Single panel automatic wooden door production line

A production line, fully automatic technology, used in wood processing appliances, manufacturing tools, bark area/debris/dust/waste removal, etc., can solve the problems of high labor intensity, high labor cost, large volume, etc., to reduce labor Strength, improving processing efficiency, reducing the effect of the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

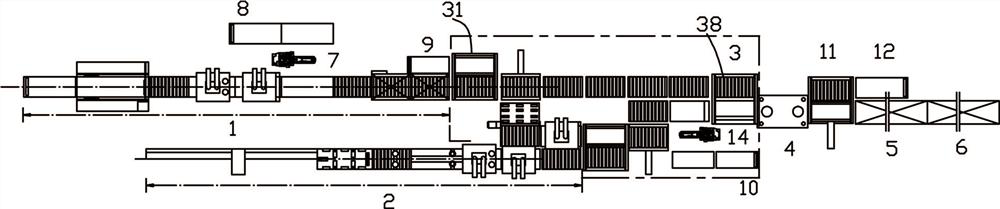

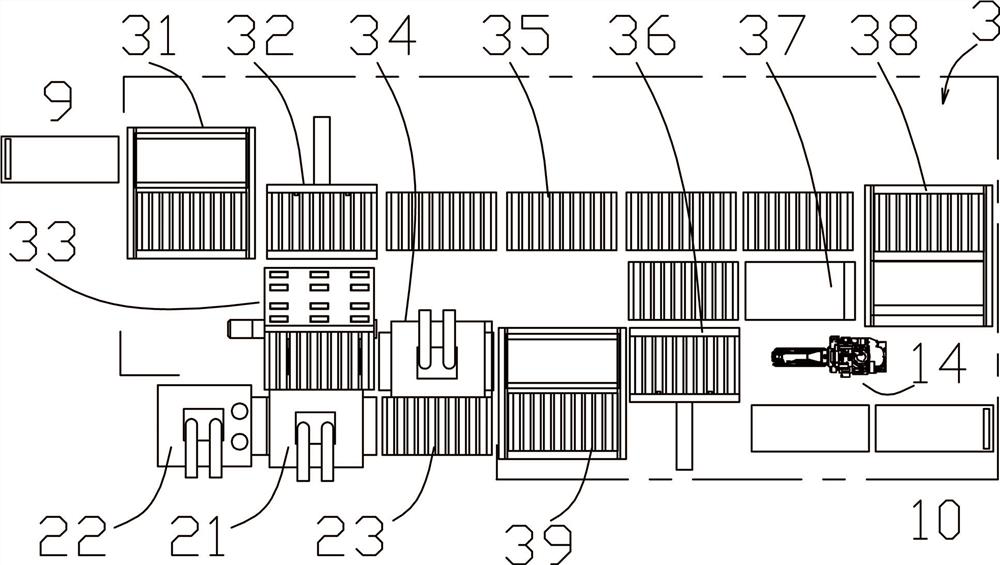

[0052] Such as figure 1 , 2 Among them, a single-panel automatic wooden door production line includes a panel production line 1 and a door frame production line 2, and also includes a combination production line 3, and the panel production line 1 is connected to the combination production line 3;

[0053] The combined production line 3 is provided with a cover board grabbing and covering station 31, which is used to grab and cover the cover board 91 on the first panel; the first cover board 91 is used to avoid the wear of the first panel, and Avoid damage to the relief pattern on the surface of the first panel.

[0054]Downstream of the cover plate grasping and covering station 31, a cover plate and a first panel pushing station 32 are provided, and the cover plate and the first panel pushing station 32 are used to push the cover plate and the first panel to the turning station 33;

[0055] The overturning station 33 is used to turn over the cover plate and the first panel; ...

Embodiment 2

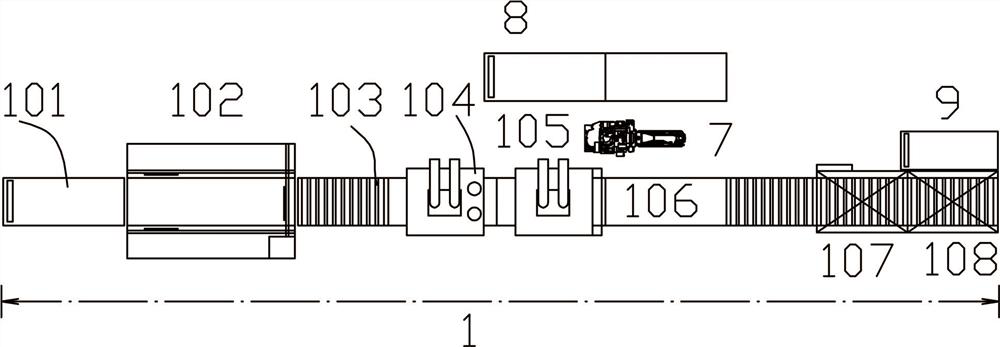

[0083] On the basis of Example 1, such as Figure 1~8 , take the optimal solution as an example to illustrate:

[0084] In the panel production line 1, the panel supply table 101 adopts a lifting supply table, each lift pushes a panel to the cutting and shaping station 102, and after sawing or CNC cutting to shape or engrave patterns, it passes through the panel conveying device 103, such as a conveying roller, Transported to the panel surface sanding station 104, after being sanded by a multi-stage sanding head, it enters the panel surface cleaning and gluing station 105, the surface is cleaned by the wool roller and negative pressure vacuuming, and then glued, and passes through the embossing combination station 106. The embossed piece supply table 8 is a lifting supply table, which supplies the embossed pieces one by one to one side platform of the embossed manipulator 7, and the embossed manipulator 7 grabs the embossed piece and places it on the surface of the first panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com