Patents

Literature

54results about How to "Realize automatic splicing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

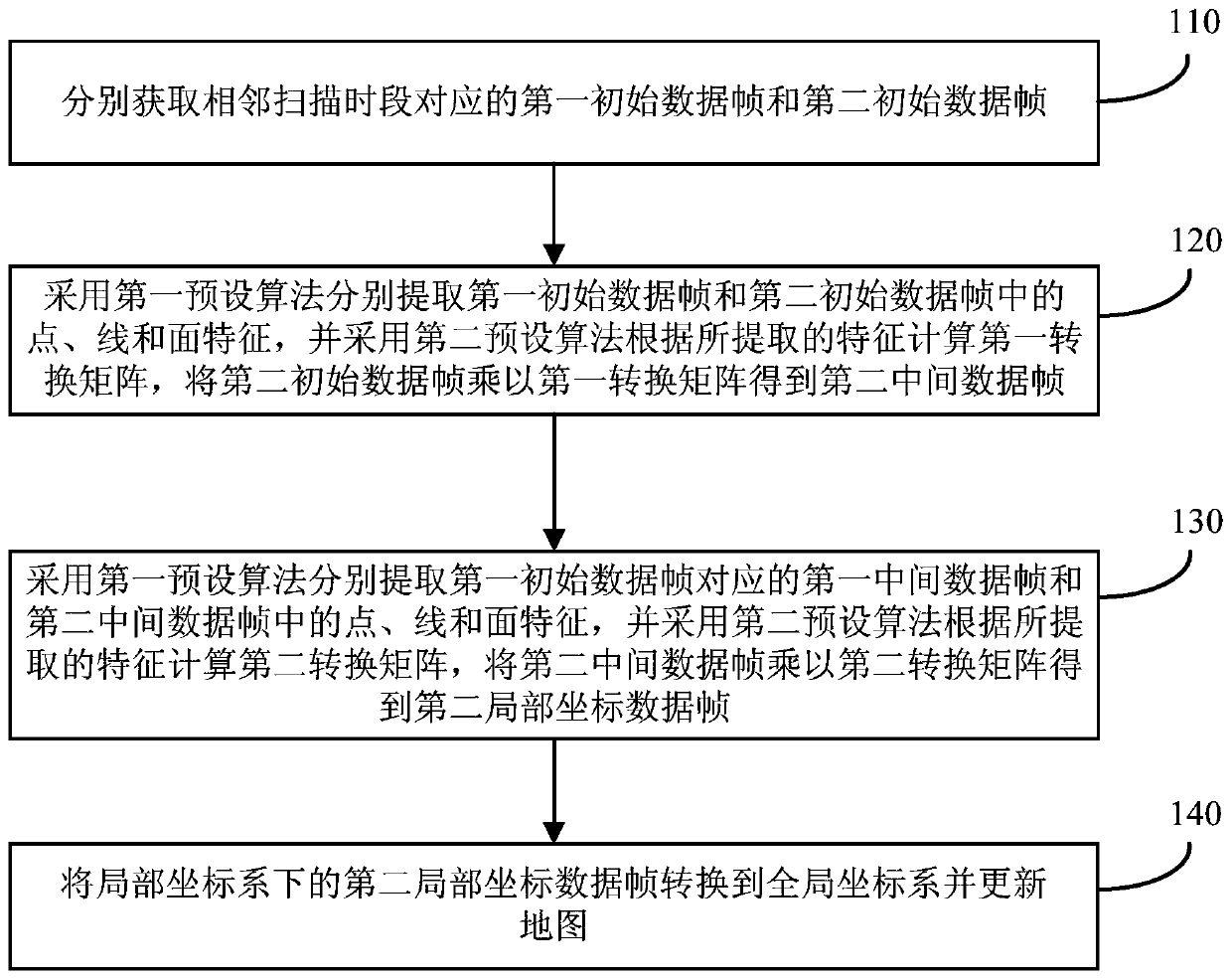

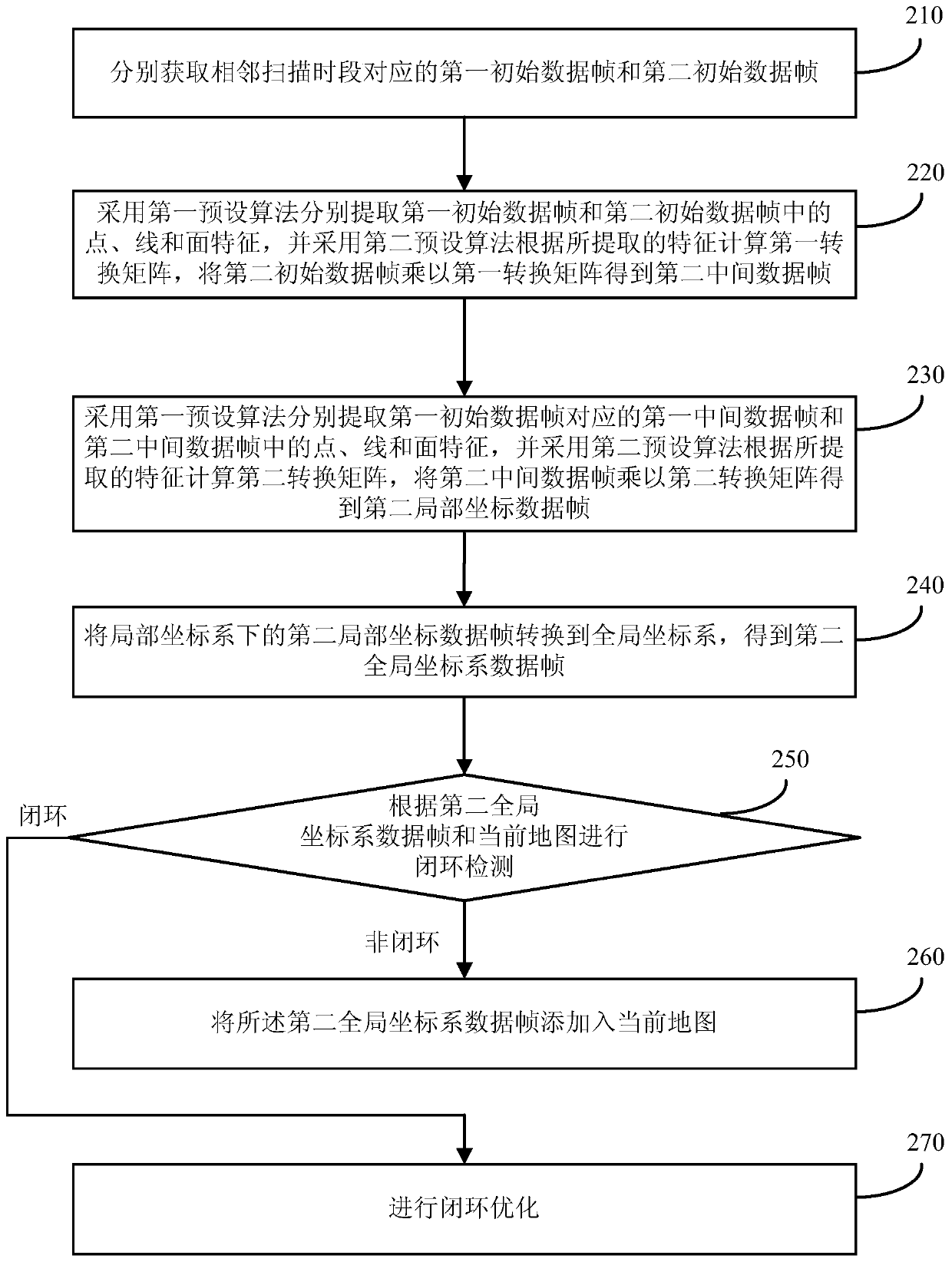

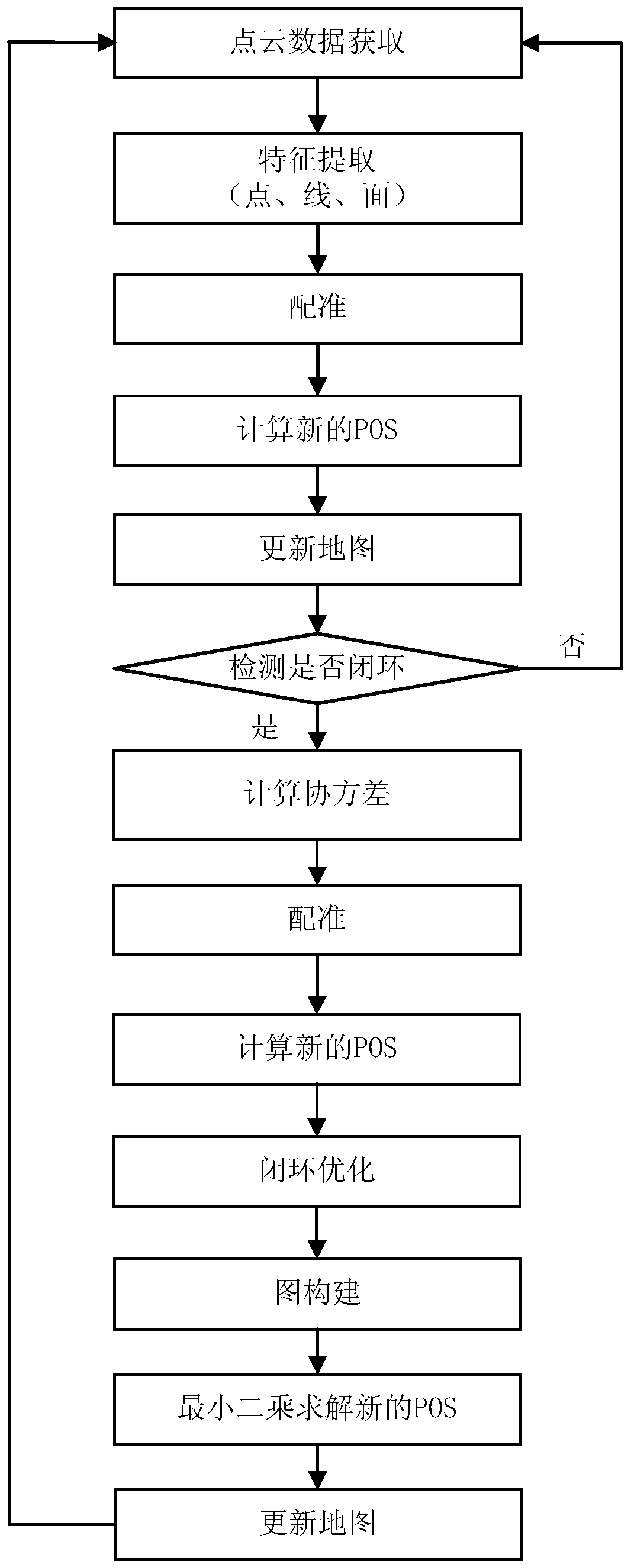

Map making method, device and system based on laser radar

ActiveCN107179086AHigh precisionImprove accuracyInstruments for road network navigationNavigational calculation instrumentsRadarTransfer matrix

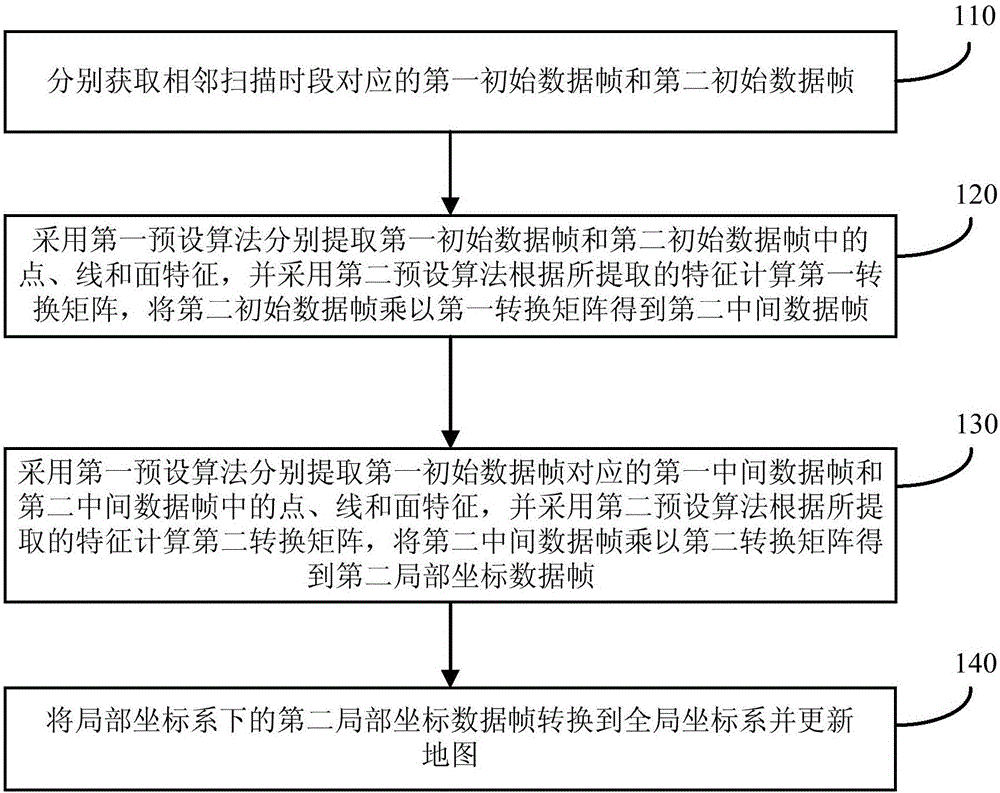

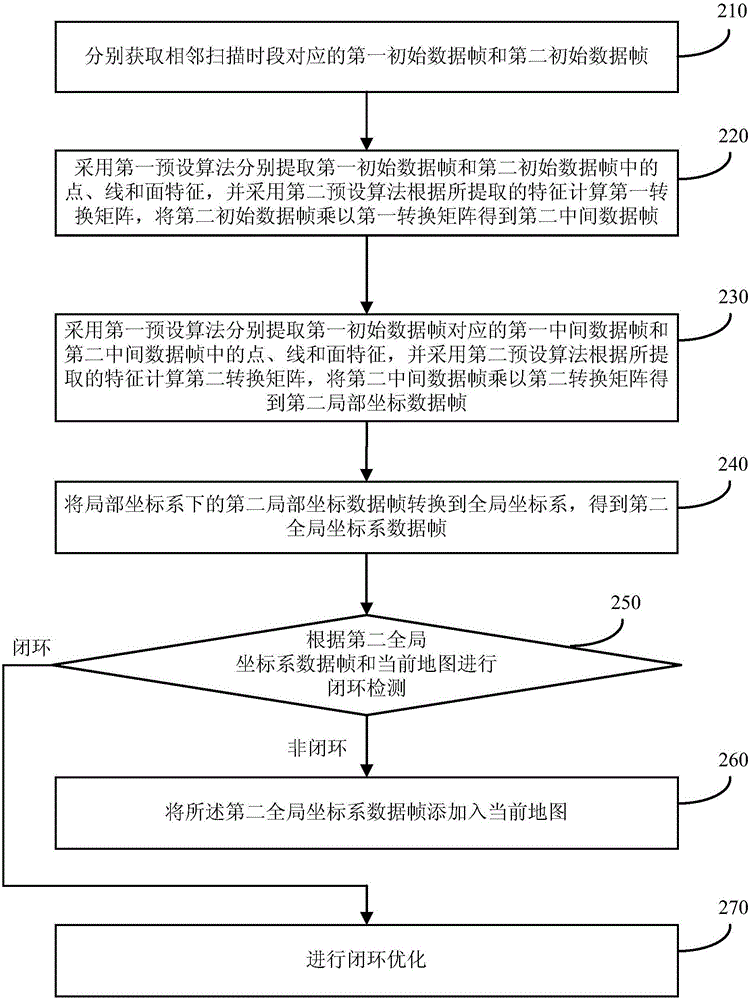

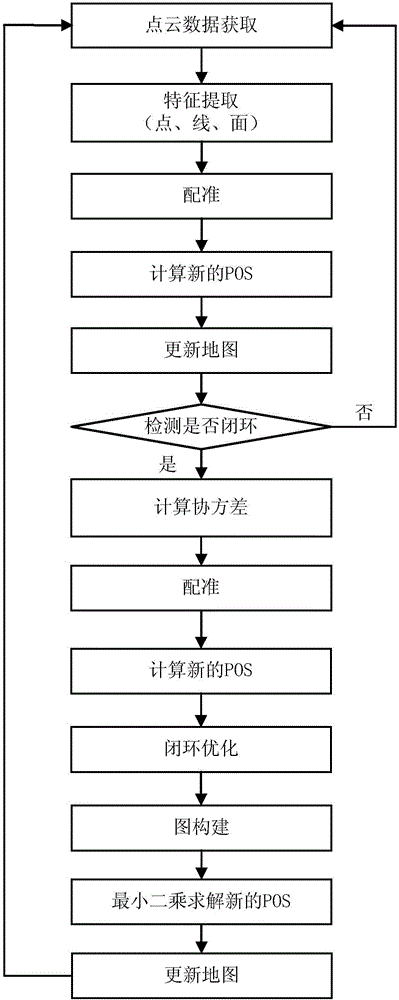

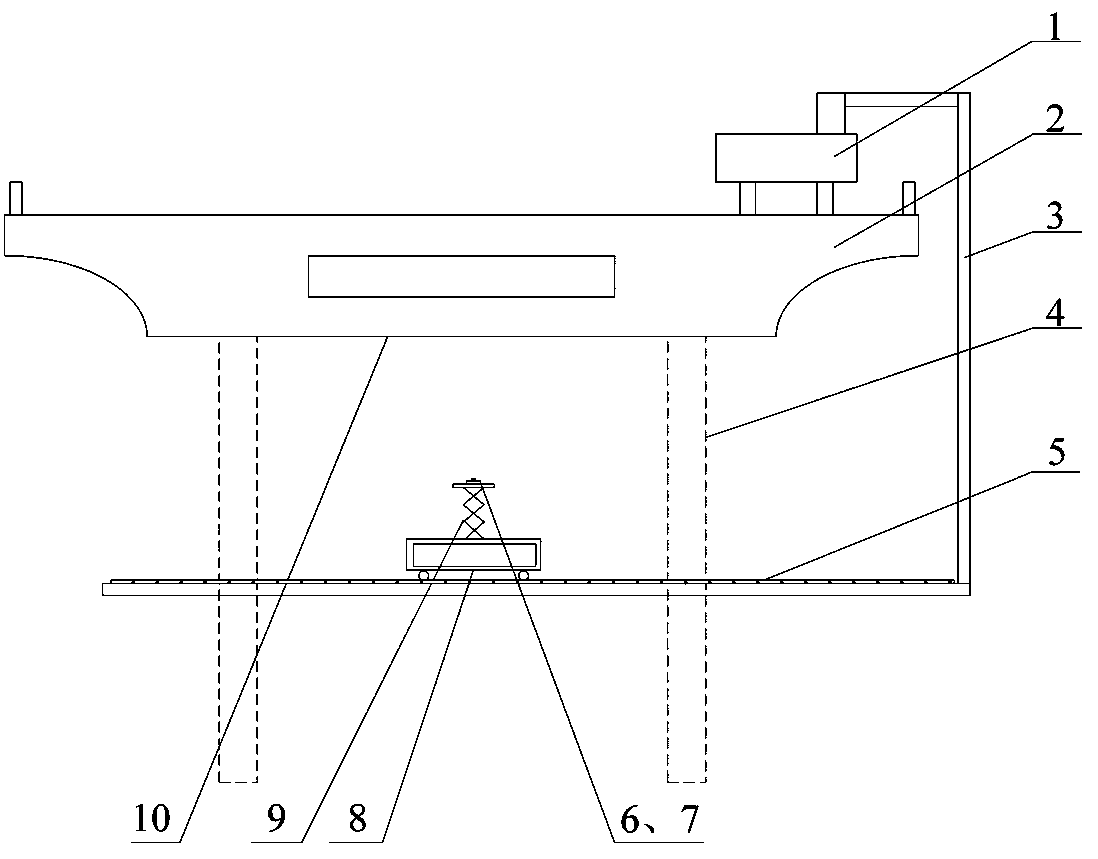

An embodiment of the invention discloses a map making method, device and system based on laser radar. The method comprises: respectively acquiring two preliminary data frames which correspond to adjacent scanning periods; respectively extracting point, line and surface features in the two preliminary data frames by a first preset algorithm; calculating a first transfer matrix by a second preset algorithm according to the extracted features; implementing registration of the two preliminary data frames; respectively extracting point, line and surface features of two middle data frames by the first preset algorithm and implementing registration again; and transforming local coordinate data frames, which are obtained by secondary registration, under a local coordinate system to a global coordinate system and updating the map. According to the technical scheme in the embodiment, the precision and accuracy of the obtained map can be improved, the map drawing efficiency is improved, and the occupied space and manufacturing cost of the system are saved.

Owner:BEIJING GREEN VALLEY TECH CO LTD

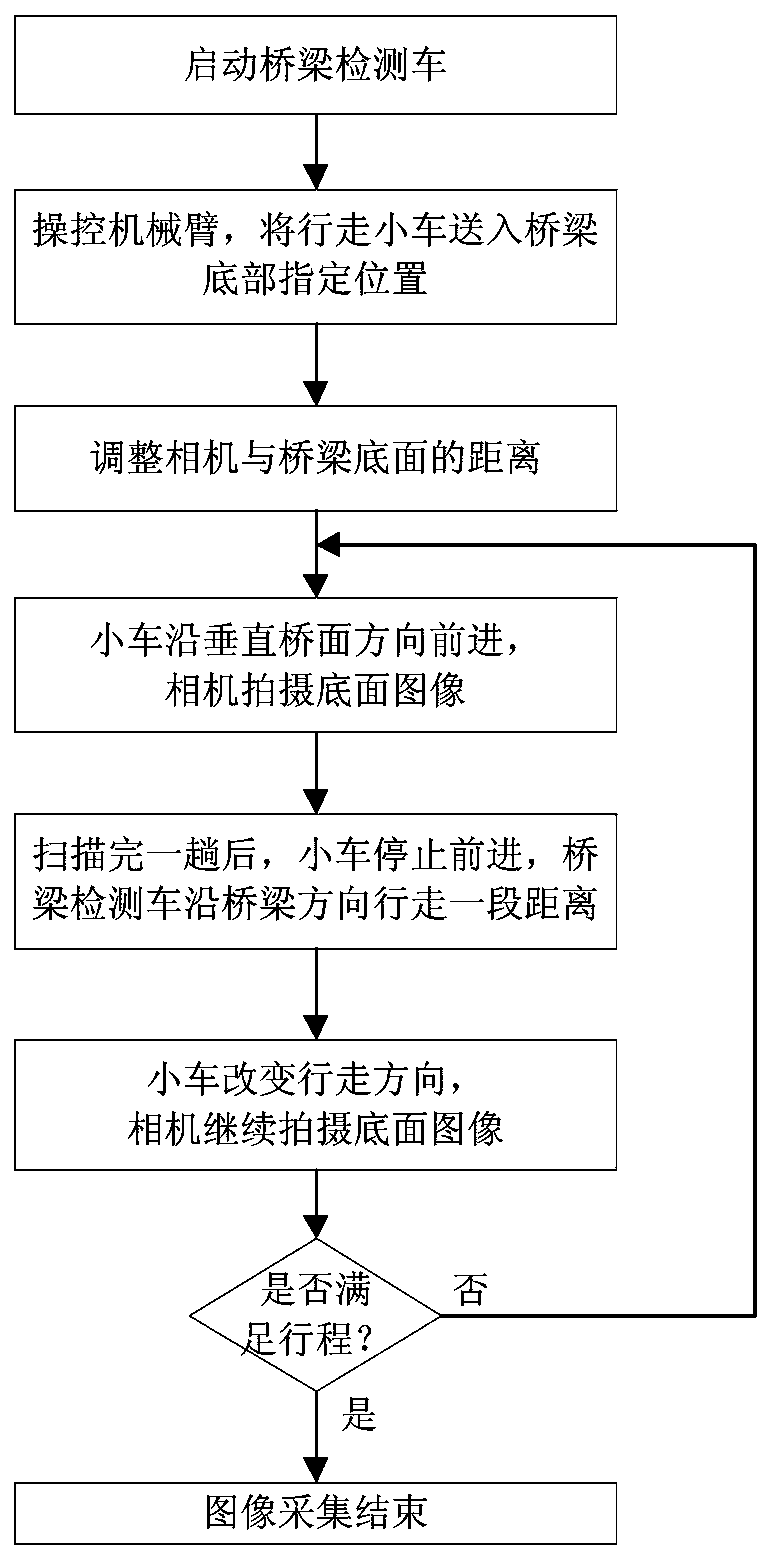

Crack splicing method in bridge quality detection

ActiveCN109754368AQuick stitchingAccurate splicingImage enhancementImage analysisMachine visionImage stitching

The invention relates to a crack splicing method in bridge quality detection. The machine vision technology, modern sensing technology, data analysis processing technology, calculation technology canbe effectively fused into bridge quality detection. Aiming at the acquired local image of the crack; the splicing of crack images is accurately completed. The automatic detection of the whole crack ofthe bridge is met; the safe use of the bridge is ensured. Method of installing an installation device, Collecting crack images, Crack image stitching, carrying out graying on the spliced image; grayscale transformation and image filtering preprocessing are carried out. The method is scientific. The bridge crack automatic splicing device is simple in structure, easy to operate, good in detectioneffect and capable of rapidly and accurately achieving automatic splicing of the same crack at different visual angles, the problem that long cracks cannot be contained in crack images is solved, themaximum crack width and the automatic detection level of the real position of the maximum crack width in bridge quality detection are further improved, and smoothness and safety of traffic transportation are effectively guaranteed.

