Method for producing a felt belt

a technology of felt belts and woven fabrics, applied in the direction of knitting, weaving, shaping/stretching tubular fabrics, etc., can solve the problems of difficult installation of press felts in paper machines, complex production, woven structures, etc., and achieve the effect of easy seaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

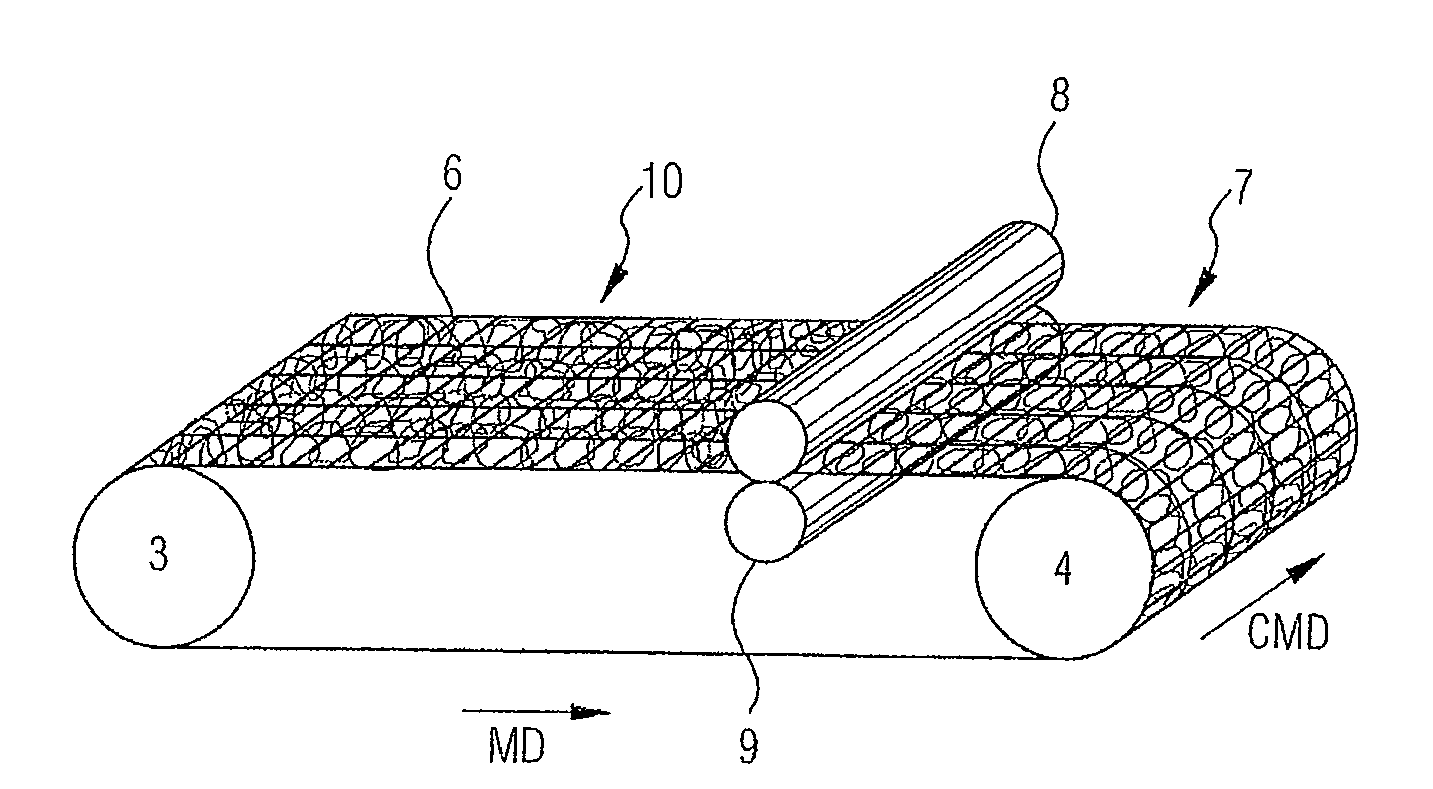

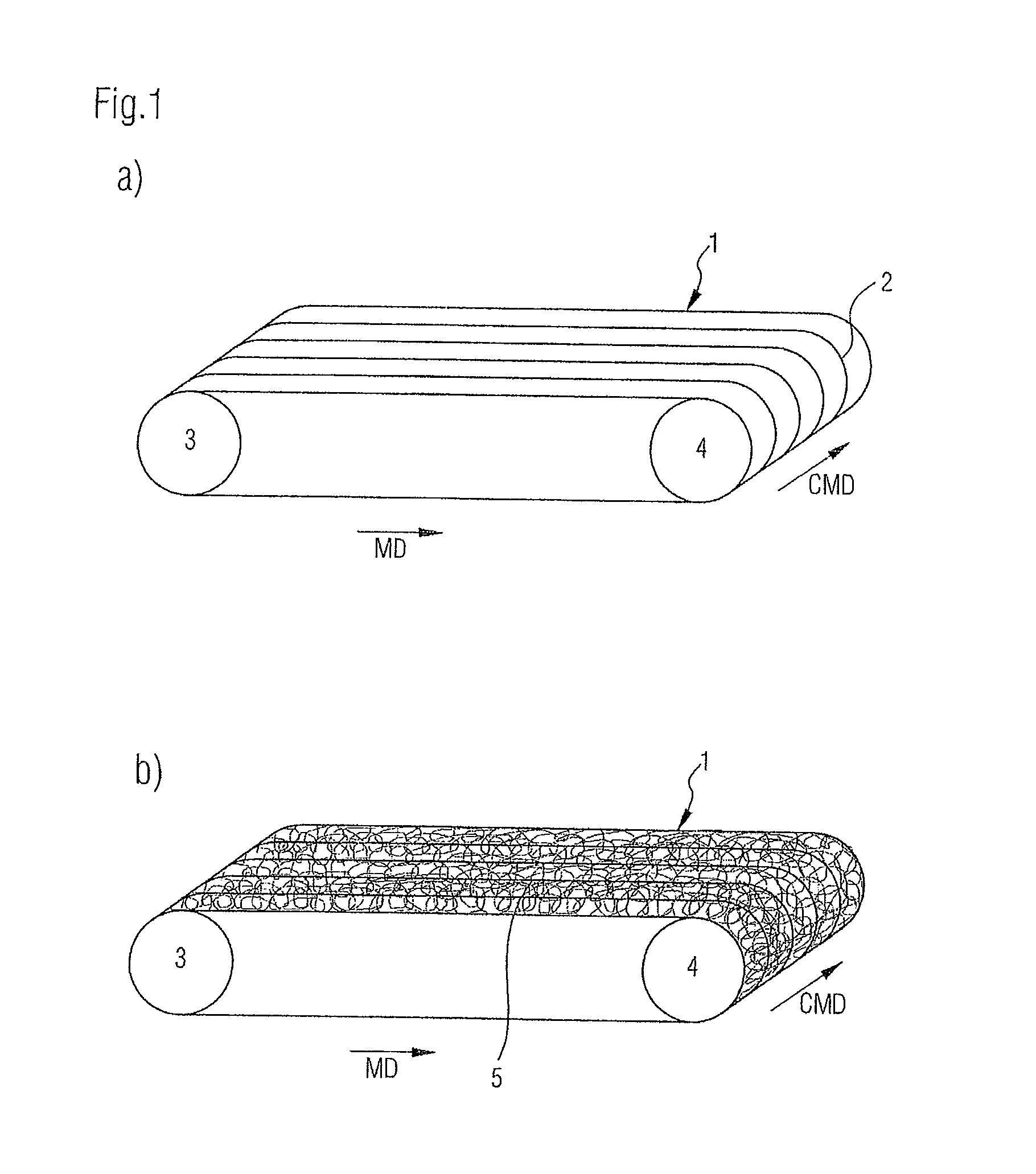

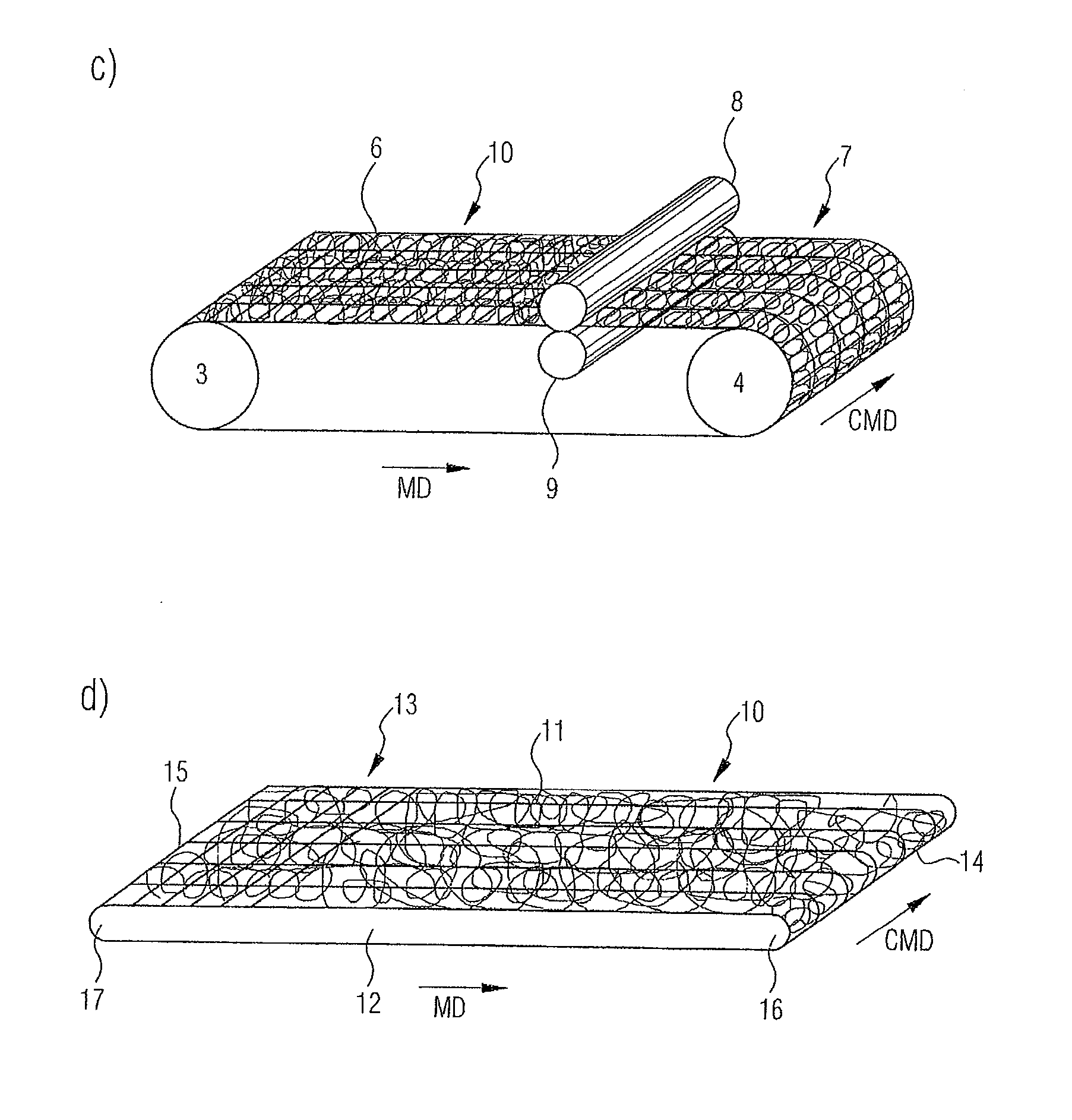

[0042]Referring now to the drawings, and more particularly to FIGS. 1a-1e, there is shown a first embodiment of a method according to the present invention for producing the base structure of a press felt.

[0043]FIG. 1a illustrates the production of longitudinal thread structure 1 of the base structure. To this end, skein of threads 2 parallel to one another are helically wound around two rollers 3, 4 disposed at a distance from and essentially parallel to one another, with the progression of the helical winding, i.e., the winding direction, occurring perpendicularly to the two rollers in the direction of the provided width (CMD) of the felt belt up to the provided width of the felt belt. Here, the length of one winding corresponds to the circumference of thread structure 1 thus formed.

[0044]In the step of the method of the present invention shown in FIG. 1b, carrier layer 5 embodied as a non-woven fibrous layer is applied to thread structure 1; the carrier layer may subsequently be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hot melt | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com