Method for automatically splicing scribing groove frame

An automatic splicing and dicing groove technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of time-consuming manual processing, error-prone, wafer scrapping, etc., and achieve the effect of automatic splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

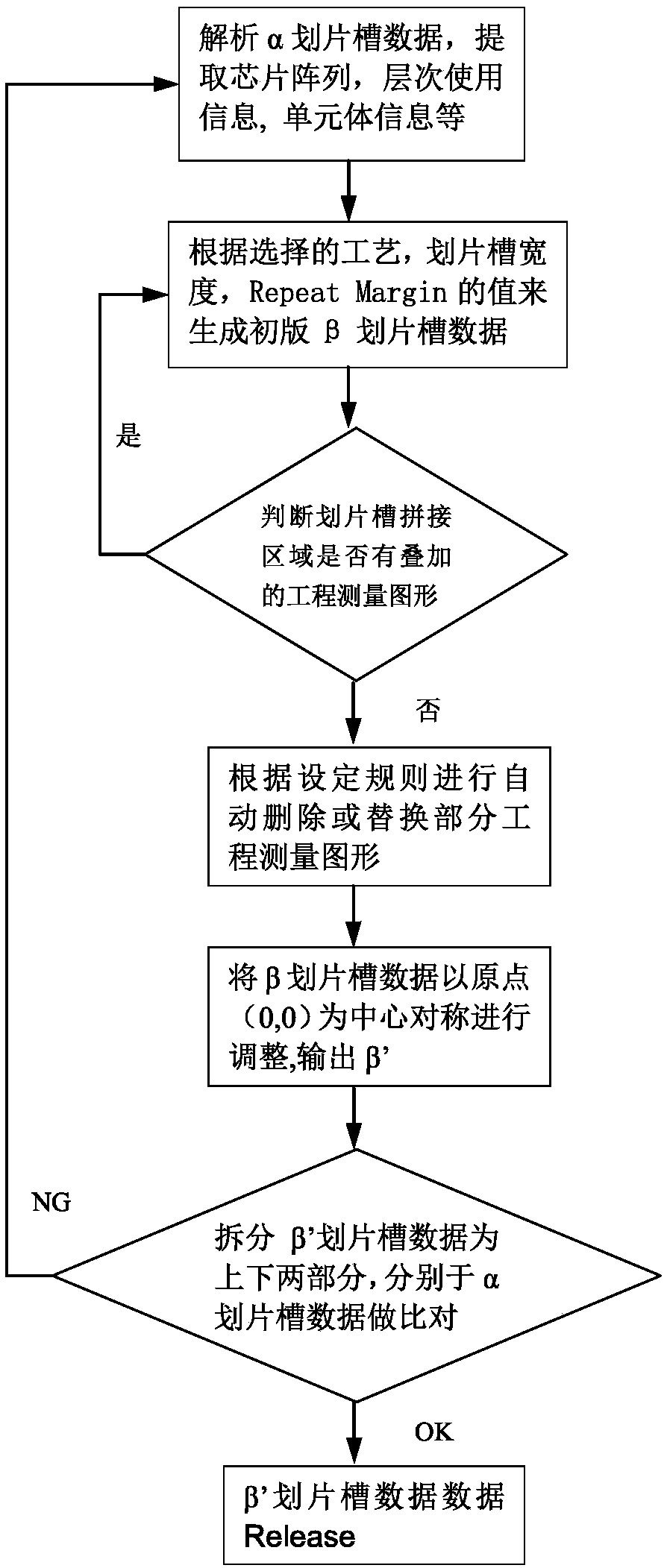

[0016] The method for realizing the automatic splicing of the scribe groove frame of the present invention is as follows: figure 1 shown, including the following steps:

[0017] Step 1: Analyzing the α-scribing groove data, extracting the chip array, layer usage information, unit body information, etc.

[0018] Due to the maximum exposure size of the 5X mask (X p ×Y p ) is 22mm×22mm, the maximum exposure size of 5X mask (X p ×Y p ) is 25mm×33mm. The width of the scribe groove is 50um / 60um / 80um optional. According to the size of the Main chip (CX: X-direction size of the customer's main chip; CY: Y-direction size of the customer's main chip) and the width of the dicing groove (SW), the value of the overlapping margin (RM), the number of chips in the horizontal direction (AX), the vertical number of chips (AY), calculate the 5X Frame Shot Size (α scribe groove exposure size):

[0019] The maximum exposure size in X direction MX=(CX+SW)×AX+2×RM (requires MX<22mm)

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com