Owner:ZHENGZHOU INST OF TECH

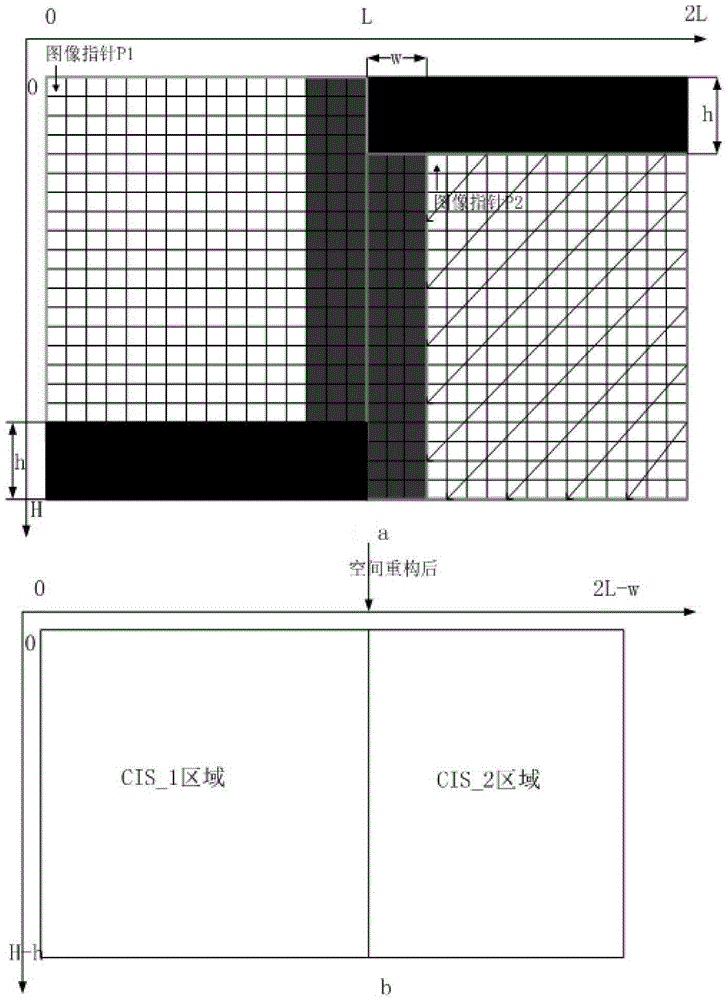

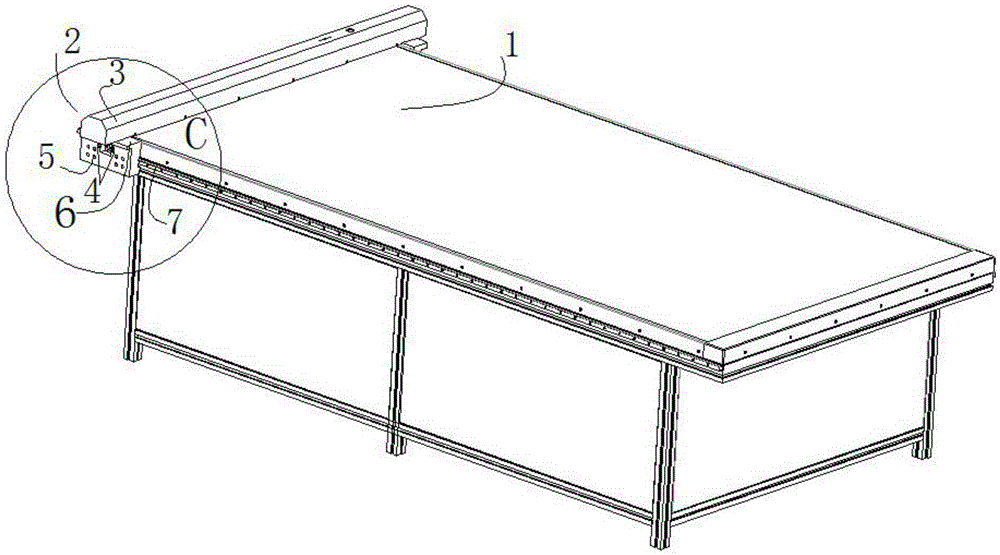

Image acquisition and reconstruction method and device based on machine vision

ActiveCN106506899ARealize automatic splicingGuaranteed to reflect the truthPictoral communicationImage stitchingReconstruction method

The invention discloses an image acquisition and reconstruction method based on machine vision. The method comprises the following steps: 1) through an image acquisition mechanism set by a full image digital acquisition instrument, image acquisition is carried out on a to-be-detected material with a specific shape or set pattern information; 2) an image processing mechanism is set to carry out the following substeps on an acquired image: a) CIS stitching processing, b) image consistency correction processing, c) image high-precision re-sampling processing and d) bitmap-to-vector processing to acquire and output vector data; and 3) according to the outputted vector data, vector reconstruction is carried out on the specific shape or the set pattern information of the specific shape. The invention also discloses a device for implementing the above method. Automatic image stitching can be realized, a perfect wide image can be presented, fast image correction is realized, the image contour edge detail fidelity capability is high, the bitmap-to-vector algorithm can complete accurate extraction on a bitmap contour of a scanned object, and a high-precision contour image can be acquired.

Owner:DONGGUAN CHITECS ELECTRONICS TECH

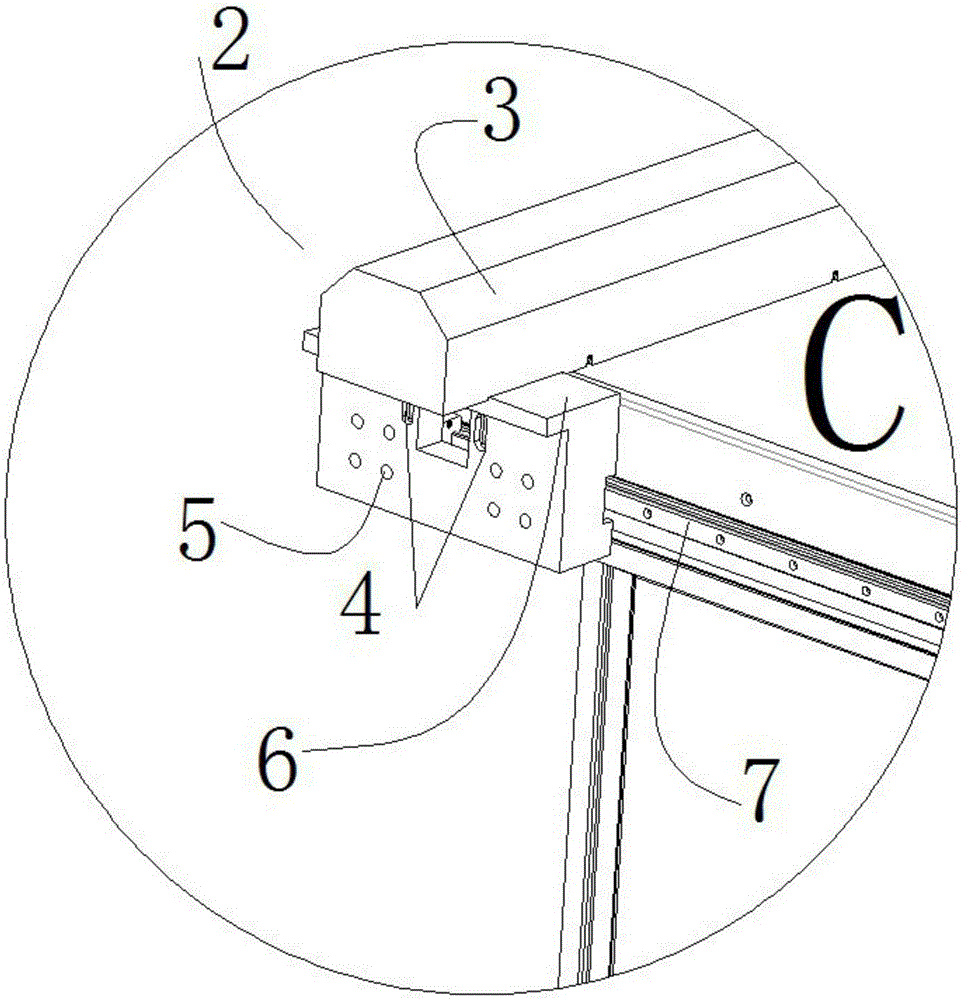

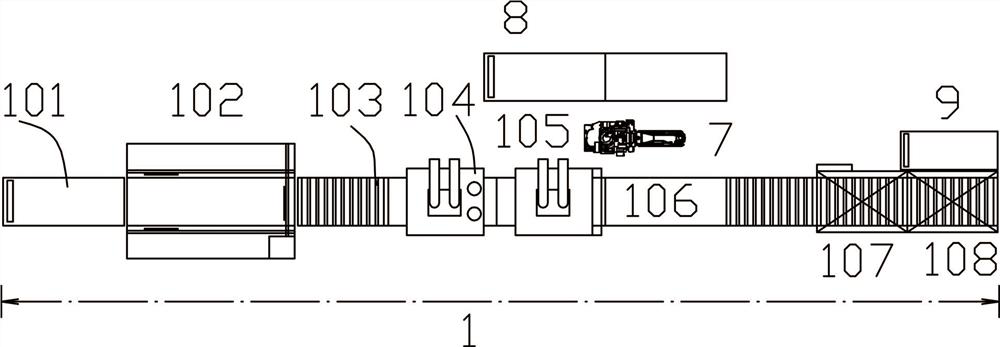

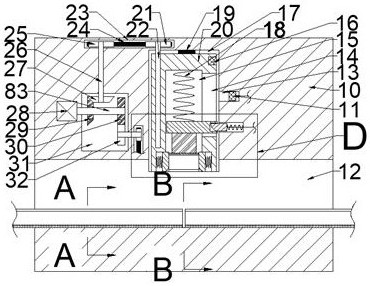

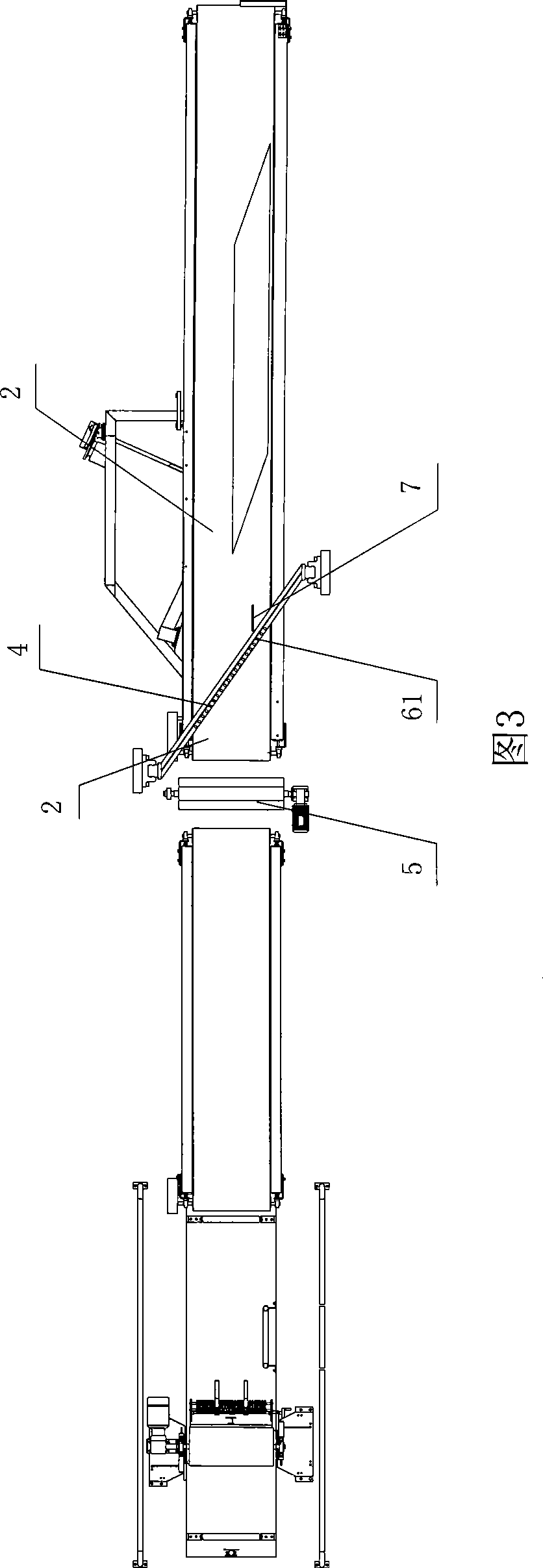

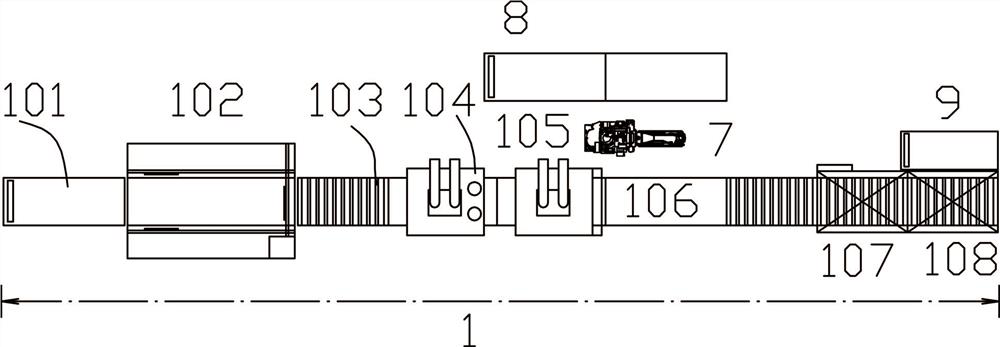

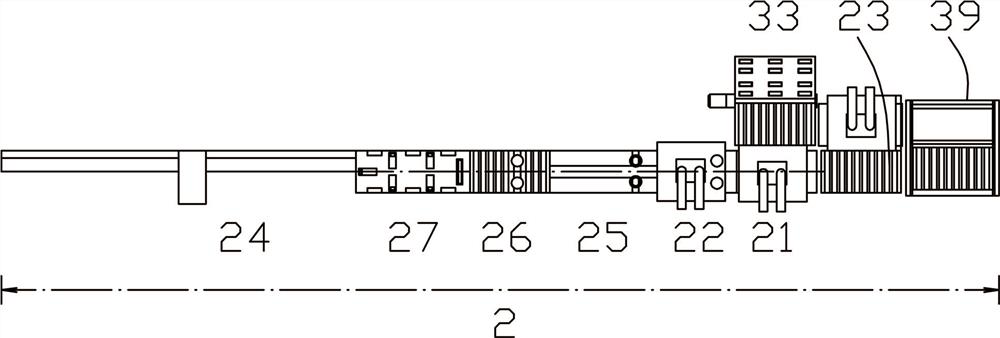

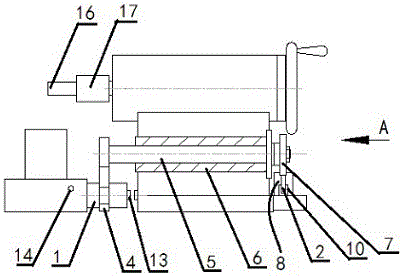

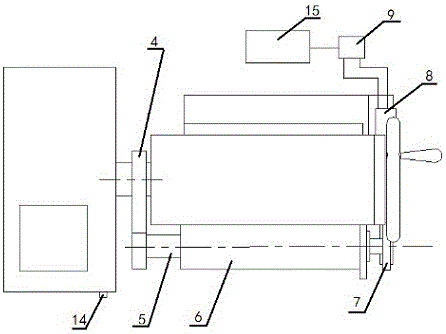

Connector device of cord fabric cutting machine and method thereof

ActiveCN101653992AReduce frictionSolve the problem of lack of motivationTyresElectric machineryEngineering

The invention provides a connector device of a cord fabric cutting machine and a method thereof, which feed the previous cord fabric and the next cord fabric in sequence forwards by adopting the same integrated connector conveying belt, and lift the tail part of the previous cord fabric from the conveying belt before the connector is stitched and position the cord fabric so as to completely solvethe problem of dynamic shortage of a strip of the cord fabric and realize a resistance-free conveying mode. The connector device of the cord fabric cutting machine is mainly provided with a frame carrying the connector conveying belt, wherein the connector conveying belt is driven by a servo motor and conveys the cord fabric along the vertical direction of the frame; the front end of the frame isprovided with a connector mechanism which is used for connecting the previous cord fabric and the next cord fabric together; the upper part of the frame is only provided with the integrated connectorconveying belt; the vertical length of the conveying belt is larger than the maximum length specification of the conveyed cord fabric; the front end of the connector conveying belt is provided with acord fabric lead device; and a cross beam of the connector mechanism is provided with an adsorption mechanism which is used for upwards lifting and positioning the end part of the cord fabric.

Owner:MESNAC

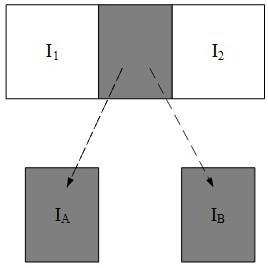

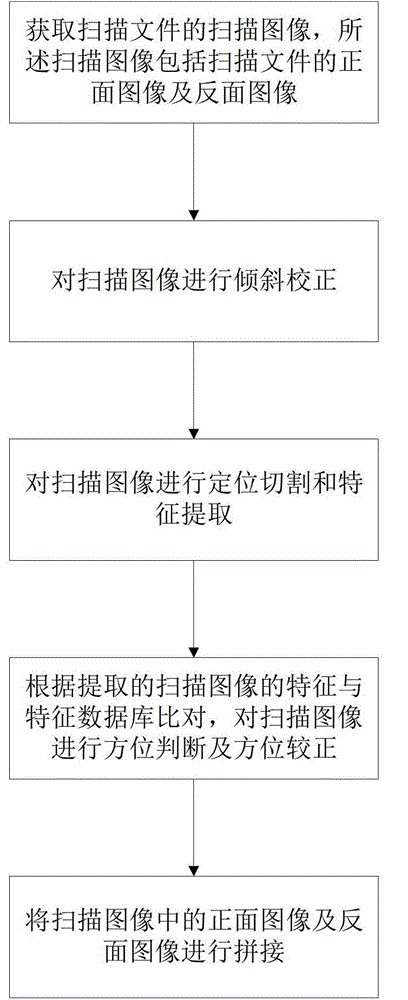

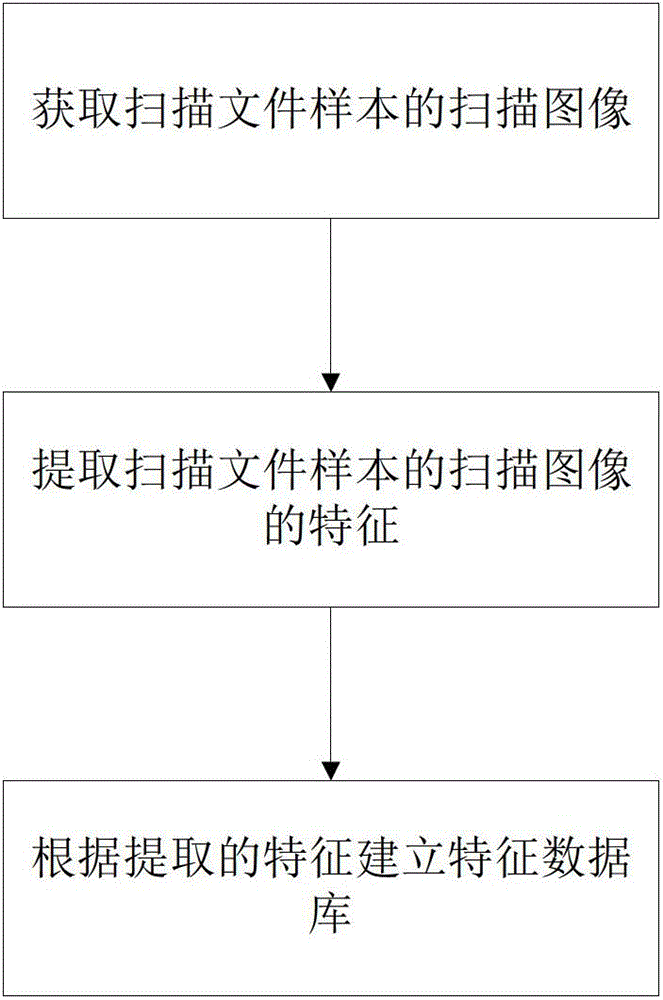

Image mosaic method and system for two-sided scanning

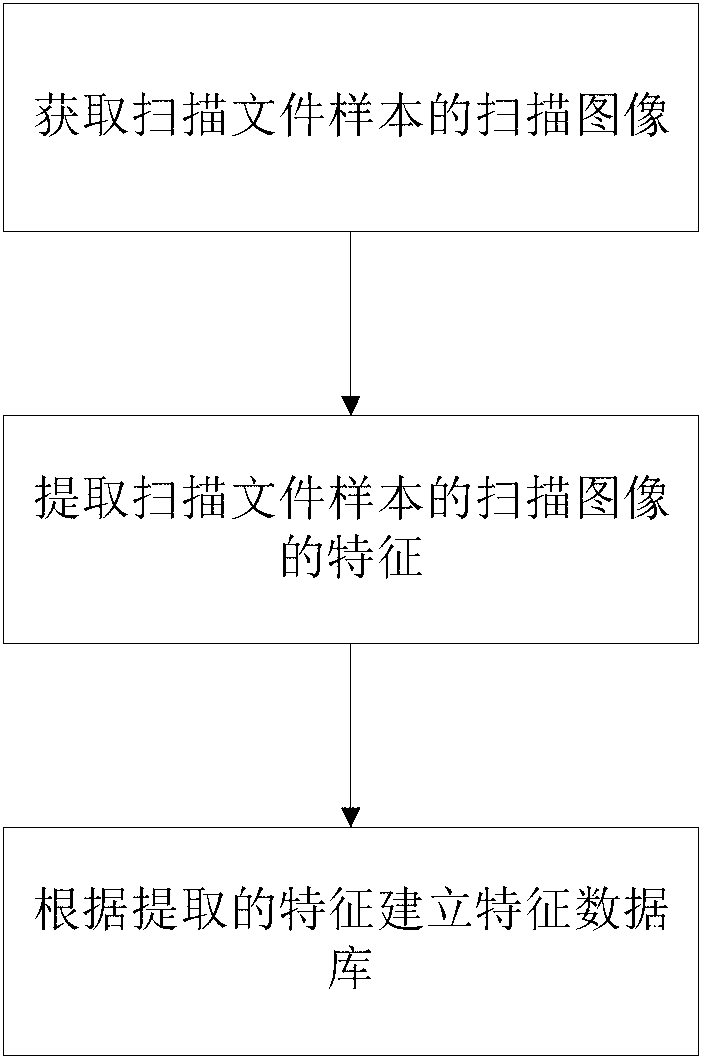

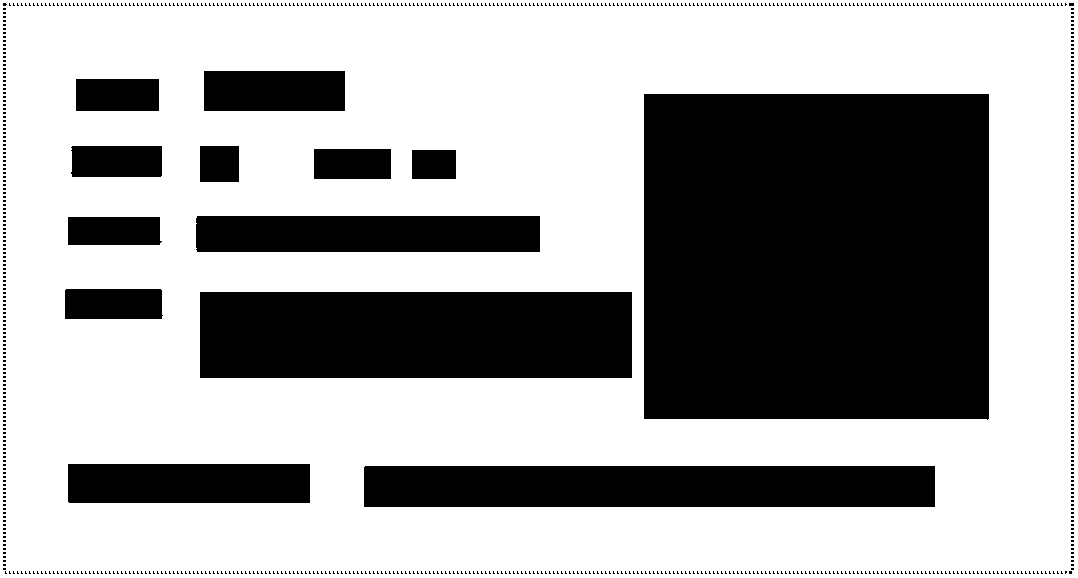

ActiveCN102708557ARealize automatic splicingConvenient duplex scanning operationImage enhancementImage analysisFeature extractionFeature data

The invention discloses an image mosaic method and a system for two-sided scanning. A feature database of scan files is built before the image mosaic method is applied. The image mosaic method includes obtaining scan images of scan files, wherein the scan images comprise front images and back images of the scan files; performing slant correction on the scan images; performing position segmentation and feature extraction on the scan images; performing direction judgment and direction correction on the scan images according to comparison of features of the extracted scan images with the feature data; and mosaicing the front images with the back images in the scan images. According to the image mosaic method and the system, two-sided scan operation of users is greatly facilitated, mosaic quality of the two-sided scan images is guaranteed, and the image mosaic method and the system can be widely applied to the image scan field.

Owner:GUANGZHOU ZONERICH COMP EQUIP

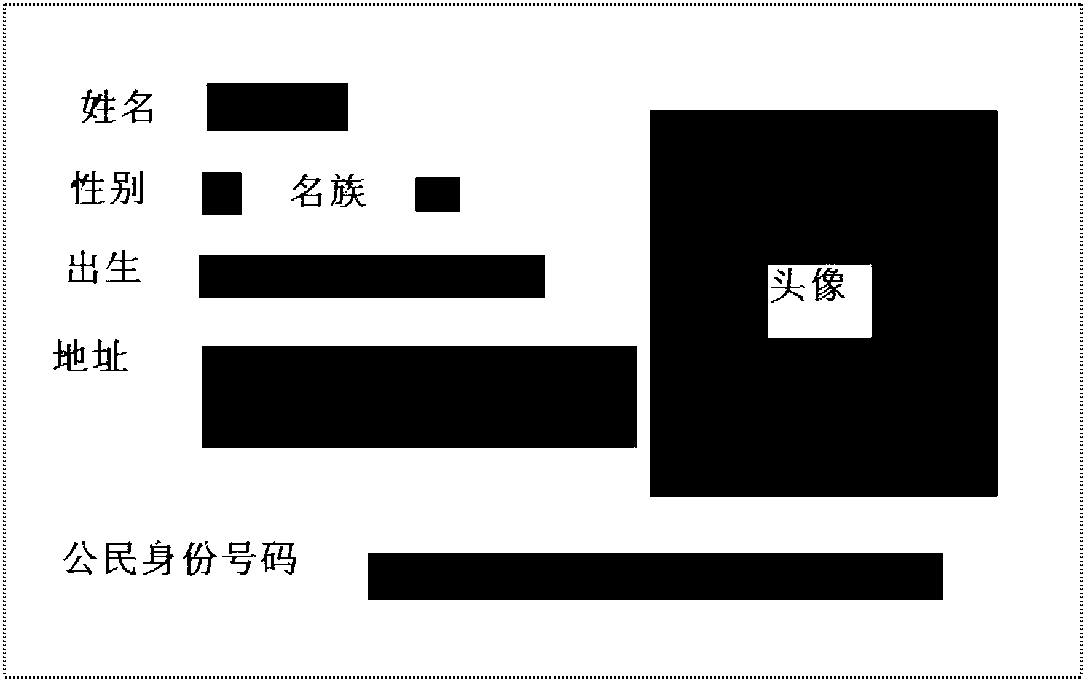

Panoramic stitching system and method for microscopic images

ActiveCN110807732AImprove clarityRealize automatic splicingImage enhancementImage analysisMicroscopic imageRadiology

