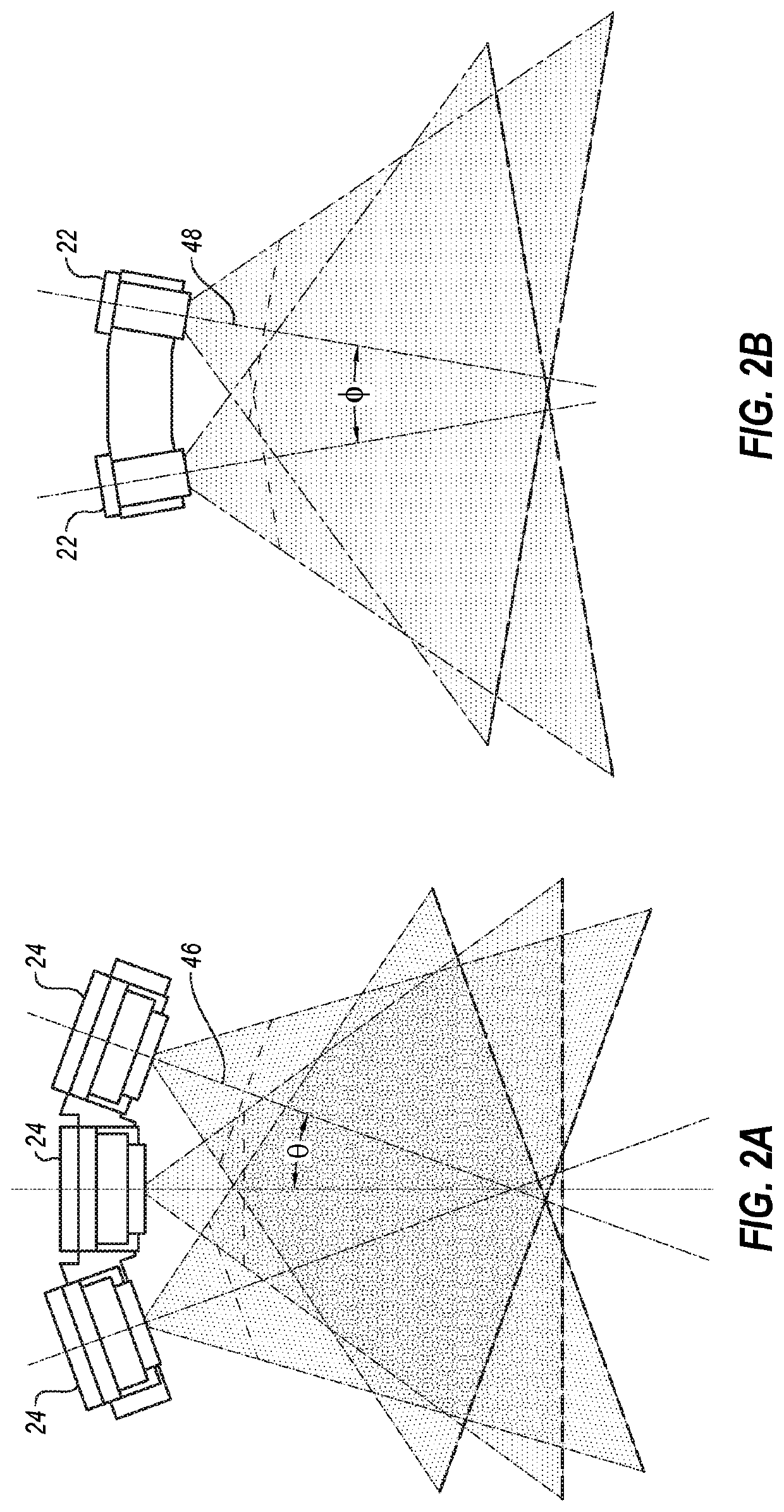

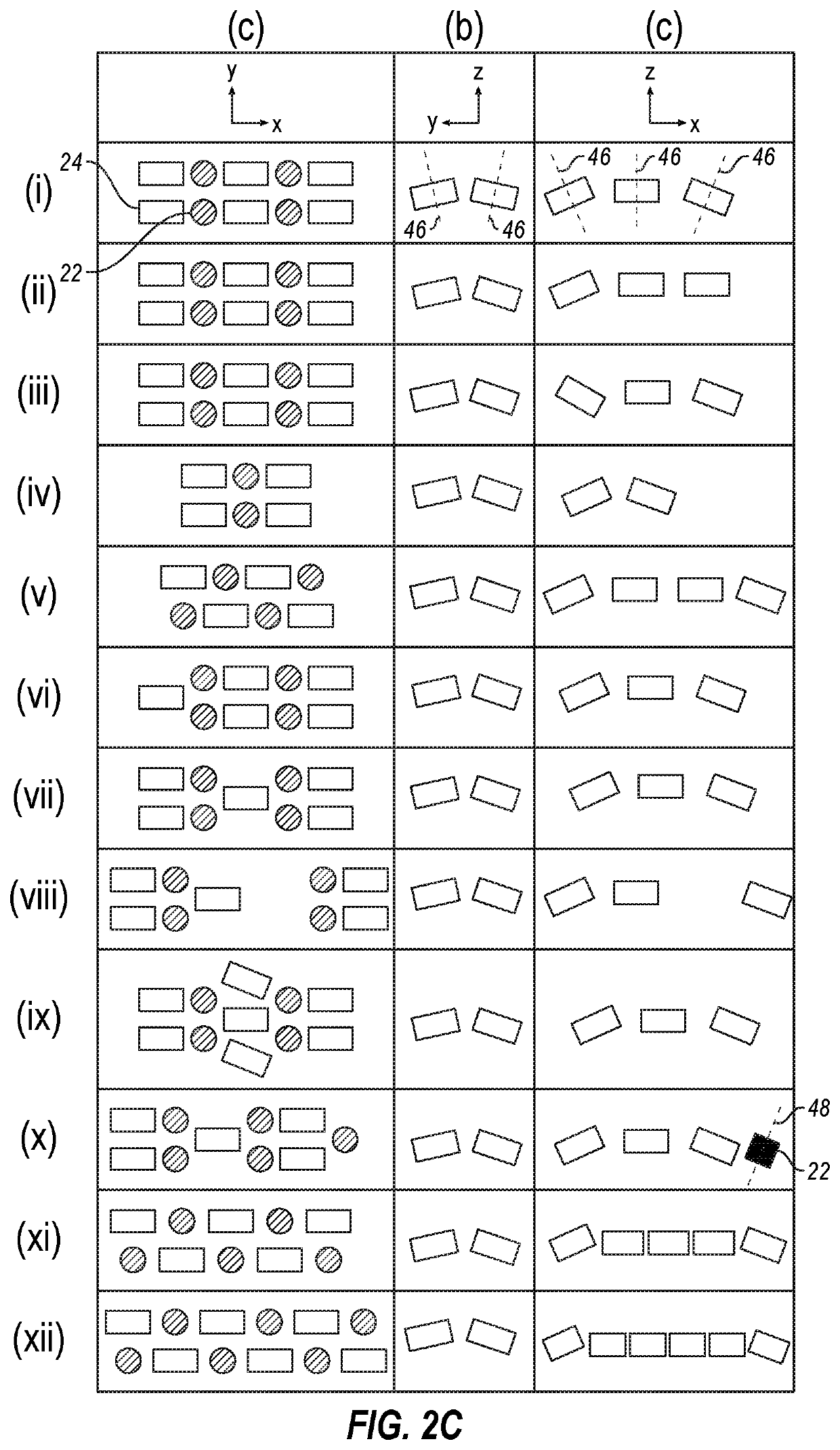

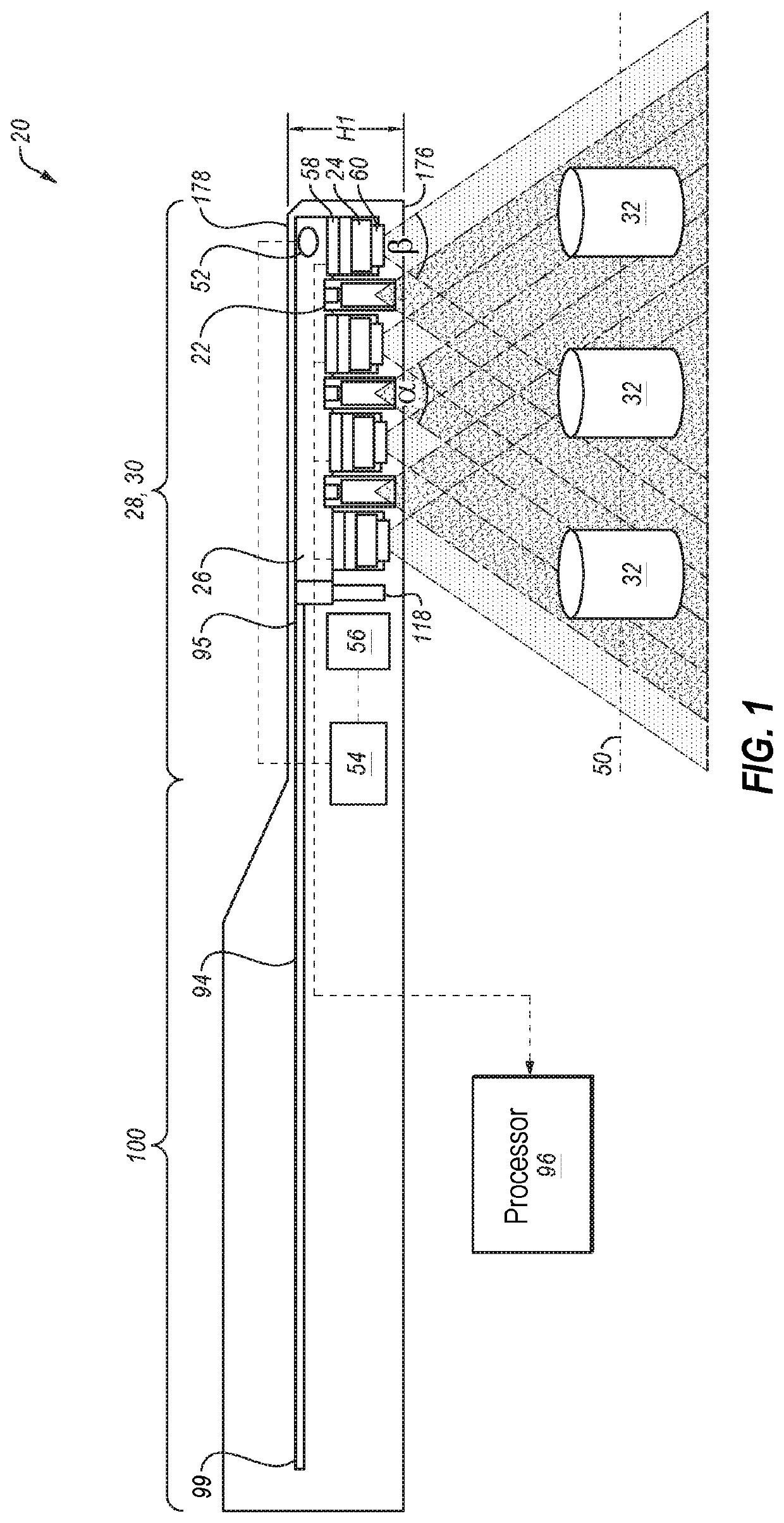

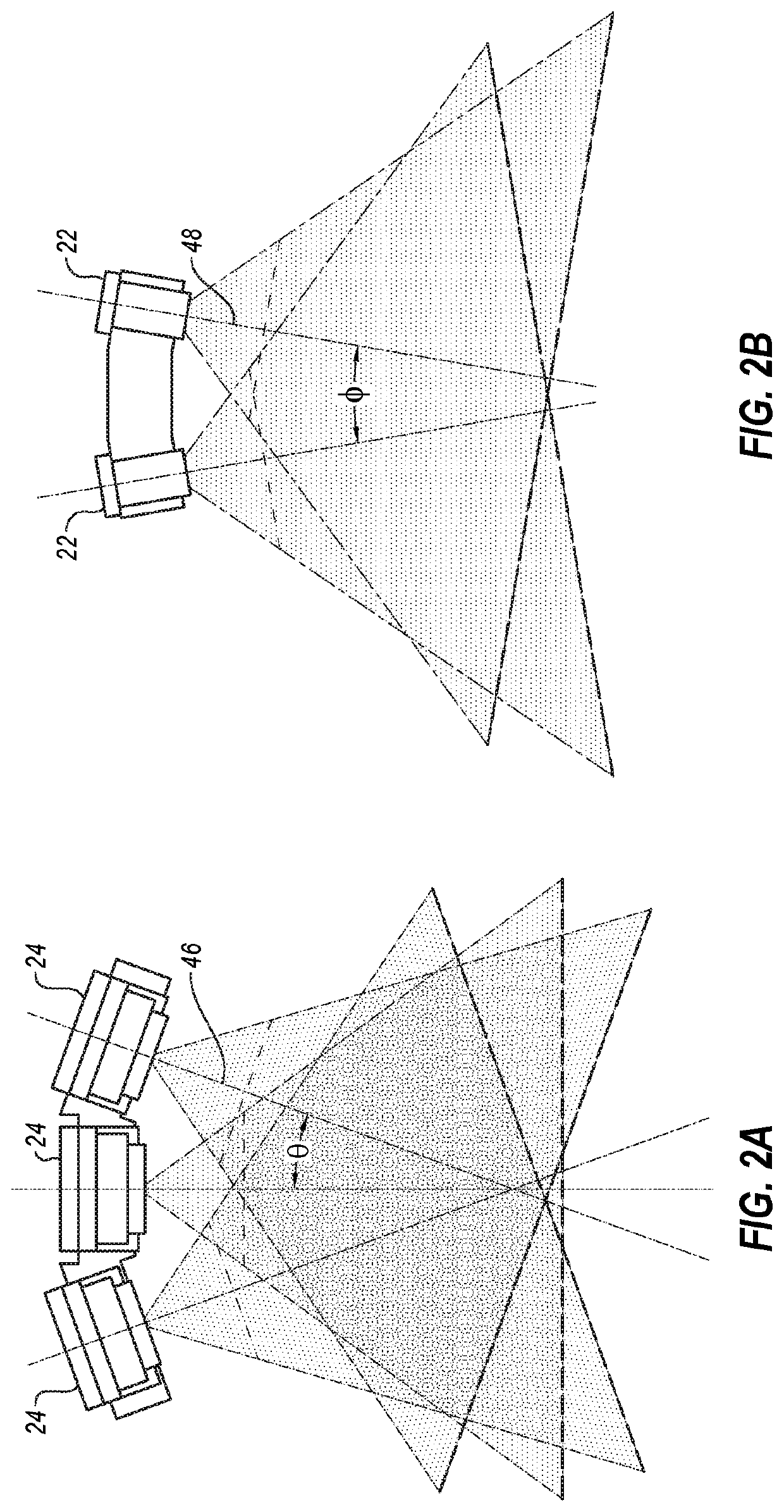

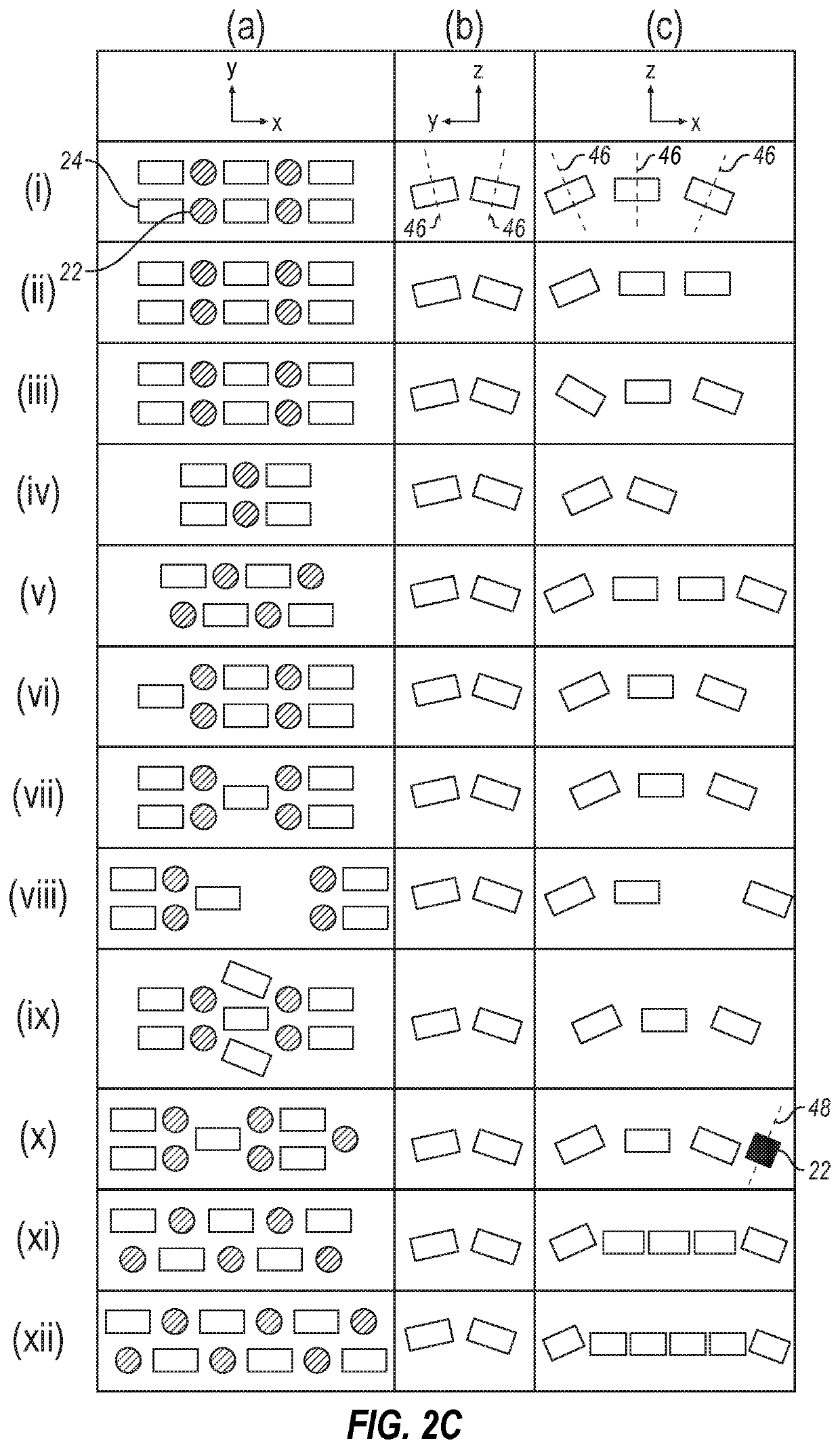

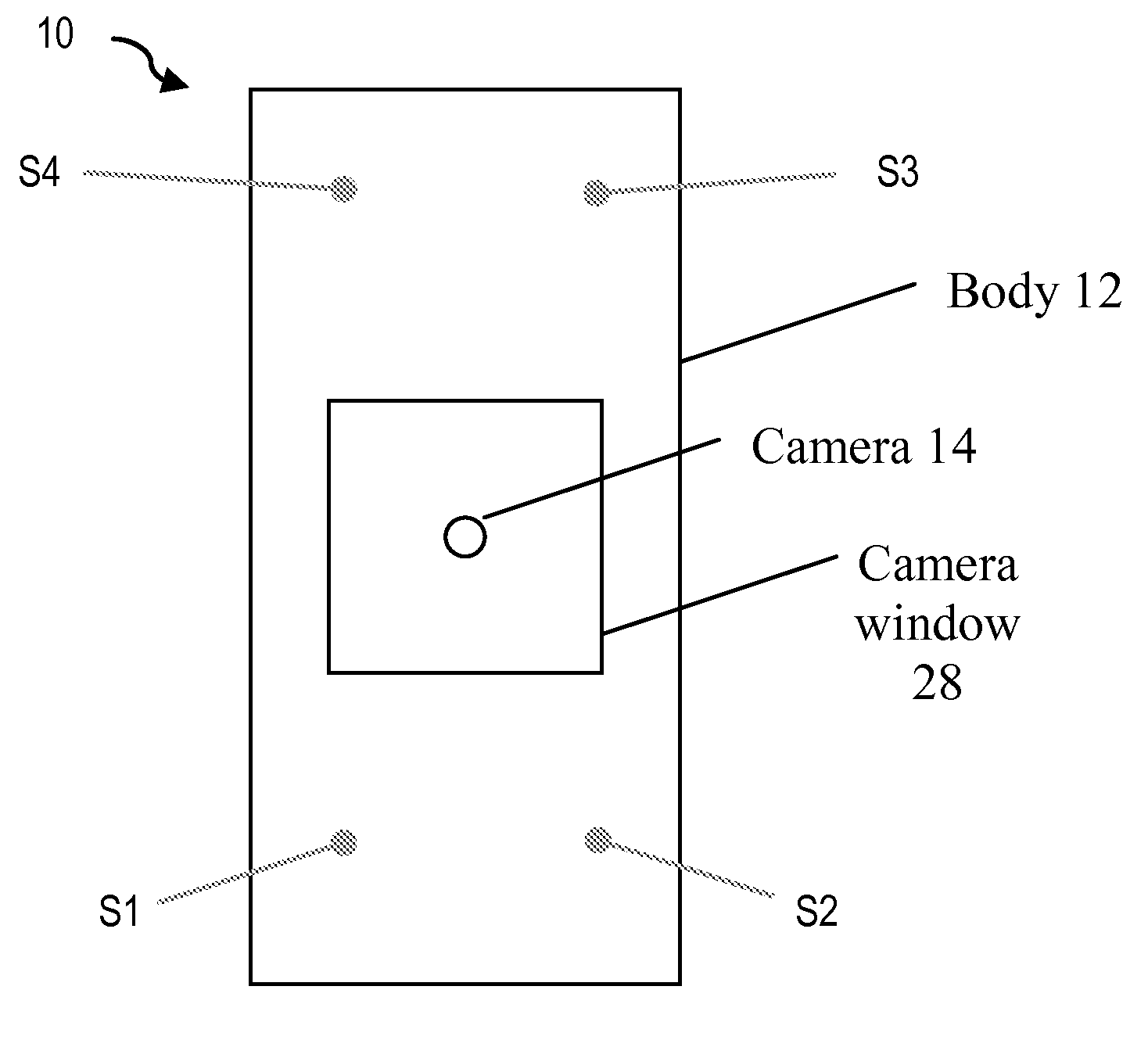

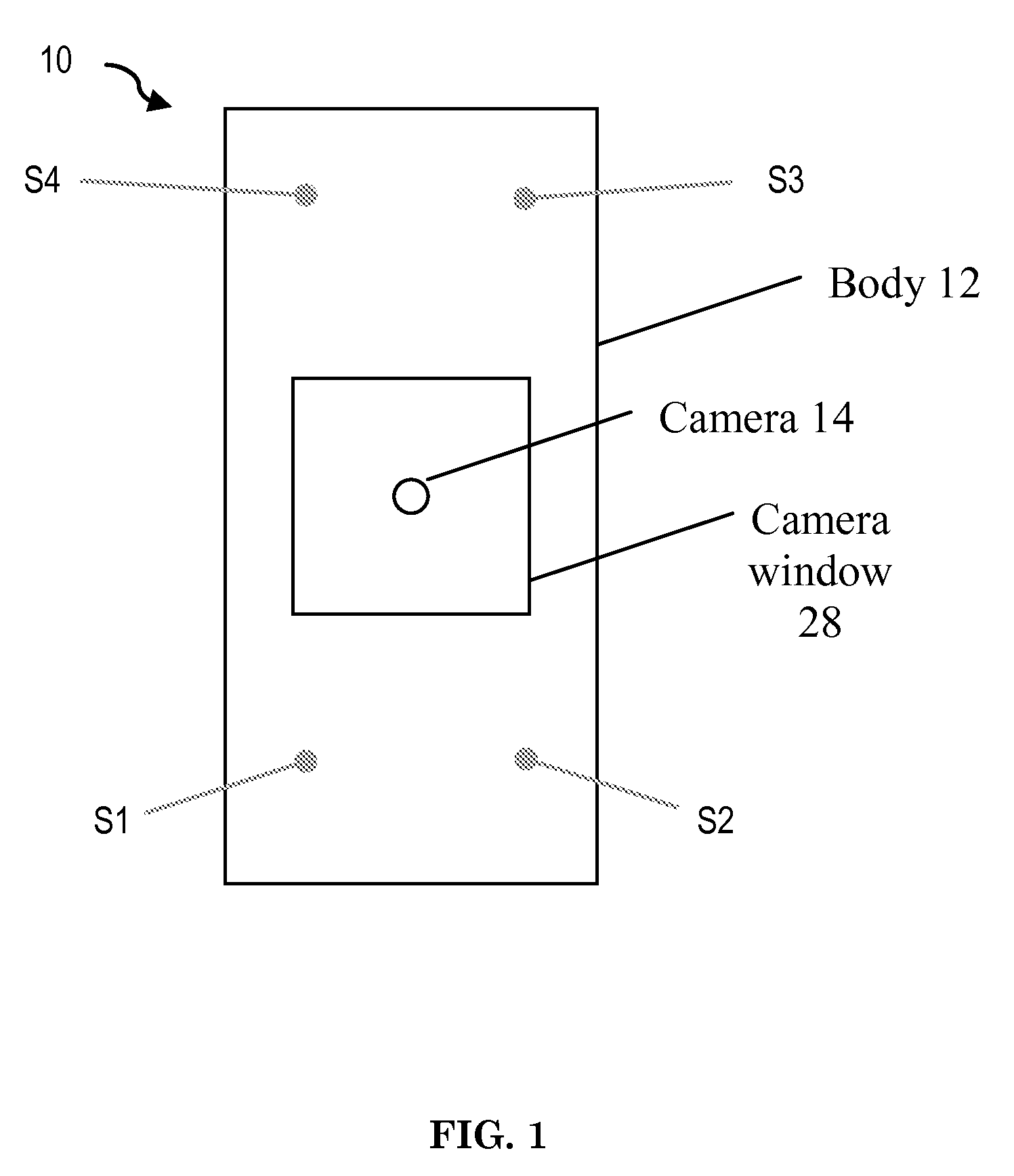

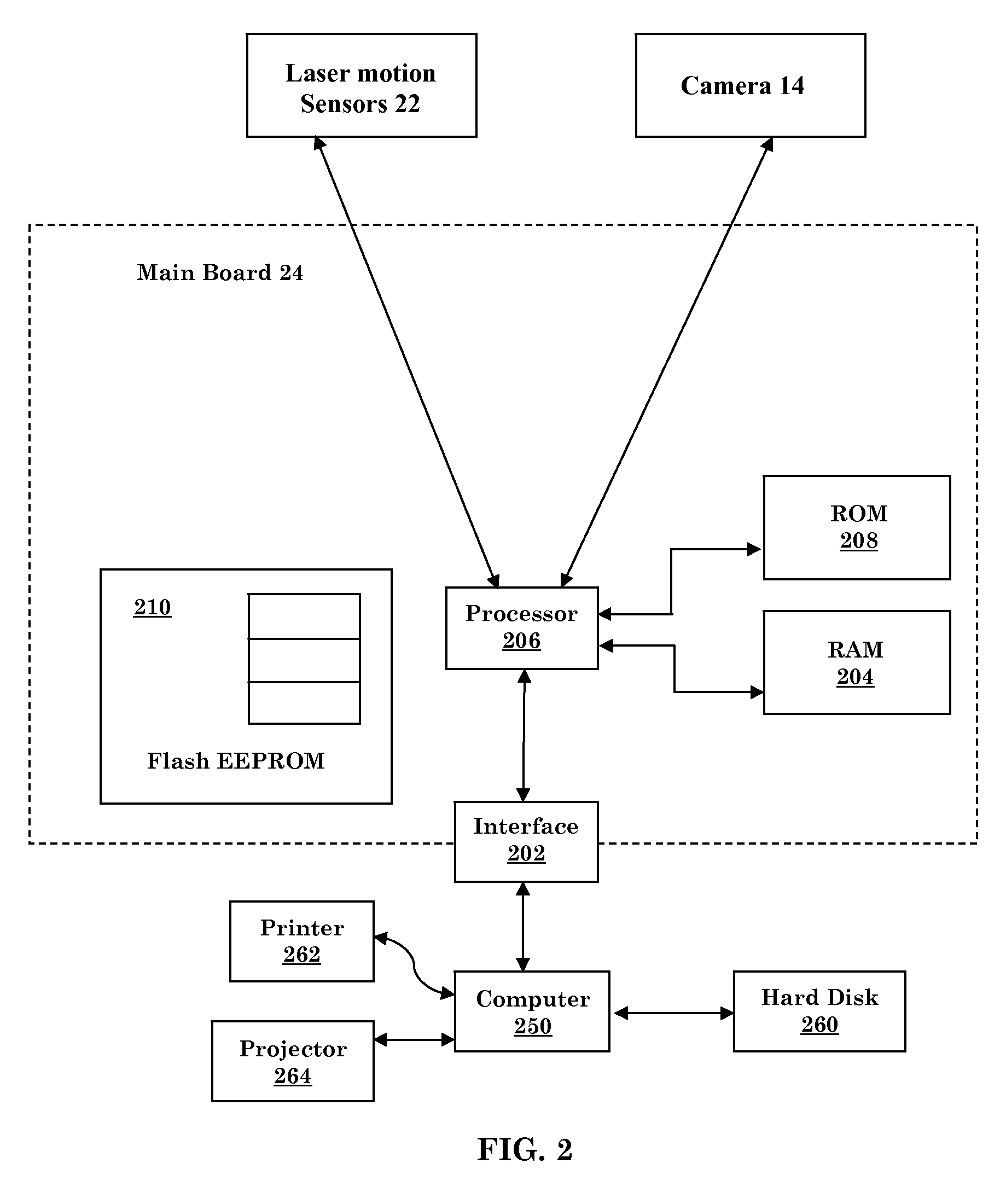

Intraoral 3D scanner employing multiple miniature cameras and multiple miniature pattern projectors

PendingUS20190388193A1Avoid heatingEnergy efficiencyImage enhancementImpression capsCamera lensProjector

An apparatus for intraoral scanning includes an elongate handheld wand that has a probe. One or more light projectors and two or more cameras are disposed within the probe. The light projectors each has a pattern generating optical element, which may use diffraction or refraction to form a light pattern. Each camera may be configured to focus between 1 mm and 30 mm from a lens that is farthest from the camera sensor. Other applications are also described.

Owner:ALIGN TECH

Light field intraoral 3D scanner with structured light illumination

ActiveUS20190388194A1Avoid heatingEnergy efficiencyImage enhancementImpression capsMedicineEngineering

A handheld wand comprises a probe at a distal end of the elongate handheld wand. The probe includes a light projector and a light field camera. The light projector includes a light source and a pattern generator configured to generate a light pattern. The light field camera includes a light field camera sensor, the light field camera sensor comprising an image sensor comprising an array of sensor pixels, and an array of micro-lenses disposed in front of the image sensor such that each micro-lens is disposed over a sub-array of the array of sensor pixels.

Owner:ALIGN TECH

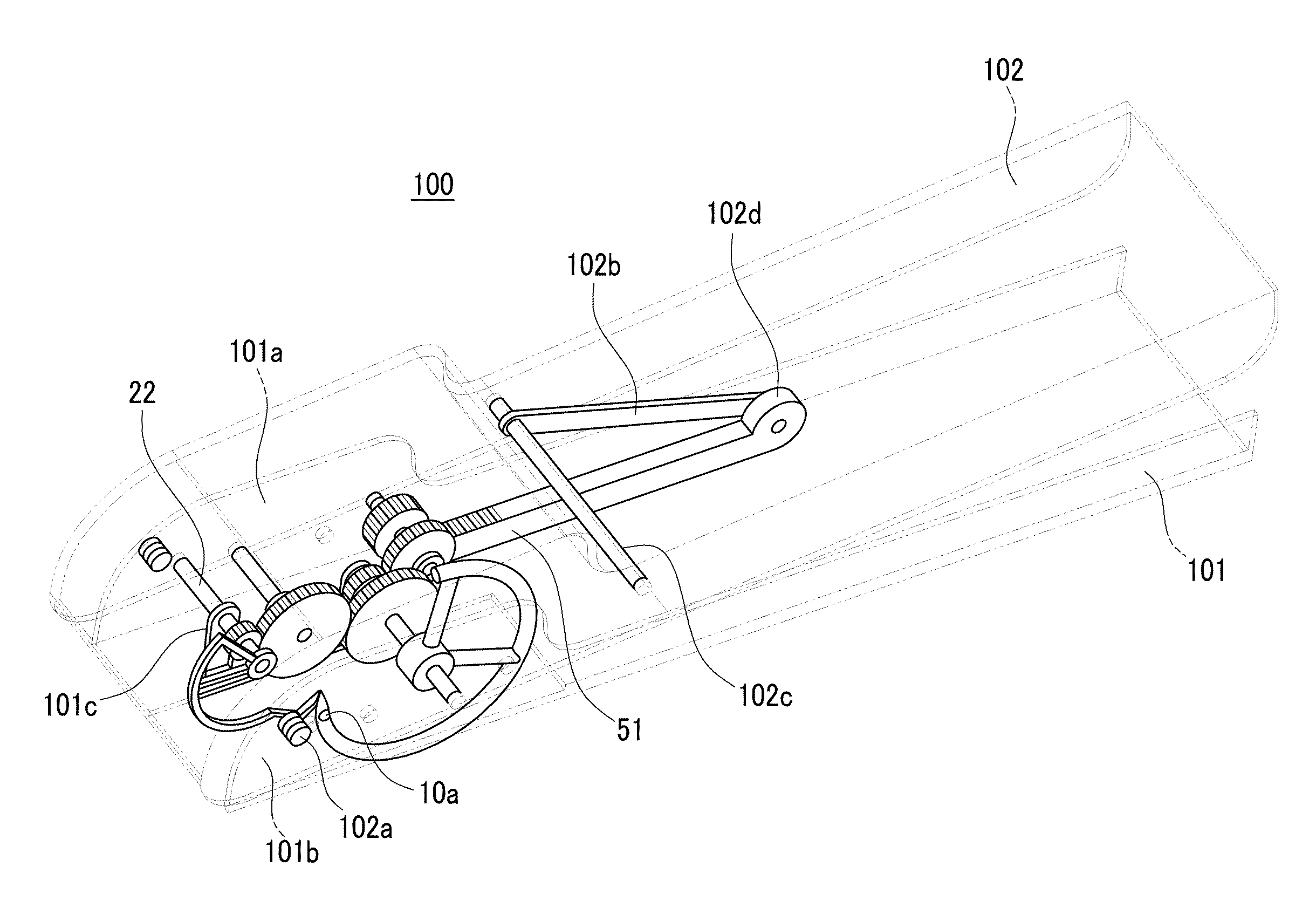

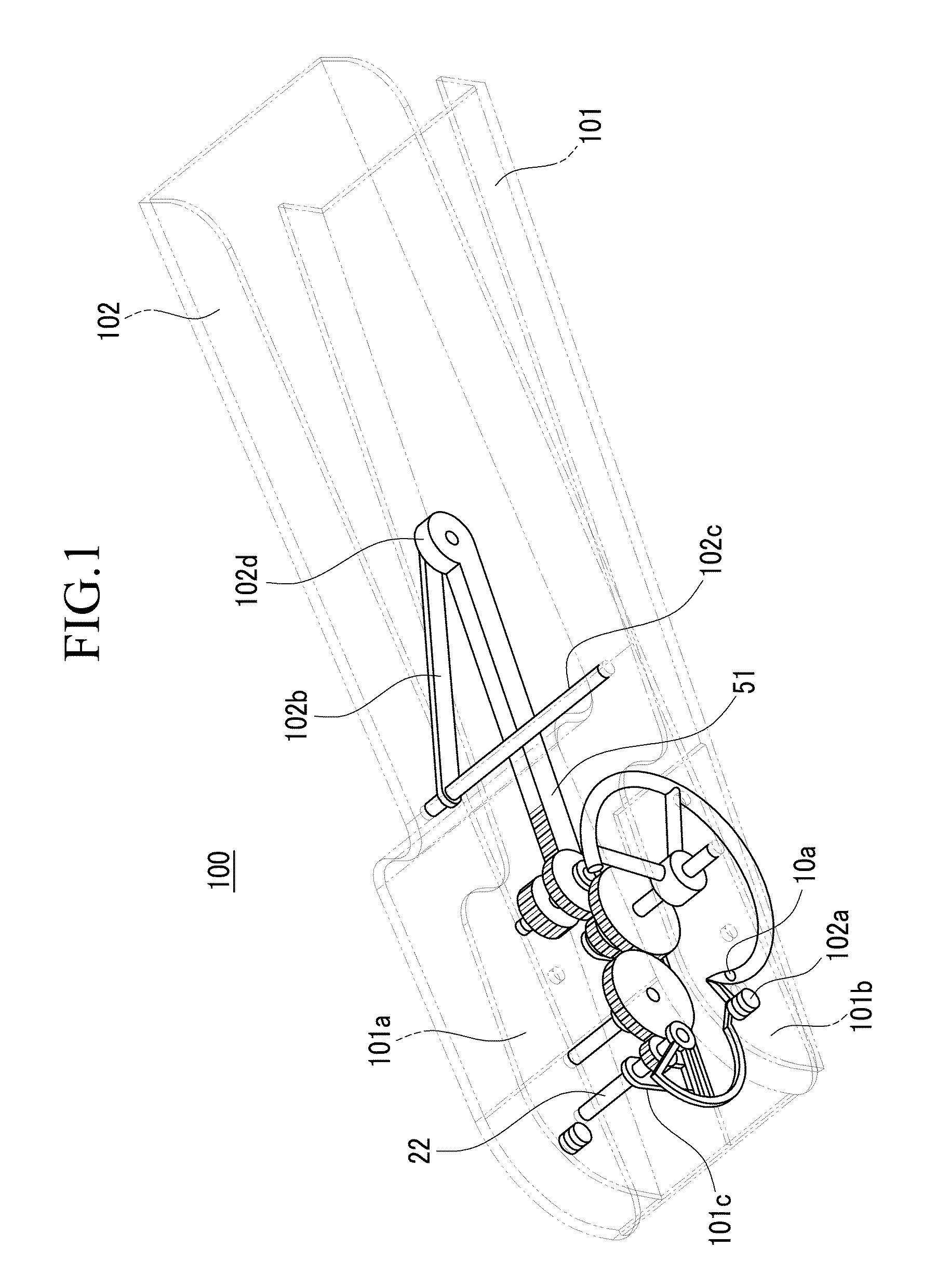

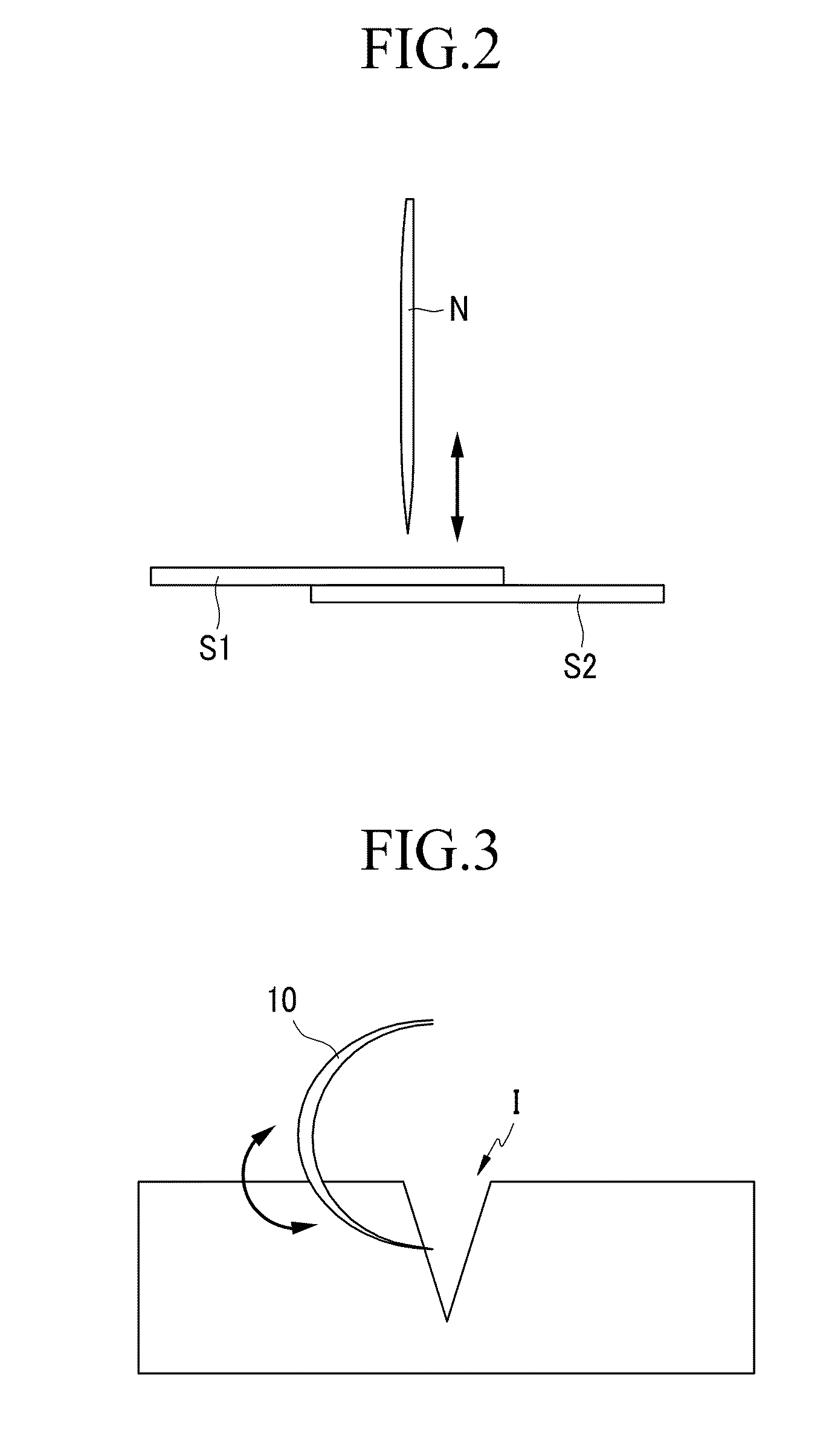

