Fixing device for zipper machine

A technology of fixing device and zipper machine, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and paper making, etc. It can solve problems such as difficult fixing, achieve the effect of reducing distance, preventing tilting and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

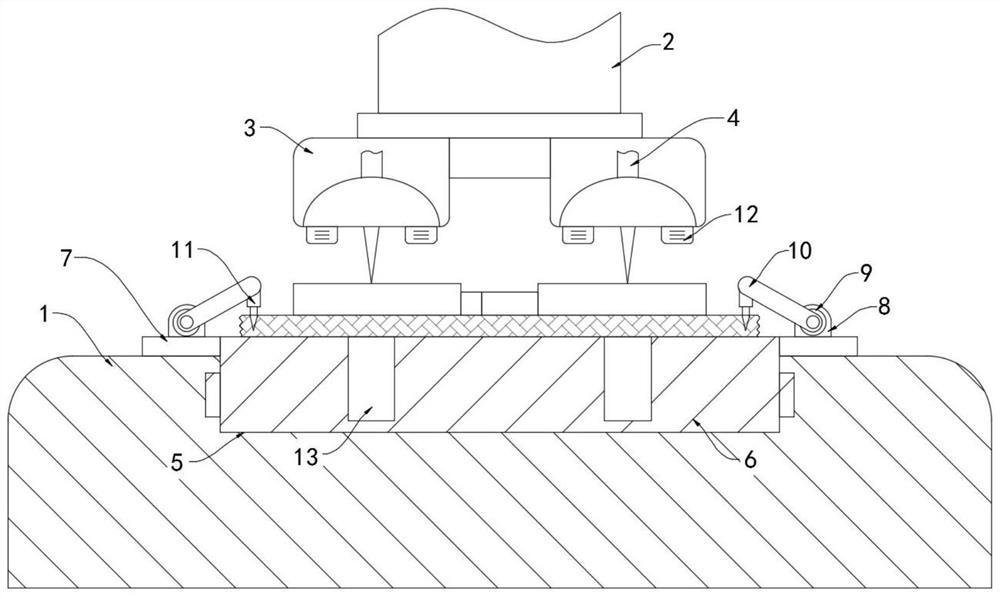

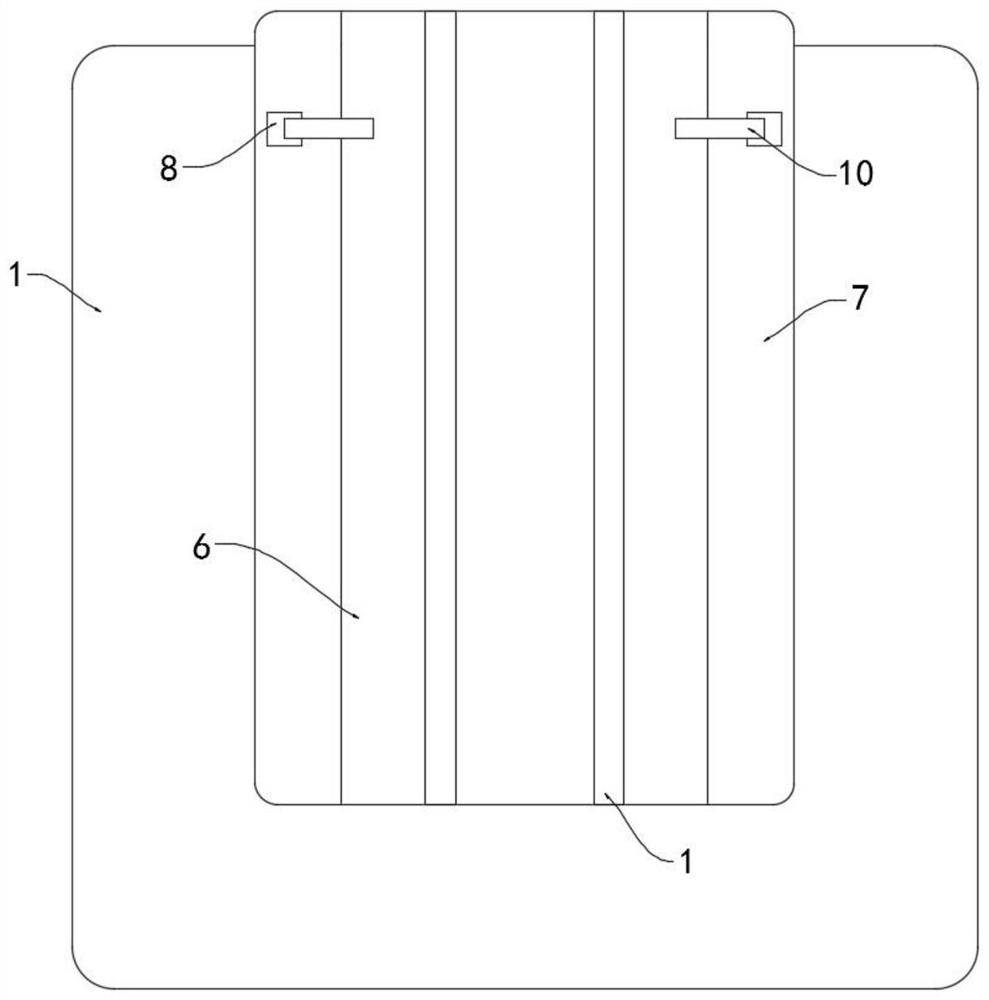

[0021] Such as Figure 1-2 As shown, a fixing device for a zipper machine includes a horizontally arranged placing table 1, the upper end of the placing table 1 is provided with a vertically arranged lifting rod 2, and the lower end of the lifting rod 2 is fixedly connected with two pressing heads 3, each pressing head 3 are provided with needles 4 throughout, and the lifting rod 2 will make the needles 4 reciprocate in the vertical direction under the drive of the driving device. The above is the prior art, and will not be repeated here.

[0022] It is worth mentioning that two symmetrically arranged rollers 12 are fixedly installed on the lower side wall of each pressing head 3, and the rollers 12 can effectively reduce the friction between the pressing head 3 and the textile, and prevent the pressing head 3 from making the placing table 1 The situation where the textile on the top is tilted occurs.