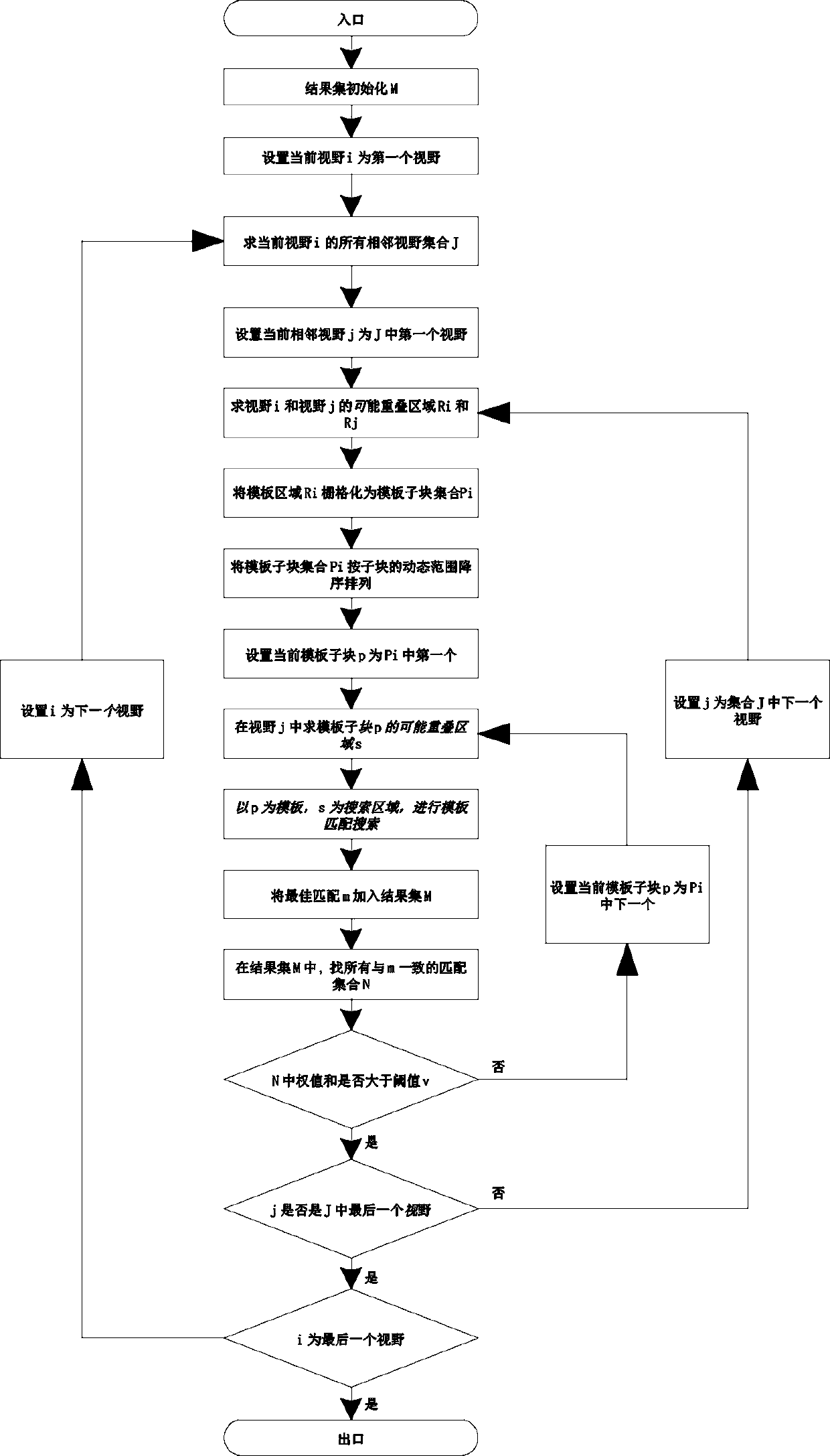

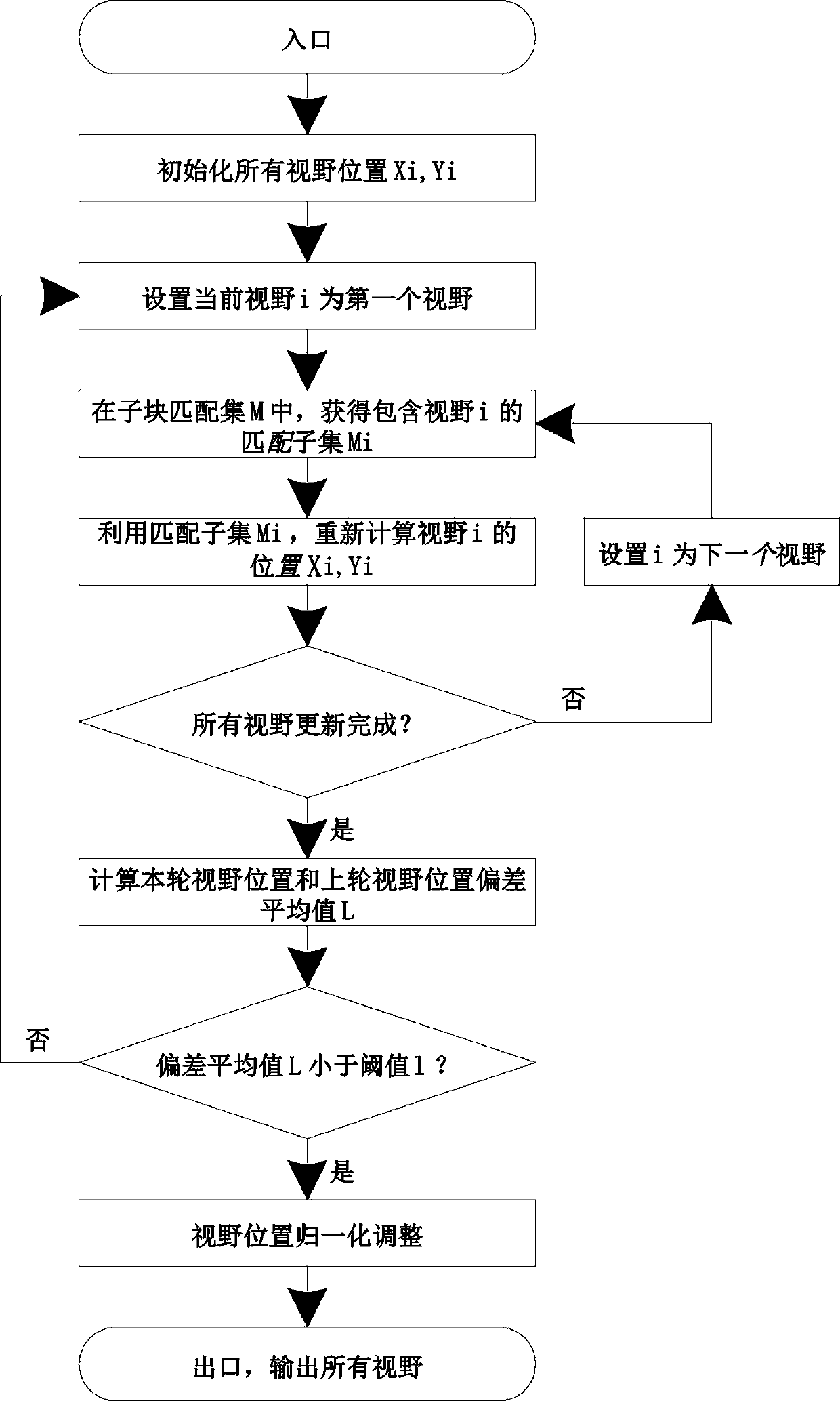

The invention provides a panoramic stitching system and method for microscopic images. The panoramic stitching system comprises a view sub-block matching module, a view position fitting module and a block extraction module, the view sub-block matching module is used for identifying an overlapping region between the images and judging an adjacent position relationship between the sub-images, so that the sub-images acquired by the microscopic scanning device are automatically arranged according to a splicing sequence of the images; the visual field position fitting module is used for finely adjusting the position according to the overlapping area between the sub-images so as to accurately splice the cell positions; and the block extraction module is used for automatically extracting a completely spliced image. By the adoption of the scheme, automatic splicing can be achieved, high-definition images can be obtained, in the splicing process, the method can adapt to disorderly-arranged images without clearly scanning the sequencing problem of the images, high compatibility is achieved, and labor intensity is greatly reduced. The splicing process of the method can be completed in a second-level range so as to adapt to the data processing intensity of large-scale diagnosis on the cloud.

Owner:WUHAN LANDING INTELLIGENCE MEDICAL CO LTD

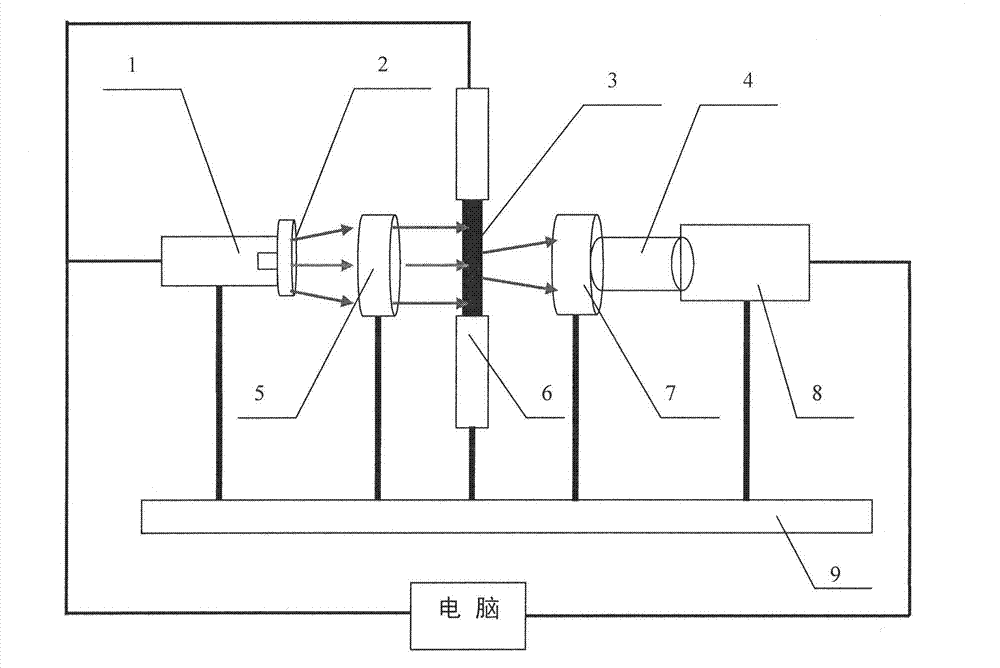

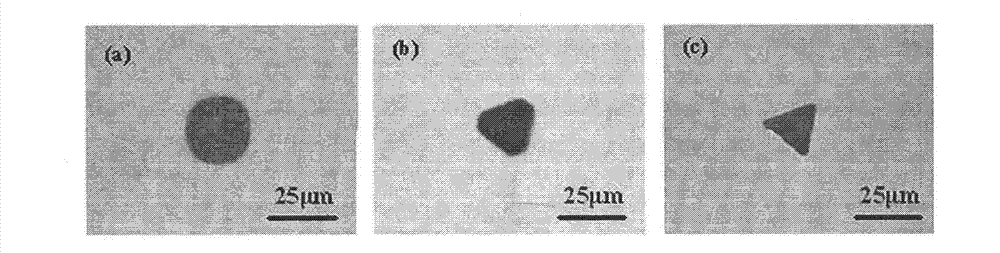

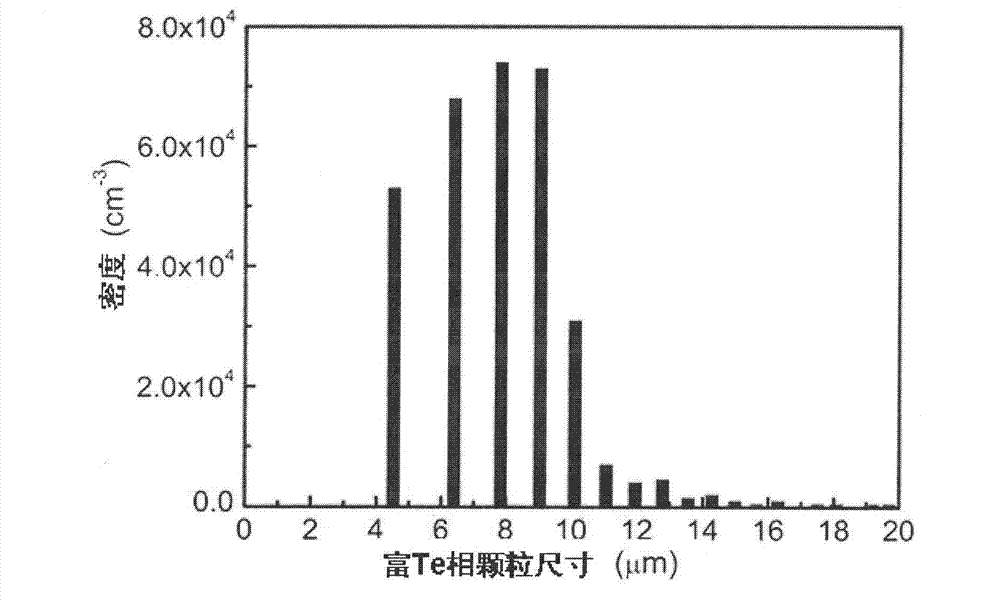

Device and method for detecting rich-Te phase in telluride semiconductor crystal

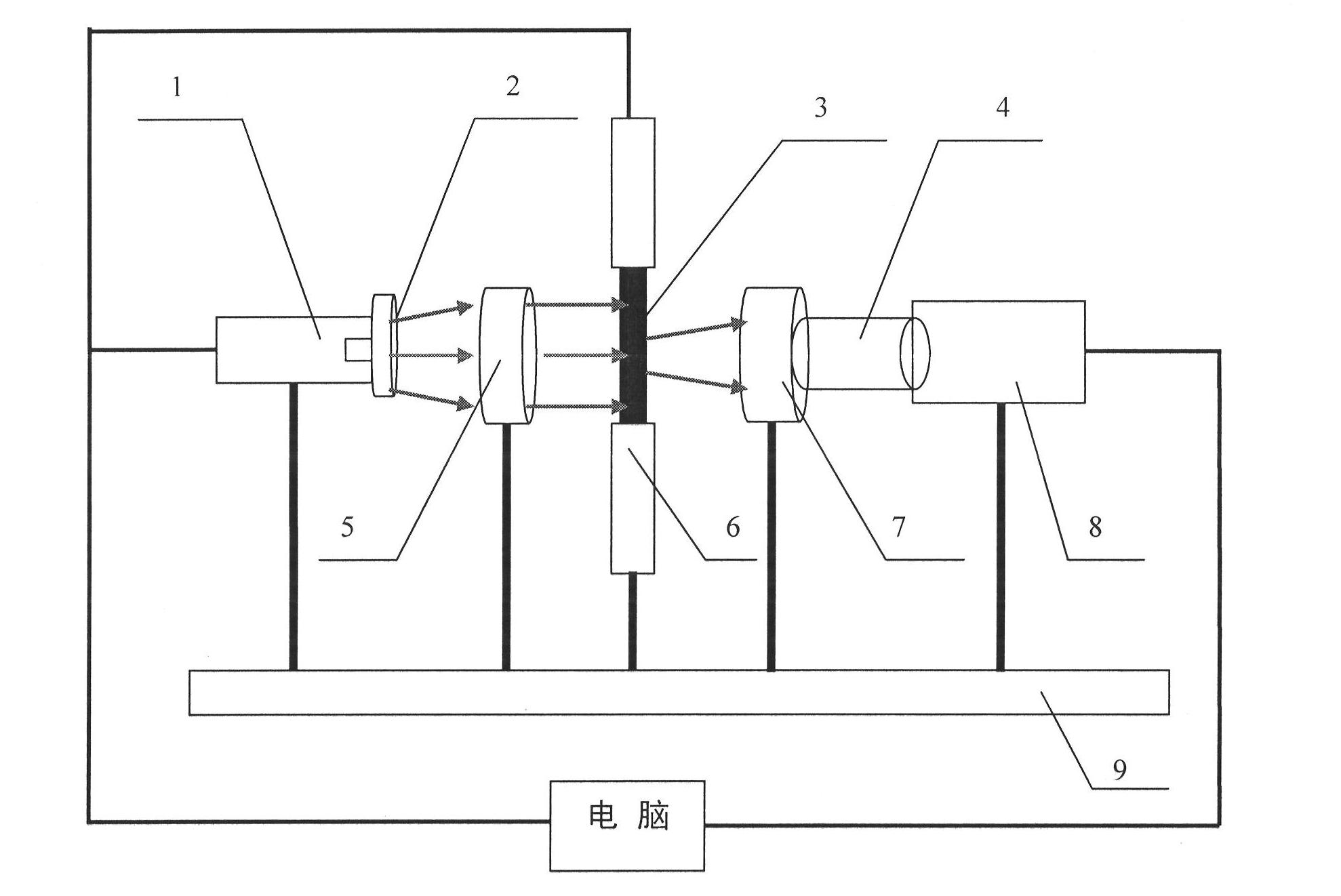

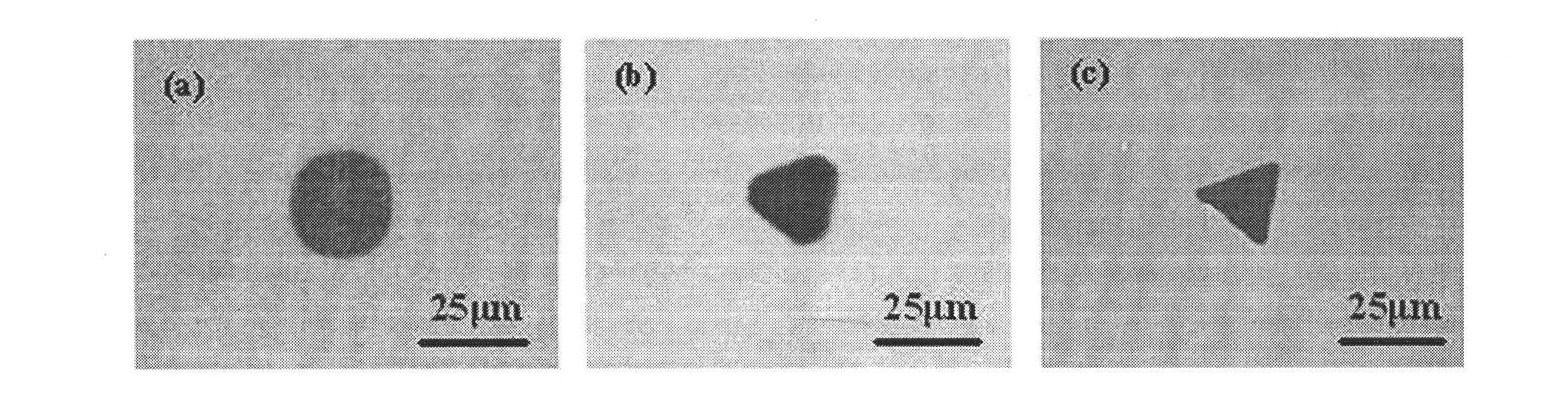

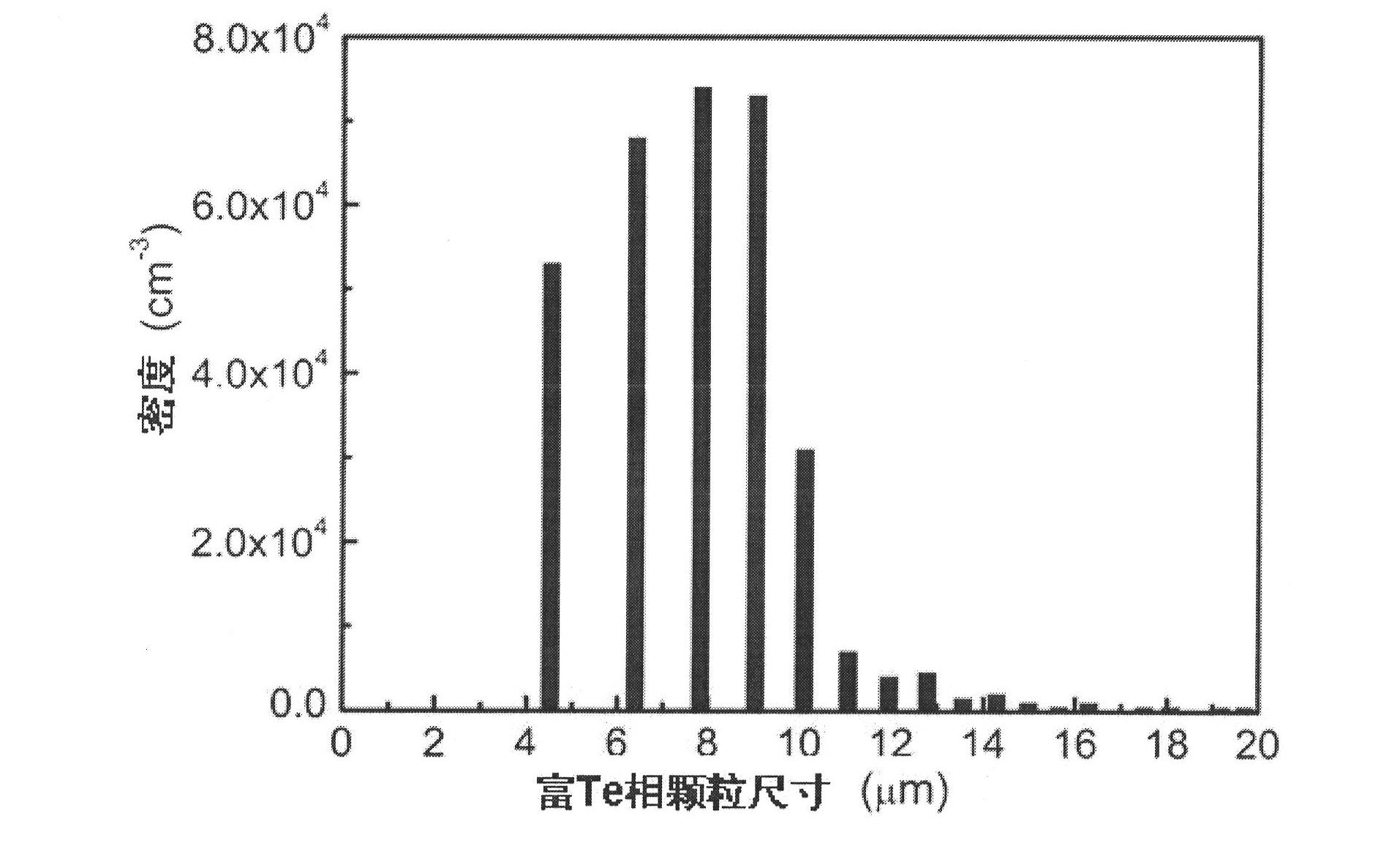

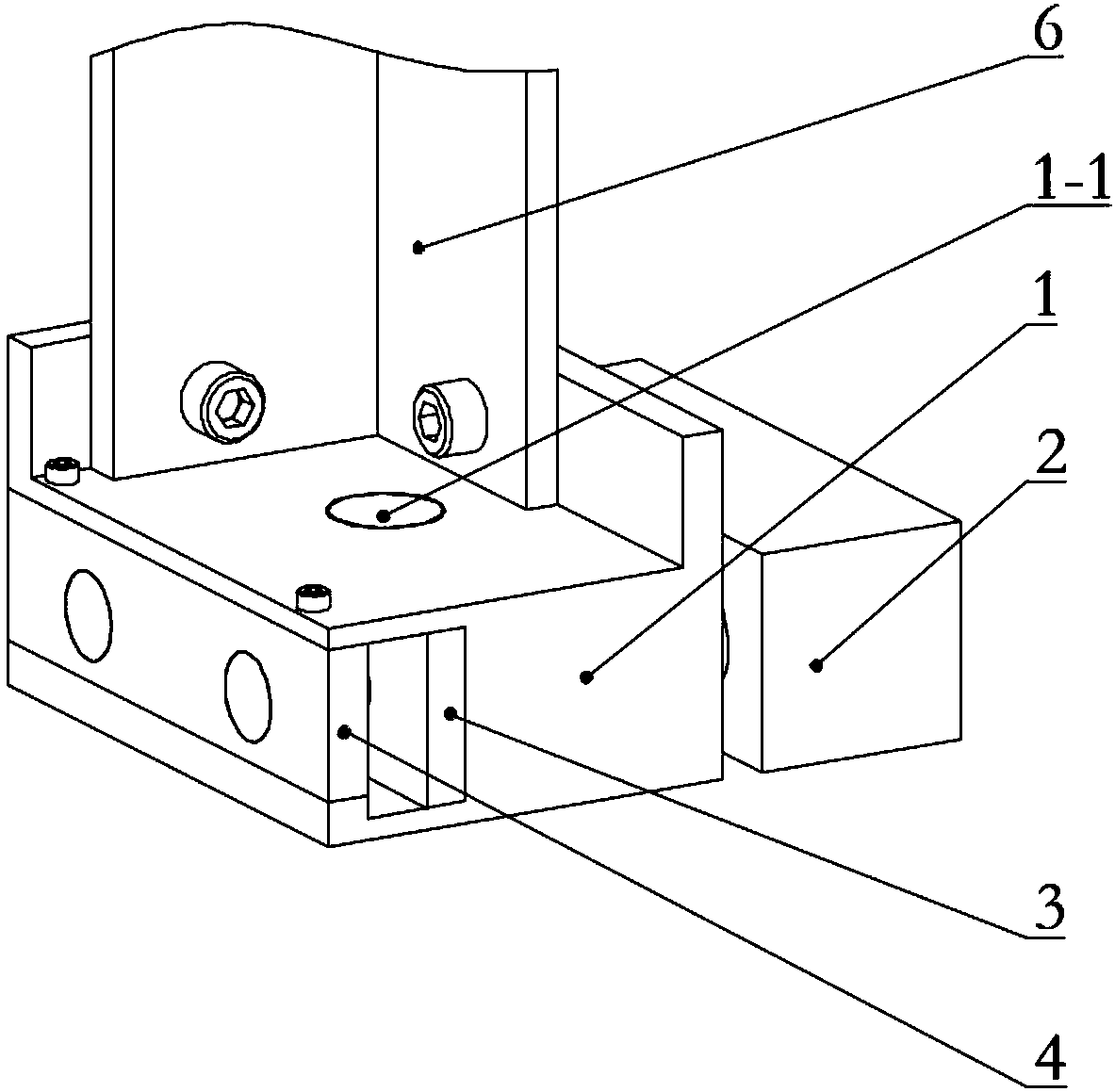

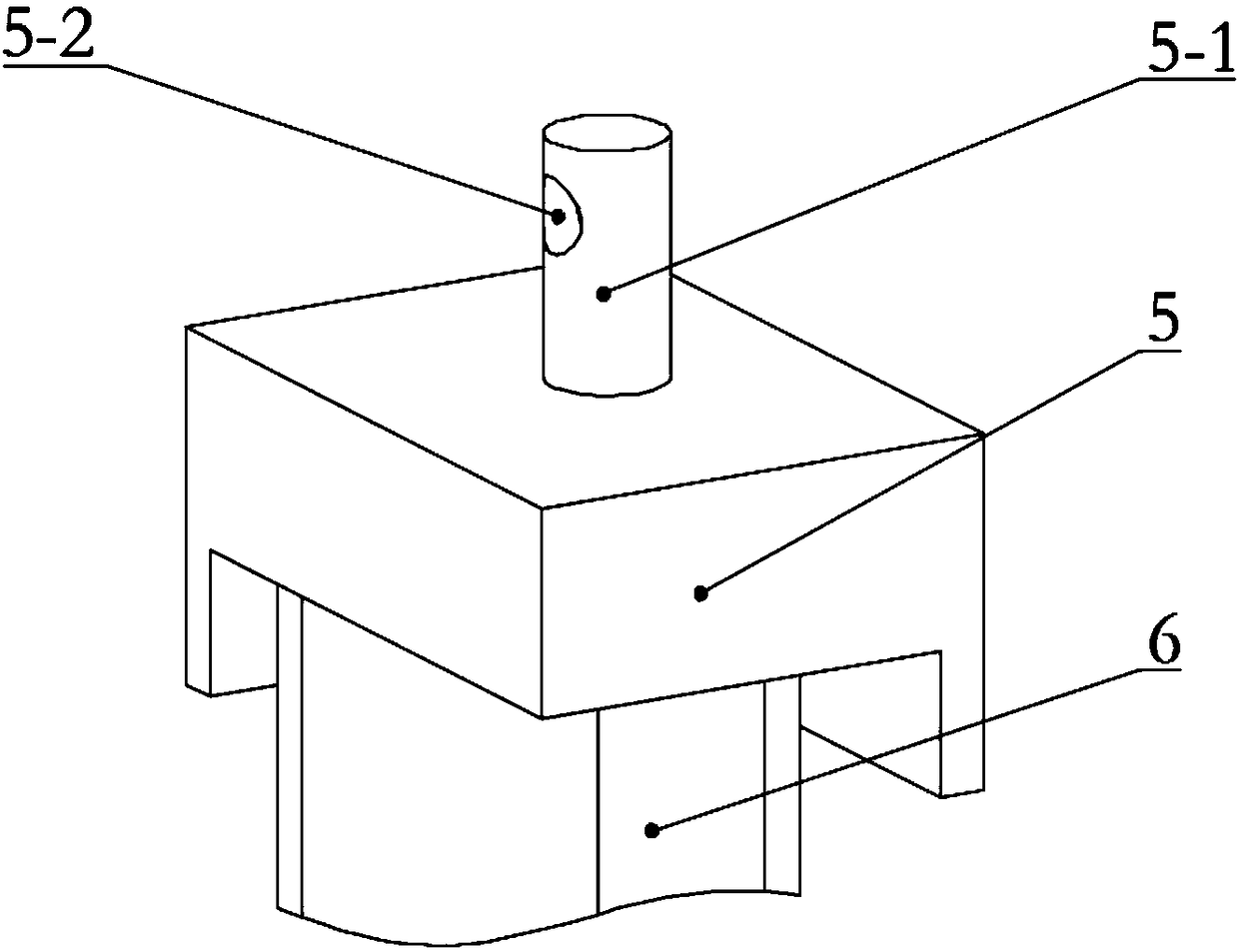

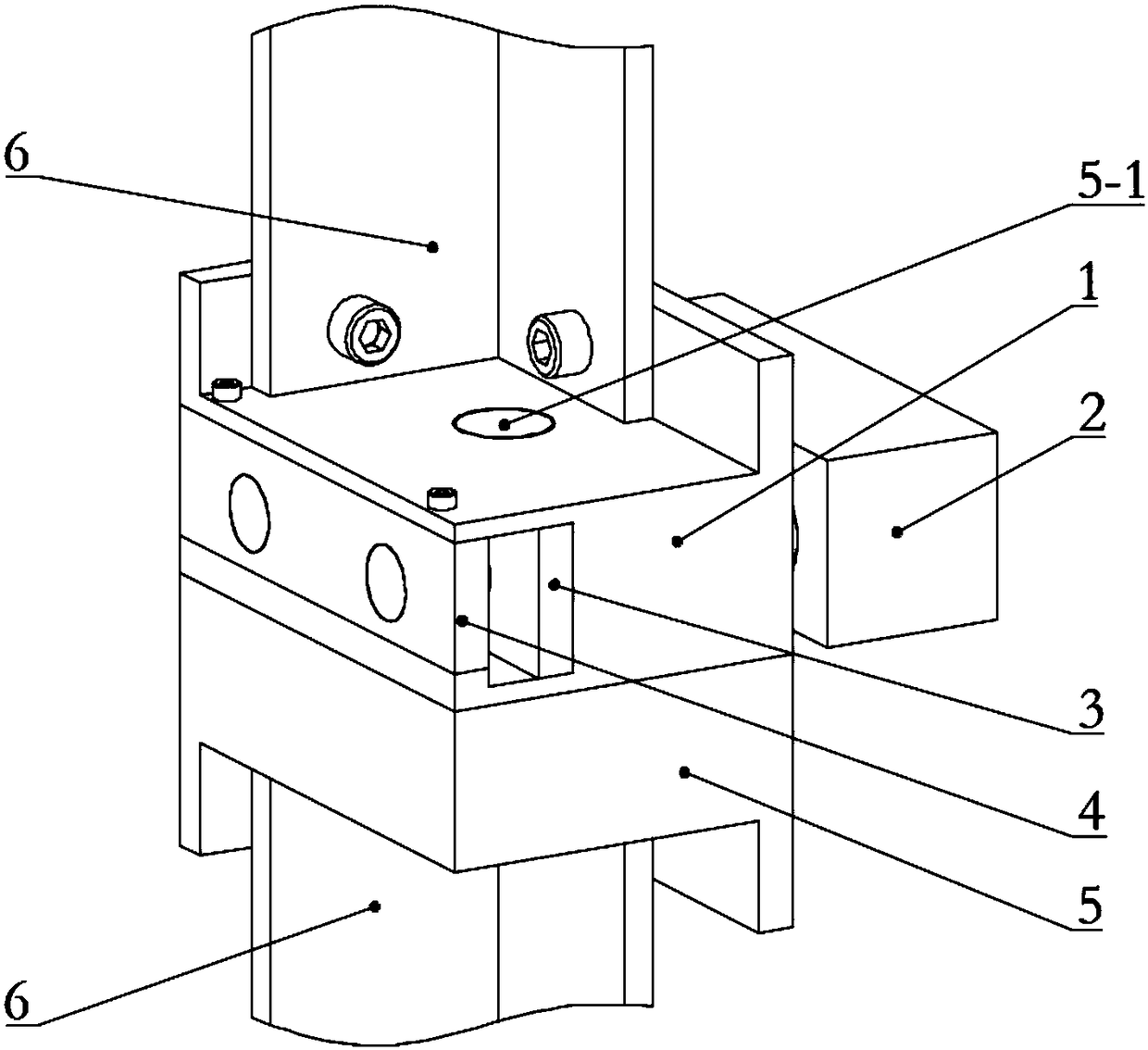

ActiveCN102169076ARealize 3D observationOvercoming two-dimensional distributionParticle size analysisSpecific gravity measurementVisual field lossBody density