Suture device for surgical operation

InactiveUS20100063519A1Easily sutureUniform suturingSuture equipmentsSurgical needlesSuture needlesSurgical department

The present invention relates to a suture device for a surgical operation that makes it easy to suture a wound or an incision. A suture device for a surgical operation of the present invention includes: a suture needle that is curved with a needle eye at one end to be threaded with a first suture, and swings at an incision; a holder that supplies a second suture, rotates in one direction, and stops, corresponding to the swing of the suture needle to weave the first suture and the second suture and suture the incision; a first rotary member that is connected to a first shaft of the suture needle; a second rotary member that is connected to a second shaft of the holder; and a third rotary member that is provided between the first rotary member and the second rotary member, and connected to a third shaft to transmit torque to the second rotary member.

Owner:POSTECH ACAD IND FOUND

Muscle-based grafts/implants

ActiveUS20050152881A1Good dimensional stabilityImproved ability to hold shapeAntibacterial agentsBiocideTissue GraftBiomedical engineering

The present invention is directed to a composition comprising a matrix suitable for implantation in humans, comprising defatted, shredded, allogeneic human muscle tissue that has been combined with an aqueous carrier and dried in a predetermined shape. Also disclosed is a tissue graft or implant comprising a matrix suitable for implantation in humans, comprising defatted, shredded, allogeneic human muscle tissue that has been combined with an aqueous carrier and dried in a predetermined shape. The composition and / or tissue graft or implant of the invention is usable in combination with seeded cells, a tissue growth factor, and / or a chemotactic agent to attract a desired cell.