[0023] The upper side wall of the placing table 1 is provided with a vert...

Embodiment 2

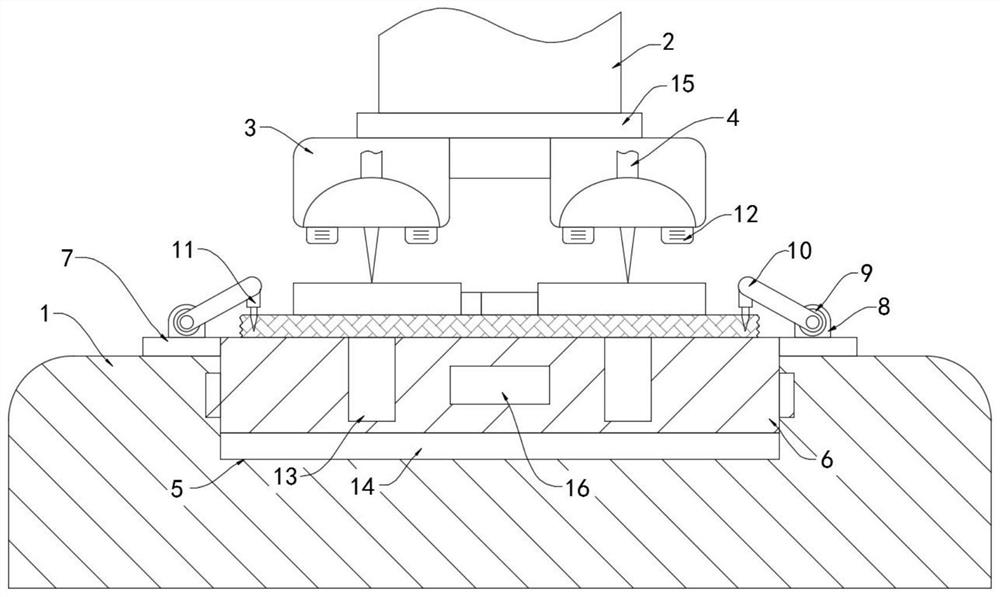

[0029] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that: the lower side wall of the carrier plate 6 is fixedly connected with the lower electrode plate 14, and the pressing head 3 is fixedly connected with the upper electrode plate 15 arranged parallel to the lower electrode plate 14, The upper electrode plate 15 and the lower electrode plate 14 form a capacitor. It should be noted that an electromagnetic block 16 is fixedly embedded in the carrier plate 6 , and the electromagnetic block 16 is coupled to the capacitor formed by the upper electrode plate 15 and the lower electrode plate 14 .

[0030] In this embodiment, in the process of the lifting rod 2 moving up and down, the distance between the upper electrode plate 15 and the lower electrode plate 14 will change momentarily, and the change of the distance between the two electrode plates in the capacitor will cause charging and discharging. Therefore, at this time, the electromagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com