The invention discloses a device and a method for detecting a rich-Te phase in a telluride semiconductor crystal. By the device and the method, the technical problems that the conventional device for detecting the rich-Te phase in the telluride semiconductor crystal cannot obtain a larger-size visual field and realize focused imaging of a layered domain in the thickness direction of the crystal can be solved. The technical scheme is that: the visual field can be adjusted by changing the magnifying power of a zoom lens barrel; meanwhile, by adoption of a high-precision four-coordinate three-dimensional automatic translational table, the body density of the rich-Te phase can be observed. By the method for detecting the rich-Te phase in the telluride semiconductor crystal by using the detecting device, the focused imaging of the layered domain is realized by adjusting the position in the thickness direction, so the form of the rich-Te phase in the crystal can be observed; and a Labview-based image collection and processing system is used for splicing every collected independent picture into a whole large image at first, counting different gray scale regions of the spliced image and analyzing the distribution of the rich-Te phase in the crystal.

Owner:IMDETEK

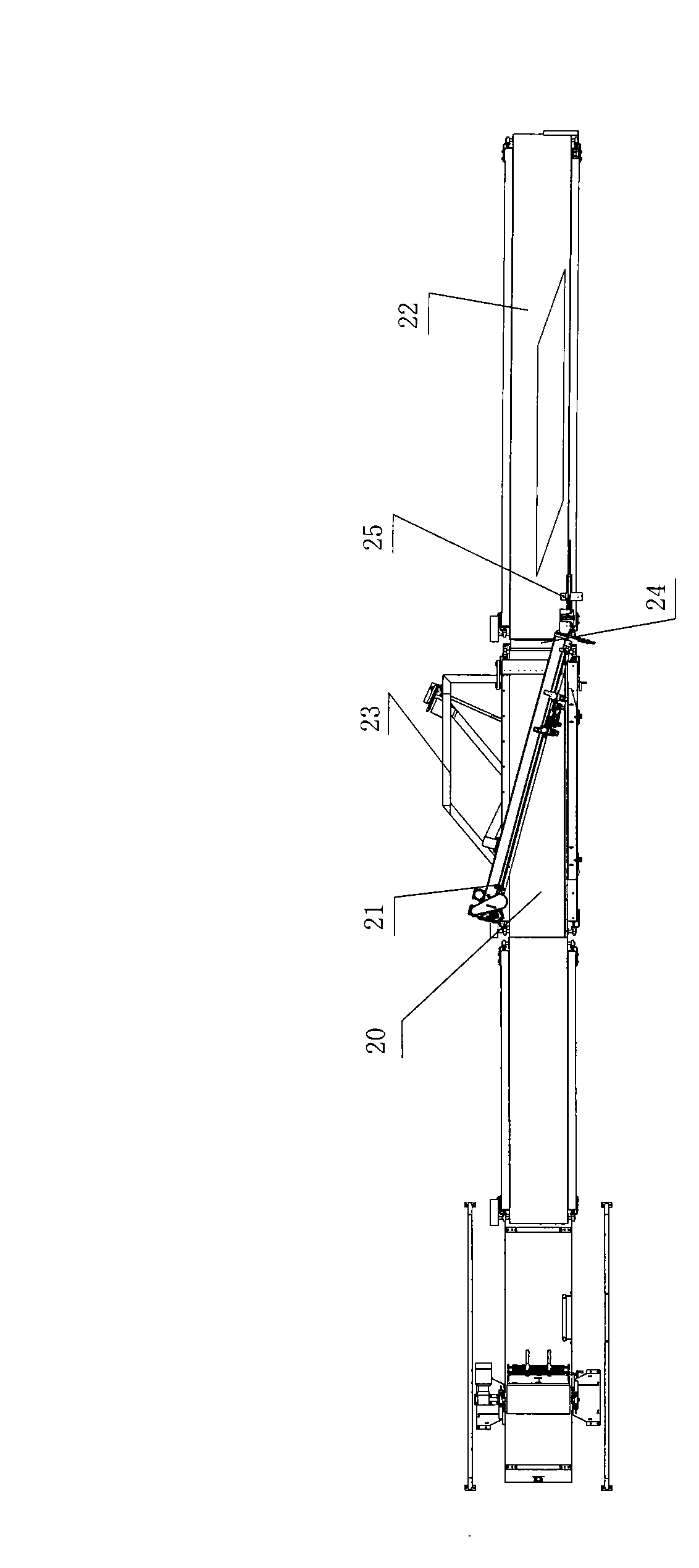

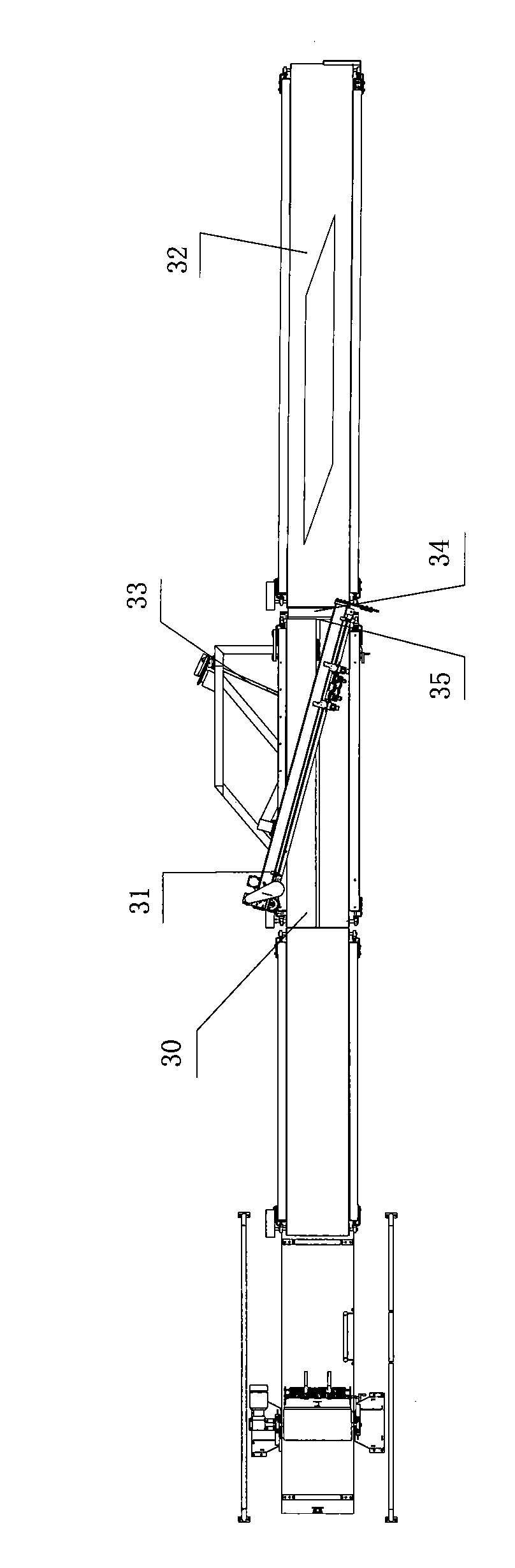

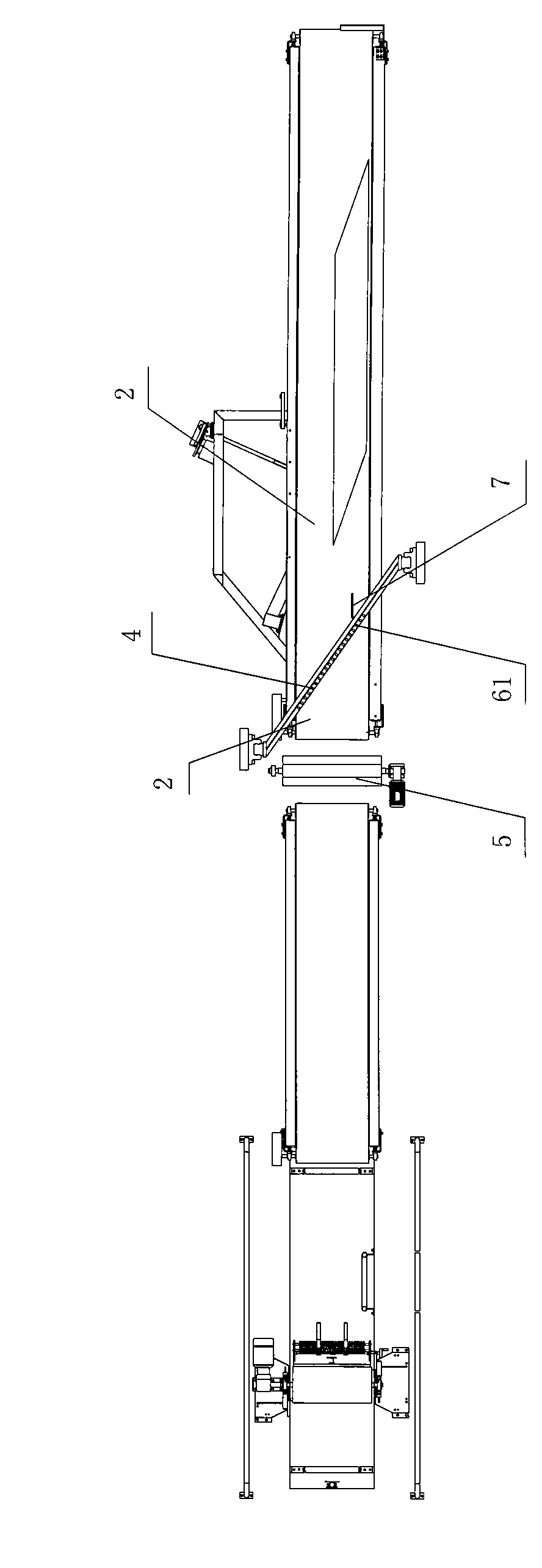

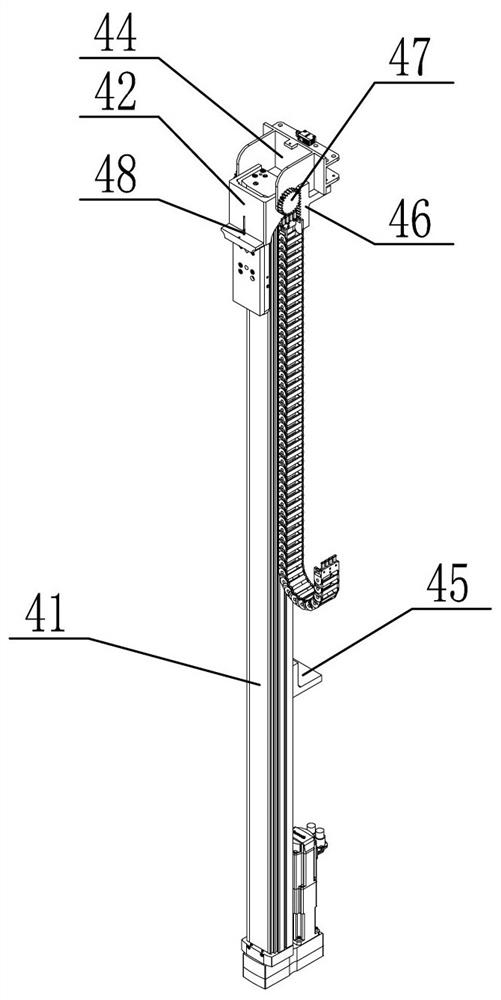

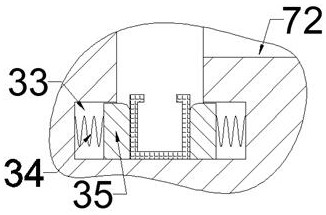

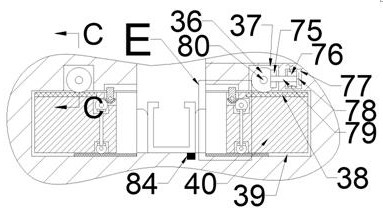

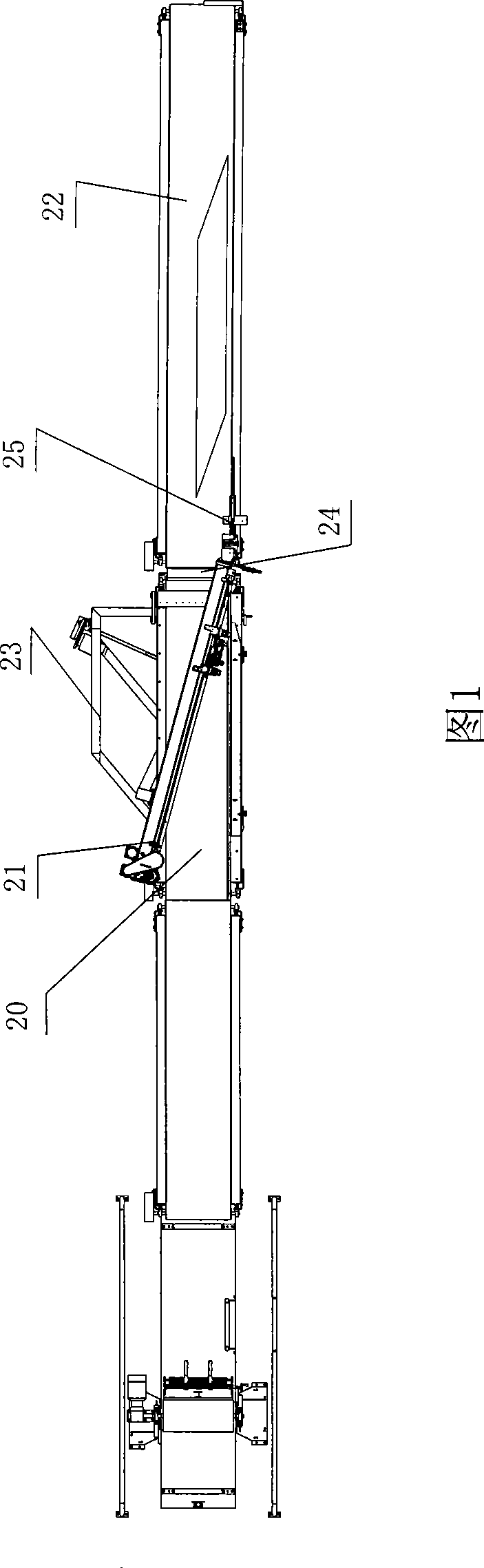

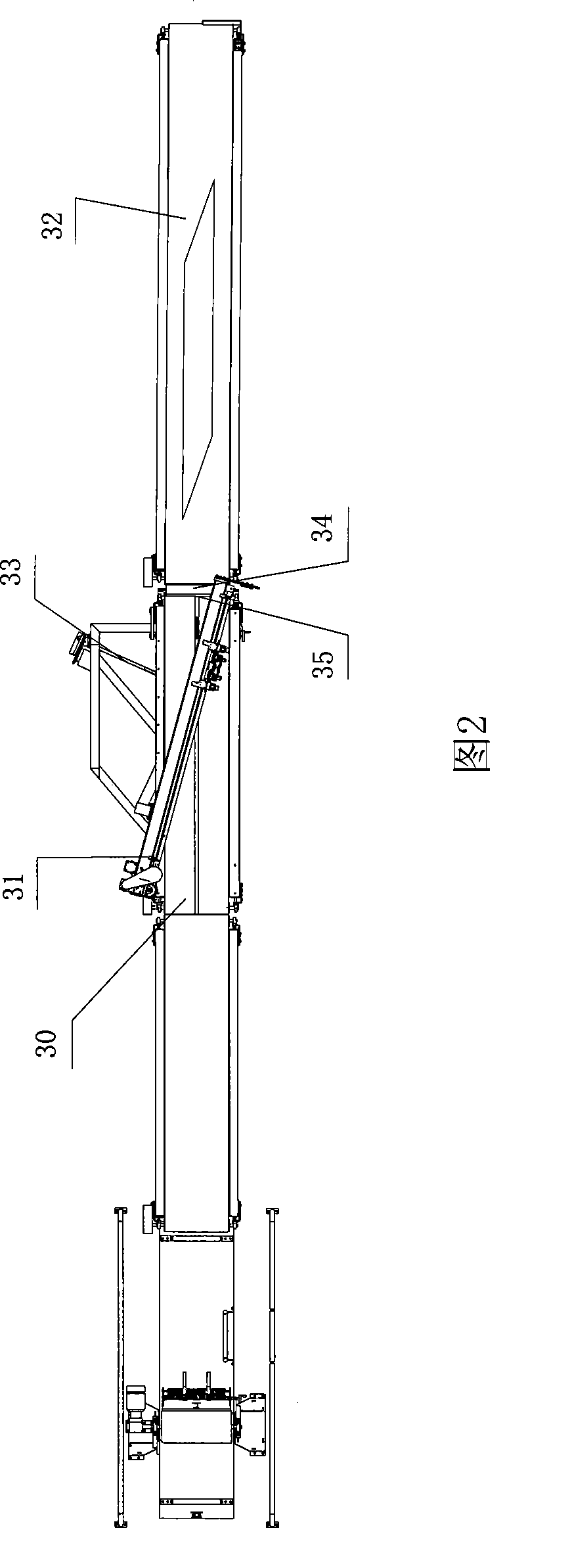

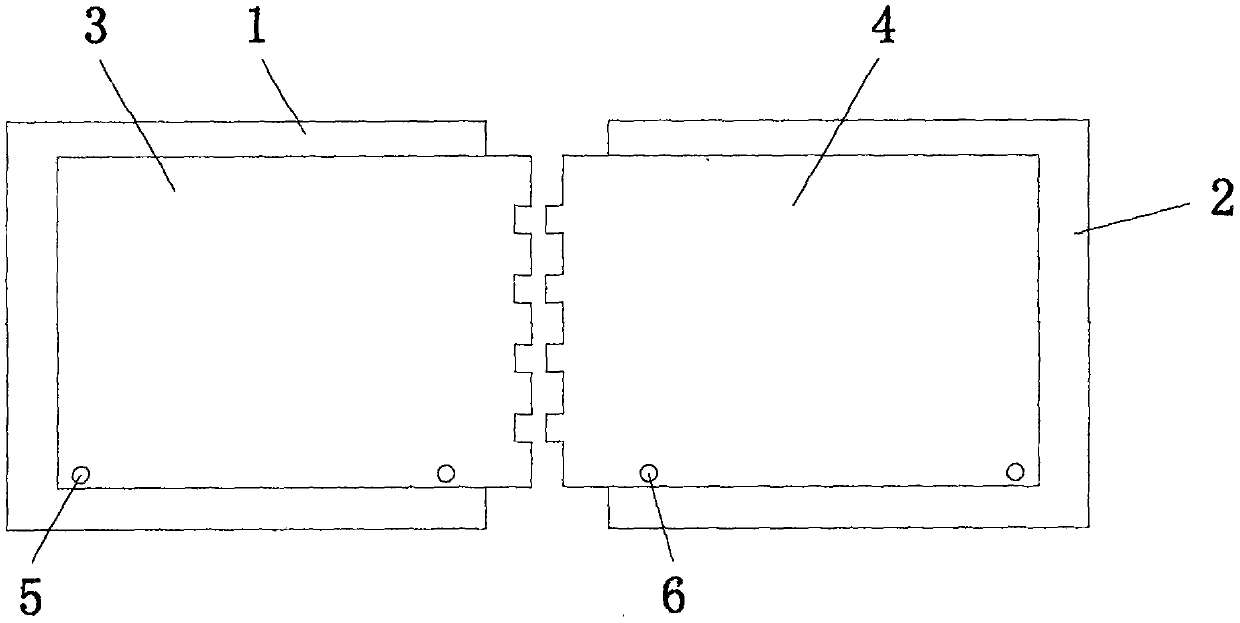

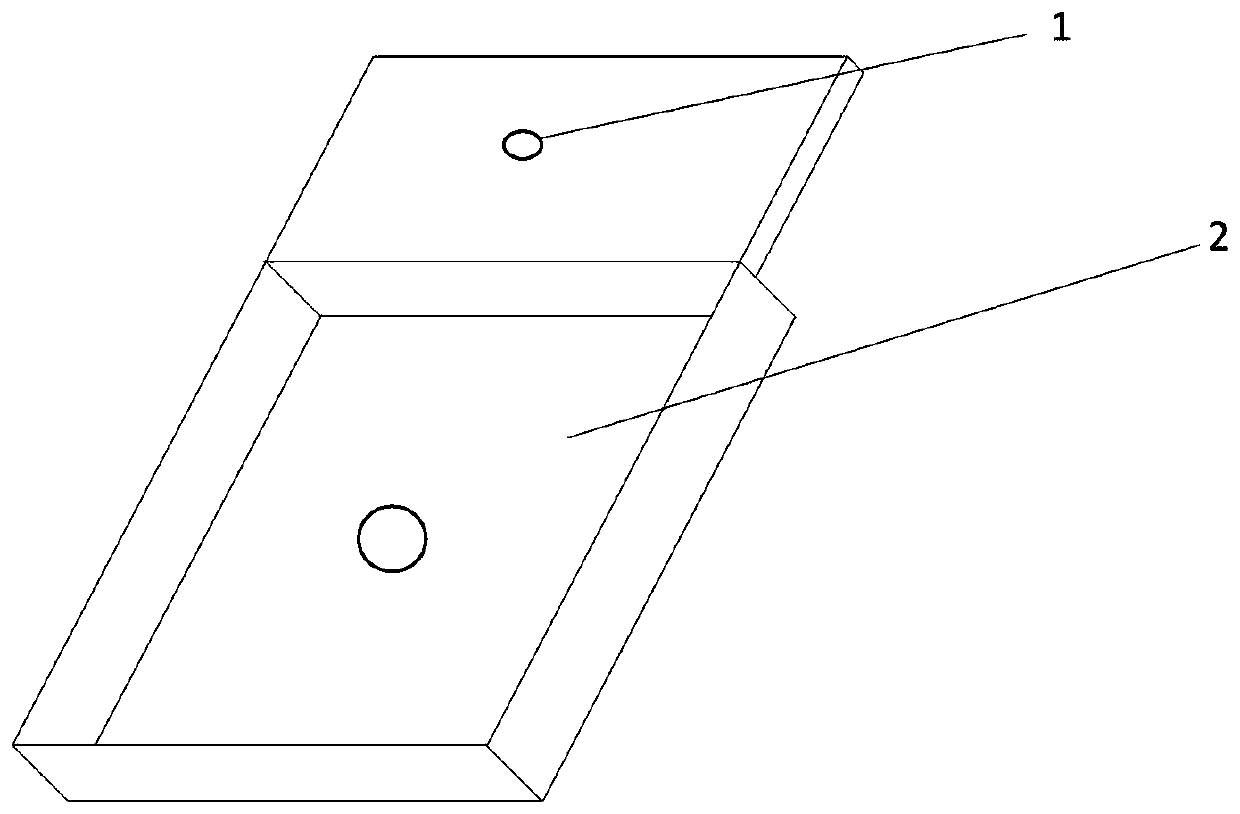

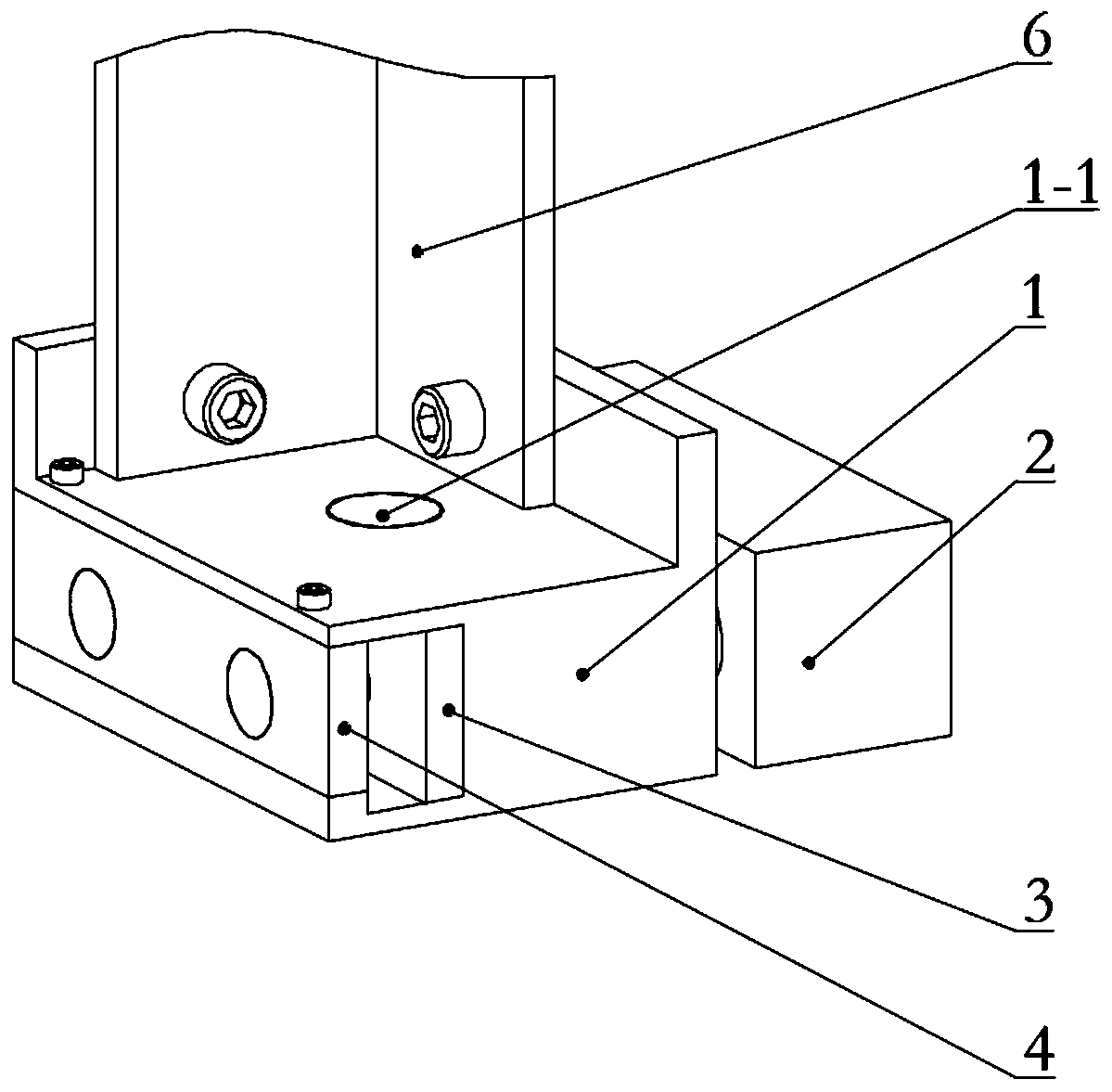

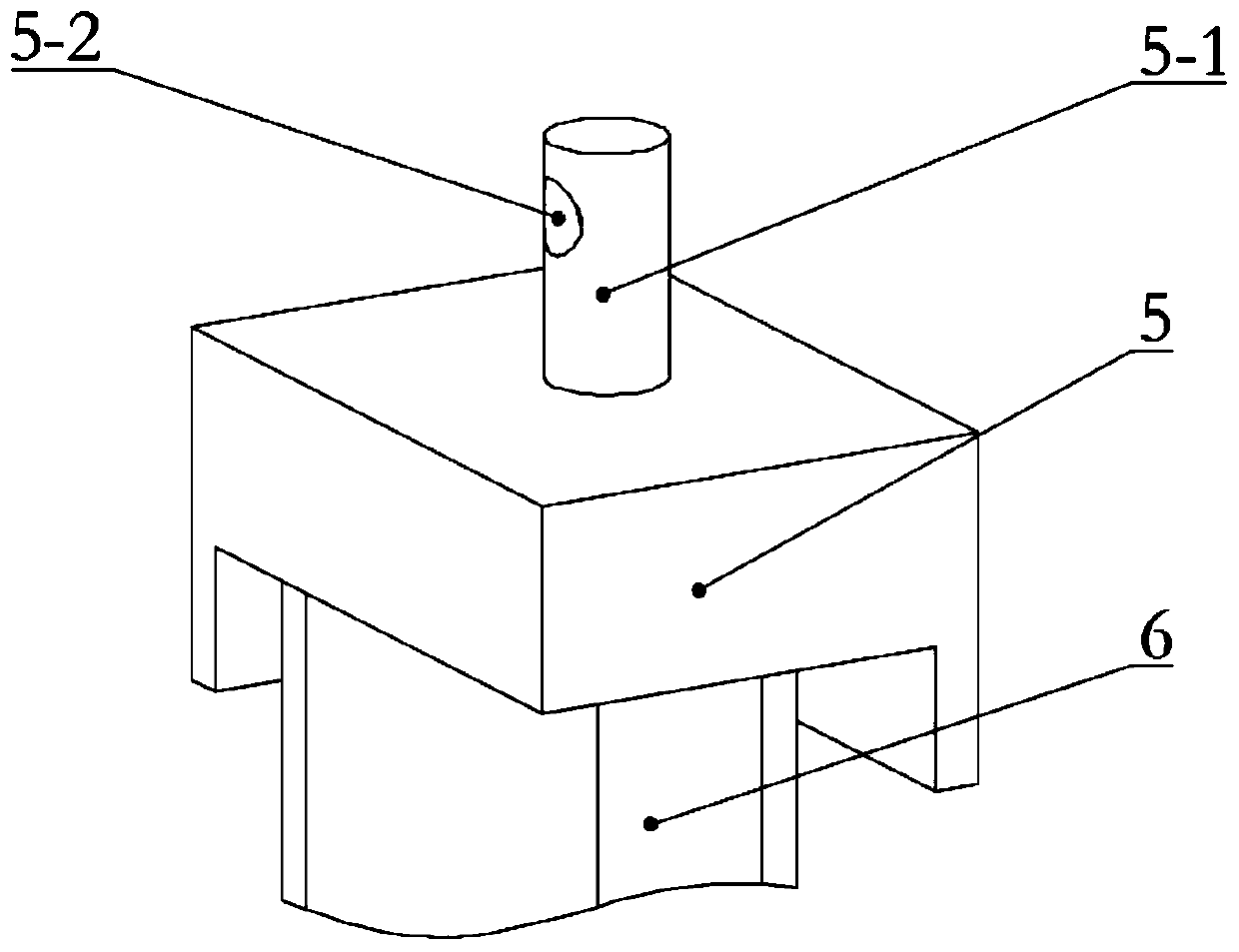

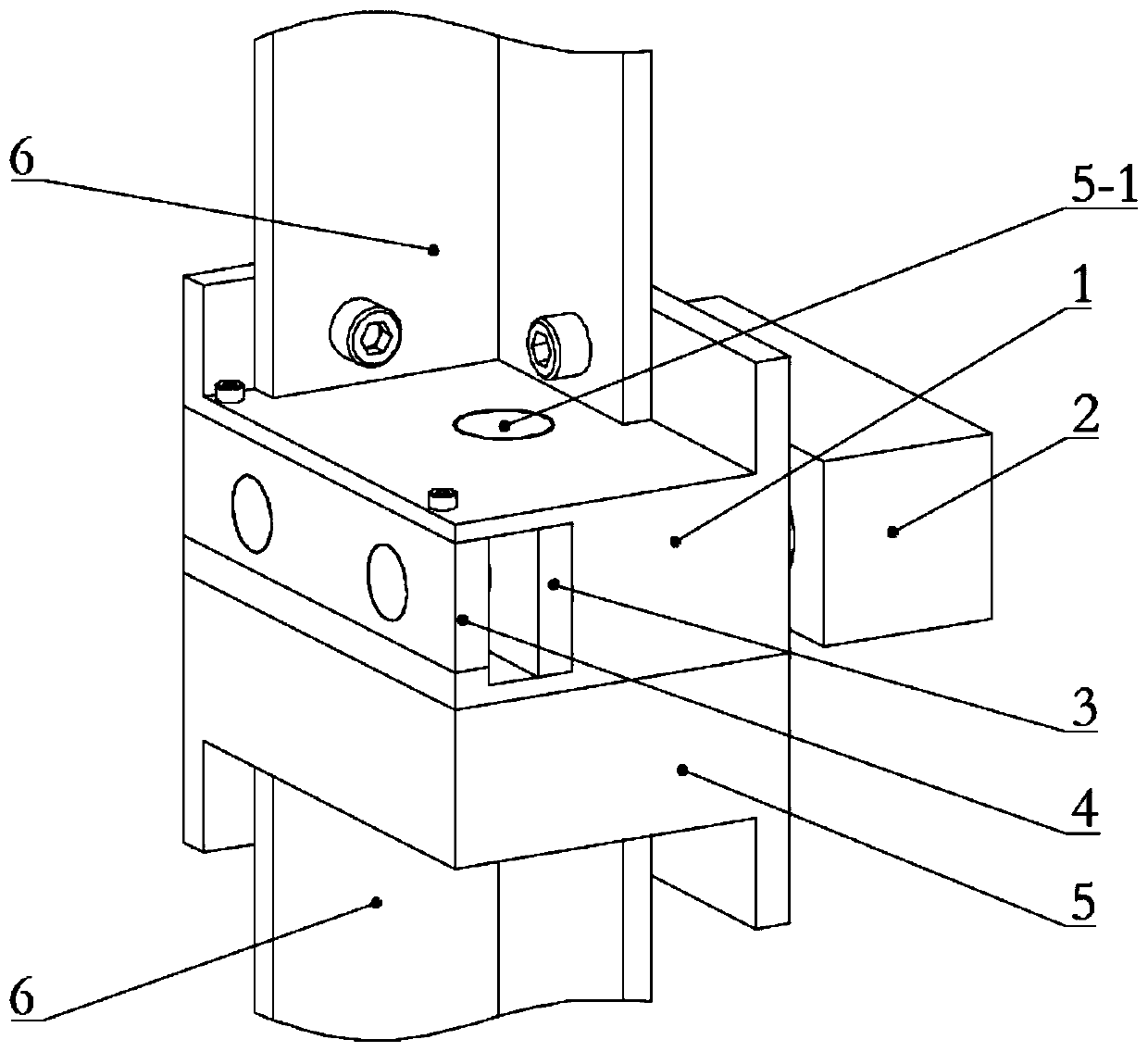

Insulation module automatic rapid connection mechanism and connection dismounting method thereof

ActiveCN108462094ACompact structureHigh working reliabilityLifting devicesCable installation apparatusUpper jointModularity

The present invention discloses an insulation module automatic rapid connection mechanism and a connection dismounting method thereof. The insulation module automatic rapid connection mechanism comprises an upper joint, a lower joint and an automatic drive device; the upper joint comprises an upper joint main body and a locking block; the upper joint main body is provided with a pin mounting holeand a bolt mounting hole which communicate to each other; the locking block is provided with a bolt, and the bolt is installed in the bolt mounting hole; the automatic drive device is configured to drive the bolt of the locking block; the automatic drive device can drive the bolt of the locking block to stretch into and pull out the pin mounting hole; the lower joint comprises a lower joint main body and a locking pin; and the locking pin is connected with the lower joint main body, and the locking pin can stretch into the pin mounting hole, wherein the bolt and the locking pin can stretch into the pin mounting hole at the same time to connect and lock the upper joint and the lower joint. The insulation module automatic rapid connection mechanism and the connection dismounting method thereof can be applied in a modularized lift platform to allow the top end of the lift platform to have high stability and allow the insulation module to automatically and effectively complete splicing.

Owner:STATE GRID SHAANXI ELECTRIC POWER RES INST +3