Owner:RTI BIOLOGICS INC

Muscle-based grafts/implants

The present invention is directed to a composition comprising a matrix suitable for implantation in humans, comprising defatted, shredded, allogeneic human muscle tissue that has been combined with an aqueous carrier and dried in a predetermined shape. Also disclosed is a tissue graft or implant comprising a matrix suitable for implantation in humans, comprising defatted, shredded, allogeneic human muscle tissue that has been combined with an aqueous carrier and dried in a predetermined shape. The composition and / or tissue graft or implant of the invention is usable in combination with seeded cells, a tissue growth factor, and / or a chemotactic agent to attract a desired cell.

Owner:RTI BIOLOGICS INC

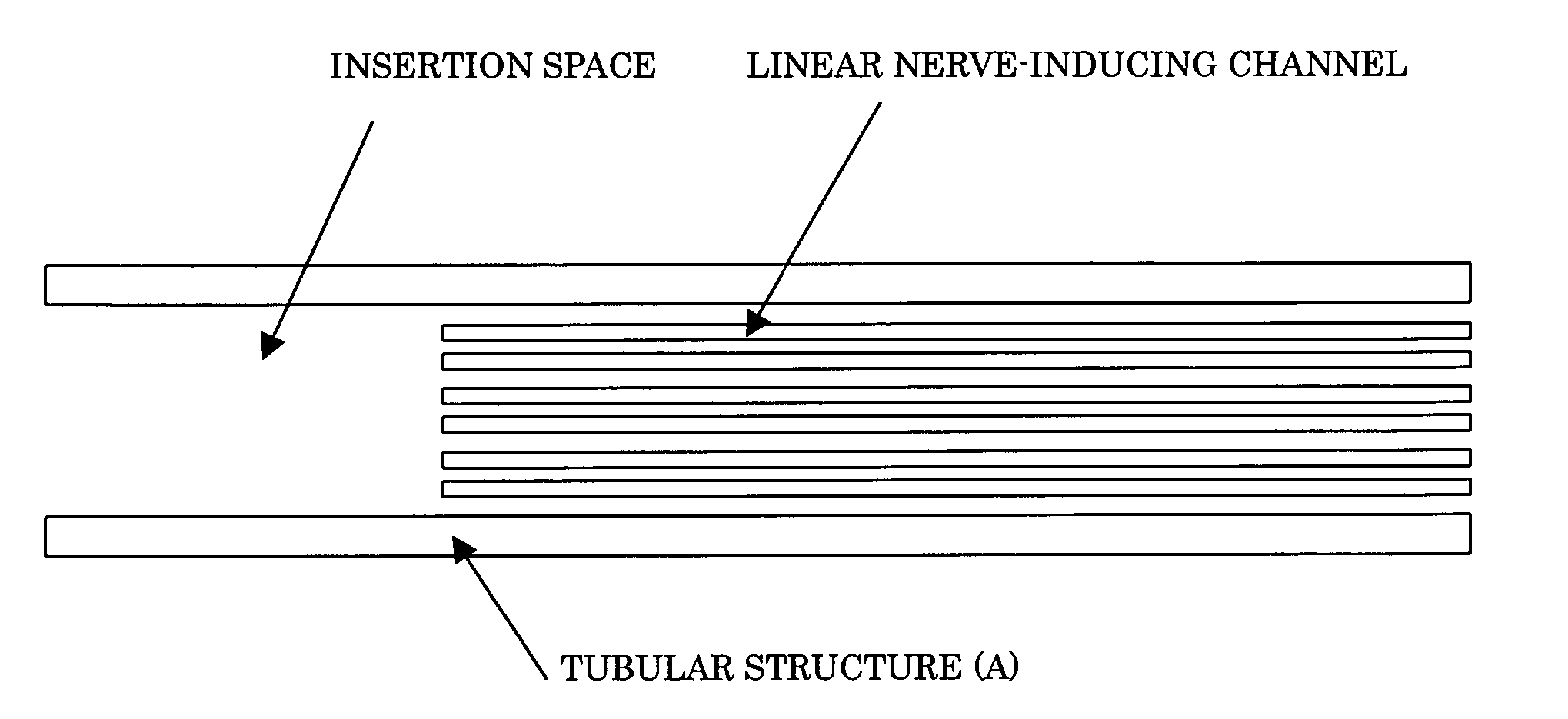

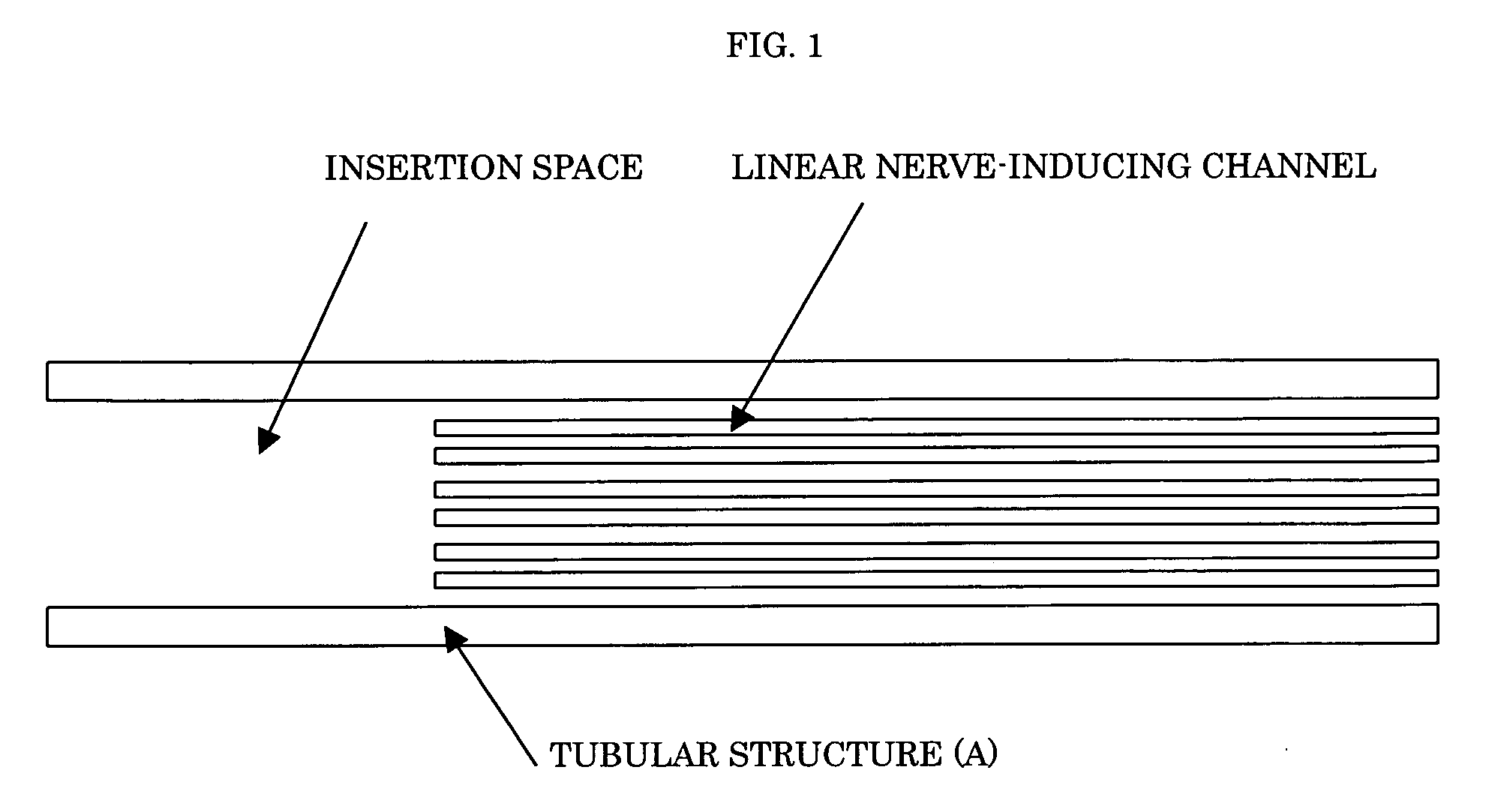

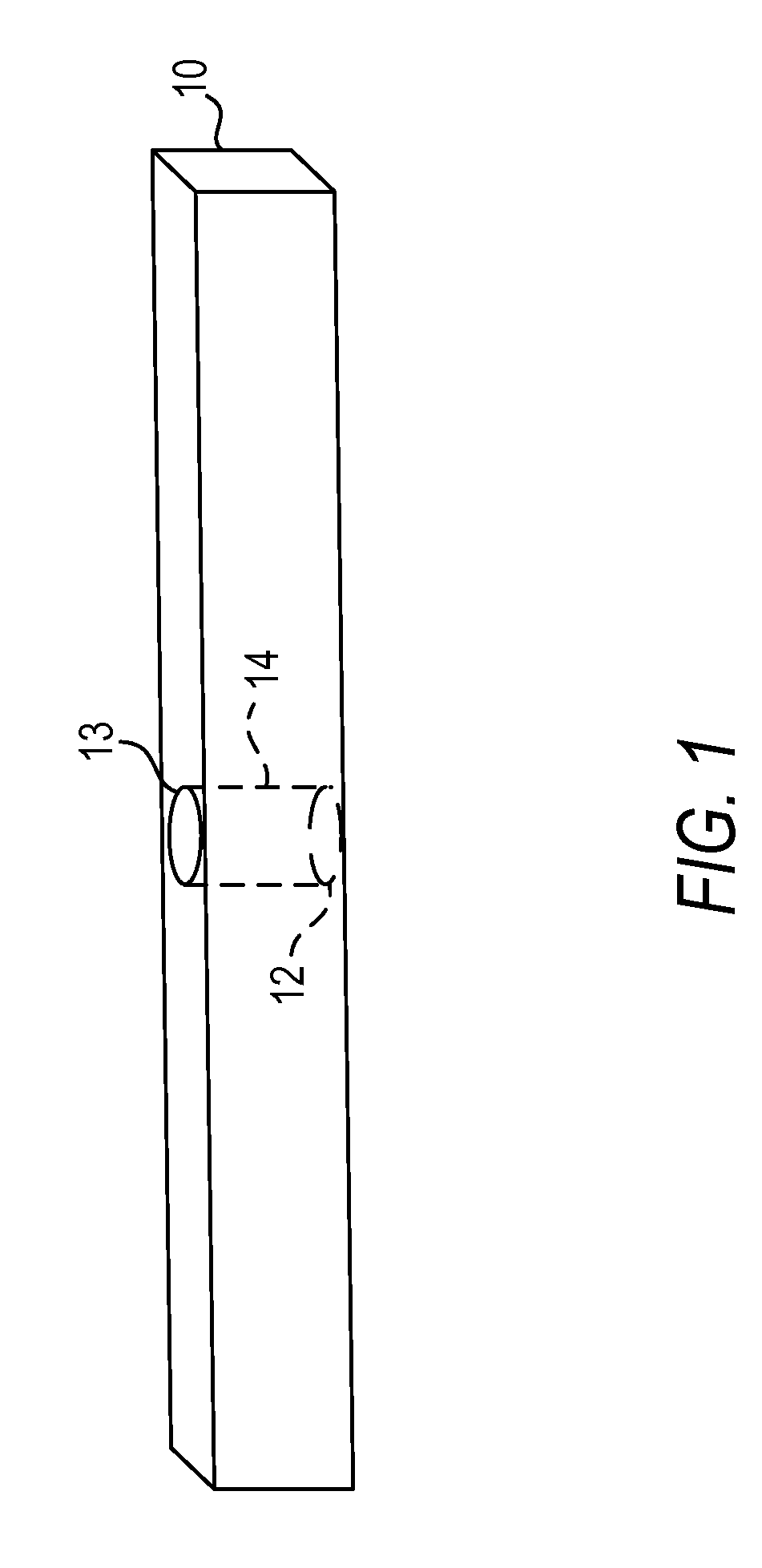

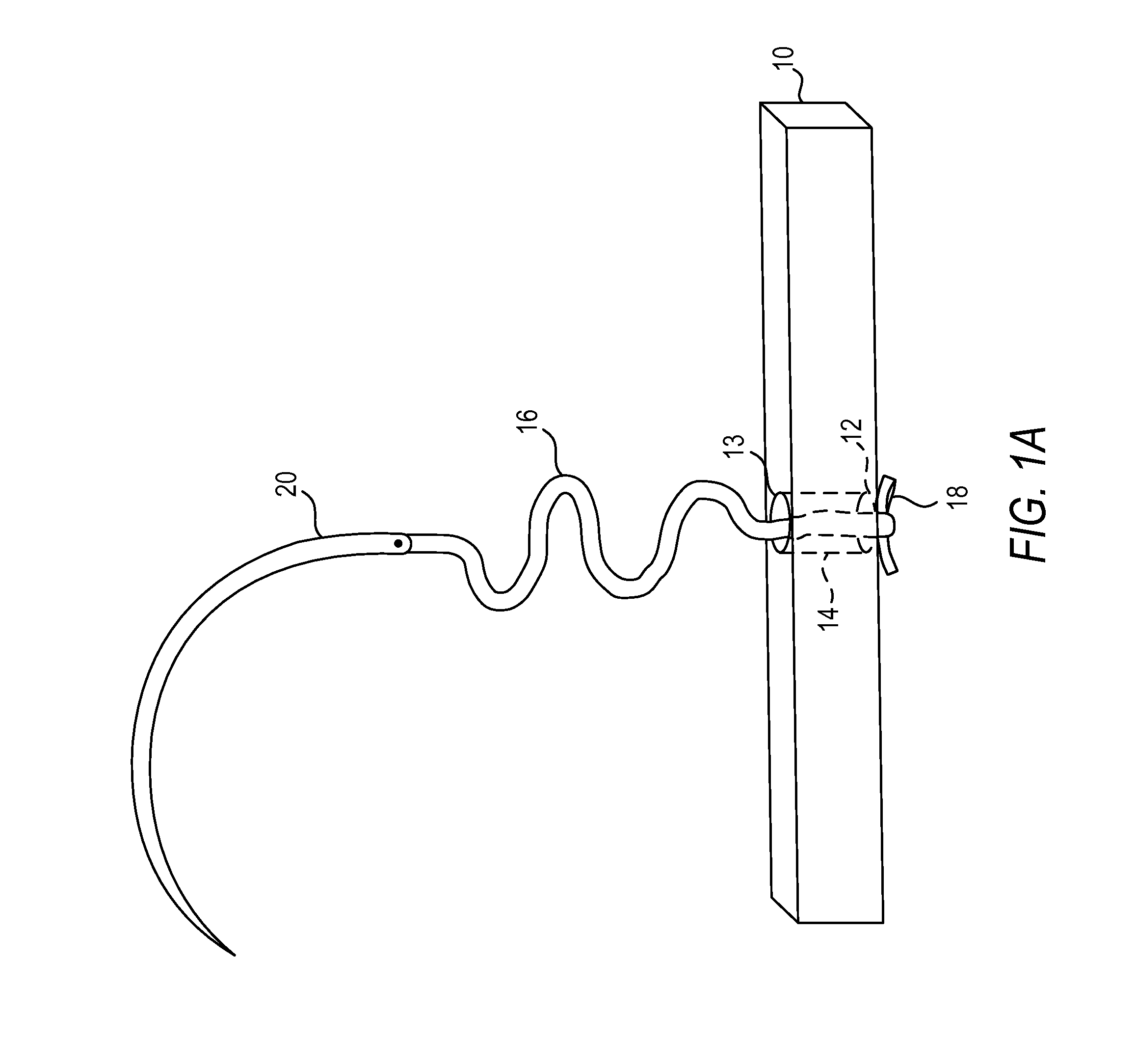

Nerve regeneration-inducing tube comprising

ActiveUS20060100647A1Guaranteed efficient growthPromote efficient proliferationTubular organ implantsTissue regenerationAnatomyAbsorbent material

The present invention provides a nerve regeneration-inducing tube in which nerve is inserted into a tubular structure and can be easily sutured and fixed without resort to any special instruments or operations, thereby allowing nerve cells to efficiently proliferate and grow in the correct direction. The nerve regeneration-inducing tube of the present invention includes: a tubular structure (A) made of a biodegradable material or a bioabsorbable material and provided inside with a matrix (B) having linear nerve-inducing channels and being made of a biodegradable material or a bioabsorbable material; and a definite space part provided at one end of the tubular structure (A).

Owner:NIPRO CORP +1

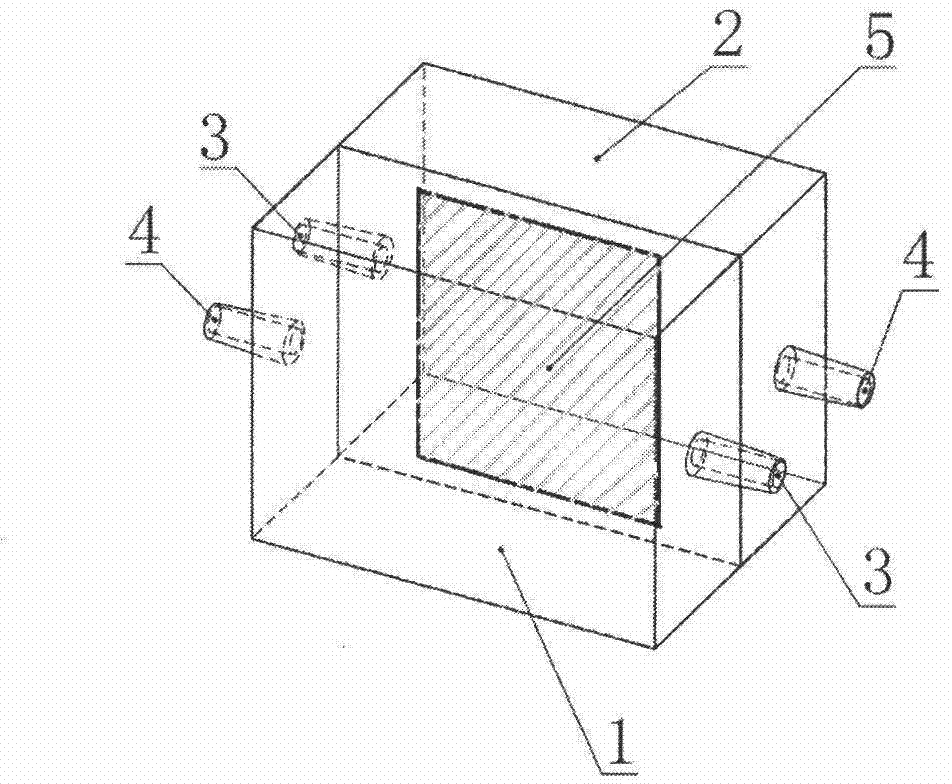

Preparation method and device of duramater/spinal dural transplanting substitute

ActiveCN102727935ASimple Surface Functional StructureWidely sourced and cheapProsthesisAntigenDefect repair

The invention provides a preparation method of a duramater / spinal dural transplanting substitute which is obtained by repeated freezing and thawing of dural tissue, rolling and cracking of cells, crosslinking fixed protection, accellular antigen extraction, dense surface fibrosis modification, packaging and sterilization, and has the advantages of simple method, wide raw material sources, cheap raw materials, and low cost. The prepared dural substitute completely removes components of cells and other antigen components simultaneously when protecting dural tissue natural structure and properties, is good in biocompatibility, free of immune rejection, safe and reliable, good in mechanical performance, and easy in clinical operation, can meet the needs of defect repair, has the function of promoting tissue regeneration as a loose surface is beneficial to the tissue fluid adsorption, active factor enrichment, and growth of blood vessels and cells, and has the advantages of rapidness in fusion with a host, biodegradable absorption, and good repair effect. The animal test shows that the defect can be completely repaired without brain or spinal fluid leakage, or adhesion with brain tissue, and significant rejection is not found.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

