Connector device of cord fabric cutting machine and method thereof

A technology of a joint device and a joint method, applied in the field of joint devices, can solve the problems of aggravating the deflection and scratching of the cloth strip, not completely solving the problems of non-resistance conveying, and inaccurate connection of the head and tail of the cloth strip, so as to achieve the effect of reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

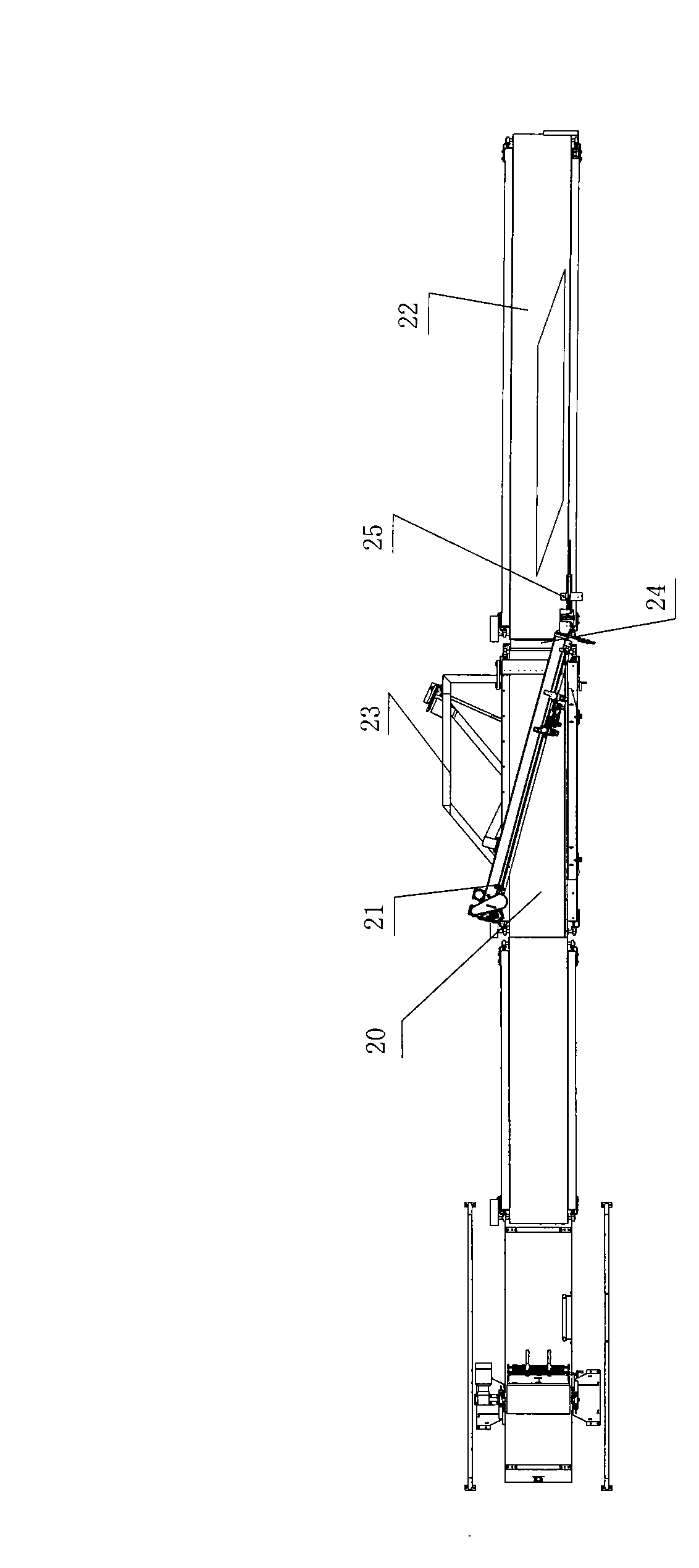

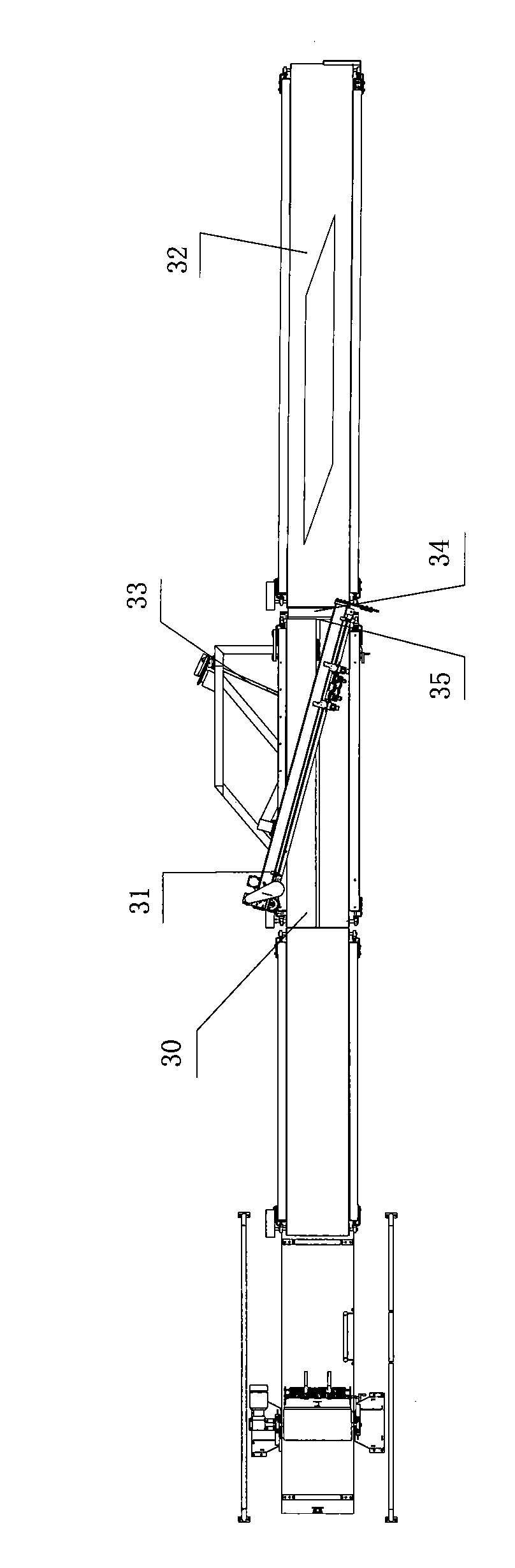

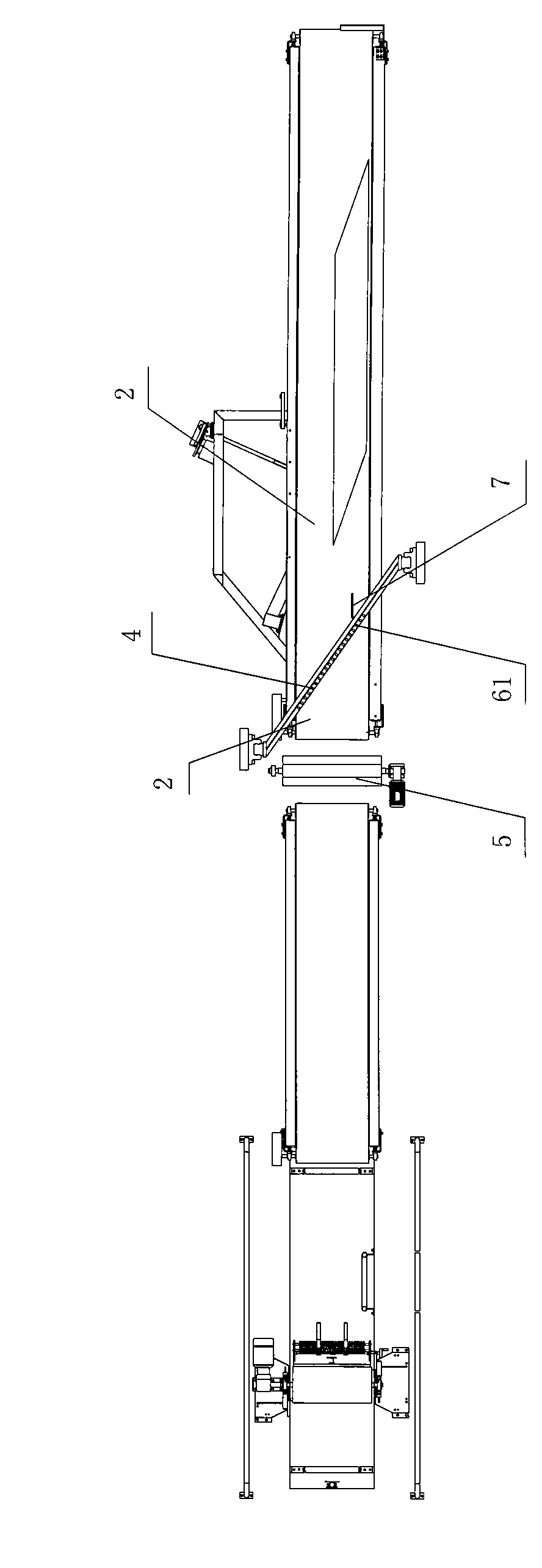

[0058] Example 1, such as Figure 3 to Figure 7-4 As shown, the joint device of the cord cutting machine mainly includes a frame 1 carrying a joint conveyor belt 2 , and only one integral joint conveyor belt 2 is provided on the upper part of the frame 1 .

[0059] The joint conveyor belt 2 is driven by a servo motor 3 and conveys the cord along the longitudinal direction of the frame 1, and its longitudinal length is 1.3 times the maximum length of the conveyed cord.

[0060] The front end of the frame 1 is provided with a joint mechanism 4 for connecting the front and rear curtains together.

[0061] A cord drawing device 5 is arranged at the front end of the splicing conveyor belt 2 , and the cord drawing device 5 includes a vertically fixed drawing idler roller 51 and a one-way pressure roller 52 arranged above the drawing idler roller 51 .

[0062] The vertical height of the lead-out idler roller 51 is higher than the joint conveyor belt 2 .

[0063] On the beam of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com