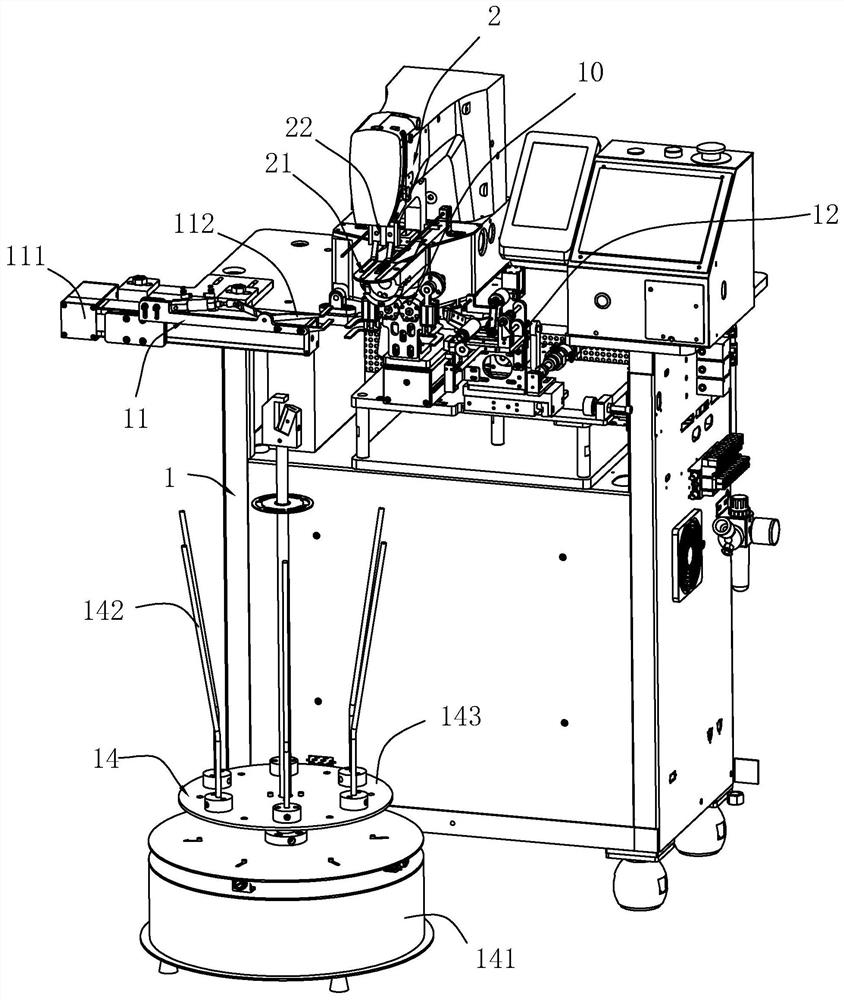

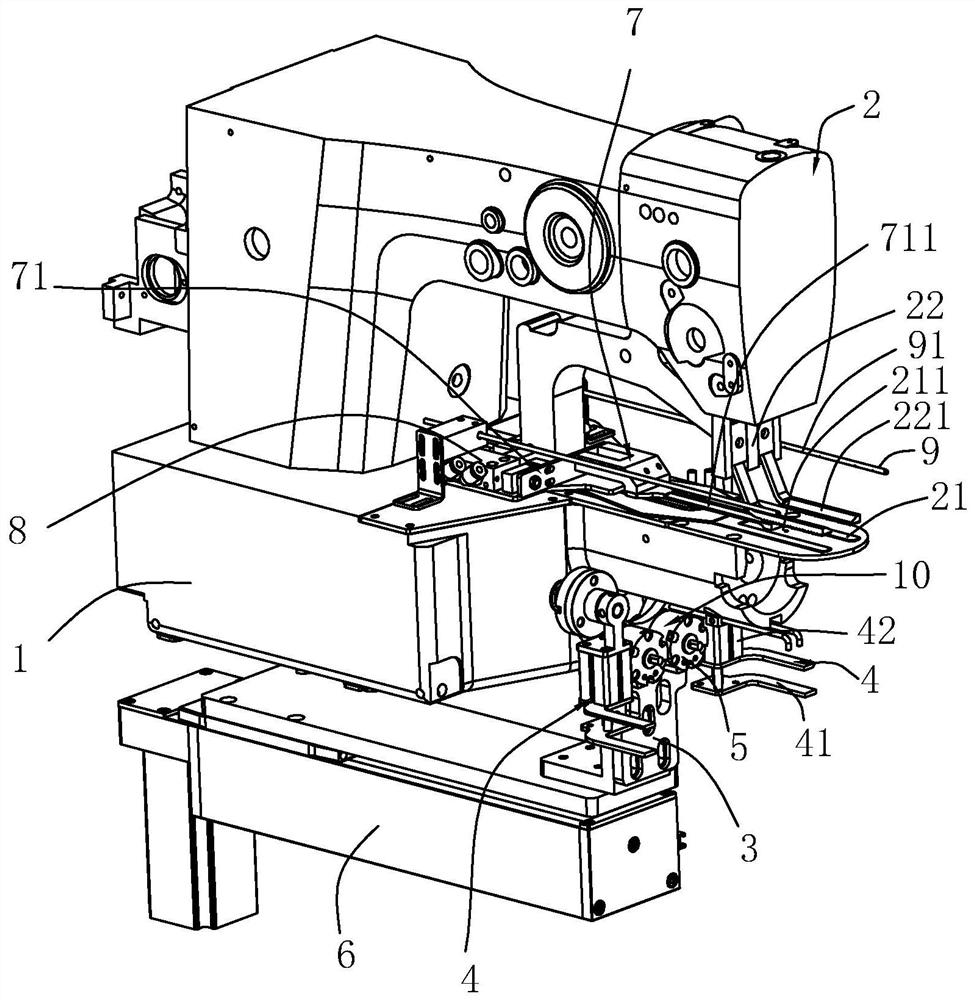

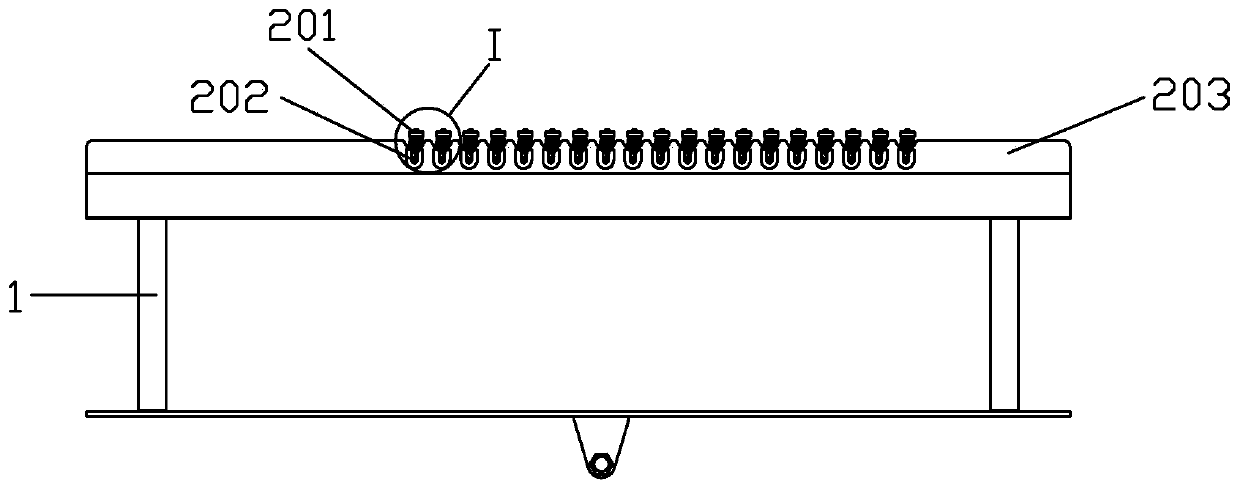

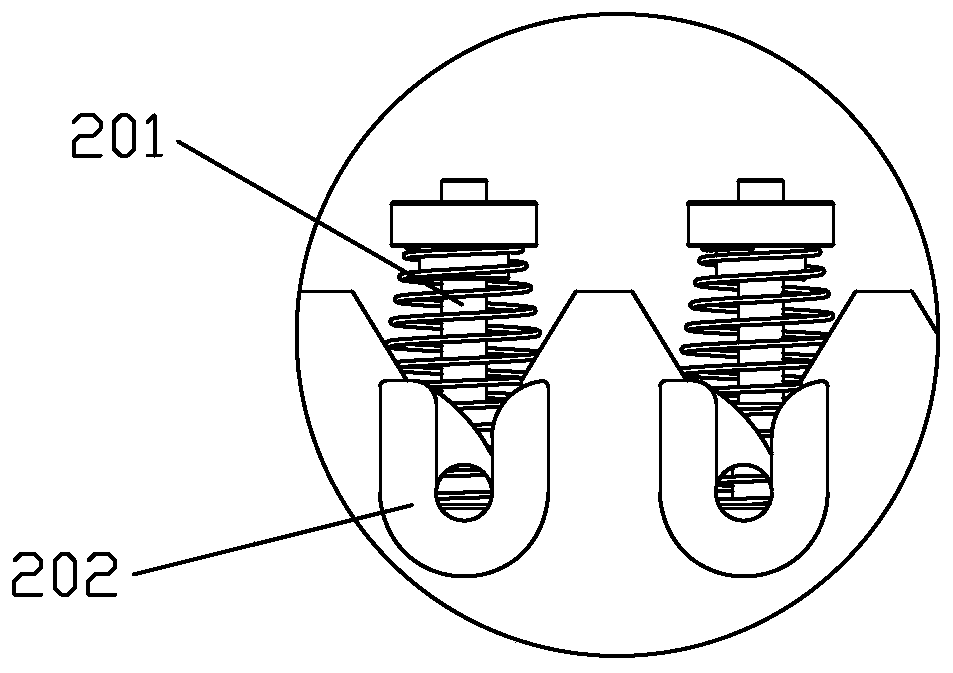

Elastic band connecting machine

PendingCN112030383AImprove processing efficiencyRealize automatic splicingWorkpiece carriersWork-feeding meansPhysicsSewing machine

The invention provides an elastic band connecting machine. The elastic band connecting machine comprises a rack, wherein a sewing machine body is installed on the rack, the sewing machine body comprises a sewing platform and a sewing head; a material clamping mechanism, a material turning mechanism and a material cutting mechanism are arranged on the rack; the material turning mechanism is locatedbelow the sewing platform and comprises a mounting table; two clamping jaws are mounted on the mounting table; a rotary driving part is arranged on the mounting table and used for driving the clamping jaws to be overturned to the position above or below the sewing platform; a sliding driving part is arranged on the rack and used for driving the mounting table to move; and the clamping jaws on themounting table can move close to or far away from a seam joint. According to the automatic sewing equipment, the actions of automatic clamping, material cutting, sewing and discharging are completed,and the overall sewing efficiency is high; and as the clamping jaws and the sliding driving part are matched with each other to complete clamping, pushing and pulling of an elastic band, a pushing mechanism for pushing the elastic band is omitted, the feeding stroke is short, and the structural compactness is high.

Owner:朗进科技(浙江)有限公司

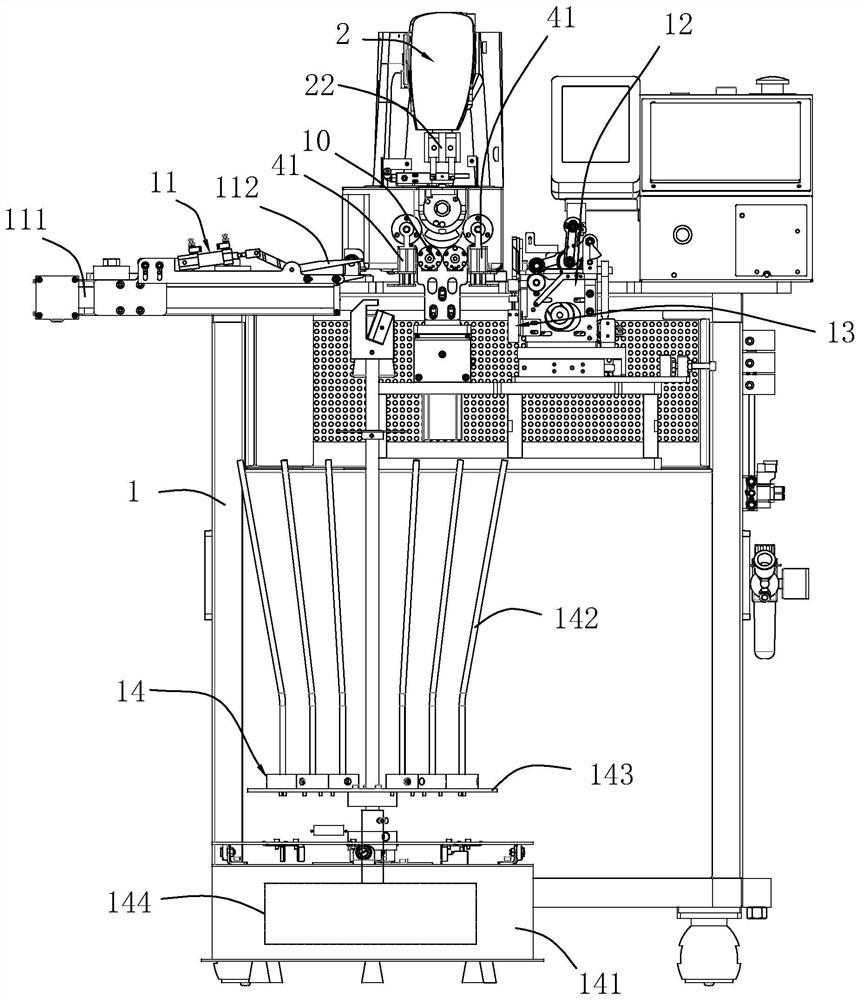

Automatic yarn replacing, twisting and connecting machine for yarn of multiple colors

The invention discloses an automatic yarn replacing, twisting and connecting machine for yarn of multiple colors. The automatic yarn replacing, twisting and connecting machine comprises a twisting andconnecting machine rack and a yarn winding mechanism. A yarn arrangement mechanism is arranged at one end of the twisting and connecting machine rack. The yarn arrangement mechanism is provided withat least two pieces of yarn. The first piece of yarn is connected to the yarn winding mechanism. The second piece of yarn is suspended on the yarn arrangement mechanism. The twisting and connecting machine rack is fixedly connected with a supporting plate. The supporting plate is provided with a yarn cutting and clamping mechanism, a yarn grabbing and clamping mechanism, a yarn pressing mechanismand a twisting and connecting device. One end of the yarn grabbing and clamping mechanism is fixed to the supporting plate. The other end of the yarn grabbing and clamping mechanism is movably connected with the twisting and connecting machine rack. The yarn pressing mechanism is arranged above the twisting and connecting device. According to the automatic yarn replacing, twisting and connecting machine, the multi-color yarn twisting and connecting process is controlled by a computer, all the mechanisms are mutually matched, automatic twisting and connecting of multiple sections of yarn of different colors is achieved, manual yarn twisting and connecting is not needed, the labor cost is saved, the production cost is reduced, the twisting and connecting efficiency of yarn of multiple colorsis improved greatly, and the twisting and connecting success rate is high.