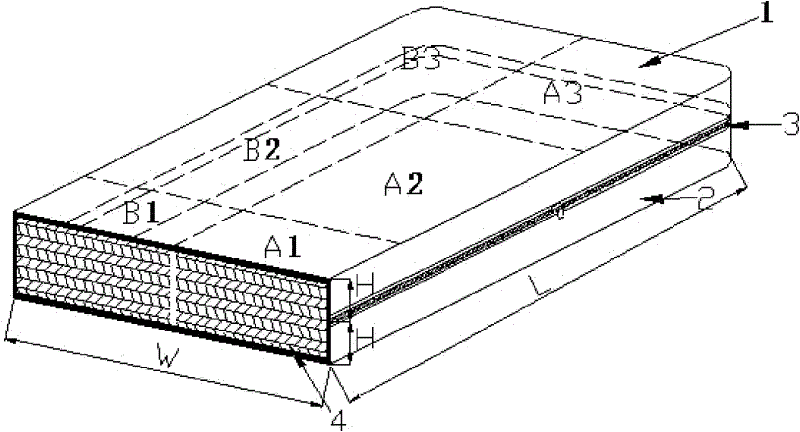

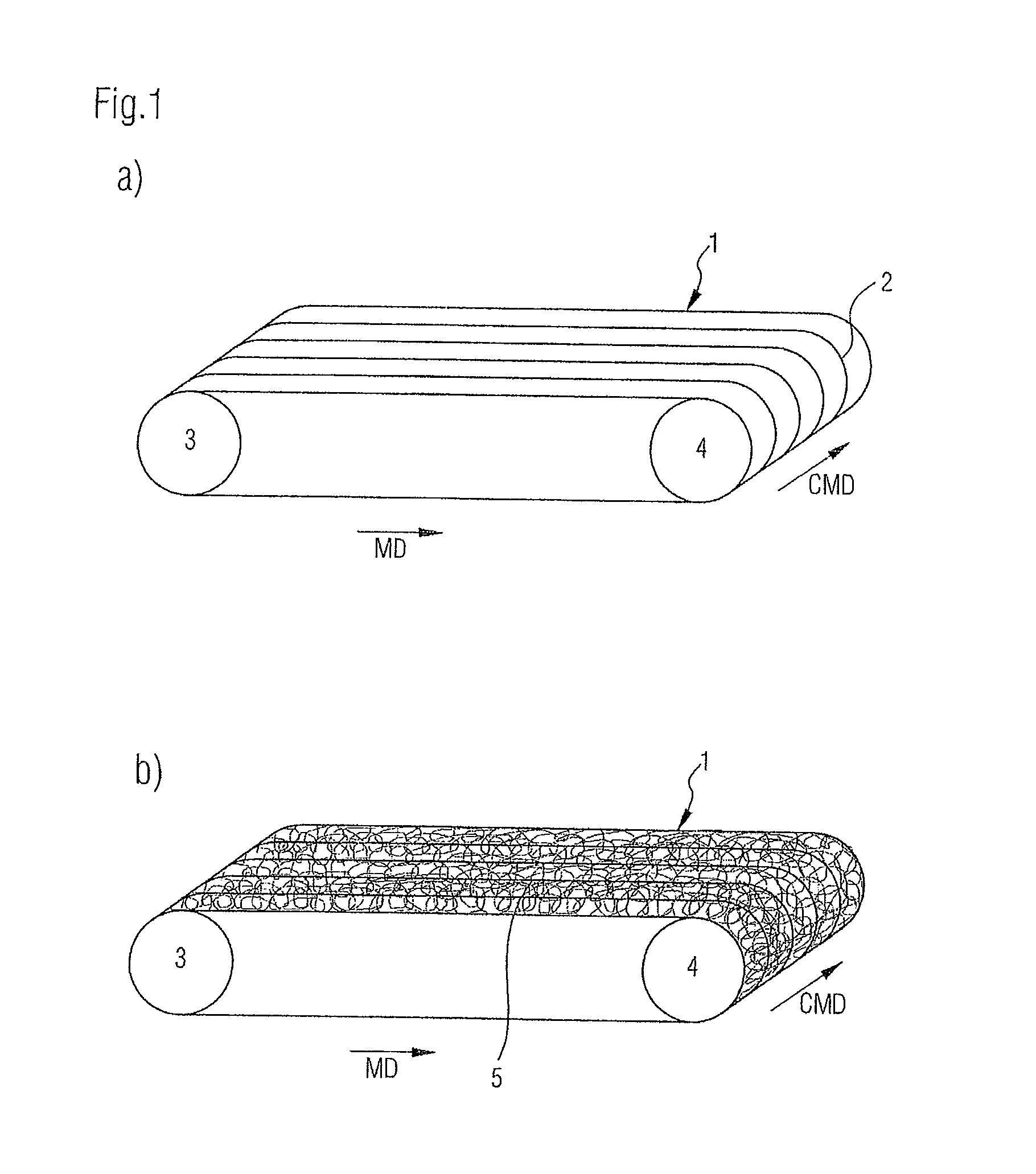

Warp knitted spacer fabric mattress and making method thereof

InactiveCN102613836AEasy to cleanEasy to assemble and disassembleStuffed mattressesSpring mattressesHuman bodySurface layer

The invention relates to the bedding field, and especially relates to a warp knitted spacer fabric mattress and a making method thereof. The mattress comprises an adjustable mattress inner liner and a stereo mattress sleeve, the mattress sleeve is obtained by sewing an upper surface layer, a lower surface layer and a side wall, and at least the upper surface layer and the side wall are warp knitted spacer fabrics; and the mattress inner liner is adjustable and comprises at least two independent inner liner bodies with different supporting strengths arranged in the mattress sleeve, each of the inner liner bodies has a multilayer structure, and at least the top layer is a wrap knitted spacer fabric, so the inner liner bodies and all the layers for forming the inner liner bodies can be reasonably combined and arranged according to ergonomic requirements to adapt to requirements of parameters of the supporting of different positions of a human body, different heights, different body weights and the like. The application of the warp knitted spacer fabric to the mattress sleeve in the invention makes the mattress sleeve have the advantages of elasticity, permeability, ergonomic conforming, bacterial growing inhibition and the like of the warp knitted spacer fabric and simultaneously have the characteristics of dismounting and mounting convenience and cleaning convenience of the mattress sleeve.

Owner:福建福联精编有限公司

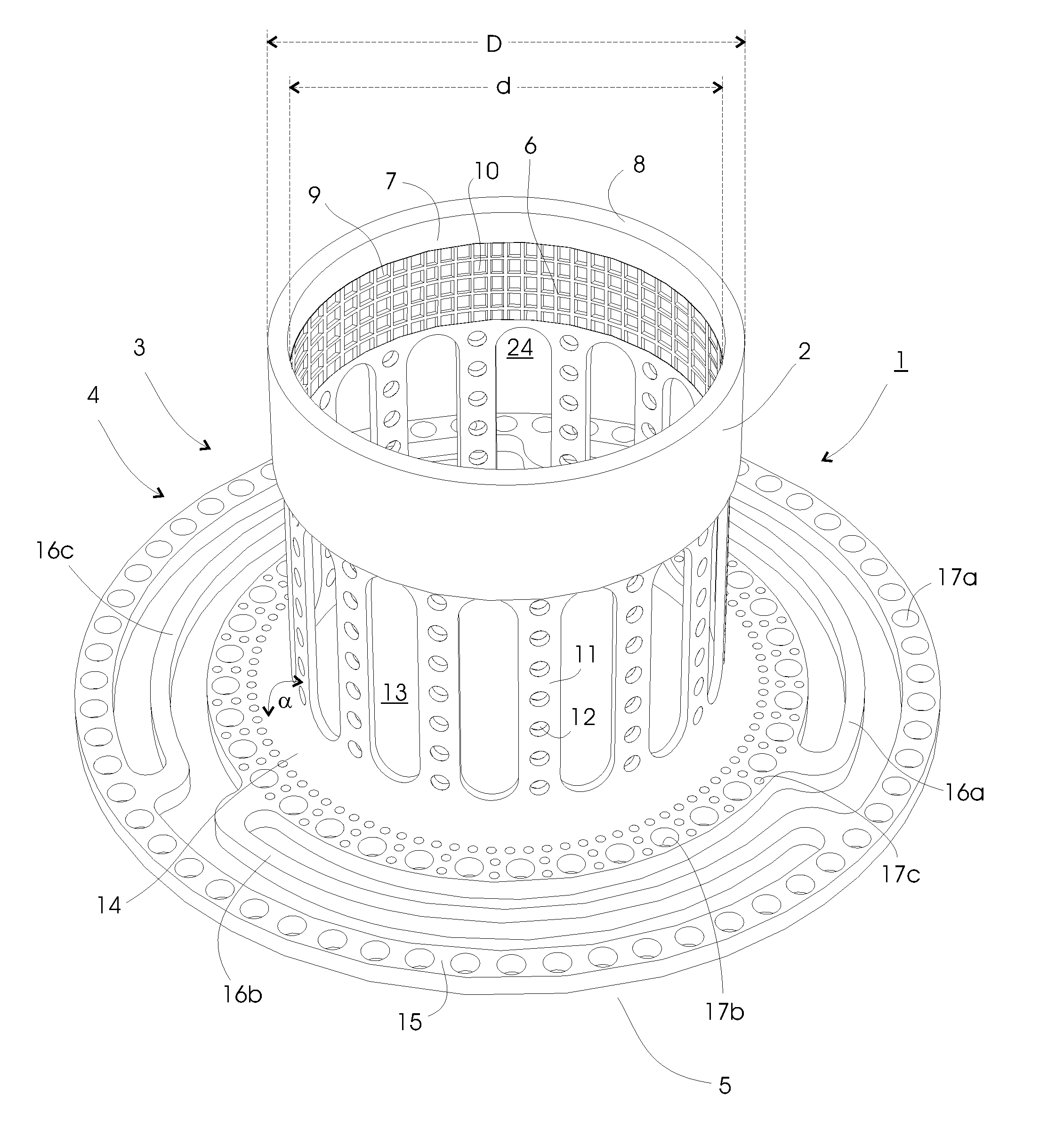

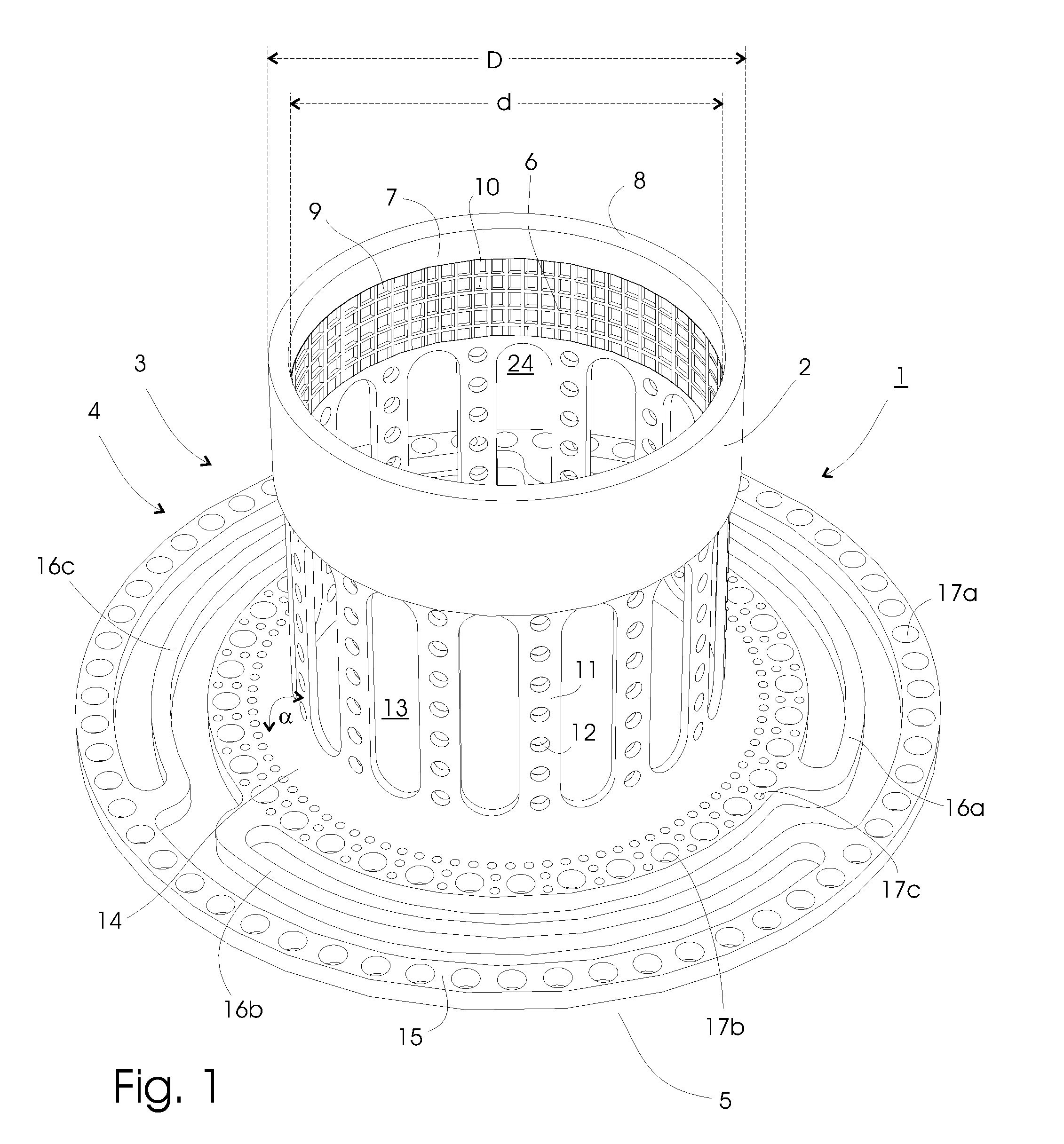

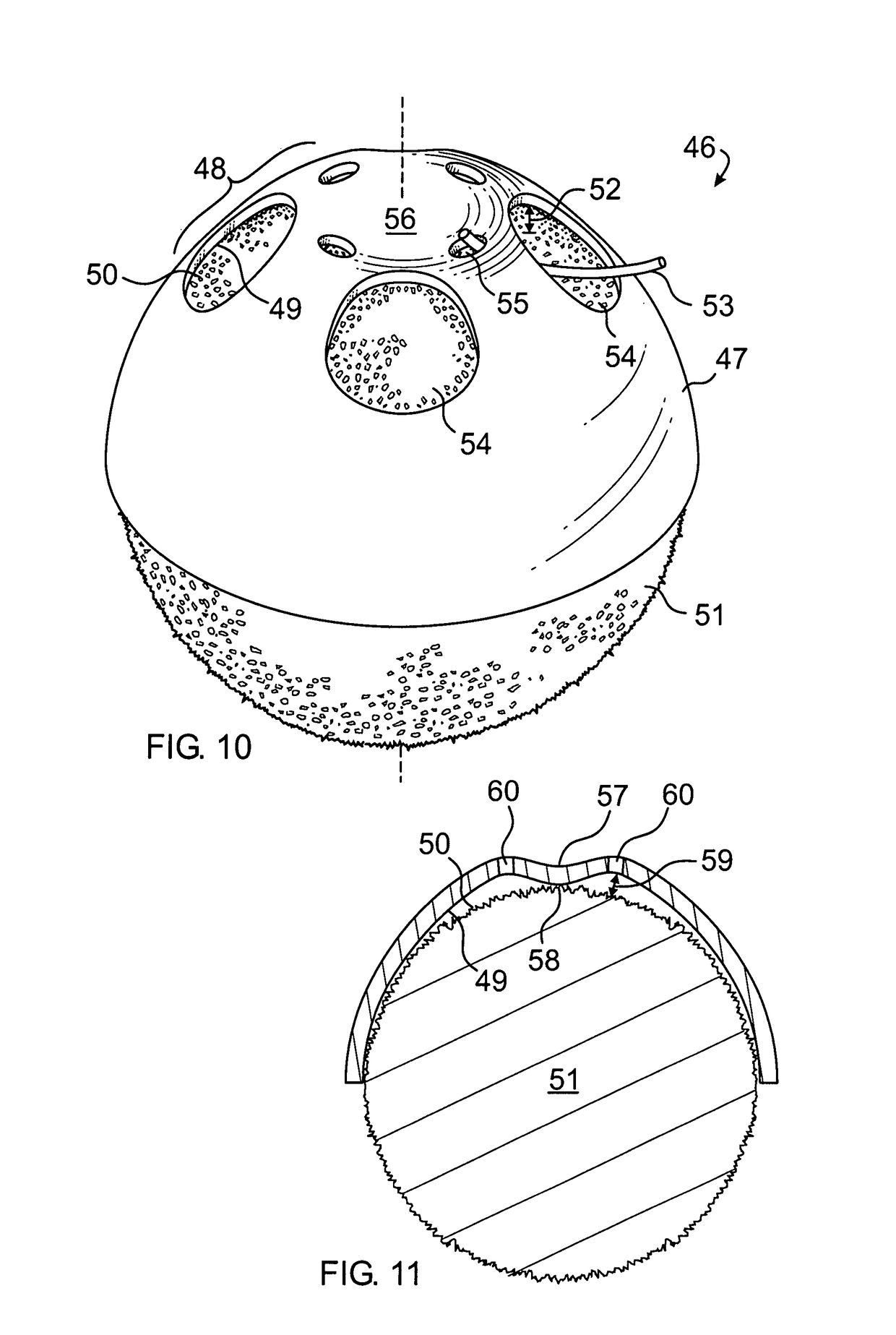

Implant and method for its manufacture

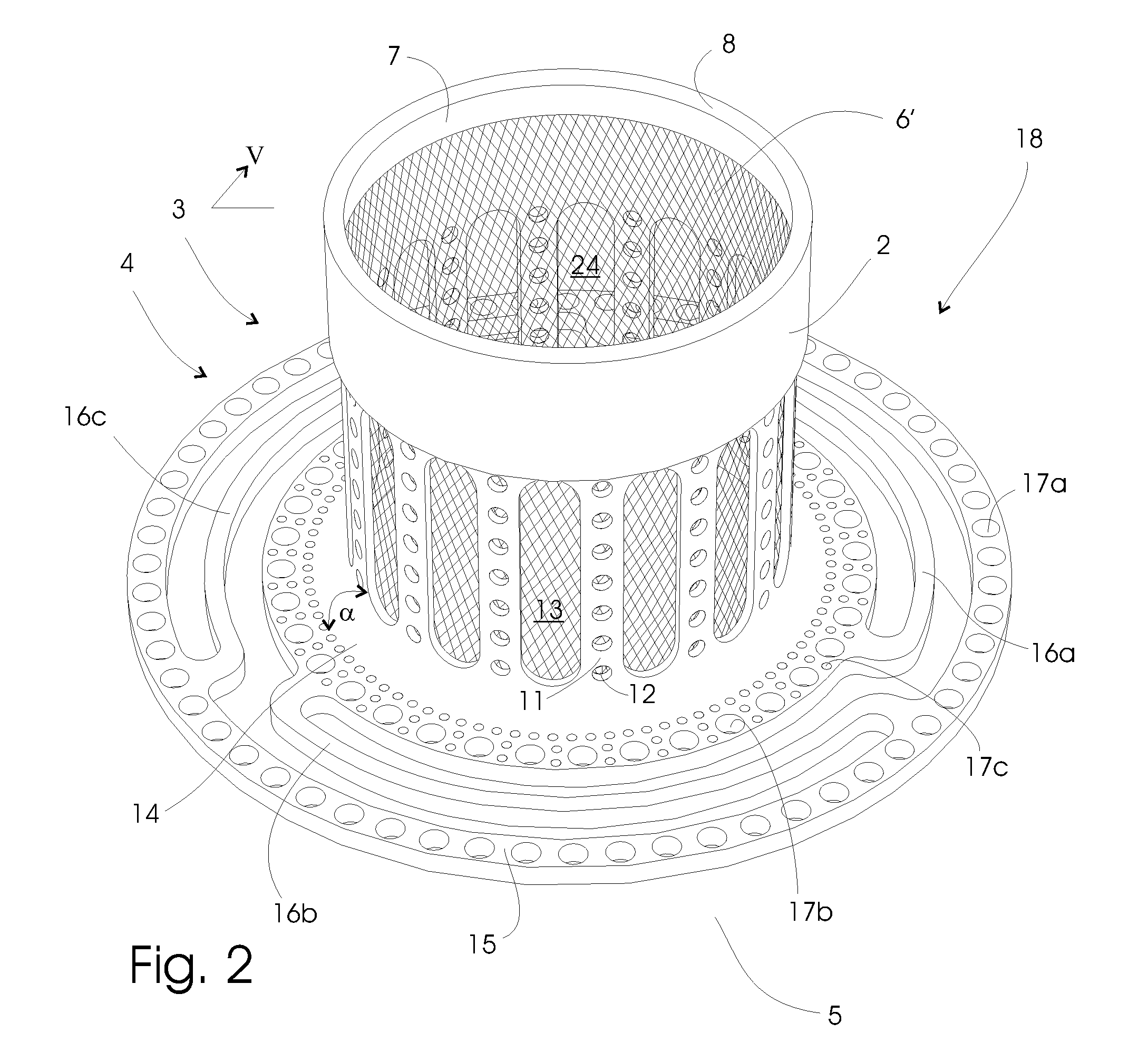

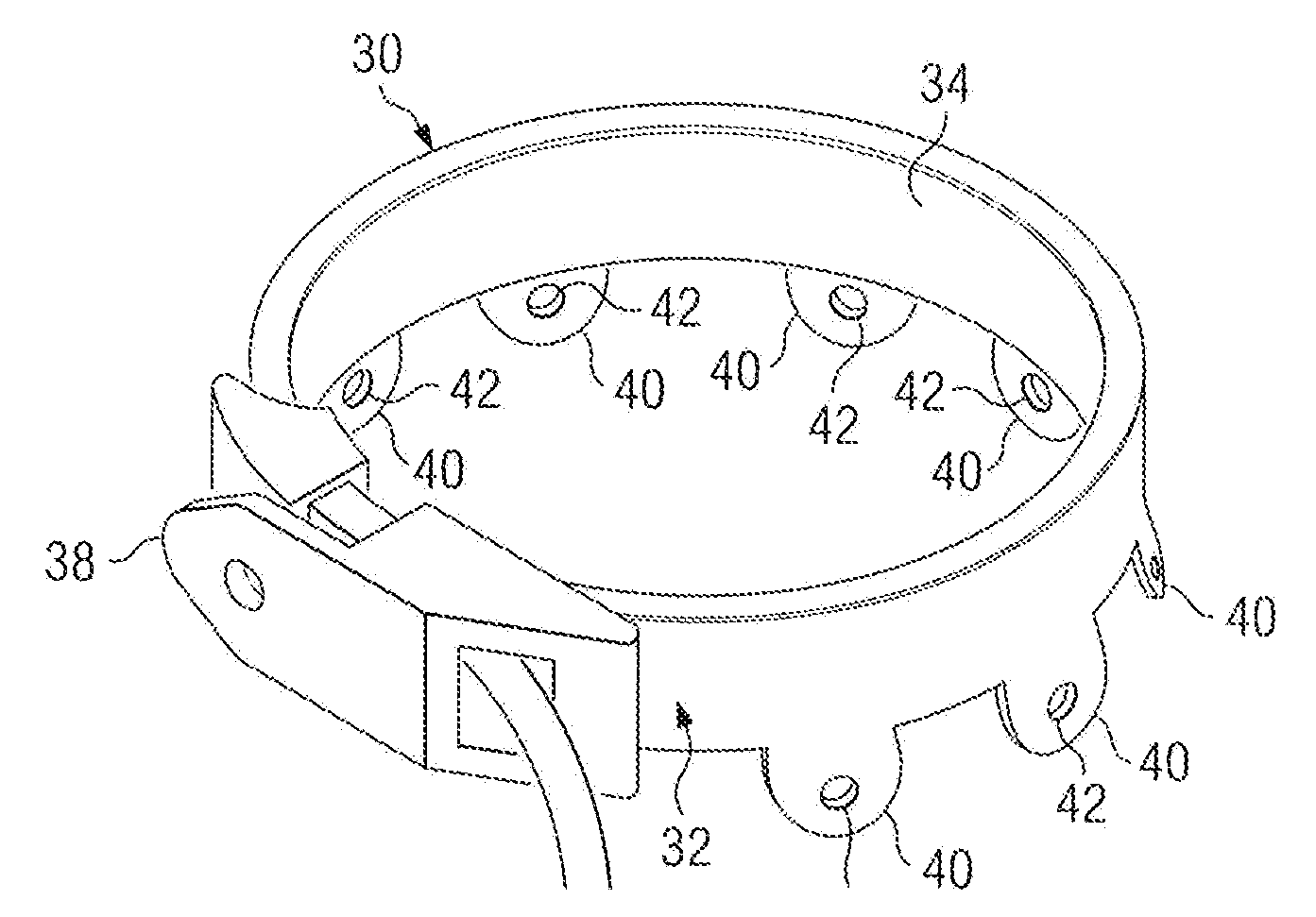

ActiveUS8647304B2Easy to sutureStable, effective and well vascularised skin-implant junctionInfusion syringesMedical devicesCatheterAbdominal wall

An implant for percutaneous implantation through the abdominal wall for encircling and engaging an externalized length of a body duct of a human or animal patient. The implant has an exterior ring section protruding outwardly from the abdominal wall with a free end which serves for mounting of a detachable device, and an interior section extending through the abdominal wall and inside the patient for internal fixation of the implant. The exterior ring section and interior section have a common axis. The internal circumference of at least a part of the exterior ring section above the interior section is arranged with a biocompatible, integrated ingrowth means for the exterior surface of the body duct wall.

