Warp knitted spacer fabric mattress and making method thereof

A warp-knitted spacer fabric, mattress technology, applied in mattresses, spring mattresses, stuffed mattresses, etc., can solve the problem of inability to support the strength and the degree of softness and hardness, affecting the disassembly and assembly process of the mattress cover, and affecting the mattress. Air permeability and other issues can prevent skin eczema, inhibit bacterial growth, and prevent cervical spondylosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

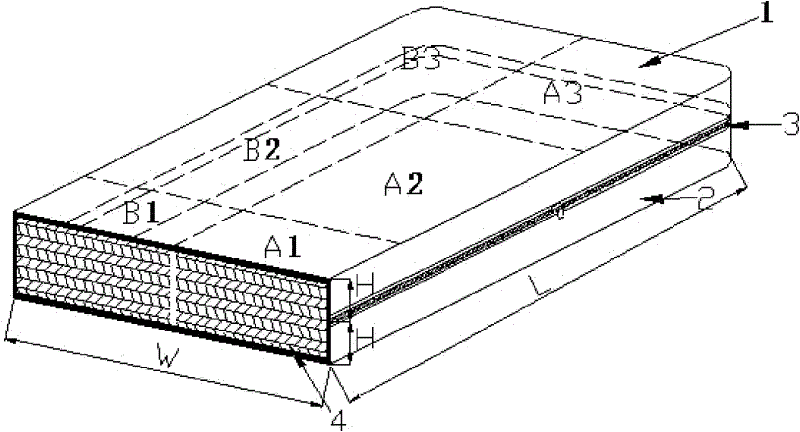

[0038] refer to figure 1 As shown, a warp knitted spacer fabric mattress includes a mattress liner 4 and a mattress cover.

[0039] The mattress cover is a square cover body sewn from an upper surface layer 1, a lower surface layer (not shown at the bottom) and a side wall 2, and the upper surface layer 1, the lower surface layer and the side wall 2 are all warp-knitted spacer fabrics, and the warp-knitted spacer The mesh shape of the fabric can be set into hexagonal, diamond, oval or square according to actual needs. In order to prevent the burrs from being exposed, the edge seam of the warp-knitted spacer fabric is sewn with a double-layer hemming structure. Large-mesh warp-knitted spacer fabric with supporting strength, the supporting pressure is 30-60Kpa, the thickness is 3-12mm, and the air permeability is above 90%. Composition, the upper and lower side belts are detachably connected through the sealing zipper 3; the upper surface layer 1 and the lower surface layer are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com