An automatic quick connection mechanism and connection and disassembly method of an insulation module

A fast connection and automatic technology, applied in the direction of lifting device, cable installation, electrical components, etc., can solve the problems of splicing requiring manual operation, time-consuming and labor-intensive efficiency, poor stability, etc., to improve splicing efficiency and good processing technology , Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

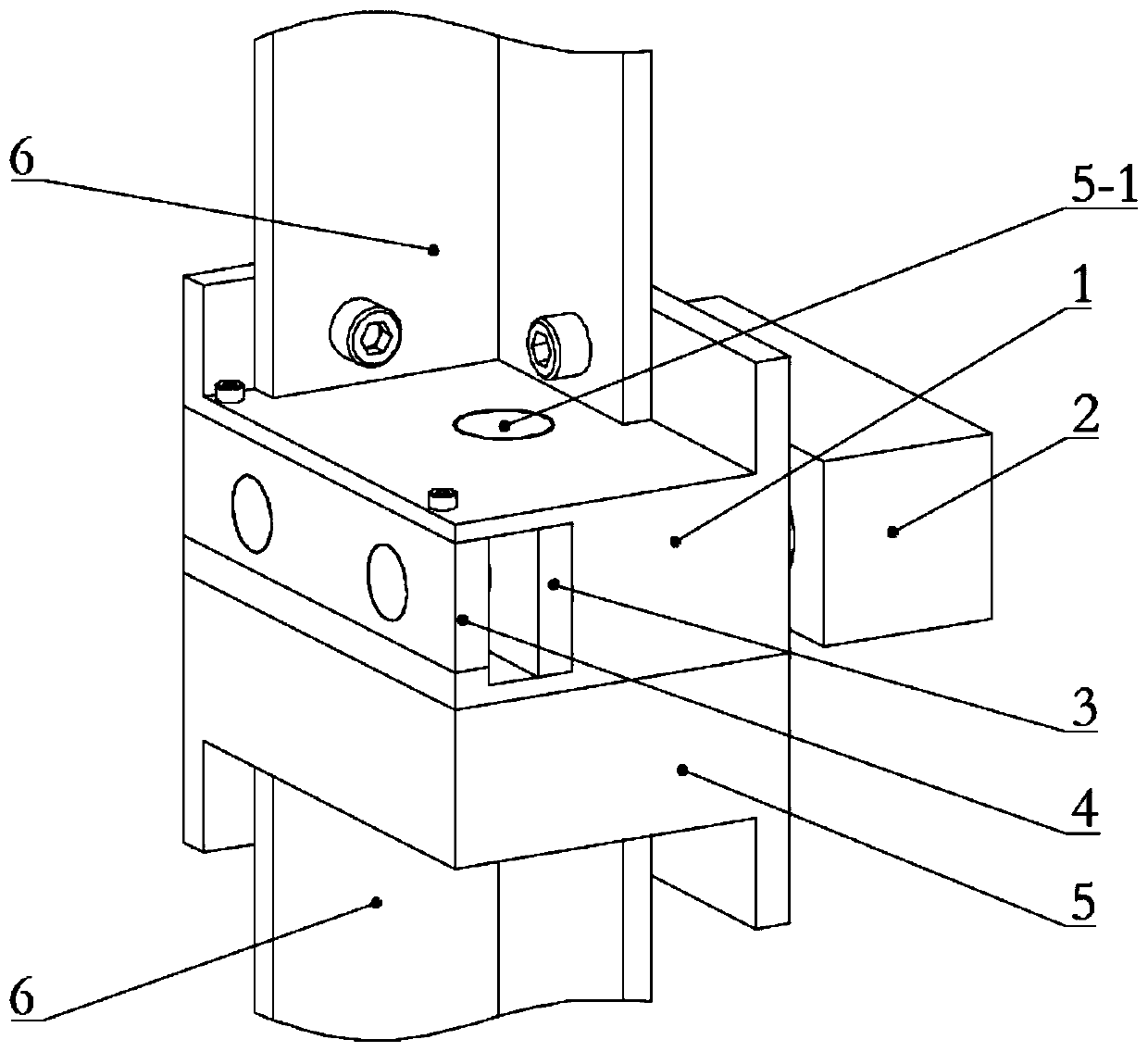

[0040] The descriptions of directions such as "up, down, left, and right" in the embodiments refer to the drawings in the specification, which are only used to explain the technical solution, and are not intended to limit the technical solution.