Owner:嵊州市南丰机械股份有限公司

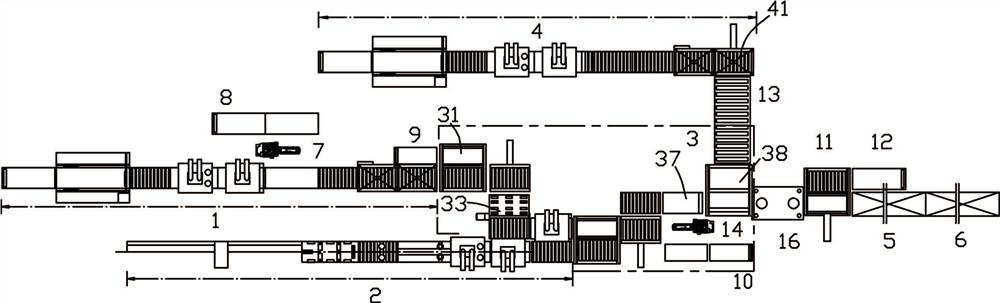

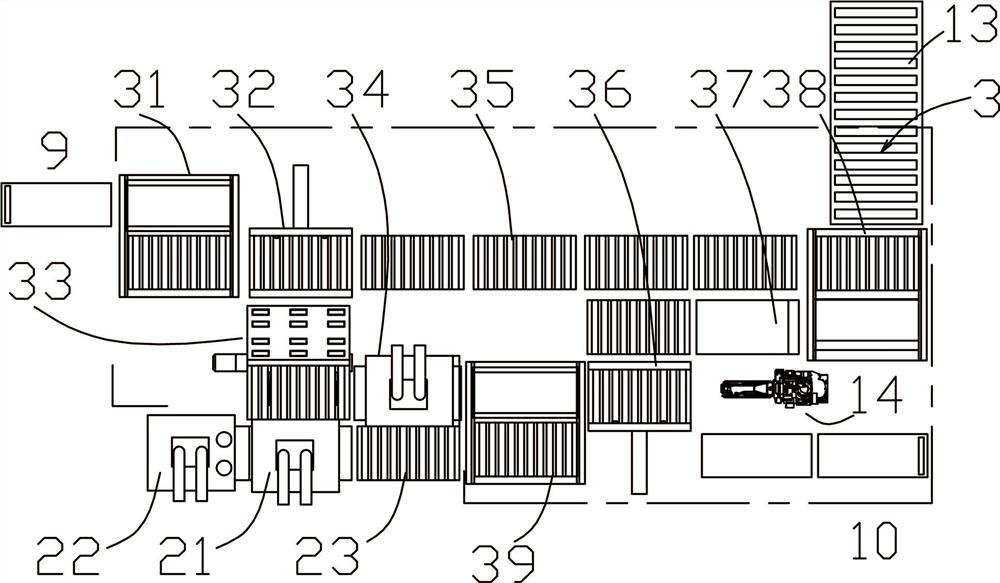

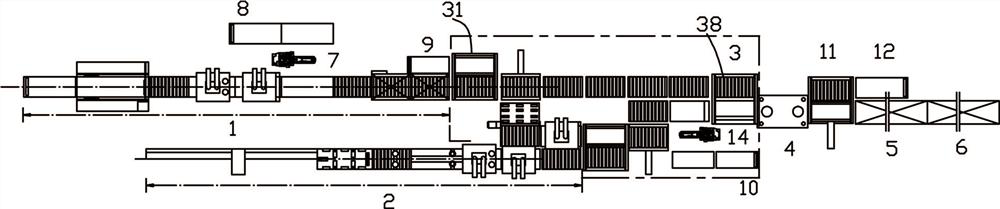

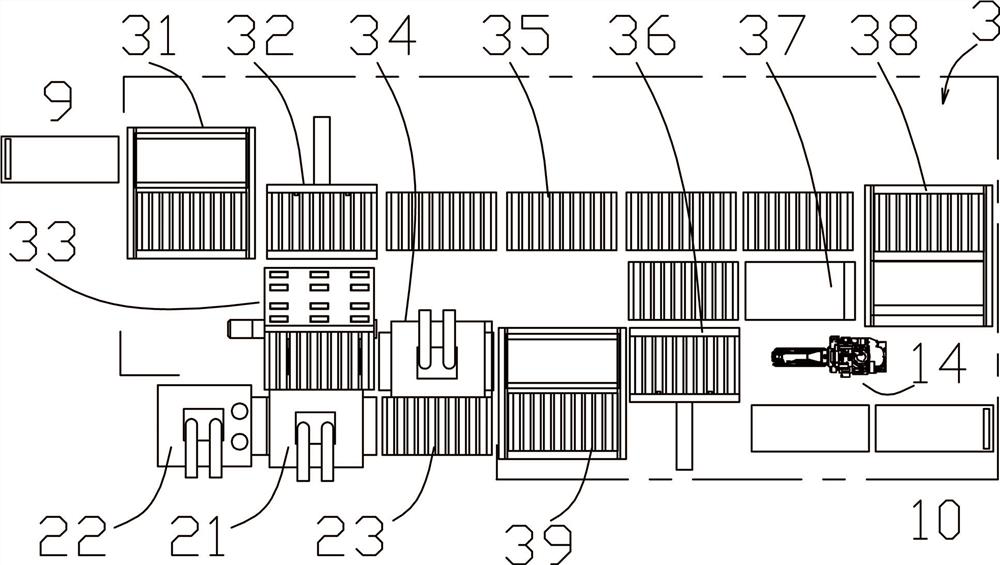

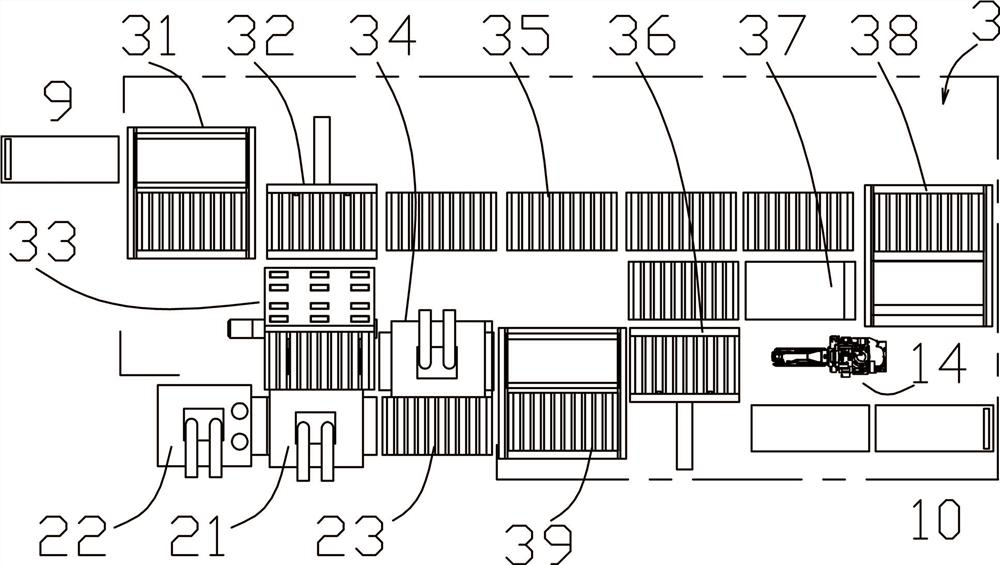

Double-face-plate full-automatic wooden door production line

ActiveCN113070963ARealize automated combinationConsistent production beatsAdhesive application devicesManufacturing lineIndustrial engineering

The invention provides a double-face-plate full-automatic wooden door production line. The production line comprises a first face plate production line, a second face plate production line and a door frame production line and further comprises a combined production line, and the first face plate production line is connected with the combined production line; a cover plate grabbing and covering station is arranged on the combined production line and used for grabbing and covering a first face plate with a cover plate; a cover plate and first face plate pushing station is arranged at the downstream of the cover plate grabbing and covering station, and the cover plate and first face plate pushing station is used for pushing the cover plate and the first face plate to a turn-over station; a door frame combination station is arranged at the downstream of the turn-over station, and the door frame production line is connected with the door frame combination station; a core frame combination station is arranged at the downstream of the door frame combination station; a second face plate covering station is arranged at the downstream of the core frame combination station; and the second face plate production line is connected with the second face plate covering station. Automatic combination of face plates and a door frame can be achieved. The face plates and the door frame are consistent in production takt, so that large-scale production can be realized conveniently.

Owner:湖北科豪门业有限公司

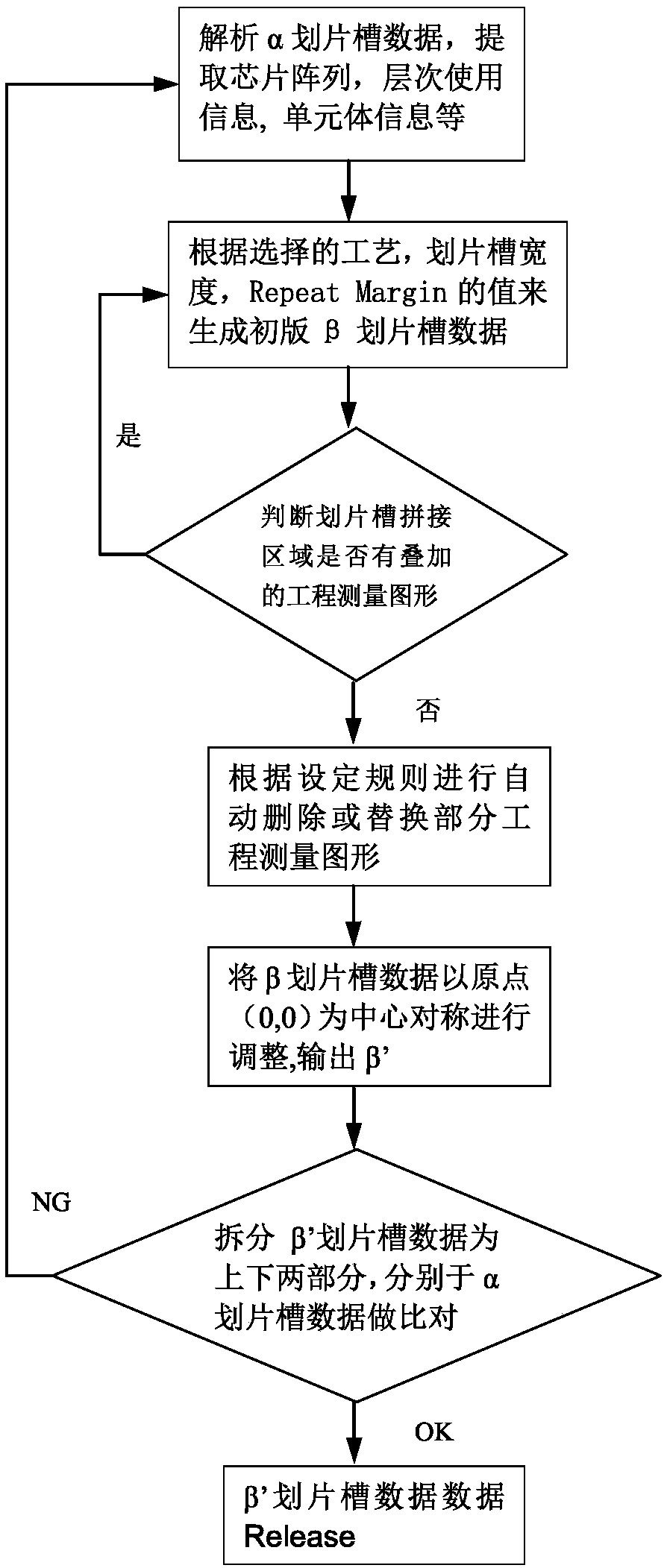

Method for automatically splicing scribing groove frame

InactiveCN108629088ARealize automatic splicingCause mutual interferenceCAD circuit designSpecial data processing applicationsComputer engineering

The invention discloses a method for automatically splicing a scribing groove frame. A chip array is determined by directly reading layout data of a scribing groove and extracting a chip identification layer, afterwards, by calculating set values like the width of the scribing groove and repeat margin, the scribing groove frame is automatically spliced, and it is ensured that engineering surveyinggraphs in a splicing region cannot mutually interfere due to overlapping.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

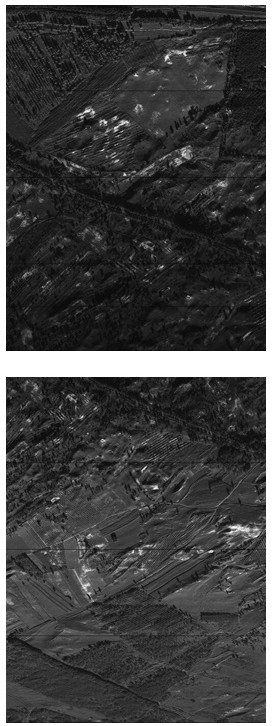

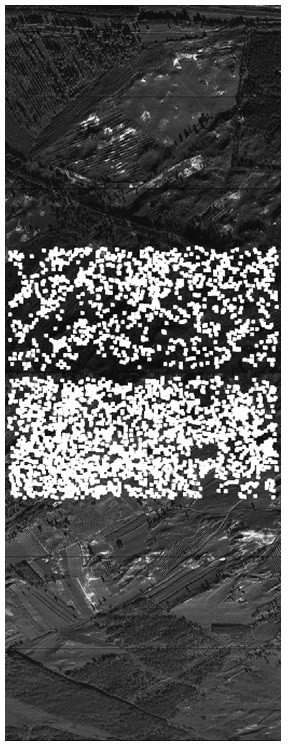

Aerial remote sensing image splicing method based on feature optimization and optimal splicing seam

ActiveCN112419160ARealize automatic splicingImprove detection efficiencyImage enhancementImage analysisImaging FeatureFeature based

The invention discloses an aerial remote sensing image splicing method based on feature optimization and an optimal splicing seam, and belongs to the technical field of image processing. The inventionaims to provide an aerial remote sensing image splicing method based on feature optimization and an optimal splicing seam. The aerial remote sensing image splicing method is used for automatically splicing remote sensing images shot by an aerial reconnaissance camera. The method comprises the following steps: carrying out rough matching on image feature points by utilizing an improved SURF algorithm, and carrying out image fusion by utilizing feature point fine matching based on normal distribution. According to the invention, manual participation is not needed, and automatic splicing of panoramic images can be realized according to the types of the image files. The splicing method provided by the invention has the characteristics of high processing speed and high splicing precision, thefeature point detection efficiency is improved by pre-defining the feature detection area, a feature point screening method is provided and can be used for calculating a more accurate transformation matrix, more accurate registration is realized. The provided splicing seam searching method can effectively protect the salient target of the overlapping region and ensure the integrity of the target.

Owner:PLA AIR FORCE AVIATION UNIVERSITY

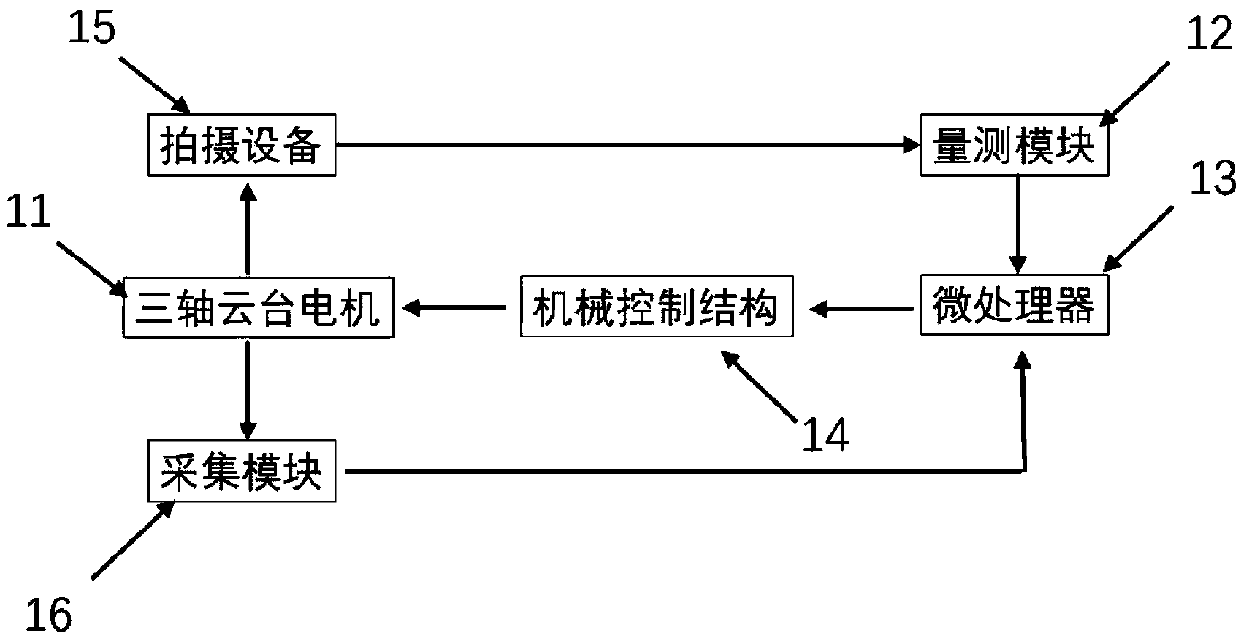

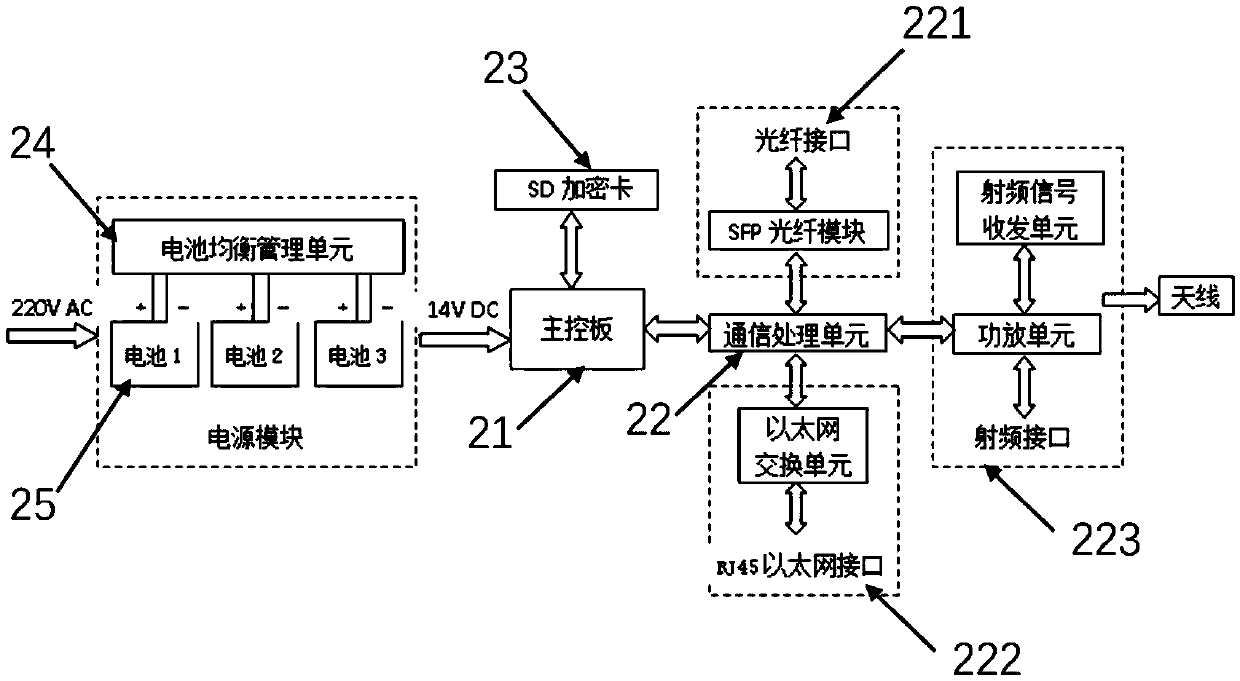

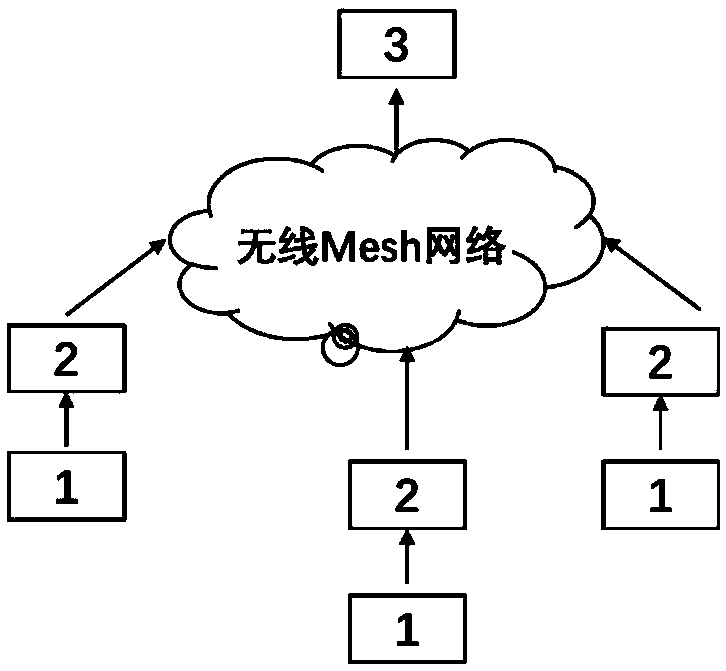

Quantum-encryption-type video monitoring system used for intelligent ad hoc network communication

ActiveCN109618135AStrong power consumptionReduce power consumptionKey distribution for secure communicationClosed circuit television systemsVideo monitoringTraffic capacity

The invention belongs to the field of network video surveillance, and particularly relates to a quantum-encryption-type video monitoring system used for intelligent ad hoc network communication. The system includes panoramic cloud platform and control systems and intelligent ad hoc network communication terminal equipment. The panoramic cloud platform and control systems are connected with the intelligent ad hoc network communication terminal equipment through network interfaces. The intelligent ad hoc network communication terminal equipment uses a wireless Mesh network to realize two-way communication with other intelligent ad hoc network communication terminal equipment and a monitoring center, and thus transmits panoramic video data through the wireless Mesh network. The intelligent adhoc network communication terminal equipment uses quantum keys for encryption, cooperates with the wireless Mesh network to realize double encryption, sets maximum values of connection point numbersand maximum values of data transmission traffic, and can carry out automatic re-connection when the connection point numbers or the data transmission traffic exceeds the maximum values. Panoramic video splicing systems are integrated in the intelligent ad hoc network communication terminal equipment, and collected panoramic video information can be processed and compressed.

Owner:喀什安德光电科技有限公司

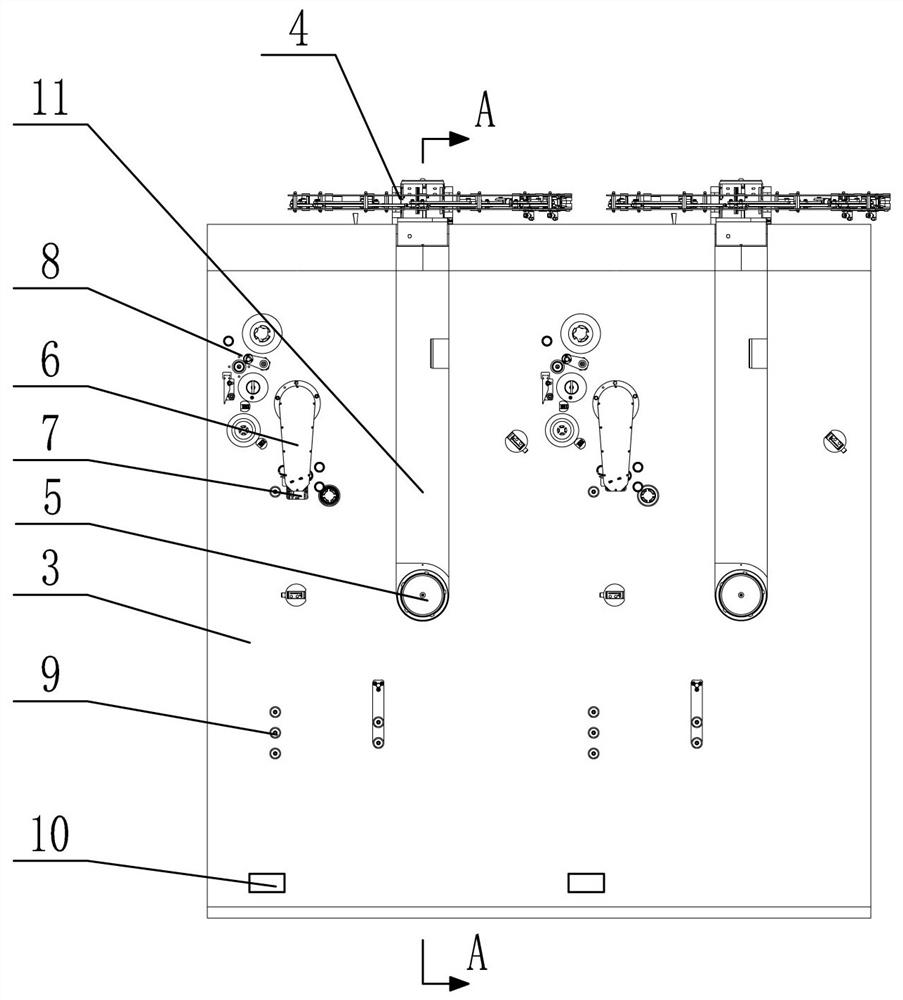

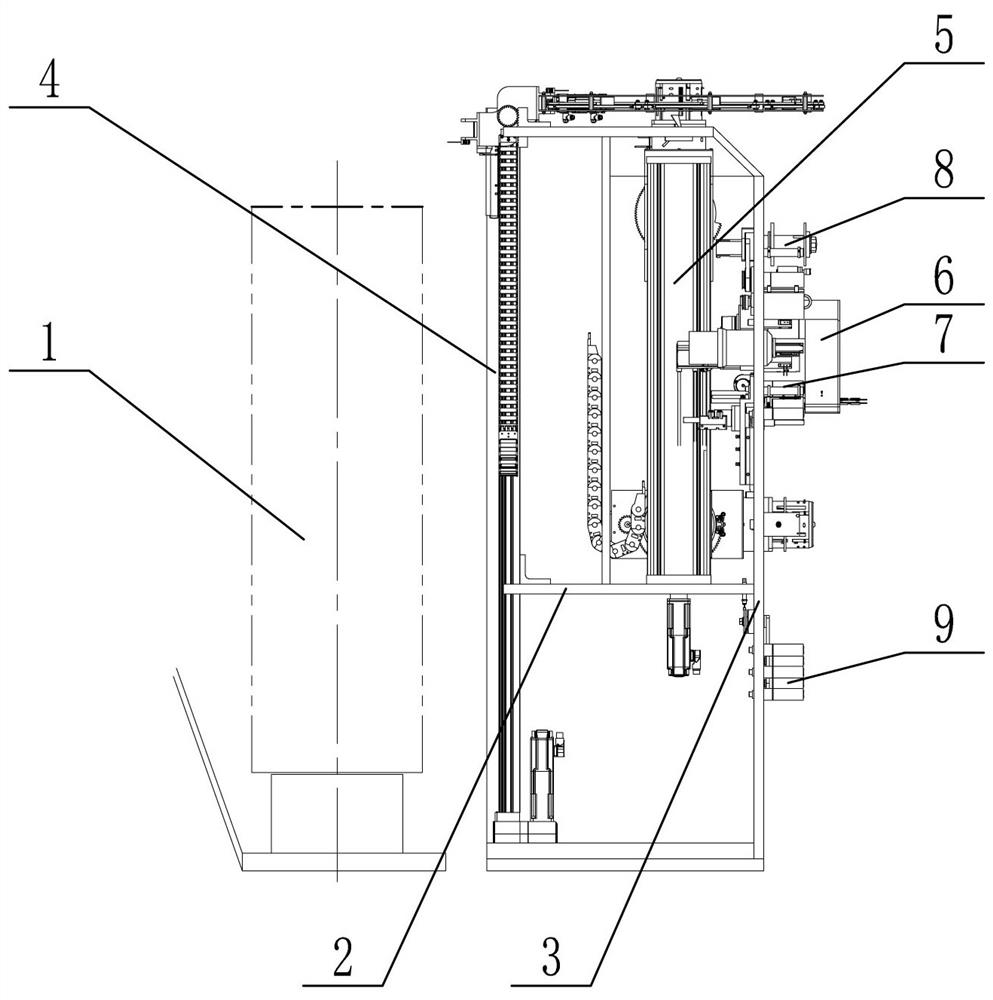

Material station for belt material processing

PendingCN111908219AGuaranteed level statusGuaranteed flip angleWebs handlingStructural engineeringMaterials processing

The invention provides a material station for belt material processing. According to the material station, a material warehouse is designed to be used for the vertical stacking of belt material trays;a grabbing and lifting device is designed to grab the belt material trays in the material warehouse and convey the belt material trays to a material supply station; a station changing and unwinding mechanism in a straight path is designed to convey one of the belt material trays at the material supply station to an unwinding station and perform the unwinding operation; a traction device is designed to pull the belt head of a new belt material tray and a double-sided adhesive sheet to an overlapping station; an overlapping device is designed to achieve the splicing of new and old belt materials; and consequently, the automatic replacement of the belt material trays during belt material production, the automatic pulling of the belt head and the double-sided adhesive sheet, as well as the automatic splicing of the new and old belt materials can be achieved, no manual operation is needed, the production efficiency can be effectively improved, and the production cost can be reduced.