Owner:OSTOMYCURE AS

Biodegradable common bile duct stent and the method for preparing thereof

InactiveUS7094260B2Easy to sutureAvoid it happening againBile ductsBlood vesselsSurgical operationLarynx structure

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

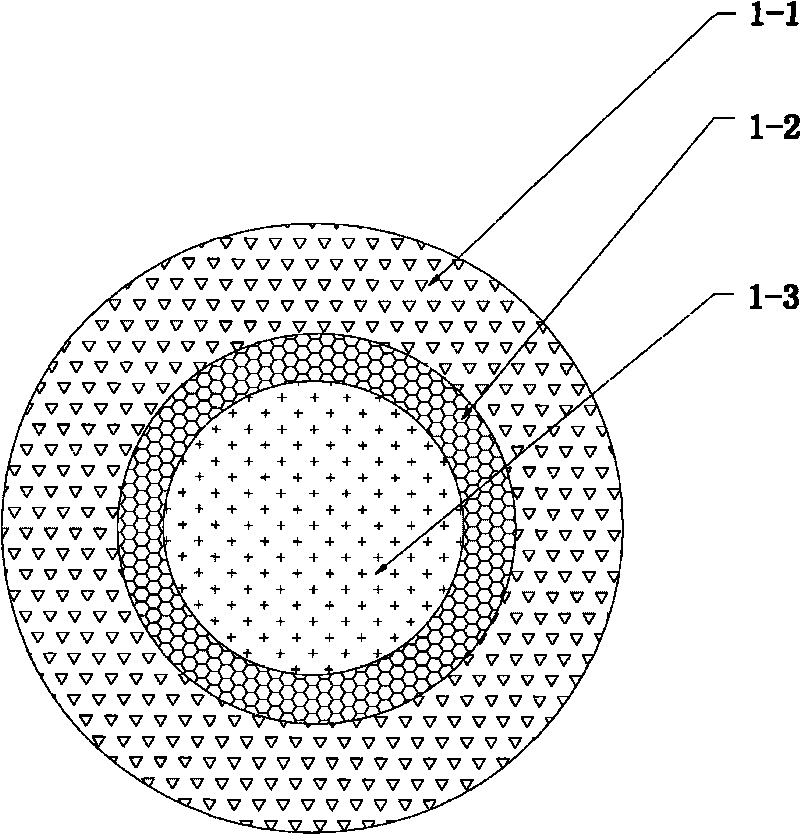

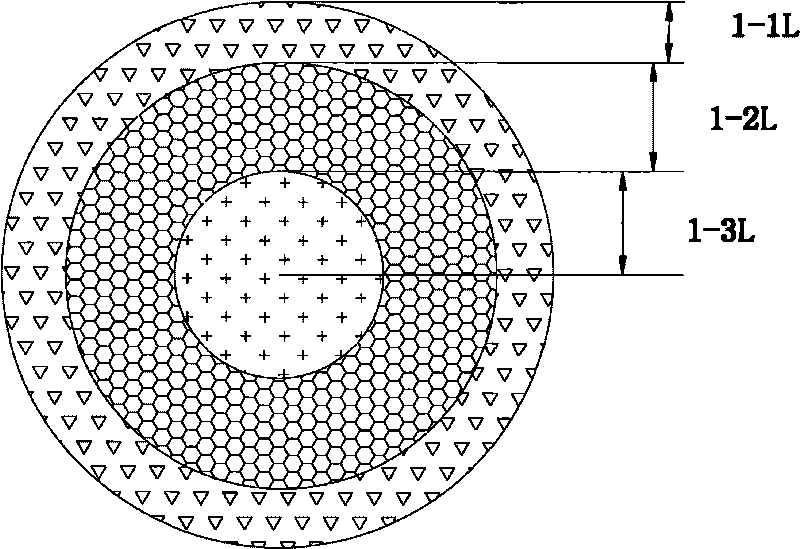

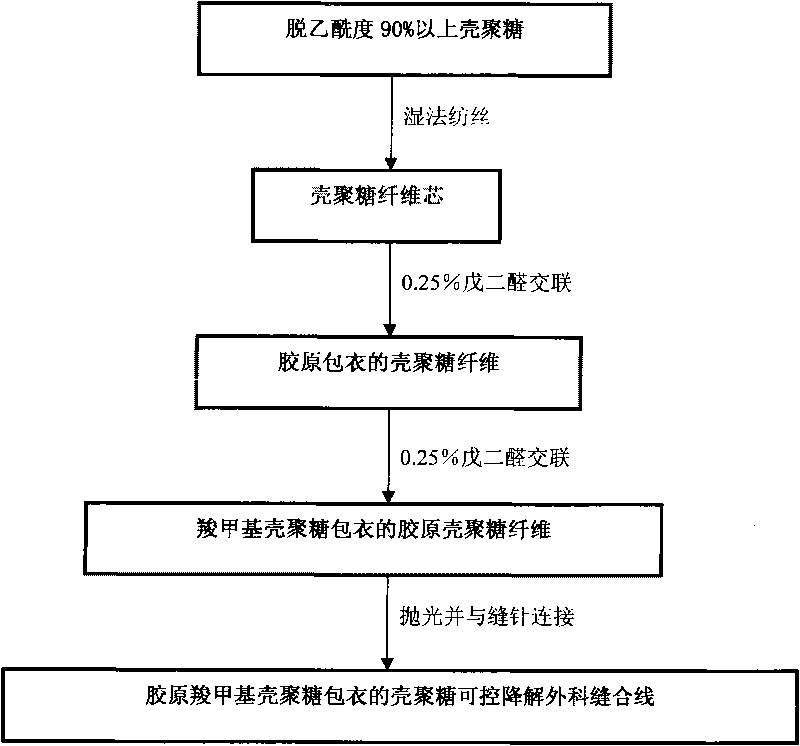

Controlled degradable surgical suture thread and fabricating method thereof

InactiveCN101703794AControllable degradation rateIncrease tensile strengthSuture equipmentsSuture needlesSurgical suture

The invention discloses a controlled degradable surgical suture thread and a fabricating method thereof. The innermost part is chitosan fiber core, the middle part is collagen layer, and the outermost part is ethyloic-chitosan layer. From innermost to outermost, the thickness ratio of each layer is 2:X:(3-X), wherein X is larger than 1 and smaller than 3. The value of X is related to degradation velocity of the surgical suture thread: the larger the value, the faster the degradation velocity of the surgical suture thread, and the shorter the healing period of wound suitable to be sutured; andthe smaller the value, the slower the degradation velocity of the surgical suture thread, and the longer the healing period of wound suitable to be sutured. The fabricating method of the surgical suture thread comprises: (1) preparing chitosan fiber core and collagen; (2) covering a layer of collagen outside the chitosan fiber; (3) covering a layer of ethyloic-chitosan outside the collagen cover of the chitosan fiber; (4) processing and polishing the suture thread prepared in (3) by an automatic coreless grinder, connecting with suture needles of different models to prepare into a finish product of surgical suture thread. The technical scheme of the invention has plentiful advantages: controllable degradation velocity, high tension strength, improved biocompatibility and anti-infectious property, quick wound healing, no obvious scars, good biocompatibility, etc.

Owner:GENERAL HOSPITAL OF THE SECOND ARTILLERY OF CHINESE PLA

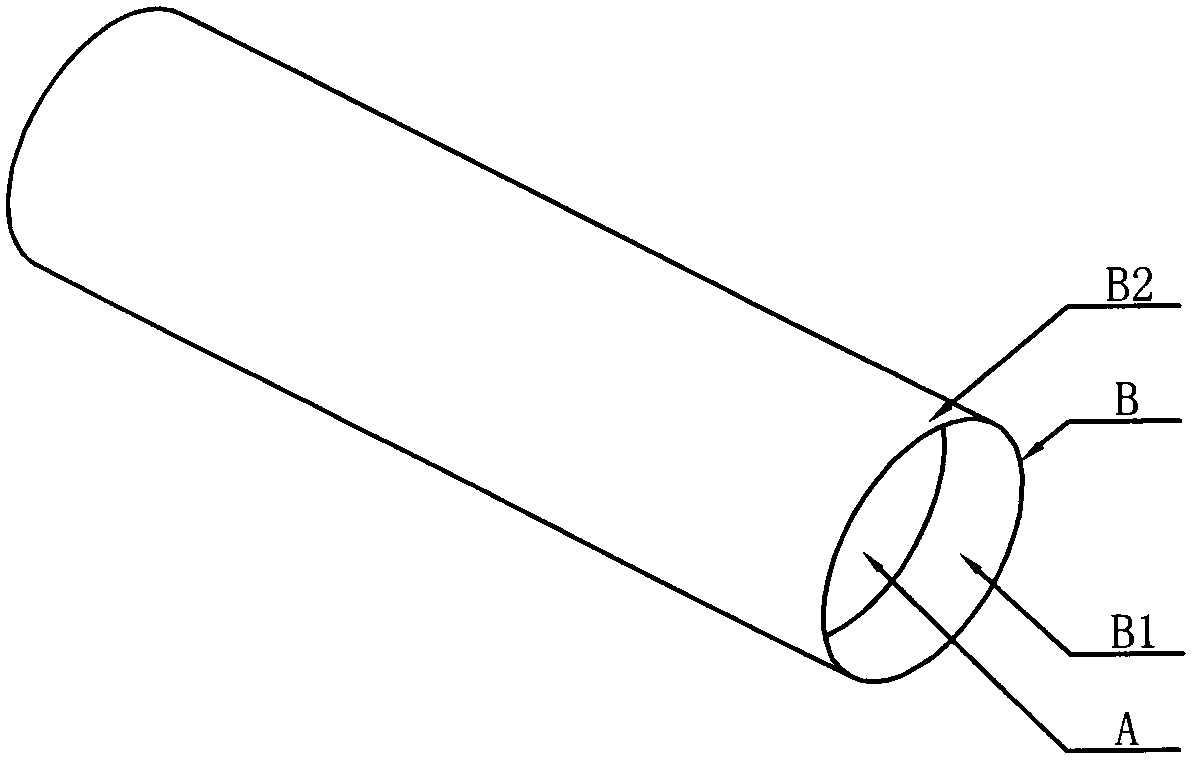

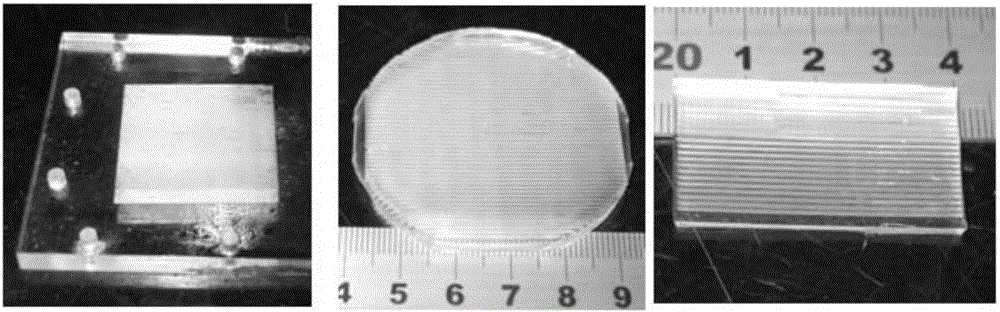

Nerve grafting object containing orientation nanofiber nerve tract and preparing method of nerve grafting object

The invention relates to the biomedical field of high molecular materials, in particular to a nerve grafting object containing an orientation nanofiber nerve tract and a preparing method of the nerve grafting object. A core (A) composed of the nanofiber tract is placed in the middle of the nerve grafting object, a sheath (B) composed of an irregular fiber layer (B2) and an orientation layer (B1) is arranged on the outer face of the nerve grafting object, the diameter of the core (A) composed of the nanofiber tract is 2-5mm, the length of the core (A) composed of the nanofiber tract is 3-15mm, the fiber diameter of the nanofiber tract is 40-300nm, the length of the sheath (B) is 9-25mm, the orientation layer (B1) comprises parallel-arrayed fibers of 100-500nm, and the irregular fiber layer (B2) comprises disorder-arrayed fibers of 100-500nm. The technology is stable, grafting object size is adjustable, the clinic requirement is met, production efficiency is improved, industrialization is convenient, guiding performance is high, using is convenient, and practicability is improved.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

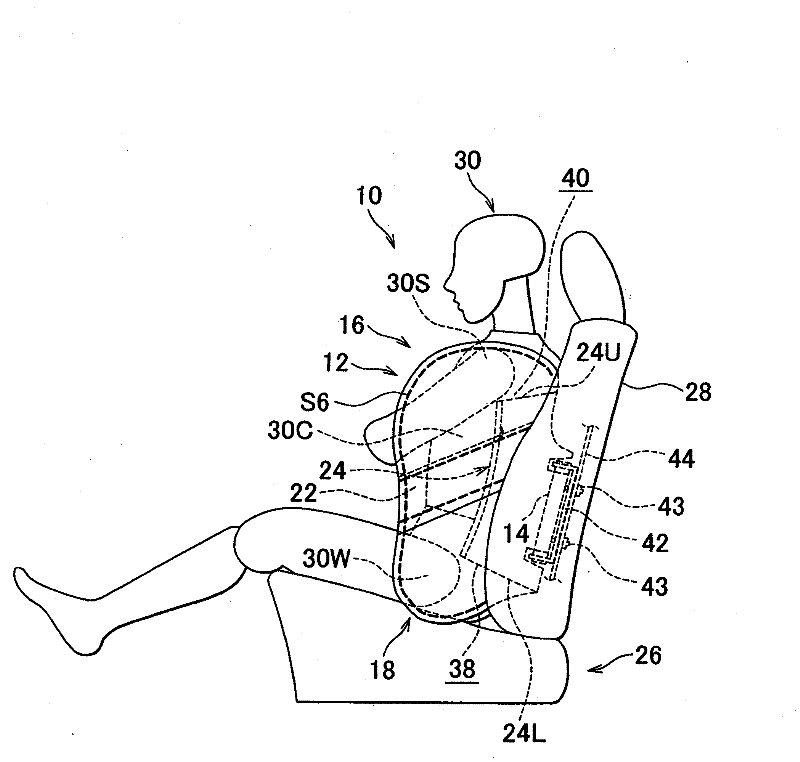

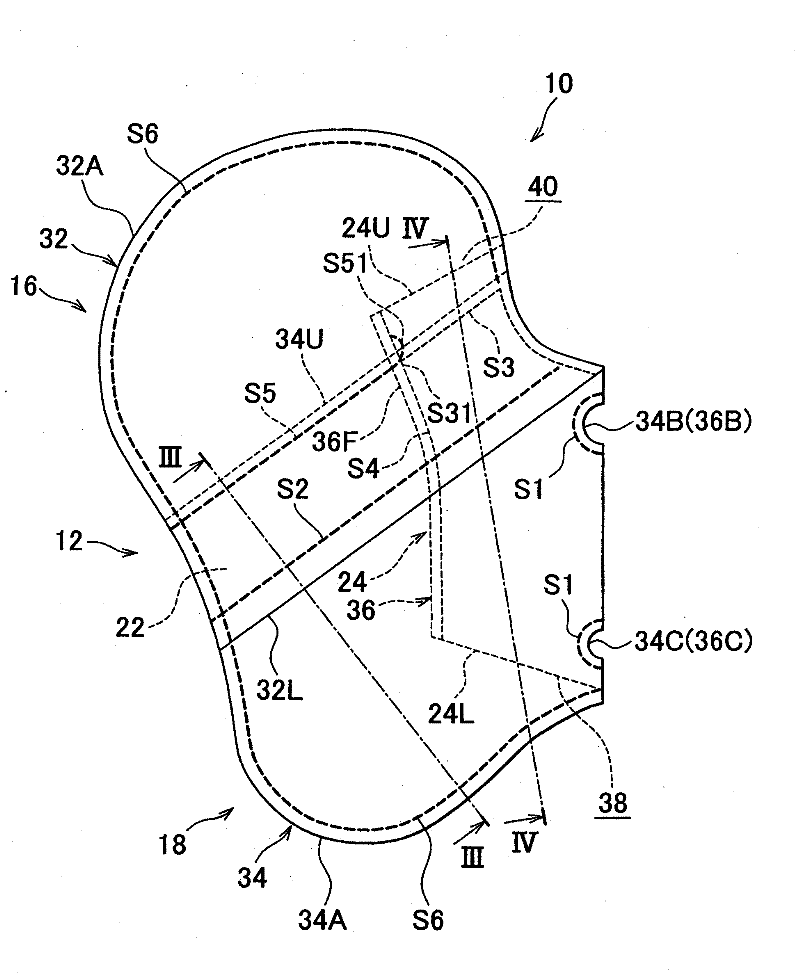

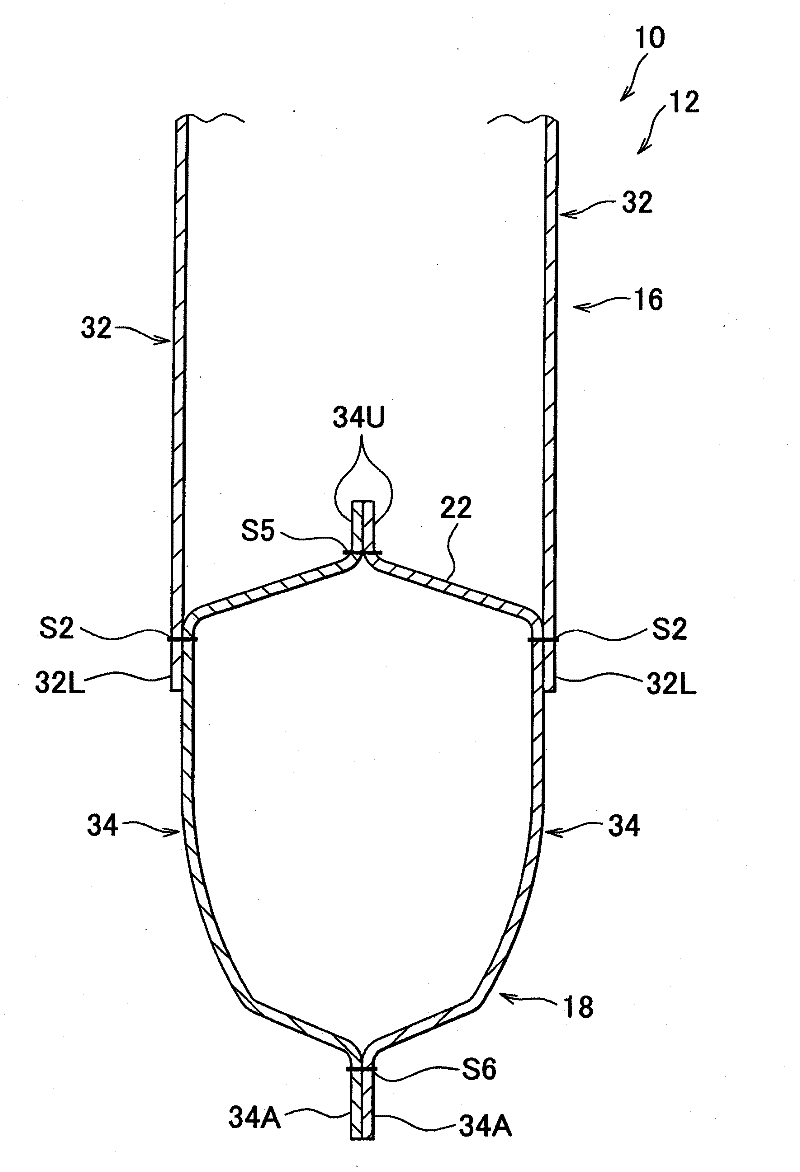

Side airbag system and method of manufacturing side airbag

InactiveCN102317122AEasy to sutureImprove air tightnessPedestrian/occupant safety arrangementLateral airbagMechanical engineering

In a side airbag system (10), a tether portion (22), which serves as a partition between an upper bag portion (16) and a lower bag portion (18), is formed of upper regions (34U) of a piece of lower base fabric (34), and is formed by sewing the upper regions (34U) of the lower base fabric (34), folded toward a vehicle front side along a fold axis, together. In addition, a tube (24) that distributes inflation gas between the upper bag portion (16) and the lower bag portion (18) extends through the tether portion (22) to the lower bag portion (18) and to the upper bag portion (16). The tube (24)is formed into a cylindrical shape in such a manner that a piece of tube base fabric (36) is sewed to the upper regions (34U) of the lower base fabric (34) and folded toward a vehicle front side along the fold axis and then front ends (36F) of the folded tube base fabric are sewed together in a tube longitudinal direction.

