Seamless type ship body splicing tool

A non-marking, marine technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of large influence of human operation, errors, time-consuming, etc., and achieve the effect of ensuring the quality of splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

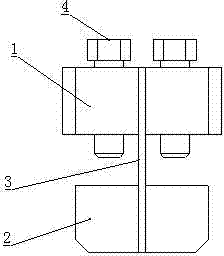

[0009] Such as figure 1 As shown, it includes an upper base plate 1, a lower base plate 2, a connecting rod 3, and an adjusting bolt 4.

[0010] The above-mentioned I-shaped positioning plate is formed by connecting and fixing the middle of the upper base plate 1 and the lower base plate 2 through the connecting rod 3, wherein the middle part of the upper base plate 1 is threadedly connected with the connecting rod 3, and the middle part of the lower base plate 2 is welded and fixed with the connecting rod 3. The two ends of 1 are provided with threaded holes, and the threaded holes are screwed to connect the vertically downward adjusting bolt 4.

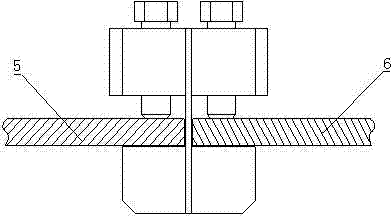

[0011] When used, such as figure 2 As shown, the middle connecting rod of the I-shaped positioning plate is aligned with the gap between the two hull splicing plates 5, 6, and the I-shaped positioning plate extends into the gap from the end of the gap, so that the upper bottom plate 1 and the lower bottom plate 2 of the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com