Owner:HENAN XINZHILIN ELECTROMECHANICAL DEVICE CO LTD

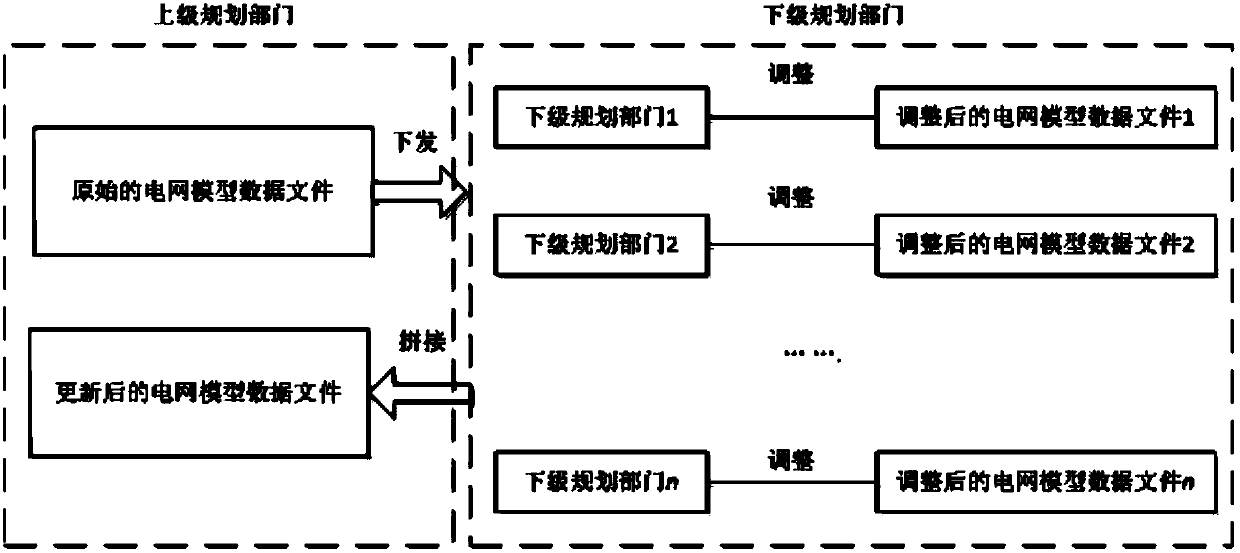

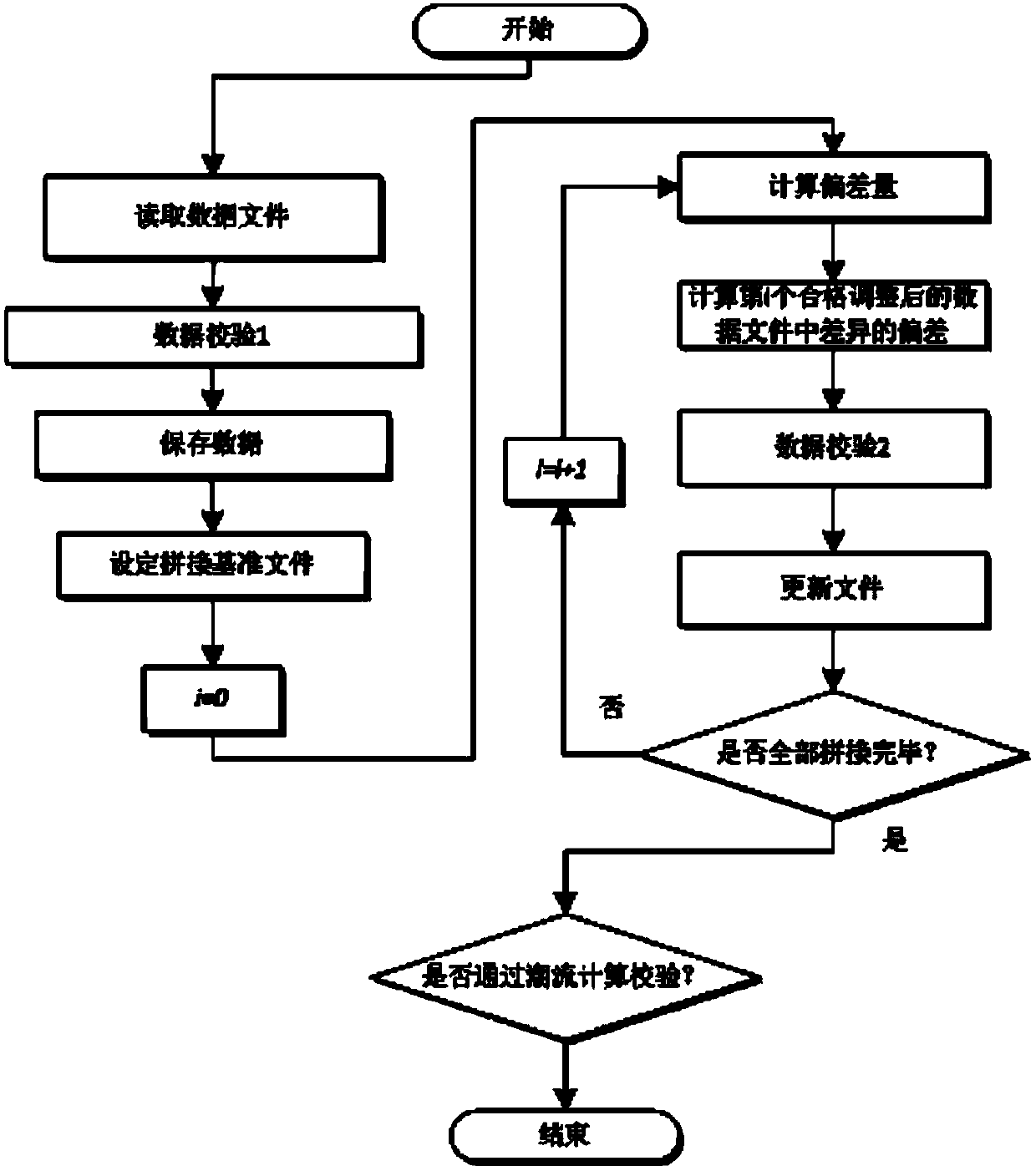

Automatic splicing method of power grid planning model data files

InactiveCN107844543ARealize automatic splicingImprove reliabilityData processing applicationsFile/folder operationsElectric power systemSource Data Verification

The invention discloses an automatic splicing method of power grid model data files, and belongs to the field of power system planning. The method comprises the steps of reading power grid model dataand the position information of each piece of data in the files from a database or the files, conducting data verification three times in sequence, saving the data, conducting difference comparison, determining splicing standards, calculating deviation amount, updating the files and the like; the power grid model data files of a large-scale power grid can be quickly, efficiently and automaticallyspliced, and therefore the automation, intelligence and accuracy of the work of splicing the power grid model data files during power grid planning can be effectively improved. The automation of the process of splicing the power grid model data files during power grid planning is achieved, the working efficiency and effectiveness of planners are greatly improved, the reliability of power grid planning model data can be improved at the same time, and the accuracy of power grid planning data and the reliability of calculation results are ensured.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

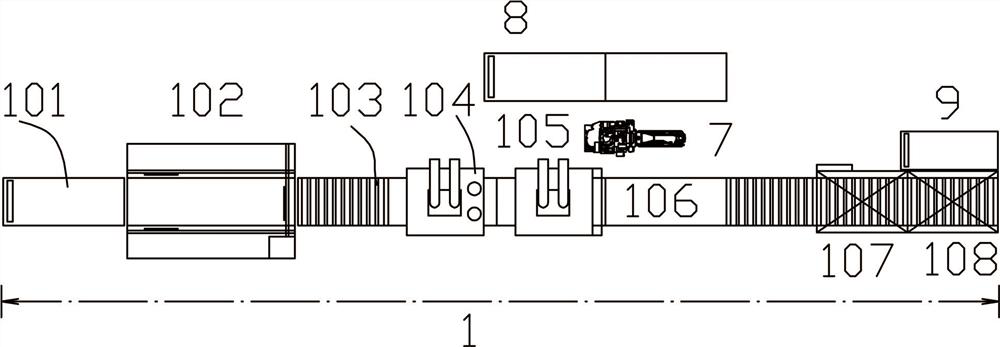

Single panel automatic wooden door production line

ActiveCN113084958BRealize automated combinationReduce in quantityBark-zones/chip/dust/waste removalManufacturing lineIndustrial engineering

The invention provides a single-panel full-automatic wooden door production line, which includes a panel production line and a door frame production line, and also includes a combined production line, the panel production line is connected to the combined production line; the combined production line is provided with a cover plate grasping and covering station for grasping the cover plate Take and cover on the first panel; the downstream of the cover plate grabbing and covering station is provided with a cover plate and a first panel pushing station, and the cover plate and the first panel pushing station are used to push the cover plate and the first panel to the flip face station; the turning station is used to turn over the cover board and the first panel; the downstream of the turning station is provided with a door frame assembly station, which is used to grab the door frame onto the first panel; the door frame assembly station There is a core frame assembly station downstream, which is used to place the core frame in the door frame; a second panel covering station is provided downstream of the core frame assembly station, which is used to grab and cover the second panel from the panel production line on the door frame superior. The invention can realize the automatic combination of the panel and the door frame, and further improves the processing efficiency.

Owner:湖北科豪门业有限公司

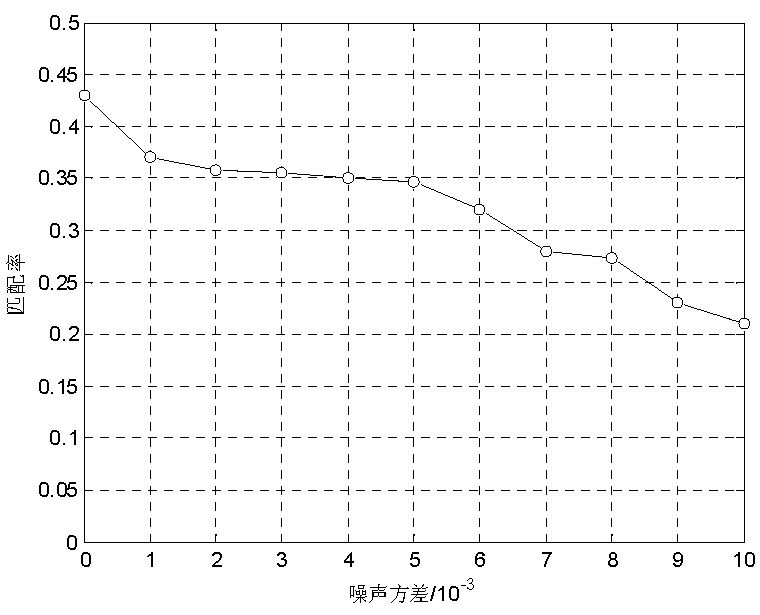

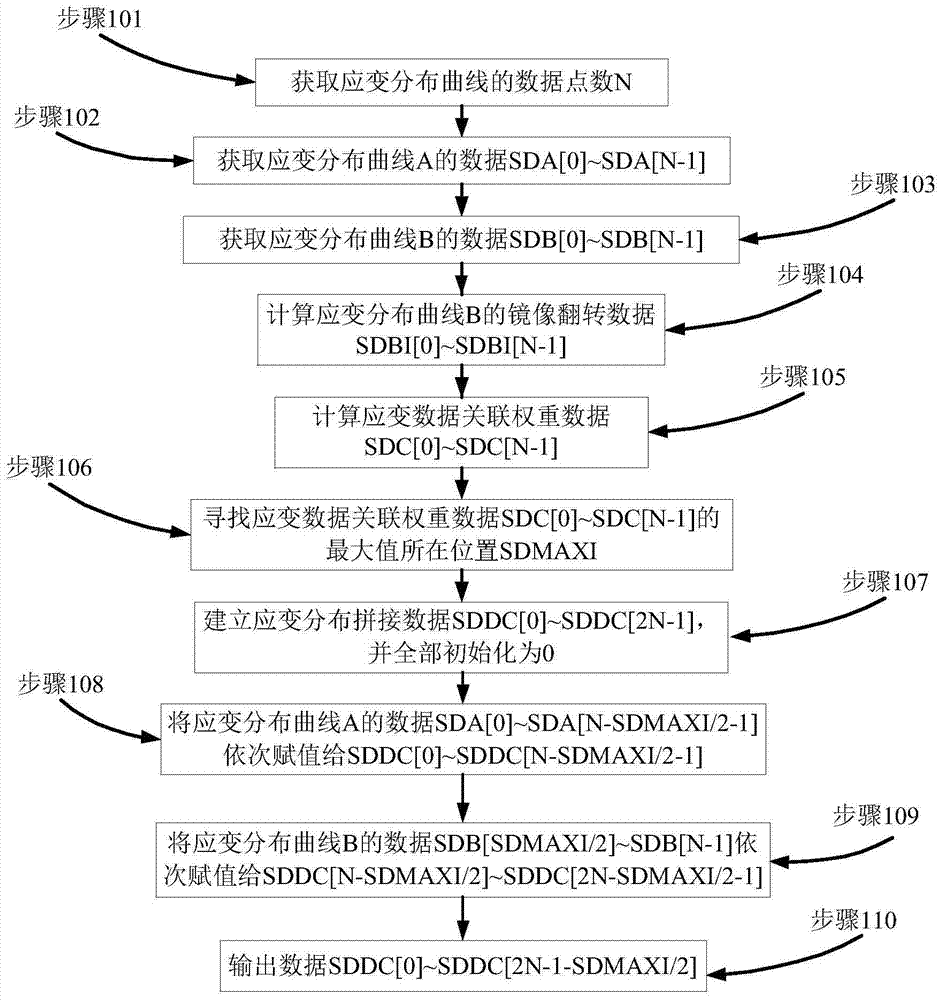

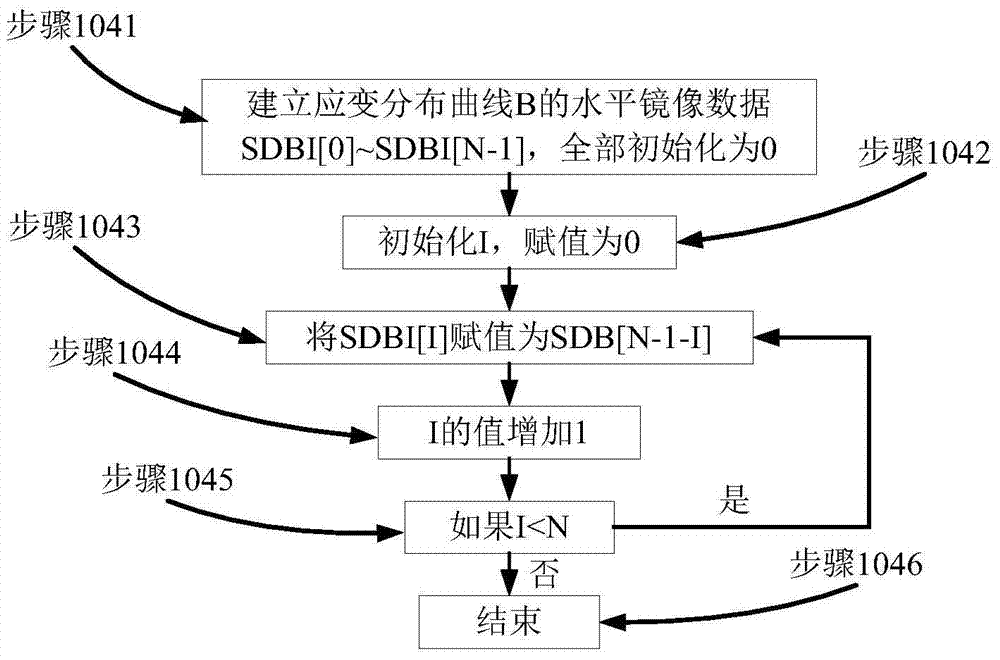

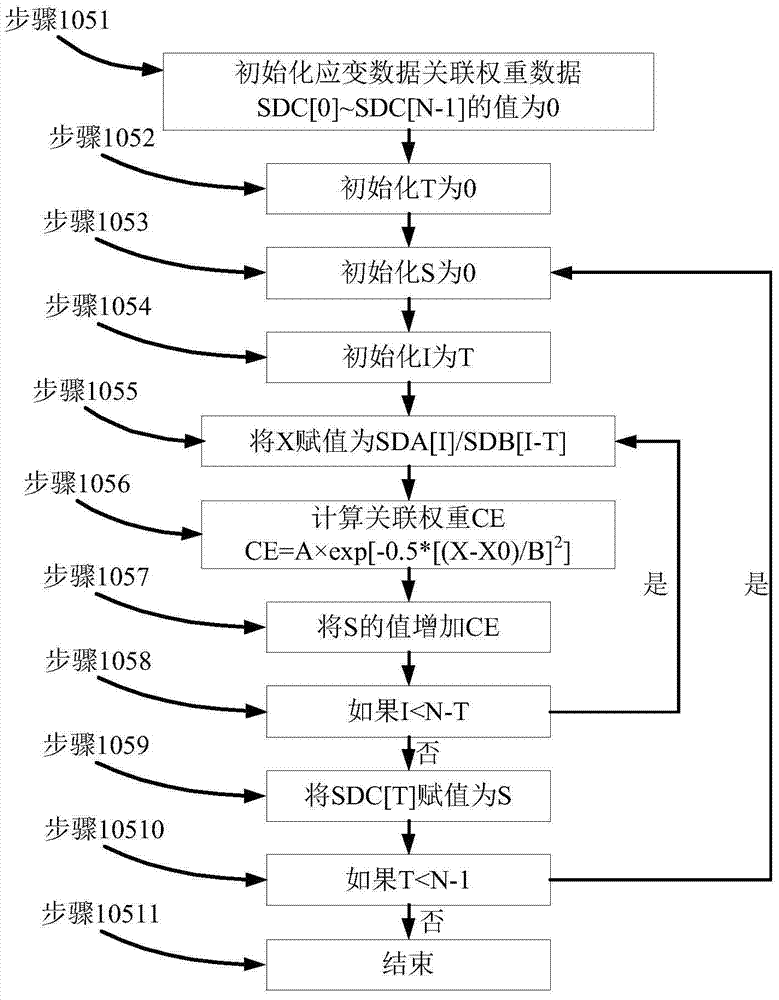

A botdr optical fiber strain distribution curve splicing method

ActiveCN104866708BRealize automatic splicingReduce the effect of splicingUsing optical meansSpecial data processing applicationsMaterials scienceSignal-to-noise ratio

The invention discloses a BOTDR optical fiber strain distribution curve splicing method. The method uses a strain data associated weight calculation method as the core and utilizes a sliding quotient solving weight integral to seek a superposed area of strain curves of two optical fibers according to strain data coincidence similarity characteristics obtained after the two ends of each optical fiber are tested, so that automatic splicing of the strain curves is realized, the influence of optical fiber tail end strain data with the lower signal noise ratio to the curve splicing is effectively reduced, the optical fiber strain distribution data splicing efficiency and splicing accuracy are greatly improved, the labor cost is reduced, the test distance of a BOTDR product is lengthened, the measuring accuracy of strain distribution of super-long distance optical fibers is ensured, and the application field of the BOTDR product is widened.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

Universal mechanical connection and spinning fixing device for aluminum squares

The invention relates to the related field of aluminum alloys, and discloses a universal mechanical connection and spinning fixing device for aluminum squares. The universal mechanical connection andspinning fixing device comprises a main box, a left-right through machining cavity is formed in the main box, a forward through cavity with a forward opening is formed in the front side of the machining cavity in a communicating mode, and two symmetric pressing movable cavities are formed in the front and rear parts of the machining cavity in a communicating mode. A pressing sliding seat is connected between the left end wall and the right end wall of the pressing movable cavity in a sliding fit mode, a pressing rack is fixedly connected into the upper end face of the pressing sliding seat, apressing gear cavity is formed in the upper side of the pressing movable cavity in a communicating mode, a lifting box drives the connecting aluminum squares to move downwards to make contact with thealuminum squares to be jointed, and the working intensity of workers is reduced. A grinding tool for installation drives the connecting aluminum squares to move downwards to be inserted into the aluminum squares to be jointed, so that automatic jointing of the aluminum squares is achieved, the attractiveness of aluminum square installation is guaranteed, a half gear ring drives a spinning plate to rotate, the spinning plate achieves spinning of materials at the joint of the aluminum squares, and therefore the stability of aluminum square connection is improved.

Owner:温州根旭电子科技有限公司

Connector device of cord fabric cutting machine and method thereof

ActiveCN101653992BSolve the problem of lack of motivationRealize resistance-free delivery modeTyresMechanical engineeringEconomic shortage

Owner:MESNAC

A mapping method, device and system based on laser radar

ActiveCN107179086BHigh precisionImprove accuracyInstruments for road network navigationNavigational calculation instrumentsRadarEngineering

Embodiments of the present invention disclose a laser radar-based mapping method, device, and system. The method includes: respectively acquiring two initial data frames corresponding to adjacent scanning periods, using a first preset algorithm to extract point, line and surface features in the two initial data frames respectively, and using a second preset algorithm according to the extracted features. The first transformation matrix is calculated from the characteristics of the first data frame, and the registration of the two initial data frames is realized. The first preset algorithm is used to extract the point, line and surface features in the two intermediate data frames respectively, and register again. The obtained local coordinate data frame in the local coordinate system is converted to the global coordinate system and the map is updated. By adopting the above technical solutions, the embodiments of the present invention can improve the precision and accuracy of the obtained map, improve the drawing efficiency, and save the space occupied by the system and the manufacturing cost.

Owner:BEIJING GREEN VALLEY TECH CO LTD

Self-positioning splicing method based on mark circle

InactiveCN110324987ARealize automatic splicingImprove stitching qualityPrinted circuit assemblingFlexible circuitsMulti degree of freedom