Owner:TOYOTA JIDOSHA KK +1

Light field intraoral 3D scanner with structured light illumination

ActiveUS11096765B2Avoid heatingEnergy efficiencyImage enhancementImpression capsMedicineLight-field camera

A handheld wand comprises a probe at a distal end of the elongate handheld wand. The probe includes a light projector and a light field camera. The light projector includes a light source and a pattern generator configured to generate a light pattern. The light field camera includes a light field camera sensor, the light field camera sensor comprising an image sensor comprising an array of sensor pixels, and an array of micro-lenses disposed in front of the image sensor such that each micro-lens is disposed over a sub-array of the array of sensor pixels.

Owner:ALIGN TECH

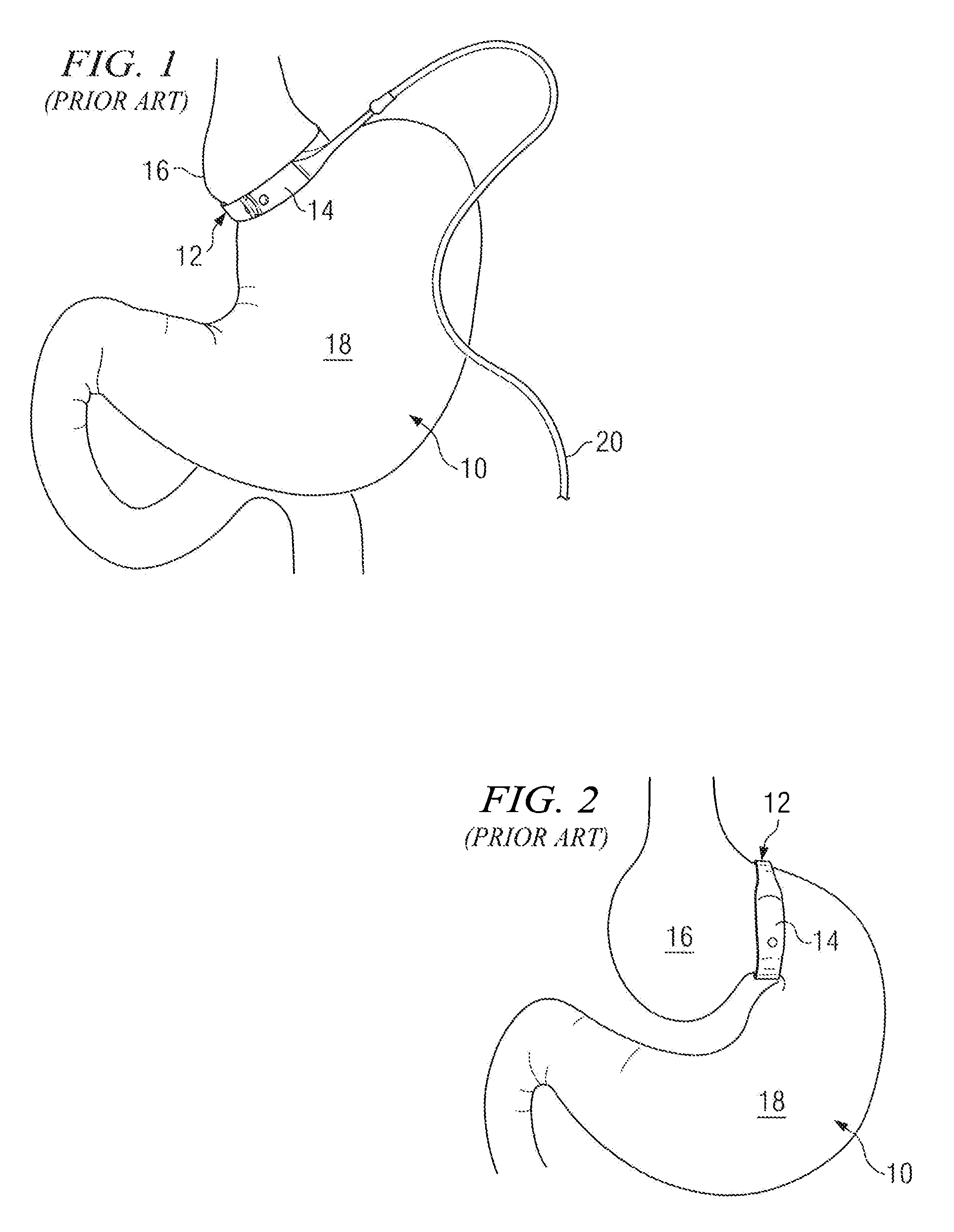

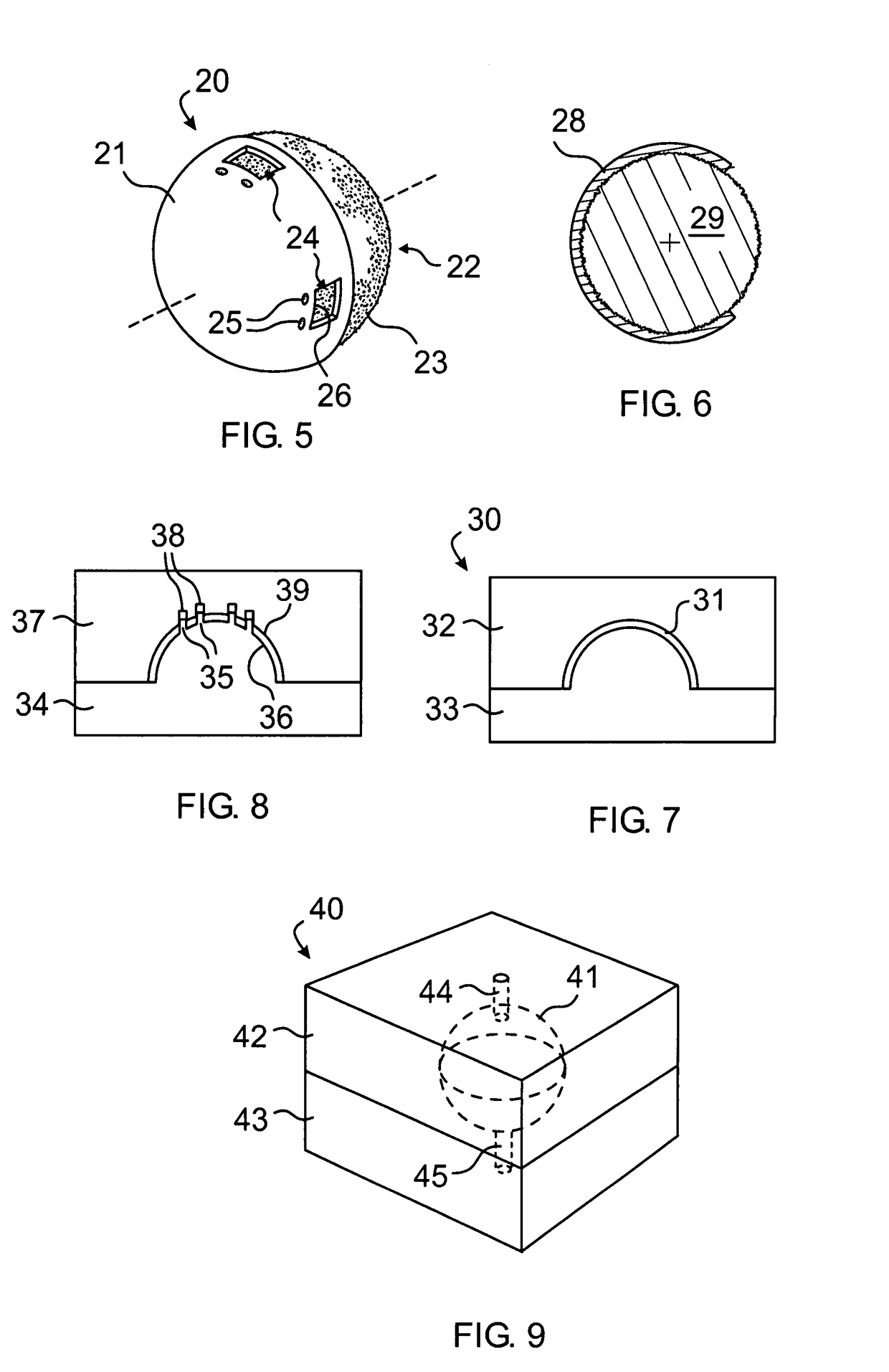

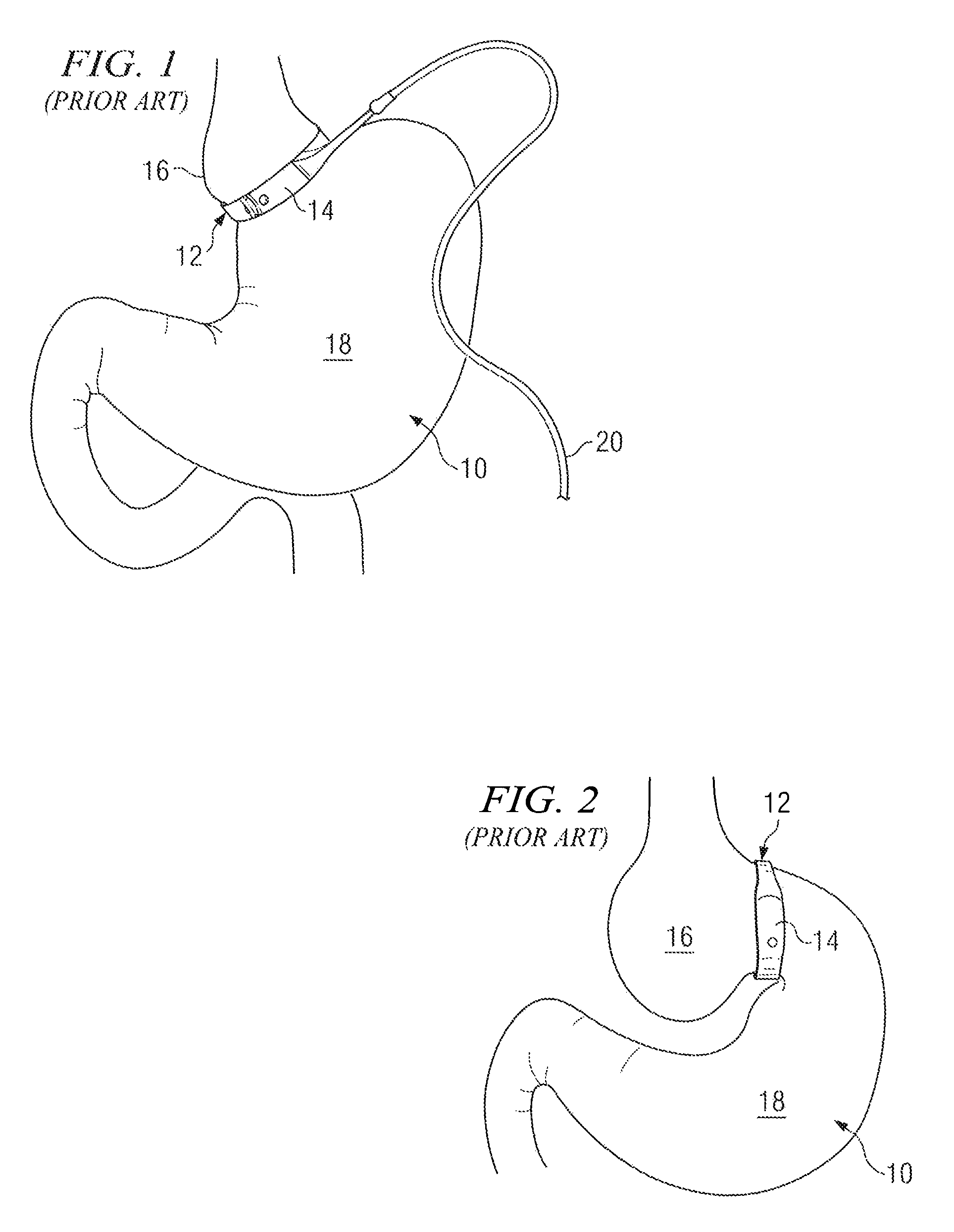

Method of and apparatus for prevention of adjustable gastric band slips

InactiveUS20070249894A1Easy to adjustEasy to sutureSuture equipmentsTourniquetsLaparoscopic adjustable gastric bandingAdjustable gastric band

A gastric restrictive device positionable around a human stomach to limit the flow of food therethrough is provided with structure for facilitating suturing of the gastric restrictive device to the stomach and thereby preventing movement of the gastric restrictive device relative to the stomach.

Owner:NICHOLSON IV WILLIAM DANIEL

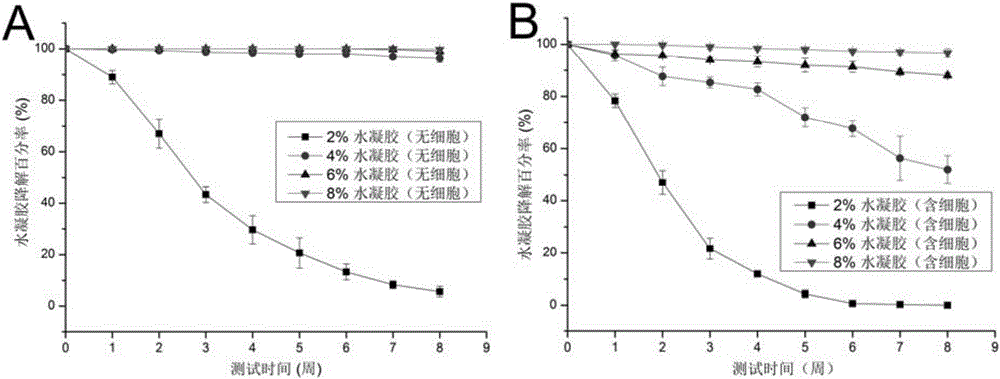

Myocardial patch and preparation method thereof

InactiveCN105749350AGood mechanical propertiesGood restorativeTissue regenerationProsthesisGramNormal growth

The invention relates to a myocardial patch and a preparation method thereof and discloses a hydrogel scaffold.The hydrogel scaffold is prepared according to a method including steps: (1) using gelatin for preparing a gelatin solution with the concentration being 4-10%w / v, then preparing a transglutaminase solution, adding the transglutaminase solution into the gelatin solution according to a proportion that per gram of gelatin is added with not less than 5U of transglutaminase, and well mixing to obtain a hydrogel solution; (2) adding cells into the hydrogel solution, well mixing to obtain a hydrogel solution containing the cells, and gelatinizing to obtain the hydrogel scaffold.The hydrogel scaffold is excellent in mechanical property, cell growth normality is guaranteed, and body injuries can be effectively repaired.The myocardial patch prepared from the hydrogel scaffold is 2-4mm in thickness and convenient for surgical suture, and normality in growth of compound cells is ensured.Furthermore, the myocardial patch is excellently effective in myocardia repair and has a promising clinical application prospect.

Owner:SICHUAN UNIV

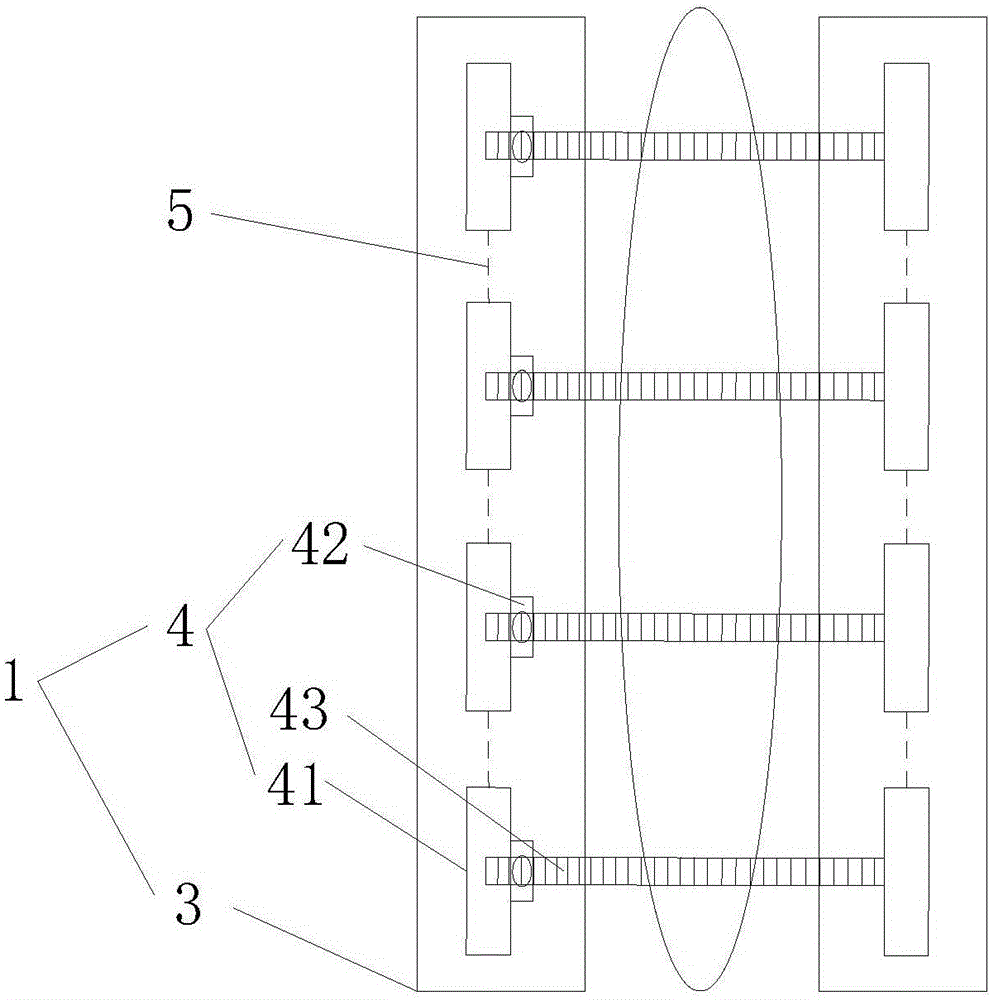

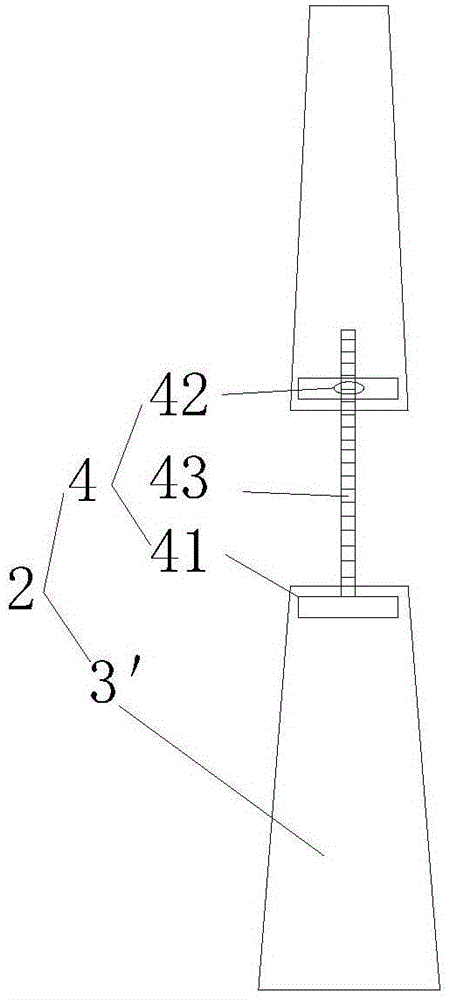

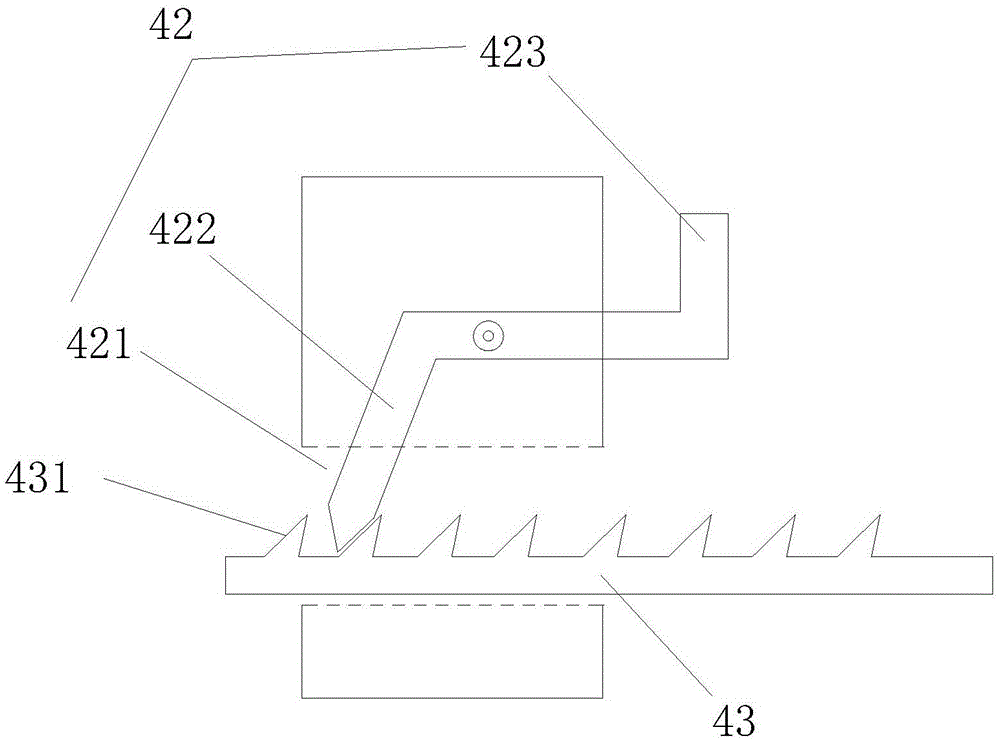

Adjustable skin wound stapler

ActiveCN106308860ASolve the direct view operationMeet the need for optimum suture forceSuture equipmentsFastenerBiomedical engineering

The invention discloses an adjustable skin wound stapler. The adjustable skin wound stapler includes main stapler bodies and patch stapler bodies which are connected mutually; the main stapler bodies and the patch stapler bodies are arranged alternatively; the main stapler bodies and the patch stapler bodies consist of two side base clothes and thorn strip locking devices; each thorn strip lock fastener device includes a support strip, a lock fastener and a thorn strip; the lower surfaces of the support strips are connected to the base clothes; the lock fasteners are arranged the base clothes at one sides of the main stapler bodies and the patch stapler bodies; and one ends of the thorn strips are arranged on the base clothes at the other sides of the main stapler bodies and the patch stapler bodies, and the other ends of the thorn strips are movably connected to the lock fasteners. The adjustable skin wound stapler is breathable, is adjustable in tightness, is wide in application range, and is excellent in suture.

