Nerve grafting object containing orientation nanofiber nerve tract and preparing method of nerve grafting object

A nanofiber and nerve transplantation technology, applied in medical science, textile and papermaking, prosthesis, etc., can solve the problem of low probability of contact between damaged nerves and guiding fibers, unstable nerve graft preparation process, and difficulty in surgical suture technology. It is easy to guide the growth of injured nerves, easy to suture in surgery, and the effect of enhanced practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of this specific embodiment is:

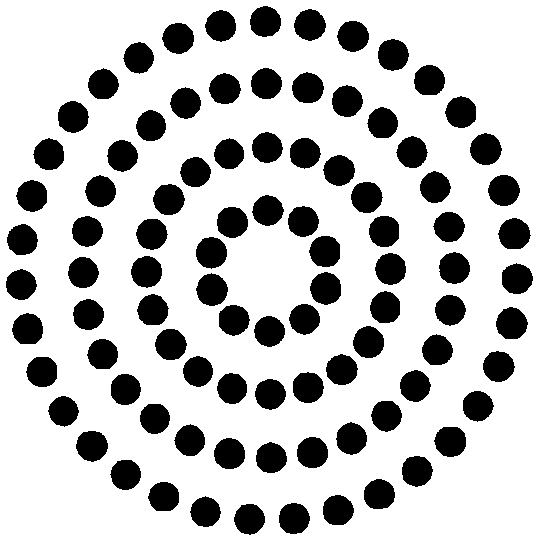

[0028] (1) Select natural high polymers and synthetic high polymers according to needs, and dissolve them in volatile solvents, use electrospinning method, use high-speed rollers to collect, obtain nano-scale fibers arranged in parallel, and fiber orientation Consistent with the direction of rotation of the roller. The diameter of the rotating roller is 200-300mm, and the rotating speed is 0-4000rpm.

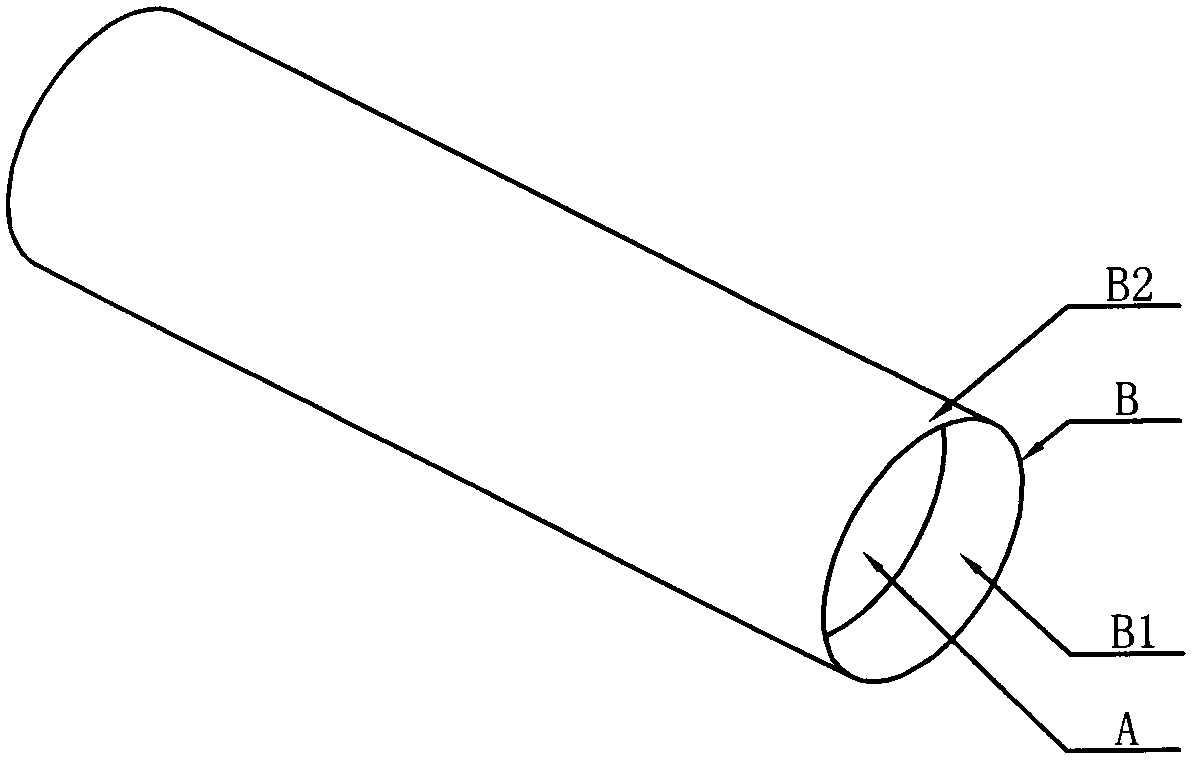

[0029] (2) Remove the fiber film on the rotating roller, cut the fiber film into 3-15mm strips perpendicular to the fiber orientation, and then wrap it on a metal rotating roller with a diameter of 0.1mm. The fiber orientation and the rotating roller axis In parallel, a fiber bundle with a diameter of 2-5mm is formed, which serves as the "core" A of the nerve graft.

[0030] (3) Near the two ends of the fiber bundle, put cylinders with the same diameter as the fiber bundle on the rotating rollers respectively, wit...

Embodiment 1

[0037] 1. Dissolving polyglycolic acid (PGA) in a mixed solvent of chloroform and acetone (2:1 by volume) to obtain a spinning solution with a concentration of 8%. The electrospinning process conditions are: voltage 20KV, distance 11cm, flow rate 3ml / h, collected by a rotating roller, the rotating speed of the rotating roller is 3000rpm, the diameter of the rotating roller is 200mm, electrospinning for 10h, forming an oriented fiber with a width of 10cm and a thickness of 35um membrane.

[0038] 2. Cut the fiber film into 3mm strips perpendicular to the fiber arrangement direction, and wrap them on a rotating roller with a diameter of 0.1mm to form a fiber bundle with a length of 3mm and a diameter of 3mm.

[0039] 3. At both ends of the fiber bundle, put a cylinder with a diameter and a length of 3 mm.

[0040] 4. Cut the fiber membrane into 9mm strips perpendicular to the fiber arrangement direction, and wrap it on the surface of the cylinder and the fiber bundle, wrapping ...

Embodiment 2

[0044] 1. Dissolve PLGA (LA / GA=65:35) in chloroform / N, N-dimethylformamide (DMF) (8:2 by volume) mixed solvent to obtain a spinning solution with a concentration of 15% . The electrospinning process conditions are: voltage 18KV, distance 11cm, flow rate 2ml / h, collected by a rotating roller, the rotating speed of the rotating roller is 1700rpm, the diameter of the rotating roller is 250mm, electrospinning for 10h, forming an oriented fiber with a width of 10cm and a thickness of 38um membrane.

[0045] 2. Cut the fiber film into 5mm strips perpendicular to the direction of fiber arrangement, and wrap them on a rotating roller with a diameter of 0.1mm to form a fiber bundle with a length of 5mm and a diameter of 4mm.

[0046] 3. At both ends of the fiber bundle, put a cylinder with a diameter and a length of 4 mm.

[0047] 4. Cut the fiber membrane into 13mm strips perpendicular to the fiber arrangement direction, and wrap them on the surface of the cylinder and the fiber bun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com