Owner:上海凌渡电子科技有限公司

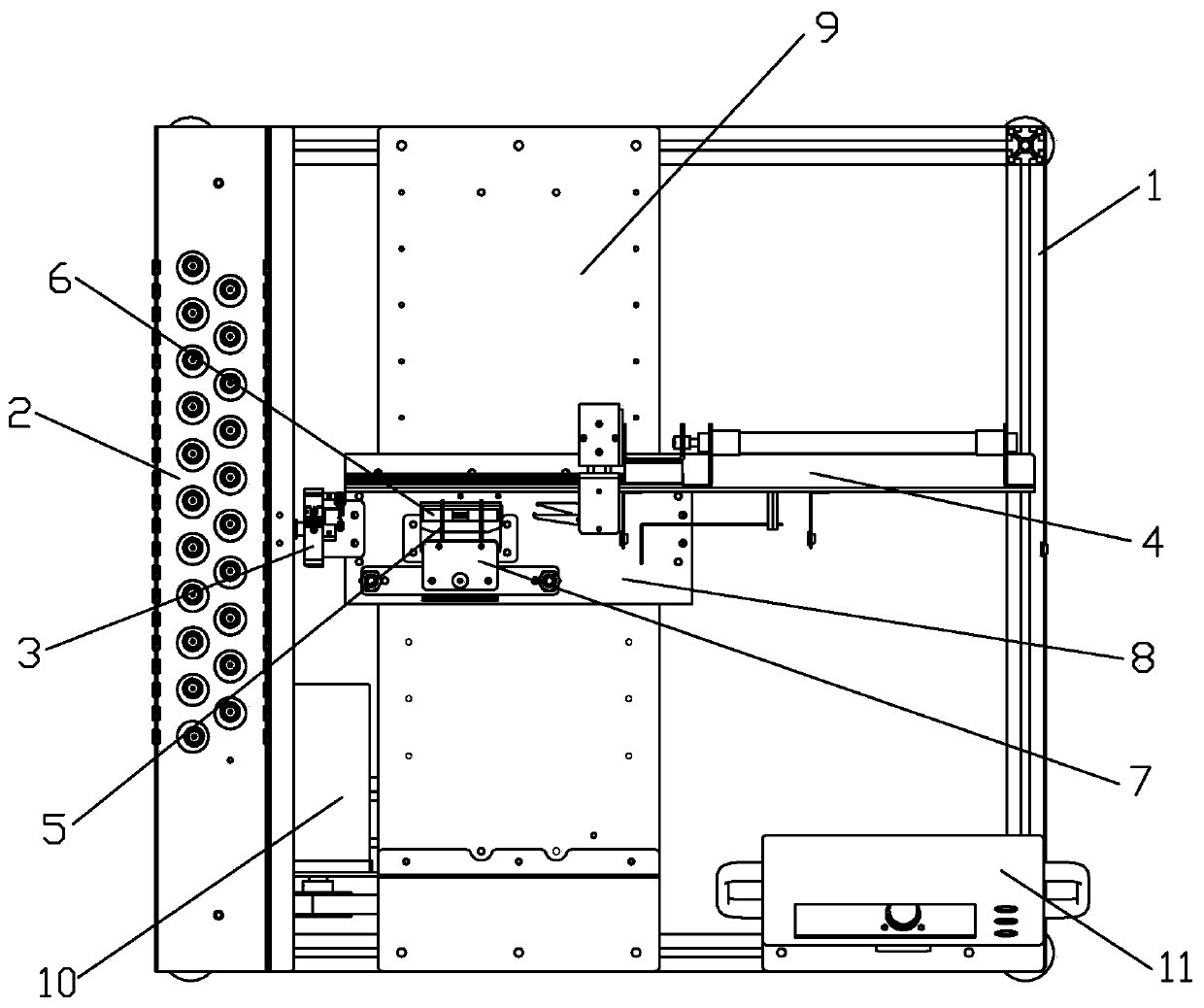

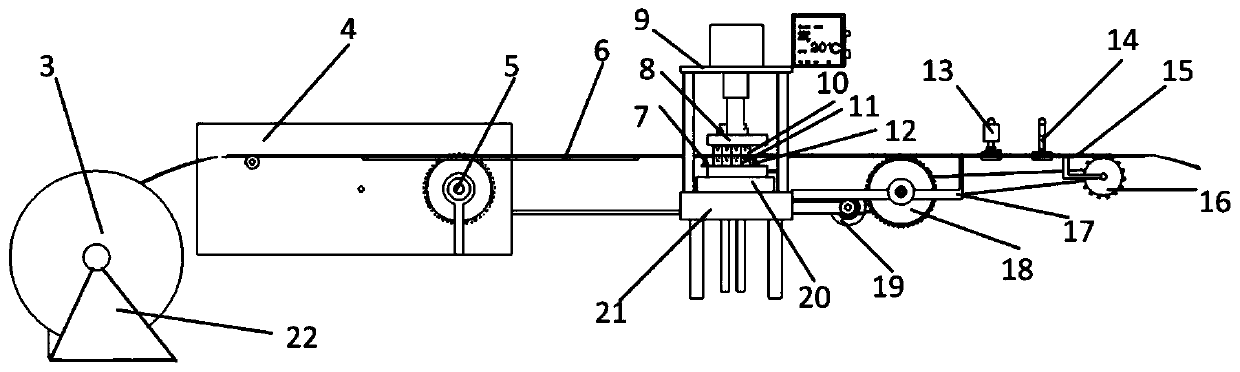

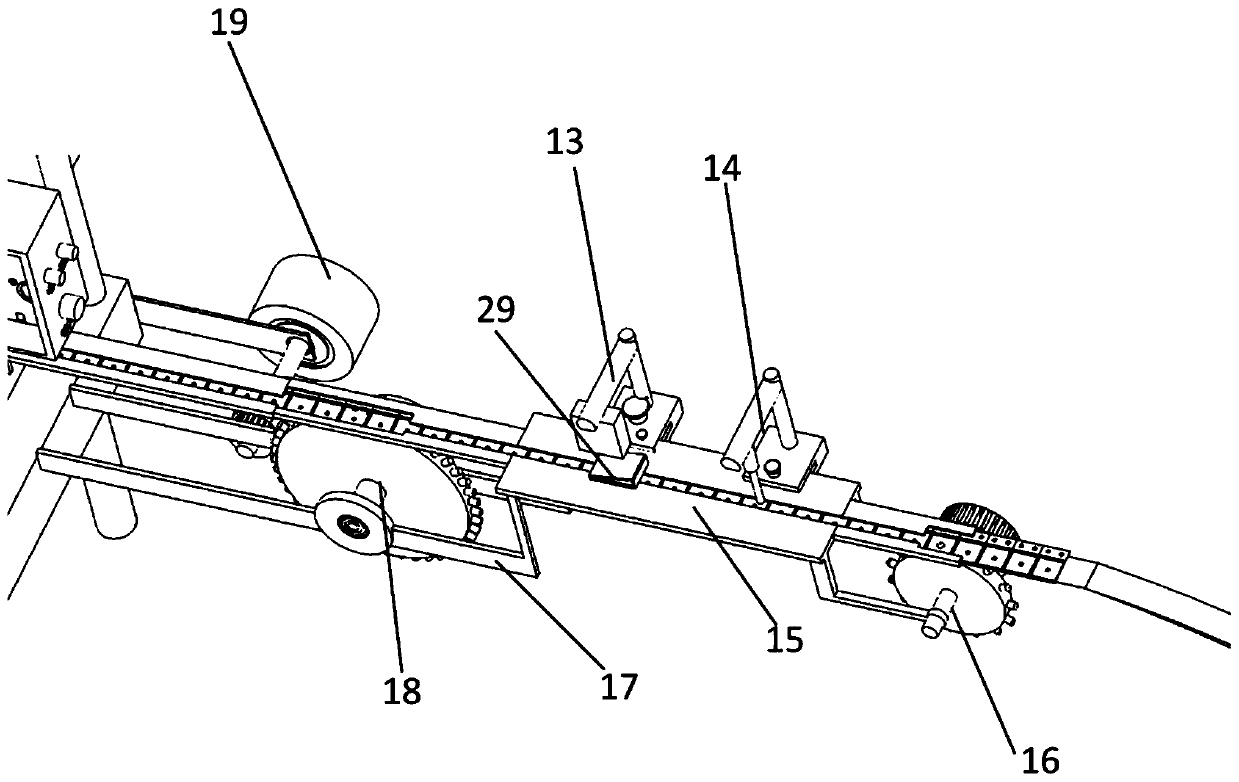

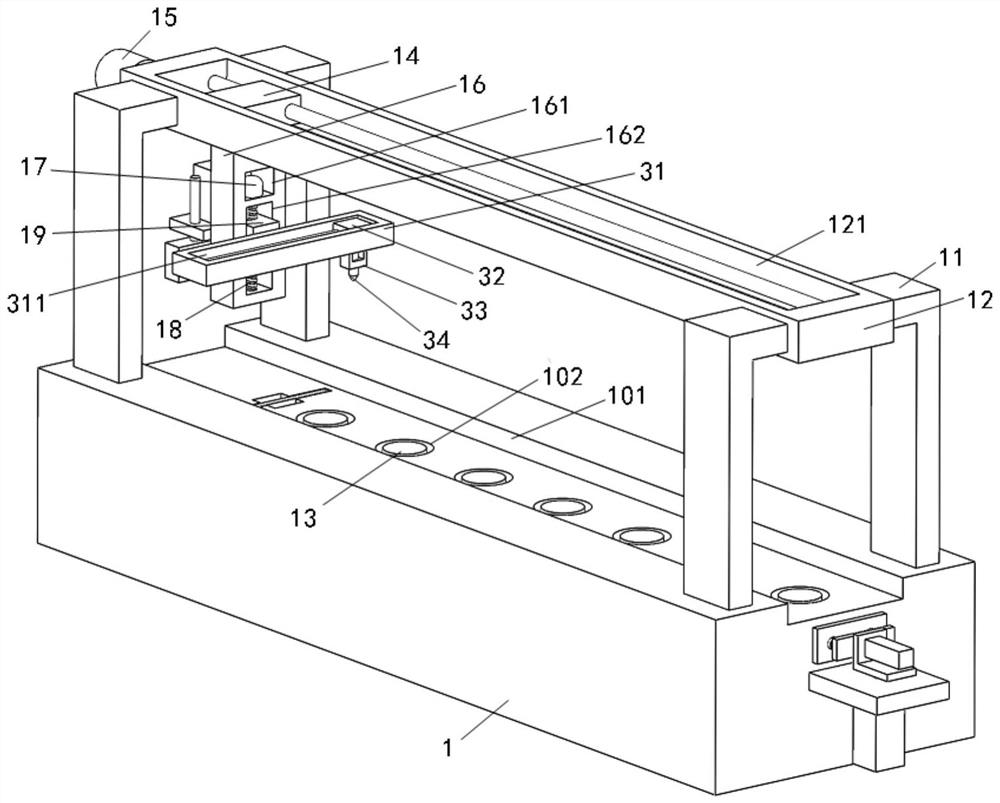

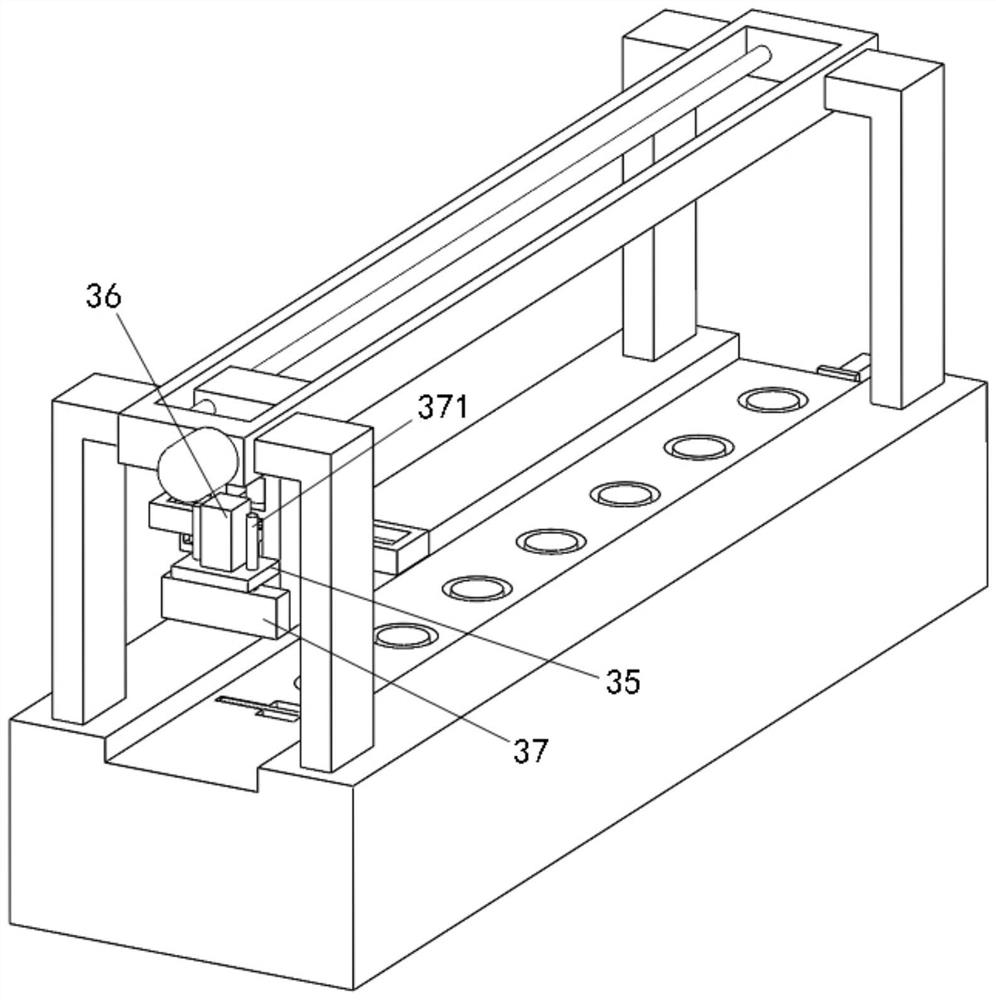

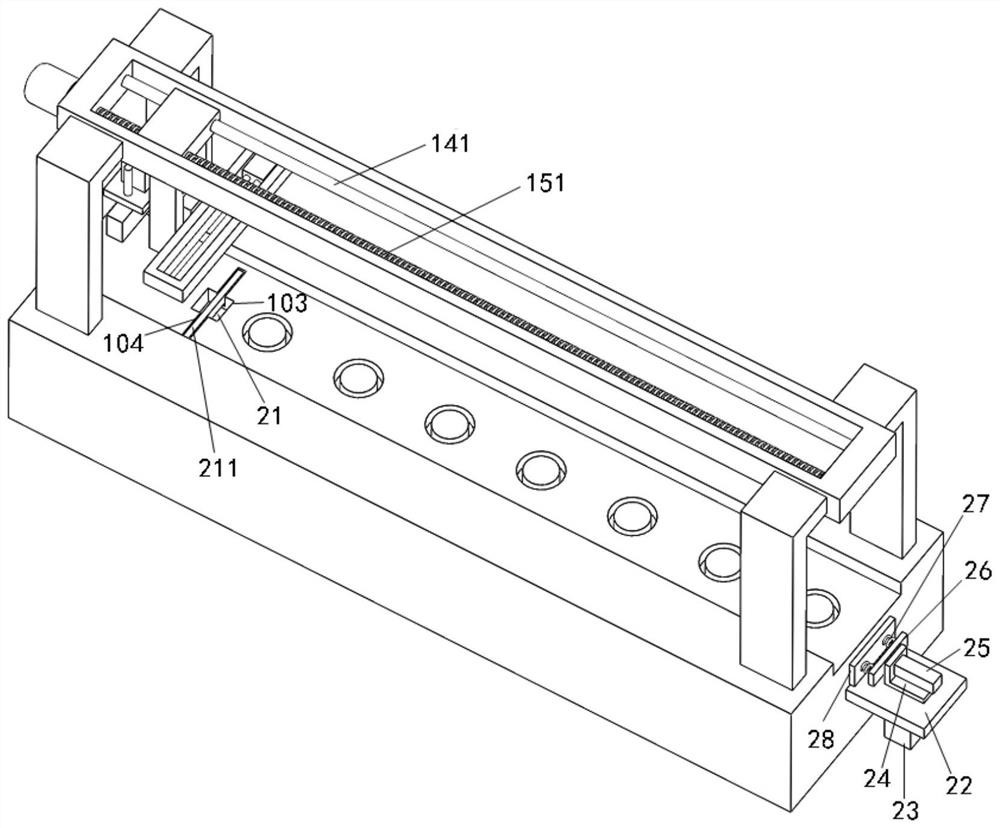

Thermoplastics type plastic carrier band recycling splicing using device and work method thereof

ActiveCN110370534ARealize automatic splicingRealize automatic winding functionBeltsElectricityThermoplastic

The invention belongs to the field of automation equipment, and particularly relates to a thermoplastics type plastic carrier band recycling splicing using device and a work method thereof. The thermoplastics type plastic carrier band recycling splicing using device capable of carrying out automatic splicing and winding is created and comprises a power supply system, a support, a plastic carrier band and a control system and further comprises an injection molding device, a pressurizing device, a winding device and a transmission device. The injection molding device is arranged on the support,is fixedly connected with the support, is electrically connected with the power supply system and is in communication connection with the control system; the pressurizing device is arranged on the support, is fixedly connected with the support, is electrically connected with the power supply system and is in communication connection with the control system, the winding device is arranged on the support, is fixedly connected with the support, is electrically connected with the power supply system and is in communication connection with the control system, and the transmission device is arrangedon the support, is fixedly connected with the support, is electrically connected with the power supply system and is in communication connection with the control system.

Owner:上海芯哲微电子科技股份有限公司

Device and method for detecting rich-Te phase in telluride semiconductor crystal

ActiveCN102169076BRealize 3D observationOvercoming two-dimensional distributionParticle size analysisSpecific gravity measurementVisual field lossBody density

The invention discloses a device and a method for detecting a rich-Te phase in a telluride semiconductor crystal. By the device and the method, the technical problems that the conventional device for detecting the rich-Te phase in the telluride semiconductor crystal cannot obtain a larger-size visual field and realize focused imaging of a layered domain in the thickness direction of the crystal can be solved. The technical scheme is that: the visual field can be adjusted by changing the magnifying power of a zoom lens barrel; meanwhile, by adoption of a high-precision four-coordinate three-dimensional automatic translational table, the body density of the rich-Te phase can be observed. By the method for detecting the rich-Te phase in the telluride semiconductor crystal by using the detecting device, the focused imaging of the layered domain is realized by adjusting the position in the thickness direction, so the form of the rich-Te phase in the crystal can be observed; and a Labview-based image collection and processing system is used for splicing every collected independent picture into a whole large image at first, counting different gray scale regions of the spliced image and analyzing the distribution of the rich-Te phase in the crystal.

Owner:IMDETEK

Automatic wooden door combination production line

ActiveCN113021557BRealize automated combinationOptimize production lineWood working apparatusProcess engineeringManufacturing line

The invention provides a fully automatic wooden door combined production line, including a panel production line and a door frame production line, as well as a combined production line. The panel production line is connected with the combined production line at at least two places, and the door frame production line is connected with the combined production line. The combined production line is sequentially provided with: The station is used to turn the first panel; the door frame combination station is used to place the door frame on the first panel after turning over; the second panel covering station is used to place the second panel on the combined panel. on the door frame. The invention can realize the automatic combination of the panel and the door frame. The existing production line has been greatly optimized, and the processing efficiency has been further improved.

Owner:湖北科豪门业有限公司

Image mosaic method and system for double-sided scanning

ActiveCN102708557BRealize automatic splicingConvenient duplex scanning operationImage enhancementImage analysisFeature extractionFeature data

The invention discloses an image mosaic method and a system for two-sided scanning. A feature database of scan files is built before the image mosaic method is applied. The image mosaic method includes obtaining scan images of scan files, wherein the scan images comprise front images and back images of the scan files; performing slant correction on the scan images; performing position segmentation and feature extraction on the scan images; performing direction judgment and direction correction on the scan images according to comparison of features of the extracted scan images with the feature data; and mosaicing the front images with the back images in the scan images. According to the image mosaic method and the system, two-sided scan operation of users is greatly facilitated, mosaic quality of the two-sided scan images is guaranteed, and the image mosaic method and the system can be widely applied to the image scan field.

Owner:GUANGZHOU ZONERICH COMP EQUIP

Continuous automatic welding device for steel plates

InactiveCN112643269ARealize automatic splicingGood automation effectWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMachining

The invention discloses a continuous automatic welding device for steel plates. The continuous automatic welding device comprises a machining base, wherein a containing groove is formed in the center of the top face of the machining base, and a movable plate is arranged over the containing groove; a fixed base is arranged on the bottom face of the movable plate, and a lifting block capable of ascending and descending is arranged in the fixed base; a longitudinal welding plate base is fixed to the front side wall of the lifting block; and a longitudinally-moving welding head is arranged at the top of the longitudinal welding plate base. The continuous automatic welding device has the advantages that a plurality of steel plates with the same size can be arranged on the machining base in order and are limited and fixed through two movable limiting pressing plates; a welding gun head capable of ascending, descending and moving is arranged above the steel plates, and the welding gun head can automatically move to the joint of two adjacent steel plates for welding, so that automatic splicing of the steel plates is achieved; and the automation effect is good, and resources are saved.

Owner:汪祖平

An automatic quick connection mechanism and connection and disassembly method of an insulation module

ActiveCN108462094BCompact structureHigh working reliabilityLifting devicesCable installation apparatusUpper jointStructural engineering

The present invention discloses an insulation module automatic rapid connection mechanism and a connection dismounting method thereof. The insulation module automatic rapid connection mechanism comprises an upper joint, a lower joint and an automatic drive device; the upper joint comprises an upper joint main body and a locking block; the upper joint main body is provided with a pin mounting holeand a bolt mounting hole which communicate to each other; the locking block is provided with a bolt, and the bolt is installed in the bolt mounting hole; the automatic drive device is configured to drive the bolt of the locking block; the automatic drive device can drive the bolt of the locking block to stretch into and pull out the pin mounting hole; the lower joint comprises a lower joint main body and a locking pin; and the locking pin is connected with the lower joint main body, and the locking pin can stretch into the pin mounting hole, wherein the bolt and the locking pin can stretch into the pin mounting hole at the same time to connect and lock the upper joint and the lower joint. The insulation module automatic rapid connection mechanism and the connection dismounting method thereof can be applied in a modularized lift platform to allow the top end of the lift platform to have high stability and allow the insulation module to automatically and effectively complete splicing.

Owner:STATE GRID SHAANXI ELECTRIC POWER RES INST +3

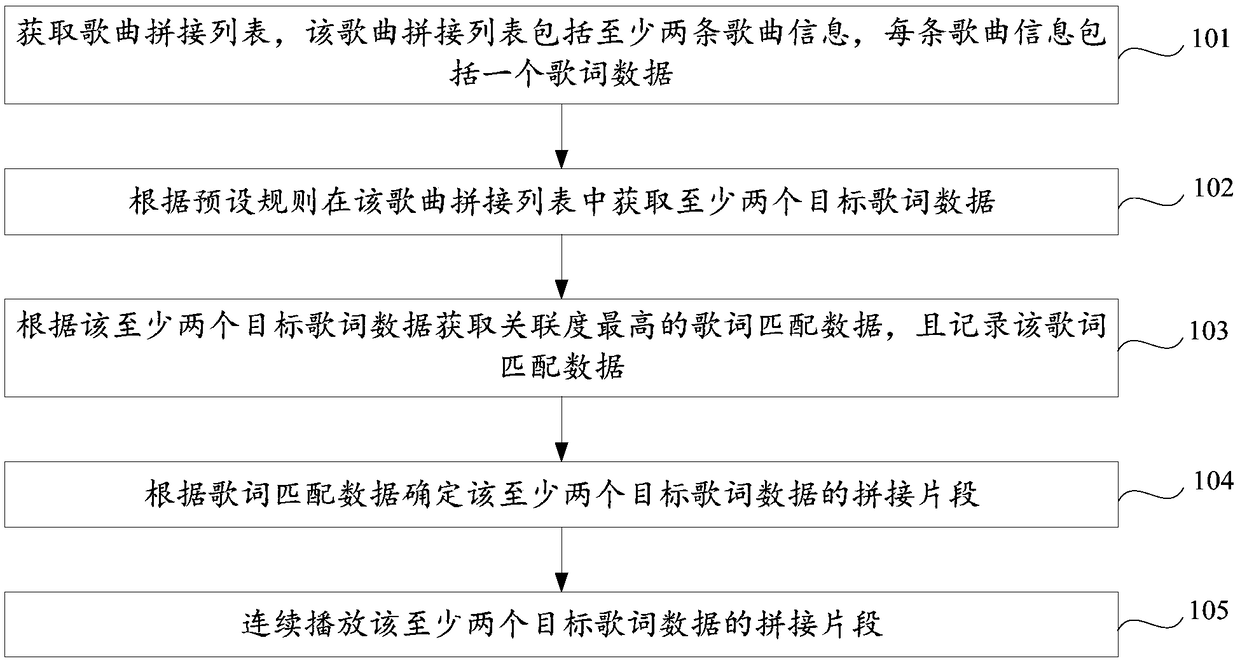

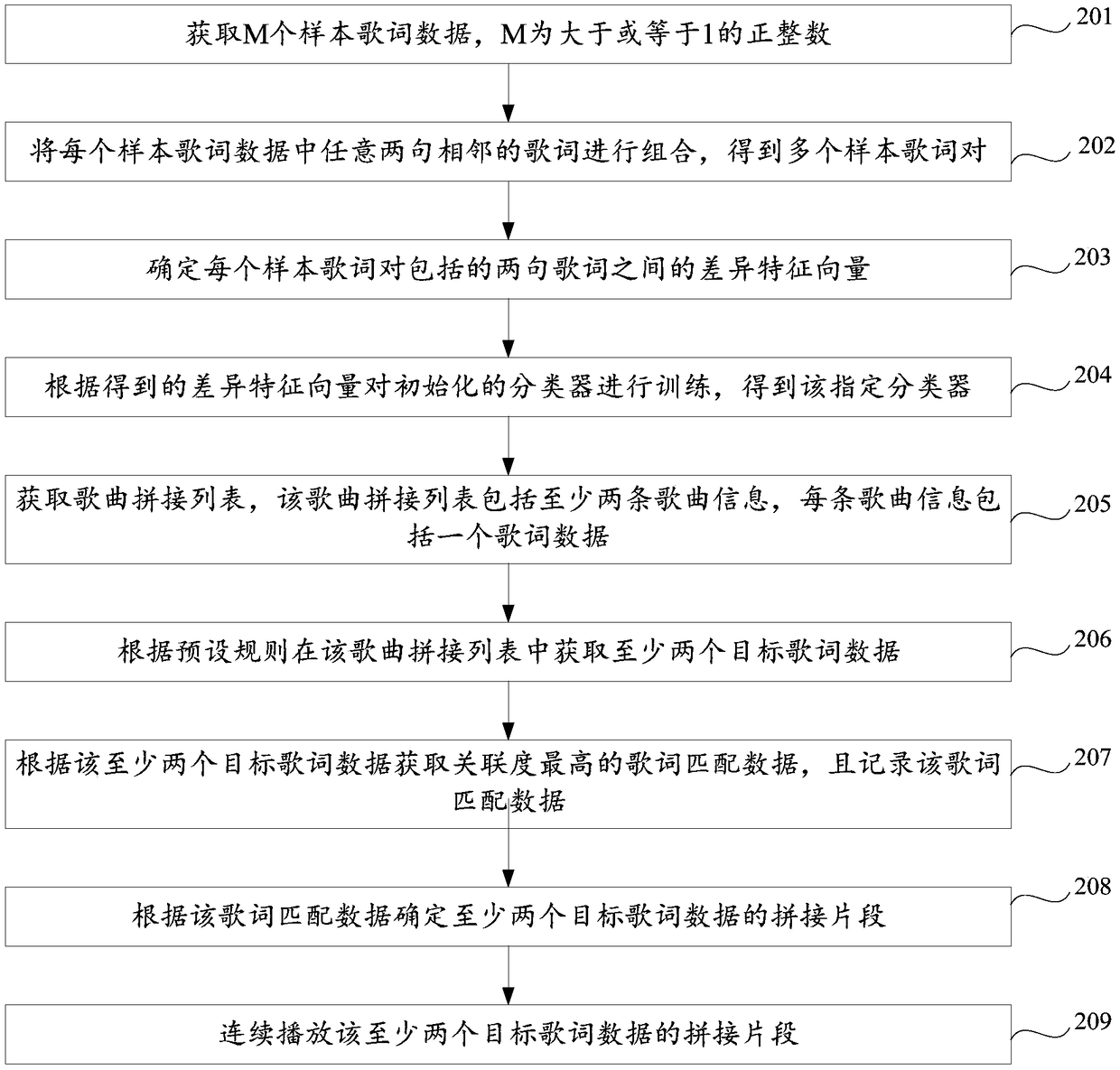

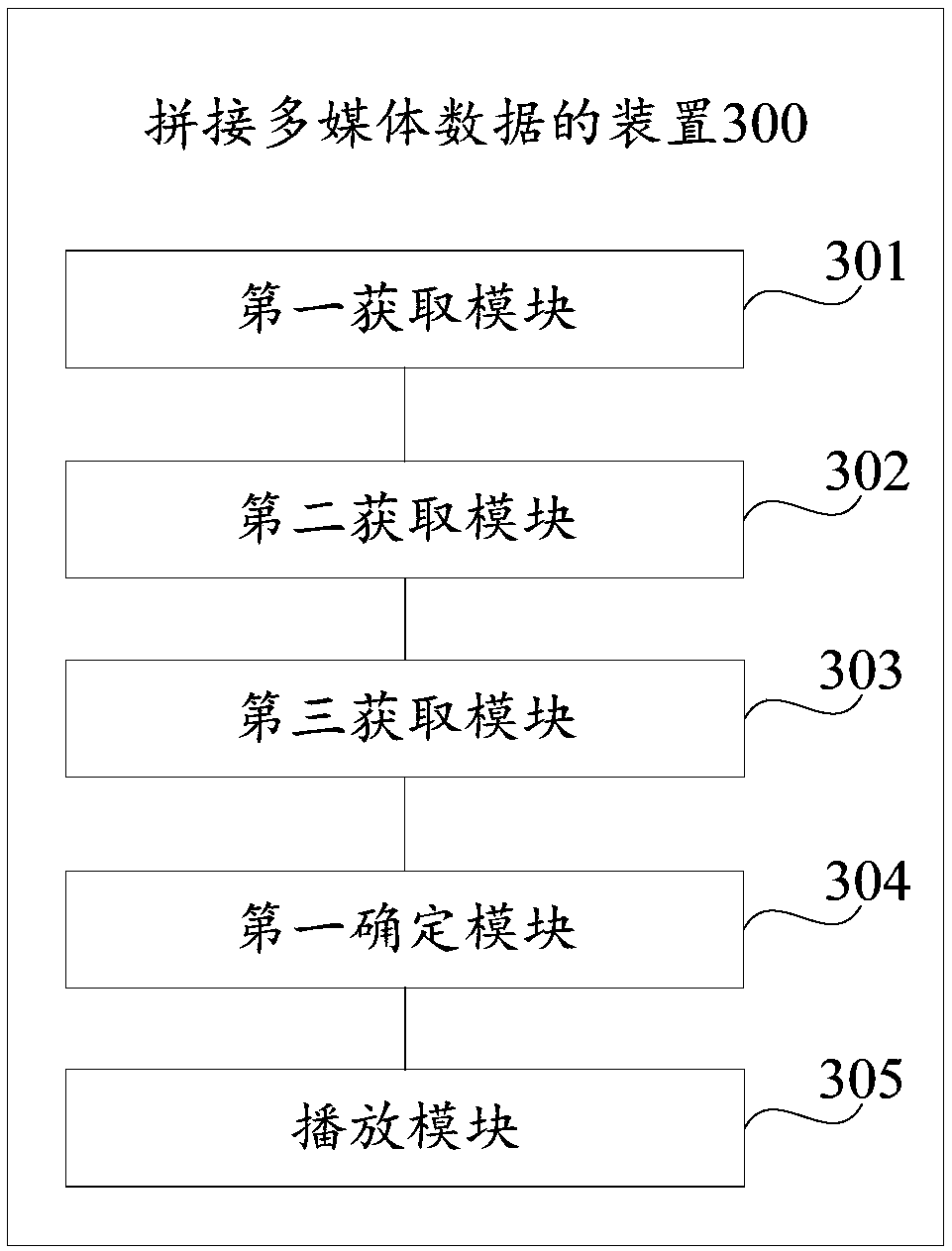

Method and device for merging multi-media data and storage medium

InactiveCN108717849ARealize splicingRealize automatic splicingElectrophonic musical instrumentsElectronic editing digitised analogue information signalsData miningThe Internet

The invention discloses a method and device for merging multi-media data and a storage medium, and belongs to the field of Internet. The method comprises the steps that after a song merging list is obtained, at least two pieces of target lyric data are obtained in the song merging list; according to the target lyric data, lyric matching data which is highest in association degree is obtained, andthe lyric matching data is recorded; according to the lyric matching data, merging fragments of the target lyric data are determined; the merging fragments of the target lyric data are continuously played, so that it is achieved that at least two pieces of song information in the song merging list are automatically merged. The situation that mergence of the song information can be manually achieved through specialized persons is avoided, and the song merging flexibility is improved.

Owner:TENCENT MUSIC ENTERTAINMENT TECH SHENZHEN CO LTD

Cylinder driving type digital controlled lathe tailstock automatic feeding control method capable of achieving floating tapping

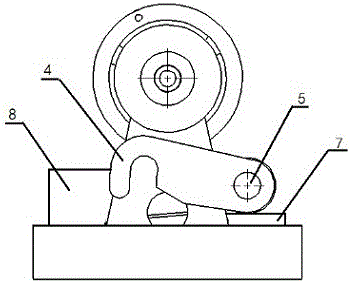

ActiveCN106001634ARealize synchronized movementRealize automatic splicingThread cutting machinesTailstocks/centresDigital controlTailstock

The invention provides a cylinder driving type digital controlled lathe tailstock automatic feeding control method capable of achieving floating tapping. A digital controlled lathe saddle and tailstock engaging and disengaging connecting device is adopted and comprises a connecting pillar, a rotating arm component, a driving component and a screw tap component, wherein a ring slot is formed in the middle of the connecting pillar, and a pair of sensors are arranged at the shaft end of the connecting pillar and on the side face of a tailstock; the rotating arm component comprises a rotating arm, a rotating shaft, a shaft sleeve and a big gear, and the shaft sleeve is fixed to the front side face of the digital controlled lathe tailstock; the rotating shaft penetrates through the shaft sleeve, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the big gear, and a hook part capable of being clamped into the ring slot is arranged at the front end of the rotating arm; the driving component comprises a rack, a cylinder, an electromagnetic directional valve, a rack guiding groove, a reset switch and a controller, the controller is installed in a machine tool power distribution cabinet and electrically connected with a digital control system and the electromagnetic directional valve, and the reset switch is installed on the front side of a digital controlled lathe saddle and electrically connected with the controller.

Owner:上海华兑金属有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com