Owner:胡波 +2

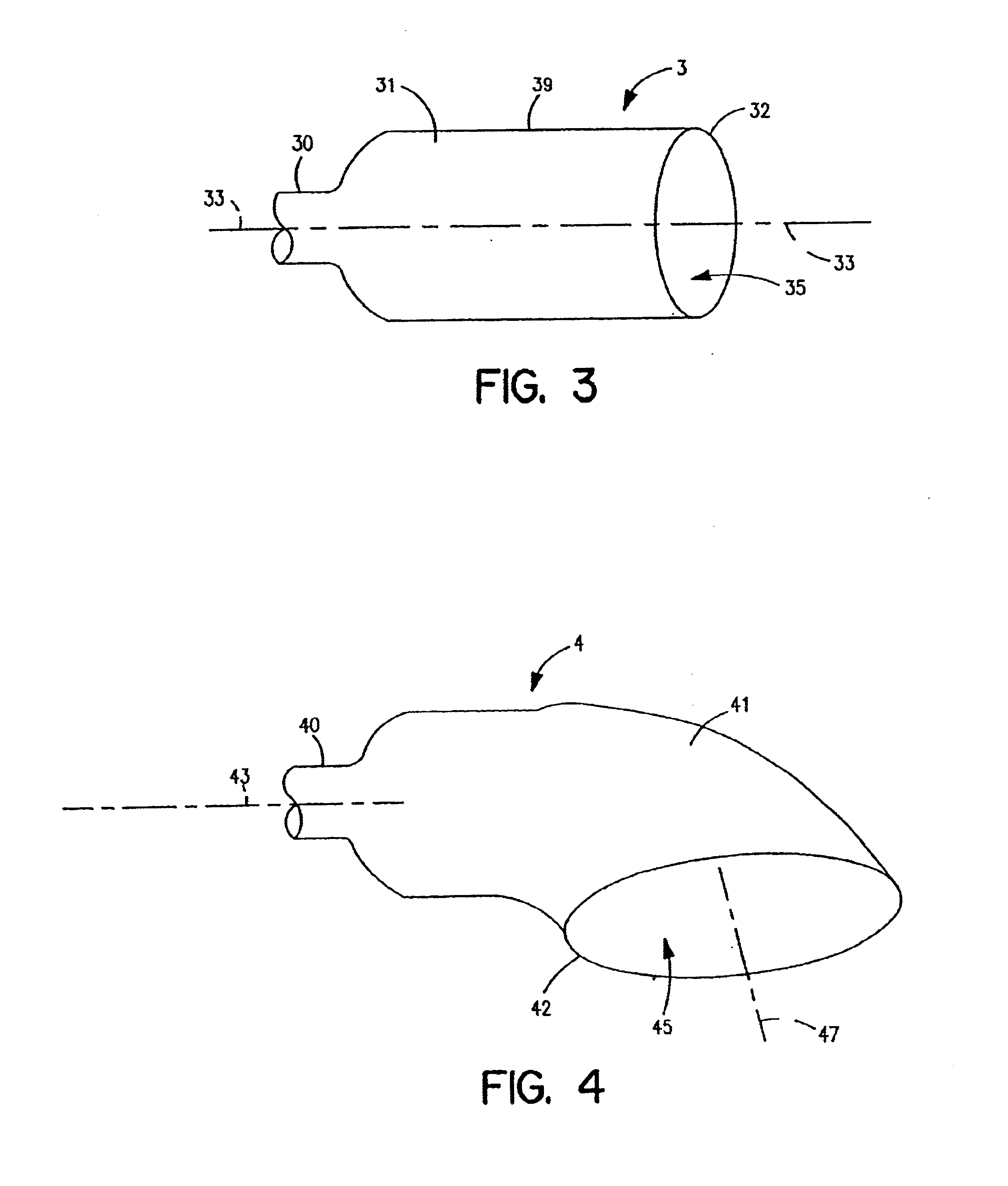

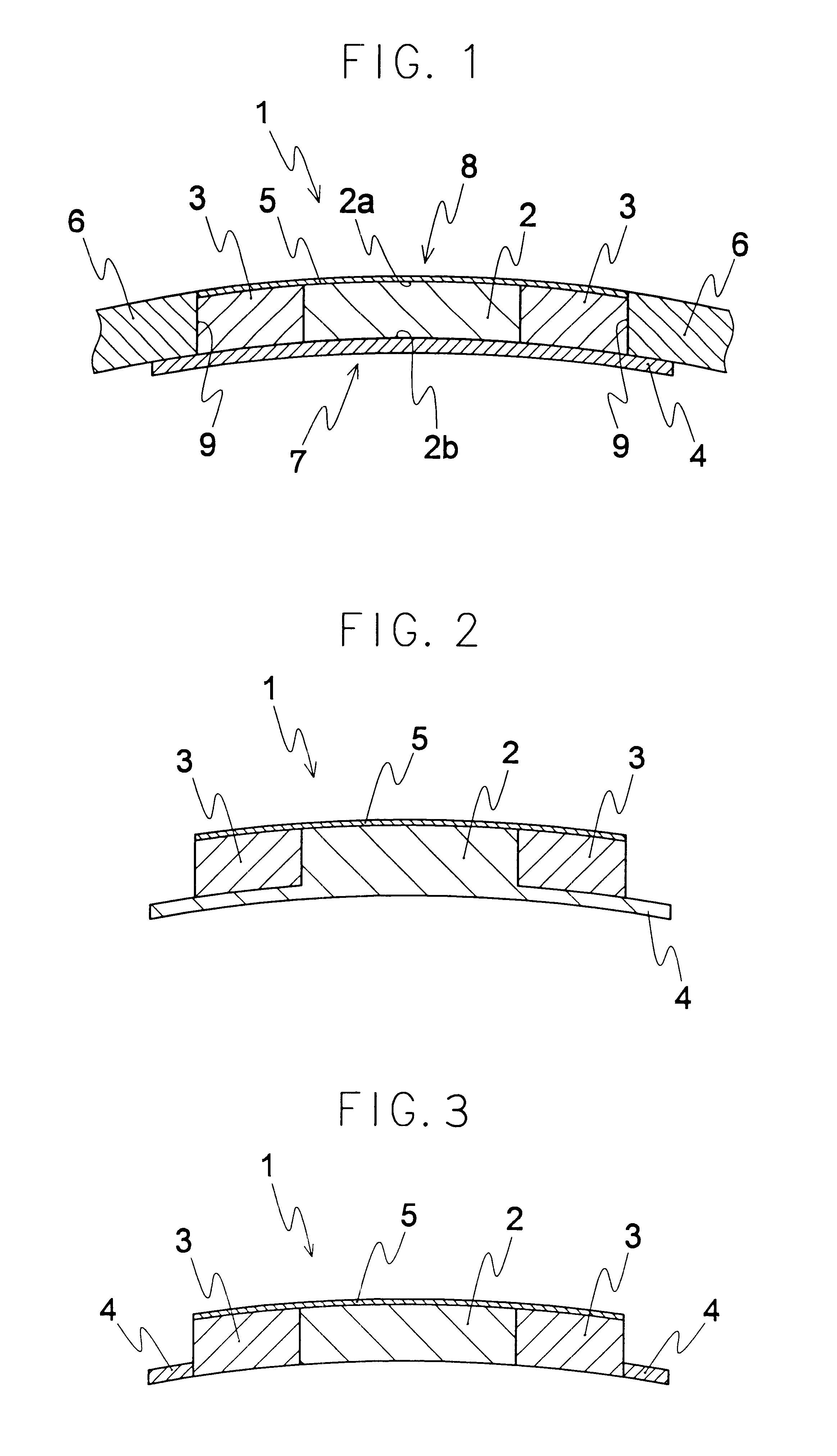

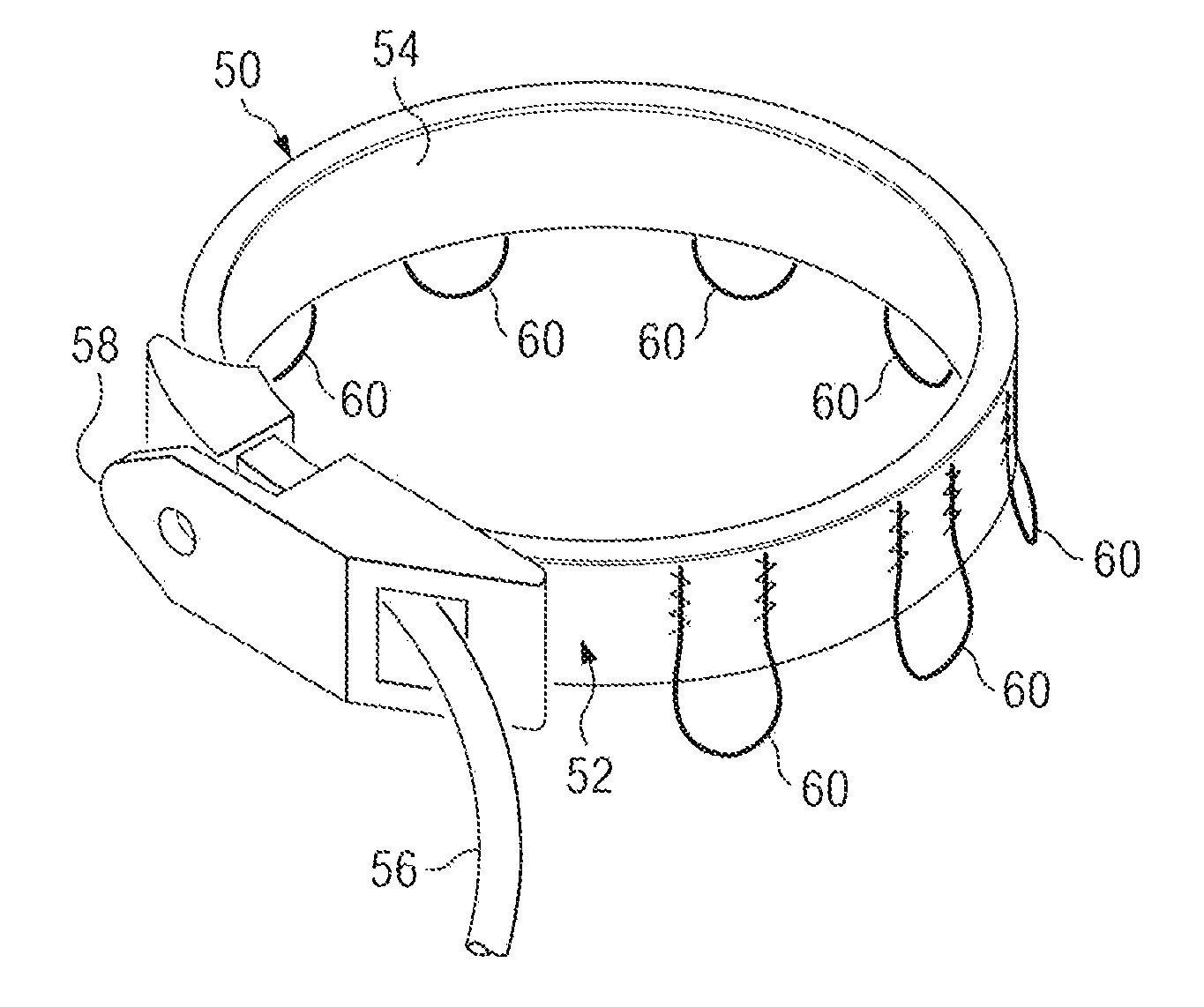

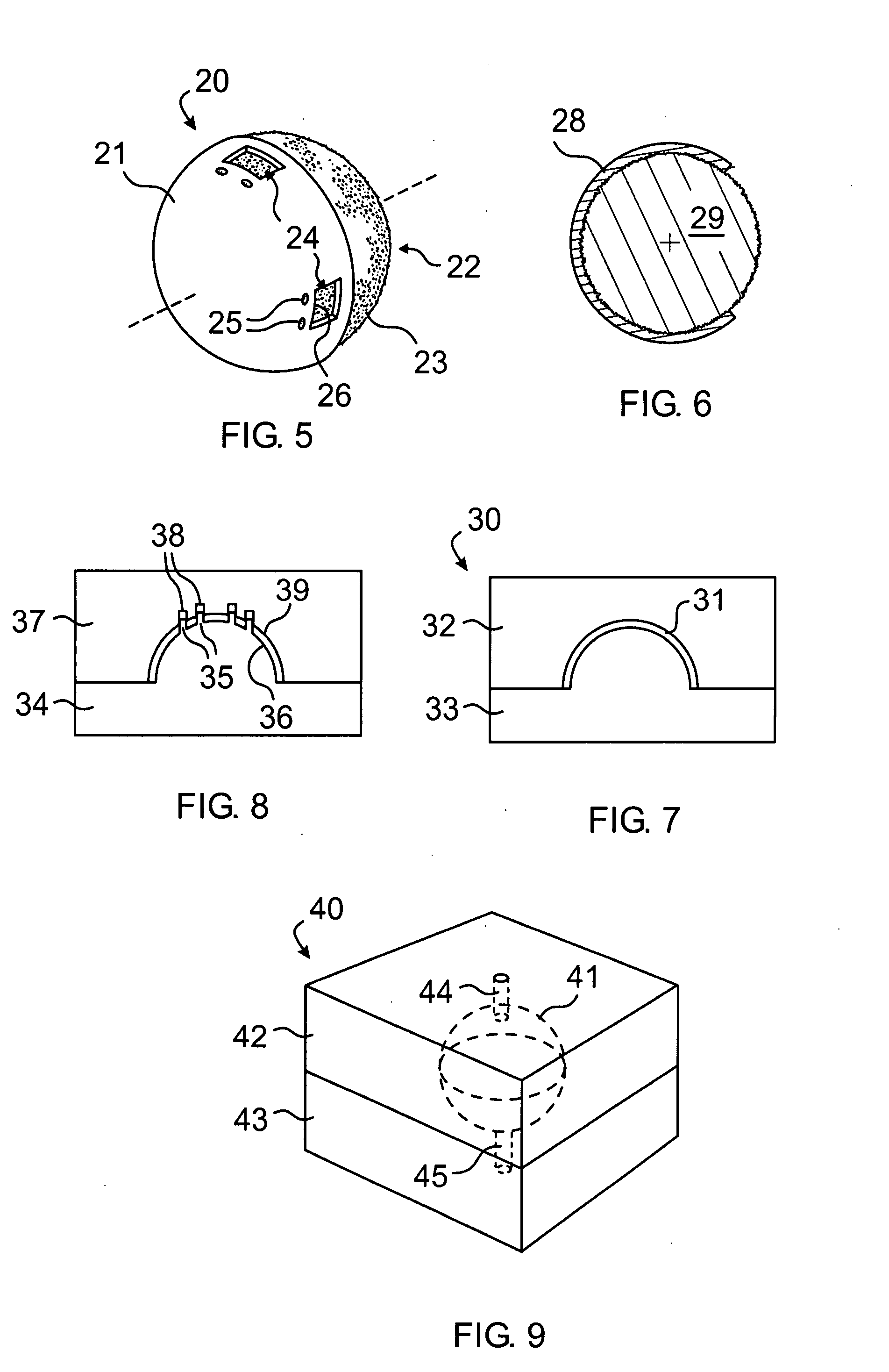

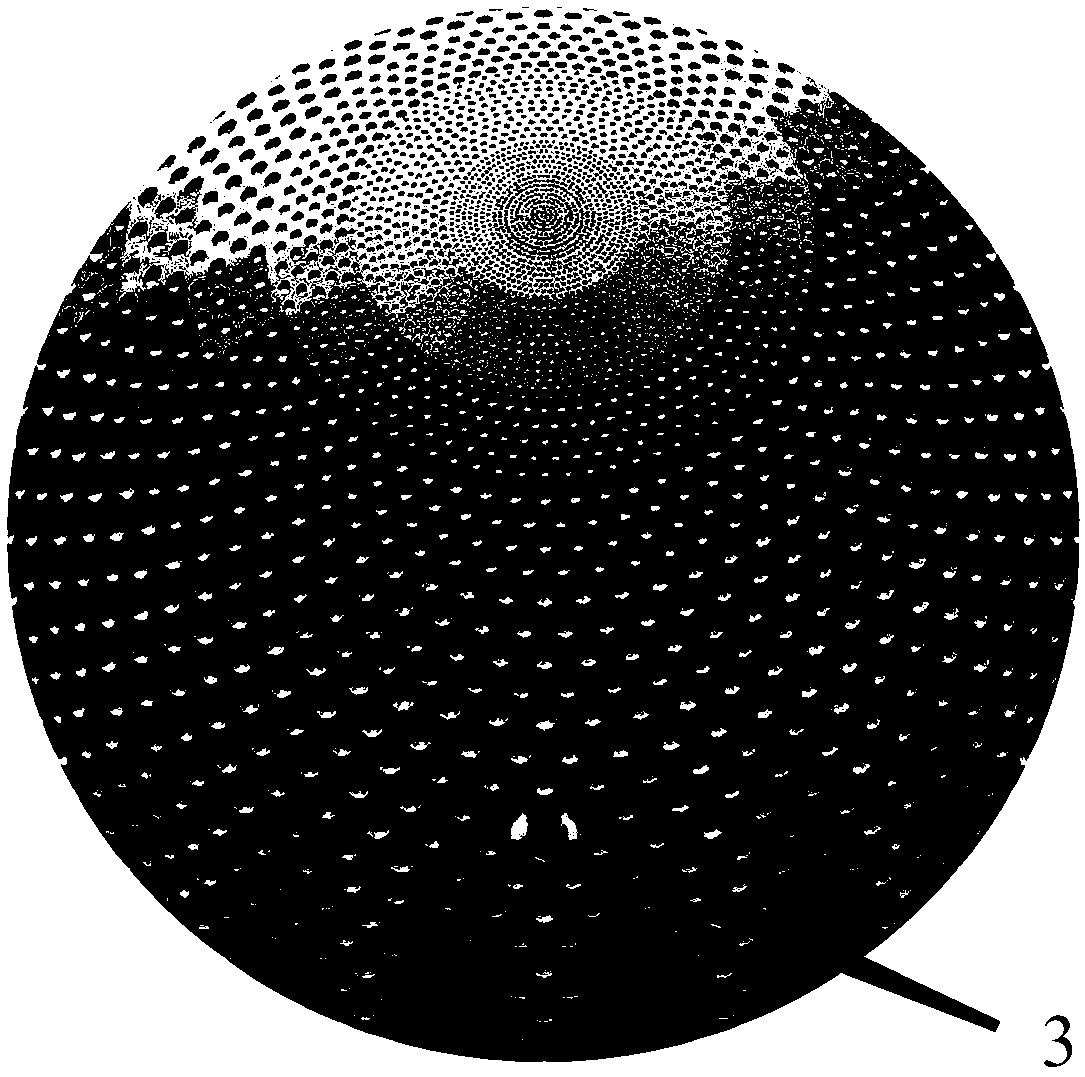

Orbital implant coating having bulbously raised suture zone

A coating for an orbital implant where the coating has an anterior portion having a different, longer term bioabsorbability than a posterior portion. This allows the implant to have a smooth surface for insertion and to provide reduced irritation to neighboring tissues, to help prevent exposure of the porous core of the implant, and to provide a stable anchorment for extraocular muscles, but which also encourages rapid fibrovascular ingrowth. The coating is marked with a visual indicator to facilitate proper orientation. Shell materials are further selected to allow for sterile packaging, the securing of therapeutic agents thereon, and to provide adequately strong securing of the coating to the core. Apertures are formed through the coating to enhance fluid flow to and from the core, and to provide exposure of the surface of the core to extraocular muscles, and for sutures. The apertures are sized and shaped to reduce irritating surface contact with orbital tissues. In an alternate embodiment, one of the coating portions has a bulbous raised zone encompassing suture holes. The gap created between the undersurface of the raised zone and the core facilitates threading of the sutures.

Owner:PERRY ARTHUR C

Method of and apparatus for prevention of adjustable gastric band slips

InactiveUS7566298B2Easy to controlTotal caloric intake is reducedSuture equipmentsTourniquetsLaparoscopic adjustable gastric bandingAdjustable gastric band

A gastric restrictive device positionable around a human stomach to limit the flow of food therethrough is provided with structure for facilitating suturing of the gastric restrictive device to the stomach and thereby preventing movement of the gastric restrictive device relative to the stomach.

