A packaging bag processing device for fat powder

A processing device and packaging bag technology, applied in packaging, transportation and packaging, bag making operations, etc., can solve the problems of high manual operation intensity, easy hand injury, leakage, etc., so as to reduce the labor intensity of manual operation and avoid manual labor. Operation injury, the effect of ensuring the quality of suture

Active Publication Date: 2019-01-18

深圳友邦塑料印刷包装有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Because the traditional feed bag is relatively thin, it is difficult to add a thinner plastic bag to the thin feed bag. Usually it is filled manually. After filling, the edges of the two bags need to be stitched. If there is no Make the edges tidy, it is easy to cause internal leakage and produce unqualified products when sewing, and it is easy to hurt hands when sewing manually, which is unsafe, low in efficiency, and manual operation is strong. Therefore, in order to solve For these problems, it is necessary to design an automatic processing device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0025] Embodiment 2: The fixing frame shell is replaced by a set bolt, which can also achieve a fixing effect, and other structures are the same as in Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

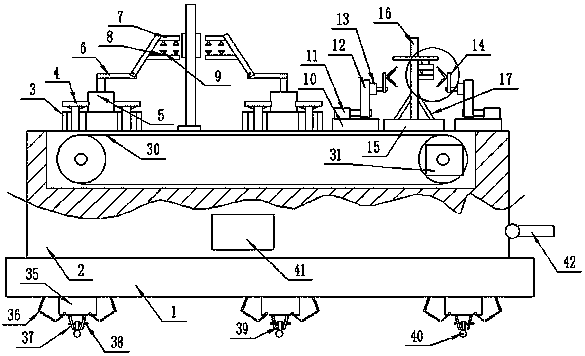

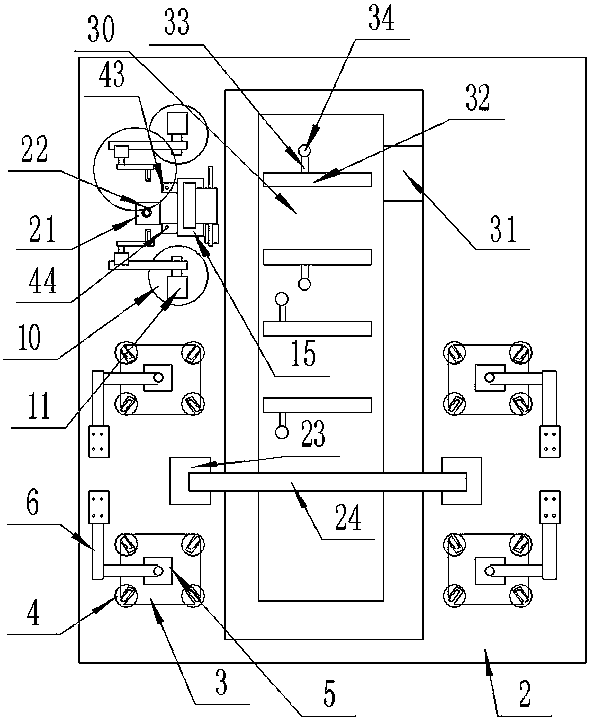

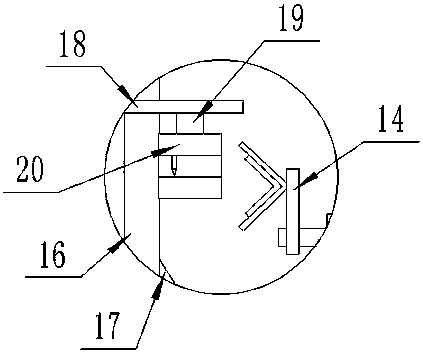

The invention discloses a machining device for a packaging bag for fatty powder. The machining device comprises a strip type bearing base, wherein the upper surface of the strip type bearing base is fixedly connected with a strip type working table; a conveying mechanism is arranged at the center of the upper surface of the strip type working table; clamping and combining mechanisms are arranged at 2 / 5 positions, which are located on the left and right sides of a position stretching over the center of the conveying mechanism, on the upper surface of the strip type working table; a sealing mechanism is arranged at the center of the upper surface of the strip type working table and stretches over the conveying mechanism; an inner and outer bag combining mechanism is arranged at a position, which is located on the rear side of a rotating mechanism, on the 4 / 5 right side of the center of the upper surface of the strip type working table; and a moving mechanism is arranged on the lower surface of the strip type bearing base. The machining device has the beneficial effects of being relatively simple in operation, relieving the operation labor intensity of a worker, improving the production efficiency, avoiding the worker from being hurt during operation and guaranteeing the stitching quality.

Description

technical field [0001] The invention relates to the field of feed bag processing, in particular to a packaging bag processing device for fat powder. Background technique [0002] Feed bags are used to hold feed. Because of the different types of feed, the feed bags used to hold them are also different. For fat powder, ordinary feed bags cannot carry it well because of the fine particles. Therefore need to add a kind of thin plastic film in common feed bag to guarantee that fat powder does not leak outside. [0003] Because the traditional feed bag is relatively thin, it is difficult to add a thinner plastic bag to the thin feed bag. Usually it is filled manually. After filling, the edges of the two bags need to be stitched. If there is no Make the edges tidy, it is easy to cause internal leakage and produce unqualified products when sewing, and it is easy to hurt hands when sewing manually, which is unsafe, low in efficiency, and manual operation is strong. Therefore, in or...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B31B70/64B31B70/68B31B70/74B31B170/20

Inventor 赵蓉

Owner 深圳友邦塑料印刷包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com