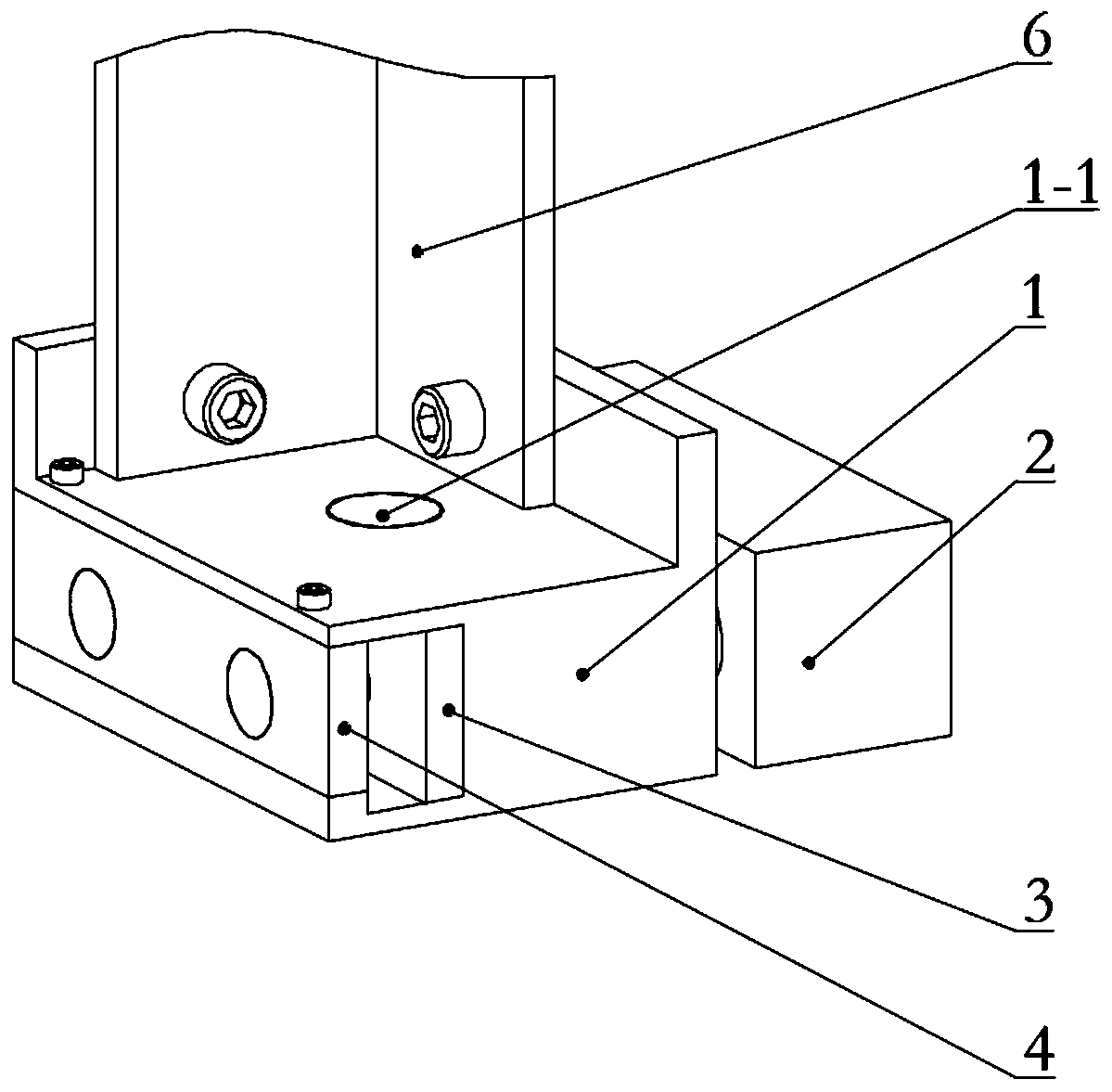

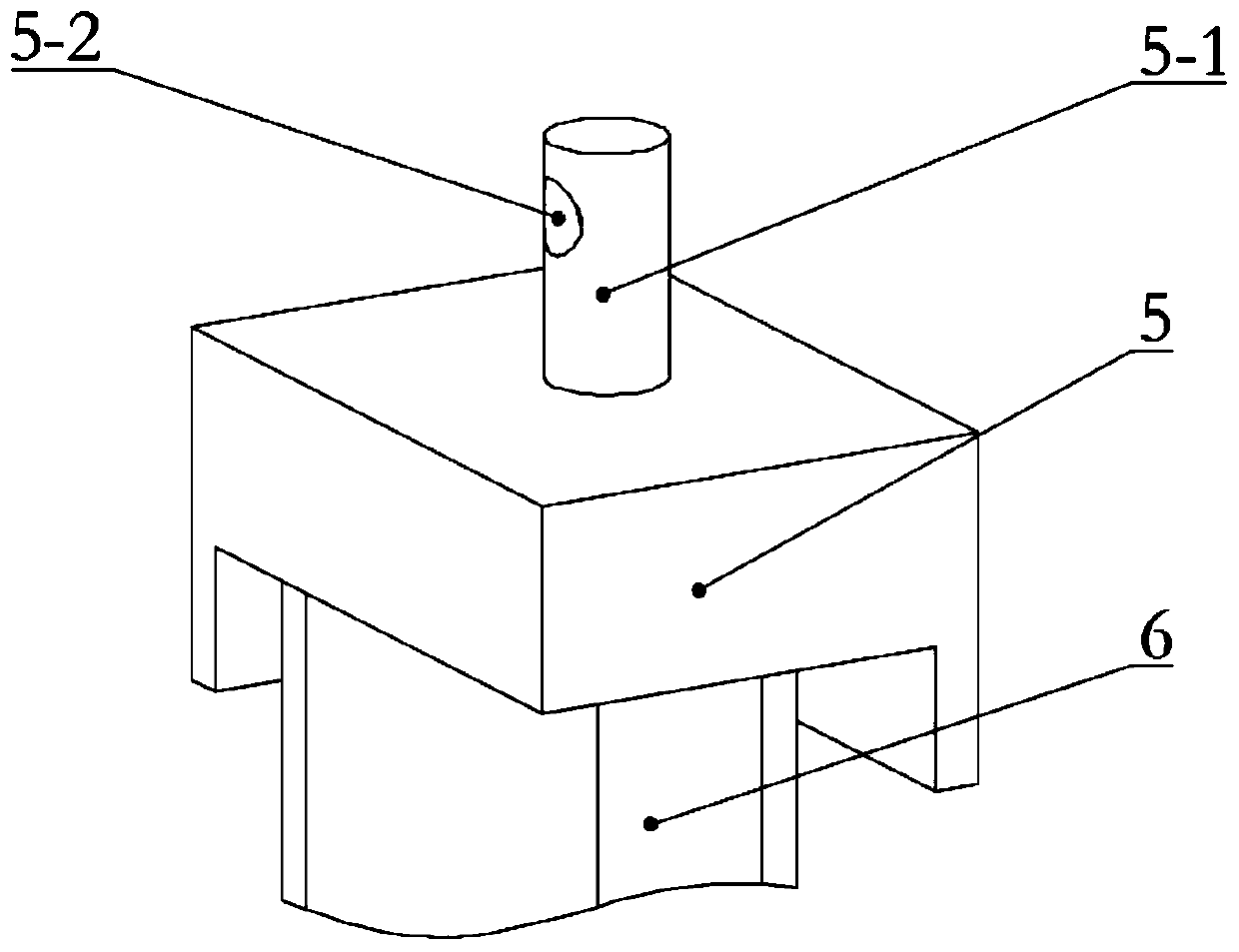

[0041] refer to Figure 1 to Figure 6 , an automatic quick connection mechanism for insulation modules of the present invention, comprising: an upper joint, a lower joint and an unlocking device.

[0042] The upper joint includes an upper joint main body 1, a guide plate 4, a locking block 3 and a locking spring 7. The upper joint main body 1 is a rectangular block, and the upper joint main body 1 is provided with a vertical through hole as a pin installation hole 1-1 , the side wall of the upper joint main body 1 on the lower side of the pin installation hole 1-1 is fixedly connected with a guide plate 4, and the left and right sides of the pin installation hole 1-1 respectively have a horizontal through hole that runs through the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com