Owner:NICHOLSON IV WILLIAM DANIEL

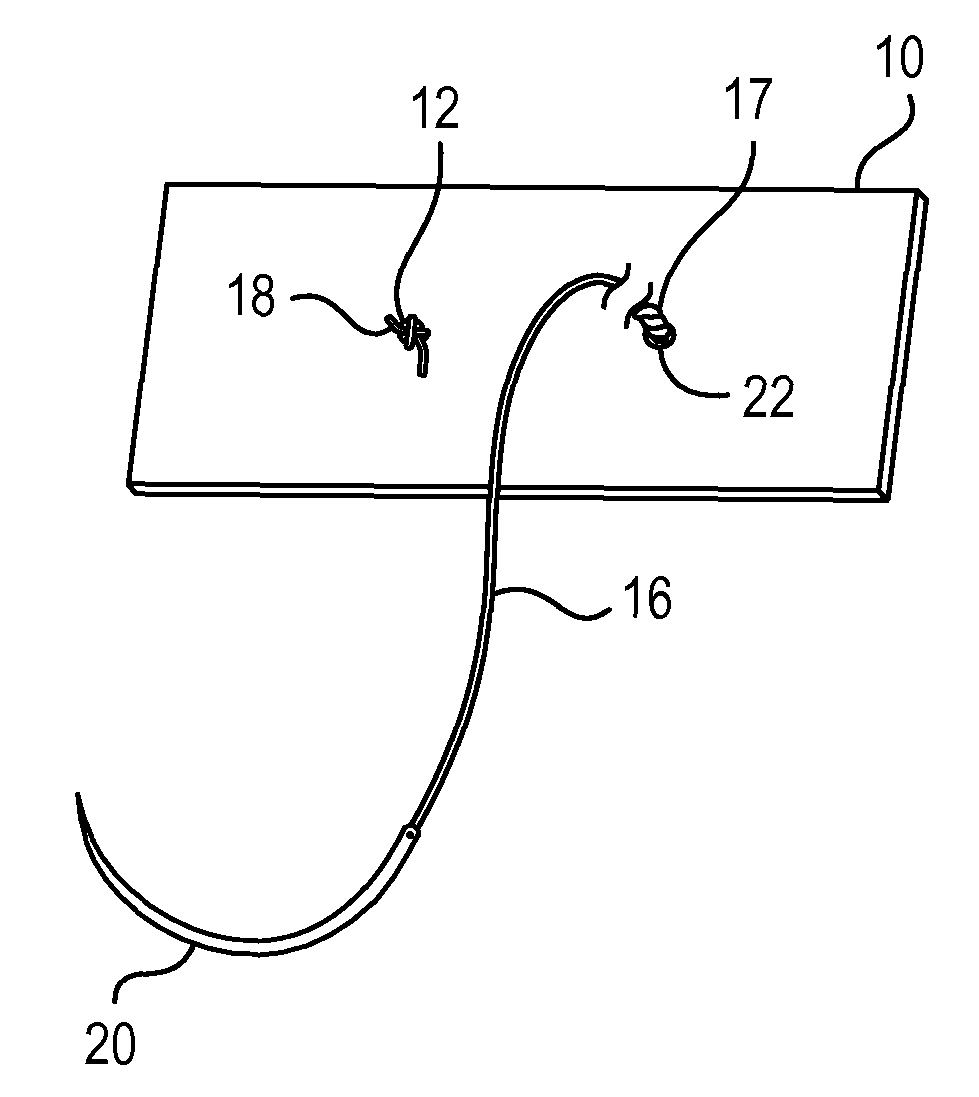

Drug depots having one or more anchoring members

ActiveUS8202531B2Reduces unwanted migrationImprove efficacySuture equipmentsAntipyreticTarget tissueInflammation

A drug depot implantable at or near a target tissue site beneath the skin of a patient is provided, the drug depot comprising a therapeutically effective amount of a drug and at least one surface adapted to receive one or more anchoring members so as to limit movement of the drug depot at or near the target tissue site, wherein at least one region of the drug depot is capable of releasing the therapeutically effective amount of the drug over a period of at least one day. In some embodiments, the drug depot provided can include an effective amount of at least analgesic and at least one anti-inflammatory agent at or near a target site, and can reduce, prevent or treat inflammation and / or pain, particularly postoperative pain.

Owner:WARSAW ORTHOPEDIC INC

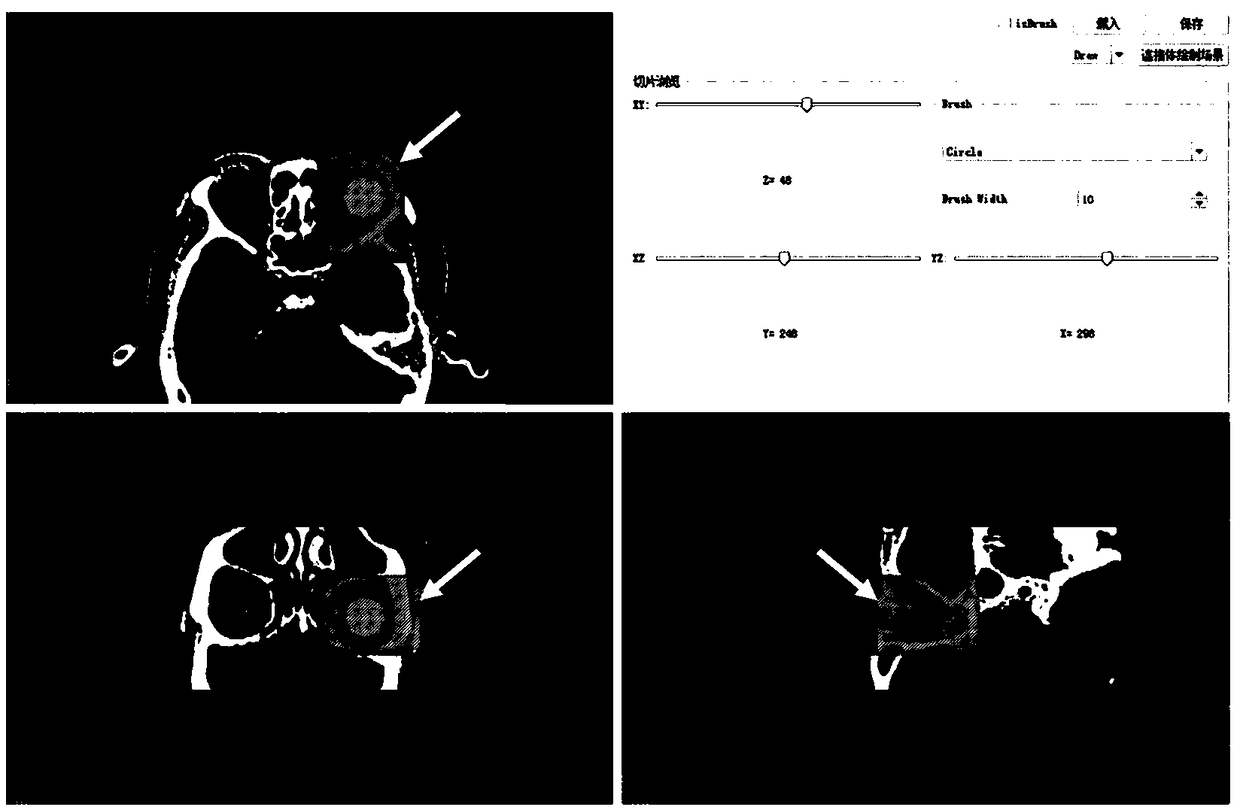

System And Method For Integrated Pair-Wise Registration Of Images Using Image Based Information And Sensor Coordinate And Error Information

ActiveUS20120194879A1High accuracyExcessive weightCharacter and pattern recognitionPictoral communicationImage resolutionImage based

Two images are stitched together through minimization of a cost function that consists of registration errors from image data of the two images, as well as the estimated errors from a set of sensors. The weight function in the cost function is derived from the confidence value of sensor estimation that considers the sensor errors including lift and off page as well as a measure of accuracy of the sensor readings. Weights are used to adjust image registration accuracy against sensor accuracy to produce a set of registration parameters that would best stitch the two images together. In order to handle large errors for initial registration parameters and to avoid local minima in the minimization process, the image pair may be registered in a lower resolution and then refined in a higher resolution.

Owner:SEIKO EPSON CORP

Orbital implant coating having bulbously raised suture zone

InactiveUS20070191942A1Reduce stimulationGood adhesionIntraocular lensOrbital implantExtraocular muscles

A coating for an orbital implant where the coating has an anterior portion having a different, longer term bioabsorbability than a posterior portion. This allows the implant to have a smooth surface for insertion and to provide reduced irritation to neighboring tissues, to help prevent exposure of the porous core of the implant, and to provide a stable anchorment for extraocular muscles, but which also encourages rapid fibrovascular ingrowth. The coating is marked with a visual indicator to facilitate proper orientation. Shell materials are further selected to allow for sterile packaging, the securing of therapeutic agents thereon, and to provide adequately strong securing of the coating to the core. Apertures are formed through the coating to enhance fluid flow to and from the core, and to provide exposure of the surface of the core to extraocular muscles, and for sutures. The apertures are sized and shaped to reduce irritating surface contact with orbital tissues. In an alternate embodiment, one of the coating portions has a bulbous raised zone encompassing suture holes. The gap created between the undersurface of the raised zone and the core facilitates threading of the sutures.

Owner:PERRY ARTHUR C

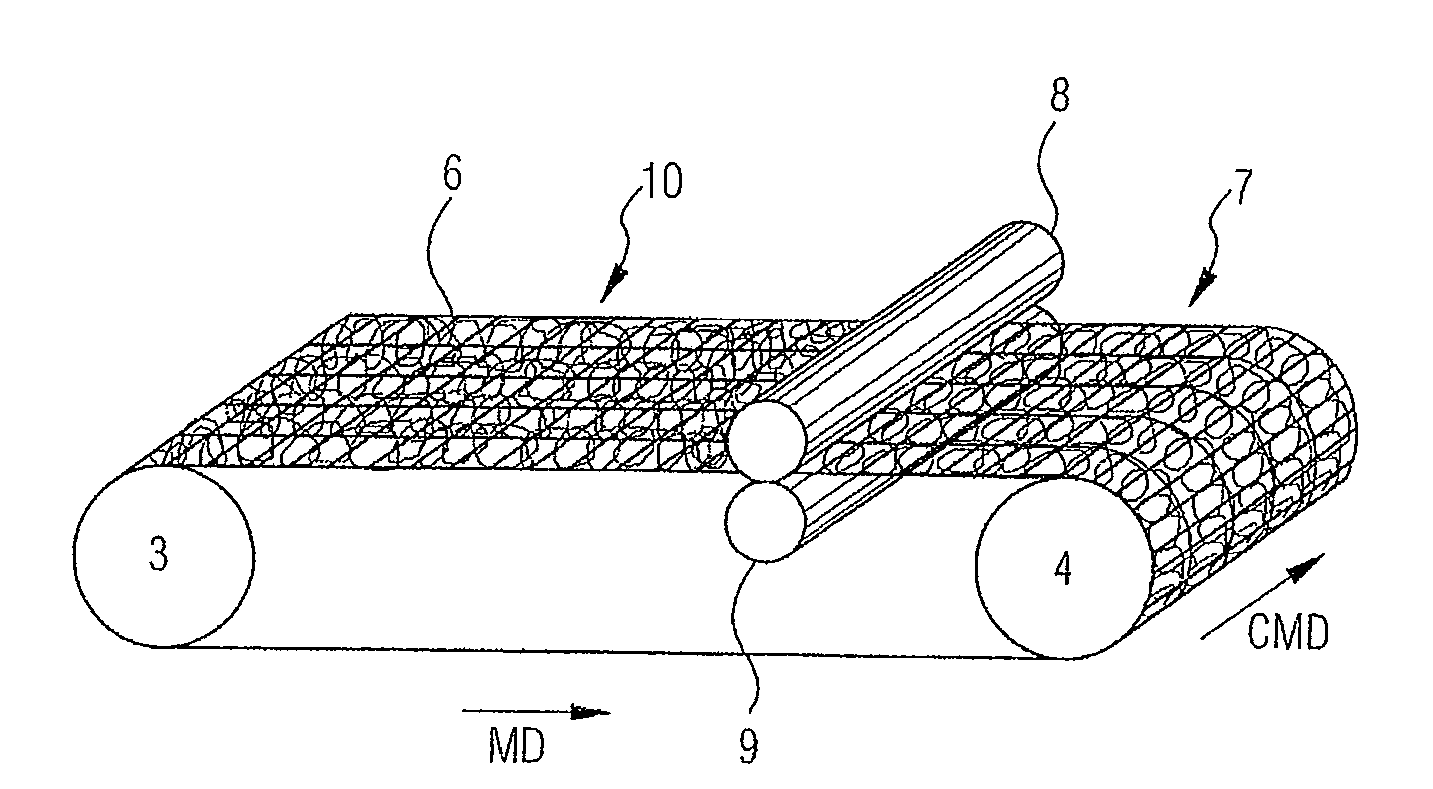

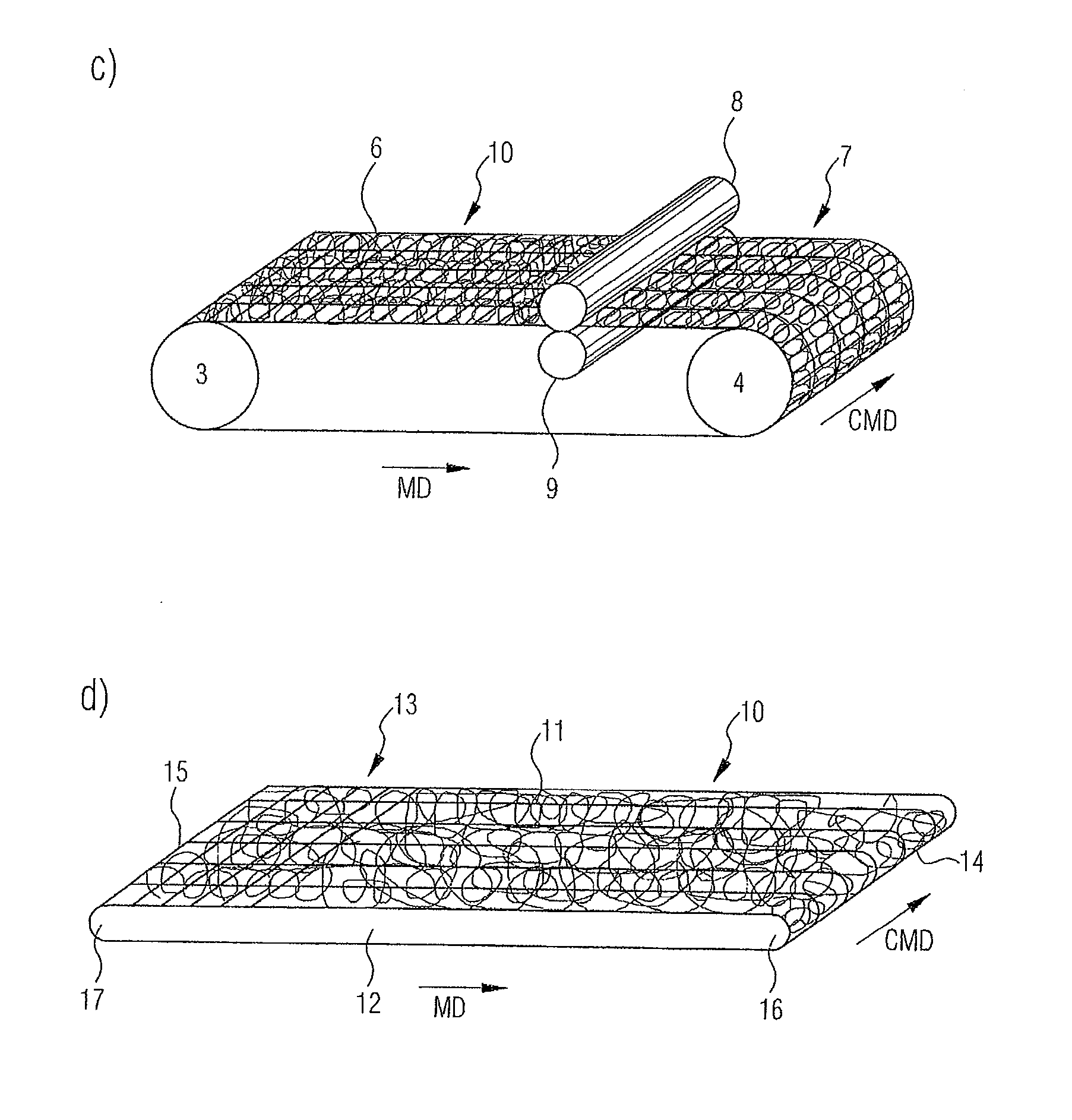

Method for producing a felt belt

The present invention relates to a method for producing a felt belt, particularly a press felt for a paper machine, including the steps of producing a longitudinal thread structure by continuous helical winding of at least one longitudinal thread in the direction of the provided width of the felt belt, particularly up to the provided width of the felt belt; placing a transverse reinforcement structure on the longitudinal thread structure and connecting the same to the longitudinal thread structure to form a tube-like composite structure; placing opposing sections of the tube-like structure one atop the other such that the tube-like structure forms a flat structure whose length corresponds to approximately half the circumference of the tube-like structure and which provides seam loops on its opposing longitudinal sides, the loops being formed by the at least one helically wound longitudinal thread; making the flat structure continuous by merging the opposing seam loops and connecting the same to one another; and connecting the sections of the flat structure placed one atop the other to form a base structure.

Owner:VOITH PATENT GMBH

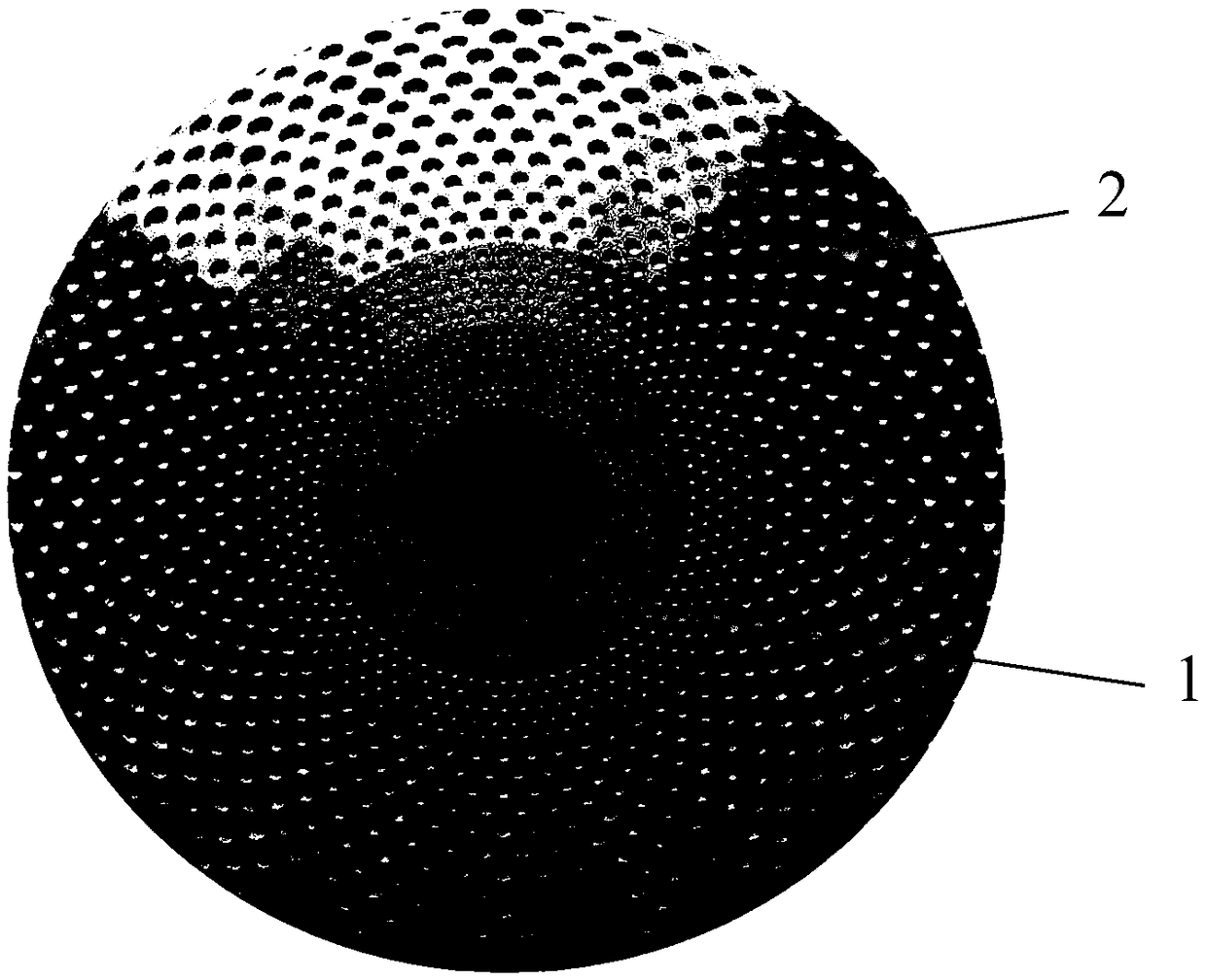

Individualized 3D printing multifunctional artificial orbital implant and preparation method thereof

PendingCN109087387AImprove matchGood clinical application valueImage enhancementImage analysisOphthalmic prosthesisBiomedical engineering

The invention discloses an individualized 3D printing multifunctional artificial orbital implant and a preparation method thereof. The surface of the artificial orbital implant has a porous structure,the pores of the porous structure are circular pores, and the porous structure of the surface is arranged in a gradient manner, and the pores in the porous structure are arranged on the surface of the artificial orbital implant spaced apart; a special structure for fixing four extraocular muscles is arranged on the artificial orbital implant, the special structure consists of two elliptical holeswhich penetrate each other and are arranged close to each other, the preset sutures on the extraocular muscles pass through the two elliptical foramen and are knotted and fixed at the intersection of30 degree north latitude and 0 degree, 90 degree, 180 degree and 270 degree longitude respectively. The prosthetic orbital implant is printed directly by the digital model of the prosthetic orbital implant using 3D printing technology. The artificial orbital implant has high matching degree with the healthy eye and reduces the risk of exposure and infection after implantation of the orbital implant. The artificial orbital implant has good mobility and good simulation effect with individualized ophthalmic prosthesis, and has good clinical application value.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com