Rotary detection device for accurate looping of linking machine

A technology of rotation detection and sewing machines, which is applied in sewing equipment, looping machines connecting knitted fabrics, textiles and papermaking, etc., and can solve problems affecting the sewing quality of garment pieces, wrong stitches by operators, missing stitches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

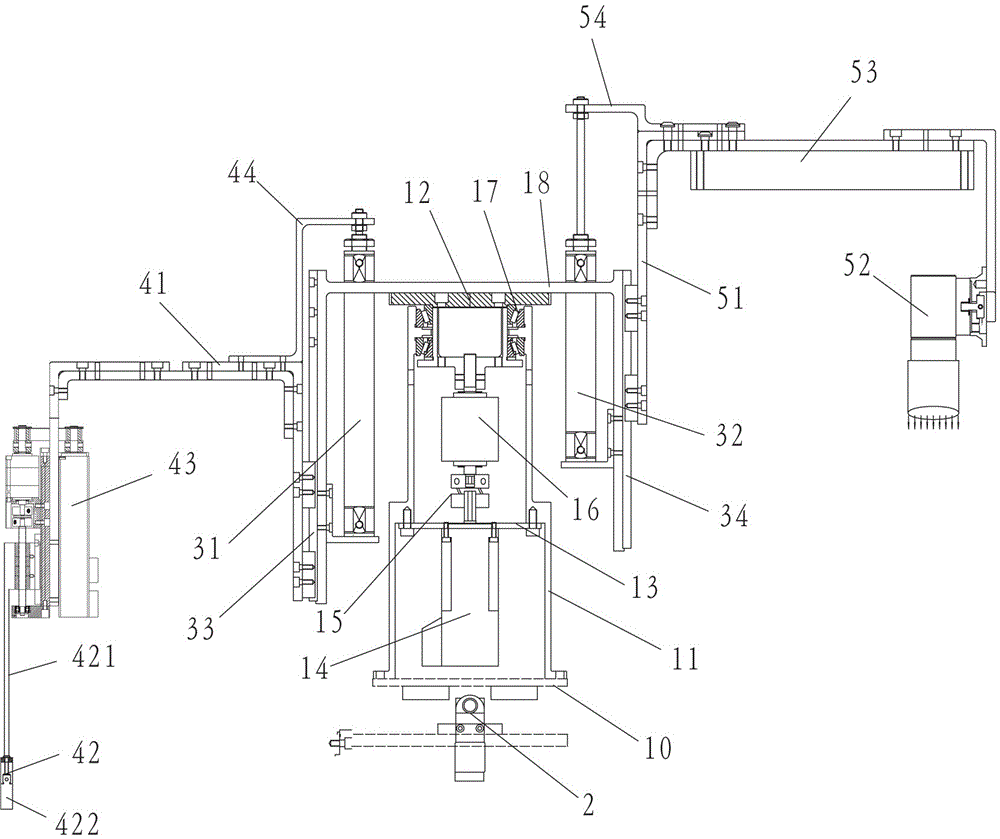

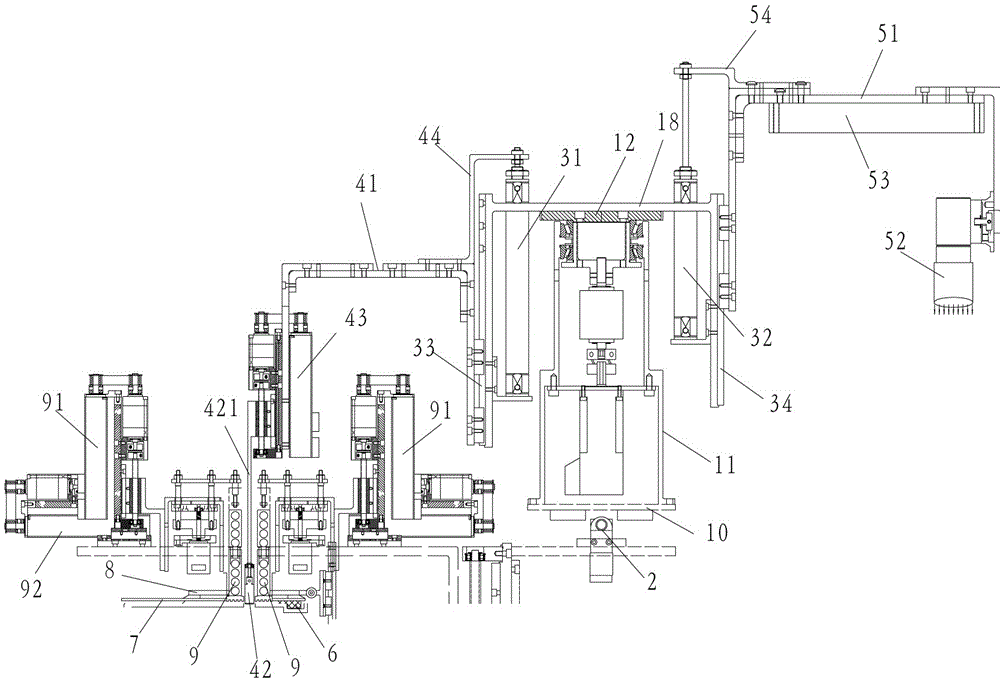

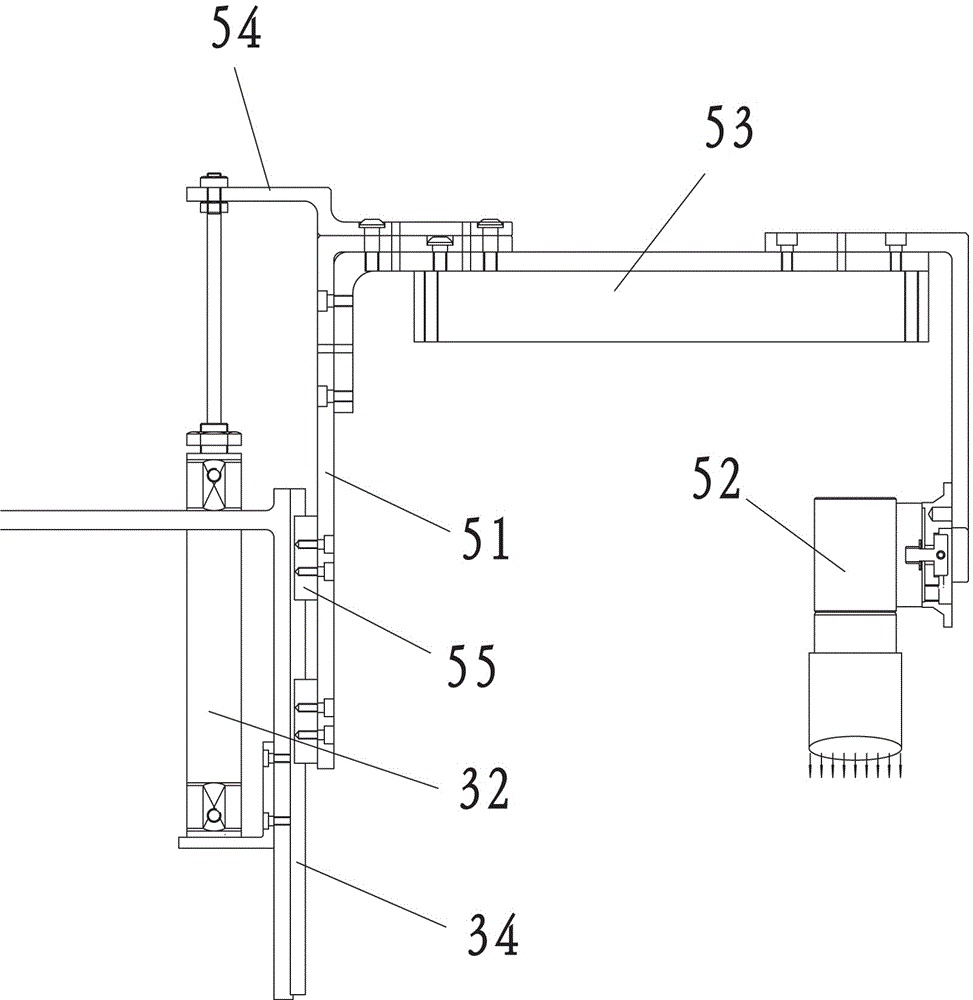

[0026] See attached picture. This embodiment includes a rotating base 10, a second linear slide assembly 2 arranged horizontally is arranged below the rotating base 10, a second screw rod 21 is provided on the second linear slide assembly 2, and a second screw rod 21 is provided on the second screw rod 21. Rotate the two matched sliders 22 , the rotating base 10 is fixed on the sliding blocks 22 , and the rotating base 10 can move forward and backward along the second threaded rod 21 . Rotating support 11 is fixed on rotating base 10, and rotating support 11 top has rotating table 12; A motor fixing plate 13 is installed in rotating supporting frame 11, and rotating motor 14 is installed on the motor fixing plate 13, and the motor shaft of rotating motor 14 passes coupling The reducer 15 is connected to the input end of the reducer 16, and the output end of the reducer 16 is fixed below the turntable 12; there is a thrust bearing 17 between the turntable 12 and the swivel supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com